Role of Surface Morphology Evolution in the Tribological Behavior of Superalloy Under High-Temperature Fretting

Abstract

1. Introduction

2. Experimental Details

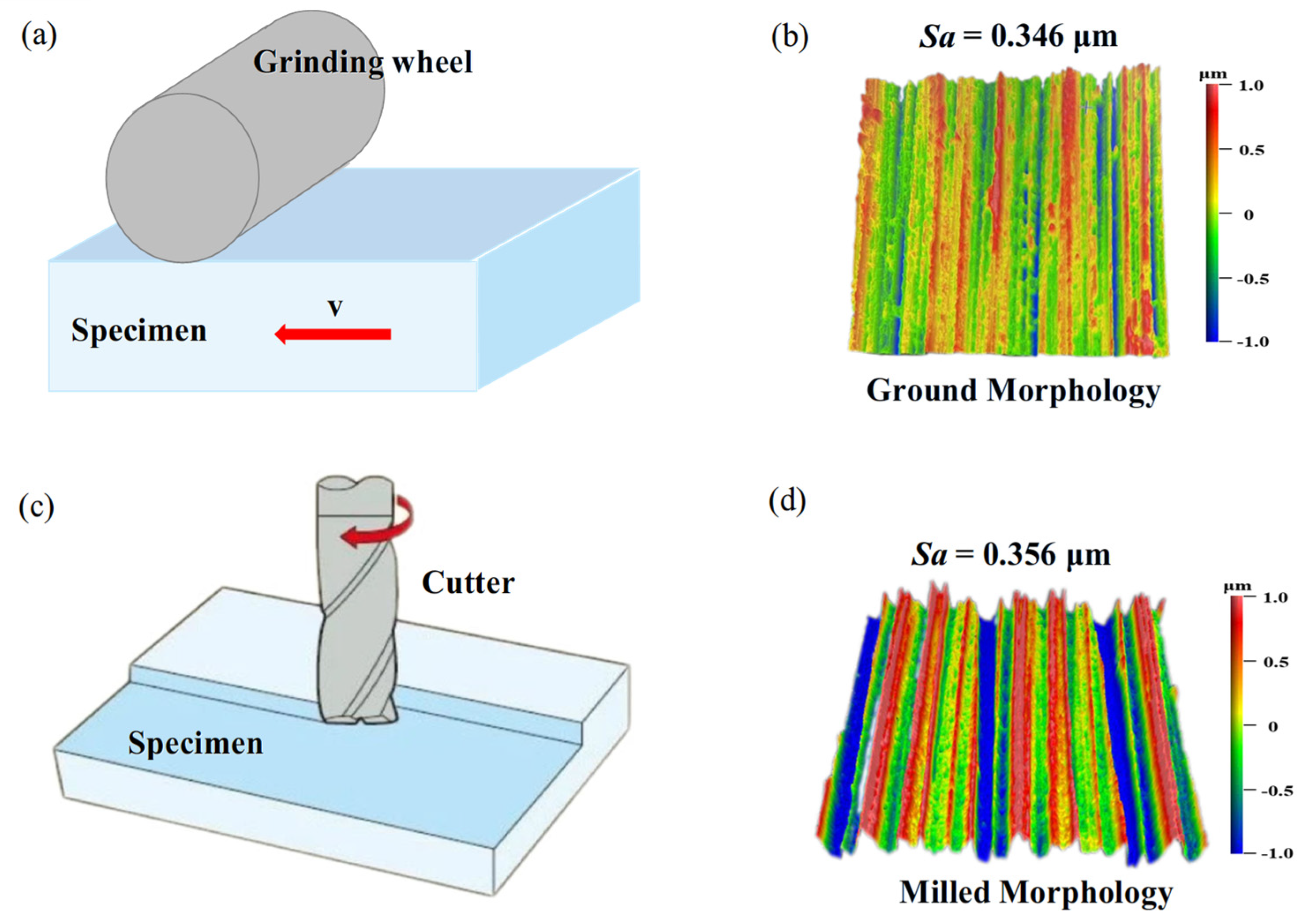

2.1. Materials and Preparations

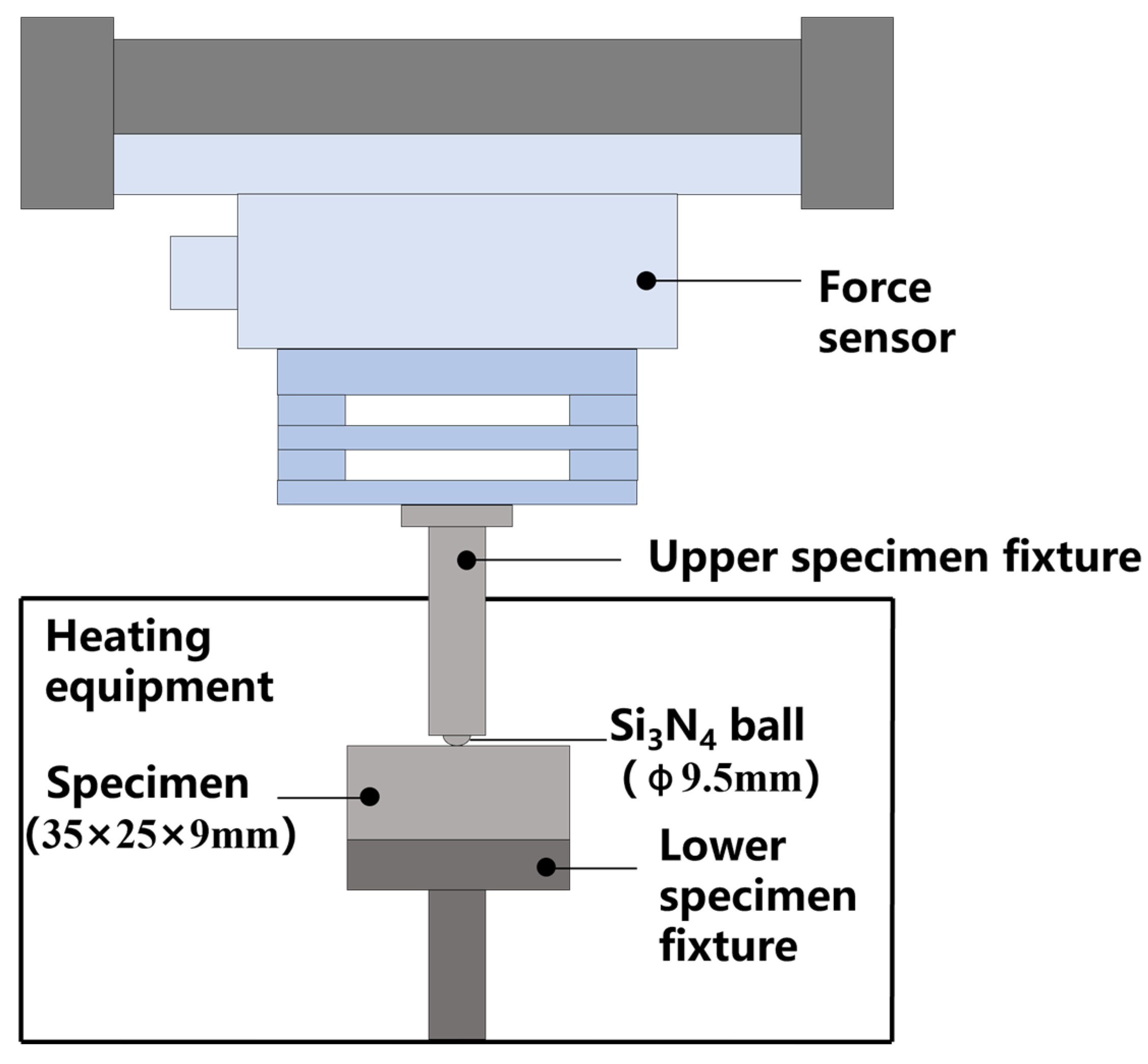

2.2. Tribological Test

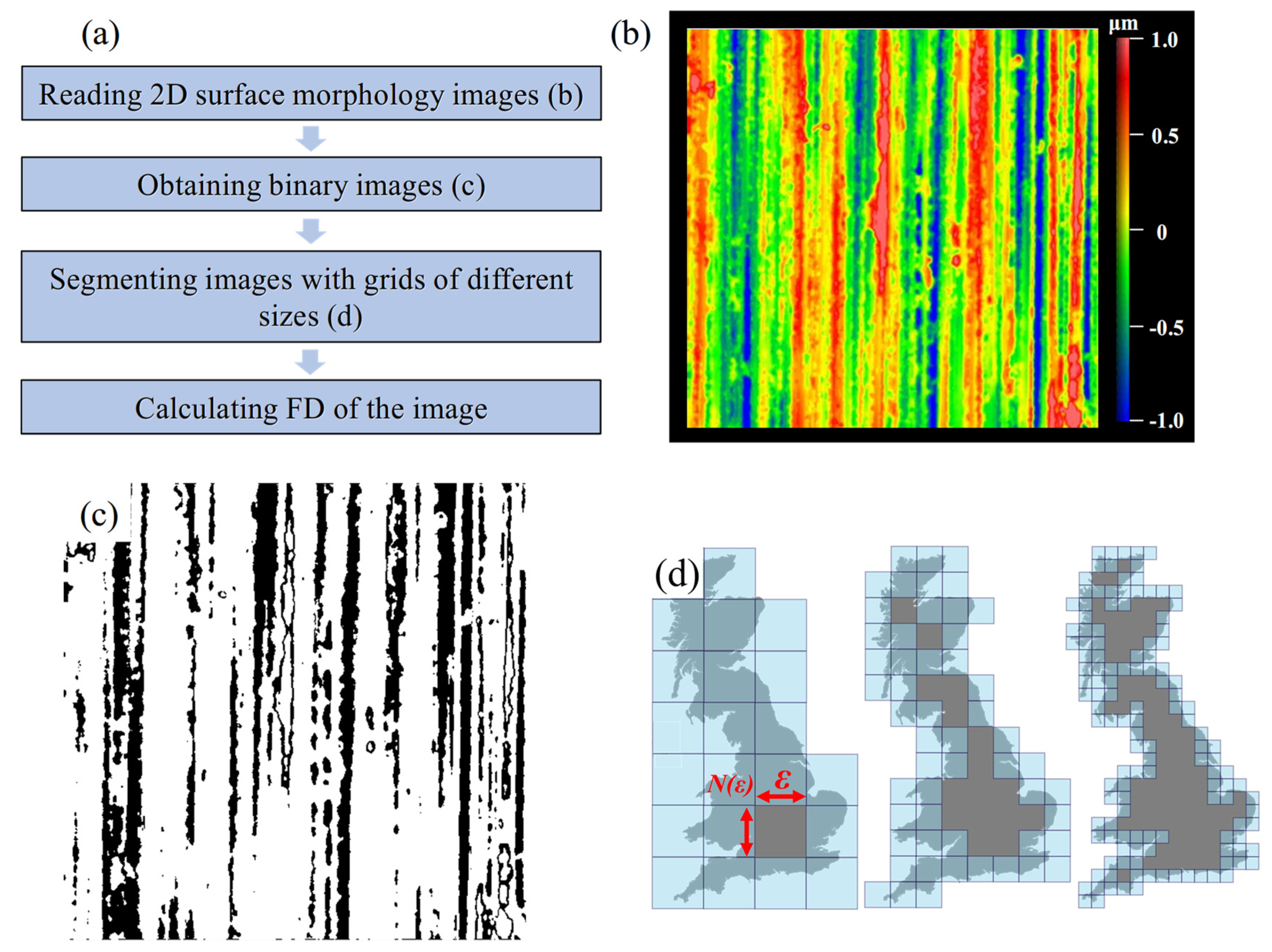

2.3. Box-Counting Method for Calculating Fractal Dimension

3. Results and Discussion

3.1. Effect of Surface Morphology on Tribology Characteristics

3.1.1. Effect of Surface Morphology on CoF

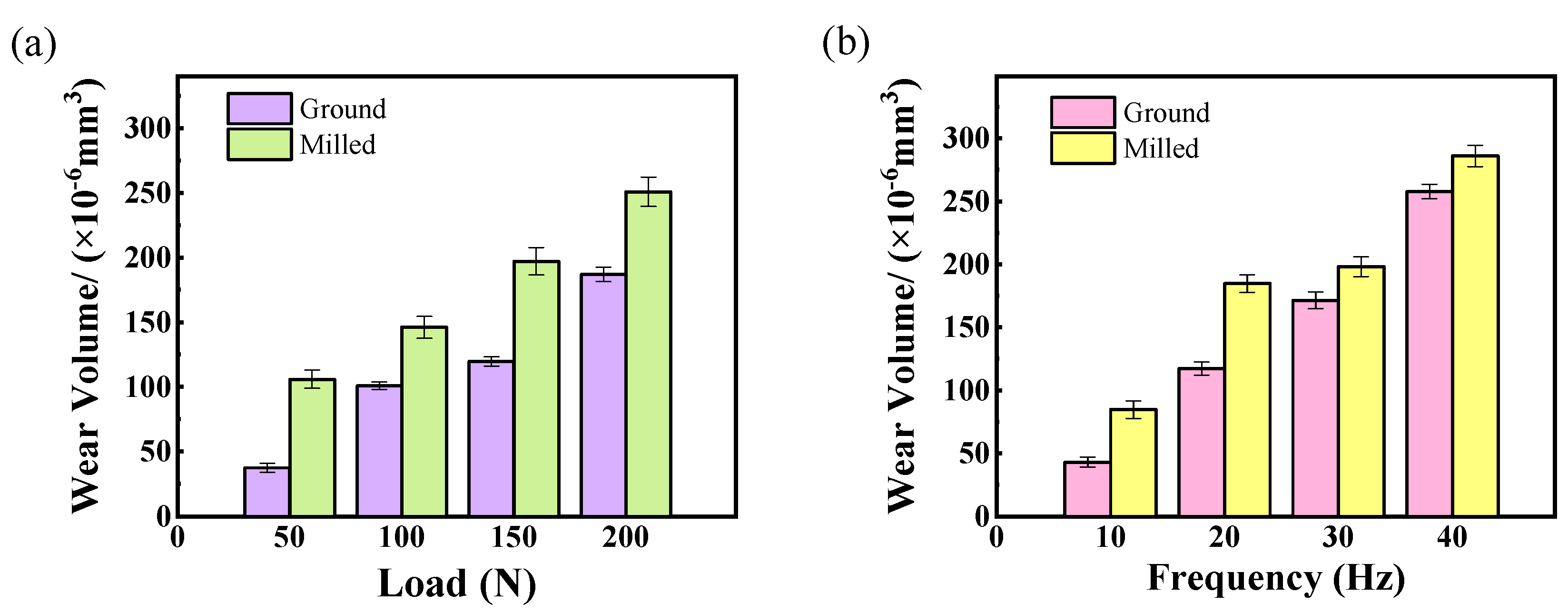

3.1.2. Effect of Surface Morphology on Wear Volume

3.2. Wear Mechanism

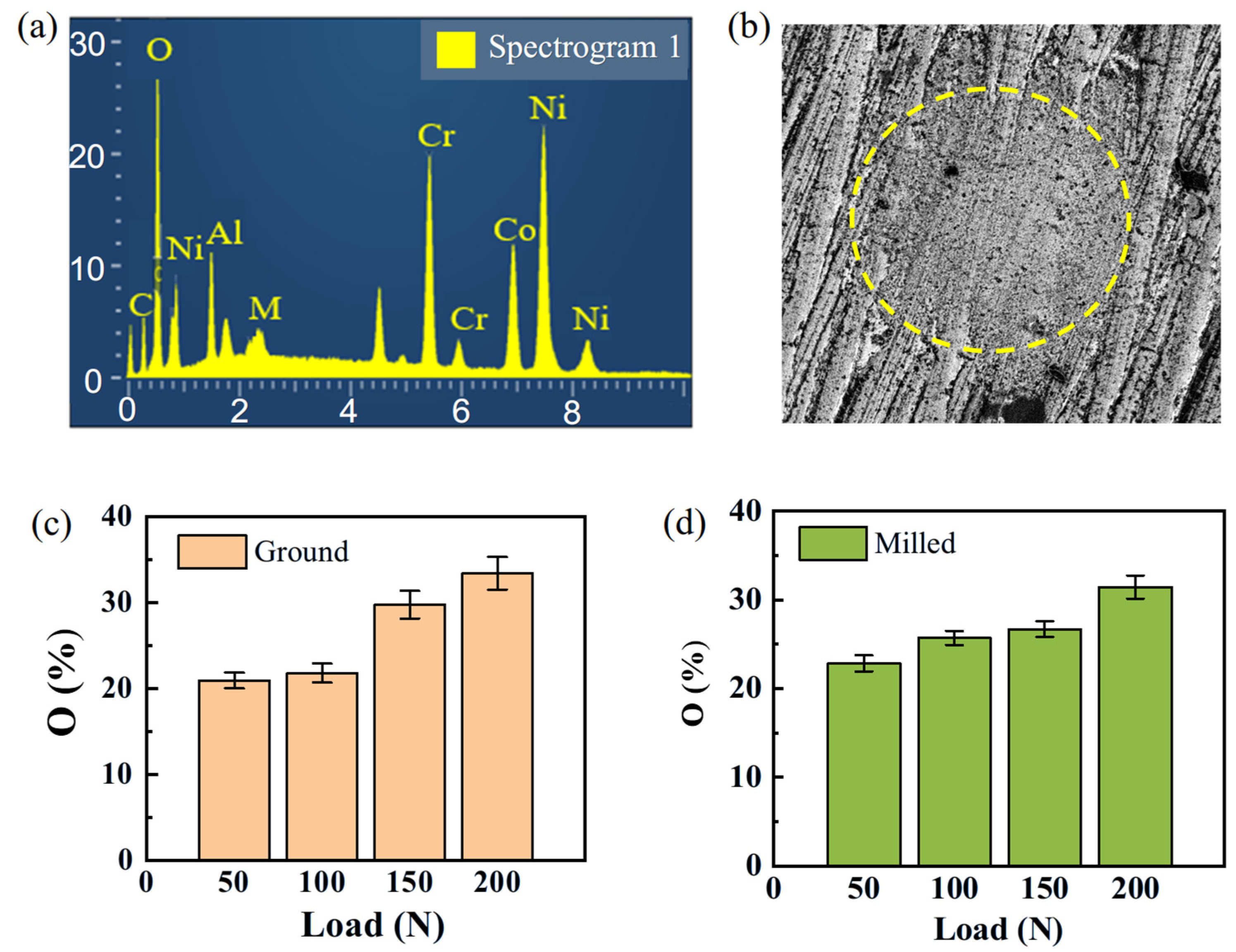

3.2.1. Effect of Surface Morphology on Wear Mechanism Under Different Loads

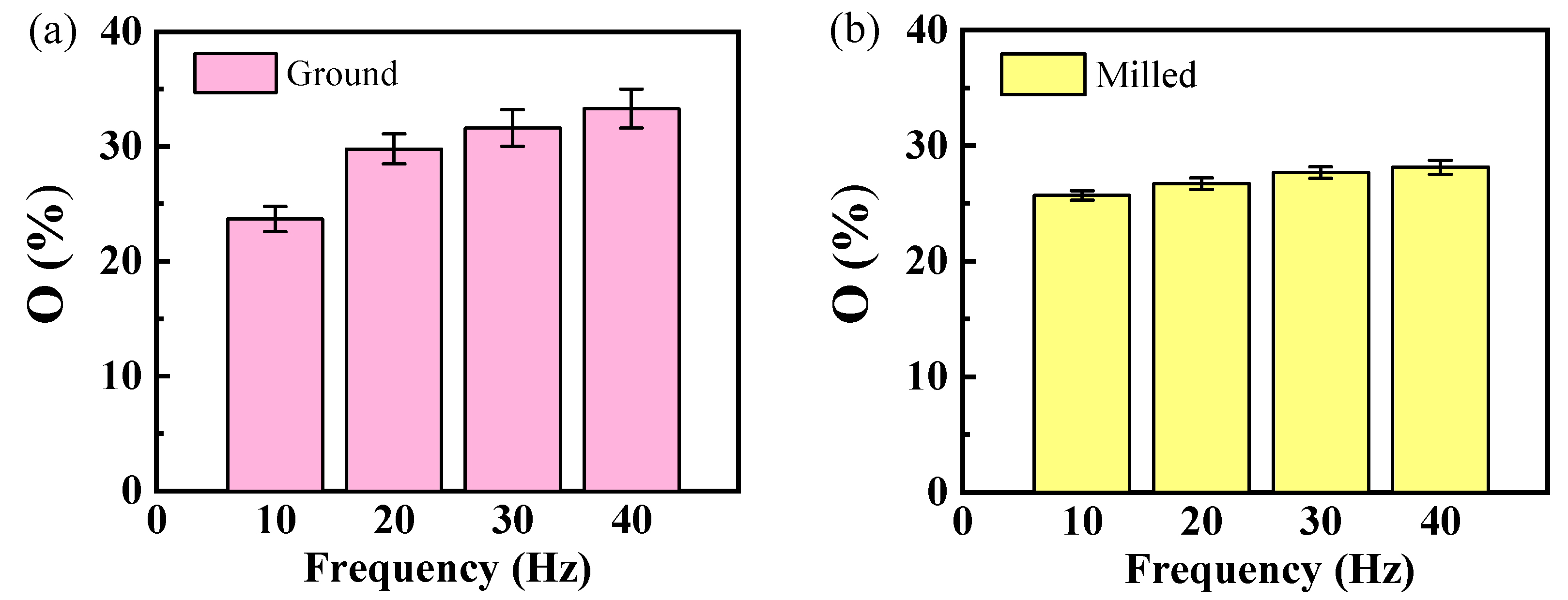

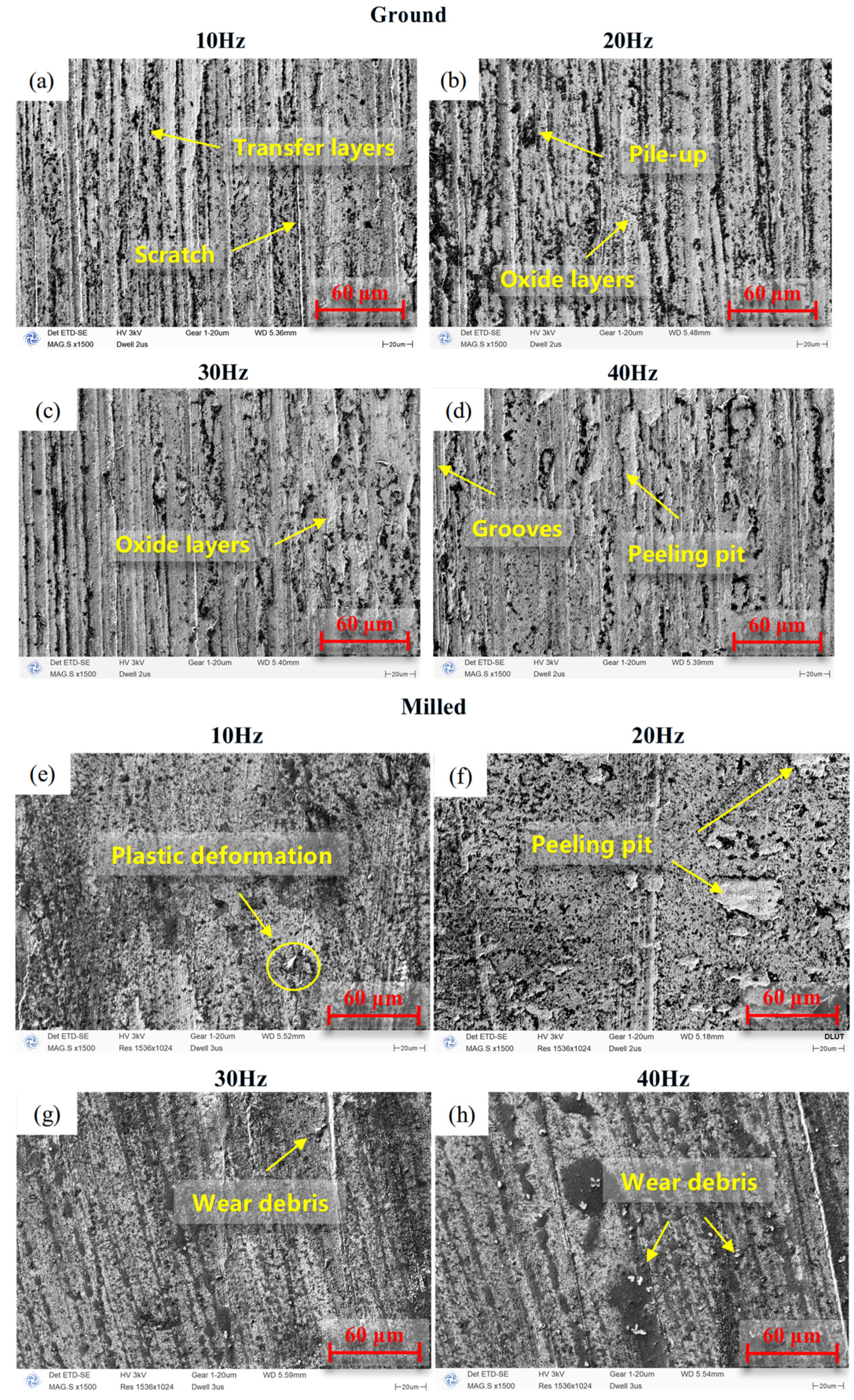

3.2.2. Effect of Surface Morphology on Wear Mechanism Under Different Frequencies

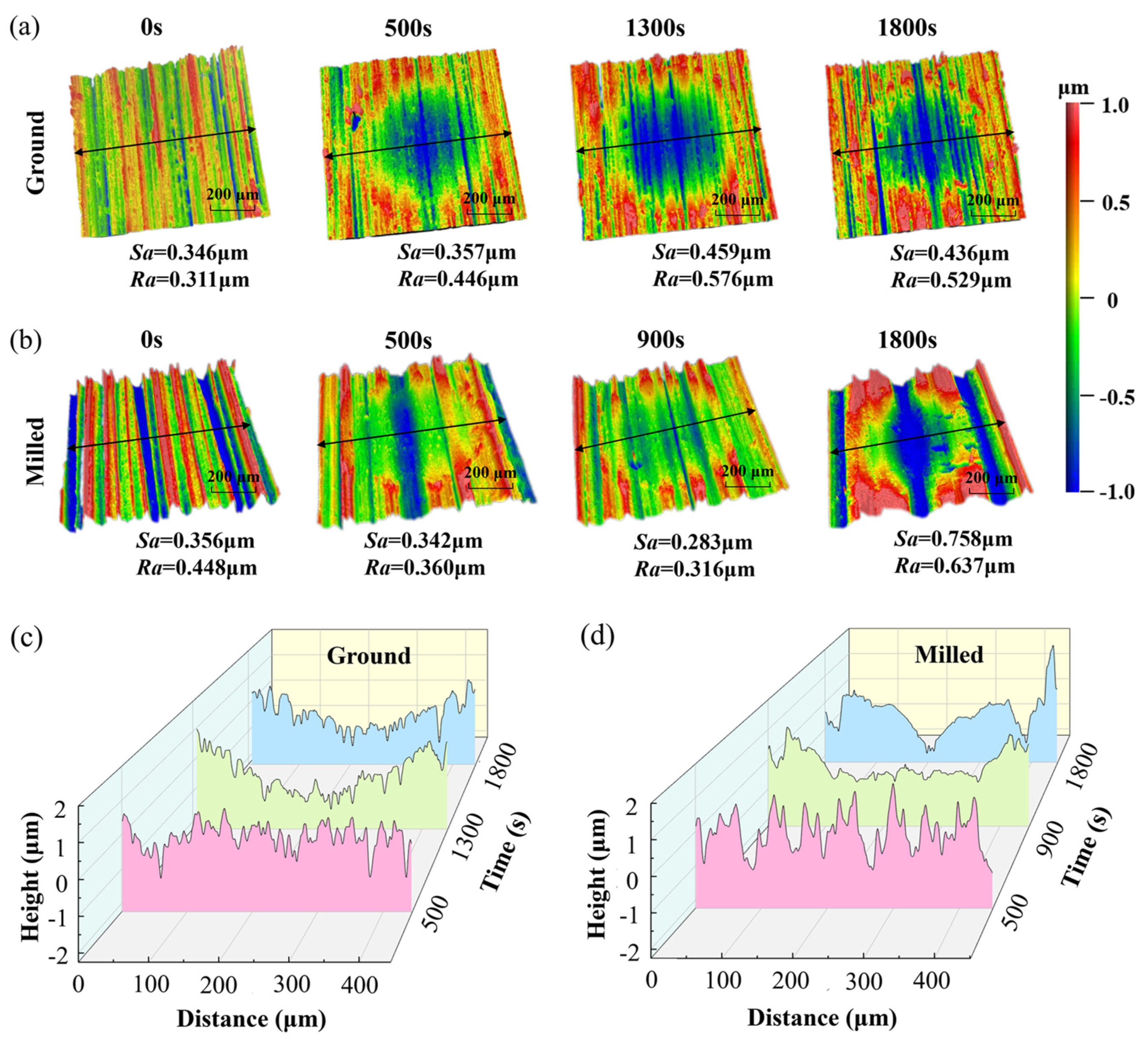

3.3. Surface Morphology Characterization for High-Temperature Fretting Wear

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fang, X.; Wang, Z.; Wang, W.; Cao, X.; Li, D.; Wang, Z.; Gong, J.; Cai, Z. Improvement mechanism of fretting fatigue lifetime of turbine dovetail tenon by shot peening combined with CuNiIn coating at 500 °C. Surf. Coat. Technol. 2024, 494, 131538. [Google Scholar] [CrossRef]

- Sista, V.; Kahvecioglu, O.; Kartal, G.; Zeng, Q.Z.; Kim, J.H.; Eryilmaz, O.L.; Erdemir, A. Evaluation of electrochemical boriding of Inconel 600. Surf. Coat. Technol. 2013, 215, 452–459. [Google Scholar] [CrossRef]

- Luo, Y.; Li, K.; Wei, Z.; Chen, B.; Hou, Y.; Wang, Y.; Cui, S.; Ni, J.; Wang, J.; Cai, Z. Effect of milling on fretting wear performance of GH4169 superalloy. Mater. Today Commun. 2025, 44, 111845. [Google Scholar] [CrossRef]

- Wang, J.; Gao, Y.; Wei, X. Investigations of the effects of combination treatments on the fretting fatigue resistance of GH4169 superalloy at an elevated temperature. Surf. Coat. Technol. 2021, 426, 127758. [Google Scholar] [CrossRef]

- Sarikaya, M.; Gupta, M.K.; Tomaz, I.; Pimenov, D.Y.; Kuntoglu, M.; Khanna, N.; Yildirim, C.V.; Krolczyk, G.M. A state-of-the-art review on tool wear and surface integrity characteristics in machining of superalloys. CIRP J. Manuf. Sci. Technol. 2021, 35, 624–658. [Google Scholar] [CrossRef]

- Amanov, A.; Pyun, Y.-S. Local heat treatment with and without ultrasonic nanocrystal surface modification of Ti-6Al-4V alloy: Mechanical and tribological properties. Surf. Coat. Technol. 2017, 326, 343–354. [Google Scholar] [CrossRef]

- Alkelae, F.; Fouvry, S. Identification of parameters influencing the glaze layer formation and stability at high temperature for a Waspaloy/Rene125 contact under fretting wear conditions. Wear 2017, 390–391, 41–48. [Google Scholar] [CrossRef]

- Song, J.; Yuan, H.; Schinow, V. Fretting corrosion behavior of electrical contacts with tin coating in atmosphere and vacuum. Wear 2019, 426, 1439–1445. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, X.; Jia, H.; Yang, X.; Chai, L.; Wang, S. High-temperature fretting wear behavior of IN738LC alloy formed by laser powder bed fusion. Tribol. Int. 2024, 199, 110017. [Google Scholar] [CrossRef]

- Zurcher, T.; Bouvard, G.; Abry, J.-C.; Fridrici, V.; Charkaluk, E. Effect of the elevated temperature on the wear behavior of Laser Metal Deposition IN718 repairs. Tribol. Int. 2024, 192, 109276. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, X.; Jia, H.; Yang, X.; Chai, L.; Wang, S. Fretting wear behavior and wear mechanism of selective laser melting IN738LC alloy with various loads and micro-structures. Tribol. Int. 2024, 197, 109796. [Google Scholar] [CrossRef]

- Jeong, S.H.; Cho, C.W.; Lee, Y.Z. Friction and wear of Inconel 690 for steam generator tube in elevated temperature water under fretting condition. Tribol. Int. 2005, 38, 283–288. [Google Scholar] [CrossRef]

- Fretting Wear Behavior of GH2132 Superalloy at Different Temperatures-Web of Science Core Collection. Available online: https://webofscience.clarivate.cn/wos/woscc/full-record/WOS:001407866300001 (accessed on 28 February 2025).

- Kubiak, K.J.; Mathia, T.G.; Fouvry, S. Interface roughness effect on friction map under fretting contact conditions. Tribol. Int. 2010, 43, 1500–1507. [Google Scholar] [CrossRef]

- Wang, X.; Ren, X.; Xue, Y.; Luan, B. Investigation on microstructure and high-temperature wear properties of high-speed laser cladding Inconel 625 alloy. J. Mater. Res. Technol-JMRT 2024, 30, 626–639. [Google Scholar] [CrossRef]

- ASTM G99-04; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. iTeh Standards: West Conshohocken, PA, USA, 2004.

- Elevated Temperature Fretting Wear Study of Additively Manufactured Inconel 625 superalloy-Web of Science Core Collection. Available online: https://webofscience.clarivate.cn/wos/woscc/full-record/WOS:000956732800001 (accessed on 28 April 2025).

- Yang, Q.; Zhou, W.; Gai, P.; Zhang, X.; Fu, X.; Chen, G.; Li, Z. Investigation on the fretting fatigue behaviors of Ti-6Al-4V dovetail joint specimens treated with shot-peening. Wear 2017, 372–373, 81–90. [Google Scholar] [CrossRef]

- Feng, K.; Shao, T. The evolution mechanism of tribo-oxide layer during high temperature dry sliding wear for nickel-based superalloy. Wear 2021, 476, 203747. [Google Scholar] [CrossRef]

- Ham, M.; Powers, B.M. Roughness Parameter Selection for Novel Manufacturing Processes. Scanning 2014, 36, 21–29. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, Y.; Wang, J.F.; Li, Z. Research on the fractal of surface topography of grinding. Int. J. Mach. Tools Manuf. 2001, 41, 2045–2049. [Google Scholar] [CrossRef]

- Kang, M.C.; Kim, J.S.; Kim, K.H. Fractal dimension analysis of machined surface depending on coated tool wear. Surf. Coat. Technol. 2005, 193, 259–265. [Google Scholar] [CrossRef]

- Jiang, Z.; Wang, H.; Fei, B. Research into the application of fractal geometry in characterising machined surfaces. Int. J. Mach. Tools Manuf. 2001, 41, 2179–2185. [Google Scholar] [CrossRef]

- Li, J.; Du, Q.; Sun, C. An improved box-counting method for image fractal dimension estimation. Pattern Recognit. 2009, 42, 2460–2469. [Google Scholar] [CrossRef]

- Ahmadi, A.; Sadeghi, F.; Shaffer, S. In-situ friction and fretting wear measurements of Inconel 617 at elevated temperatures. Wear 2018, 410, 110–118. [Google Scholar] [CrossRef]

- Khonsari, M.M.; Ghatrehsamani, S.; Akbarzadeh, S. On the running-in nature of metallic tribo-components: A review. Wear 2021, 474–475, 203871. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.; Zhang, S.; Liang, Y.; Zhang, Y.; Zhang, S.; Li, X.; Zhang, L.; Zhang, P.; Liu, N.; et al. Diffusion behavior of oxygen in FGH96 superalloys during consolidation process. Corros. Sci. 2024, 238, 112357. [Google Scholar] [CrossRef]

- Qu, Z.; Liu, K.; Wang, B.; Chen, Z. Fretting Fatigue Experiment and Finite Element Analysis for Dovetail Specimen at High Temperature. Appl. Sci. 2021, 11, 9913. [Google Scholar] [CrossRef]

- Yu, X.; Wang, Y.; Zhang, P.; Zhai, Y.; Li, L. Surface integrity and wear evolution of high strength aluminum alloy after high-speed oblique cutting. Proc. Inst. Mech. Eng. Part J-J. Eng. Tribol. 2022, 236, 881–891. [Google Scholar] [CrossRef]

- Hager, C.H.; Sanders, J.H.; Sharma, S. Effect of high temperature on the characterization of fretting wear regimes at Ti6Al4V interfaces. Wear 2006, 260, 493–508. [Google Scholar] [CrossRef]

- Zhang, X.-Y.; Liu, J.-H.; Cai, Z.-B.; Peng, J.-F.; Zhu, M.-H.; Ren, P.-D. Experimental Study of the Fretting Wear Behavior of Incoloy 800 Alloy at High Temperature. Tribol. Trans. 2017, 60, 1110–1119. [Google Scholar] [CrossRef]

- He, T.; Li, H.; He, J.; Weng, Z.; Xu, Y.; Liu, J.; Peng, J.; Zhu, M. Fretting wear behavior of GH2132 superalloy at different temperatures. Tribol. Int. 2025, 204, 110502. [Google Scholar] [CrossRef]

- Yu, Y.; Ma, T.; Gong, J.; Chen, T.; Zhou, L.; Cai, Z. Effect of laser shock peening without coating on fretting wear behavior of GH4169 superalloy at high-temperature. Wear 2024, 546, 205349. [Google Scholar] [CrossRef]

- Xu, Z.; Lu, Z.; Zhang, J.; Li, D.; Liu, J.; Lin, C. The Friction and Wear Behaviours of Inconel 718 Superalloys at Elevated Temperature. Front. Mater. 2021, 8, 794701. [Google Scholar] [CrossRef]

- Baby, A.K.; Priyaranjan, M.; Lawrence, K.D.; Rajendrakumar, P.K. Tribological behaviour of hypereutectic Al-Si automotive cylinder liner material under dry sliding wear condition in severe wear regime. Proc. Inst. Mech. Eng. Part J-J. Eng. Tribol. 2021, 235, 1450–1462. [Google Scholar] [CrossRef]

- Shi, Z.; Xu, L.; Deng, C.; Liu, M.; Liao, H.; Darut, G.; Planche, M.-P. Effects of frequency on the fretting wear behavior of aluminum bronze coatings. Surf. Coat. Technol. 2023, 457, 129306. [Google Scholar] [CrossRef]

- Xu, C.; Peng, Y.; Zhu, Z.; Tang, W.; Huang, K. Fretting Behaviors of Steel Wires with Tensile-Torsional Coupling Force Under Different Wire Diameters and Crossing Angles. Tribol. Lett. 2020, 68, 91. [Google Scholar] [CrossRef]

| Element | Cr | Co | W | Mo | Al | Ti | Nb | Zr | C | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| wt% | 16.20 | 13.10 | 1.03 | 4.08 | 2.18 | 3.66 | 0.71 | 0.04 | 0.04 | Bal. |

| Materials | Hardness (HV) | σ0.2 (MPa) | σb (MPa) | ε (%) |

|---|---|---|---|---|

| FGH96 | 502.4 ± 6.8 | 1140 ± 48.7 | 2020 ± 132.0 | 34.5 ± 7.4 |

| Influence Factor | Frequency (Hz) | Load (N) | Hertz Contact Pressure (MPa) | Test Duration (s) |

|---|---|---|---|---|

| Load | 20 | 50 | 2223 | 1800 |

| 100 | 2801 | |||

| 150 | 3207 | |||

| 200 | 3529 | |||

| Frequency | 10, 20, 30, 40 | 150 | 3207 | 1800 |

| Test duration | 20 | 150 | 3207 | 500 |

| 900 | ||||

| 1300 | ||||

| 1800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, X.; Wang, Z.; Yan, Y.; Zheng, K.; Bai, Q. Role of Surface Morphology Evolution in the Tribological Behavior of Superalloy Under High-Temperature Fretting. Materials 2025, 18, 2350. https://doi.org/10.3390/ma18102350

He X, Wang Z, Yan Y, Zheng K, Bai Q. Role of Surface Morphology Evolution in the Tribological Behavior of Superalloy Under High-Temperature Fretting. Materials. 2025; 18(10):2350. https://doi.org/10.3390/ma18102350

Chicago/Turabian StyleHe, Xuan, Zidan Wang, Ying Yan, Kailun Zheng, and Qian Bai. 2025. "Role of Surface Morphology Evolution in the Tribological Behavior of Superalloy Under High-Temperature Fretting" Materials 18, no. 10: 2350. https://doi.org/10.3390/ma18102350

APA StyleHe, X., Wang, Z., Yan, Y., Zheng, K., & Bai, Q. (2025). Role of Surface Morphology Evolution in the Tribological Behavior of Superalloy Under High-Temperature Fretting. Materials, 18(10), 2350. https://doi.org/10.3390/ma18102350