Material Properties Changes Caused by High Temperature Drying—Corn Cobs Case Study

Abstract

1. Introduction

1.1. Biomass Composition and Structure

1.2. Thermal Treatments of Biomass

- Drying;

- Pyrolysis, including torrefaction;

- Gasification;

- Combustion.

1.3. Changes of Biomass During Thermal Treatments

1.4. Importance of Drying in Pellets Production

1.5. Grinding

2. Materials and Methods

2.1. Material

2.2. Drying

2.3. Energy Parameters

2.4. Grinding

2.5. Compressibility and Compactability

3. Results

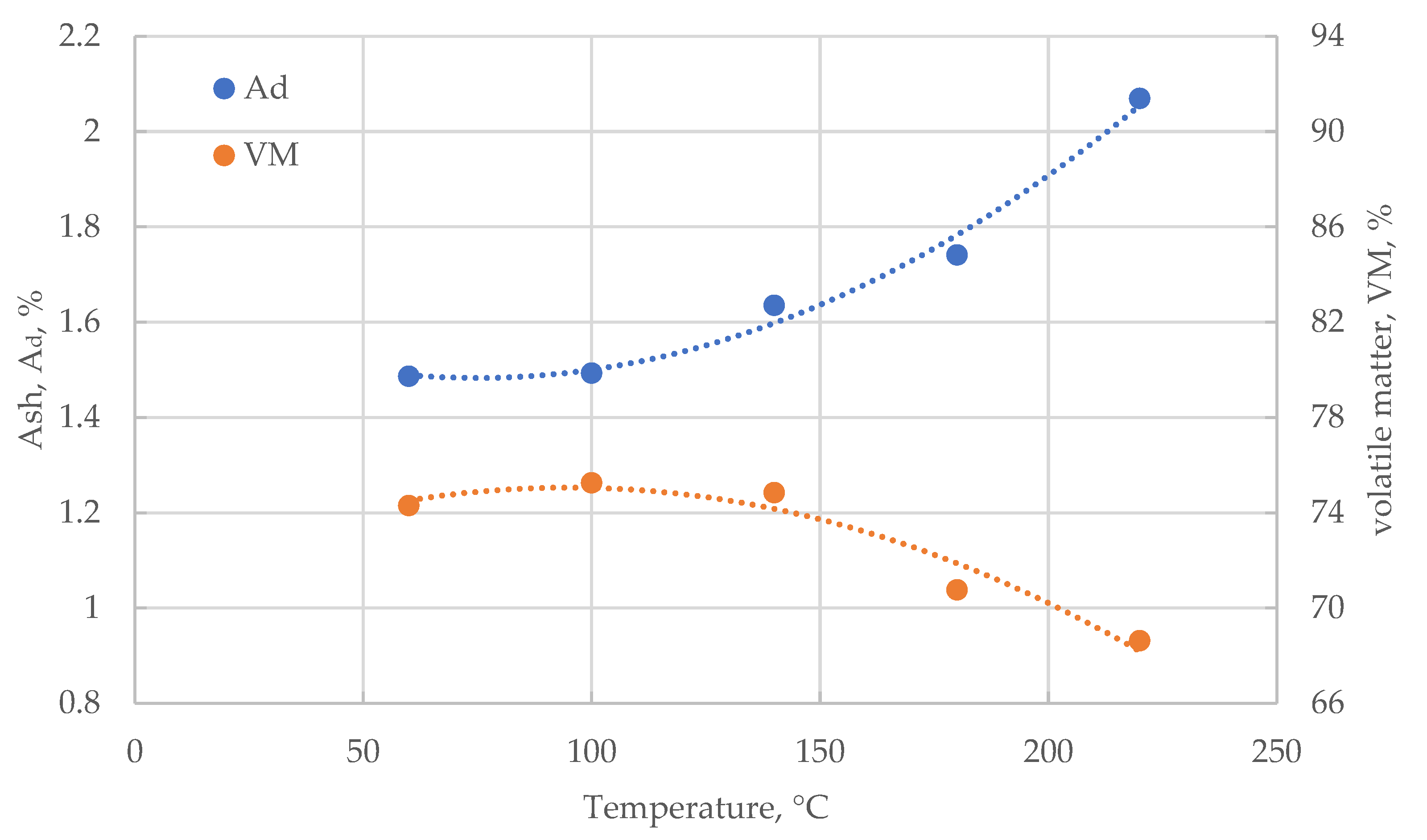

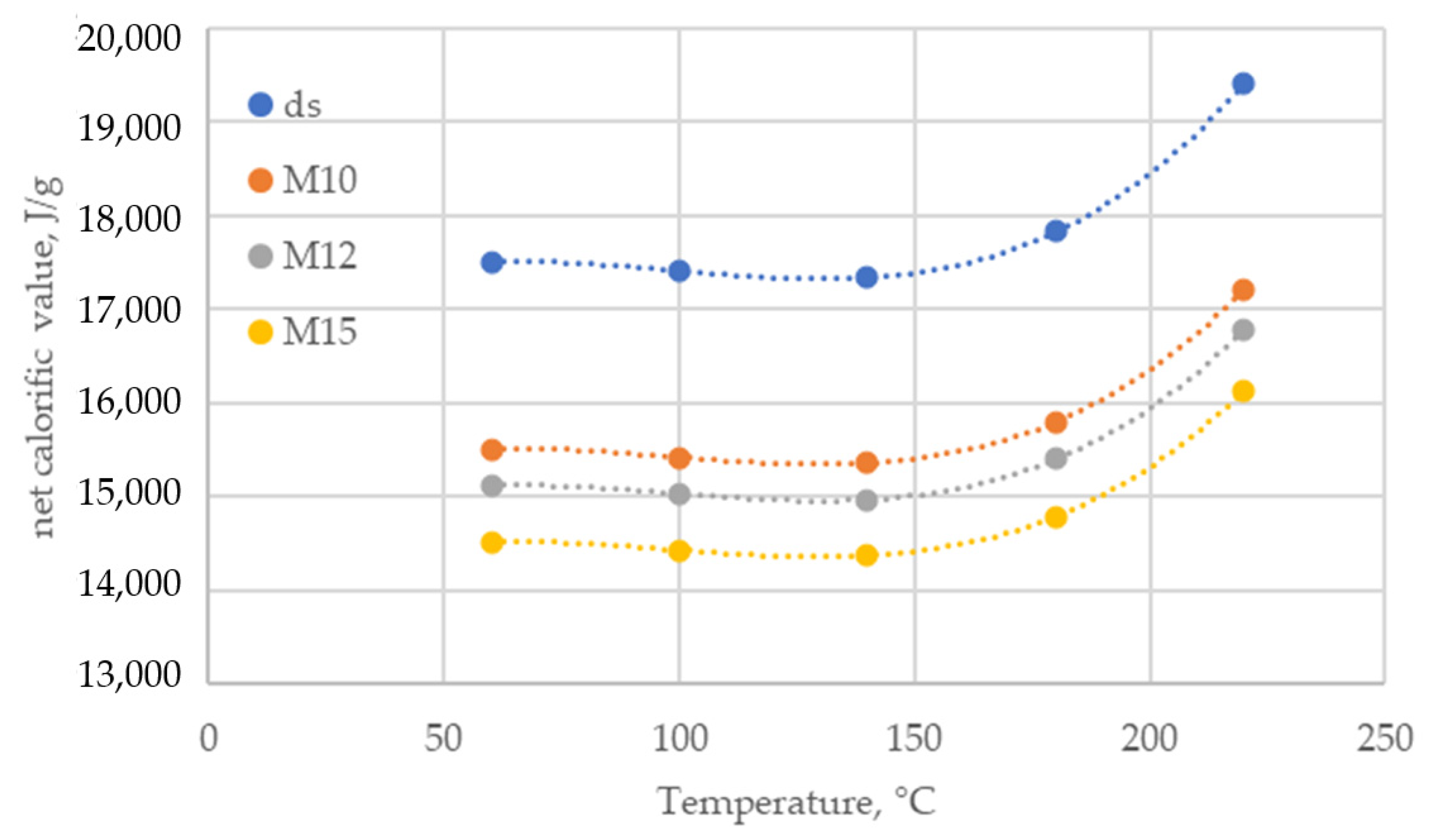

3.1. Energy Parameters

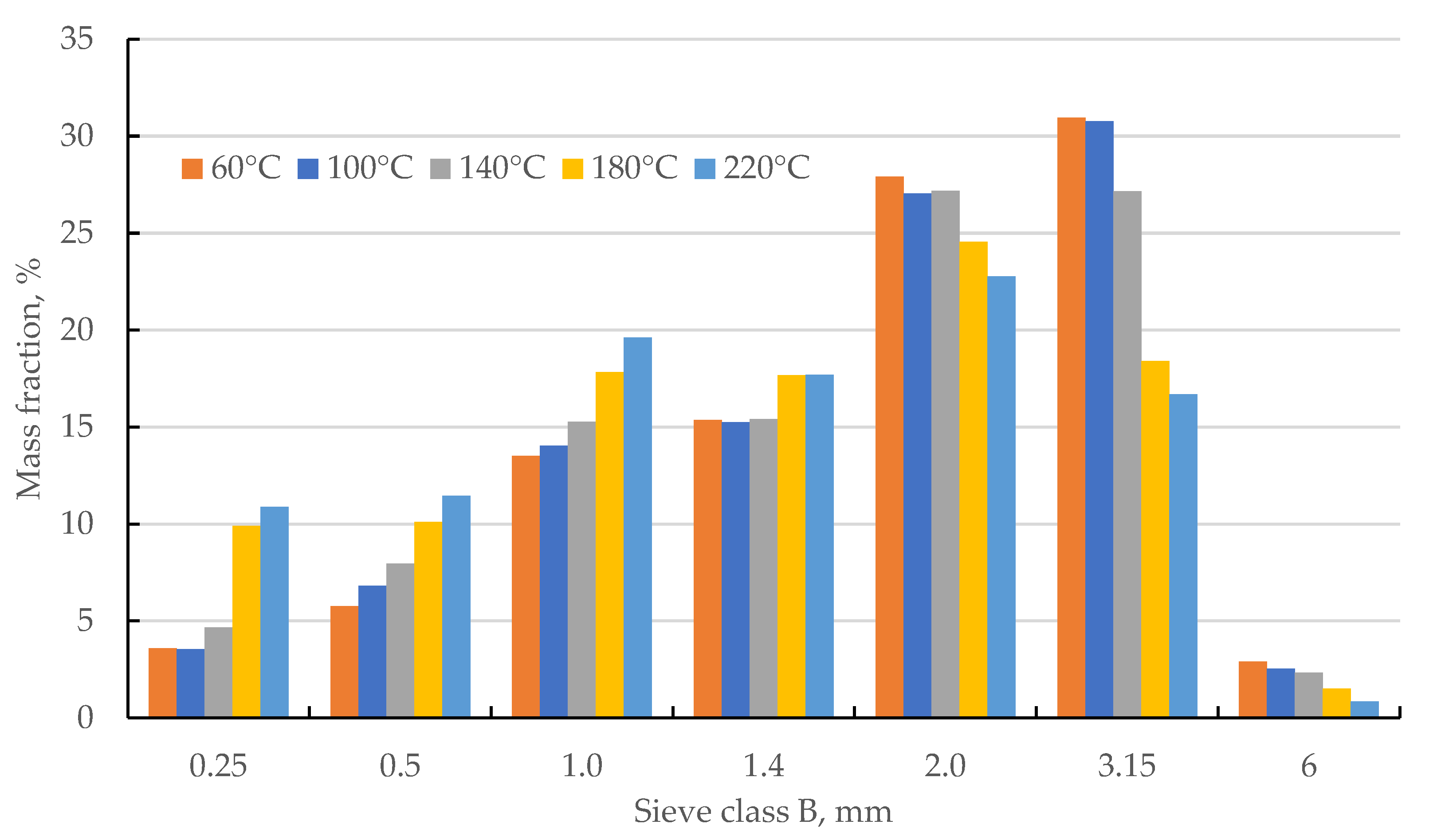

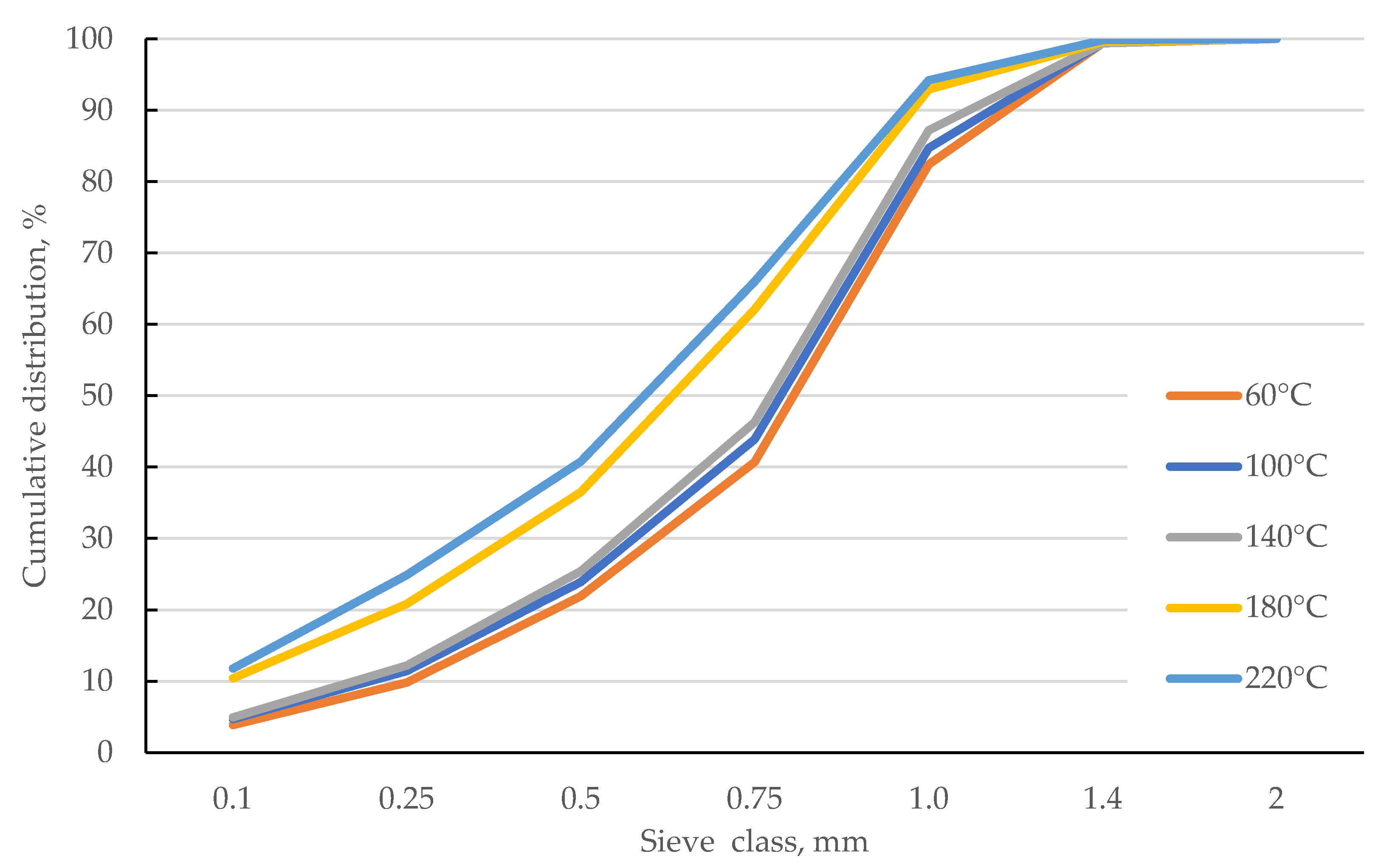

3.2. Grindability in Aspect of Particle Size Distribution Changes

3.3. Corn Cobs Compressibility and Compactability

4. Conclusions

- Ash content increases with temperature, which is an undesirable but expected phenomenon and consistent with the results available in the literature.

- Volatile content and calorific value increase, which is a desirable phenomenon, and is also confirmed in the literature.

- In the case of specific density, the obtained values are close to each other, so the drying temperature has no significant effect on this parameter.

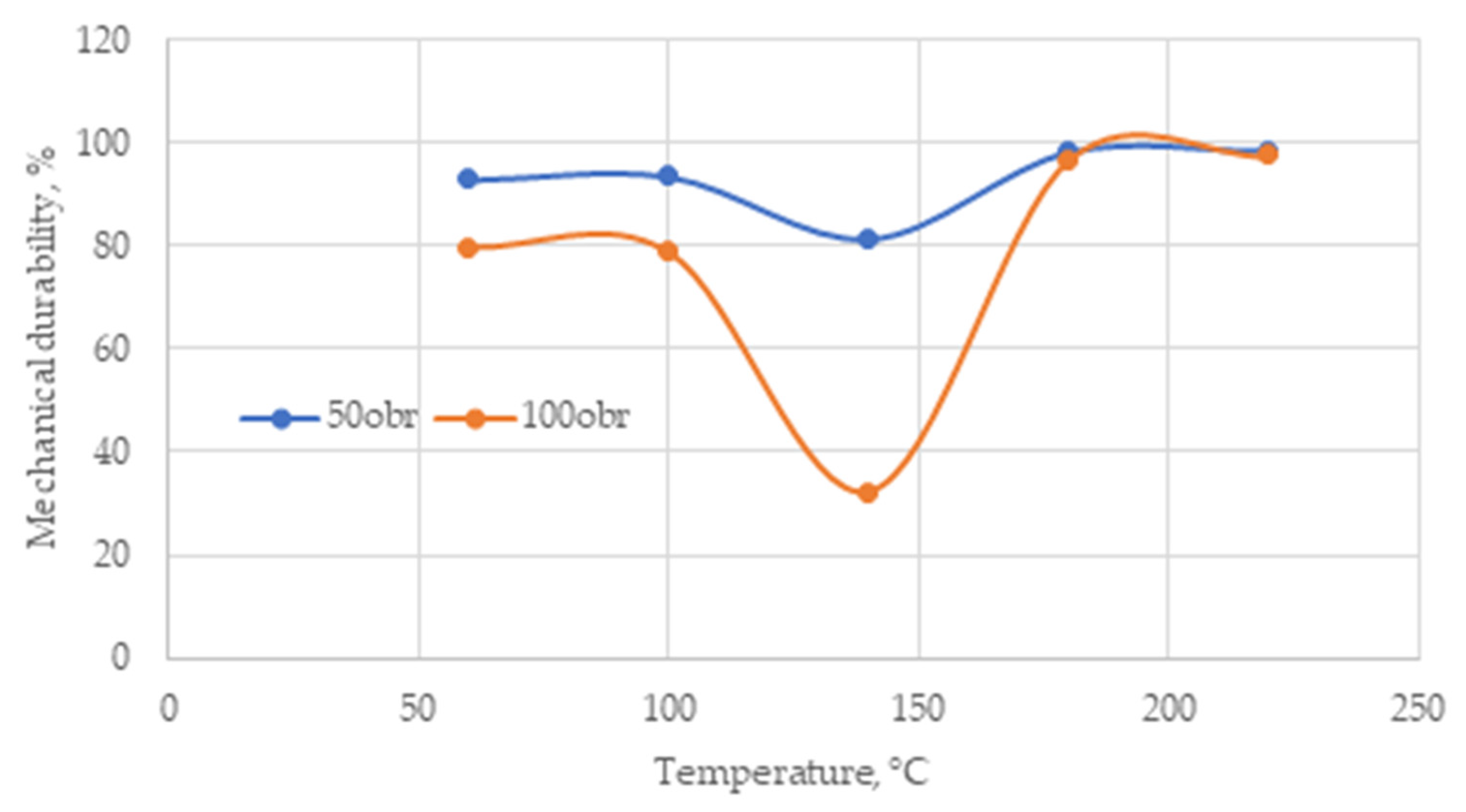

- The most interesting relationship was observed for the mechanical durability of the pellets. The temperature of 140 °C negatively affected this parameter. According to the literature, roasting worsens compactibility [52]. In the case studied, temperatures of 180 and 220 °C caused the pellets to obtain the highest DU values. The literature states that material dried and actually roasted at 300 °C is more difficult to compact than material roasted at 250 °C. However, the quality of pellets made from steam-exploded Douglas fir has elasticity and higher mechanical strength than those from raw biomass [53]. In our case, the temperature was lower than the typical torrefaction temperature, and perhaps this is where the differences came from. The temperature range studied does not yet result in the decomposition of lignin, which is the main binder during compaction [54].

- The drying of the material in the presented temperature range not only improves its energy parameters (an increase in and a decrease in volatile parts), but leads to an improvement in the pro-agglomeration properties of the material. In addition, the temperature range studied does not yet require the use of reactors that protect the material from oxygen and thus prevent ignition of the material during roasting.

- Since the presented research has a lab-scale character, further research is required that allows verification of the results on a technical scale. This will allow us to determine the further direction of research on this topic.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mukherjee, A.; Patra, B.R.; Podder, J.; Dalai, A.K. Synthesis of Biochar From Lignocellulosic Biomass for Diverse Industrial Applications and Energy Harvesting: Effects of Pyrolysis Conditions on the Physicochemical Properties of Biochar. Front. Mater. 2022, 9, 870184. [Google Scholar] [CrossRef]

- Wang, P.; Howard, B. Impact of Thermal Pretreatment Temperatures on Woody Biomass Chemical Composition, Physical Properties and Microstructure. Energies 2017, 11, 25. [Google Scholar] [CrossRef]

- Li, M.; Cao, S.; Meng, X.; Studer, M.; Wyman, C.E.; Ragauskas, A.J.; Pu, Y. The Effect of Liquid Hot Water Pretreatment on the Chemical–Structural Alteration and the Reduced Recalcitrance in Poplar. Biotechnol. Biofuels 2017, 10, 237. [Google Scholar] [CrossRef]

- Kapoor, K.; Tyagi, A.K.; Das, M.; Kumar, V. Comparative Analysis of Morphological and Structural Changes in Gamma and Electron Beam Irradiated Sugarcane Bagasse. Cellul. Chem. Technol. 2023, 57, 61–70. [Google Scholar] [CrossRef]

- Wang, P.; Howard, B.; Hedges, S.; Morreale, B.; Van Essendelft, D.; Berry, D. Thermal Pretreatment of Wood for Co-Gasification/Co-Firing of Biomass and Coal; National Energy Technology Laboratory (NETL): Pittsburgh, PA, USA; Morgantown, WV, USA, 2013.

- Yang, X.; Zhao, Y.; Zhang, L.; Wang, Z.; Zhao, Z.; Zhu, W.; Ma, J.; Shen, B. Effects of Torrefaction Pretreatment on the Structural Features and Combustion Characteristics of Biomass-Based Fuel. Molecules 2023, 28, 4732. [Google Scholar] [CrossRef]

- Vural, D.; Gainaru, C.; O’Neill, H.; Pu, Y.; Smith, M.D.; Parks, J.M.; Pingali, S.V.; Mamontov, E.; Davison, B.H.; Sokolov, A.P.; et al. Impact of Hydration and Temperature History on the Structure and Dynamics of Lignin. Green Chem. 2018, 20, 1602–1611. [Google Scholar] [CrossRef]

- Uddin, M.N.; Techato, K.; Taweekun, J.; Rahman, M.M.; Rasul, M.G.; Mahlia, T.M.I.; Ashrafur, S.M. An Overview of Recent Developments in Biomass Pyrolysis Technologies. Energies 2018, 11, 3115. [Google Scholar] [CrossRef]

- Yaacob, N.; Rahman, N.A.; Matali, S.; Idris, S.S.; Alias, A.B. An Overview of Oil Palm Biomass Torrefaction: Effects of Temperature and Residence Time. IOP Conf. Ser. Earth Environ. Sci. 2016, 36, 012038. [Google Scholar] [CrossRef]

- Eseyin, A.E.; Steele, P.H.; Pittman, C.U., Jr. Current Trends in the Production and Applications of Torrefied Wood/Biomass—A Review. Bioresources 2015, 10, 8812–8858. [Google Scholar] [CrossRef]

- Liu, Q.; Chmely, S.C.; Abdoulmoumine, N. Biomass Treatment Strategies for Thermochemical Conversion. Energy Fuels 2017, 31, 3525–3536. [Google Scholar] [CrossRef]

- Chen, D.; Zhou, J.; Zhang, Q.; Zhu, X.; Lu, Q. Upgrading of Rice Husk by Torrefaction and Its Influence on the Fuel Properties. Bioresources 2014, 9, 5893–5905. [Google Scholar] [CrossRef]

- Ribeiro, J.M.C.; Godina, R.; Matias, J.C.d.O.; Nunes, L.J.R. Future Perspectives of Biomass Torrefaction: Review of the Current State-Of-The-Art and Research Development. Sustainability 2018, 10, 2323. [Google Scholar] [CrossRef]

- Arias, B.; Pevida, C.; Fermoso, J.; Plaza, M.G.; Rubiera, F.; Pis, J.J. Influence of Torrefaction on the Grindability and Reactivity of Woody Biomass. Fuel Process. Technol. 2008, 89, 169–175. [Google Scholar] [CrossRef]

- Jewiarz, M.; Wróbel, M.; Mudryk, K.; Szufa, S. Impact of the Drying Temperature and Grinding Technique on Biomass Grindability. Energies 2020, 13, 3392. [Google Scholar] [CrossRef]

- Commandré, J.M.; Leboeuf, A. Volatile Yields and Solid Grindability after Torrefaction of Various Biomass Types. Environ. Prog. Sustain. Energy 2015, 34, 1180–1186. [Google Scholar] [CrossRef]

- Cai, J.; Zhu, L.; Wei, Q.; Huang, D.; Luo, M.; Tang, X. Drying Kinetics of a Single Biomass Particle Using Fick’s Second Law of Diffusion. Processes 2023, 11, 984. [Google Scholar] [CrossRef]

- Gustafson, R.J.; Morey, R.V. Study of Factors Affecting Quality Changes During High-Temperature Drying. Trans. ASAE 1979, 22, 0926–0932. [Google Scholar] [CrossRef]

- Sorokova, N.; Korinchuk, D. Mathematical Modeling of the Dynamics of Heat and Mass Transfer, Phase Transformations and Thermal Decomposition at High Temperature Drying of Biomass. In Proceedings of the Chemical Technology and Engineering, Lviv, Ukraine, 24–28 June 2019; pp. 299–302. [Google Scholar]

- Mu, C.; Zhang, S.; Li, Y.; Li, H.; Wu, S.; Huang, X. Evolution of Microstructure and Combustion Reactivity of Lignite during High-Temperature Drying Process. Dry. Technol. 2018, 36, 1170–1178. [Google Scholar] [CrossRef]

- Liang, Z.; Tong, L.; Yin, S.; Liu, C.; Wang, L. Bidirectional Hot Air Drying: An Effective Inhibitor of the Browning of Biomass Similar to Thick-Layered Honeysuckle. Dry. Technol. 2022, 40, 116–126. [Google Scholar] [CrossRef]

- Keil, C.; Grebenteuch, S.; Kröncke, N.; Kulow, F.; Pfeif, S.; Kanzler, C.; Rohn, S.; Boeck, G.; Benning, R.; Haase, H. Systematic Studies on the Antioxidant Capacity and Volatile Compound Profile of Yellow Mealworm Larvae (T. molitor L.) under Different Drying Regimes. Insects 2022, 13, 166. [Google Scholar] [CrossRef]

- Szufa, S.; Piersa, P.; Adrian, Ł.; Czerwińska, J.; Lewandowski, A.; Lewandowska, W.; Sielski, J.; Dzikuć, M.; Wróbel, M.; Jewiarz, M.; et al. Sustainable Drying and Torrefaction Processes of Miscanthus for Use as a Pelletized Solid Biofuel and Biocarbon-Carrier for Fertilizers. Molecules 2021, 26, 1014. [Google Scholar] [CrossRef] [PubMed]

- Klement, I.; Marko, P. Colour Changes of Beech Wood (Fagus sylvatica L.) During High Temperature Drying Process. Wood Res. 2009, 54, 45–54. [Google Scholar]

- Möttönen, V.; Kärki, T. Color Changes of Birch Wood During High-Temperature Drying. Dry. Technol. 2008, 26, 1125–1128. [Google Scholar] [CrossRef]

- Pradhan, P.; Arora, A.; Mahajani, S.M. Factors Affecting the Quality of Fuel Pellets Produced from Waste Biomass. IOP Conf. Ser. Earth Environ. Sci. 2020, 463, 012013. [Google Scholar] [CrossRef]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and Utilization of Fuel Pellets from Biomass: A Review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Mudryk, K.; Fraczek, J.; Wrobel, M.; Jewiarz, M. Pressure Agglomeration Herbaceous Raw Materials Intended for Consumer Purposes. In Proceedings of the Engineering for Rural Development, Jelgava, Latvia, 23–25 May 2018; Volume 17. [Google Scholar]

- Whittaker, C.; Shield, I. Factors Affecting Wood, Energy Grass and Straw Pellet Durability—A Review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Moliner, C.; Lagazzo, A.; Bosio, B.; Botter, R.; Arato, E. Production, Characterization, and Evaluation of Pellets from Rice Harvest Residues. Energies 2020, 13, 479. [Google Scholar] [CrossRef]

- Rupasinghe, R.L.; Perera, P.; Bandara, R.; Amarasekera, H.; Vlosky, R. Insights into Properties of Biomass Energy Pellets Made from Mixtures of Woody and Non-Woody Biomass: A Meta-Analysis. Energies 2023, 17, 54. [Google Scholar] [CrossRef]

- Alege, F.P.; Miito, G.J.; DeVetter, L.W.; Tao, H.; Ndegwa, P.M. Effects of Blending Dairy Manure Compost and Canola Meal on Pellet Quality and Nutrient Concentrations. Trans. ASABE 2021, 64, 353–363. [Google Scholar] [CrossRef]

- No 440/2008; Council Regulation (EC) No 440/2008 of 30 May 2008. Laying down Test Methods Pursuant to Regulation (EC) No 1907/2006 of the European Parliament and of the Council on the Registration, Evaluation, Authorisation and Restriction of Chemicals; European Union: Brussels, Belgium, 2008.

- Mudryk, K.; Jewiarz, M.; Wróbel, M.; Niemiec, M.; Dyjakon, A. Evaluation of Urban Tree Leaf Biomass-Potential, Physico-Mechanical and Chemical Parameters of Raw Material and Solid Biofuel. Energies 2021, 14, 818. [Google Scholar] [CrossRef]

- ISO 18122:2023; Solid Biofuels—Determination of Ash Content. International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 18123:2023; Solid Biofuels—Determination of the Content of Volatile Matter. International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 18125:2017; Solid Biofuels—Determination of Calorific Value. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 14780:2017; Solid Biofuels—Sample Preparation. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 17827-2:2024; Solid Biofuels—Determination of Particle Size Distribution for Uncompressed Fuels—Part 2: Vibrating Screen Method Using Sieves with Apertures of 3.15 Mm and Below. International Organization for Standardization: Geneva, Switzerland, 2024.

- ISO 17831-1:2015; Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes—Part 1: Pellets. International Organization for Standardization: Geneva, Switzerland, 2015.

- United States Pharmacopeia. Tablet Friability; United States Pharmacopeia: North Bethesda, MD, USA, 2023. [Google Scholar]

- ISO 17225-6:2021; Solid Biofuels—Fuel Specifications and Classes—Part 6: Graded Non-Woody Pellets. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 17225-2:2021; Solid Biofuels—Fuel Specifications and Classes Part 2: Graded Wood Pellets. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 17225-1:2021; Solid Biofuels—Fuel Specifications and Classes Part 1: General Requirements. International Organization for Standardization: Geneva, Switzerland, 2021.

- Phanphanich, M.; Mani, S. Impact of Torrefaction on the Grindability and Fuel Characteristics of Forest Biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef] [PubMed]

- Hari, J.; Khalsa, A.; Leistner, D.; Weller, N.; Darvell, L.I.; Dooley, B. Torrefied Biomass Pellets—Comparing Grindability in Different Laboratory Mills. Energies 2016, 9, 794. [Google Scholar] [CrossRef]

- Bridgeman, T.G.; Jones, J.M.; Williams, A.; Waldron, D.J. An Investigation of the Grindability of Two Torrefied Energy Crops. Fuel 2010, 89, 3911–3918. [Google Scholar] [CrossRef]

- ImageJ—Image Processing and Analysis in Java. Available online: https://imagej.net/ij/ (accessed on 14 April 2025).

- Bergström, D.; Israelsson, S.; Öhman, M.; Dahlqvist, S.-A.; Gref, R.; Boman, C.; Wästerlund, I. Effects of Raw Material Particle Size Distribution on the Characteristics of Scots Pine Sawdust Fuel Pellets. Fuel Process. Technol. 2008, 89, 1324–1329. [Google Scholar] [CrossRef]

- Zafari, A.; Kianmehr, M.H. Factors Affecting Mechanical Properties of Biomass Pellet from Compost. Environ. Technol. 2014, 35, 478–486. [Google Scholar] [CrossRef]

- Zawiślak, K.; Sobczak, P.; Kraszkiewicz, A.; Niedziółka, I.; Parafiniuk, S.; Kuna-Broniowska, I.; Tanaś, W.; Żukiewicz-Sobczak, W.; Obidziński, S. The Use of Lignocellulosic Waste in the Production of Pellets for Energy Purposes. Renew. Energy 2020, 145, 997–1003. [Google Scholar] [CrossRef]

- Stelte, W.; Nielsen, N.P.K.; Hansen, H.O.; Dahl, J.; Shang, L.; Sanadi, A.R. Pelletizing Properties of Torrefied Wheat Straw. Biomass Bioenergy 2013, 49, 214–221. [Google Scholar] [CrossRef]

- Lam, P.S.; Sokhansanj, S.; Bi, X.; Lim, C.J.; Melin, S. Energy Input and Quality of Pellets Made from Steam-Exploded Douglas Fir (Pseudotsuga menziesii). Energy Fuels 2011, 25, 1521–1528. [Google Scholar] [CrossRef]

- Chen, W.-H.; Lin, B.-J.; Lin, Y.-Y.; Chu, Y.-S.; Ubando, A.T.; Show, P.L.; Ong, H.C.; Chang, J.-S.; Ho, S.-H.; Culaba, A.B.; et al. Progress in Biomass Torrefaction: Principles, Applications and Challenges. Prog. Energy Combust. Sci. 2021, 82, 100887. [Google Scholar] [CrossRef]

| Sieve Classes (mm) | B1:0.25 | B2:0.5 | B3:1 | B4:1.4 | B5:2 | B6:3.15 | B7:6 | B8:+6 |

|---|---|---|---|---|---|---|---|---|

| Particle diameter d (mm) | d ≤ 0.25 | 0.25 < d ≤ 0.5 | 0.5 < d ≤ 1 | 1 < d ≤ 1.4 | 1.4 < d ≤ 2 | 2 < d ≤ 3.15 | 3.15 < d ≤ 6 | d > 6 |

| Sieve Classes (mm) | B3:1 | B4:1.4 | B5:2 |

|---|---|---|---|

| Share (%) | 43 | 26 | 31 |

| Sieve Classes (mm) | C1:0.1 | C2:0.25 | C3:0.5 | C4:0.71 | C5:1 | C6:1.4 | C7:2 |

|---|---|---|---|---|---|---|---|

| Particle diameter d (mm) | d ≤ 0.25 | 0.25 < d ≤ 0.5 | 0.5 < d ≤ 1 | 1 < d ≤ 1.4 | 1.4 < d ≤ 2 | 2 < d ≤ 3.15 | 3.15 < d ≤ 6 |

| Temperature (°C) | 60 | 100 | 140 | 180 | 220 |

|---|---|---|---|---|---|

| d10 (mm) | 0.25 | 0.22 | 0.2 | <0.1 | <0.1 |

| d50 (mm) | 0.81 | 0.78 | 0.78 | 0.63 | 0.59 |

| d90 (mm) | 1.18 | 1.14 | 1.09 | 0.98 | 0.96 |

| Temperature (°C) | 60 | 100 | 140 | 180 | 220 | 220 |

|---|---|---|---|---|---|---|

| DE (g/cm3) | 1.03 | 1.03 | 1.04 | 1.17 | 1.07 | 1.07 |

| Parameter | Temperature [°C] | ISO Quality Norm | ||||

|---|---|---|---|---|---|---|

| 60 | 100 | 140 | 180 | 220 | ||

| Ad | class B | off-class | 17225-2 | |||

| all classes | 17225-6 | |||||

| VM | ||||||

| qp, net at M10% | off-class | all classes | 17225-2 | |||

| qp, net at M12% | class A | 17225-6 | ||||

| qp, net at M15% | class B | off-class | class B | 17225-6 | ||

| d50 | ||||||

| DE | all classes | 17225-2; 17225-6 | ||||

| DU | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wróbel, M.; Jewiarz, M.; Krilek, J.; Dmochowska-Kuc, L. Material Properties Changes Caused by High Temperature Drying—Corn Cobs Case Study. Materials 2025, 18, 2302. https://doi.org/10.3390/ma18102302

Wróbel M, Jewiarz M, Krilek J, Dmochowska-Kuc L. Material Properties Changes Caused by High Temperature Drying—Corn Cobs Case Study. Materials. 2025; 18(10):2302. https://doi.org/10.3390/ma18102302

Chicago/Turabian StyleWróbel, Marek, Marcin Jewiarz, Jozef Krilek, and Luiza Dmochowska-Kuc. 2025. "Material Properties Changes Caused by High Temperature Drying—Corn Cobs Case Study" Materials 18, no. 10: 2302. https://doi.org/10.3390/ma18102302

APA StyleWróbel, M., Jewiarz, M., Krilek, J., & Dmochowska-Kuc, L. (2025). Material Properties Changes Caused by High Temperature Drying—Corn Cobs Case Study. Materials, 18(10), 2302. https://doi.org/10.3390/ma18102302