Numerical Analysis of Aggregate Debonding in Asphalt Concrete

Abstract

1. Introduction

1.1. State of the Art

1.1.1. Mechanistic–Empirical Pavement Design Method

1.1.2. Continuum Models

1.1.3. Multiscale Modeling

1.1.4. Direct Finite Element Analysis

1.2. Scope of the Study

2. Materials and Methods

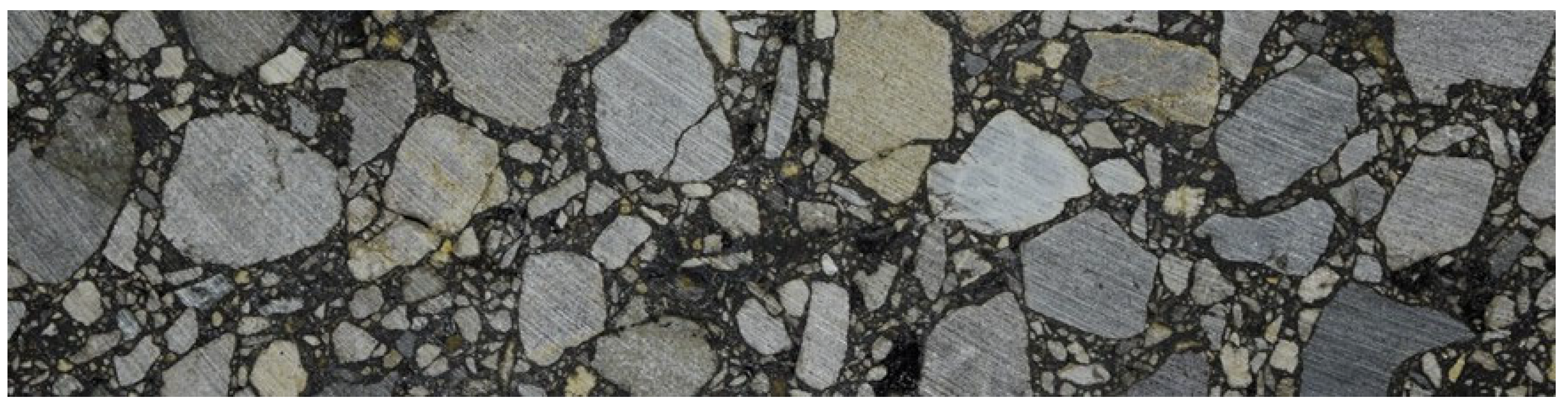

2.1. Asphalt Concrete Specimen

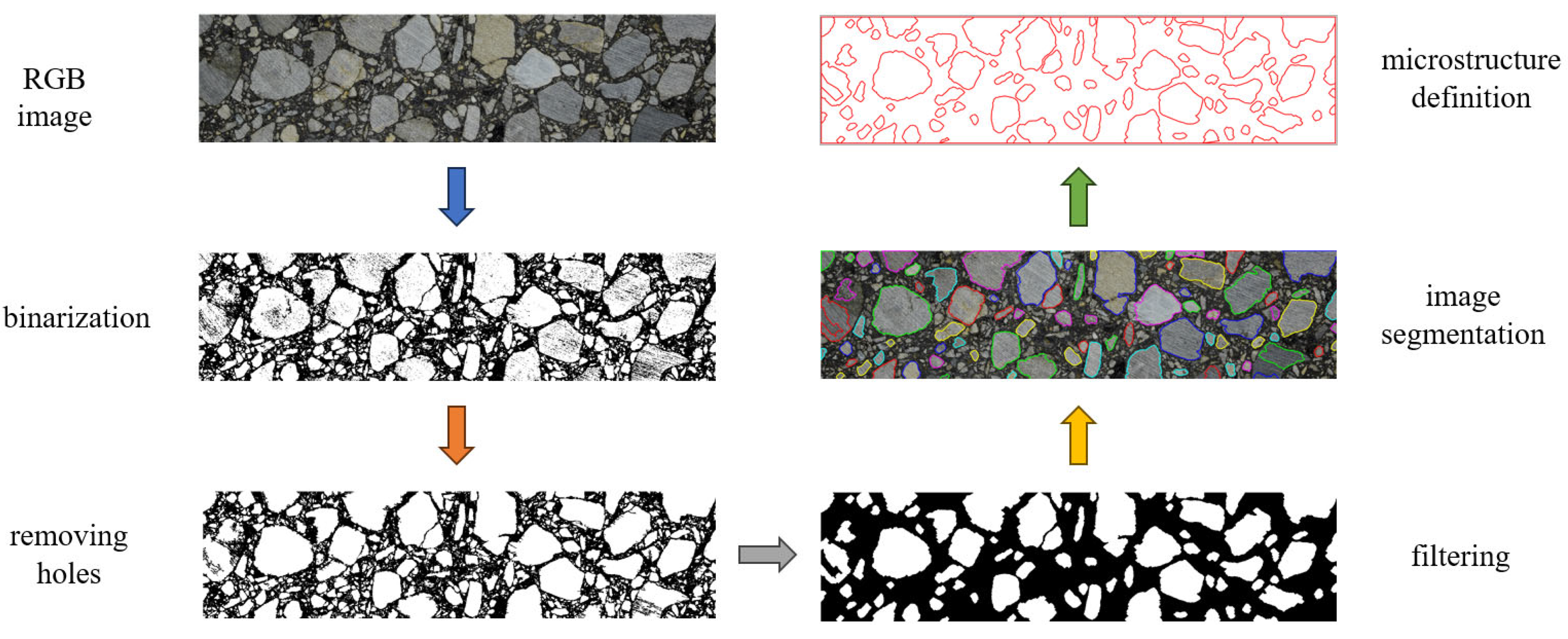

2.2. Digital Reconstruction of Asphalt Concrete Microstructure

- The RGB image was converted to a grayscale form;

- Binarization was performed to distinguish only two phases;

- A threshold was set to eliminate objects smaller than 2 mm, typical for AC;

- Unrealistic holes in the aggregate particles were removed;

- The boundaries of the aggregate particles were detected and stored in vector graphics format.

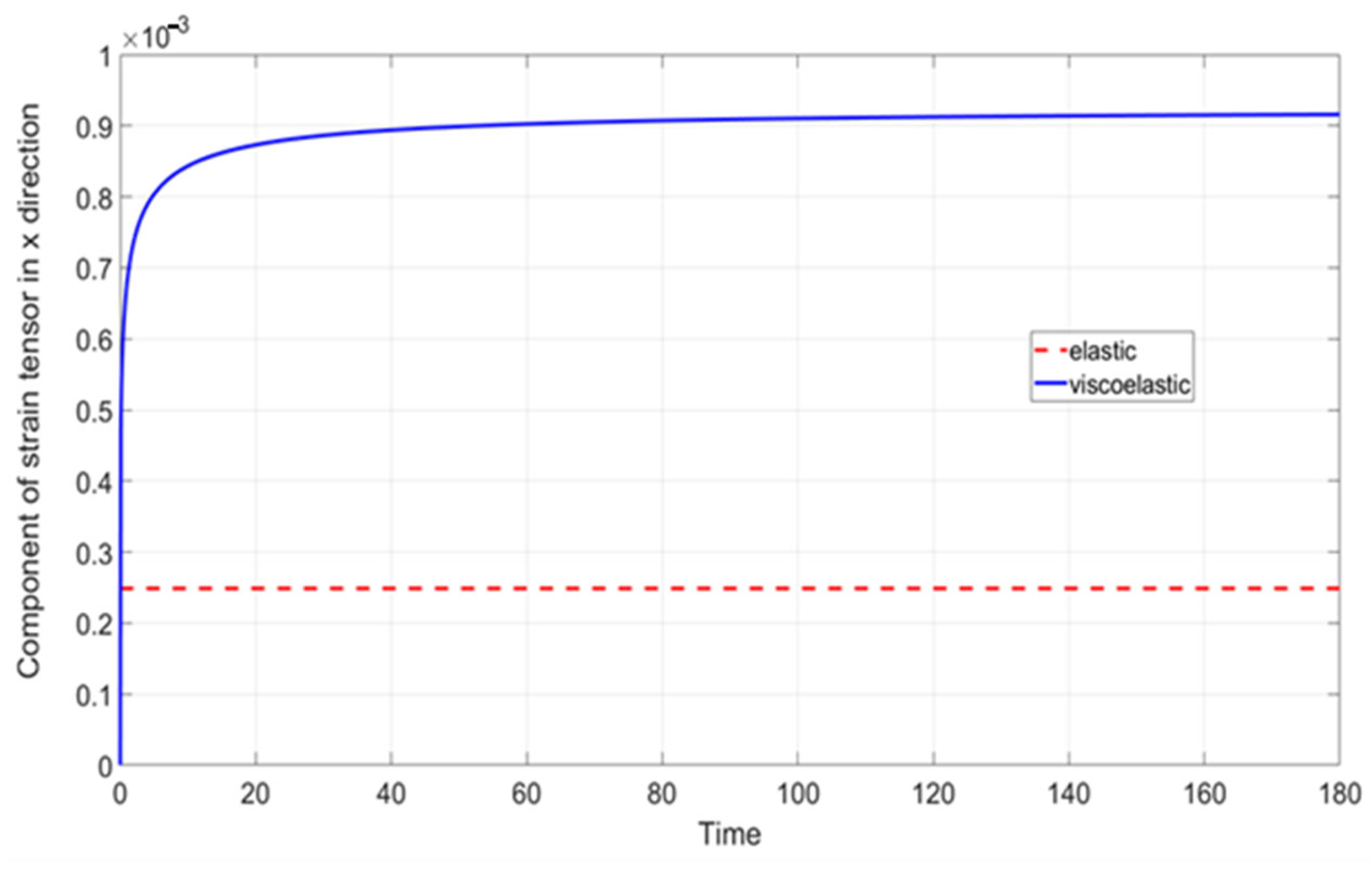

2.3. Prony Series Linear Viscoelastic Model

2.4. Contact Modeling

- If > 0, the surfaces are not in contact;

- If 0, contact is established;

- If < 0, interpenetration occurs, which is physically unrealistic and must be prevented.

- Penalty Contact (Soft Constraint): Allows slight penetration by introducing a stiffness parameter;

- Lagrange Multiplier Contact (Hard Constraint): Ensures strict non-penetration for higher accuracy at the cost of increased computational effort.

3. Results

3.1. Initial Test

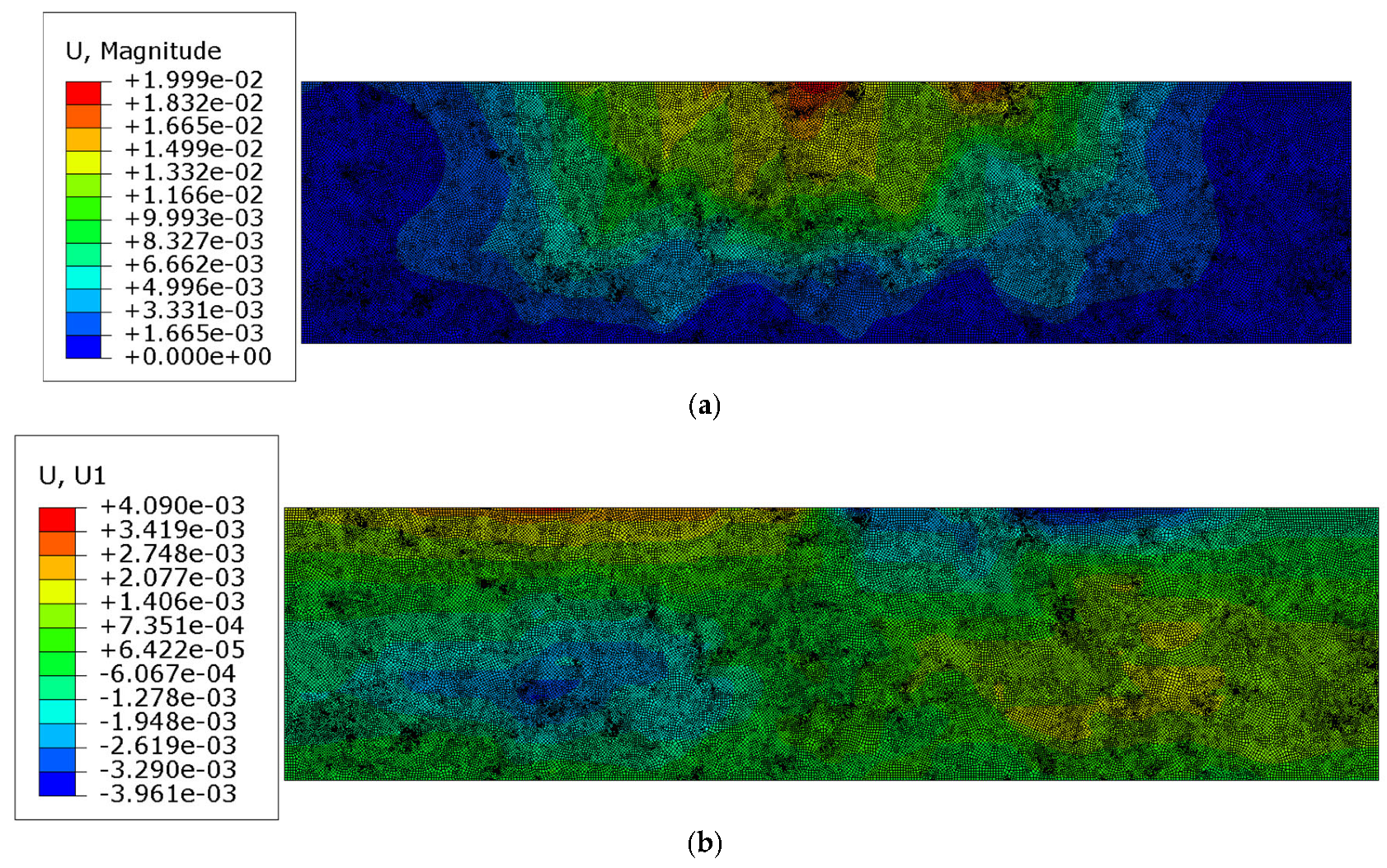

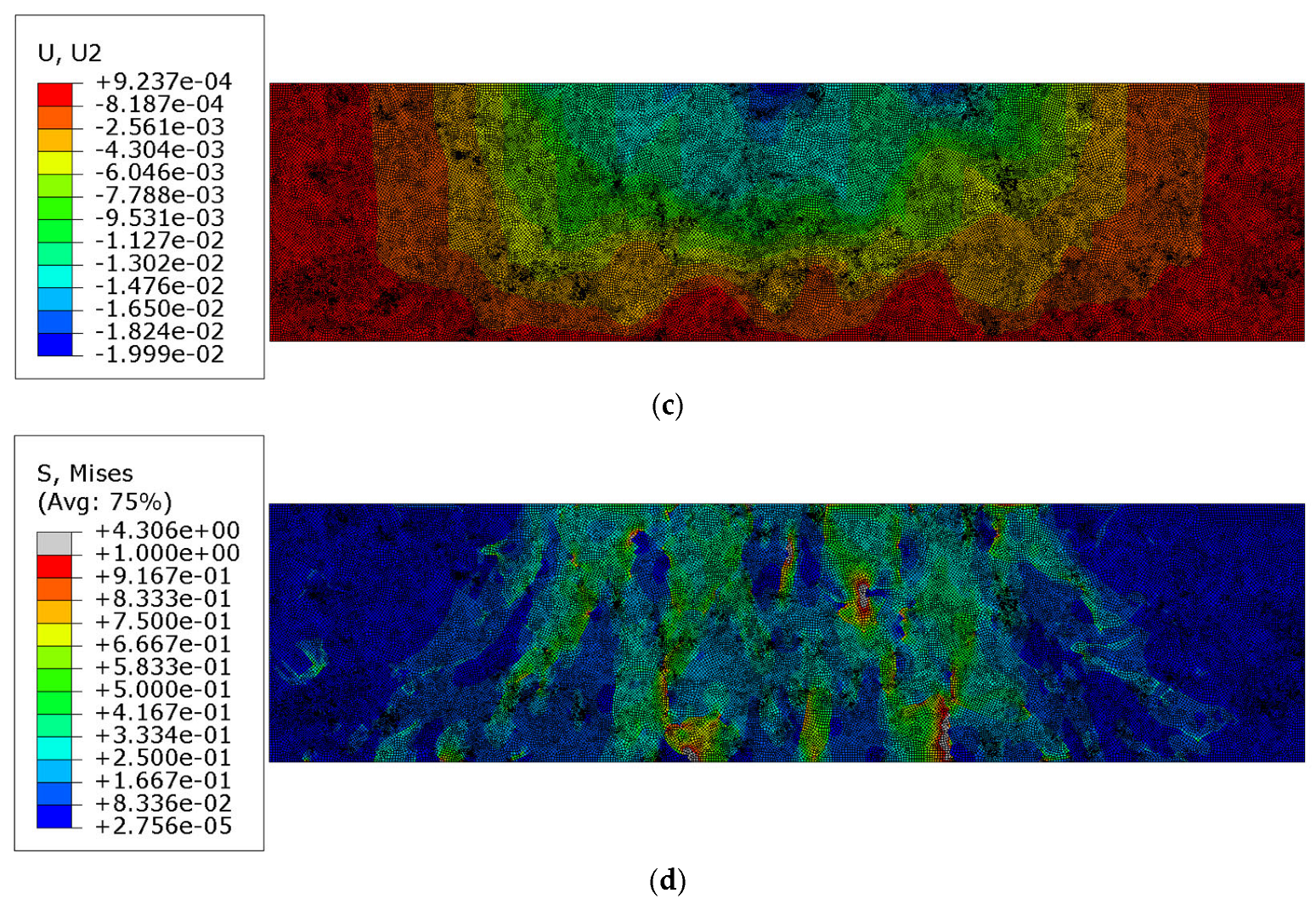

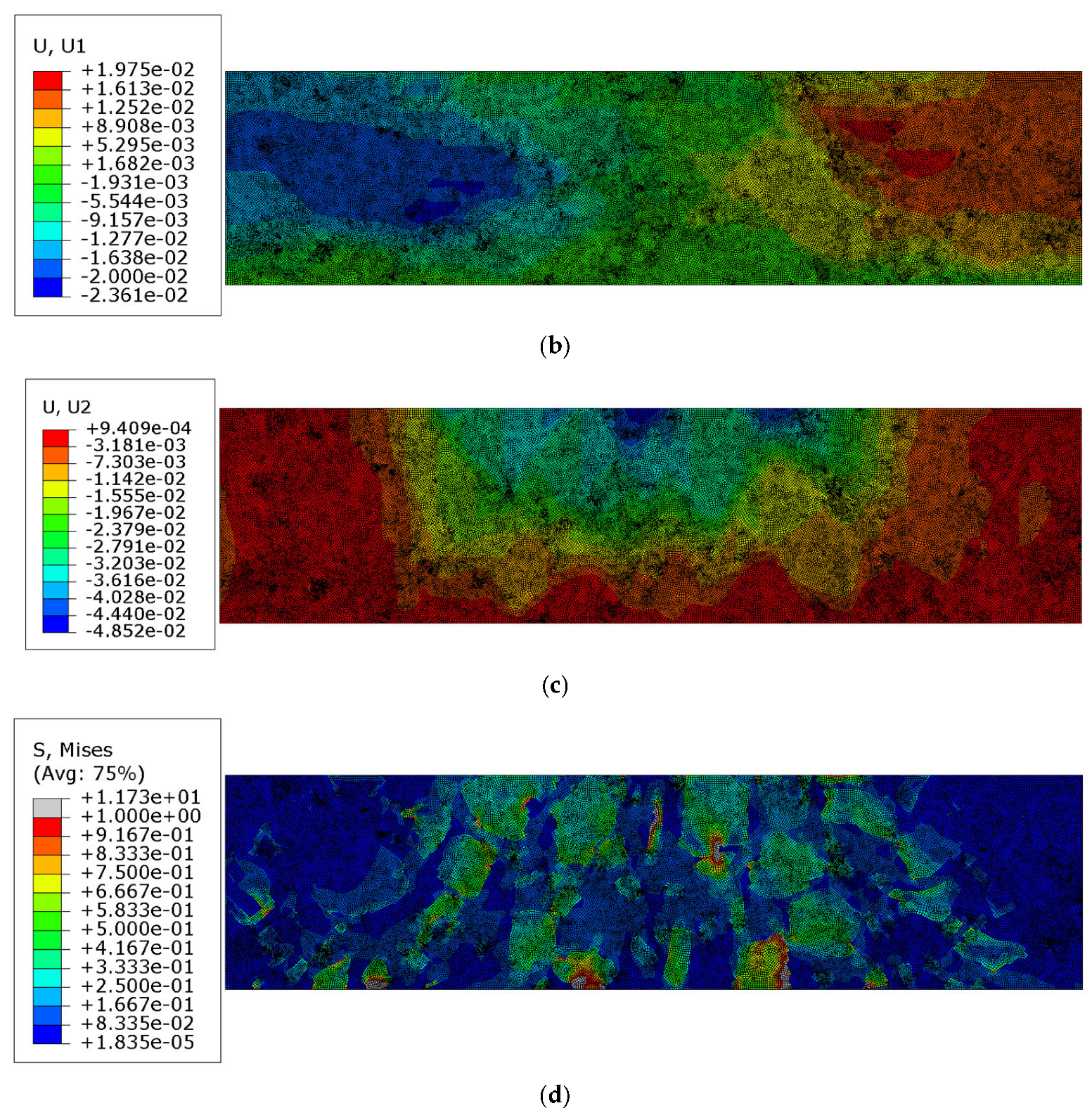

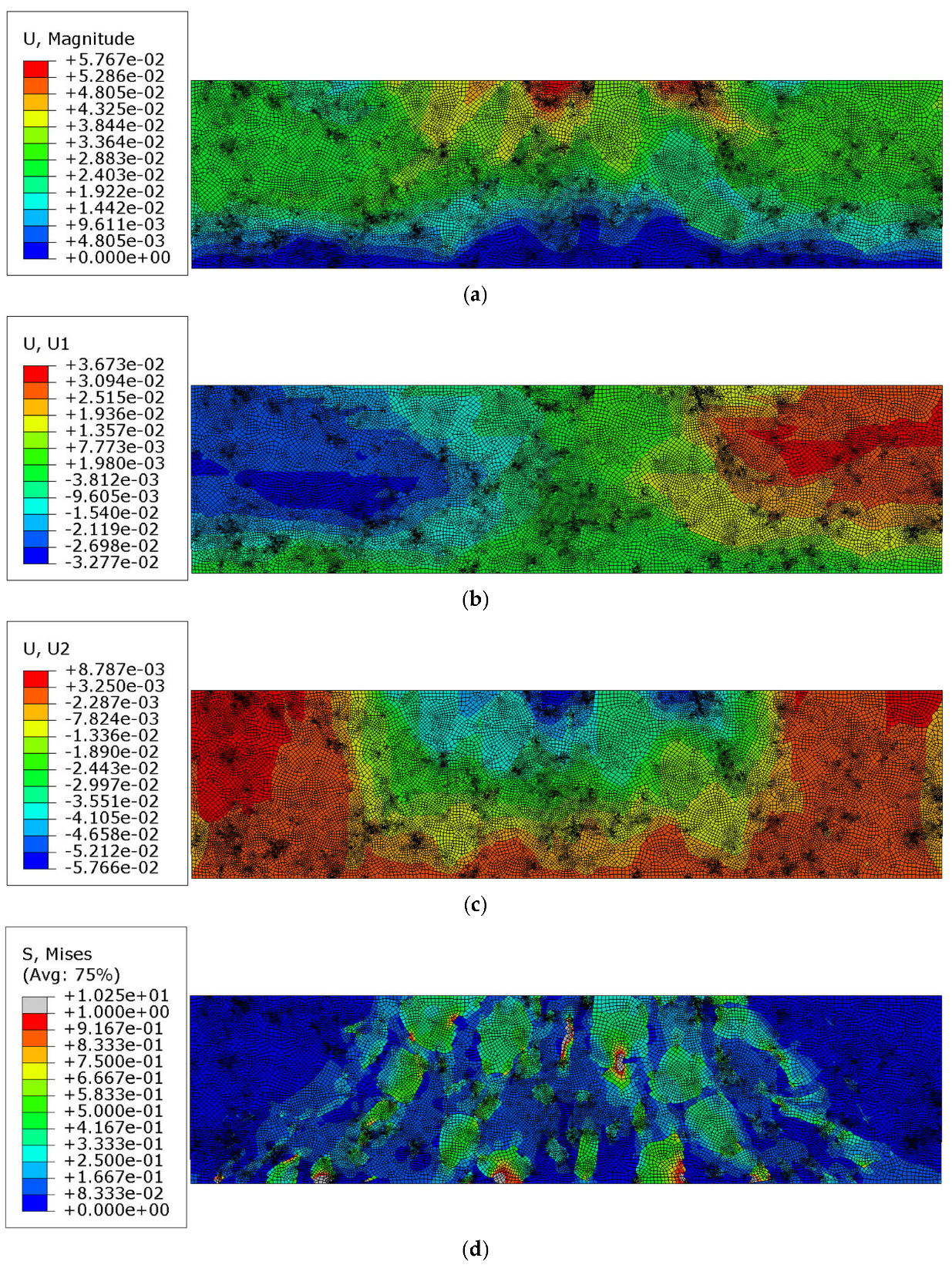

3.2. Test 1—AC Linear Elastic Analysis

3.3. Test 2—AC Linear Viscoelastic Analysis

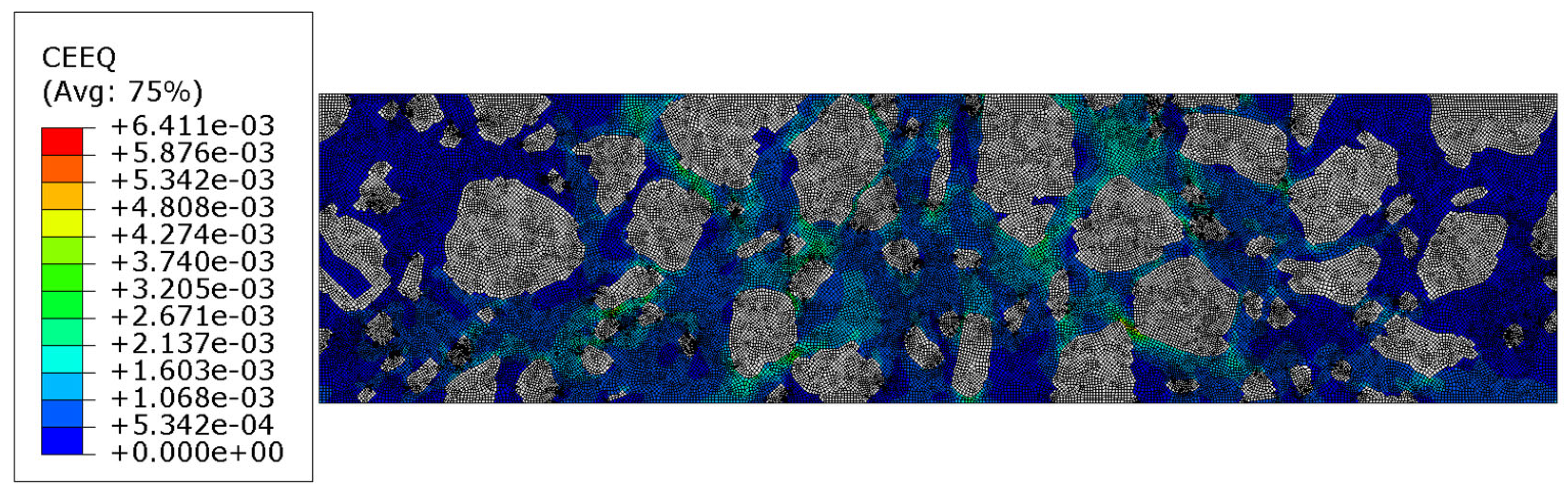

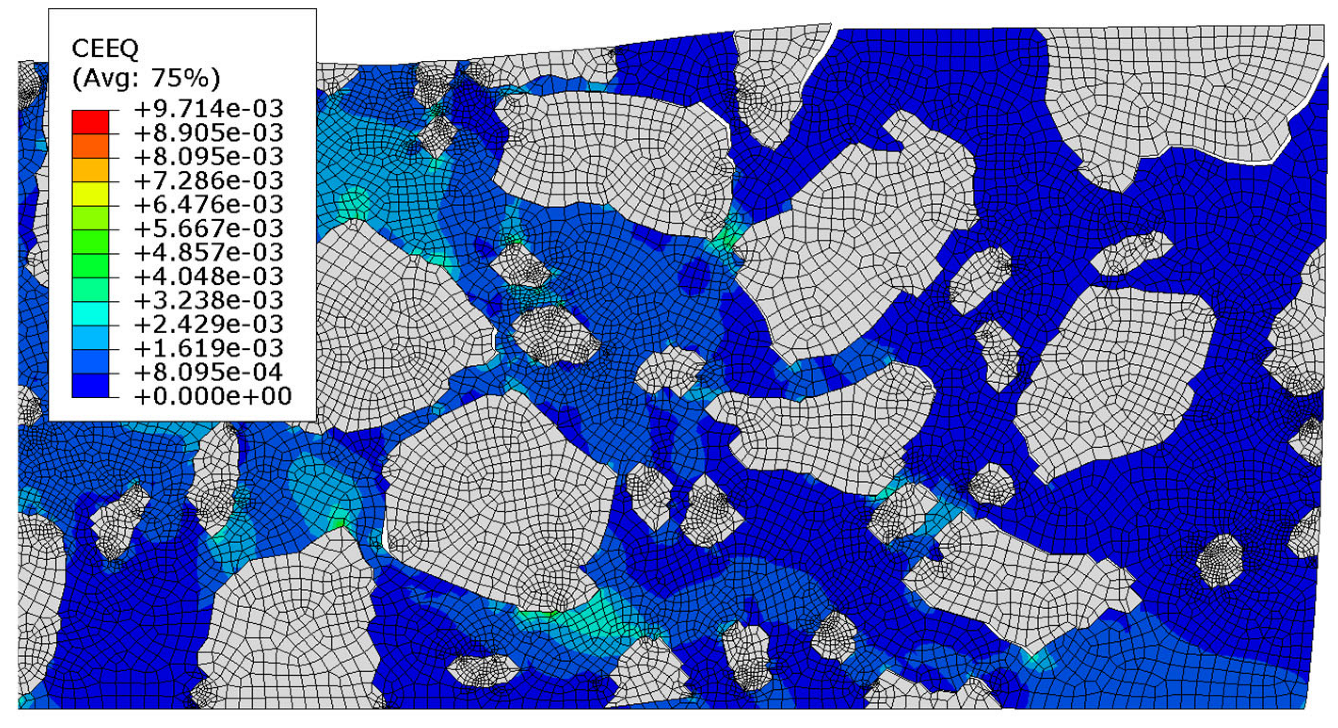

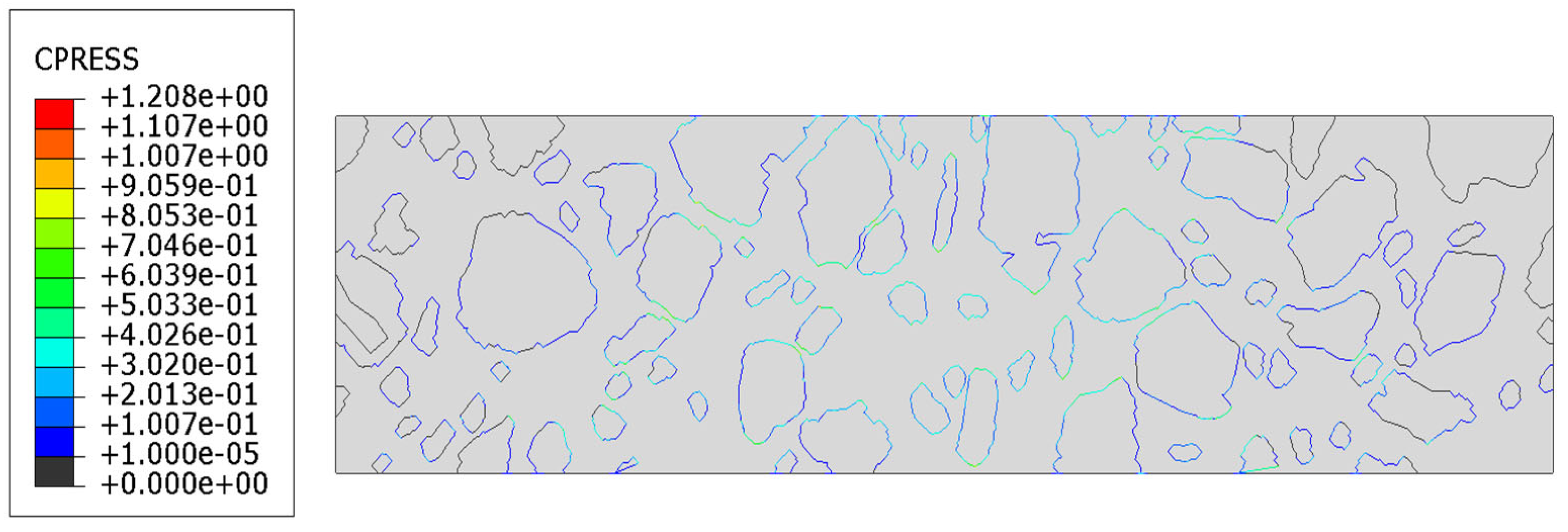

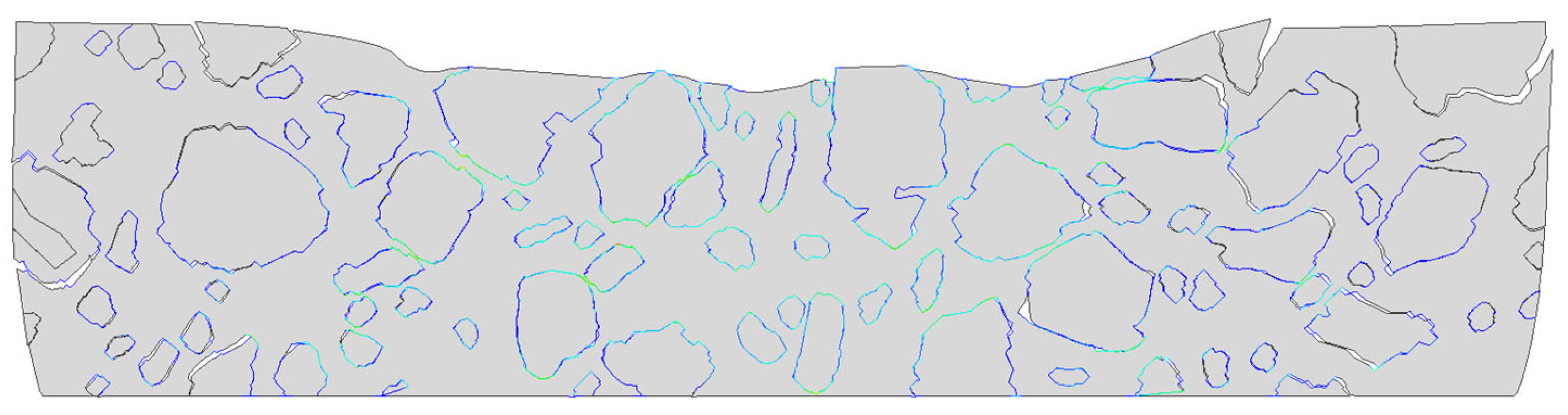

3.4. Test 3—AC Linear Viscoelastic Analysis with Contact

4. Discussion

- In Test 2, with the viscoelastic model for the mastic, the minimum vertical displacement increased by 142.72%;

- In Test 3, with the viscoelastic model for the mastic and contact analysis included, the minimum vertical displacement increased by 188.44%.

5. Conclusions

- Linear elastic analysis of asphalt concrete is practically insufficient; the viscoelastic behavior of the mastic should be accounted for in the reliable numerical analysis;

- Future enhancements should consider possible debonding between the aggregate particles and mastic, facilitating a more accurate model of asphalt concrete failure;

- Digital reconstruction of asphalt concrete microstructure enables the virtual analysis of realistic specimens.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AC | asphalt concrete |

| BVP | boundary value problem |

| FEA | finite element analysis |

| FEM | finite element method |

| ITZ | interfacial transition zone |

| MsFEM | multiscale finite element method |

| RVE | representative volume element |

| SCB | semi-circular bending |

| XRCT | X-ray computed tomography |

References

- American Association of State Highway and Transportation Officials AASHTO. Mechanistic–Empirical Pavement Design Guide, A Manual of Practice; AASHTO: Washington, DC, USA, 2008. [Google Scholar]

- Asphalt Institute. Thickness Design-Asphalt Pavements for Highways and Streets; Asphalt Institute: Lexington, KY, USA, 1999. [Google Scholar]

- Kim, Y.-R. Modeling of Asphalt Concrete, 1st ed.; McGraw Hill: New York, NY, USA, 2009. [Google Scholar]

- Collop, A.; Scarpas, A.; Kasbergen, C.; de Bondt, A. Development and finite element implementation of a stress dependent elasto-visco-plastic constitutive model with damage for asphalt. Transp. Res. Rec. 2003, 1832, 96–104. [Google Scholar] [CrossRef]

- Underwood, B.S. A continuum damage model for asphalt cement and asphalt mastic fatigue. Int. J. Fatigue 2016, 82, 387–401. [Google Scholar] [CrossRef]

- Min-Chih, L.; Jian-Shiuh, C.; Ko-Wan, T. Fatigue Characteristics of Bitumen-Filler Mastics and Asphalt Mixtures. J. Mater. Civ. Eng. 2012, 24, 916–923. [Google Scholar] [CrossRef]

- Underwood, B.S.; Kim, Y.-R. A four phase micro-mechanical model for asphalt mastic modulus. Mech. Mater. 2014, 75, 13–33. [Google Scholar] [CrossRef]

- Graziani, A.; Cardone, F.; Virgili, A. Characterization of the three-dimensional linear viscoelastic behavior of asphalt concrete mixtures. Constr. Build. Mater. 2016, 105, 356–364. [Google Scholar] [CrossRef]

- Boudabbous, M.; Millien, A.; Petit, C.; Neji, L. Energy approach for the fatigue of thermoviscoelastic materials: Application to asphalt materials in pavement surface layers. Int. J. Fatigue 2013, 47, 308–318. [Google Scholar] [CrossRef]

- Kim, Y.-R.; Baek, C.; Underwood, B.S.; Subramanian, V.; Guddati, M.N.; Lee, K. Application of viscoelastic continuum damage model based finite element analysis to predict the fatigue performance of asphalt pavements. KSCE J. Civ. Eng. 2008, 12, 109–120. [Google Scholar] [CrossRef]

- Schapery, R.A. On the characterization of nonlinear viscoelastic materials. Polym. Eng. Sci. 1969, 9, 295–310. [Google Scholar] [CrossRef]

- Fish, J. Practical Multiscaling; Wiley: Chichester, UK, 2014. [Google Scholar]

- Geers, M.; Kouznetsova, V.; Brekelmans, W. Multi-scale computational homogenization: Trends and challenges. J. Comput. Appl. Math. 2010, 234, 2175–2182. [Google Scholar] [CrossRef]

- Alawneh, M.; Soliman, H. Using Imaging Techniques to Analyze the Microstructure of Asphalt Concrete Mixtures: Literature Review. Appl. Sci. 2023, 13, 7813. [Google Scholar] [CrossRef]

- Li, X.; Shi, L.; Liao, W.; Wang, Y.; Nie, W. Study on the influence of coarse aggregate morphology on the meso-mechanical properties of asphalt mixtures using discrete element method. Constr. Build. Mater. 2024, 426, 136252. [Google Scholar] [CrossRef]

- Neumann, J.; Simon, J.-W.; Mollenhauer, K.; Reese, S. A framework for 3D synthetic mesoscale models of hot mix asphalt for the finite element method. Build. Mater. 2017, 148, 857–873. [Google Scholar] [CrossRef]

- Klimczak, M.; Cecot, W. Synthetic Microstructure Generation and Multiscale Analysis of Asphalt Concrete. Appl. Sci. 2020, 10, 765. [Google Scholar] [CrossRef]

- Kouznetsova, V.; Geers, M.G.D.; Brekelmans, W.A.M. Multi-scale constitutive modelling of heterogeneous materials with a gradient-enhanced computational homogenization scheme. Int. J. Numer. Methods Eng. 2002, 54, 1235–1260. [Google Scholar] [CrossRef]

- Klimczak, M.; Oleksy, M. Higher order numerical homogenization in modeling of asphalt concrete. J. Theor. Appl. Mech. 2024, 62, 351–364. [Google Scholar] [CrossRef]

- Schüller, T.; Jänicke, R.; Steeb, H. Nonlinear modeling and computational homogenization of asphalt concrete on the basis of XRCT scans. Constr. Build. Mater. 2016, 109, 96–108. [Google Scholar] [CrossRef]

- Cecot, W.; Oleksy, M. High order FEM for multigrid homogenization. Comput. Math. Appl. 2015, 70, 1391–1400. [Google Scholar] [CrossRef]

- Klimczak, M.; Cecot, W. Towards asphalt concrete modeling by the multiscale finite element method. Finite Elem. Anal. Des. 2020, 171, 103367. [Google Scholar] [CrossRef]

- Zhu, X.; Yuan, Y.; Li, L.; Du, Y.; Li, F. Identification of interfacial transition zone in asphalt concrete based on nano-scale metrology techniques. Mater. Des. 2017, 129, 91–102. [Google Scholar] [CrossRef]

- Wang, H.; Wang, J.; Chen, J. Micromechanical analysis of asphalt mixture fracture with adhesive and cohesive failure. Eng. Fract. Mech. 2014, 132, 104–119. [Google Scholar] [CrossRef]

- PN-EN 12697-31; Bituminous Mixtures. Test Methods. Specimen Preparation by Gyratory Compactor. Polish Committee for Standardization: Warsaw, Poland, 2019.

- Klimczak, M. Viscoelastic Analysis of Asphalt Concrete with a Digitally Reconstructed Microstructure. Materials 2024, 17, 2443. [Google Scholar] [CrossRef]

- Klimczak, M.; Jaworska, I.; Tekieli, M. 2D Digital Reconstruction of Asphalt Concrete Microstructure for Numerical Modeling Purposes. Materials 2022, 15, 5553. [Google Scholar] [CrossRef]

- Brinson, H.F.; Brinson, L.C. Polymer Engineering Science and Viscoelasticity: An Introduction; Springer: New York, NY, USA, 2008. [Google Scholar]

- Christensen, R.M. Theory of Viscoelasticity; Academic Press: New York, NY, USA, 1971. [Google Scholar]

- Ferry, J.D. Viscoelastic Properties of Polymers; John Wiley & Sons: New York, NY, USA, 1980. [Google Scholar]

- De Prony, G.R. Essai Experimentale at analitique. J. Ecole Polytech. 1795, 1, 24–76. [Google Scholar]

- Mauro, J.C.; Mauro, Y.Z. On the Prony representation of stretched exponential relaxation. Phys. A 2018, 506, 75–87. [Google Scholar] [CrossRef]

- Wriggers, P. Computational Contact Mechanics; Springer: Heidelberg, Germany, 2006. [Google Scholar]

- Zavarise, G.; Wriggers, P. Contact with friction between beams in 3D. Int. J. Numer. Methods Eng. 2000, 48, 1201–1218. [Google Scholar] [CrossRef]

- Perić, D.; Owen, D.R.J. Computational model for contact problems with friction based on the penalty method. Int. J. Numer. Methods Eng. 1992, 36, 1289–1309. [Google Scholar] [CrossRef]

- Fadil, H.; Jelagin, D.; Partl, M.N. A new viscoelastic micromechanical model for bitumen-filler mastic. Constr. Build. Mater. 2020, 253, 119062. [Google Scholar] [CrossRef]

- Qiu, Q. Computational simulation of alternating current (AC) impedance of hardened cement mortar. Electrochim. Acta 2025, 511, 145412. [Google Scholar] [CrossRef]

- Wang, H.; Wang, C.; You, Z.; Yang, X.; Huang, Z. Characterising the asphalt concrete fracture performance from X-ray CT Imaging and finite element modelling. Int. J. Pavement Eng. 2018, 19, 307–318. [Google Scholar] [CrossRef]

- Coleri, E.; Harvey, J.T.; Yang, K.; Boone, J.M. Development of a micromechanical finite element model from computed tomography images for shear modulus simulation of asphalt mixtures. Constr. Build. Mater. 2012, 30, 783–793. [Google Scholar] [CrossRef]

- Moretti, L.; Palozza, L.; D’Andrea, A. Causes of Asphalt Pavement Blistering: A Review. Appl. Sci. 2024, 14, 2189. [Google Scholar] [CrossRef]

| [-] | [s] |

|---|---|

| 0.1621 | 0.001 |

| 0.267 | 0.0036 |

| 0.144 | 0.0479 |

| 0.099 | 0.1741 |

| 0.064 | 0.6325 |

| 0.0375 | 2.2974 |

| 0.0202 | 8.3453 |

| 0.0097 | 30.3443 |

| 0.0042 | 110.1169 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klimczak, M.; Oleksy, M. Numerical Analysis of Aggregate Debonding in Asphalt Concrete. Materials 2025, 18, 2297. https://doi.org/10.3390/ma18102297

Klimczak M, Oleksy M. Numerical Analysis of Aggregate Debonding in Asphalt Concrete. Materials. 2025; 18(10):2297. https://doi.org/10.3390/ma18102297

Chicago/Turabian StyleKlimczak, Marek, and Marta Oleksy. 2025. "Numerical Analysis of Aggregate Debonding in Asphalt Concrete" Materials 18, no. 10: 2297. https://doi.org/10.3390/ma18102297

APA StyleKlimczak, M., & Oleksy, M. (2025). Numerical Analysis of Aggregate Debonding in Asphalt Concrete. Materials, 18(10), 2297. https://doi.org/10.3390/ma18102297