1. Introduction

The construction industry in cold regions faces challenges due to the harsh environmental conditions that impede conventional concrete curing processes [

1,

2]. Subzero temperatures retard hydration reactions, leading to delayed strength development, prolonged construction cycles, and compromised durability of concrete structures [

3,

4]. Traditional curing methods, such as external heating or insulation, often prove inefficient in extreme cold climates, as they struggle to maintain uniform thermal conditions and consume substantial energy resources. Even if they can be used in negative-temperature environments, the environmental temperature is restricted to not be lower than −10 °C to ensure a promising curing quality [

5,

6,

7]. Moreover, the formation of ice within the concrete matrix during early-age freezing can induce internal stresses, resulting in microcracking and reduced long-term performance [

8,

9]. Under this circumstance, it is of importance to find a novel curing regime for concrete construction under severely low temperatures.

The utilization of fiber-reinforced concrete (FRC) in cold regions has gained significant attention due to its enhanced durability under freeze–thaw cycling and deicing salt exposure. Incorporating discrete fibers (steel, polypropylene, or basalt) at a 0.5–2.0% volume fraction effectively mitigated thermal-stress-induced cracking through crack-bridging mechanisms. To promise a higher performance to resist the harsh environment in cold regions, high-performance concrete (HPC), characterized by its ultra-dense microstructure, low permeability, and exceptional mechanical resilience, presents a compelling solution for infrastructure projects in harsh environments [

10,

11,

12]. Through the incorporation of supplementary cementitious materials (SCMs) like silica fume, fly ash, and slag, along with optimized water-to-binder ratios and superplasticizers [

13,

14,

15], HPC achieves superior compressive strength (>100 MPa) and resistance to chemical aggression [

16,

17,

18]. However, the very attributes that render HPC advantageous under standard conditions become liabilities in cold climates. The reduced water content and highly packed particle matrix limit the availability of free water for hydration, while low ambient temperatures further suppress reaction rates, resulting in prolonged setting times and insufficient early-age strength [

19,

20,

21]. Compounding these issues, the introduction of steel fibers—a common strategy to enhance fracture toughness and ductility—introduces new complexities. Although steel fibers effectively bridge microcracks and improve post-cracking behavior, their uneven dispersion within the cementitious matrix can create localized weak zones, undermining both mechanical performance and functional characteristics such as electrical conductivity [

22,

23]. This paradox underscores a critical challenge: while HPC is theoretically ideal for demanding cold-region applications, conventional curing approaches fail to reconcile its material potential with the thermodynamic constraints imposed by subfreezing environments.

Electrically assisted curing methods, particularly electric-induced heating techniques, have garnered increasing attention as a paradigm-shifting approach to address these limitations [

24,

25]. By embedding conductive elements such as steel fibers or carbon-based materials within the concrete matrix, researchers can harness electrical resistance heating to generate internal thermal energy, creating a self-curing system that actively counteracts ambient cold [

26,

27]. This method offers distinct advantages over external heating approaches, including energy efficiency, spatial uniformity of temperature distribution, and compatibility with automated control systems [

28,

29]. Crucially, electric-induced heating curing synergizes with the intrinsic properties of steel-fiber-reinforced HPC—the fibers not only serve as reinforcement but also form percolating conductive networks that enable efficient electrical–thermal conversion. Recent studies have demonstrated that elevated curing temperatures (≥40 °C) achieved through electric-induced heating can accelerate pozzolanic reactions, enhance early-age strength development, and refine pore structures even in low-temperature environments [

24,

30]. Nevertheless, the practical implementation of this technology remains constrained by insufficient understanding of how material composition and processing parameters govern the behavior of the composite system. Key knowledge gaps persist regarding the optimization of conductive filler content, the interplay between binder chemistry and electrical conductivity, and the effects of mixture proportioning on both curing efficiency and final material properties.

In this work, electric-induced heating curing was used to prepare steel-fiber-reinforced high-performance concrete (SF-HPC) at −20 °C. The specific effect of the mix proportion on the performance of electric-induced heating cured SF-HPC was clarified including the steel fiber content, water-to-binder ratio, silica fume content, and fine aggregate gradation. Once the optimal SF-HPC mix proportion was determined, electric heating curing was conducted, and the performance of SF-HPC was compared with that of the specimens cured by room-temperature curing and high-temperature steam curing. The hydration degree and pore structure of the specimens were further investigated to disclose the benefits of electric-induced heating curing as a negative-temperature concrete curing method.

2. Materials and Methods

2.1. Raw Materials

P.O. 42.5 cement produced by Yatai Ltd., Harbin China (Tian et al., 2024) [

27] and silica fume were used as the main cementitious materials for the preparation of SF-HPC. The main chemical composition and physical properties of the cement are listed in

Table 1 and

Table 2. Silica sand with a diameter of 0.84–2 mm was used as the fine aggregate. The diameter and length of steel fiber were 0.22 mm and 13 mm, respectively. There is no bar reinforcement in the specimen.

2.2. Test Methods

2.2.1. Electrical Resistance Measurement

The two-electrode testing method was used in this work to measure the electric resistance of the SF-HPC specimens, in which two electrodes were inserted at both ends of the specimen. This method was simple to operate, and the electrode placement method facilitates subsequent mechanical property testing. A Tonghui TH2810D high-frequency digital LCR meter (Tonghui Ltd., Changzhou, China) was used as the test equipment (Ouyang et al., 2022) [

21], and the test frequency was set to 10 kHz, which can effectively eliminate the interface resistance between the electrodes and the specimen. Under this circumstance, the resistance measured by the LCR meter can be regarded as the actual resistance of the specimen. Further, the electric resistivity of the specimen was then calculated using Equation (1) based on the measured resistance values (Tian et al., 2024) [

28].

Here, ρ is the electric resistivity of the specimen, S is the contact area between the electrode and the specimen, d is the distance between the electrodes, and R is the measured electric resistance of the specimen.

2.2.2. Temperature Measurement

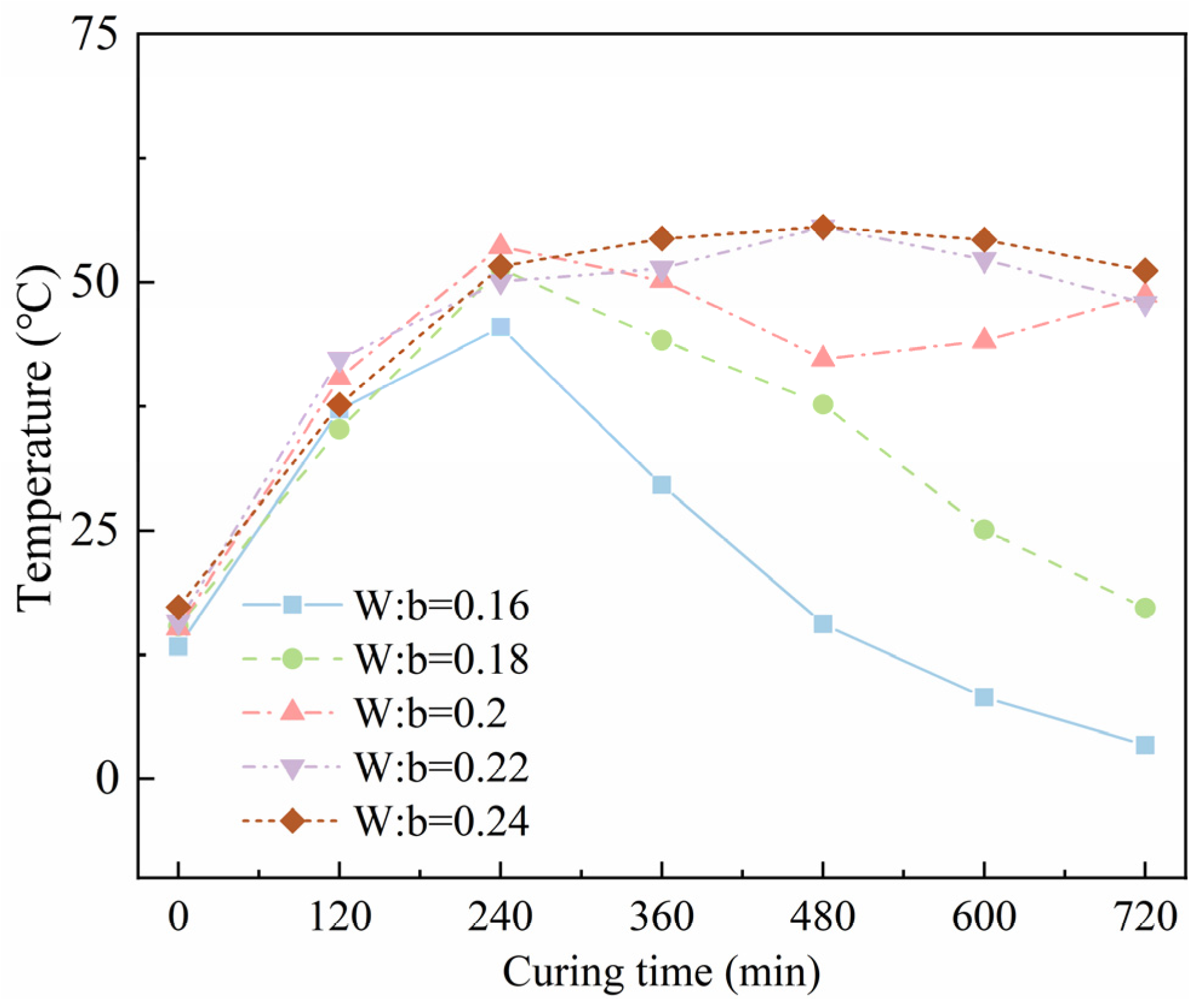

For SF-HPC cured by electric-induced heating in a negative-temperature environment, the curing temperature determines the performance of the specimens. Therefore, real-time monitoring of the specimen’s curing temperature is required during experiments. Specifically, a multi-channel temperature data logger was used to measure the temperature of SF-HPC specimens during the curing process, and the thermocouple was placed at the center of the specimen. To prevent the electric current flow through the thermocouple during the curing process from interfering with temperature recording, the thermocouple was insulated by adhesive tape. During the experimental process, the temperature data logger was configured to record the central temperature of the specimen every 30 s.

2.2.3. Mechanical Strength Test

SF-HPC specimens with a size of 40 mm × 40 mm × 40 mm were used for the compressive strength test, and the test procedure was referenced from ASTM C109/C109M-11. The loading rate was 2.4 ± 0.2 kN/s during the test process, and a total of six specimens were tested for each batch for reliable results.

2.3. Curing Regimes

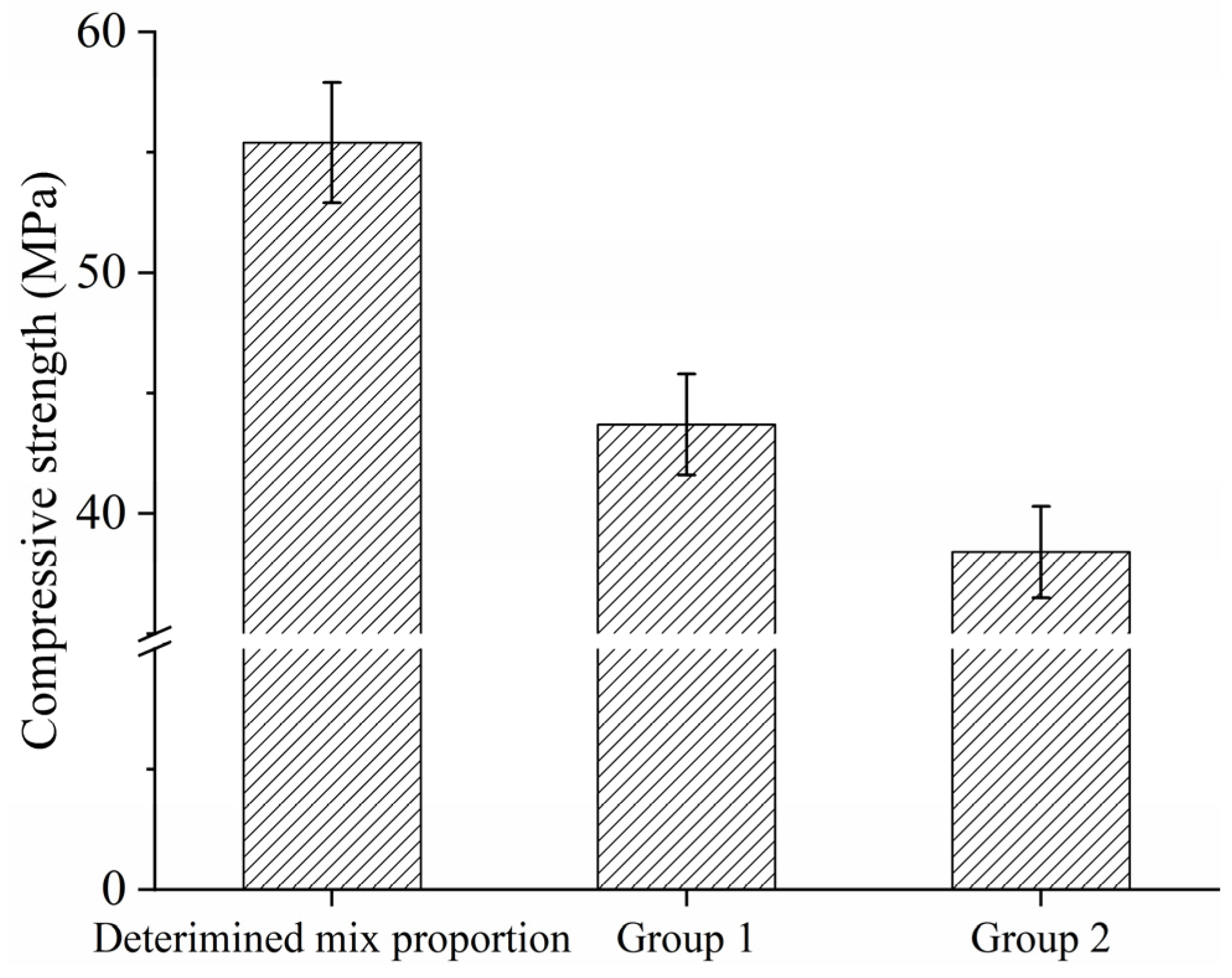

An electric heating curing regime was used to ensure the strength formation of SF-HPC under severely low temperature. Room-temperature curing at 20 ± 2 °C and humidity of >95% was conducted for comparison, as well as high-temperature steam curing at 60 °C and humidity of >95%. To be more specific, a 12 h electric heating curing regime was conducted to determine the effect of various factors on the performance of the samples, and a 2-day electric heating curing regime was employed to prepare the sample with optimized mix proportions.

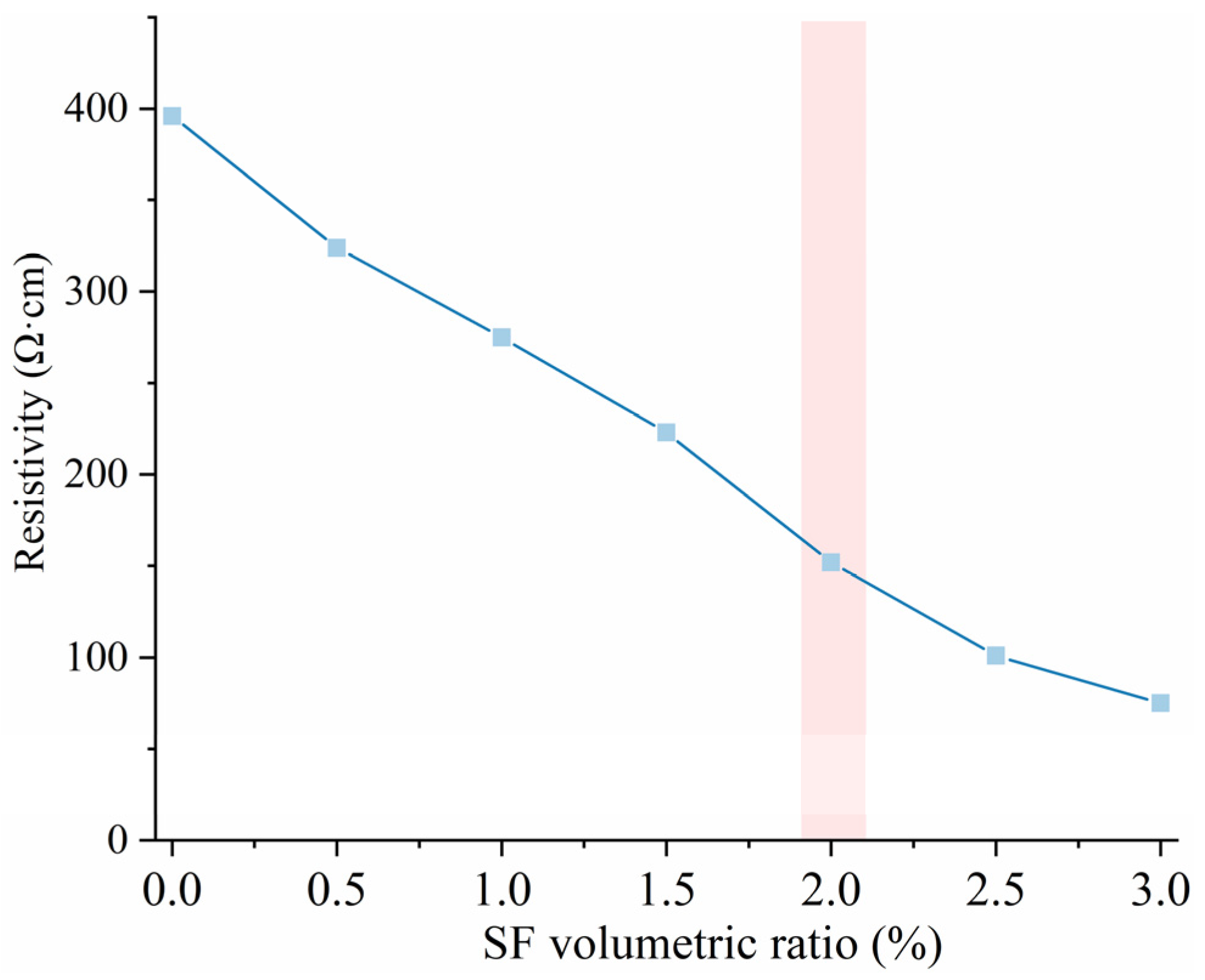

2.4. SF Content Determination

Among the multiple factors, the determination of SF contents is of significance, because it is the foundation for the continuous electric-induced heating curing process. Excessive steel fiber content adversely affects the fluidity of the mixture. Therefore, steel fiber content in concrete structures should not be overly high. However, when steel fiber content is too low, the internal steel fibers in high-performance concrete become insufficient to form fully interconnected conductive pathways, leading to excessively high initial resistivity that hinders electrical energy supply. Consequently, it is essential to determine an optimal steel fiber dosage to ensure a successful electric-induced heating curing process and facilitate the effective preparation of SF-HPC in low-temperature environments. In this work, the optimal SF contents were determined based on the experimentally measured percolation threshold, taking the initial resistivity as the judgement standard.

2.5. Microstructural Characterization

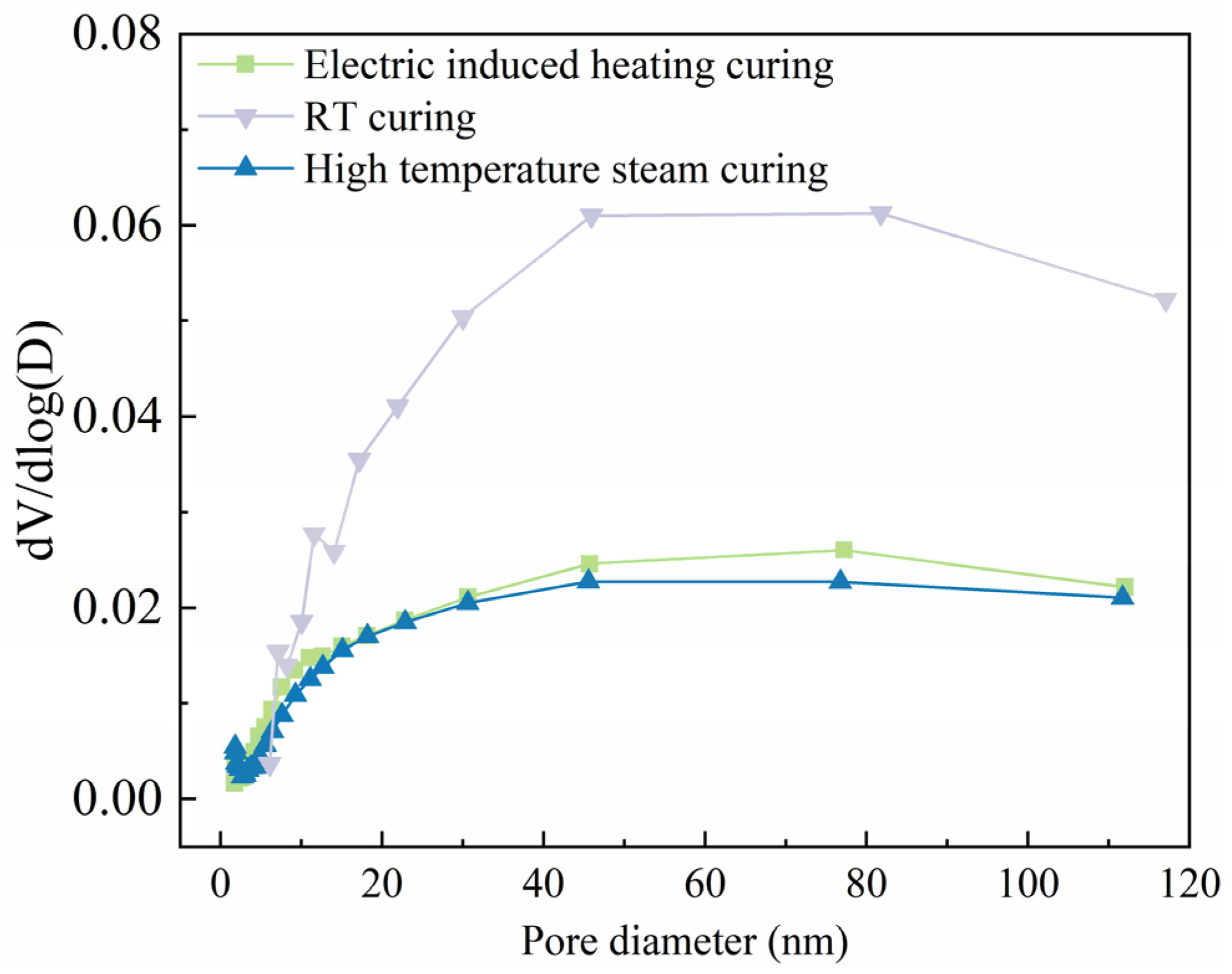

The pore structure development of SF-HPC specimens cured by different methods was disclosed by Brunner–Emmet–Teller (BET) measurement. The specimens were broken into small pieces and immersed in ethanol to stop the hydration reaction. Then, a 48 h drying operation was conducted, and the specimens were degassed using a vacuum at 80 °C for 6 h, and nitrogen (N2) was the adsorbate.

4. Conclusions

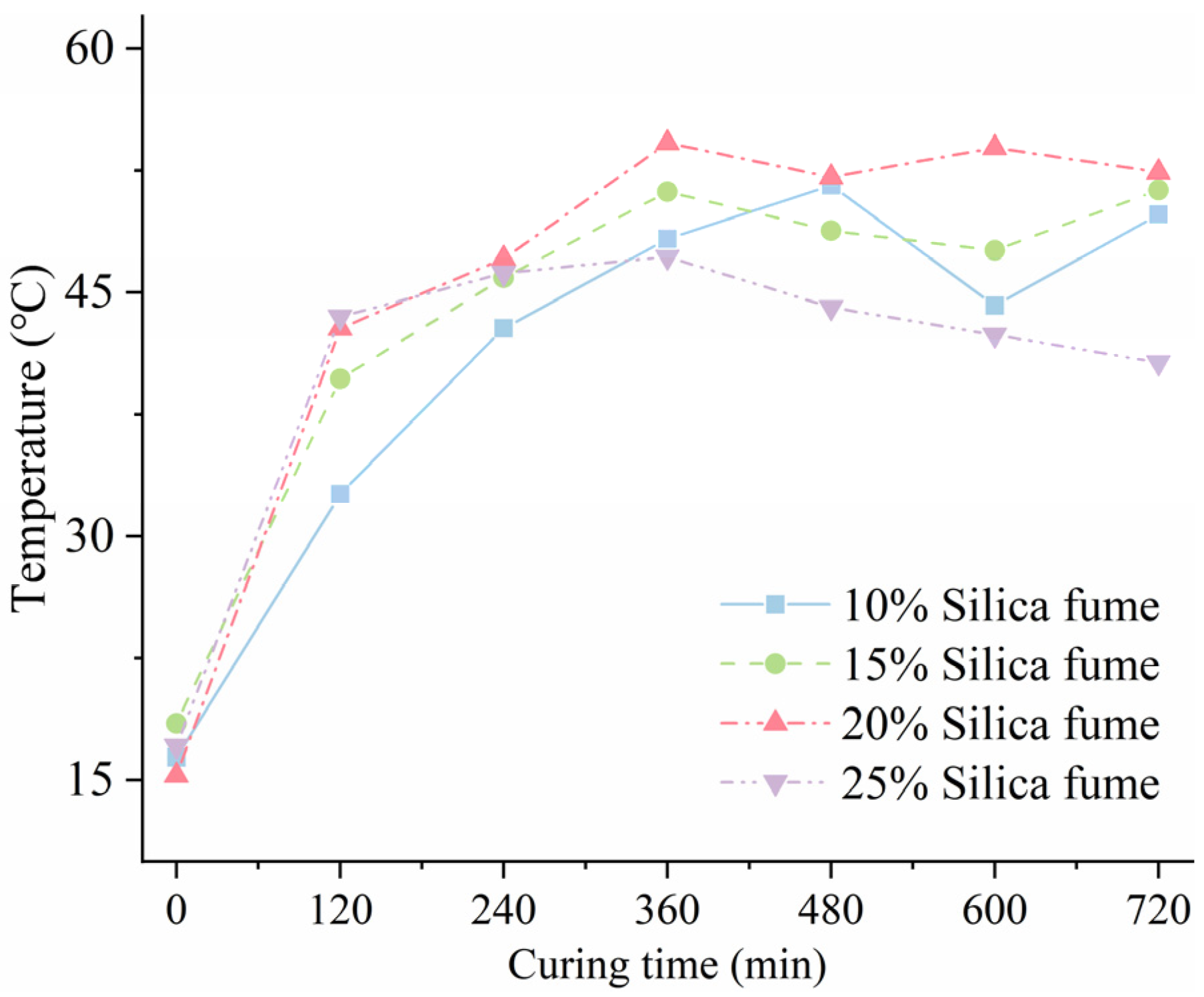

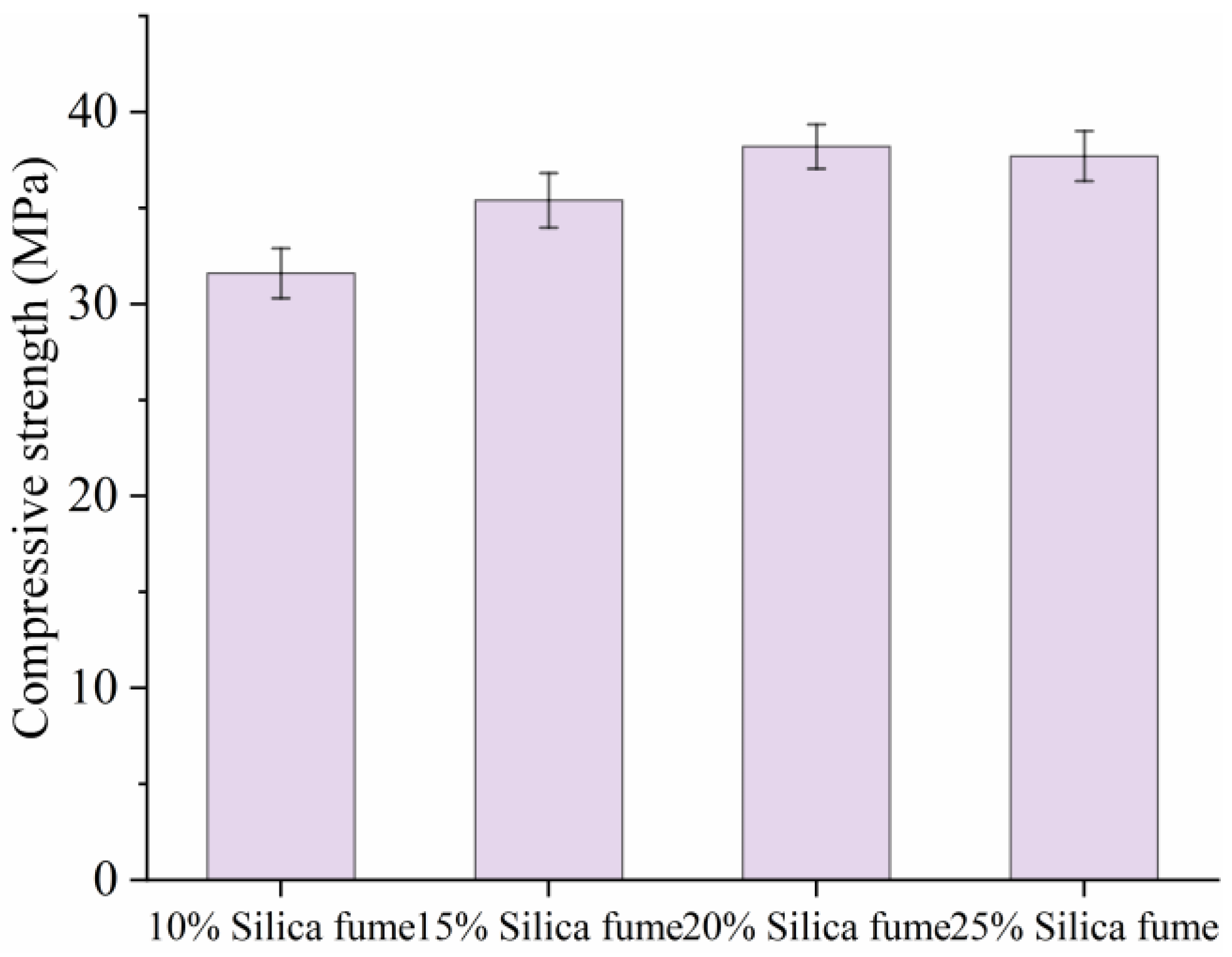

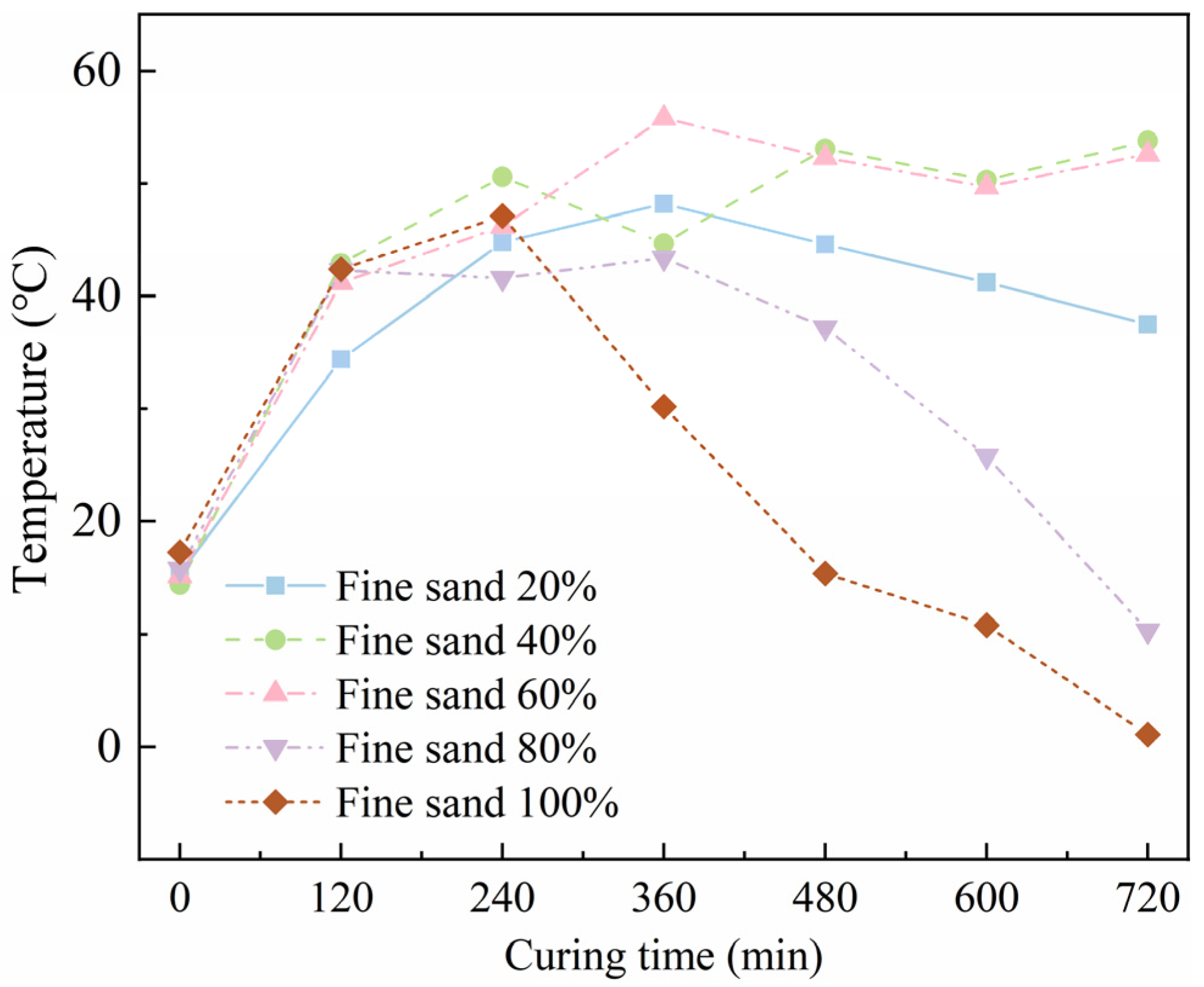

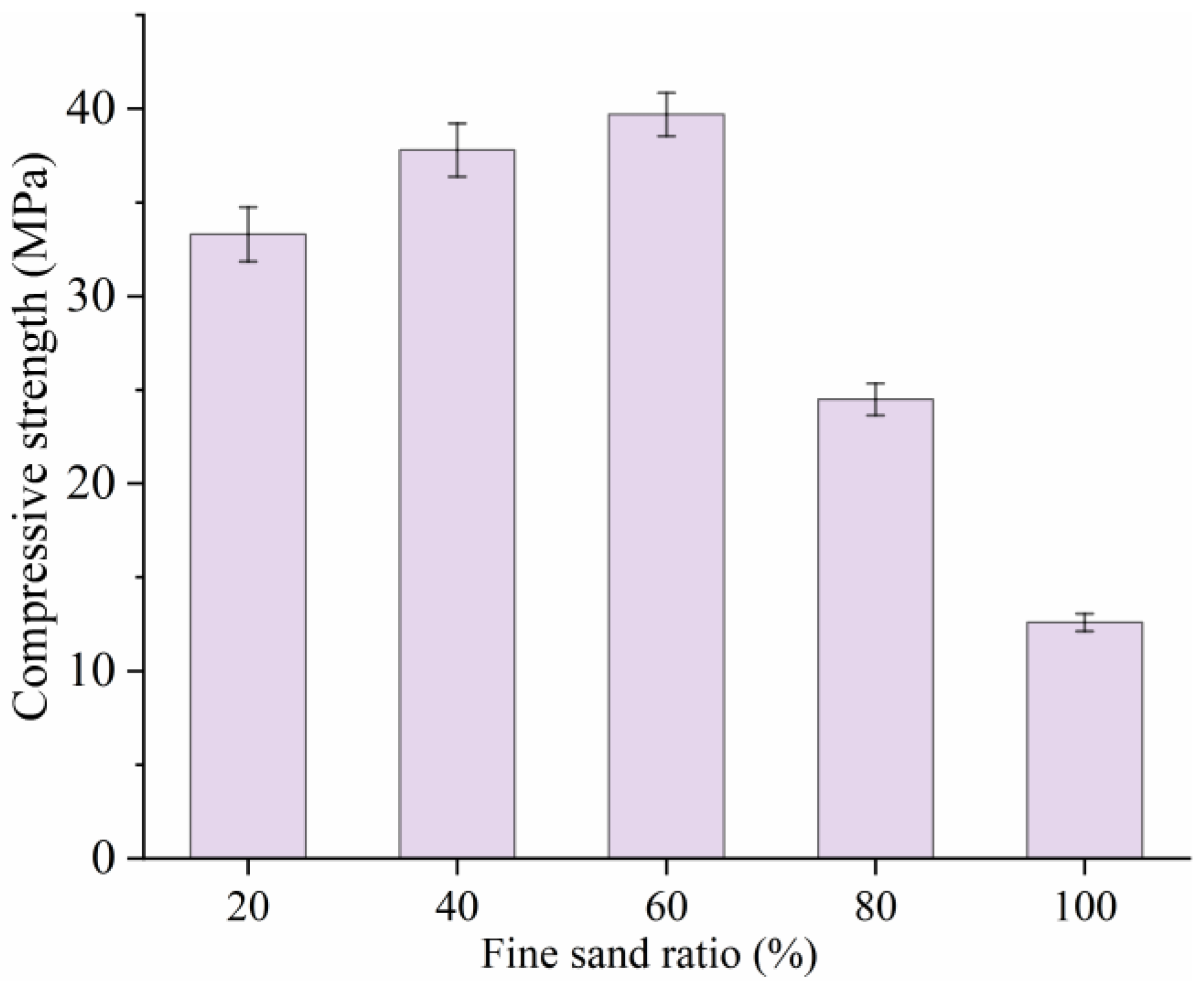

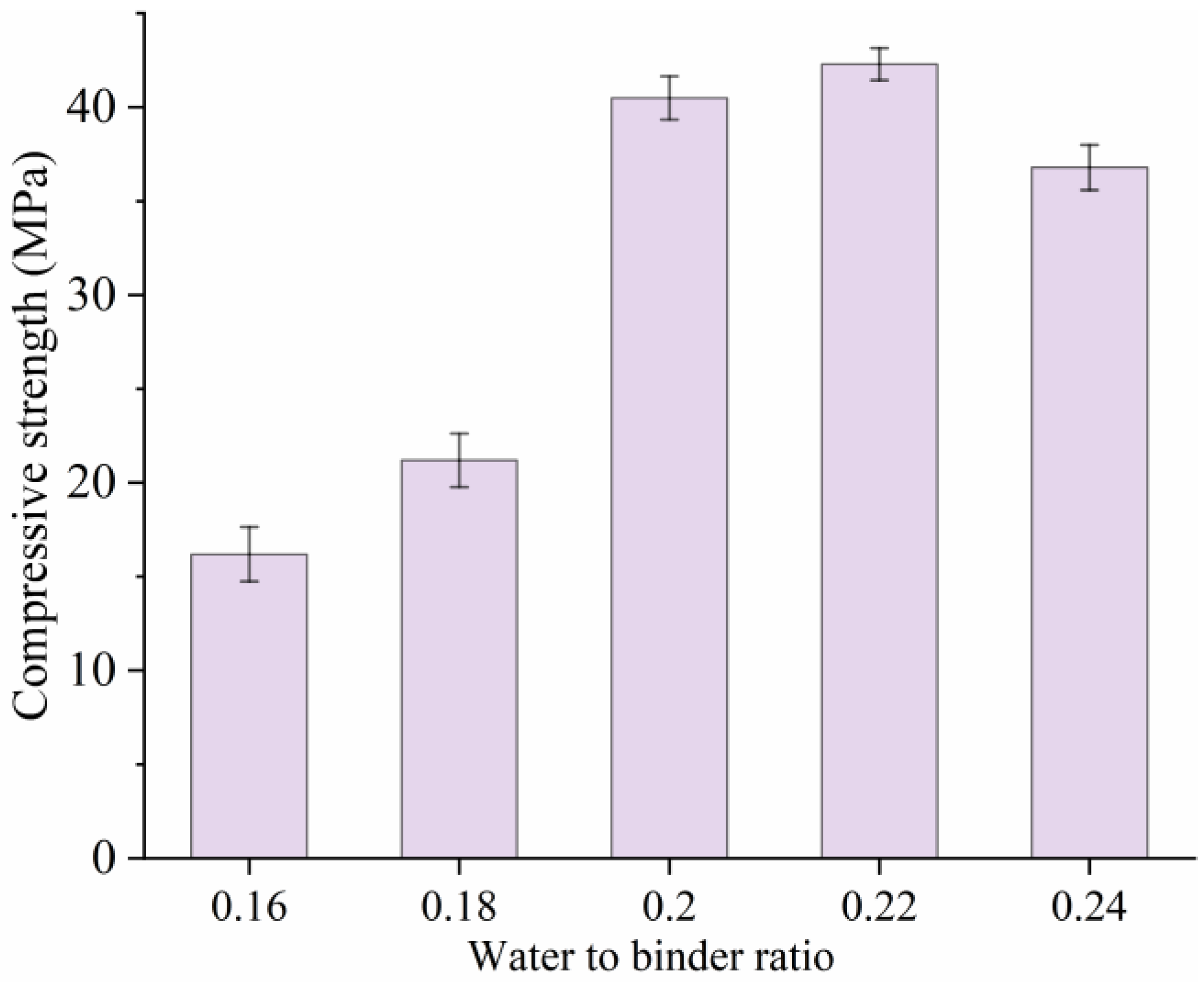

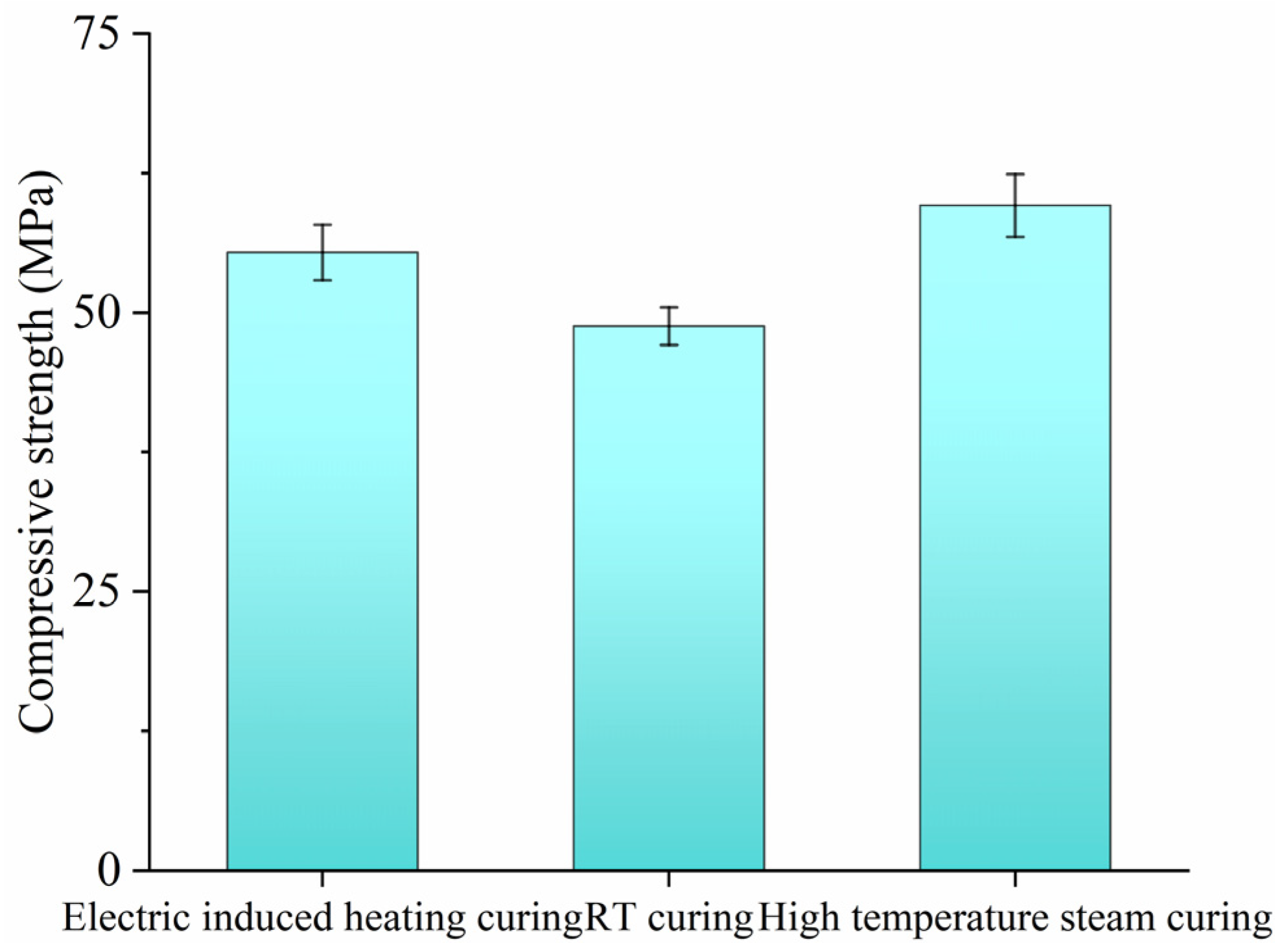

This study demonstrated the efficiency of electric-induced heating curing as a novel method to overcome the challenge of insufficient early strength development in steel-fiber-reinforced high-performance concrete (SF-HPC) fabricated at subzero temperatures (−20 °C). Through systematic investigation of mix parameters, including steel fiber content (0–3.0 vol%), water-to-binder ratio (0.16–0.24), silica fume dosage (10–25%), and fine aggregate replacement ratio (0–100%), the optimal SF-HPC mix proportion was determined by evaluating curing temperature and compressive strength. Experimental results delineated that the compressive strength of electric-induced heating cured specimens showed an increasing trend and then a decreasing trend as the silica fume content and fine aggregate replacement ratio increased. Moreover, the increased water-to-binder ratio illustrated a positive effect on the curing temperature and strength development for the specimens. The optimal steel fiber content was 2.0 vol%, the water-to-binder ratio was 0.22, and the silica fume content was 20% with a fine aggregate replacement ratio of 60%. Comparative analysis with conventional room-temperature curing and high-temperature steam curing highlighted the superiority of electric-induced heating curing in promoting early-age mechanical performance, attributed to its uniform heating effect that mitigated low-temperature inhibition on cement hydration. BET analysis further proved that electric-induced heating curing refined the pore structure of SF-HPC. This work provides new insights into high-quality concrete construction in cold environments.