Study on Formability and Microstructure Evolution of Usibor®2000 Sheet Under Different Forming Temperatures in Deep Drawing Process

Abstract

1. Introduction

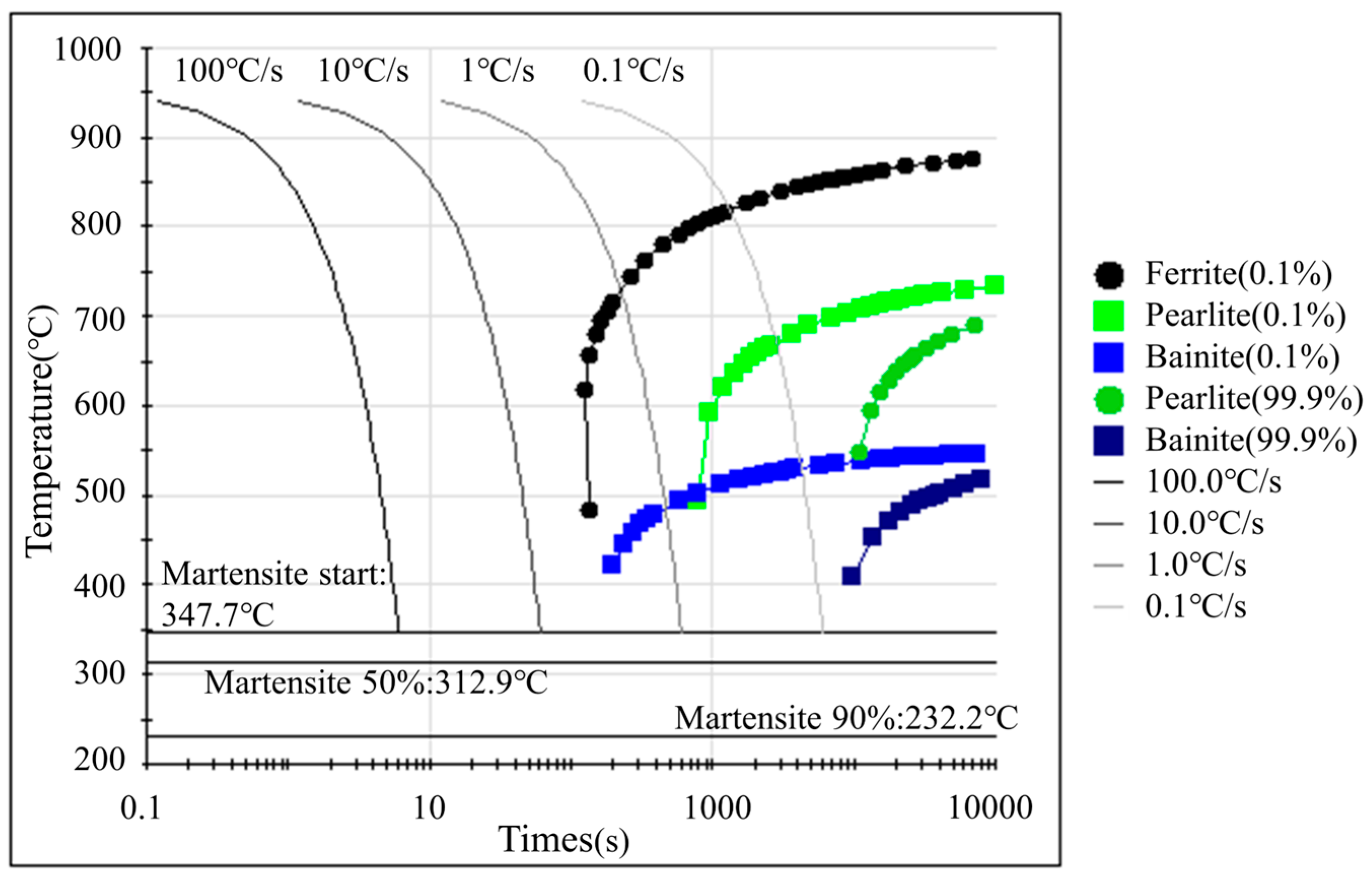

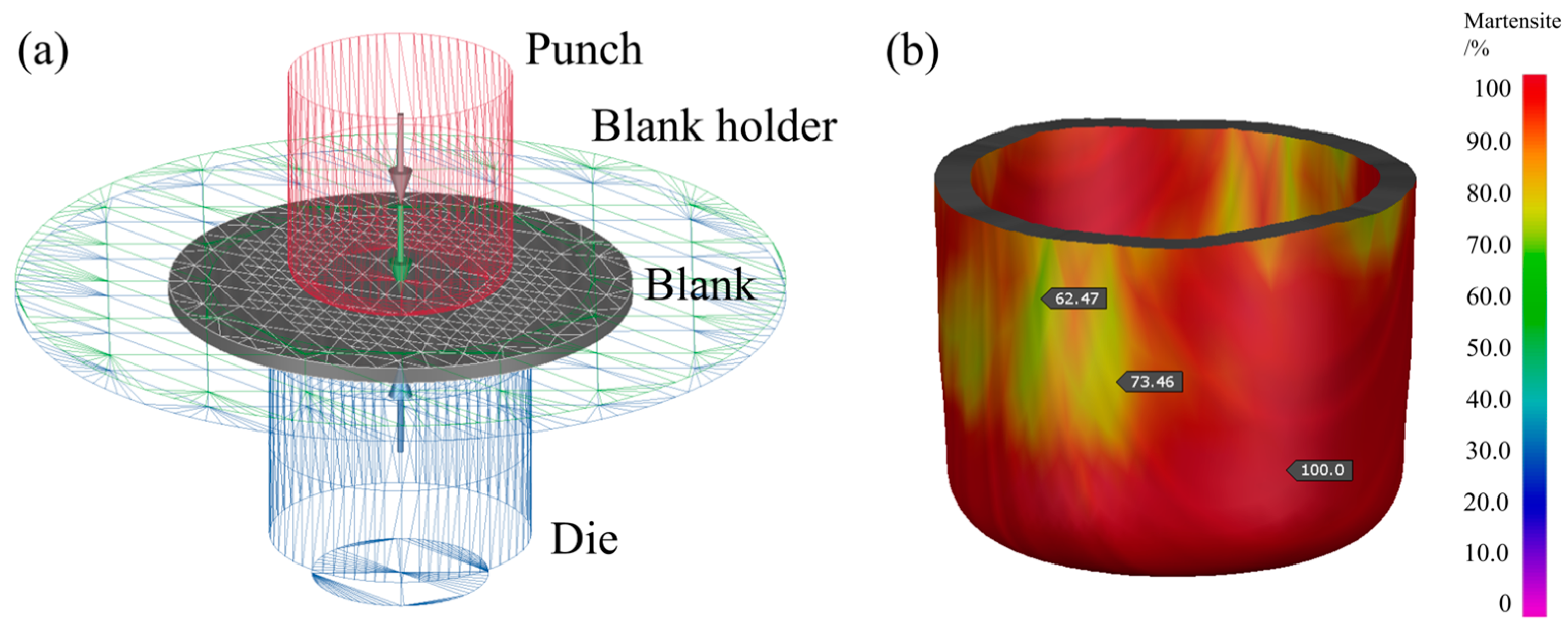

2. Numerical Simulation

3. Materials and Methods

Lubrication and Tooling Surface Treatment

4. Results and Discussions

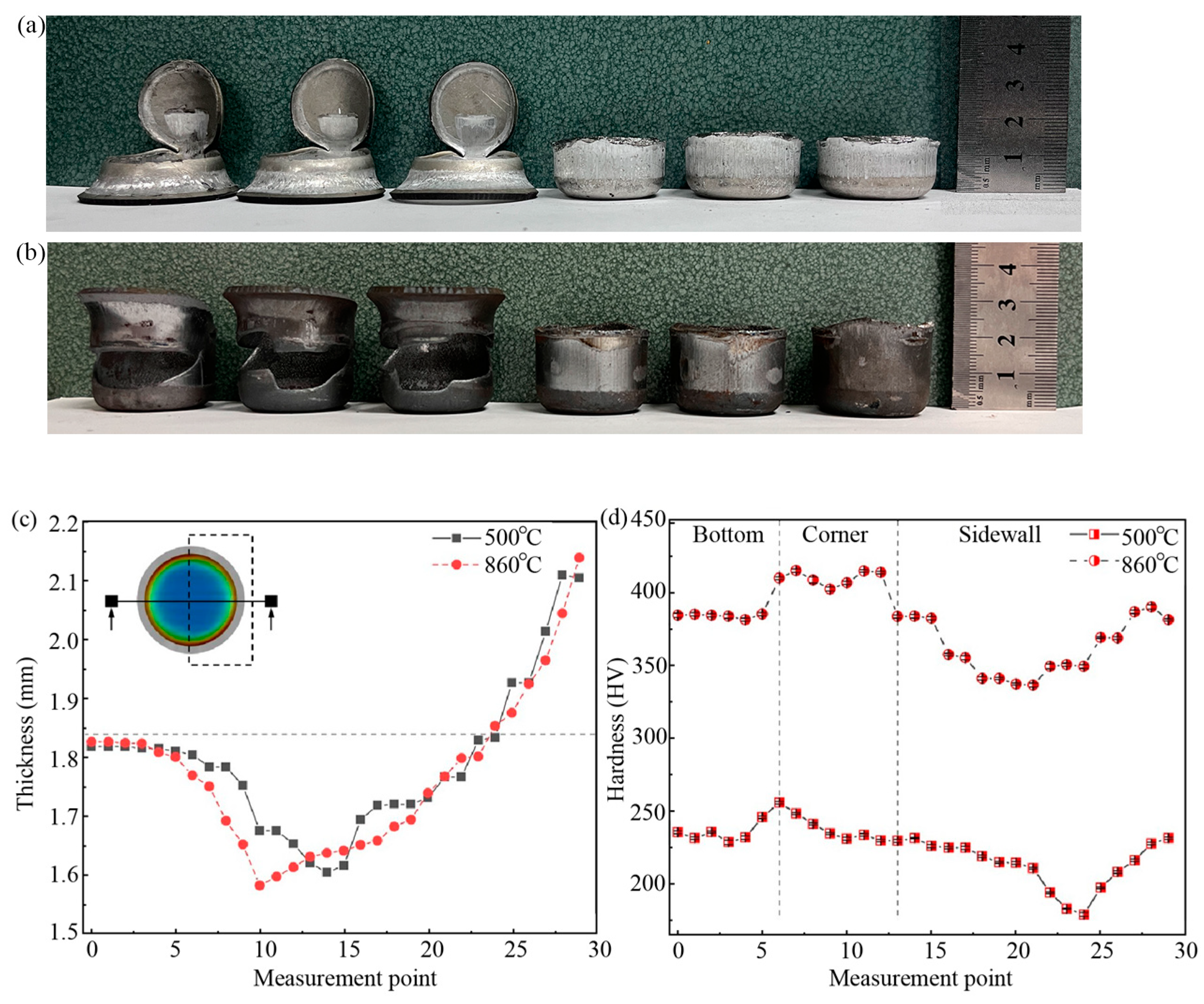

4.1. Formability Analysis

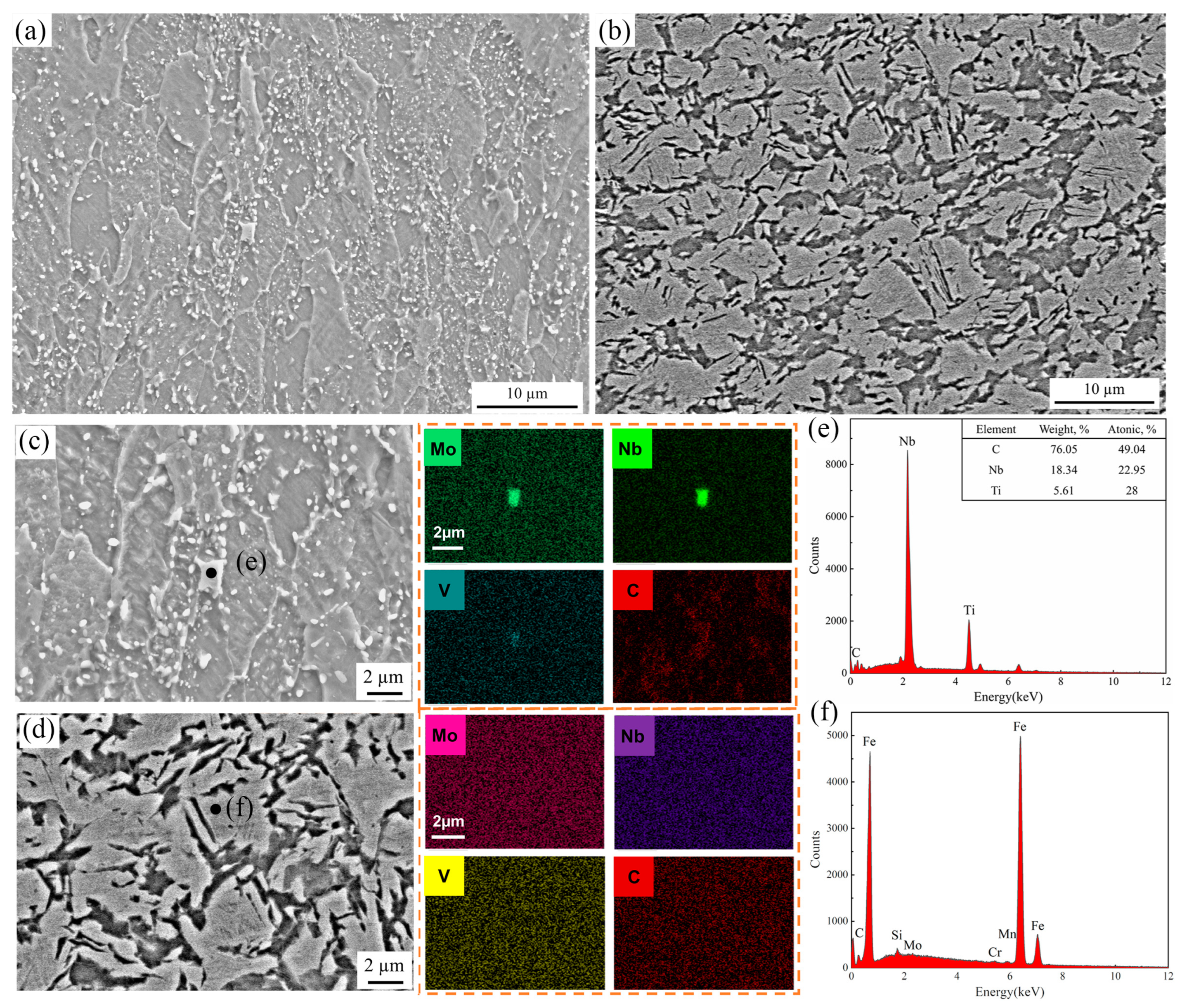

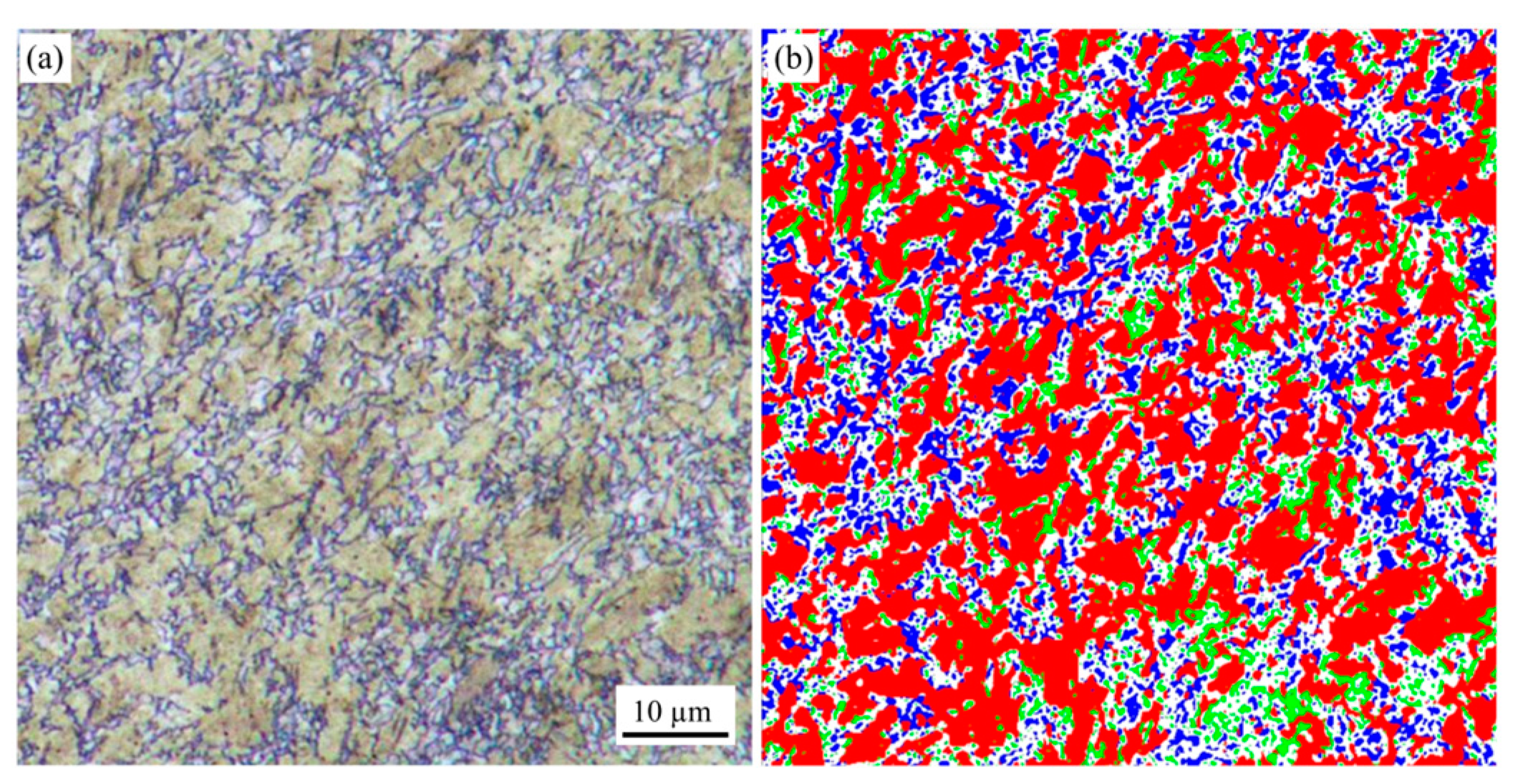

4.2. Phase Composition Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Merklein, M.; Wieland, M.; Lechner, M.; Bruschi, S.; Ghiotti, A. Hot stamping of boron steel sheets with tailored properties: A review. J. Mater. Process. Technol. 2016, 228, 11–24. [Google Scholar] [CrossRef]

- Barcellona, A.; Palmeri, D. Effect of Plastic Hot Deformation on the Hardness and Continuous Cooling Transformations of 22MnB5 Microalloyed Boron Steel. Metall. Mater. Trans. A 2009, 40, 1160–1174. [Google Scholar] [CrossRef]

- Eriksson, M.; Oldenburg, M.; Somani, M.C.; Karjalainen, L.P. Testing and evaluation of material data for analysis of forming and hardening of boron steel components. Model. Simul. Mater. Sci. Eng. 2002, 10, 277. [Google Scholar] [CrossRef]

- Liu, Y.; Lian, J.; Han, X.; Yang, Y.; Yuan, H. Hydrogen embrittlement studies of hot-stamped boron steel with different prior austenite grain sizes. J. Mater. Sci. 2023, 58, 18187–18206. [Google Scholar] [CrossRef]

- Valentini, R.; Tedesco, M.M.; Corsinovi, S.; Bacchi, L.; Villa, M. Investigation of Mechanical Tests for Hydrogen Embrittlement in Automotive PHS Steels. Metals 2019, 9, 934. [Google Scholar] [CrossRef]

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Li, Y.; Li, S.; He, J.; Chen, Y.; Yue, L. Identification methods on blank-die interfacial heat transfer coefficient in press hardening. Appl. Therm. Eng. 2019, 152, 865–877. [Google Scholar] [CrossRef]

- Abe, Y.; Ohmi, T.; Mori, K.; Masuda, T. Improvement of formability in deep drawing of ultra-high strength steel sheets by coating of die. J. Mater. Process. Technol. 2014, 214, 1838–1843. [Google Scholar] [CrossRef]

- Gu, Z.; Lü, M.; Lu, G.; Li, X.; Xu, H. Effect of Contact Pressure during Quenching on Microstructures and Mechanical Properties of Hot-stamping Parts. J. Iron Steel Res. Int. 2015, 22, 1138–1143. [Google Scholar] [CrossRef]

- Kolleck, R.; Veit, R.; Merklein, M.; Lechler, J.; Geiger, M. Investigation on induction heating for hot stamping of boron alloyed steels. CIRP Ann. 2009, 58, 275–278. [Google Scholar] [CrossRef]

- Mori, K.; Maki, S.; Tanaka, Y. Warm and Hot Stamping of Ultra High Tensile Strength Steel Sheets Using Resistance Heating. CIRP Ann. 2005, 54, 209–212. [Google Scholar] [CrossRef]

- Merklein, M.; Lechler, J.; Geiger, M. Characterisation of the Flow Properties of the Quenchenable Ultra High Strength Steel 22MnB5. CIRP Ann. 2006, 55, 229–232. [Google Scholar] [CrossRef]

- Merklein, M.; Lechler, J. Investigation of the thermo-mechanical properties of hot stamping steels. J. Mater. Process. Technol. 2006, 177, 452–455. [Google Scholar] [CrossRef]

- Mori, K.; Maeno, T.; Yamada, H.; Matsumoto, H. 1-Shot hot stamping of ultra-high strength steel parts consisting of resistance heating, forming, shearing and die quenching. Int. J. Mach. Tools Manuf. 2015, 89, 124–131. [Google Scholar] [CrossRef]

- Merklein, M.; Lechler, J. Determination of Material and Process Characteristics for Hot Stamping Processes of Quenchenable Ultra High Strength Steels with Respect to a FE-based Process Design. SAE Int. J. Mater. Manuf. 2009, 1, 411–426. [Google Scholar] [CrossRef]

- Geiger, M.; Merklein, M.; Hoff, C. Basic Investigations on the Hot Stamping Steel 22MnB5. Adv. Mater. Res. 2005, 6–8, 795–804. [Google Scholar] [CrossRef]

- Liu, H.; Jin, X.; Dong, H.; Shi, J. Martensitic microstructural transformations from the hot stamping, quenching and partitioning process. Mater. Charact. 2011, 62, 223–227. [Google Scholar] [CrossRef]

- Liu, H.; Lu, X.; Jin, X.; Dong, H.; Shi, J. Enhanced mechanical properties of a hot stamped advanced high-strength steel treated by quenching and partitioning process. Scr. Mater. 2011, 64, 749–752. [Google Scholar] [CrossRef]

- Palmieri, M.E.; Tricarico, L. Comparison of Flow Behaviors at High Temperature of Two Press Hardening Boron Steels with Different Hardenability. Metals 2022, 12, 1935. [Google Scholar] [CrossRef]

- Palmieri, M.E.; Galetta, F.R.; Tricarico, L. Study of Tailored Hot Stamping Process on Advanced High-Strength Steels. J. Manuf. Mater. Process. 2022, 6, 11. [Google Scholar] [CrossRef]

- Palmieri, M.E.; Tricarico, L. Process Window Definition to Predict Mechanical Properties of Press Hardened Parts of Boron Steel with Tailored Properties. Key Eng. Mater. 2022, 926, 635–644. [Google Scholar] [CrossRef]

- Hou, J.; Deng, P.; Wang, Y.; Xu, H.; Shi, Y.; Wang, Y.; Li, J. Investigation of microstructure evolution and recrystallization refinement of Usibor®2000 press hardening steel sheets during deep drawing process. J. Mater. Sci. 2024, 59, 16292–16308. [Google Scholar] [CrossRef]

- Liang, J.; Lu, H.; Zhang, L.; Li, F.; Cao, R.; Liu, K.; Pan, H.; Teng, H.; Li, X.; Guo, A.; et al. A 2000 MPa grade Nb bearing hot stamping steel with ultra-high yield strength. Mater. Sci. Eng. A 2021, 801, 140419. [Google Scholar] [CrossRef]

- GB/T 4156–2020; Metallic Materials—Sheet and Strip—Erichsen Cupping Test. Standards Press of China: Beijing, China, 2020.

- Hou, J.; Deng, P.; Wang, S.; Xu, H.; Shi, Y. Study on formability and microstructure evolution of hot deep drawing manufactured 7005 aluminum alloy sheet metal. Mater. Today Commun. 2023, 36, 106794. [Google Scholar] [CrossRef]

- De, A.K.; Speer, J.G.; Matlock, D.K. Color tint-etching for multiphase steels. Adv. Mater. Amp. Process. 2003, 161, 27–31. [Google Scholar]

- Bardelcik, A.; Worswick, M.J.; Wells, M.A. The influence of martensite, bainite and ferrite on the as-quenched constitutive response of simultaneously quenched and deformed boron steel—Experiments and model. Mater. Des. 2014, 55, 509–525. [Google Scholar] [CrossRef]

- George, R.; Bardelcik, A.; Worswick, M.J. Hot forming of boron steels using heated and cooled tooling for tailored properties. J. Mater. Process. Technol. 2012, 212, 2386–2399. [Google Scholar] [CrossRef]

- Grajcar, A.; Radwański, K.; Krztoń, H.J. Microstructural Analysis of a Thermomechanically Processed Si-Al TRIP Steel Characterized by EBSD and X-Ray Techniques. Solid State Phenom. 2013, 203–204, 34–37. [Google Scholar] [CrossRef]

- Hong, S.G.; Kang, K.B.; Park, C.G. Strain-induced precipitation of NbC in Nb and Nb–Ti microalloyed HSLA steels. Scr. Mater. 2002, 46, 163–168. [Google Scholar] [CrossRef]

- Grajcar, A. Thermodynamic analysis of precipitation processes in Nb–Ti-microalloyed Si–Al TRIP steel. J. Therm. Anal. Calorim. 2014, 118, 1011–1020. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Christian, J.W. Bainite in steels. Metall. Trans. A 1990, 21, 767–797. [Google Scholar] [CrossRef]

- Saeidi, N.; Ekrami, A. Comparison of mechanical properties of martensite/ferrite and bainite/ferrite dual phase 4340 steels. Mater. Sci. Eng. A 2009, 523, 125–129. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Hou, J.; Deng, P.; Shi, Y.; Song, J. Study on Formability and Microstructure Evolution of Usibor®2000 Sheet Under Different Forming Temperatures in Deep Drawing Process. Materials 2025, 18, 2224. https://doi.org/10.3390/ma18102224

Wang Y, Hou J, Deng P, Shi Y, Song J. Study on Formability and Microstructure Evolution of Usibor®2000 Sheet Under Different Forming Temperatures in Deep Drawing Process. Materials. 2025; 18(10):2224. https://doi.org/10.3390/ma18102224

Chicago/Turabian StyleWang, Yuxuan, Jinyu Hou, Peiran Deng, Yongze Shi, and Jiacheng Song. 2025. "Study on Formability and Microstructure Evolution of Usibor®2000 Sheet Under Different Forming Temperatures in Deep Drawing Process" Materials 18, no. 10: 2224. https://doi.org/10.3390/ma18102224

APA StyleWang, Y., Hou, J., Deng, P., Shi, Y., & Song, J. (2025). Study on Formability and Microstructure Evolution of Usibor®2000 Sheet Under Different Forming Temperatures in Deep Drawing Process. Materials, 18(10), 2224. https://doi.org/10.3390/ma18102224