Utilizing Agro-Waste as Aggregate in Cement Composites: A Comprehensive Review of Properties, Global Trends, and Applications

Abstract

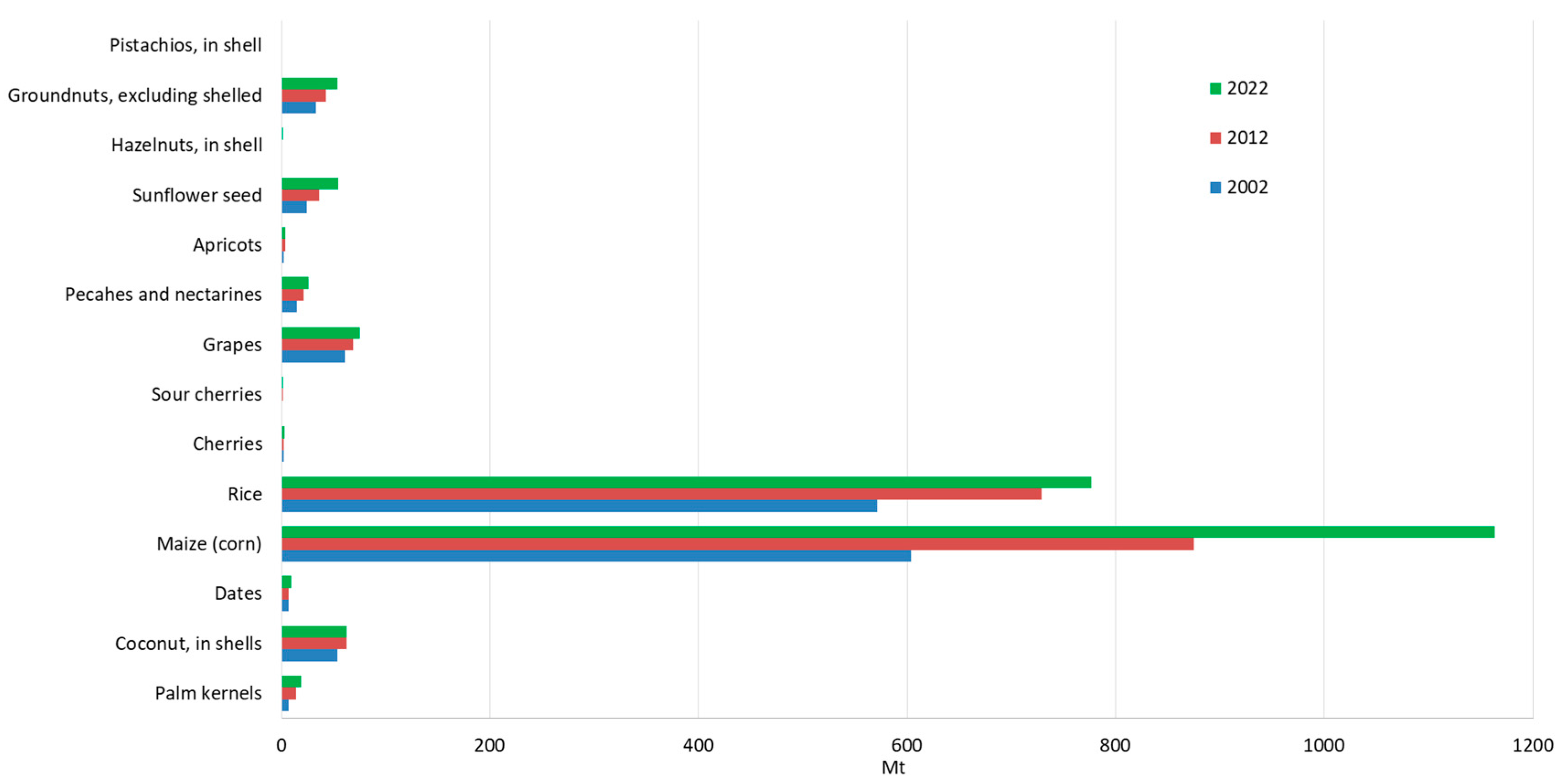

:1. Introduction

2. Properties of Agro-Waste Aggregate (AWA)

3. Production and Properties of Agro-Waste Aggregate Concrete (AWAC) and Examples of Its Application

3.1. Palm Kernel Shells

3.1.1. Production and Properties of Palm Kernel Shells

3.1.2. Palm Kernel Shells as AWA

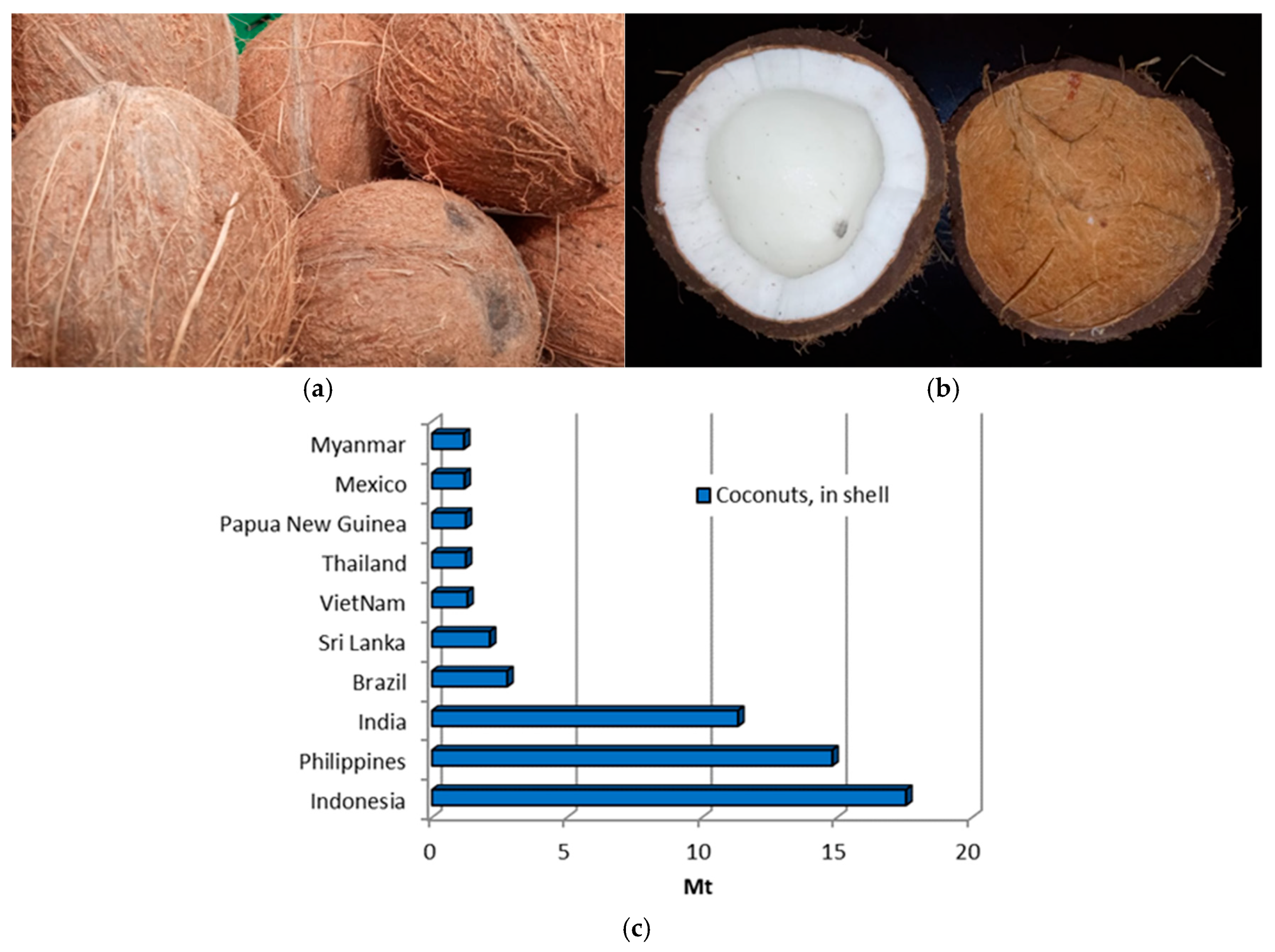

3.2. Coconut Shells

3.2.1. Production and Properties of Coconut Shells

3.2.2. Coconut Shells as AWA

3.3. Hazelnut, Peanuts, and Pistachios Shells

3.3.1. Production and Properties of Hazelnut, Peanuts, and Pistachios Shells

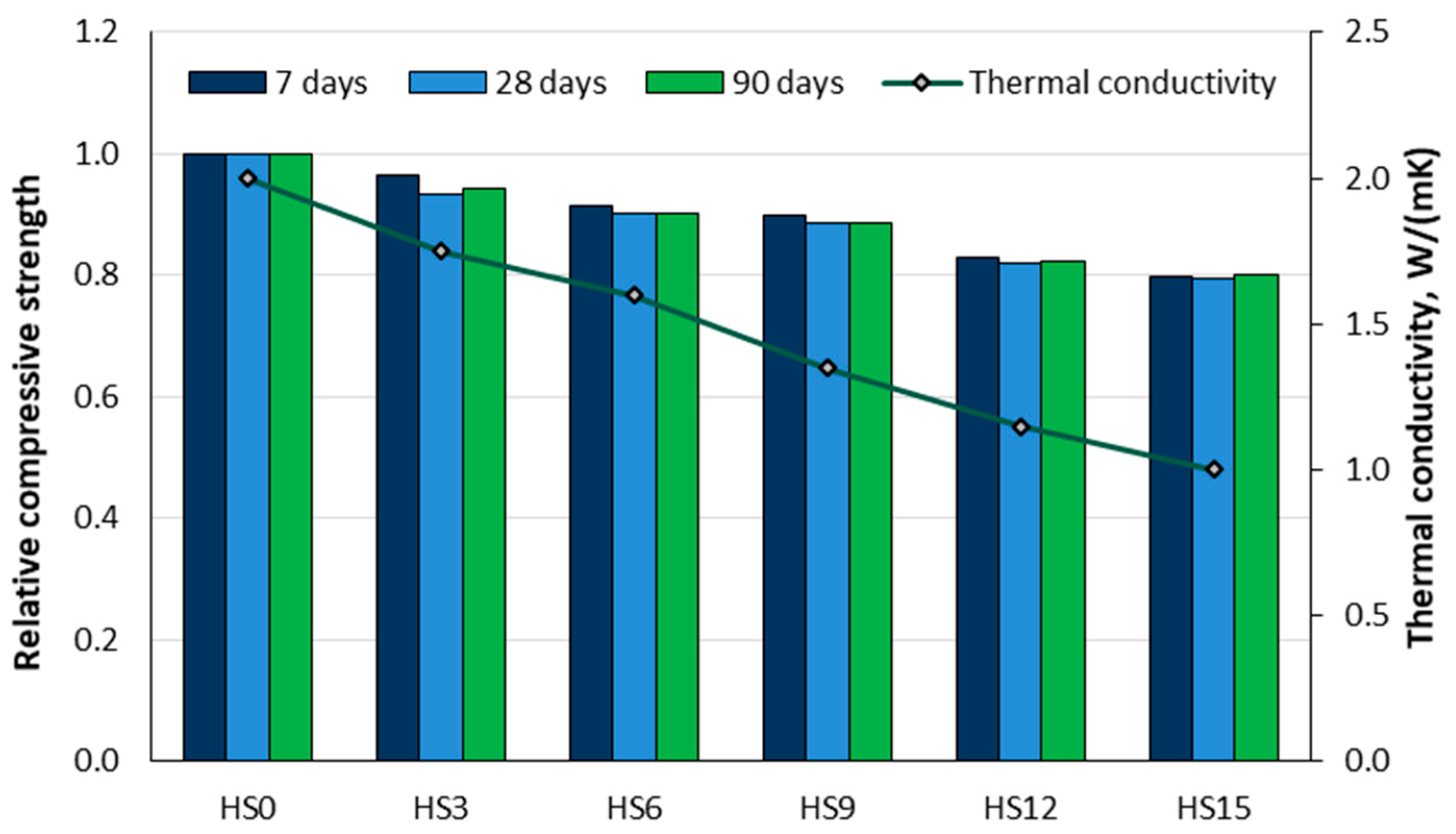

3.3.2. Hazelnut Shells, Groundnuts (Peanut) Shells, and Pistachio Shells as AWA

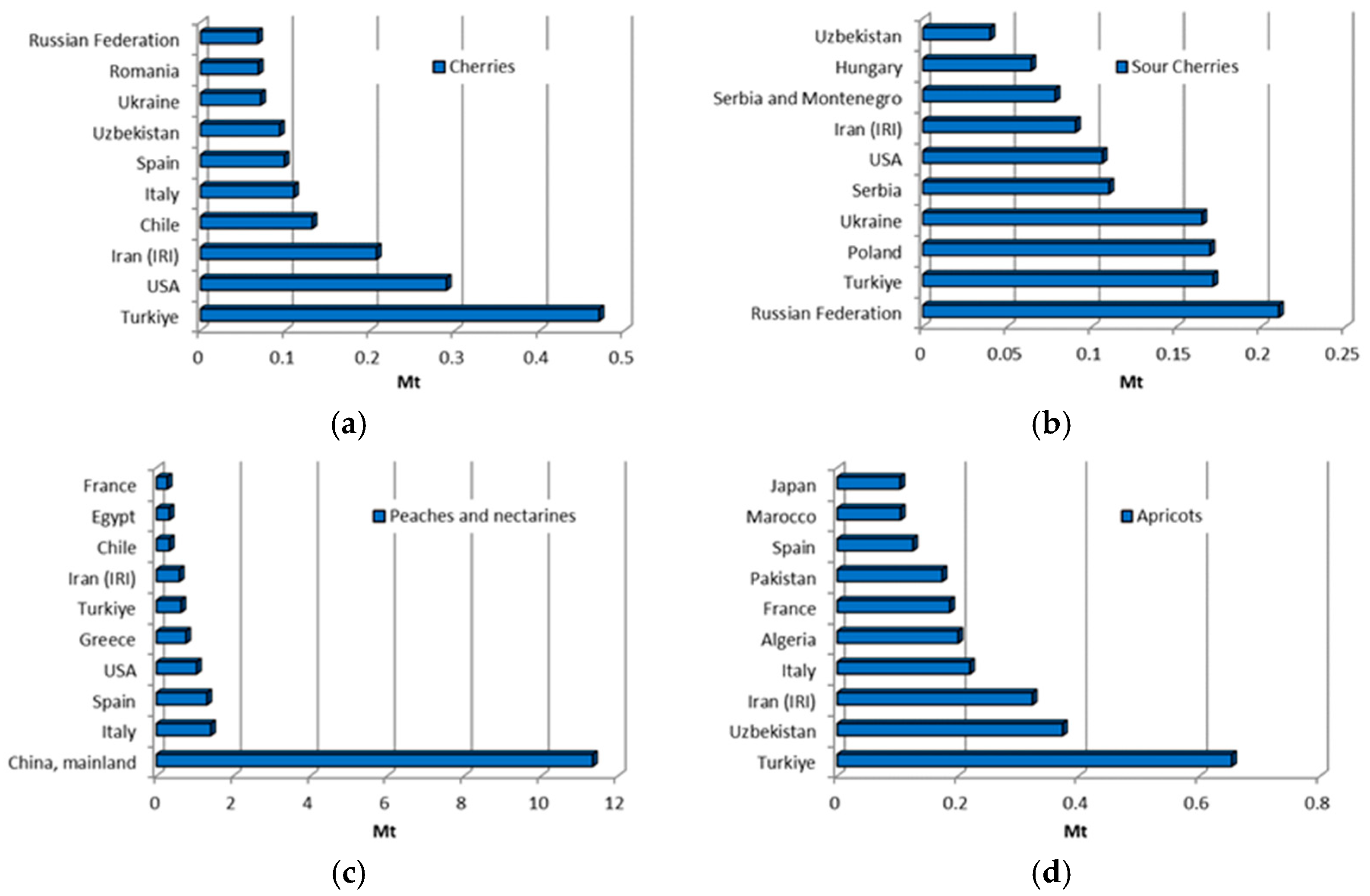

3.4. Stone Fruit Shells and Pits

3.4.1. Production and Properties of Stone Fruit Shells and Pits

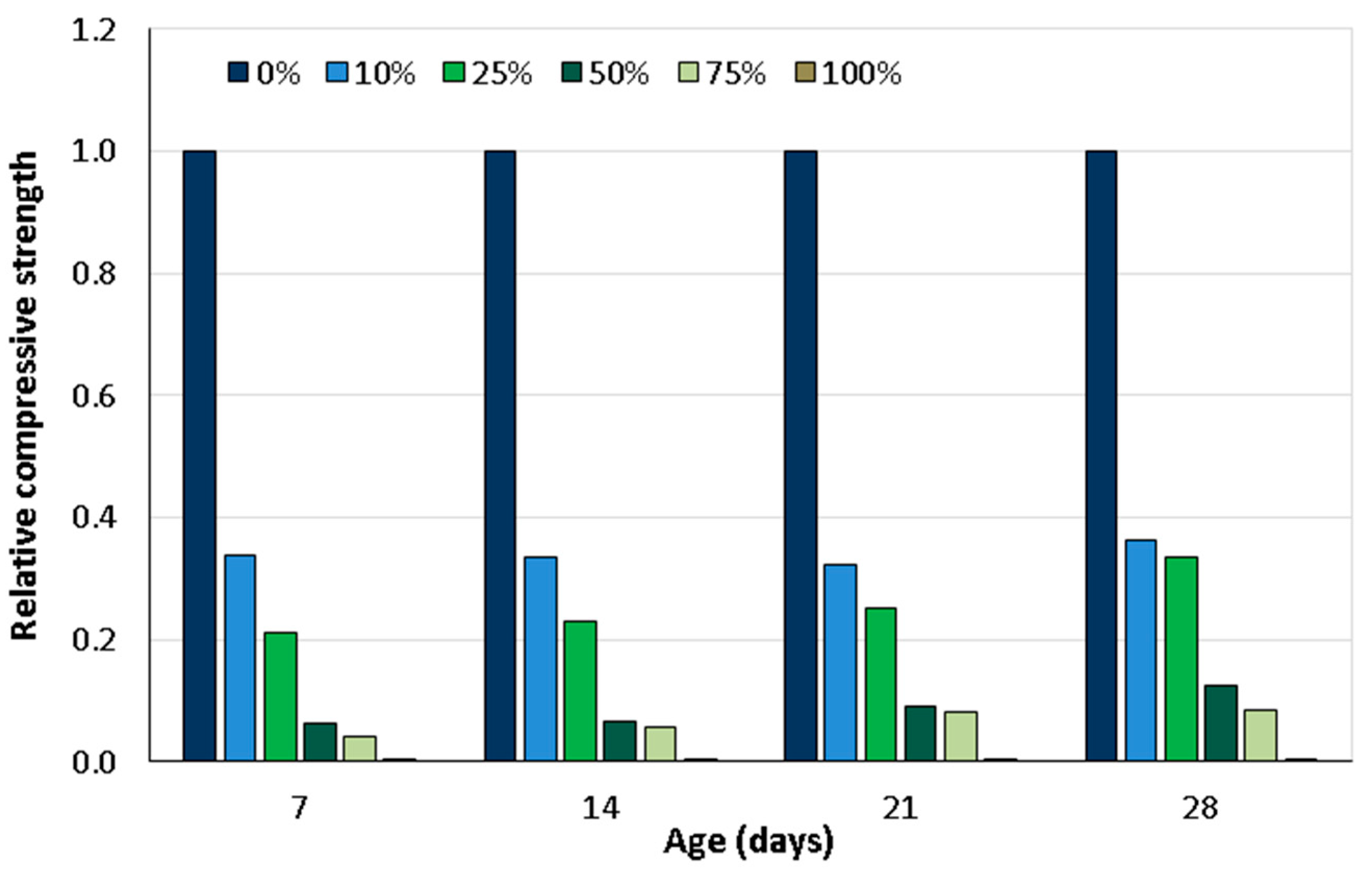

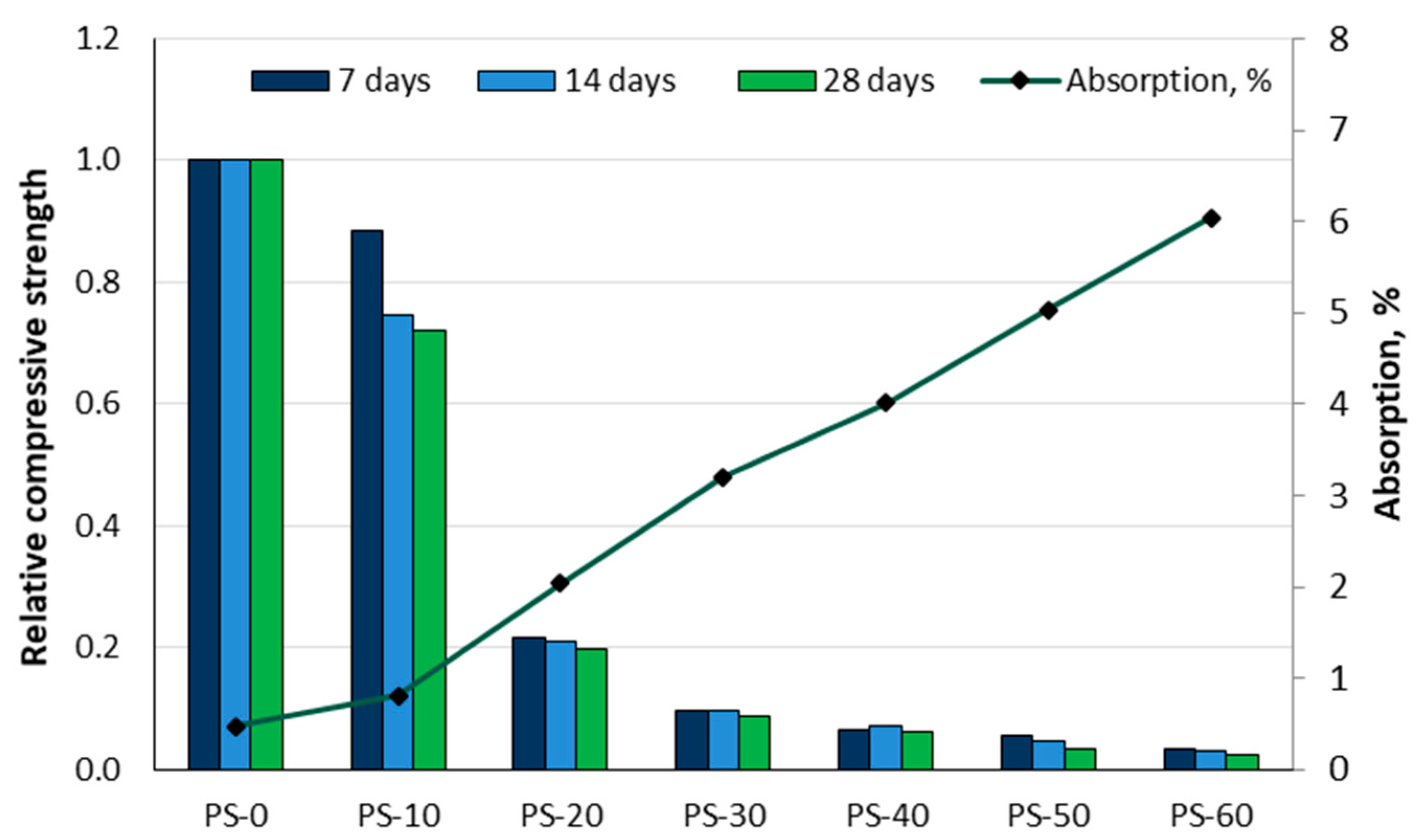

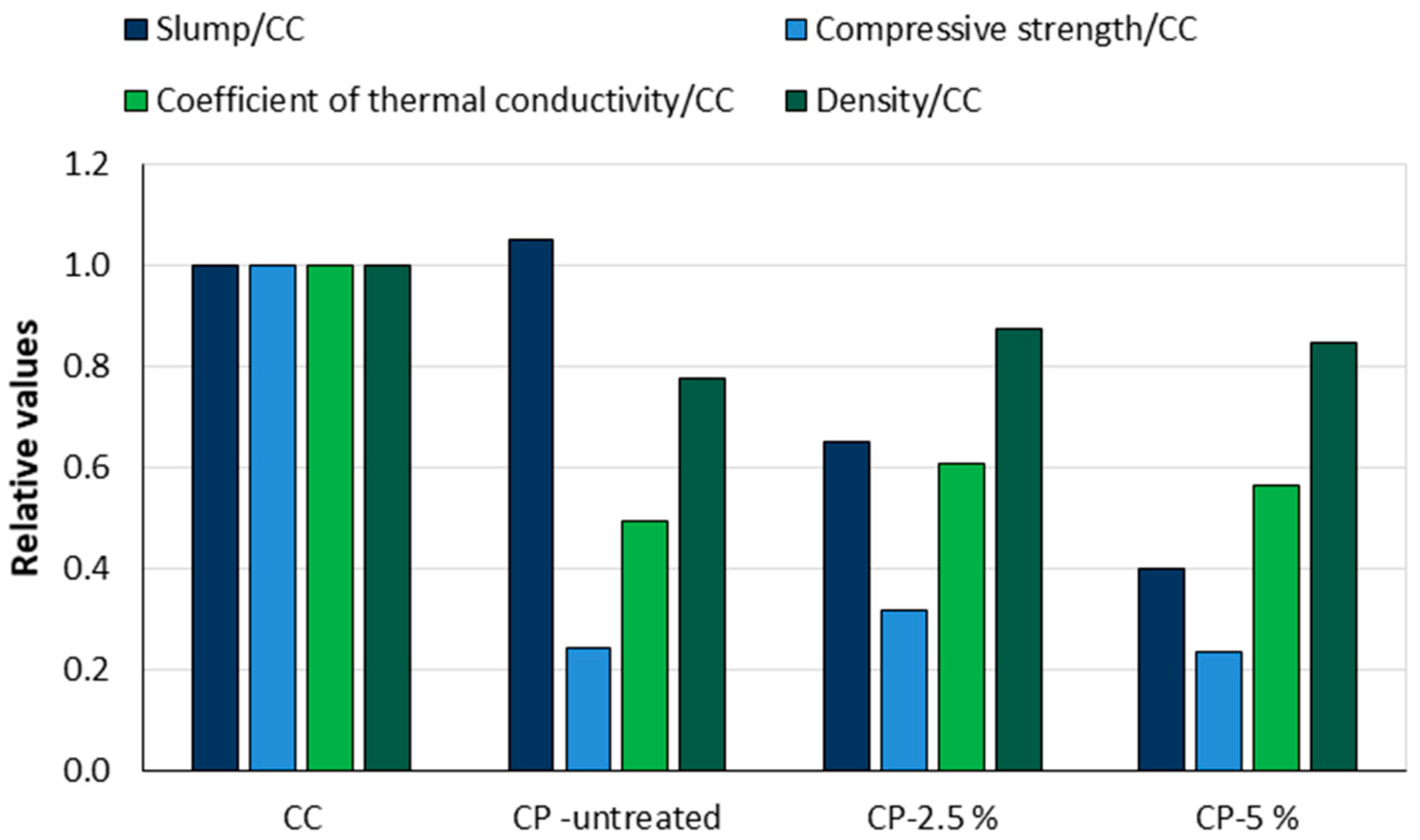

3.4.2. Stone Fruit Shells and Pits as AWA

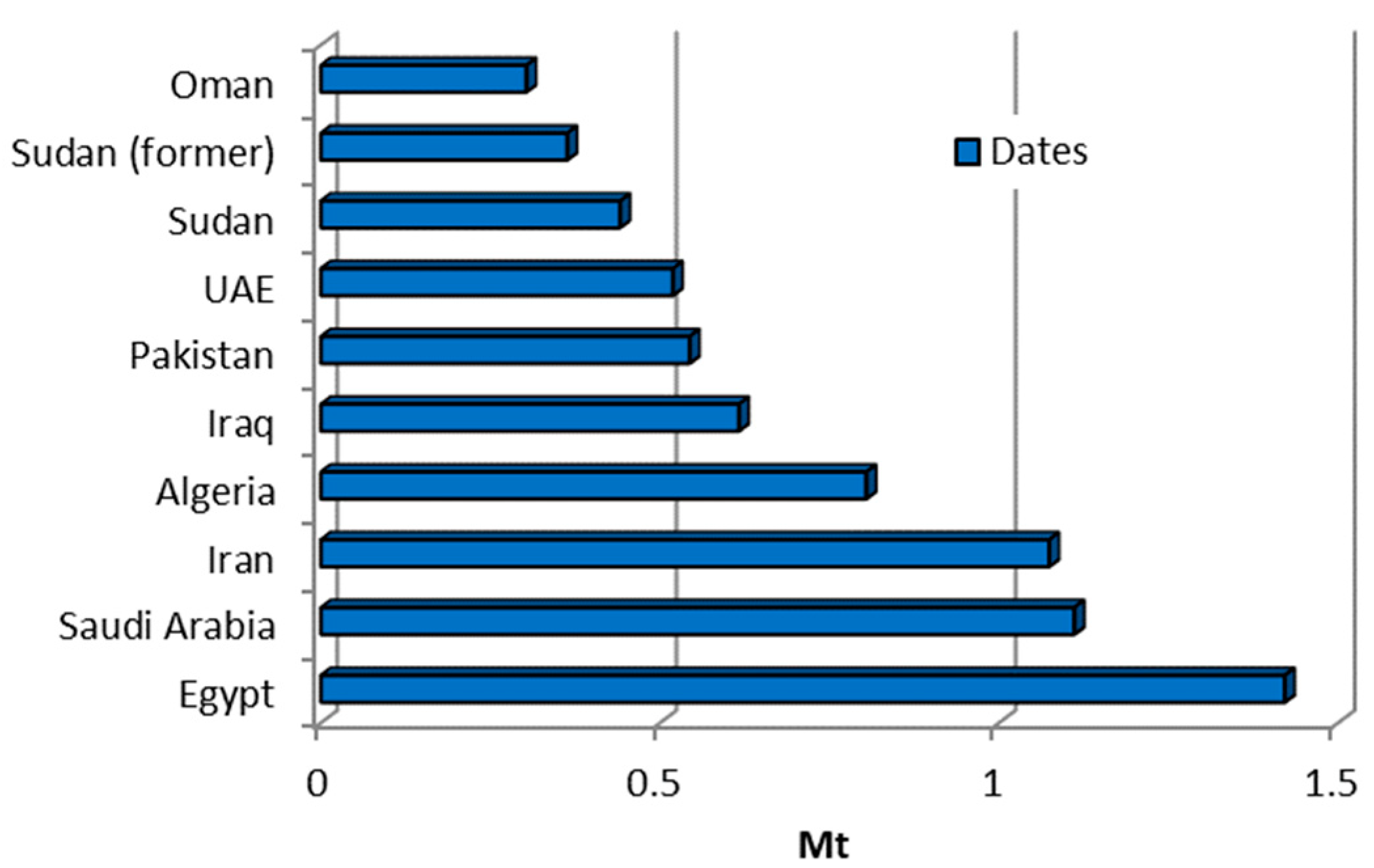

3.5. Date Seeds

3.5.1. Production and Properties of Date Seeds

3.5.2. Date Seeds as AWA

3.6. Grape Seeds

3.6.1. Production and Properties of Grape Seeds

3.6.2. Grape Seeds as AWA

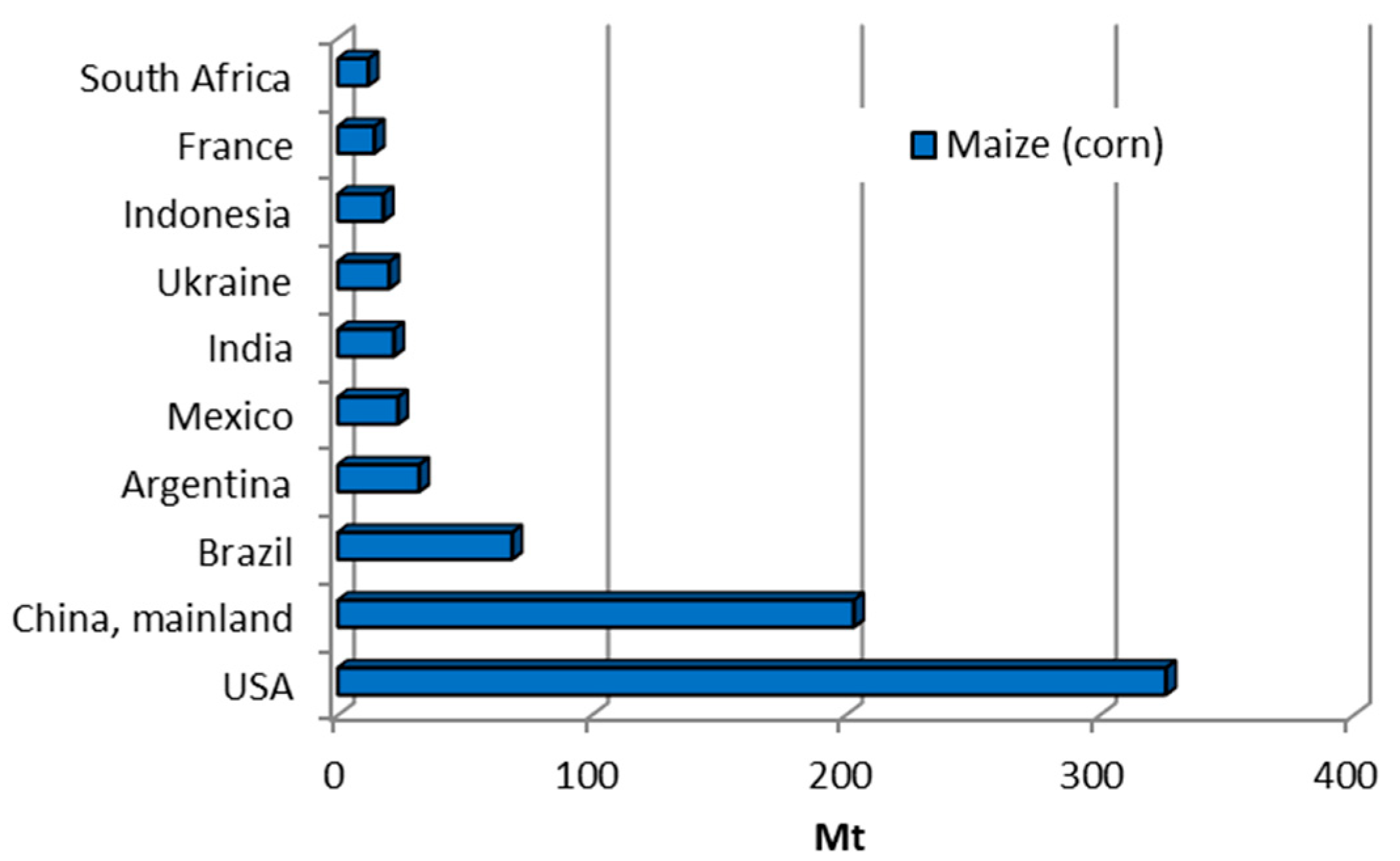

3.7. Maize (Corn) Cobs

3.7.1. Production and Properties

3.7.2. Maize (Corn) Cobs as AWA

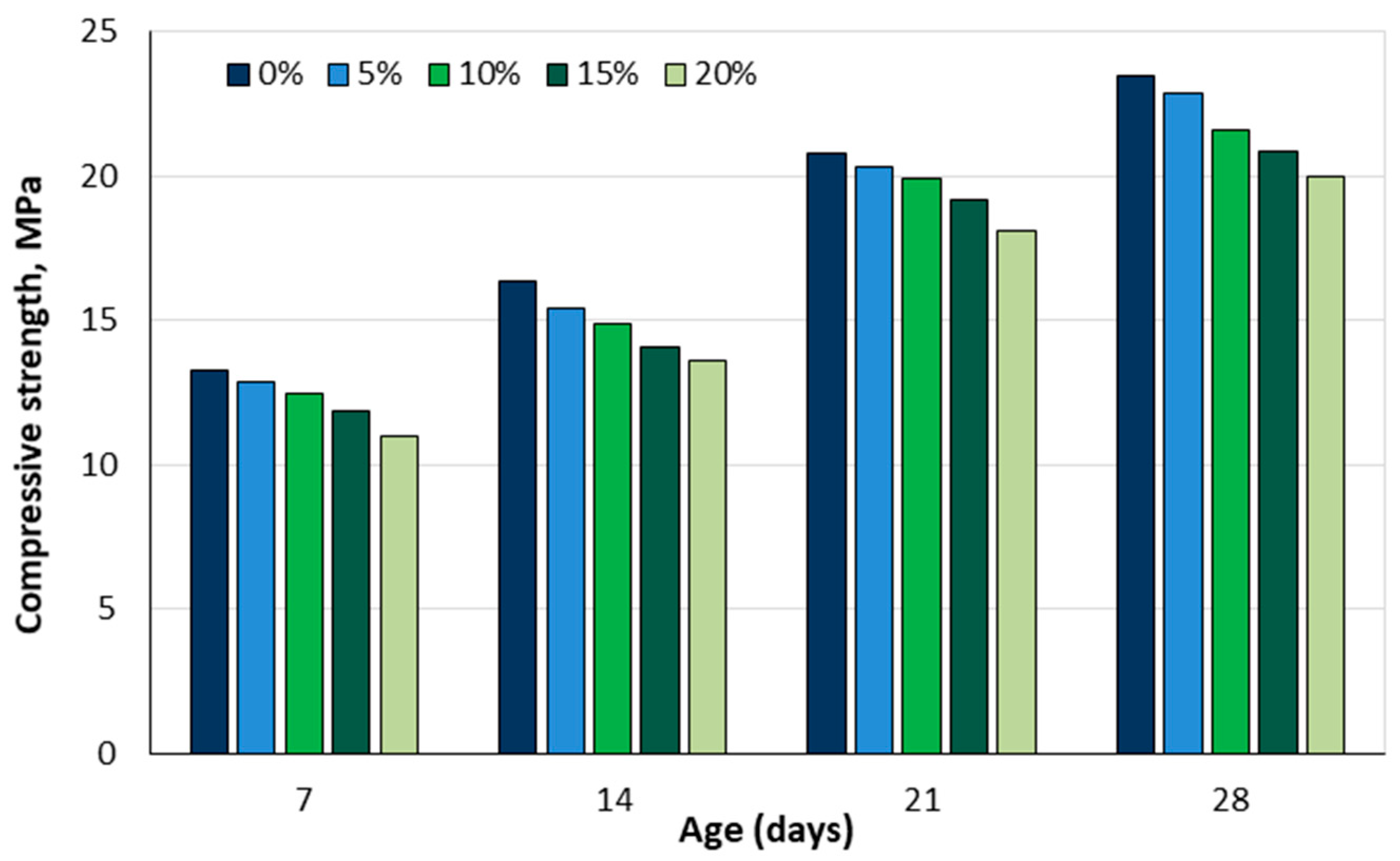

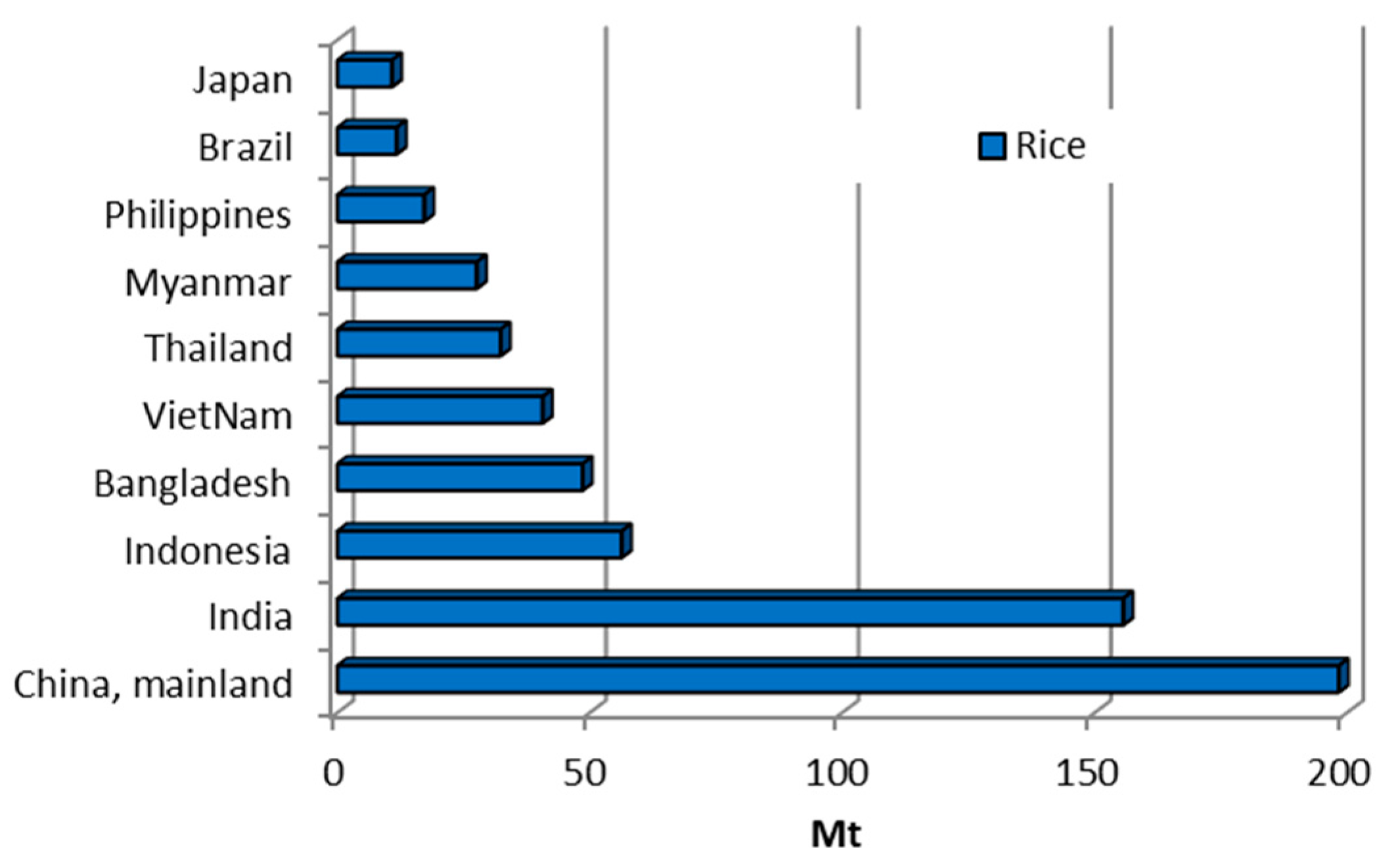

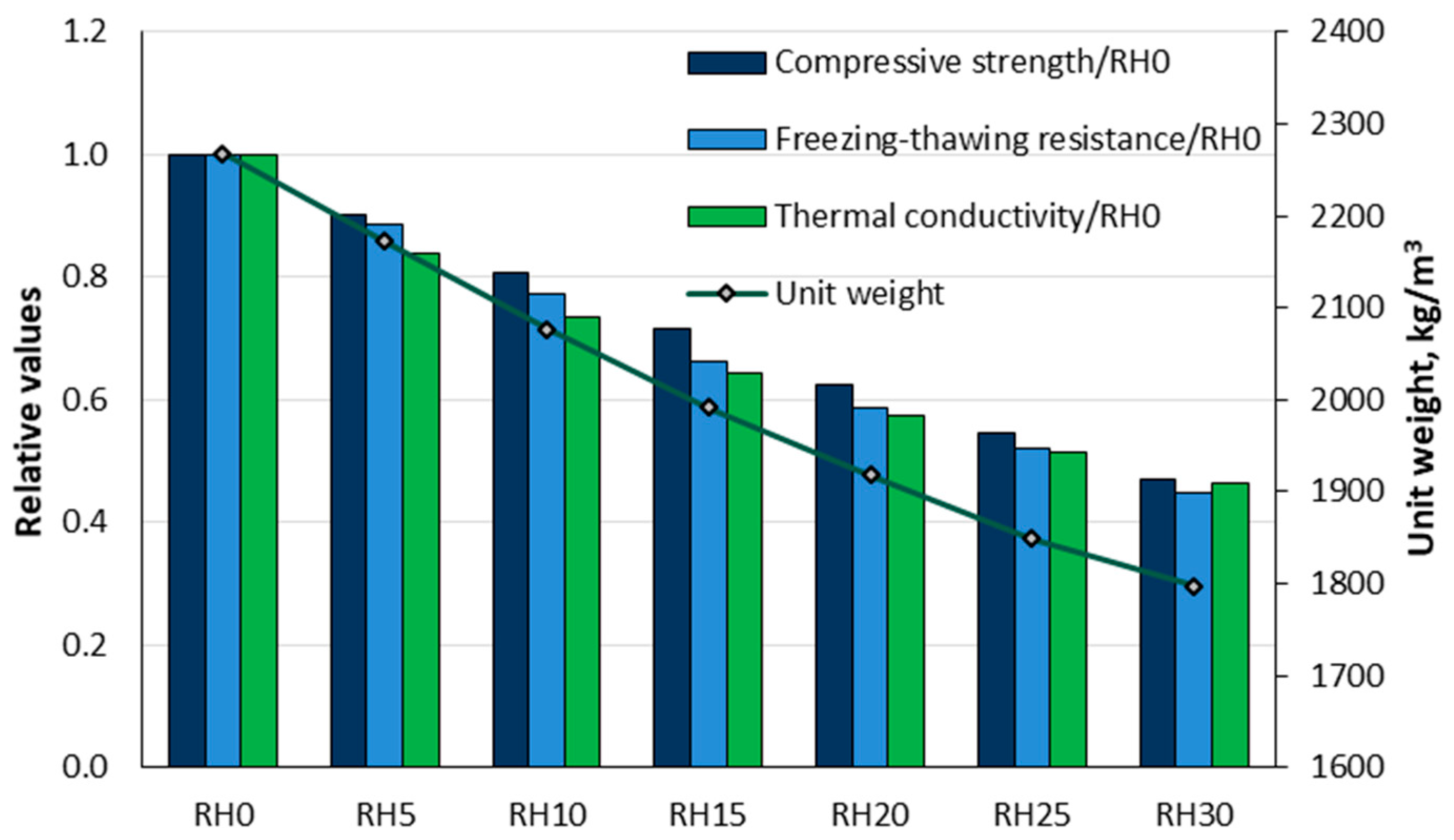

3.8. Rice Husk

3.8.1. Production and Properties of Rice Husk

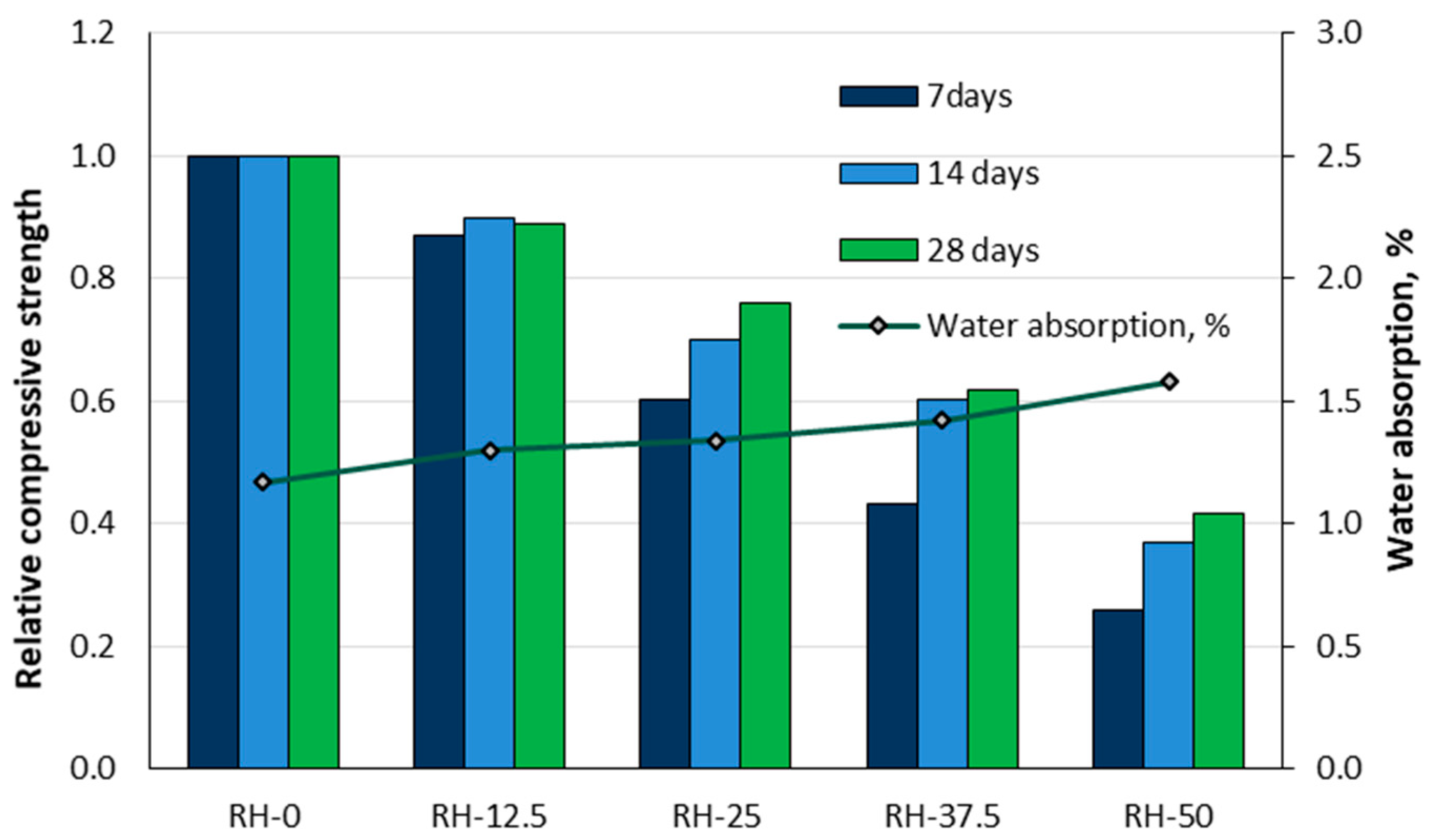

3.8.2. Rise Husk as AWA

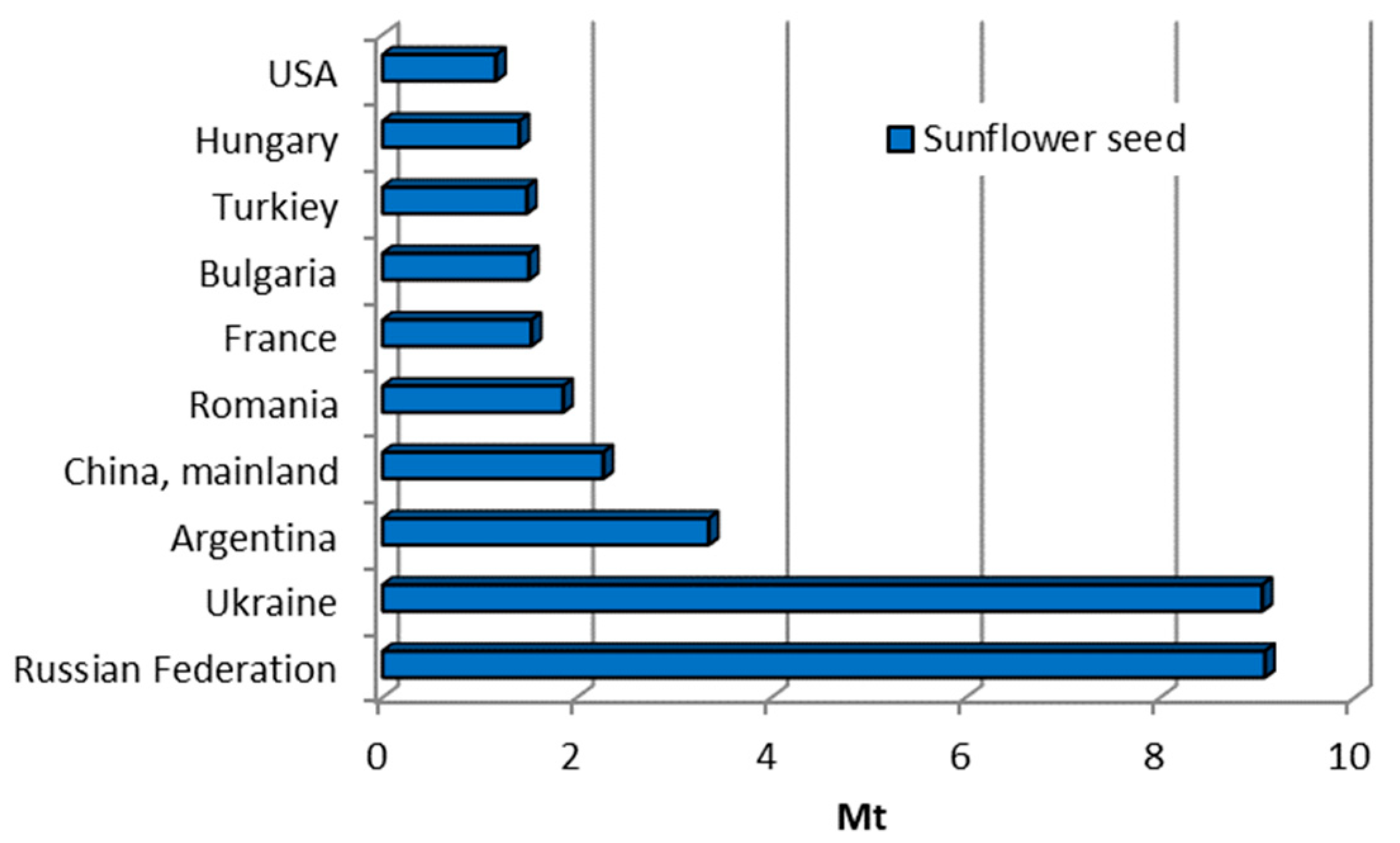

3.9. Sunflower Seed Hulls

3.9.1. Production and Properties of Sunflower Seed Hulls

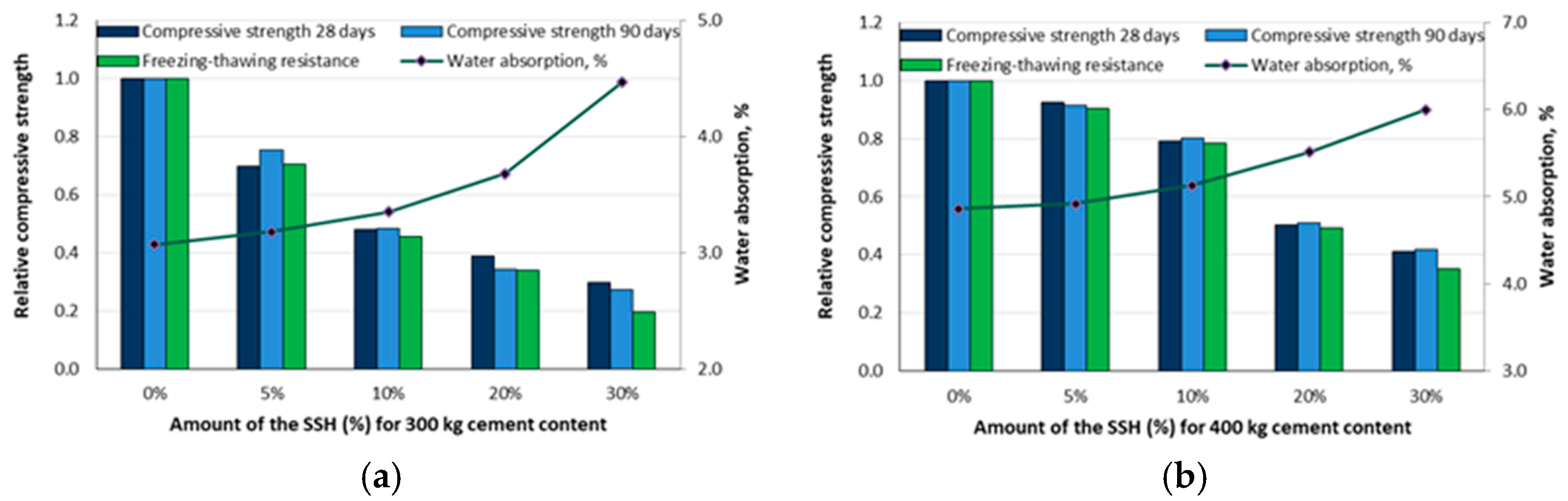

3.9.2. Sunflower Seed Hulls as AWA

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Naderi, M.; Kaboudan, A. Experimental Study of the Effect of Aggregate Type on Concrete Strength and Permeability. J. Build. Eng. 2021, 37, 101928. [Google Scholar] [CrossRef]

- Vahidi, A.; Mostaani, A.; Teklay Gebremariam, A.; Di Maio, F.; Rem, P. Feasibility of Utilizing Recycled Coarse Aggregates in Commercial Concrete Production. J. Clean. Prod. 2024, 474, 143578. [Google Scholar] [CrossRef]

- Watari, T.; Cao, Z.; Serrenho, A.C.; Cullen, J. Growing Role of Concrete in Sand and Climate Crises. iScience 2023, 26, 106782. [Google Scholar] [CrossRef]

- Debbarma, S.; Chong, B.W.; Shi, X.; Singh, S.; Brand, A.S. Sustainable Recycled Aggregate Concrete Materials and Structures. In Sustainable Concrete Materials and Structures; Elsevier: Amsterdam, The Netherlands, 2024; pp. 145–192. [Google Scholar]

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Cortés-García, F.J.; Camacho-Ferre, F. Agricultural Waste: Review of the Evolution, Approaches and Perspectives on Alternative Uses. Glob. Ecol. Conserv. 2020, 22, e00902. [Google Scholar] [CrossRef]

- Cai, J.; Li, X.; Liu, L.; Chen, Y.; Wang, X.; Lu, S. Coupling and Coordinated Development of New Urbanization and Agro-Ecological Environment in China. Sci. Total Environ. 2021, 776, 145837. [Google Scholar] [CrossRef]

- Karić, N.; Maia, A.S.; Teodorović, A.; Atanasova, N.; Langergraber, G.; Crini, G.; Ribeiro, A.R.L.; Đolić, M. Bio-Waste Valorisation: Agricultural Wastes as Biosorbents for Removal of (in)Organic Pollutants in Wastewater Treatment. Chem. Eng. J. Adv. 2022, 9, 100239. [Google Scholar] [CrossRef]

- Yang, M.; Chen, L.; Wang, J.; Msigwa, G.; Osman, A.I.; Fawzy, S.; Rooney, D.W.; Yap, P.-S. Circular Economy Strategies for Combating Climate Change and Other Environmental Issues. Environ. Chem. Lett. 2023, 21, 55–80. [Google Scholar] [CrossRef]

- Iqbal, N.; Agrawal, A.; Dubey, S.; Kumar, J. Role of Decomposers in Agricultural Waste Management. In Biotechnological Applications of Biomass; IntechOpen: London, UK, 2021. [Google Scholar]

- FAO. Available online: https://www.fao.org/faostat/en/#data/QCL/visualize (accessed on 1 January 2025).

- Kaab, A.; Sharifi, M.; Mobli, H.; Nabavi-Pelesaraei, A.; Chau, K. Combined Life Cycle Assessment and Artificial Intelligence for Prediction of Output Energy and Environmental Impacts of Sugarcane Production. Sci. Total Environ. 2019, 664, 1005–1019. [Google Scholar] [CrossRef]

- Awogbemi, O.; Von Kallon, D.V. Application of Biochar Derived from Crops Residues for Biofuel Production. Fuel Commun. 2023, 15, 100088. [Google Scholar] [CrossRef]

- Riseh, R.S.; Vazvani, M.G.; Hassanisaadi, M.; Thakur, V.K. Agricultural Wastes: A Practical and Potential Source for the Isolation and Preparation of Cellulose and Application in Agriculture and Different Industries. Ind. Crops Prod. 2024, 208, 117904. [Google Scholar] [CrossRef]

- Alharthai, M.; Othuman Mydin, M.A.; Cyriaque Kaze, R.; Majeed, S.S.; Tayeh, B.A. Properties of Ultra Lightweight Foamed Concrete Utilizing Agro Waste Ashes as an Alkaline Activated Material. J. Build. Eng. 2024, 90, 109347. [Google Scholar] [CrossRef]

- Charitha, V.; Athira, V.S.; Jittin, V.; Bahurudeen, A.; Nanthagopalan, P. Use of Different Agro-Waste Ashes in Concrete for Effective Upcycling of Locally Available Resources. Constr. Build. Mater. 2021, 285, 122851. [Google Scholar] [CrossRef]

- Sell Junior, F.K.; Wally, G.B.; Magalhães, F.C.; de Pires, M.M.; Kulakowski, M.P.; das Dores do Nascimento, C.; Flores, W.H.; Avellaneda, C.A.O. Effects of Bamboo Leaf Ashes on Concrete Compressive Strength, Water Absorption, and Chloride Penetration. J. Build. Eng. 2024, 97, 110986. [Google Scholar] [CrossRef]

- Aliu, A.O.; Olalusi, O.B.; Awoyera, P.O.; Kiliswa, M. Evaluation of Pozzolanic Reactivity of Maize Straw Ash as a Binder Supplement in Concrete. Case Stud. Constr. Mater. 2023, 18, e01790. [Google Scholar] [CrossRef]

- Eziefula, U.G. Developments in Utilisation of Agricultural and Aquaculture By-Products as Aggregate in Concrete—A Review. Environ. Technol. Rev. 2018, 7, 19–45. [Google Scholar] [CrossRef]

- Prusty, J.K.; Patro, S.K. Properties of Fresh and Hardened Concrete Using Agro-Waste as Partial Replacement of Coarse Aggregate—A Review. Constr. Build. Mater. 2015, 82, 101–113. [Google Scholar] [CrossRef]

- Adefemi, A.; Nensok, M.H.; Tersoo, E.; Wuna, I.A. Exploratory Study of Date Seed as Coarse Aggregate in Concrete Production. Civ. Environ. Res. 2013, 3, 85–93. [Google Scholar]

- Pinto, J.; Cruz, D.; Paiva, A.; Pereira, S.; Tavares, P.; Fernandes, L.; Varum, H. Characterization of Corn Cob as a Possible Raw Building Material. Constr. Build. Mater. 2012, 34, 28–33. [Google Scholar] [CrossRef]

- Zhang, Y.; Ghaly, A.E.; Li, B. Physical Properties of Corn Residues. Am. J. Biochem. Biotechnol. 2012, 8, 44–53. [Google Scholar] [CrossRef]

- Khan, M.; Musab, K.; Ur Rahmaan, M.H. Utilization Of Corn Cob As A Partial Replacement Of Coarse Aggregate In Concrete Blocks. IOP Conf. Ser. Earth Environ. Sci. 2022, 1026, 012063. [Google Scholar] [CrossRef]

- Mohanta, K.; Kumar, D.; Parkash, O. Properties and Industrial Applications of Rice Husk: A Review. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 86–90. [Google Scholar]

- de Lima Moura Paiva, R.; dos Santos, D.O.J.; de Aguiar, A.L.D.; da Cunha Gomes, B.M.; Bezerra, C.G.; Hasparyk, N.P.; Filho, R.D.T. Influence of Bio-Aggregates on the Physical and Hygrothermal Properties of Bio-Concretes. Constr. Build. Mater. 2024, 456, 139218. [Google Scholar] [CrossRef]

- Amantino, G.M.; Hasparyk, N.P.; Tiecher, F.; Toledo Filho, R.D. Assessment of Bio-Aggregate Concretes’ Properties with Rice Residue. J. Build. Eng. 2022, 52, 104348. [Google Scholar] [CrossRef]

- Wu, F.; Liu, C.; Zhang, L.; Lu, Y.; Ma, Y. Comparative Study of Carbonized Peach Shell and Carbonized Apricot Shell to Improve the Performance of Lightweight Concrete. Constr. Build. Mater. 2018, 188, 758–771. [Google Scholar] [CrossRef]

- Kamandari, H.; Hashemipour, H.; Saeednia, L.; Najjarzadeh, H. Experimental and Modeling Study on Production of Activated Carbon from Pistachio Shells in Rotary Reactor. Res. Chem. Intermed. 2014, 40, 509–521. [Google Scholar] [CrossRef]

- Alsalami, Z.H.A. Study the Effect of Partially Replacement Sand by Waste Pistachio Shells in Cement Mortar. Appl. Adhes. Sci. 2017, 5, 19. [Google Scholar] [CrossRef]

- Turzyński, T.; Kluska, J.; Ochnio, M.; Kardaś, D. Comparative Analysis of Pelletized and Unpelletized Sunflower Husks Combustion Process in a Batch-Type Reactor. Materials 2021, 14, 2484. [Google Scholar] [CrossRef]

- Jerzak, W.; Kalicka, Z.; Kawecka-Cebula, E.; Kuźnia, M. Comparison of Hazelnut and Peanut Shells Combustion in Bubbling Fluidized-Bed Combustor. Energy Sources Part A Recover. Util. Environ. Eff. 2016, 38, 2272–2281. [Google Scholar] [CrossRef]

- Cintura, E.; Faria, P.; Duarte, M.; Nunes, L. Eco-Efficient Boards with Agro-Industrial Wastes—Assessment of Different Adhesives. Constr. Build. Mater. 2023, 404, 132665. [Google Scholar] [CrossRef]

- Milošević, T.; Milošević, N. Determination of Size and Shape Features of Hazelnuts Using Multivariate Analysis. Acta Sci. Pol. Hortorum Cultus 2017, 16, 49–61. [Google Scholar] [CrossRef]

- Netinger Grubeša, I.; Marković, B.; Nyarko, M.H.; Krstić, H.; Brdarić, J.; Filipović, N.; Szenti, I.; Kukovecz, Á. Potential of Fruit Pits as Aggregate in Concrete. Constr. Build. Mater. 2022, 345, 128366. [Google Scholar] [CrossRef]

- Milani, J.; Moetamedzadegan, A. Moisture Dependent Physical Properties of Grape Seeds. Int. J. Food Eng. 2010, 6, 10. [Google Scholar] [CrossRef]

- D’Eusanio, V.; Bertacchini, L.; Marchetti, A.; Mariani, M.; Pastorelli, S.; Silvestri, M.; Tassi, L. Rosaceae Nut-Shells as Sustainable Aggregate for Potential Use in Non-Structural Lightweight Concrete. Waste 2023, 1, 549–568. [Google Scholar] [CrossRef]

- Sada, B.H.; Amartey, Y.D.; Bako, S. An Investigation Into the Use of Groundnut Shell As Fine Aggregate Replacement. Niger. J. Technol. 2013, 32, 54–60. [Google Scholar]

- Gandhare, P.K.U. Effect on Concrete Properties after Substituting Fine Aggregate by Crushed Groundnut Shells and Addition of Sugarcane Bagasse Ash. Int. J. Trend Sci. Res. Dev. 2018, 2, 1490–1494. [Google Scholar] [CrossRef]

- Almograbi, M. Durability Study of Lightweight Concrete Material Made from Date Palma Seeds (DPS). WIT Trans. Built Environ. 2010, 112, 69–75. [Google Scholar]

- Wu, F.; Liu, C.; Sun, W.; Zhang, L. Mechanical Properties of Bio-Based Concrete Containing Blended Peach Shell and Apricot Shell Waste. Mater. Tehnol. 2018, 52, 645–651. [Google Scholar] [CrossRef]

- Dołżyńska, M.; Obidziński, S.; Kowczyk-Sadowy, M.; Krasowska, M. Densification and Combustion of Cherry Stones. Energies 2019, 12, 3042. [Google Scholar] [CrossRef]

- Cintura, E.; Faria, P.; Molari, L.; Barbaresi, L.; D’Orazio, D.; Nunes, L. A Feasible Re-Use of an Agro-Industrial by-Product: Hazelnut Shells as High-Mass Bio-Aggregate in Boards for Indoor Applications. J. Clean. Prod. 2024, 434, 140297. [Google Scholar] [CrossRef]

- Wu, F.; Liu, C.; Sun, W.; Ma, Y.; Zhang, L. Effect of Peach Shell as Lightweight Aggregate on Mechanics and Creep Properties of Concrete. Eur. J. Environ. Civ. Eng. 2020, 24, 2534–2552. [Google Scholar] [CrossRef]

- Chen, L.; Yang, M.; Chen, Z.; Xie, Z.; Huang, L.; Osman, A.I.; Farghali, M.; Sandanayake, M.; Liu, E.; Ahn, Y.H.; et al. Conversion of Waste into Sustainable Construction Materials: A Review of Recent Developments and Prospects. Mater. Today Sustain. 2024, 27, 100930. [Google Scholar] [CrossRef]

- Zhang, Y.; Ghaly, A.E.; Li, B. Physical Properties of Rice Residues as Affected by Variety and Climatic and Cultivation Onditions in Three Continents. Am. J. Appl. Sci. 2012, 9, 1757–1768. [Google Scholar] [CrossRef]

- Akinwumi, I.I.; Awoyera, P.O.; Olofinnade, O.M.; Busari, A.A.; Okotie, M. Rice Husk as a Concrete Constituent: Workability, Water Absorption and Strength of the Concrete. ASIAN J. Civ. Eng. 2016, 17, 887–898. [Google Scholar]

- Murphy, D.J.; Goggin, K.; Paterson, R.R.M. Oil Palm in the 2020s and beyond: Challenges and Solutions. CABI Agric. Biosci. 2021, 2, 39. [Google Scholar] [CrossRef]

- Shafigh, P.; Mahmud, H.B.; Jumaat, M.Z.; Zargar, M. Agricultural Wastes as Aggregate in Concrete Mixtures—A Review. Constr. Build. Mater. 2014, 53, 110–117. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Mahmud, H.; Jumaat, M.Z. Comparison of Mechanical and Bond Properties of Oil Palm Kernel Shell Concrete with Normal Weight Concrete. Int. J. Phys. Sci. 2010, 5, 1231–1239. [Google Scholar]

- Mannan, M.; Ganapathy, C. Concrete from an Agricultural Waste-Oil Palm Shell (OPS). Build. Environ. 2004, 39, 441–448. [Google Scholar] [CrossRef]

- Ali, A.; Abdullah, A.; Abdus, S.S.K.; Rahim, A.A. Basic Strength Properties of Lightweight Concrete Using Agricultural Wastes as Aggregates. In Proceedings of the International Conference on Low Cost Housing for Developing Countries, Roorkee, India, 12–17 November 1984; pp. 12–17. [Google Scholar]

- Okafor, F.O. Palm Kernel Shell as a Lightweight Aggregate for Concrete. Cem. Concr. Res. 1988, 18, 901–910. [Google Scholar] [CrossRef]

- Yew, M.K.; Mahmud, H.B.; Ang, B.C.; Yew, M.C. Effects of Heat Treatment on Oil Palm Shell Coarse Aggregates for High Strength Lightweight Concrete. Mater. Des. 2014, 54, 702–707. [Google Scholar] [CrossRef]

- Ndoke, P. Performance of Palm Kernel Shells as a Partial Replacement for Coarse Aggregate in Asphalt Concrete Leonardo Electronic Journal of Practices and Technologies Performance of Palm Kernel Shells as a Partial Replacement for Coarse Aggregate in Asphalt Concre. Leonardo Electron. J. Pract. Technol. 2006, 5, 145–152. [Google Scholar]

- Ifeanyi, O.E.; Chima, A.D.; Chukwudubem, N.J. Structural Behavior of Concrete Produced Using Palm Kernel Shell (PKS) as a Partial Substitute for Coarse Aggregate. Am. J. Innov. Sci. Eng. 2023, 2, 1–7. [Google Scholar] [CrossRef]

- Khankhaje, E.; Salim, M.R.; Mirza, J.; Hussin, M.W.; Rafieizonooz, M. Properties of Sustainable Lightweight Pervious Concrete Containing Oil Palm Kernel Shell as Coarse Aggregate. Constr. Build. Mater. 2016, 126, 1054–1065. [Google Scholar] [CrossRef]

- Azunna, S.U. Compressive Strength of Concrete with Palm Kernel Shell as a Partial Replacement for Coarse Aggregate. SN Appl. Sci. 2019, 1, 342. [Google Scholar] [CrossRef]

- Serge, G.N.; Didier, F.; Gilbert, T.; Evrard, M. Study of Physico-Mechanical Properties of Concretes Based on Palm Kernel Shells Originating from the Locality of Haut Nkam in Cameroon. J. Civ. Eng. Constr. Technol. 2020, 11, 13–27. [Google Scholar] [CrossRef]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H.B.; Alengaram, U.J. A New Method of Producing High Strength Oil Palm Shell Lightweight Concrete. Mater. Des. 2011, 32, 4839–4843. [Google Scholar] [CrossRef]

- Mo, K.H.; Chin, T.S.; Alengaram, U.J.; Jumaat, M.Z. Material and Structural Properties of Waste-Oil Palm Shell Concrete Incorporating Ground Granulated Blast-Furnace Slag Reinforced with Low-Volume Steel Fibres. J. Clean. Prod. 2016, 133, 414–426. [Google Scholar] [CrossRef]

- Olanipekun, E.A.; Olusola, K.O.; Ata, O. A Comparative Study of Concrete Properties Using Coconut Shell and Palm Kernel Shell as Coarse Aggregates. Build. Environ. 2006, 41, 297–301. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Mahmud, H.; Jumaat, M.Z.; Shirazi, S.M. Effect of Aggregate Size and Proportion on Strength Properties of Palm Kernel Shell Concrete. Int. J. Phys. Sci. 2010, 5, 1848–1856. [Google Scholar]

- Gibigaye, M.; Godonou, G.F.; Katte, R.; Degan, G. Structured Mixture Proportioning for Oil Palm Kernel Shell Concrete. Case Stud. Constr. Mater. 2017, 6, 219–224. [Google Scholar] [CrossRef]

- Danso, H.; Appiah-Agyei, F. Size Variation of Palm Kernel Shells as Replacement of Coarse Aggregate for Lightweight Concrete Production. Open J. Civ. Eng. 2021, 11, 153–165. [Google Scholar] [CrossRef]

- Beveridge, F.C.; Kalaipandian, S.; Yang, C.; Adkins, S.W. Fruit Biology of Coconut (Cocos nucifera L.). Plants 2022, 11, 3293. [Google Scholar] [CrossRef] [PubMed]

- Ranjith, R. A Review Study on Coconut Shell Aggregate Concrete. J. Struct. Technol. 2023, 2, 1–7. [Google Scholar]

- Yerramala, A.; Ramachandrudu, C. Properties of Concrete with Coconut Shells as Aggregate Replacement. Int. J. Eng. Invent. 2012, 1, 2278–7461. [Google Scholar]

- Gunasekaran, K.; Kumar, P.S. Lightweight Concrete Using Coconut Shells as Aggregate. In Proceedings of the ICACC-2008. International Conference on Advances in Concrete and Construction, Hyderabad, India, 7–9 February 2008; pp. 450–459. [Google Scholar]

- Osei, D.Y. Experimental Assessment on Coconut Shells as Aggregate in Concrete. Int. J. Eng. Sci. Invent. 2013, 2, 7–11. [Google Scholar] [CrossRef]

- Kanojia, A.; Jain, S.K. Performance of Coconut Shell as Coarse Aggregate in Concrete. Constr. Build. Mater. 2017, 140, 150–156. [Google Scholar] [CrossRef]

- Azunna, S.U.; Abd.Aziz, F.N.A.; Abu Bakar, N.; Mohd Nasir, N.A. Mechanical Properties of Concrete with Coconut Shell as Partial Replacement of Aggregates. IOP Conf. Ser. Mater. Sci. Eng. 2018, 431, 032001. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Kumar, P.S.; Lakshmipathy, M. Mechanical and Bond Properties of Coconut Shell Concrete. Constr. Build. Mater. 2011, 25, 92–98. [Google Scholar] [CrossRef]

- Deepak, T.J.; Jalam, A.A.; Loh, E.; Tong, S.Y.; Nair, S. Prognostication of Concrete Characteristics with Coconut Shell as Coarse Aggregate Partial Percentile Replacement Prognostication of Concrete Characteristics with Coconut Shell as Coarse Aggregate Partial Percentile Replacement. Int. J. Sci. Res. Sci. Eng. Technol. 2015, 1, 45–50. [Google Scholar]

- Rajendran, T.; Abdul Rahman, N. Mechanical Properties of Concrete Containing Coconut Shells as Coarse Aggregate Partial Replacement. Malays. J. Sci. Adv. Technol. 2022, 2, 35–42. [Google Scholar] [CrossRef]

- Manaloto, J.A.R. Investigation of the Compressive Strengths of Coconut Shells as Partial Alternative of Coarse Aggregates in Concrete Mix. MUHON J. Archit. Landsc. Archit. Des. Environ. 2023, 9, 1–14. [Google Scholar]

- Manterola-Barroso, C.; Padilla Contreras, D.; Ondrasek, G.; Horvatinec, J.; Gavilán CuiCui, G.; Meriño-Gergichevich, C. Hazelnut and Walnut Nutshell Features as Emerging Added-Value Byproducts of the Nut Industry: A Review. Plants 2024, 13, 1034. [Google Scholar] [CrossRef] [PubMed]

- Ryšavý, J.; Serenčíšová, J.; Horák, J.; Ochodek, T. The Co-Combustion of Pellets with Pistachio Shells in Residential Units Additionally Equipped by Pt-Based Catalyst. Biomass Convers. Biorefinery 2023, 13, 16511–16527. [Google Scholar] [CrossRef]

- Čolnik, M.; Irgolič, M.; Perva, A.; Škerget, M. The Conversion of Pistachio and Walnut Shell Waste into Valuable Components with Subcritical Water. Processes 2024, 12, 195. [Google Scholar] [CrossRef]

- Benli, H.; Bahtiyari, M.İ. An Approach for the Valorization of Bio-Waste Pistachio Shells (Pistacia vera L.): Dyeing of Cellulose-Based Fabrics. J. Clean. Prod. 2024, 445, 141213. [Google Scholar] [CrossRef]

- Islam, M.S.; Jamal, S.; Ahmed, S.J.U.; Alshehri, K.; Uddin, M.J. The Impact of Recycled Pistachio Shells on the Fresh and Hardened Properties The Impact of Recycled Pistachio Shells on the Fresh and Hardened Properties of Concrete. In Proceedings of the 2nd International Conference on Structural Engineering Research (iCSER2019), Dhaka, Bangladesh, 19–22 January 2019. [Google Scholar]

- Özocak, M.; Sisman, C.B. Opportunities for the Use of Hazelnut Shell as a Lightweight Aggregate in the Production of Concrete. Cem. Wapno Bet. 2021, 26, 454–464. [Google Scholar] [CrossRef]

- Wang, L.; Yu, H. Biodiesel from Siberian Apricot (Prunus sibirica L.) Seed Kernel Oil. Bioresour. Technol. 2012, 112, 355–358. [Google Scholar] [CrossRef]

- Zwicky, D. Mechanical Properties of Organic-Based Lightweight Concretes and Their Impact on Economic and Ecological Performances. Constr. Build. Mater. 2020, 245, 118413. [Google Scholar] [CrossRef]

- Unal, A.; Demirdalmis, O. The Effects of Using Apricot Kernel Shell, an Environmentally Friendly Material, in Composite Brake Pads on Friction Performance. Tribol. Int. 2024, 197, 109734. [Google Scholar] [CrossRef]

- Koprivica, M.R.; Trifković, J.Đ.; Dramićanin, A.M.; Gašić, U.M.; Akšić, M.M.F.; Milojković-Opsenica, D.M. Determination of the Phenolic Profile of Peach (Prunus persica L.) Kernels Using UHPLC–LTQ OrbiTrap MS/MS Technique. Eur. Food Res. Technol. 2018, 244, 2051–2064. [Google Scholar] [CrossRef]

- Stanojević, M.; Trifković, J.; Akšić, M.F.; Rakonjac, V.; Nikolić, D.; Šegan, S.; Milojković-Opsenica, D. Sugar Profile of Kernels as a Marker of Origin and Ripening Time of Peach (Prunus persicae L.). Plant Foods Hum. Nutr. 2015, 70, 433–440. [Google Scholar] [CrossRef]

- Wu, F.; Liu, C.; Diao, Z.; Feng, B.; Sun, W.; Li, X.; Zhao, S. Improvement of Mechanical Properties in Polypropylene- and Glass-Fibre-Reinforced Peach Shell Lightweight Concrete. Adv. Mater. Sci. Eng. 2018, 2018, 6250941. [Google Scholar] [CrossRef]

- Yildiz, S.; Emiroglu, M.; Atalar, O. Apricot Pip Shells Used as Aggregate Replacement. J. Civ. Eng. Manag. 2012, 18, 318–322. [Google Scholar] [CrossRef]

- Chao, C.T.; Krueger, R.R. The Date Palm (Phoenix dactylifera L.): Overview of Biology, Uses, and Cultivation. HortScience 2007, 42, 1077–1082. [Google Scholar] [CrossRef]

- Ahmed, A.; Mangi, S.A.; Muhammad, A.W.; Din, N.U. Strength Performance of Concrete Containing Date Seeds as Partial Replacement of Coarse Aggregates under the Exposure of NaCl and Na2SO4. Indones. J. Soc. Environ. Issues 2020, 1, 206–212. [Google Scholar] [CrossRef]

- Palh, A.R.; Mangi, S.A.; Odho, M.A.; Kalhoro, A.A. Experimental Study on Concrete Incorporating Date Seed As Partial Replacement Of Coarse Aggregates. Neutron 2021, 20, 113–122. [Google Scholar] [CrossRef]

- Yusuf, A.; Jamal, J.O.; Abubakar, M.; Aminulai, H.O. Statistical Model for Predicting Slump and Strength of Concrete Containing Date Seeds. Covenant. J. Eng. Technol. 2021, 5. Available online: https://journals.covenantuniversity.edu.ng/index.php/cjet/article/view/2587 (accessed on 1 January 2025).

- Beres, C.; Costa, G.N.S.; Cabezudo, I.; da Silva-James, N.K.; Teles, A.S.C.; Cruz, A.P.G.; Mellinger-Silva, C.; Tonon, R.V.; Cabral, L.M.C.; Freitas, S.P. Towards Integral Utilization of Grape Pomace from Winemaking Process: A Review. Waste Manag. 2017, 68, 581–594. [Google Scholar] [CrossRef]

- Sarathkumar, S.C. Experimental Investigation on Concrete with Partial Replacement of Fine Aggregate by Date and Tamarind Seed. Int. J. Adv. Res. Ideas Innov. Technol. 2022, 8, 45–52. [Google Scholar]

- Jin, Q.; O’Keefe, S.F.; Stewart, A.C.; Neilson, A.P.; Kim, Y.-T.; Huang, H. Techno-Economic Analysis of a Grape Pomace Biorefinery: Production of Seed Oil, Polyphenols, and Biochar. Food Bioprod. Process. 2021, 127, 139–151. [Google Scholar] [CrossRef]

- Ustun Argon, Z.; Celenk, V.U.; Gumus, Z.P. Cold Pressed Grape (Vitis vinifera) Seed Oil. In Cold Pressed Oils; Elsevier: Amsterdam, The Netherlands, 2020; pp. 39–52. [Google Scholar]

- Novoselec, J. Nusproizvodi Vinske Industrije u Hranidbi Ovaca i Koza. In Proceedings of the 22. Savjetovanje Uzgajivača Ovaca i Koza u Republici Hrvatskoj i 21. Izložba Hrvatskih Ovčjih i Kozjih Sireva, Osijek, Croatia, 25 November 2020. [Google Scholar]

- Beres, C.; Simas-Tosin, F.F.; Cabezudo, I.; Freitas, S.P.; Iacomini, M.; Mellinger-Silva, C.; Cabral, L.M.C. Antioxidant Dietary Fibre Recovery from Brazilian Pinot Noir Grape Pomace. Food Chem. 2016, 201, 145–152. [Google Scholar] [CrossRef]

- Ashour, A.; Amer, M.; Marzouk, A.; Shimizu, K.; Kondo, R.; El-Sharkawy, S. Corncobs as a Potential Source of Functional Chemicals. Molecules 2013, 18, 13823–13830. [Google Scholar] [CrossRef] [PubMed]

- Pinto, J.; Vieira, B.; Pereira, H.; Jacinto, C.; Vilela, P.; Paiva, A.; Pereira, S.; Cunha, V.M.C.F.; Varum, H. Corn Cob Lightweight Concrete for Non-Structural Applications. Constr. Build. Mater. 2012, 34, 346–351. [Google Scholar] [CrossRef]

- Faustino, J.; Silva, E.; Pinto, J.; Soares, E.; Cunha, V.M.C.F.; Soares, S. Lightweight Concrete Masonry Units Based on Processed Granulate of Corn Cob as Aggregate. Mater. Construcción 2015, 65, e055. [Google Scholar] [CrossRef]

- Helepciuc, C.M.; Barbuta, M.; Serbanoiu, A.A.; Burlacu, A. A Variant of Green Concrete with Industrial and Agricultural Waste. In Proceedings of the 21st International Symposium “The Environment and the Industry”, SIMI 2018, Bucharest, Romania, 20–21 September 2018. [Google Scholar]

- Polat, S. A Research on the Usage of Corn Cob in Producing Lightweight Concrete. Nat. Resour. 2021, 12, 339–347. [Google Scholar] [CrossRef]

- Grădinaru, C.M.; Șerbănoiu, A.A.; Șerbănoiu, B.V. Sunflower Stalks versus Corn Cobs as Raw Materials for Sustainable Concrete. Materials 2021, 14, 5078. [Google Scholar] [CrossRef]

- Grădinaru, C.M.; Barbuta, M.; Vasilică, C.; Serbanoiu, A.A. Characterization of a Lightweight Concrete with Corn Cob Aggregates. In Proceedings of the 17 International Multidisciplinary Scientific GeoConference SGEM 2017, Albena, Bulgaria, 29 June–5 July 2017. [Google Scholar]

- Fang, M.; Yang, L.; Chen, G.; Shi, Z.; Luo, Z.; Cen, K. Experimental Study on Rice Husk Combustion in a Circulating Fluidized Bed. Fuel Process. Technol. 2004, 85, 1273–1282. [Google Scholar] [CrossRef]

- Rodríguez de Sensale, G. Strength Development of Concrete with Rice-Husk Ash. Cem. Concr. Compos. 2006, 28, 158–160. [Google Scholar] [CrossRef]

- Chao-Lung, H.; Anh-Tuan, B.L.; Chun-Tsun, C. Effect of Rice Husk Ash on the Strength and Durability Characteristics of Concrete. Constr. Build. Mater. 2011, 25, 3768–3772. [Google Scholar] [CrossRef]

- Salas, J.; Alvarez, M.; Veras, J. Lightweight Insulating Concretes with Rice Husk. Int. J. Cem. Compos. Light. Concr. 1986, 8, 171–180. [Google Scholar] [CrossRef]

- Sisman, C.B.; Gezer, E.; Kocaman, I. Effects of Organic Waste (Rice Husk) on the Concrete Properties for Farm Buildings. Bulg. J. Agric. Sci. 2011, 17, 40–48. [Google Scholar]

- Yuzer, N.; Cinar, Z.; Akoz, F.; Biricik, H.; Yalcin Gurkan, Y.; Kabay, N.; Kizilkanat, A.B. Influence of Raw Rice Husk Addition on Structure and Properties of Concrete. Constr. Build. Mater. 2013, 44, 54–62. [Google Scholar] [CrossRef]

- Obilade, I.O. Use of Rice Husk Ash as Partial Replacement for Cement in Concrete. Int. J. Eng. Appl. Sci. 2014, 5, 11–16. [Google Scholar]

- Winarno, S. Comparative Strength and Cost of Rice Husk Concrete Block. MATEC Web Conf. 2019, 280, 04002. [Google Scholar] [CrossRef]

- Chabi, E.; Doko, V.; Hounkpè, S.P.; Adjovi, E.C. Study of Cement Composites on Addition of Rice Husk. Case Stud. Constr. Mater. 2020, 12, e00345. [Google Scholar] [CrossRef]

- Reffaee, A.; El-Nashar, D.; Yaseen, A.; Abd-El-Messieh, S. Sunflower SeedHusk AsGreen Agro-Waste Filler for EPDM Rubber. Egypt. J. Chem. 2021, 64, 5853–5861. [Google Scholar] [CrossRef]

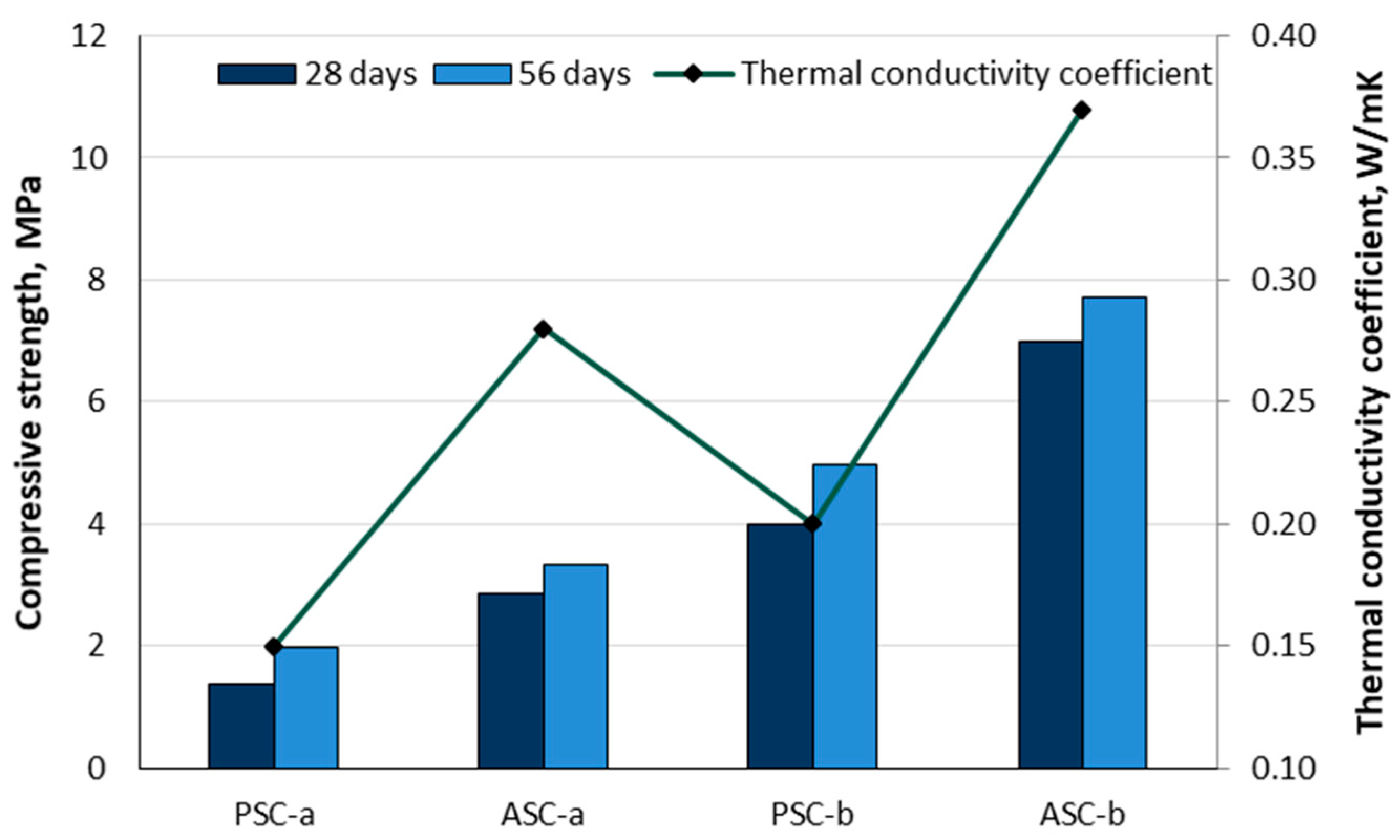

- Sisman, C.B.; Gezer, E. Sunflower Seed Waste as Lightweight Aggregate in Concrete Production. Int. J. Environ. Waste Manag. 2013, 12, 203. [Google Scholar] [CrossRef]

- Popa, I.; Petcu, C.; Enache, F.; Mureşanu, A. Using Sunflower Seed Husks Waste for Sustainable Thermal Isolating Coatings. Constructii 2020, 21, 3–10. [Google Scholar]

| Specific Gravity | Loose Bulk Density (kg/m3) | Compacted Bulk Density (kg/m3) | Bulk Density (kg/m3) | Water Absorption, %, | Moisture Content, % | Crushing Value, % | Impact Value, % | Los Angeles Abrasion Value, % | Flakiness Index, % | Shell Thickness, mm | Porosity, % | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Palm kernel shells | 1.02–1.62 | 500–600 | 596–685 | - | 9–33 | 4.35–15 | 0.2–10 | 2.03–8 | 3–5.70 | 65 | 0.5–8 | 28–37 |

| Coconut shells | 1.05–1.74 | 476–550 | 593–800 | - | 20–25 | 4–5.2 | 2–3 | 7–8.5 | 1.4–1.65 | - | 0.15–8 | 19 |

| Hazelnut shell | - | 550.50 | - | - | - | 14.38 | - | - | - | - | 0.95–2.41 | - |

| Groundnuts (peanut) shell | 0.3 | - | - | 254.55 | - | 6.39 | - | - | - | - | - | - |

| Pistachios shell | 0.12 | - | - | 286.9 | - | 4.04 | - | - | - | - | - | - |

| Cherry pit | - | - | - | 472.88 | - | 9.30 | - | - | - | - | - | - |

| Peach shell | 1.26–1.28 | - | - | 536–556 | 15.2–16.7 | 4.2 | - | 1.95 | 6–6.21 | 41–48 | - | - |

| Apricot shell | 1.42–1.44 | - | - | 600–630 | 10.9–13.8 | 2.8 | - | 2.95 | 6.82–7.83 | 48–56 | - | - |

| Date seed | 1.13–1.39 | 462 | 526 | - | 8.1–36 | 23 | 7.1 | 6.83–22 | 5.1 | 19.5 | ||

| Grape seed | - | - | - | 469.3–546.3 | 31 | 12.26–24.61 | - | - | - | - | - | 52.87–55.67 |

| Maize (corn) cob | 0.957 | - | - | 170–298 | 327 | 4.51–6.38 | - | - | - | - | - | 46.54–67.93 |

| Rice husk | 0.17 | - | - | 96–380.5 | 112–130 | 4.6–11.8 | - | - | - | - | 0.2 | 63.64–73.23 |

| Sunflower seed | - | - | - | 139 | - | 9.61 | - | - | - | - | - | |

| Crushed granite | 2.60–2.70 | 1300 | 1420–1470 | - | <1 | - | 20 | 13–17 | 24 | - | 25 | - |

| River sand | 2.56–2.65 | - | - | 1538–1680 | 1.2 | - | - | - | - | - | - | 0.04 |

| Authors | Year | Replacement Percentage | w/c Ratio | Compressive Strength Range (MPa) |

|---|---|---|---|---|

| Mannan and Ganapathy [50] | 2004 | PKS as 100% coarse aggregate volume | 0.41 | 12.61–30.05 MPa curing condition: full water 12.61–24.74 MPa curing condition: partial water 11.51–29.69 MPa curing condition: plastic film |

| Ifeanyi et al. [55] | 2023 | PKS as 10%, 20%, and 30% replacement for coarse aggregate volume | - | 13.4–34.1 MPa |

| Khankhaje et al. [56] | 2016 | 0–75% PKS as coarse aggregate + 25–75% limestone (by mass); PKS grain size 4.75–6.30 mm and 6.30–9.5 mm | 0.32 | 6–12 MPa |

| Azunna [57] | 2019 | PKS as 10% and 25% replacement for coarse aggregate mass | 0.50 | 4.78 and 4.44 MPa |

| Ngagoum et al. [58] | 2020 | PKS as 25, 50, 75, and 100% aggregate volume | 0.59, 0.64, 0.68, 0.73 | 5.37–19.66 MPa |

| Shafigh et al. [59] | 2011 | PKS as 100% coarse aggregate volume | 0.30, 0.34, 0.35, 0.44 | 34–53 MPa |

| Mo et al. [60] | 2016 | PKS as 100% coarse aggregate and 20–60% GGGS as replacement for cement | 0.40 | 24.4–46.0 MPa za PKS concrete water curing 12.5–20.2 MPa PKS concrete air curing |

| Olanipekun et al. [61] | 2005 | PKS as 25, 50, 75, and 100% aggregate volume | 0.5, 0.75 | 17.5–24.9 MPa |

| Alengaram et al. [62] | 2010 | PKS as 100% coarse aggregate, 5% fly ash, and 10% silica fume | 0.35 | About 26 MPa |

| Gibigaye et al. [63] | 2016 | PKS/fine aggregate mass in range 0.4–0.75 | 0.45 | 18.63 MPa |

| Danso and Appiah-Agyei [64] | 2021 | PKS as 100% coarse aggregate mass | 0.60 | 8.8–10.2 MPa |

| Authors | Year | Replacement Percentage | w/c Ratio | Compressive Strength Range (MPa) |

|---|---|---|---|---|

| Olanipekun et al. [61] | 2006 | 25, 50, 75, 100% CS as a replacement for coarse aggregate volume | 0.5, 0.75 | 16–27.5 MPa |

| Yerramala and Ramachandrudu [67] | 2012 | 10, 15, 20% CS as a replacement for coarse aggregate mass | 0.60 | 9.33–13.56 MPa |

| Gunasekaran et al. [68] | 2008 | 100% CS as coarse aggregate | 0.42 | 19.1 MPa |

| Osei [69] | 2013 | 20, 30, 40, 50%, and 100% CS as a replacement for coarse aggregate volume | 0.6 | 9.29–19.7 MPa |

| Kanojia and Jain [70] | 2017 | 10, 20, 30, 40% CS as a replacement for coarse aggregate volume | 0.55 | 22.2–25.6 MPa |

| Azunna et al. [71] | 2018 | 10, 20, 30% CS as a replacement for fine and coarse aggregate mass | 0.45 | 25.21–38.37 MPa |

| Gunasekaran et al. [72] | 2011 | 100% CS as coarse aggregate | 0.42–0.72 | 4.95–26.7 MPa |

| Deepak et al. [73] | 2015 | 10, 20, 30, 40, 50% CS as a replacement for coarse aggregate mass | 0.45 | 18.4–33 MPa |

| Rajendran and Abdul Rahman [74] | 2022 | 10, 20, 30% CS as a replacement for coarse aggregate mass | 0.50 | 33.16–37.50 MPa |

| Manaloto [75] | 2023 | 2.5, 5, 7.5, 10, 15, 20, 100% CS as a replacement for coarse aggregate mass | 0.647 | 16–20.69 MPa |

| Authors | Year | Replacement Percentage | w/c Ratio | Compressive Strength Range (MPa) |

|---|---|---|---|---|

| Wu et al. [27] | 2018 | 100% crushed PS and AS as coarse aggregate | 0.40 | 19.6 and 26.9 MPa |

| Netinger Grubeša et al. [34] | 2022 | volume of coarse aggregate fraction was replaced with cherry pits untreated and treated with 2.5 and 5% NaOH | 0.40 | 14.46–19.64 MPa |

| D’Eusanio et al. [36] | 2023 | 100% PS and AS as coarse aggregate | 0.40–0.45 | 1–4 MPa 2.8–7 MPa |

| Wu et al. [40] | 2018 | 12.5, 25, 37.5, 50% crushed PS and AS as a replacement for coarse and fine aggregate volume | 0.35 | 33.5–46.2 MPa |

| Wu et al. [43] | 2020 | 25, 50, 75, 100% PS as a replacement for normal weight aggregate volume | 0.35 | 25.7–38.7 MPa |

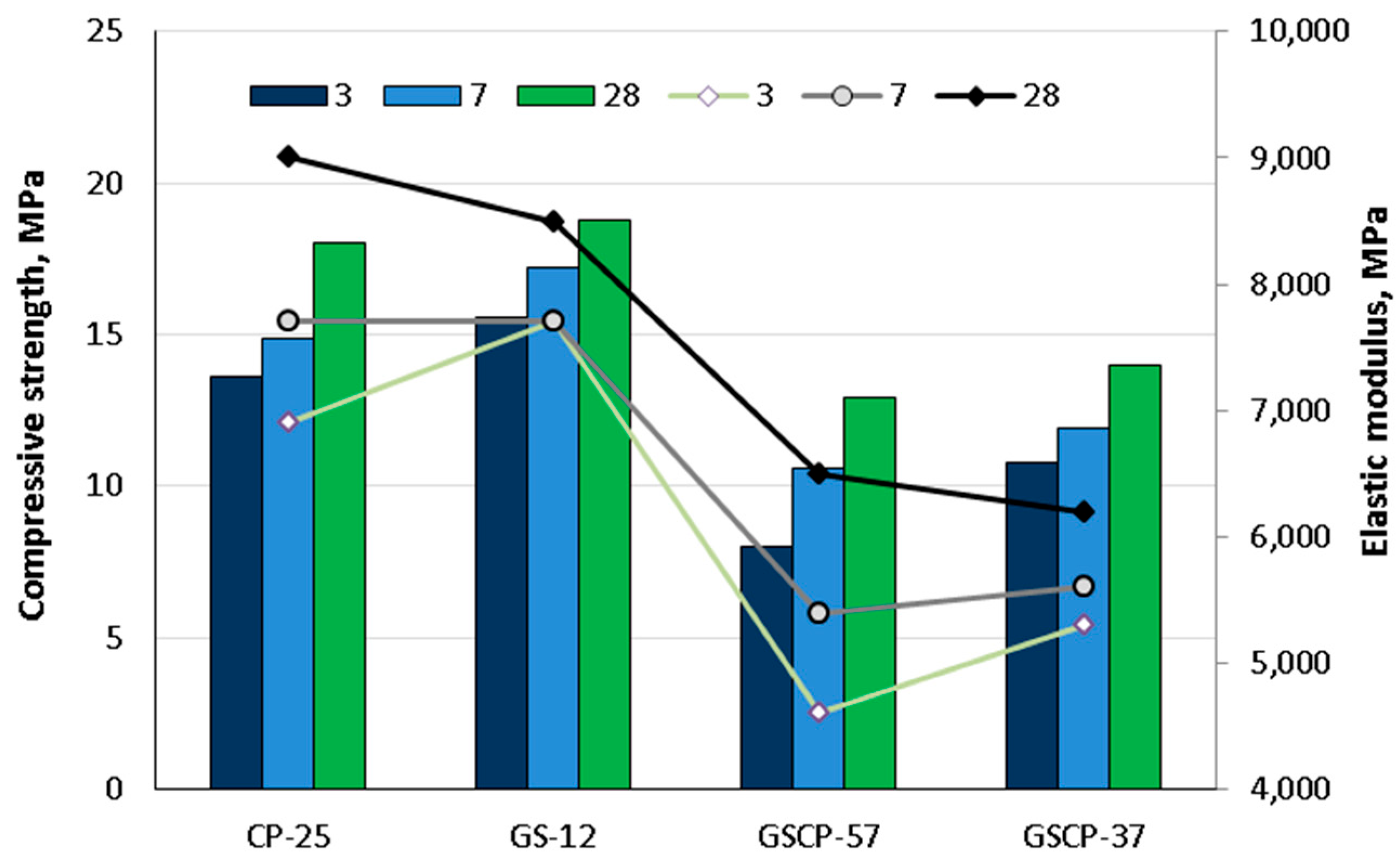

| Zwicky [83] | 2020 | 12% GS, 25% CP, 57% GSCP, and 37% GSCP as a replacement for natural aggregate volume | - | 12.9–18 MPa |

| Wu et al. [87] | 2018 | 100% PS as coarse aggregate | 0.33 | 24.6 MPa |

| Yildiz et al. [88] | 2012 | 5–40% replacement of limestone aggregate volume with AS | 0.55 | 14.92–32.05 MPa |

| Authors | Year | Replacement Percentage | w/c Ratio | Compressive Strength Range (MPa) |

|---|---|---|---|---|

| Adefemi et al. [20] | 2013 | 25, 50, and 75% DS as a replacement for coarse aggregate mass | 0.6 and 0.65 | 16–23.44 MPa 9–14.4 MPa |

| Ahmed et al. [90] | 2020 | 2, 3, and 4% DS as a replacement for coarse aggregate mass | 0.50 | 11.76–13.83 MPa |

| Palh et al. [91] | 2021 | 2, 3, and 4% DS as a replacement for coarse aggregate volume | 0.6 | 13.63–20.87 MPa |

| Yusuf et al. [92] | 2021 | 5, 10, 15, and 20% DS as a replacement for coarse aggregate mass | 0.50 | 18.1–20.3 MPa |

| Sarathkumar et al. [94] | 2022 | 10 to 20% of DS and 1.5 to 2.5% of tamarind seed as a partial replacement for fine aggregate mass | 0.45 | 26.40–28.43 MPa |

| Authors | Year | Replacement Percentage | w/c Ratio | Compressive Strength Range (MPa) |

|---|---|---|---|---|

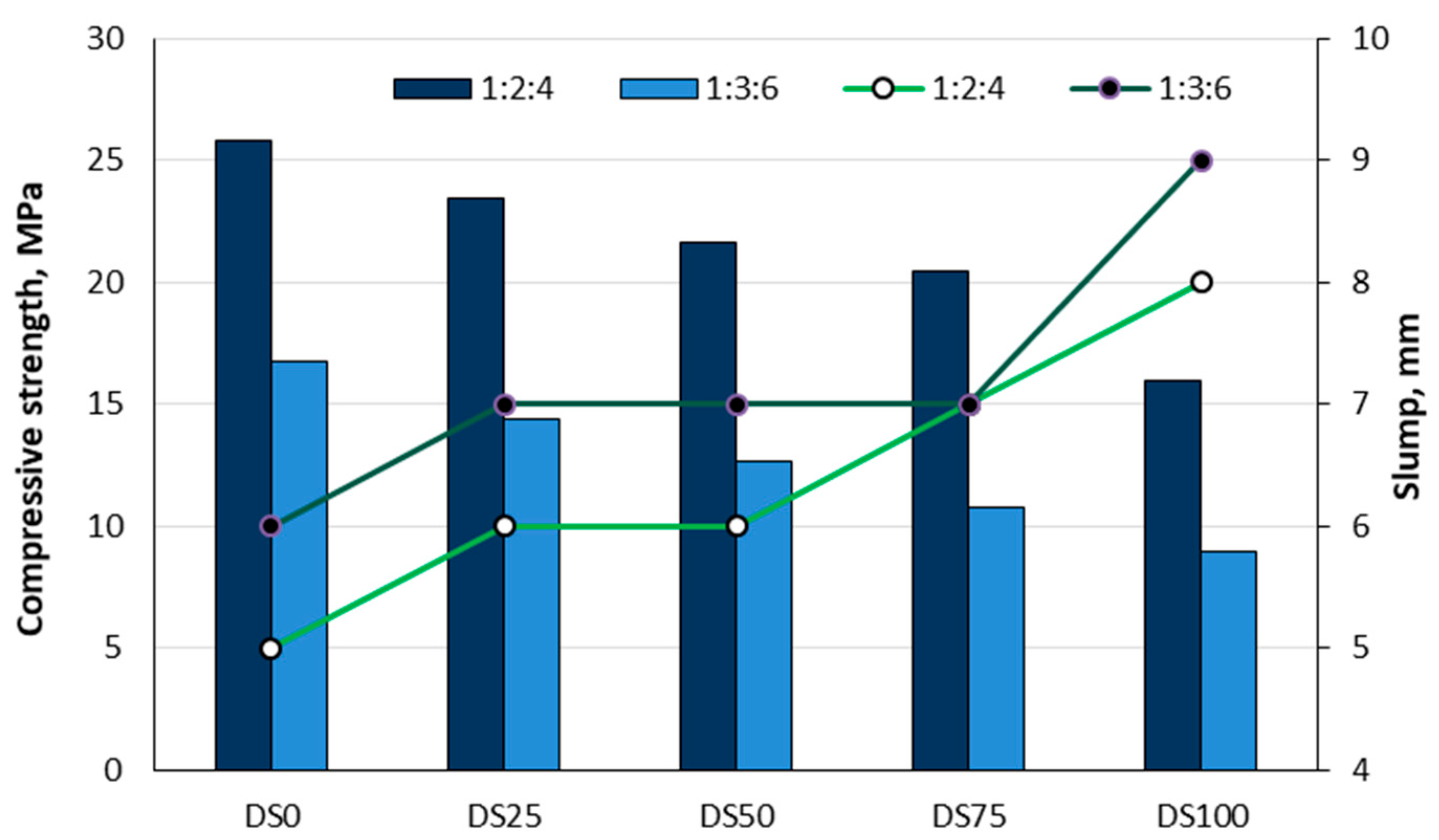

| Khan et al. [23] | 2022 | 10, 20, 30, 40, and 50% CC as a replacement for coarse aggregate volume | 0.50 | 21.6–24.25 |

| Pinto et al. [100] | 2012 | 100% CC as coarse aggregate | - | 0.39–0.51 |

| Grădinaru et al. [105] | 2017 | 50% CC as a replacement for coarse aggregate volume | 0.43 | 0.27–10.21 |

| Helepciuc et al. [102] | 2018 | 50% CC as a replacement for coarse aggregate volume and 10, 20, and 30% fly ash as a replacement of cement | - | 3.35–5.10 |

| Polat [103] | 2021 | 100% CC as coarse aggregate | 0.44–0.77 | 0.14–5.52 |

| Gradinaru et al. [104] | 2021 | 20, 35, 50, 65, and 80% CC as a replacement for coarse aggregate volume | 0.50 | 3.04–9.79 |

| Authors | Year | Replacement Percentage | w/c Ratio | Compressive Strength Range (MPa) |

|---|---|---|---|---|

| Amantino et al. [26] | 2022 | 5 and 10% RH as a replacement for natural sand volume | 0.58 | 15–19 MPa |

| Akinwumi et al. [46] | 2016 | 12.5, 25, 37.5, and 50% RH as a replacement for sand volume | 0.50 | 8.8–18.5 MPa |

| Salas et al. [109] | 1986 | 80, 60, 40, 20, and 10% untreated RH as a replacement for aggregate volume and 40, 20, 10, and 5% treated RH as a replacement for aggregate volume | 0.71 | 0.16–14.96 MPa 0.36–0.66 MPa |

| Sisman et al. [110] | 2011 | 5, 10, 15, 20, 25, and 30% RH as replacement for aggregate volume | 0.60 | 17.6–37.5 MPa |

| Winarno et al. [113] | 2019 | 100% RH as aggregate | 0.40 | 1.1–1.9 MPa |

| Chabi et al. [114] | 2020 | 100% RH as fine aggregate | 0.30–0.45 | 1.93–15.63 MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Netinger Grubeša, I.; Šamec, D.; Juradin, S.; Hadzima-Nyarko, M. Utilizing Agro-Waste as Aggregate in Cement Composites: A Comprehensive Review of Properties, Global Trends, and Applications. Materials 2025, 18, 2195. https://doi.org/10.3390/ma18102195

Netinger Grubeša I, Šamec D, Juradin S, Hadzima-Nyarko M. Utilizing Agro-Waste as Aggregate in Cement Composites: A Comprehensive Review of Properties, Global Trends, and Applications. Materials. 2025; 18(10):2195. https://doi.org/10.3390/ma18102195

Chicago/Turabian StyleNetinger Grubeša, Ivanka, Dunja Šamec, Sandra Juradin, and Marijana Hadzima-Nyarko. 2025. "Utilizing Agro-Waste as Aggregate in Cement Composites: A Comprehensive Review of Properties, Global Trends, and Applications" Materials 18, no. 10: 2195. https://doi.org/10.3390/ma18102195

APA StyleNetinger Grubeša, I., Šamec, D., Juradin, S., & Hadzima-Nyarko, M. (2025). Utilizing Agro-Waste as Aggregate in Cement Composites: A Comprehensive Review of Properties, Global Trends, and Applications. Materials, 18(10), 2195. https://doi.org/10.3390/ma18102195