Corrosion Characteristics and Tensile Performance of Bolted Spherical Joints in Aggressive Environments

Abstract

:1. Introduction

2. Experimental Overview

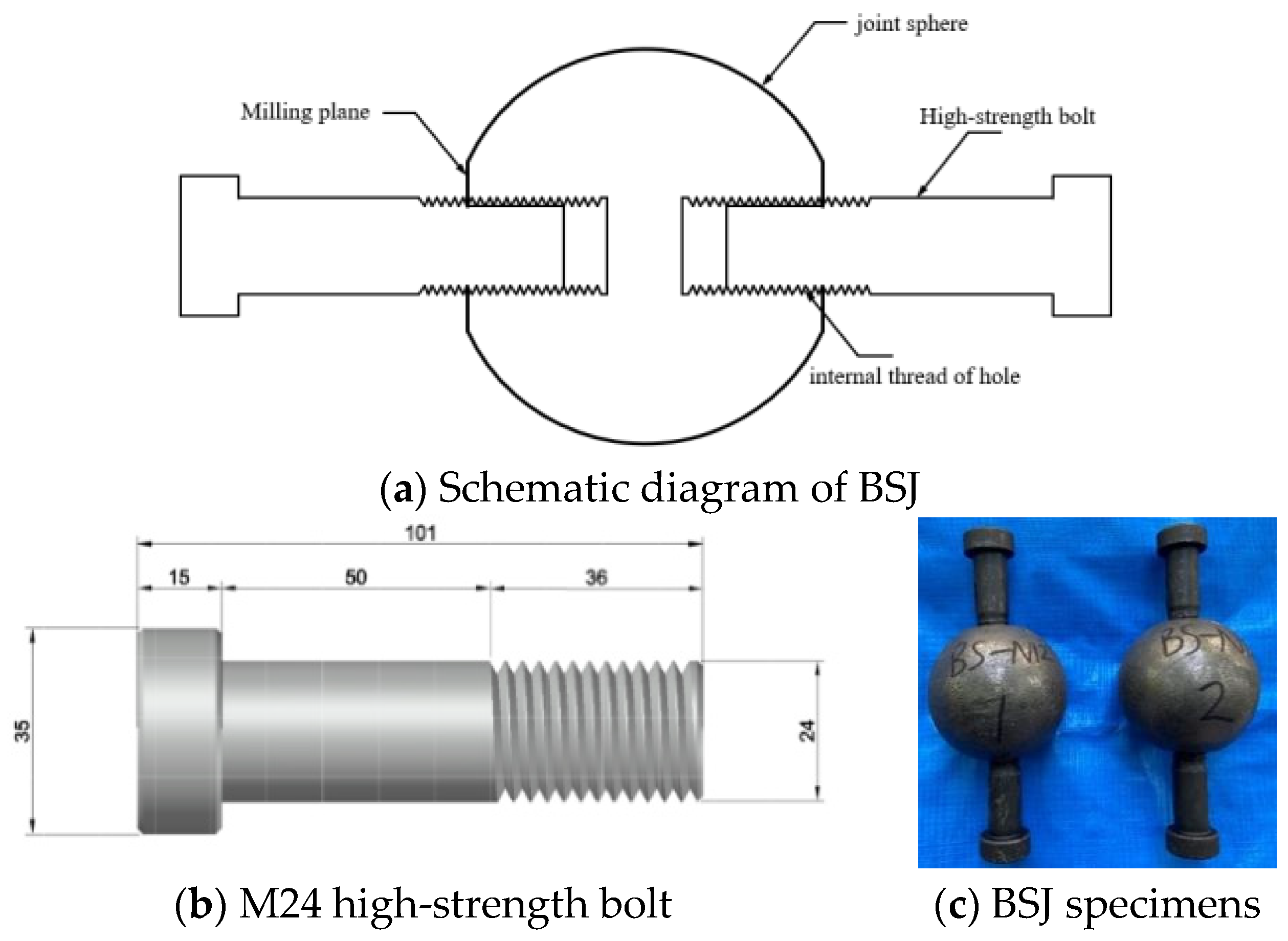

2.1. Design of BSJ

2.2. Chloride Exposure

2.3. Experimental Grouping

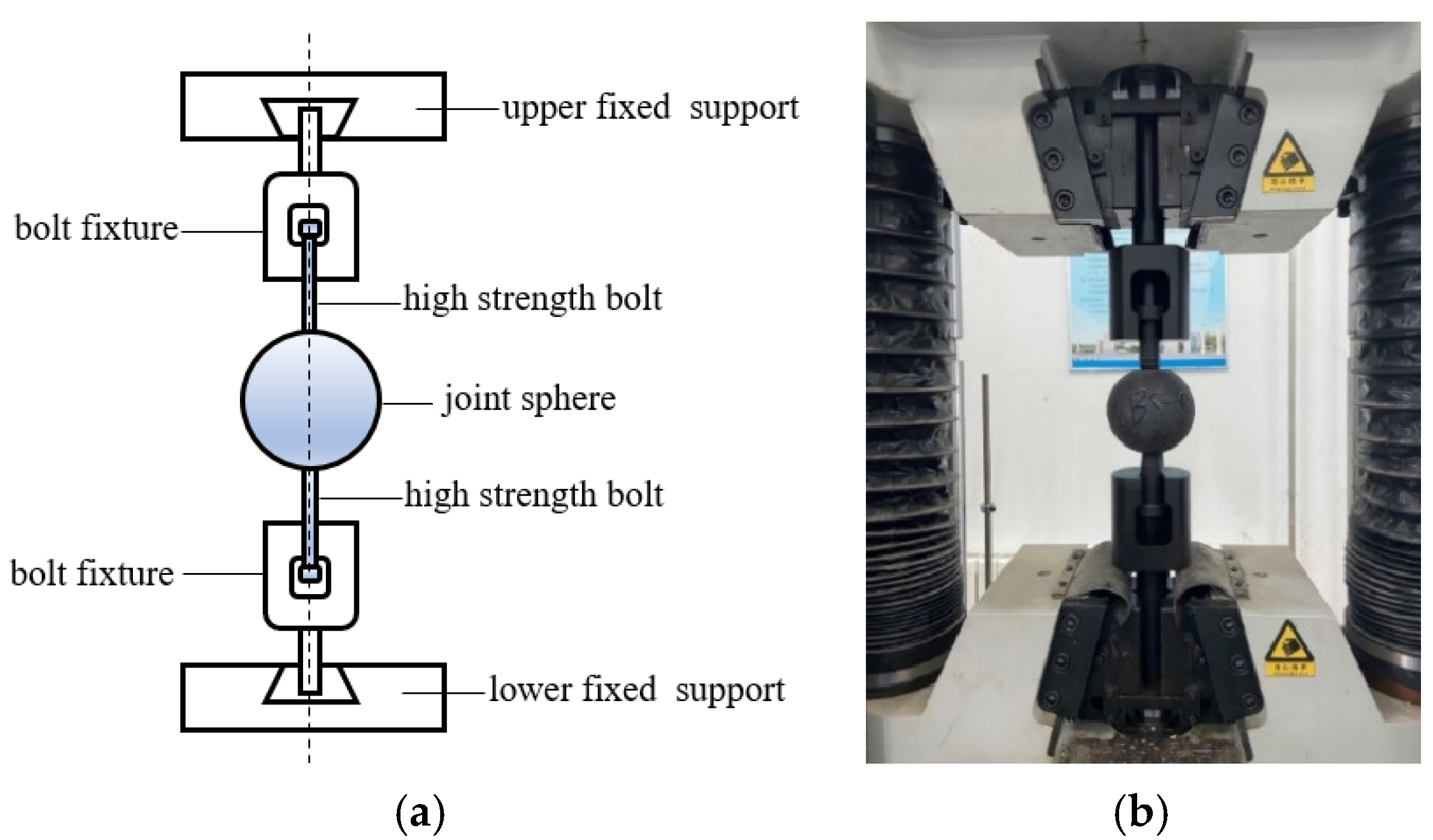

2.4. Uniaxial Tensile Test

3. Results and Discussion

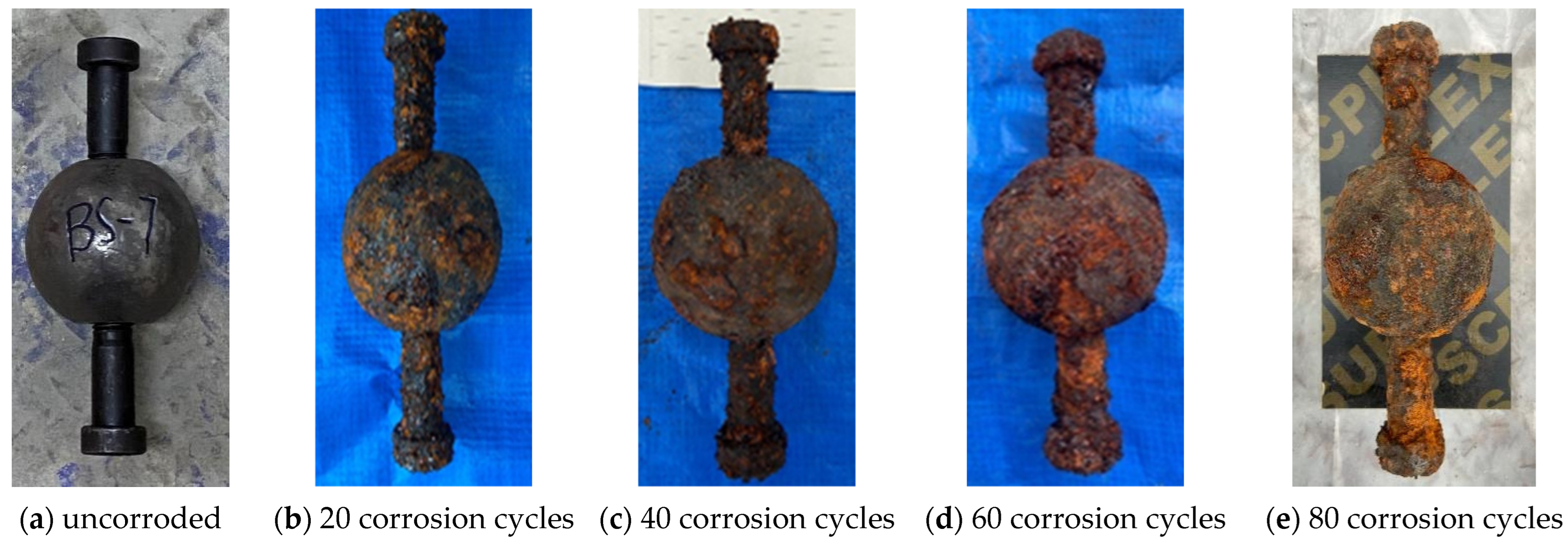

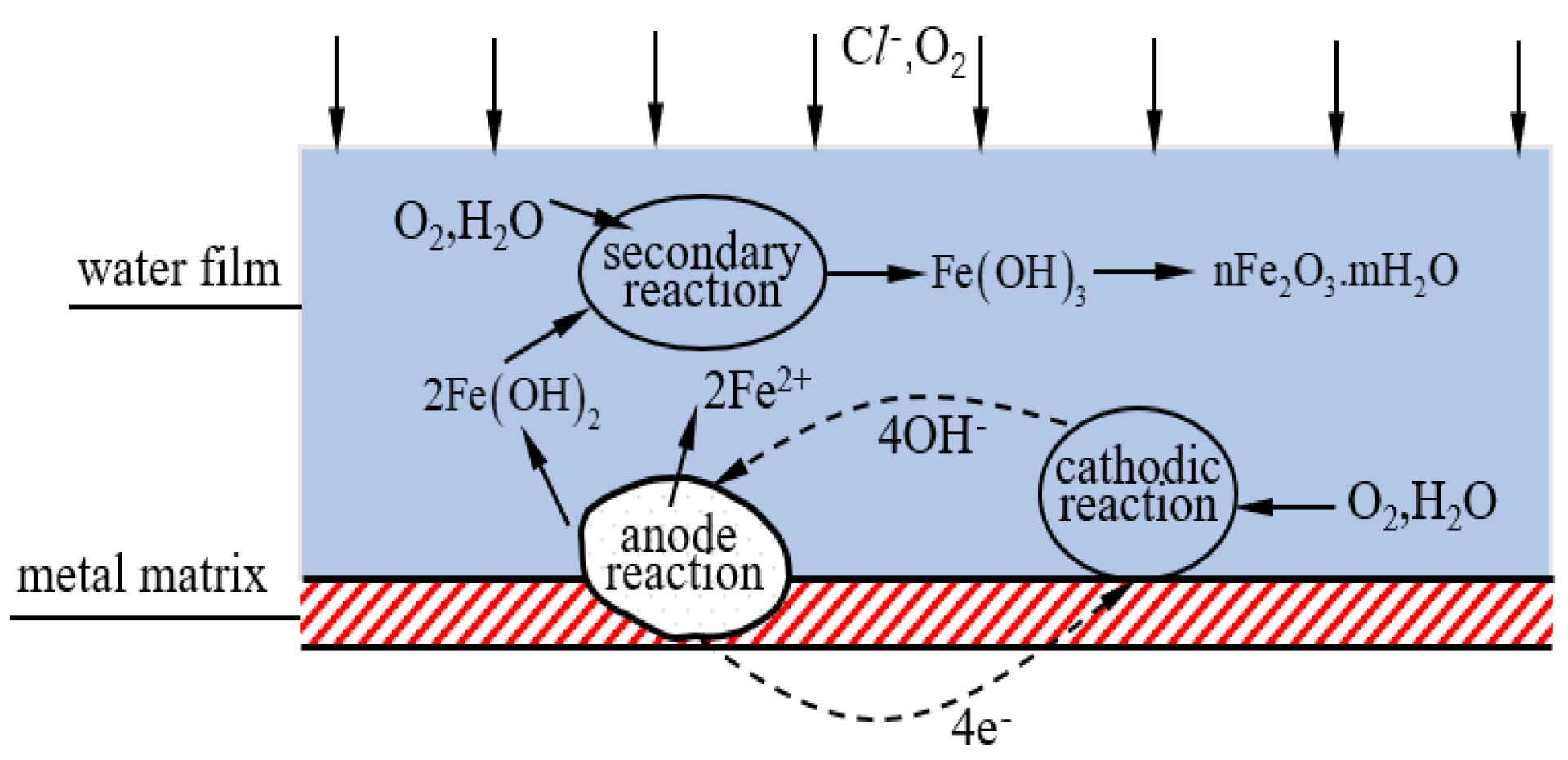

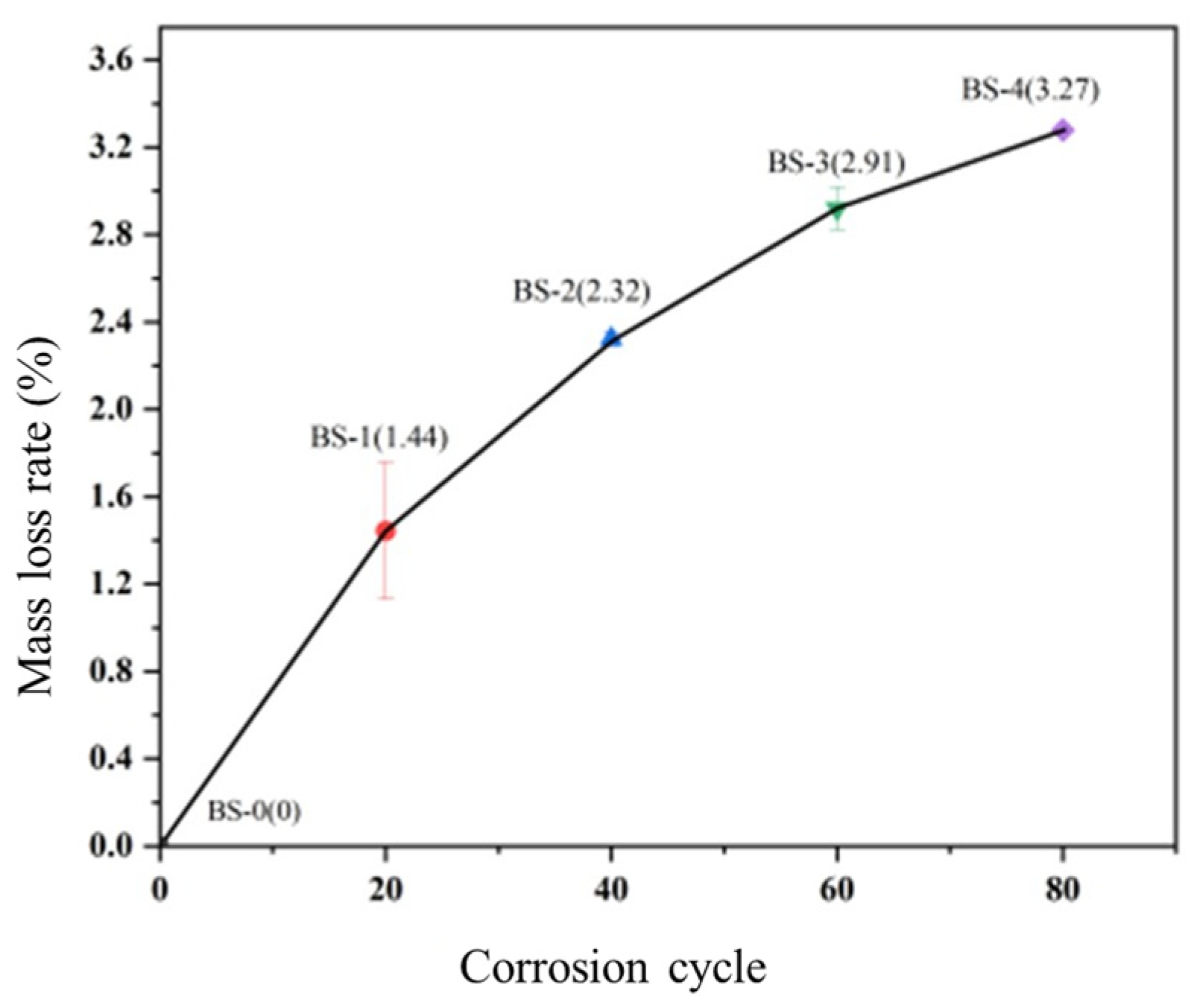

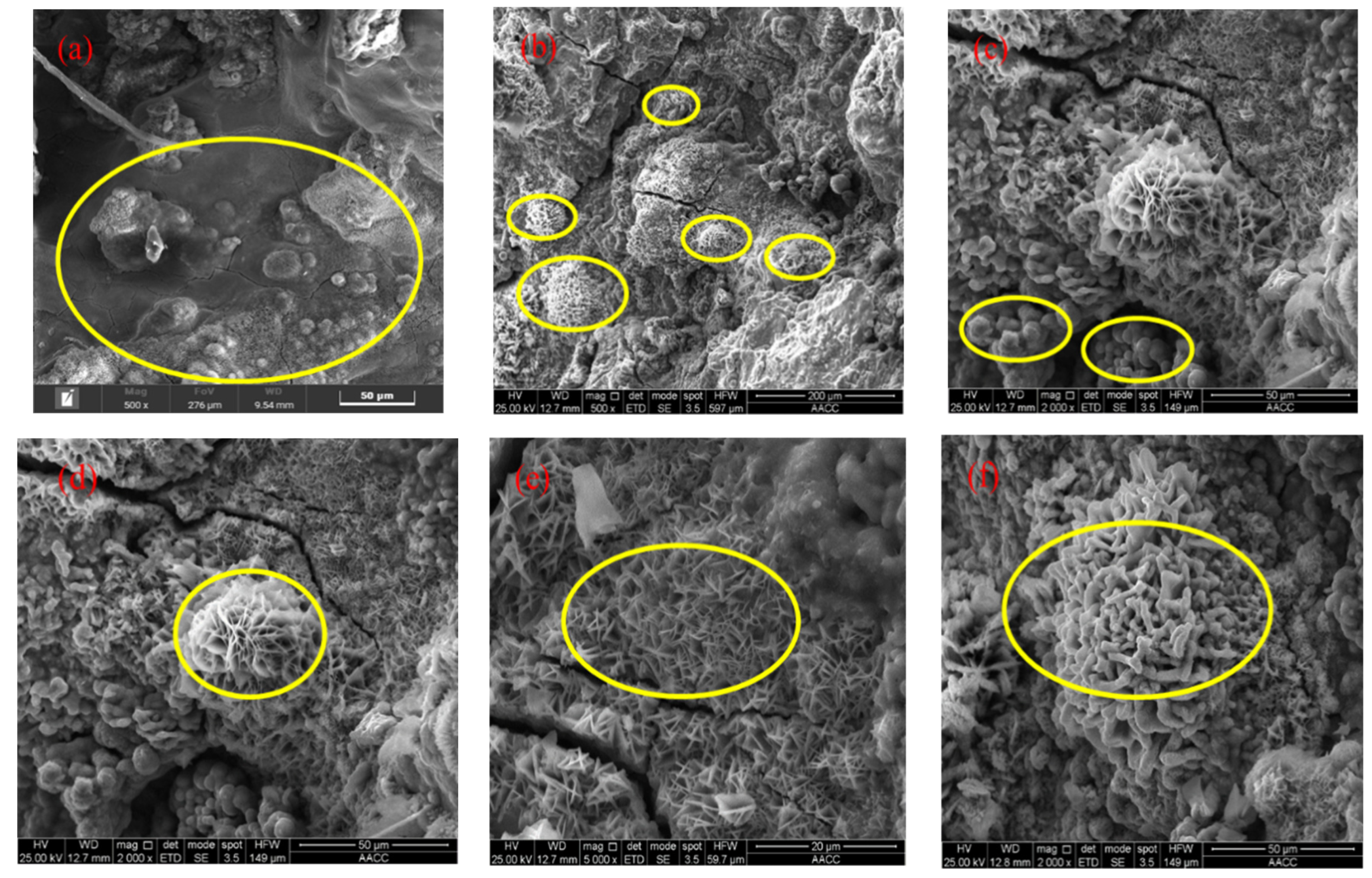

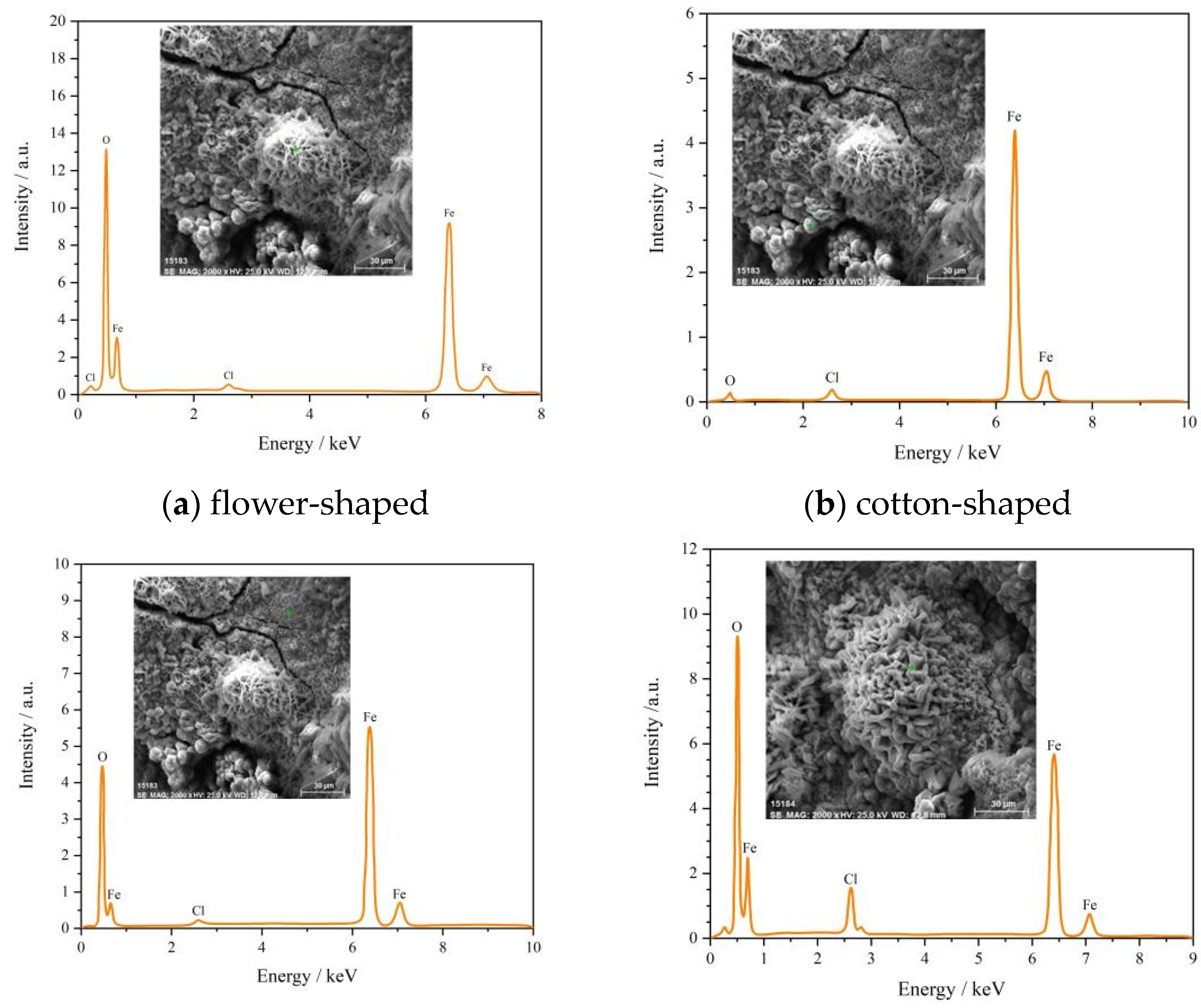

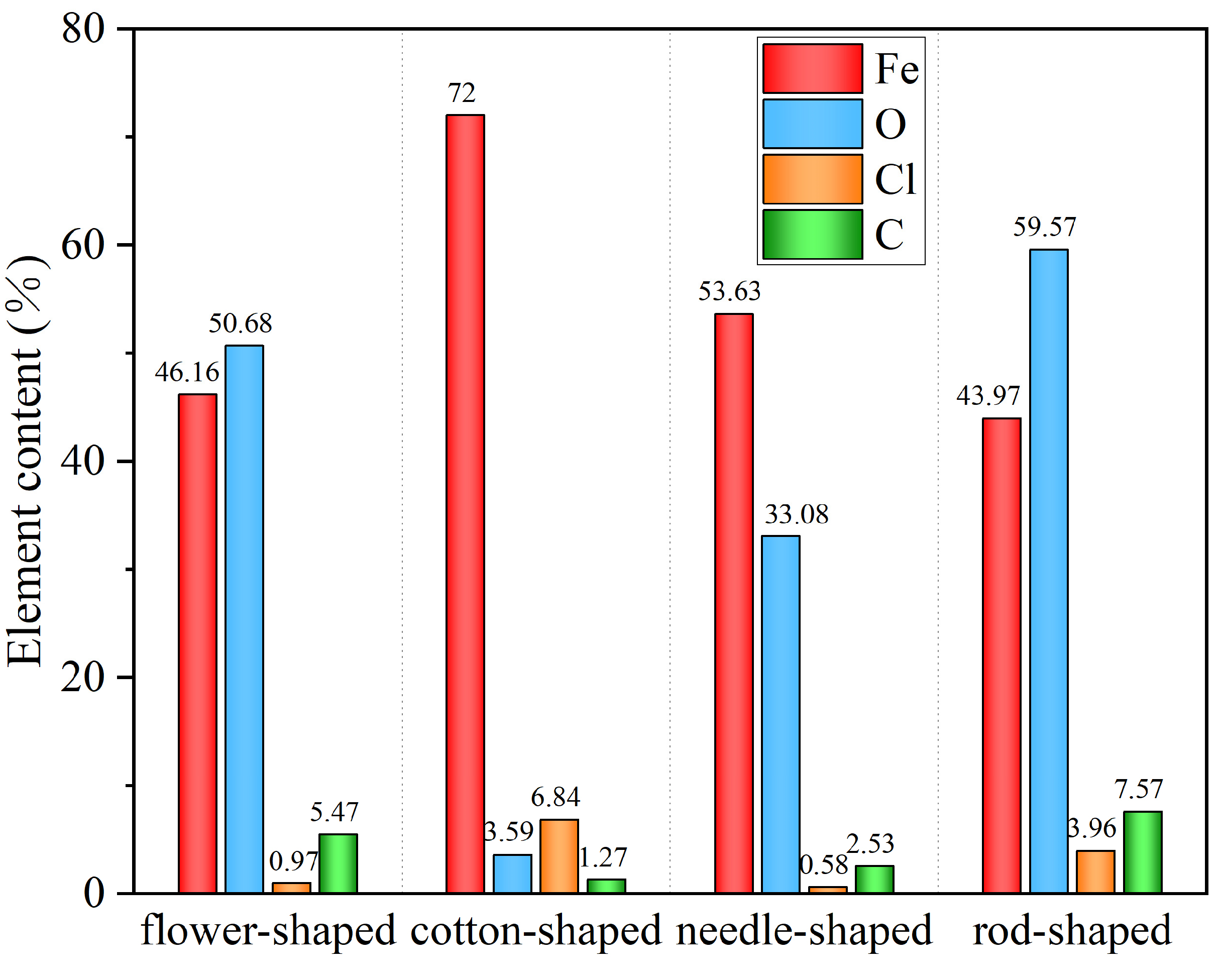

3.1. Corrosion Results and Discussion

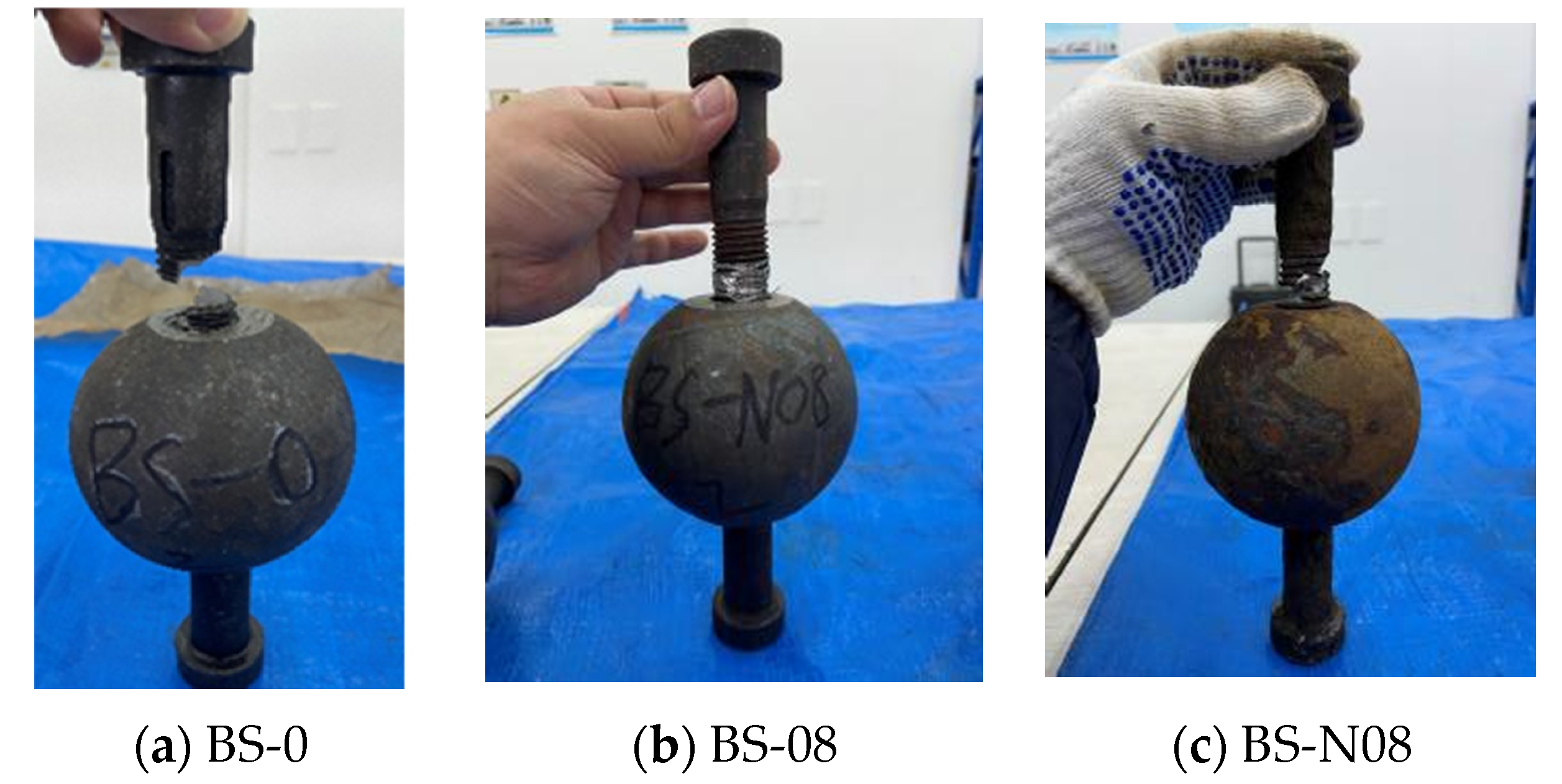

3.2. Failure Modes

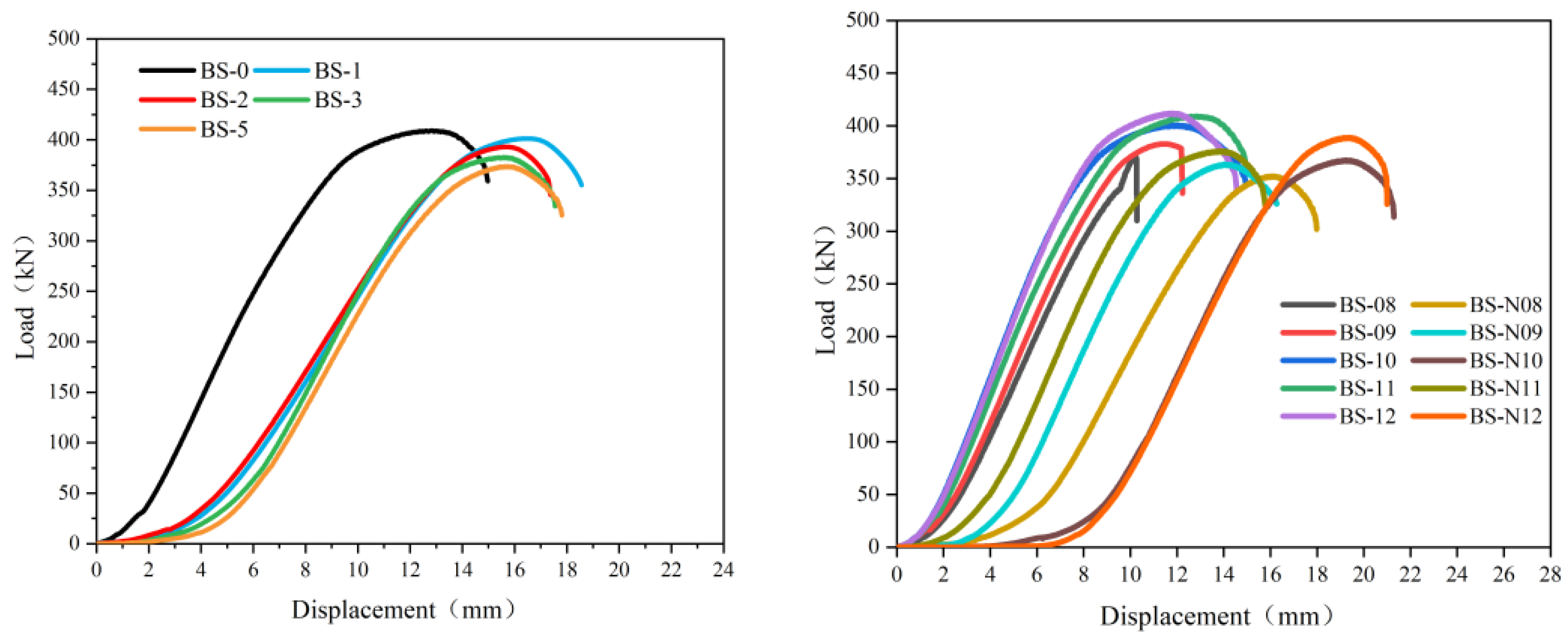

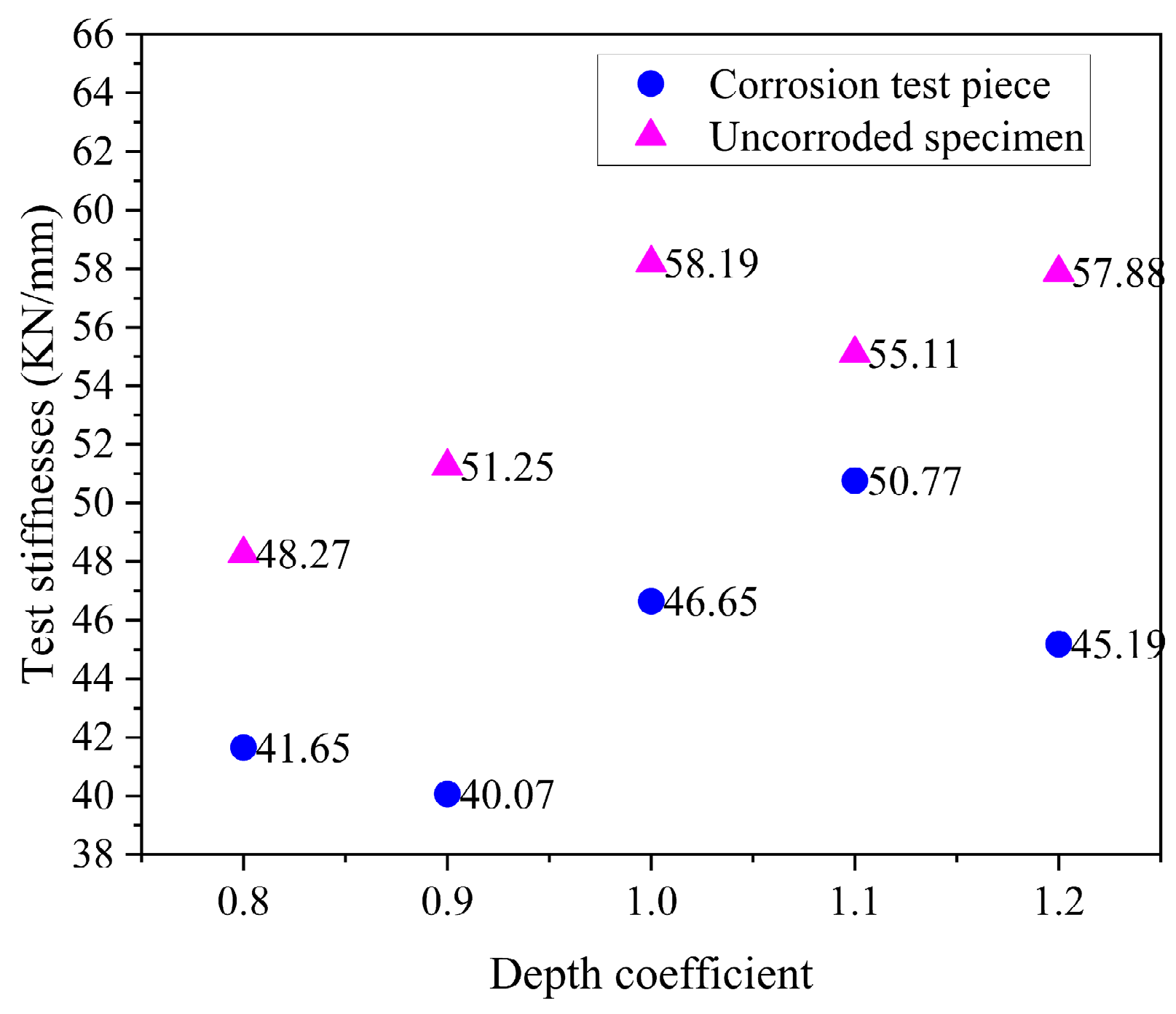

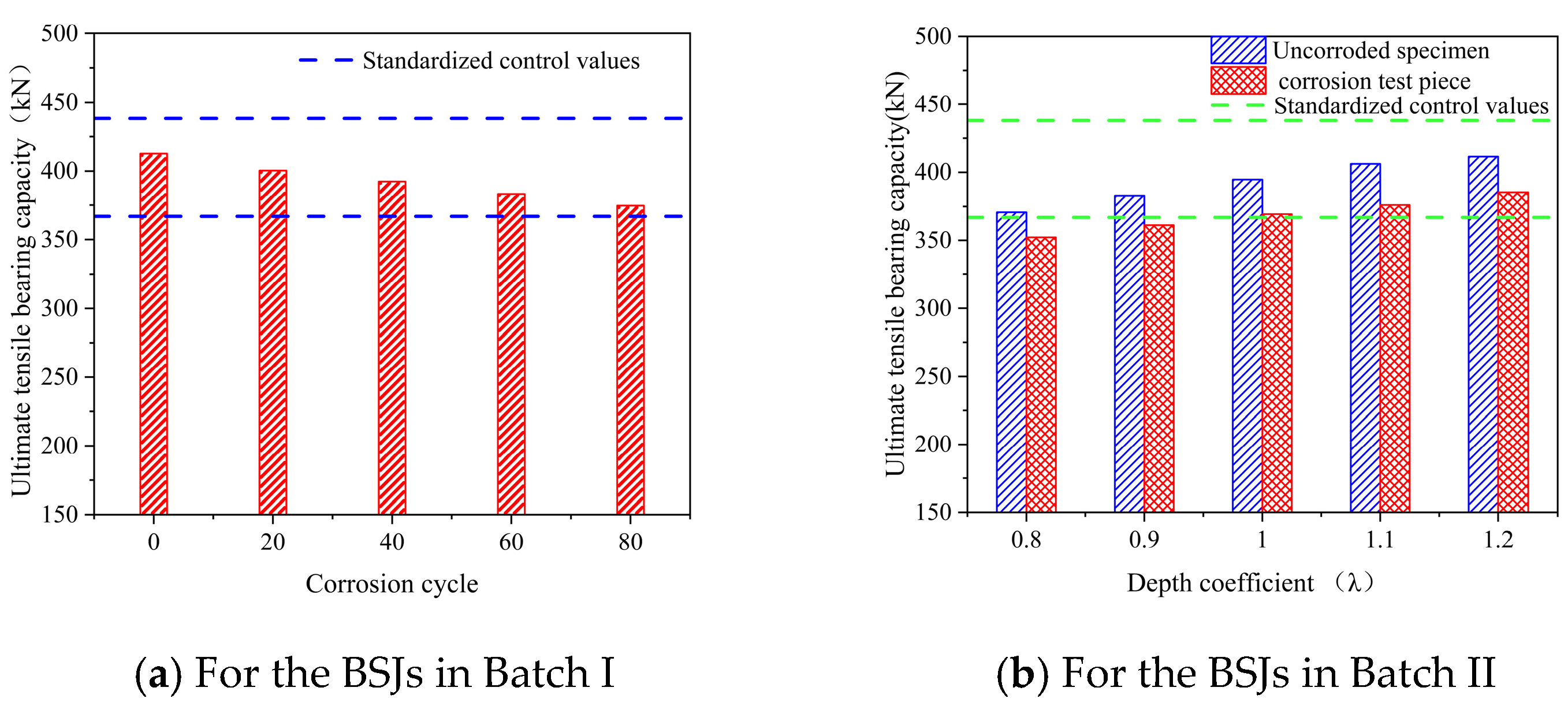

3.3. Force–Displacement Curves and Tensile Bearing Capacity

4. Conclusions

- (1)

- In chloride-rich environments, BSJs experience progressive electrochemical corrosion, with pitting corrosion more severe on high-strength bolts than on joint spheres. Corrosion product color and mass loss increased with longer exposure.

- (2)

- Four distinct microscopic corrosion morphologies—flower-shaped, cotton-shaped, needle-shaped, and rod-shaped—were identified. Their composition was influenced by variations in elemental oxygen and chlorine content.

- (3)

- For BSJs with a screwing depth of 1.1 d, the failure mode remained bolt fracture, regardless of corrosion. Fractures consistently initiated at the root of exposed threads, where stress concentration occurred. Corroded samples exhibited rougher fracture surfaces.

- (4)

- Uncorroded BSJs with λ < 1.0 showed pull-out failure, whereas corroded counterparts underwent bolt fracture. This shift was attributed to corrosion-induced reduction in the effective cross-sectional area of exposed threads.

- (5)

- The ultimate tensile capacity of BSJs decreased with both increasing corrosion exposure and decreasing screwing depth. BSJs with λ < 1.0 after 60 corrosion cycles failed to meet the minimum bearing capacity specified by design standards.

- (6)

- Although this study focused on as-received BSJ specimens without additional treatments, future research should explore how thermal (e.g., tempering) and chemical (e.g., passivation and coating) treatments influence the corrosion resistance and tensile performance. Such treatments could potentially mitigate pitting corrosion and delay failure under chloride environments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, L. Design, Development, and Mechanical Performance Research of Large-Diameter Bolted Ball Joints in Spatial Grid Structures; Shandong Jianzhu University: Jinan, China, 2023. [Google Scholar]

- Ding, B.; Zhao, Y.; Huang, Z.; Cai, L.; Wang, N. Tensile bearing capacity for bolted spherical joints with different screwing depths of high-strength bolts. Eng. Struct. 2020, 225, 111255. [Google Scholar] [CrossRef]

- Sun, G.; Li, B.; Wu, J.; Ma, J. Experimental study on mechanical properties of conical head for bolted spherical joints. Structures 2024, 63, 106293. [Google Scholar] [CrossRef]

- Yuan, H.; Liu, H.; Ren, X.; Zhang, X.; Ai, D.; Luo, Y. The bearing performance of the bolt-sphere joints with stochastic pitting corrosion damage. J. Constr. Steel. Res. 2019, 160, 359–373. [Google Scholar] [CrossRef]

- Tan, Z.; Liu, H.; Wang, X.; Du, R. Experimental study and numerical simulation of tensile performance of corroded bolted ball joints. Ind. Build. 2019, 49, 6–11. [Google Scholar] [CrossRef]

- Liu, F.; Zhou, H.; Li, G.; Cao, H.; Ba, A. Failure Analysis and Anti corrosion Design of Steel Structure Grid in a Swimming Pool. Compr. Corros. Control 2013, 27, 51–55. [Google Scholar]

- Gao, Y. Research on Three-Dimensional Corrosion Simulation and Tensile Properties of Bolted Bolt-Ball Joints After Corrosion; Harbin Institute of Technology: Harbin, China, 2022. [Google Scholar] [CrossRef]

- GB/T 37488-2019; Requirements for Hygiene Indicators and Limits in Public Places. China Standard Quality Inspection Press: Beijing, China, 2019. [CrossRef]

- Qiu, B.; Yang, X.; Zhou, Z.; Lei, H. Experimental study on fatigue performance of M30 high-strength bolts in bolted spherical joints of grid structures. Eng. Struct. 2020, 205, 110123. [Google Scholar] [CrossRef]

- Liang, P. Research on Ultra Low Cycle Fatigue Performance of M24 High Strength Bolt Connection Node with Ø 120 Bolt Ball; Taiyuan University of Technology: Taiyuan, China, 2021. [Google Scholar] [CrossRef]

- Tian, J.; Wang, X.; Li, H.; Wang, Z.; Pan, J. Ultra-low cycle fatigue performance of grid structure with bolted spherical joints. J. Constr. Steel. Res. 2023, 201, 107728. [Google Scholar] [CrossRef]

- Huang, B.; Lu, M.; Fu, Y.; Yang, F. Experimental Investigation on Tensile Properties of the Bolt in Sphere Joints Under Fire. Int. J. Steel Struct. 2020, 20, 1355–1363. [Google Scholar] [CrossRef]

- Yang, F.; Fu, Y.; Huang, B.; Guo, F.; Qian, Y.; Mei, L. Experimental study on tensile performance of bolted ball joints under high temperature. J. Archit. Struct. 2016, 37, 55–60. [Google Scholar] [CrossRef]

- T/CSCS 043-2023; Group Standard of China Steel Structure Association, Large Diameter High Strength Bolts for Bolted Spherical node. China Architecture & Building Press: Beijing, China, 2023.

- Huang, B.; Fu, Y.; Chen, Y.; Yang, F. Experimental Study on the Depth of High Strength Bolt into Bolt-Sphere Joint. Prog. Steel Build. Struct. 2016, 18, 28–32. [Google Scholar]

- Wu, B. Study on the Performance of Bolted Ball Joints with Insufficient Screw in and the Stability of Single-Layer Mesh Shells; Harbin Institute of Technology: Harbin, China, 2022. [Google Scholar] [CrossRef]

- JGJ 7-2010; Technical Specification for Space Frame Structures. China Architecture & Building Press: Beijing, China, 2010.

- Tian, L.; Wei, J.; Hao, J. Optimization of long-span single-layer spatial grid structures to resist progressive collapse. Eng. Struct. 2019, 188, 394–405. [Google Scholar] [CrossRef]

- JG/T 10-2009; Ministry of Housing and Urban-Rural Development of the People’s Republic of China, Bolted Spherical Node of Space Grid Structures. China Architecture & Building Press: Beijing, China, 2009.

- GB/T16939-2016; High Strength Bolts for Joints of Space grid Structures. Standardization Administration of China: Beijing, China, 2016.

- GB/T 699-2015; Quality Carbon Structure Steels. National Standard of the People’s Republic of China: Beijing, China, 2015.

- GB/T 3077-2015; Alloy Structure Steels. National Standard of the People’s Republic of China: Beijing, China, 2015.

- GBT16545-2015; Corrosion of Metals and Alloys-Removal of Corrosion Products from Corrosion Test Specimens. China Standard Quality Inspection Press: Beijing, China, 2015.

- GB/T228.1-2021; Metallic Materials-Tensile Testing (Part 1: Method of Test at Room Temperature). National Standard of the People’s Republic of China: Beijing, China, 2021.

- Song, X.; Huang, S.; Wang, C.; Wang, Z. Initial Corrosion Behavior of Carbon Steel in the Atmospheric Environment of Hongyanhe Marine Industry. J. Metall. 2020, 56, 1355–1365. [Google Scholar] [CrossRef]

- Wang, B. Corrosion and Protection of Materials; Peking University Press: Beijing, China, 2012; pp. 123–127. [Google Scholar]

- Li, X. Corrosion and Protection of Materials; Central South University Press: Changsha, China, 2009; pp. 77–82. [Google Scholar]

- Wan, Y.; Tan, J.; Zhu, S.; Cui, J.; Zhang, K.; Wang, X.; Shen, X.; Li, Y.; Zhu, X. Insight into atmospheric pitting corrosion of carbon steel via a dual-beam FIB/SEM system associated with high-resolution TEM. Corros. Sci. 2019, 152, 226–233. [Google Scholar] [CrossRef]

- Wan, Y.; Song, F.; Li, L. Research on Corrosion Characteristics of Carbon Steel under the Influence of Marine Atmospheric Environmental Factors. Chin. J. Corros. Prot. 2022, 42, 851–855. [Google Scholar] [CrossRef]

- Ma, Y.; Li, Y.; Wang, F. Corrosion of low carbon steel in atmospheric environments of different chloride content. Corros. Sci. 2009, 51, 997–1006. [Google Scholar] [CrossRef]

- Du, Y.; Ou, Y.; Zhou, F. Research on the Stress Concentration Factor of Bolt Rod. Eng. Mech. 2014, 31, 174–180. [Google Scholar] [CrossRef]

| (a) | ||||||||

| Category | Elastic Modulus (MPa) | Yield Strength (MPa) | Ultimate Strength (MPa) | Ultimate Strain | Poisson’s Ratio | |||

| High-strength bolt | 2.1 × 105 | 940 | 1040 | 0.10 | 0.3 | |||

| Joint sphere | 2.1 × 105 | 355 | 600 | 0.16 | 0.3 | |||

| (b) | ||||||||

| Material | C | Si | Mn | Cr | Ni | Mo | S | P |

| #45 Carbon Steel | 0.42–0.50 | 0.17–0.37 | 0.50–0.80 | ≤0.25 | ≤0.30 | — | ≤0.035 | ≤0.035 |

| 40Cr Alloy Steel | 0.37–0.44 | 0.17–0.37 | 0.50–0.80 | 0.80–1.10 | ≤0.30 | ≤0.10 | ≤0.035 | ≤0.035 |

| Temperature inside the test chamber | 35 °C ± 1 °C |

| Relative humidity during spray | ≥95% |

| NaCl solution concentration (mass fraction) | 5% |

| Solution pH value | 6.5–7.2 |

| Salt spray deposition amount | 1–2 mL/(80 cm2·h) |

| Pressure control during spray | 0.2 MPa |

| Cycle design of periodic spray | Salt spraying of 9 h, and drying for 9 h |

| Test in Batches | Sample Number | Depth Coefficient (λ) | Numbers of Corrosion Cycles |

|---|---|---|---|

| Batch I | BS-0 (control group) | 1.1 | — |

| BS-1 | 1.1 | 20 | |

| BS-2 | 1.1 | 40 | |

| BS-3 | 1.1 | 60 | |

| BS-4 | 1.1 | 80 | |

| Batch II | BS-08 | 0.8 | — |

| BS-09 | 0.9 | — | |

| BS-10 | 1.0 | — | |

| BS-11 | 1.1 | — | |

| BS-12 | 1.2 | — | |

| BS-N08 | 0.8 | 60 | |

| BS-N09 | 0.9 | 60 | |

| BS-N10 | 1.0 | 60 | |

| BS-N11 | 1.1 | 60 | |

| BS-N12 | 1.2 | 60 |

| Specimen ID | Corrosion Cycles | Screwing Depth λ | Failure Mode |

|---|---|---|---|

| BS-0 | 0 | 1.1 | Bolt fracture |

| BS-1 | 20 | 1.1 | Bolt fracture |

| BS-2 | 40 | 1.1 | Bolt fracture |

| BS-3 | 60 | 1.1 | Bolt fracture |

| BS-4 | 80 | 1.1 | Bolt fracture |

| BS-08 | 0 | 0.8 | Bolt pull-out |

| BS-09 | 0 | 0.9 | Bolt pull-out |

| BS-10 | 0 | 1.0 | Bolt fracture |

| BS-11 | 0 | 1.1 | Bolt fracture |

| BS-12 | 0 | 1.2 | Bolt fracture |

| BS-N08 | 60 | 0.8 | Bolt fracture (corroded) |

| BS-N09 | 60 | 0.9 | Bolt fracture (corroded) |

| BS-N10 | 60 | 1.0 | Bolt fracture (corroded) |

| BS-N11 | 60 | 1.1 | Bolt fracture (corroded) |

| BS-N12 | 60 | 1.2 | Bolt fracture (corroded) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Li, Y.; Yang, S.; Hao, C.; Yang, Y.; Chen, C.; Zhou, Q.; Yuan, G.; Lu, C. Corrosion Characteristics and Tensile Performance of Bolted Spherical Joints in Aggressive Environments. Materials 2025, 18, 2185. https://doi.org/10.3390/ma18102185

Li J, Li Y, Yang S, Hao C, Yang Y, Chen C, Zhou Q, Yuan G, Lu C. Corrosion Characteristics and Tensile Performance of Bolted Spherical Joints in Aggressive Environments. Materials. 2025; 18(10):2185. https://doi.org/10.3390/ma18102185

Chicago/Turabian StyleLi, Jianguo, Yanhong Li, Sheng Yang, Chenling Hao, Yun Yang, Chong Chen, Qingsong Zhou, Guanglin Yuan, and Caifeng Lu. 2025. "Corrosion Characteristics and Tensile Performance of Bolted Spherical Joints in Aggressive Environments" Materials 18, no. 10: 2185. https://doi.org/10.3390/ma18102185

APA StyleLi, J., Li, Y., Yang, S., Hao, C., Yang, Y., Chen, C., Zhou, Q., Yuan, G., & Lu, C. (2025). Corrosion Characteristics and Tensile Performance of Bolted Spherical Joints in Aggressive Environments. Materials, 18(10), 2185. https://doi.org/10.3390/ma18102185