Superspreading-Based Fabrication of Poly(methyl methacrylate) Films with High Toughness for Ultra-Wideband Flexible Transparent Antenna

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

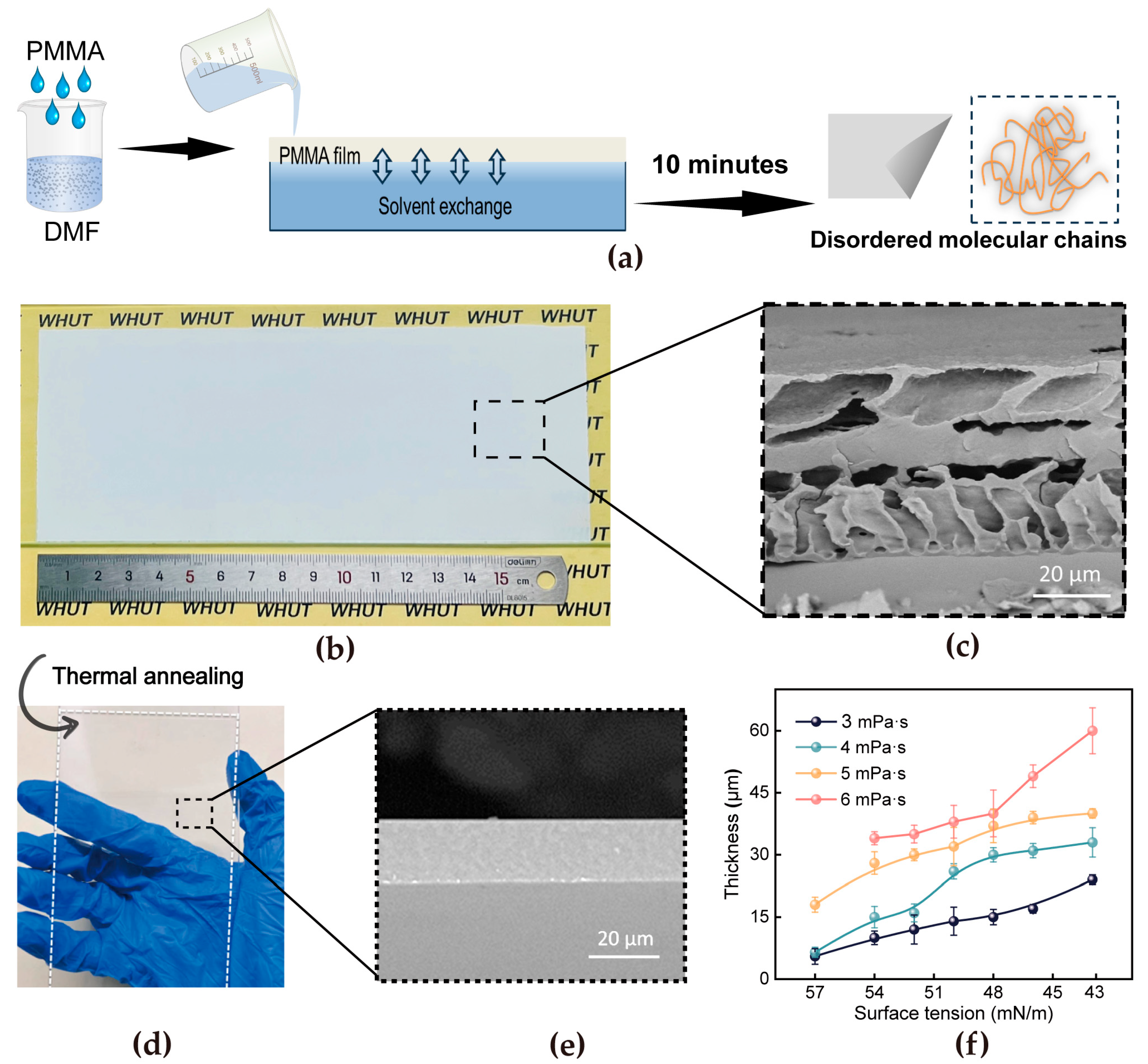

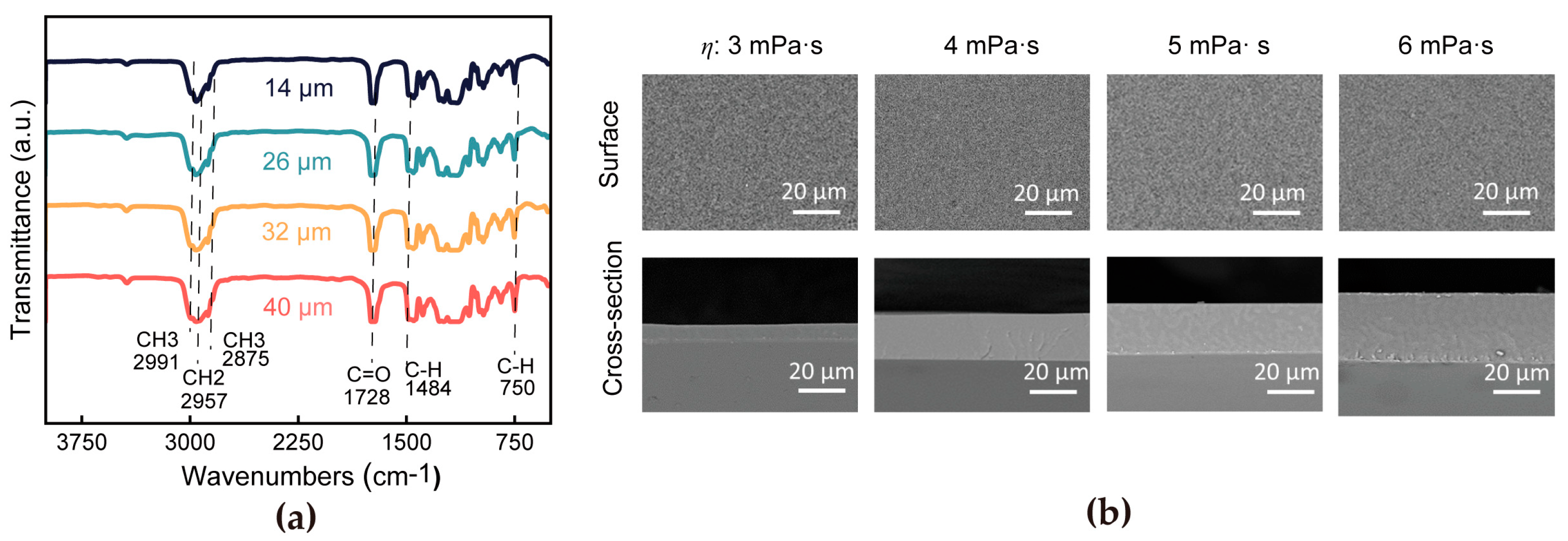

2.2. Sample Preparation

2.3. Characterization of PMMA Films

2.4. Antenna Performance Metrics

2.5. Statistical Analysis

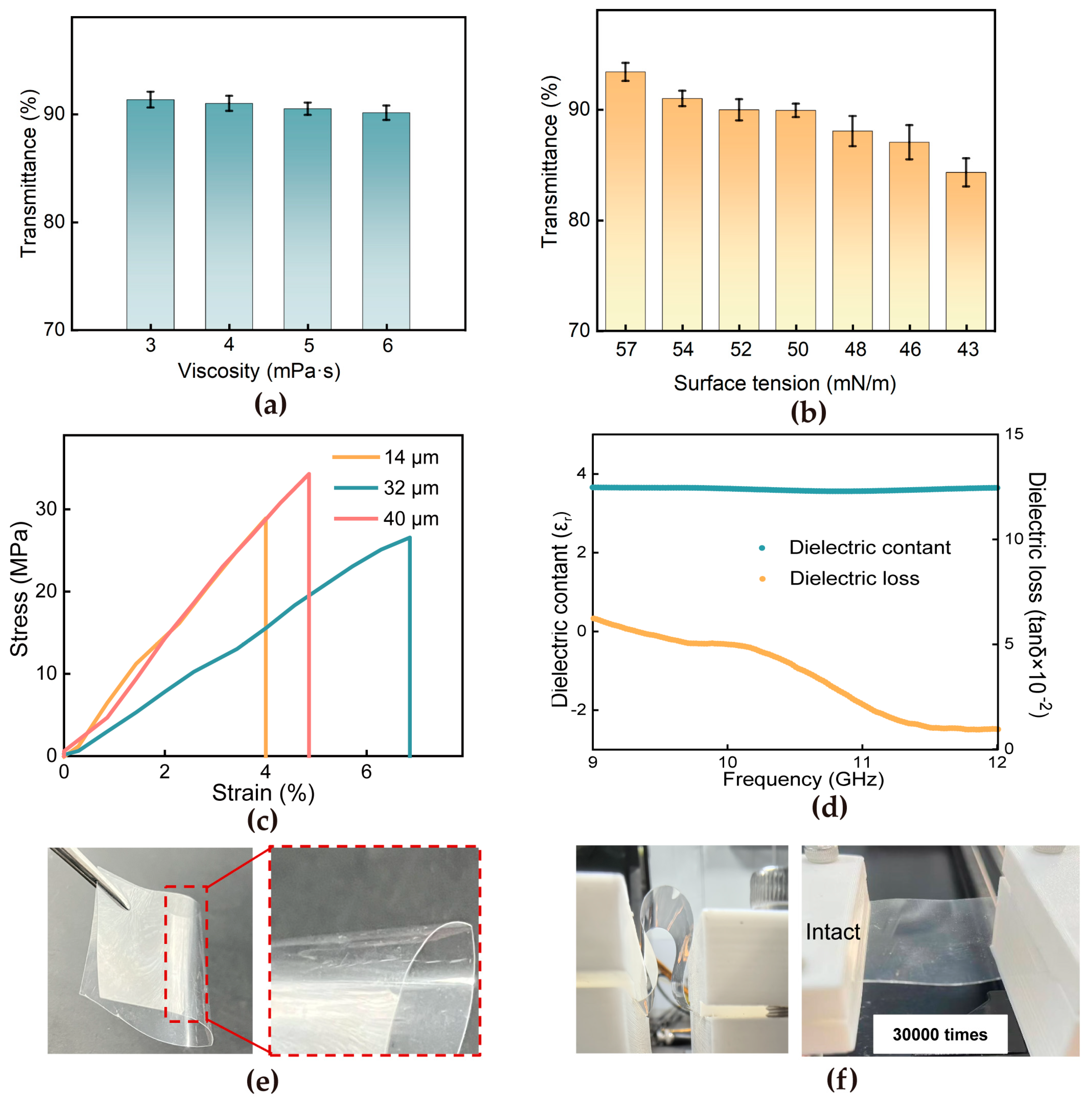

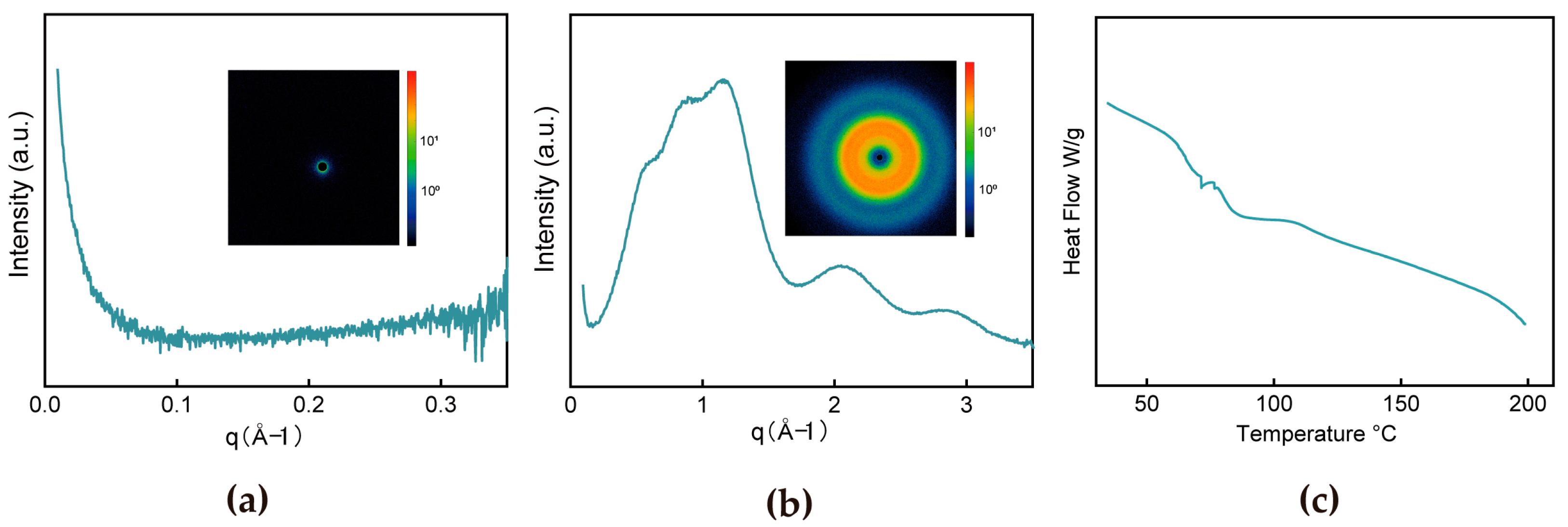

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, C.; Zhao, Y.S. Flexible photonic materials and devices: Synthetic strategies, sensing properties, and wearable applications. Adv. Mater. 2024, 37, 2415856. [Google Scholar] [CrossRef] [PubMed]

- Reyes-Vera, E.; Montoya-Villada, S.; Umaña-Idarraga, F.; Bedoya-Londoño, S.; Araujo-Muñoz, J.; Ossa-Molina, O. High-sensitivity strain sensing using a flexible microstrip antenna with metamaterial resonator. IEEE Sens. J. 2025, 25, 647–654. [Google Scholar] [CrossRef]

- Chang, X.; Sun, S.; Sun, S.; Liu, T.; Xiong, X.; Lei, Y.; Dong, L.; Yin, Y. ZnO nanorods/carbon black-based flexible strain sensor for detecting human motions. J. Alloys Compd. 2018, 738, 111–117. [Google Scholar] [CrossRef]

- Lee, J.-H.; Cho, K.; Kim, J.-K. Age of flexible electronics: Emerging trends in soft multifunctional sensors. Adv. Mater. 2024, 36, 2310505. [Google Scholar] [CrossRef]

- Hussain, M.; Zahra, H.; Abbas, S.M.; Zhu, Y. Flexible dielectric materials: Potential and applications in antennas and RF sensors. Adv. Electron. Mater. 2024, 10, 2400240. [Google Scholar] [CrossRef]

- Xu, D.; Xu, R.; Hu, B.; Hu, S.; Hong, W.; Zhang, Y.; Chai, Y.; Chen, T.; Li, H.; Zhao, Y. Flexible low profile UWB antenna on polyimide film based on silver nanoparticle direct-write dispenser printing for wireless applications. J. Mater. Sci. Mater. Electron. 2023, 34, 1297. [Google Scholar] [CrossRef]

- Li, H.; Wang, S.; Kong, X.; Yan, B.; Gong, M.; Lin, X.; Zhang, L.; Wang, D. Polyphenol-functionalized boron nitride nanosheet-reinforced sustainable polyimide dielectric films for antenna-in-package applications. ACS Appl. Electron. Mater. 2024, 6, 2667–2676. [Google Scholar] [CrossRef]

- Patil, E.C.; Lokhande, S.D.; Patil, U.A.; Patil, A.U.; Kumar, J. Optically transparent dual-band antenna for UHF and S-band applications. Opt. Mater. 2024, 147, 114615. [Google Scholar] [CrossRef]

- Dong, C.; Mao, X.; Wang, M.; Zhang, M.; Chen, J.; Hu, J.; Wu, G. Preparation of a novel SiO/PMMA nanocomposite with high transparency, thermal stability, and superior surface hardness via gamma-radiation polymerization. Polym. Adv. Technol. 2024, 35, e6290. [Google Scholar] [CrossRef]

- Ziani, D.; Belkheir, M.; Mokaddem, A.; Rouissat, M. Enhancing circular microstrip antenna performance with polydimethylsiloxane (PDMS) and polymethyl methacrylate (PMMA) substrates in sub-6 GHz: A comparative study. Int. J. Interact. Des. Manuf. 2024, 18, 5109–5120. [Google Scholar] [CrossRef]

- Douhi, S.; Boumegnane, A.; Chakhchaoui, N.; Eddiai, A.; Cherkaoui, O.; Mazroui, M. A wideband flexible antenna utilizing PMMA/PVDF-HFP/PZT polymer composite film and silver-based conductive Ink for wearable applications. Polym. Adv. Technol. 2024, 35, e6575. [Google Scholar] [CrossRef]

- Ahmed, H.M.; Aziz, S.-A.B. Dielectric properties of commercial non-polar polymers. J. Zankoy Sulaimani 2008, 11, 1–8. [Google Scholar] [CrossRef]

- Qureshi, A.A.; Klymyshyn, D.M.; Börner, M.; Guttmann, M.; Schneider, M.; Mazhar, W.; Mohr, J. On the application of micro hot embossing for mass fabrication of template-based dielectric resonator antenna arrays. Microsyst. Technol. 2018, 24, 3893–3900. [Google Scholar] [CrossRef]

- Saldanha, J.M.; Kyu, T. Influence of solvent casting on evolution of phase morphology of PC/PMMA blends. Macromolecules 1987, 20, 2840–2847. [Google Scholar] [CrossRef]

- Paul, L.C.; Pramanik, R.K.; Rashid, M.M.U.; Sarker, S.; Mahmud, M.Z.; Islam, M.T. An ITO based high gain optically transparent wide band microstrip antenna for band satellite communication. In Proceedings of the 2019 International Conference on Robotics, Electrical and Signal Processing Techniques (ICREST), Dhaka, Bangladesh, 10–12 January 2019; pp. 638–642. [Google Scholar]

- Rameshkumar, C.; Sarojini, S.; Naresh, K.; Subalakshmi, R. Preparation and characterization of pristine PMMA and PVDF thin film using solution casting process for optoelectronic devices. J. Surf. Sci. Technol. 2017, 33, 12–18. [Google Scholar] [CrossRef]

- Sugumaran, D.S.; Bellan, C. Preparation and characterization of nano scale PMMA thin films. Indian J. Pure Appl. Phys. 2014, 52, 64–67. [Google Scholar]

- Samal, S.; Svomova, B.; Spasovová, M.; Tyc, O.; Vokoun, D.; Stachiv, I. Physical, thermal, and mechanical characterization of PMMA foils fabricated by solution casting. Appl. Sci. 2023, 13, 1016. [Google Scholar] [CrossRef]

- Ahmed, R.M. Study on different solution-cast films of PMMA and PVAC. Int. J. Polym. Mater. Polym. Biomater. 2008, 57, 969–978. [Google Scholar] [CrossRef]

- Semaltianos, N.G. Spin-coated PMMA films. Microelectron. J. 2007, 38, 754–761. [Google Scholar] [CrossRef]

- Zhang, Y.; D’Ambra, C.A.; Katsumata, R.; Burns, R.L.; Somervell, M.H.; Segalman, R.A.; Hawker, C.J.; Bates, C.M. Rapid and selective deposition of patterned thin films on heterogeneous substrates via spin coating. ACS Appl. Mater. Interfaces 2019, 11, 21177–21183. [Google Scholar] [CrossRef]

- Bornside, D.E.; Macosko, C.W.; Scriven, L.E. Spin coating of a PMMA/chlorobenzene solution. J. Electrochem. Soc. 1991, 138, 317. [Google Scholar] [CrossRef]

- Tong, J.D.; Moineau, G.; Leclère, P.; Brédas; Lazzaroni, R.; Jérôme, R. Synthesis. Morphology, and mechanical properties of poly(methyl methacrylate)-b-poly(n-butyl acrylate)-b-poly(methyl methacrylate) triblocks. Ligated anionic polymerization vs atom transfer radical polymerization. Macromolecules 2000, 33, 470–479. [Google Scholar] [CrossRef]

- Iqbal, S.; Rafique, M.S.; Iqbal, N.; Bashir, S.; Arif, S.; Ahmad, R. Impact of radiation induced crosslinking on structural, morphological, mechanical and optical properties of polymethylmethacrylate thin films. Prog. Org. Coat. 2017, 111, 202–209. [Google Scholar] [CrossRef]

- Kamonkhantikul, K.; Arksornnukit, M.; Takahashi, H. Antifungal. Optical, and mechanical properties of polymethylmethacrylate material incorporated with silanized zinc oxide nanoparticles. Int. J. Nanomed. 2017, 12, 2353–2360. [Google Scholar] [CrossRef] [PubMed]

- Ho, P.S.; Poon, T.W.; Leu, J. Molecular structure and thermal/mechanical properties of polymer thin films. J. Phys. Chem. Solids 1994, 55, 1115–1124. [Google Scholar] [CrossRef]

- Boyer, R.F. Dependence of mechanical properties on molecular motion in polymers. Polym. Eng. Sci. 1968, 8, 161–185. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, P.; Zhou, J.; Qi, S.; Yamauchi, Y.; Shi, R.; Fang, R.; Ishida, Y.; Wang, S.; Tomsia, A.P. Layered nanocomposites by shear-flow-induced alignment of nanosheets. Nature 2020, 580, 210–215. [Google Scholar] [CrossRef]

- Zhou, T.; Zhao, C.; Liu, Y.; Huang, J.; Zhou, H.; Nie, Z.; Fan, M.; Zhao, T.; Cheng, Q.; Liu, M. Large-area ultrastrong and stiff layered mXene nanocomposites by shear-flow-induced alignment of nanosheets. ACS Nano 2022, 16, 12013–12023. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, F.; Zhao, C.; Wang, S.; Liu, M.; Jiang, L. Superspreading on immersed gel surfaces for the confined synthesis of thin polymer films. Angew. Chem. Int. Ed. 2016, 128, 3679–3683. [Google Scholar] [CrossRef]

- Huang, X.; Cheng, S.; Huang, C.; Han, J.; Li, M.; Liu, S.; Zhang, J.; Zhang, P.; You, Y.; Chen, W. Superspreading-based fabrication of thermostable nanoporous polyimide membranes for high safety separators of lithium-ion batteries. Small 2024, 20, 2311219. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, P.; Gu, Z.; Chen, L.; Yi, H.; Cao, Z.; Jin, J.; Liu, M.; Jiang, L. Superspreading-based fabrication of asymmetric porous PAA-g-PVDF membranes for efficient water flow gating. Adv. Mater. Interfaces 2016, 3, 1600615. [Google Scholar] [CrossRef]

- Zhang, J.; Hou, D.; Wang, J.; Liu, H.; Huang, C.; Cheng, S.; Zhou, L.; Shen, Z.; Li, B.; Zhou, J.; et al. Bioinspired dielectric nanocomposites with high charge–discharge efficiency enabled by superspreading-induced alignment of nanosheets. ACS Appl. Mater. Interfaces 2024, 16, 14162–14170. [Google Scholar] [CrossRef] [PubMed]

- Foged, L.J.; Dobbins, J.; Rodriguez, V.; Fordham, J.; Monebhurrun, V. Recent Progress in Revision of IEEE Std 1720-2012 Recommended Practice for Near-Field Antenna Measurements. In Proceedings of the 2021 IEEE International Conference on Microwaves, Antennas, Communications and Electronic Systems (COMCAS), Tel Aviv, Israel, 1–3 November 2021; pp. 224–225. [Google Scholar]

- Cui, C.W.; Yang, C.; Bao, J.; Huang, X.-J.; Zeng, X.F.; Chen, J.F. Monodispersed ZnO nanoparticle-poly(methyl methacrylate) composites with visible transparency for ultraviolet shielding applications. ACS Appl. Nano Mater. 2020, 3, 9026–9034. [Google Scholar] [CrossRef]

- Abdel-Mohti, A.; Garbash, A.; Almagahwi, S.; Shen, H. Effect of layer and film thickness and temperature on the mechanical property of micro- and nano-layered PC/PMMA films subjected to thermal aging. Materials 2015, 8, 2062–2075. [Google Scholar] [CrossRef]

- Mapesa, E.U.; Street, D.P.; Heres, M.F.; Kilbey, S.M., II; Sangoro, J. Wetting and chain packing across interfacial zones affect distribution of relaxations in polymer and polymer-grafted nanocomposites. Macromolecules 2020, 53, 5315–5325. [Google Scholar] [CrossRef]

- Arlindo, E.P.S.; Lucindo, J.A.; Bastos, C.M.O.; Emmel, P.D.; Orlandi, M.O. Electrical and optical properties of conductive and transparent ITO@PMMA nanocomposites. J. Phys. Chem. C 2012, 116, 12946–12952. [Google Scholar] [CrossRef]

- Sun, Y.; Henderson, K.J.; Jiang, Z.; Strzalka, J.W.; Wang, J.; Shull, K.R. Effects of reactive annealing on the structure of poly(methacrylic acid)–poly(methyl methacrylate) diblock copolymer thin films. Macromolecules 2011, 44, 6525–6531. [Google Scholar] [CrossRef]

- Virk, H.S.; Srivastava, A.K. Modification of optical, chemical and structural response of CR-39 polymer by 50MeV lithium-ion irradiation. Radiat. Meas. 2001, 34, 65–67. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Z.; Zhang, X.; Guo, S. Sandwich-layered dielectric film with intrinsically excellent adhesion, low dielectric constant, and ultralow dielectric loss for a high-frequency flexible printed circuit. Ind. Eng. Chem. Res. 2021, 60, 11749–11759. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhuang, S.; Xu, X.; Hu, J. Transparent and UV-shielding ZnO@PMMA nanocomposite films. Opt. Mater. 2013, 36, 169–172. [Google Scholar] [CrossRef]

- Zhai, J.H.; Zaiser, M. Properties of dislocation lines in crystals with strong atomic-scale disorder. Mater. Sci. Eng. A 2019, 740–741, 285–294. [Google Scholar] [CrossRef]

- Sengwa, R.J.; Dhatarwal, P. Polymer nanocomposites comprising PMMA matrix and ZnO, SnO2, and TiO2 nanofillers: A comparative study of structural, optical, and dielectric properties for multifunctional technological applications. Opt. Mater. 2021, 113, 110837. [Google Scholar] [CrossRef]

- Huang, C.K.; Lou, W.M.; Tsai, C.J.; Wu, T.-C.; Lin, H.-Y. Mechanical properties of polymer thin film measured by the bulge test. Thin Solid Film. 2007, 515, 7222–7226. [Google Scholar] [CrossRef]

- Ali, U.; Karim, K.J.B.A.; Buang, N.A. A review of the properties and applications of poly (Methyl Methacrylate) (PMMA). Polym. Rev. 2015, 55, 678–705. [Google Scholar] [CrossRef]

- Lu, Y.; Xiao, X.; Zhan, Y.; Cao, Z.; Cheng, H.; Huan, C.; Qi, S.; Xu, G. Functional transparent nanocomposite film with thermochromic and hydrophobic properties fabricated by electrospinning and hot-pressing approach. Ceram. Int. 2018, 44, 1013–1018. [Google Scholar] [CrossRef]

- Wu, Q.; Feng, Z.; Cai, Z.; Lan, C.; Xu, J.; Bi, K.; Hao, Y. Poly(methyl methacrylate)-based ferroelectric/dielectric laminated films with enhanced energy storage performances. Adv. Compos. Hybrid Mater. 2022, 5, 1137–1144. [Google Scholar] [CrossRef]

- Guillen, G.R.; Pan, Y.; Li, M.; Hoek, E.M.V. Preparation and characterization of membranes formed by nonsolvent induced phase separation: A review. Ind. Eng. Chem. Res. 2011, 50, 3798–3817. [Google Scholar] [CrossRef]

- Guillen, G.R.; Ramon, G.Z.; Kavehpour, H.P.; Kaner, R.B.; Hoek, E.M.V. Direct microscopic observation of membrane formation by nonsolvent induced phase separation. J. Membr. Sci. 2013, 431, 212–220. [Google Scholar] [CrossRef]

- Zu, H.R.; Wu, B.; Chen, B.; Li, W.H.; Su, T.; Liu, Y.; Tang, W.X.; He, D.P.; Cui, T.J. Optically and radiofrequency-transparent metadevices based on quasi-one-dimensional surface plasmon polariton structures. Nat. Electron. 2023, 6, 525–533. [Google Scholar] [CrossRef]

- Shanmugasundram, H.P.P.V.; Jayamani, E.; Soon, K.H. A comprehensive review on dielectric composites: Classification of dielectric composites. Renew. Sustain. Energy Rev. 2022, 157, 112075. [Google Scholar] [CrossRef]

- Cang, D.; Wang, Z.; Qu, H. A polyimide-based flexible monopole antenna fed by a coplanar waveguide. Electronics 2021, 10, 334. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, S.; Yang, Z.-Q.; Qu, X.-Y.; Zong, W.-H. A coplanar waveguide-fed flexible antenna for ultra-wideband applications. Int. J. RF Microw. Comput.-Aided Eng. 2020, 30, e22258. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Z.-L.; Cang, D.-Y.; Gong, J.-S.; Qu, H.-W. A polyimide-based flexible monopole antenna. J. Mater. Sci.: Mater. Electron. 2022, 33, 1686–1702. [Google Scholar] [CrossRef]

- Chen, W.S.; Lee, B.Y.; Chang, P.Y. A compact and small printed monopole antenna for WLAN applications. Microw. Opt. Technol. Lett. 2011, 53, 1518–1522. [Google Scholar] [CrossRef]

| Method/ Parameter | Thickness (μm) | Tensile Strength MPa | Young’s Modulus (GPa) | Elongation at Break (%) | Toughness (×105 J/m3) | Transmittance (%) |

|---|---|---|---|---|---|---|

| Solution-Casting [18,19,44,45,46] | 100–1000 | 30 | 2 | 2 | 5 | 85–90 |

| Hot-Pressing [47,48] | 100–1000 | 23.4 | 1.67 | 1.8 | 6 | 80–90 |

| Spin-Coating [20,21,22] | 0.1–10 | 50 | 2 | 5 | 4 | 90–95 |

| NIPS [49,50] | 1–100 | 60 | 0.5 | 4 | 5 | 90–95 |

| Superspreading | 1–100 | 26.6 | 0.38 | 6.85 | 9 | 85–95 |

| Ref | Gain (dBi) | Bandwidth (%) | Size (mm × mm × mm) | Substrate Dielectric Constant | Bending Radius (m−1) | Frequency (GHz) |

|---|---|---|---|---|---|---|

| This study | 2–4 | 40 | 0.032 × 15 × 25 | 3.6 | 200 | 8–12 |

| [53] | 2.98 | 28.33 | 40.6 × 50 × 0.075 | 3.5 | 25 | 2.28 |

| [54] | 1.69 | 30 | 30.4 × 38 × 0.07 | 3.5 | 100 | 3.1–10.6 |

| [55] | 3 | 36.44 | 40.6 × 50 × 0.075 | 3.5 | 16.67 | 2.4 |

| [56] | 1.5–3 | 20.2 | 25 × 20 × 1.6 | 4.4 | \ | 2.4–5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Huang, C.; Guo, J.; Zu, H.; Shen, J.; Zhang, P.; Chen, W. Superspreading-Based Fabrication of Poly(methyl methacrylate) Films with High Toughness for Ultra-Wideband Flexible Transparent Antenna. Materials 2025, 18, 2183. https://doi.org/10.3390/ma18102183

Liu Y, Huang C, Guo J, Zu H, Shen J, Zhang P, Chen W. Superspreading-Based Fabrication of Poly(methyl methacrylate) Films with High Toughness for Ultra-Wideband Flexible Transparent Antenna. Materials. 2025; 18(10):2183. https://doi.org/10.3390/ma18102183

Chicago/Turabian StyleLiu, Ying, Cheng Huang, Jiannan Guo, Haoran Zu, Jie Shen, Pengchao Zhang, and Wen Chen. 2025. "Superspreading-Based Fabrication of Poly(methyl methacrylate) Films with High Toughness for Ultra-Wideband Flexible Transparent Antenna" Materials 18, no. 10: 2183. https://doi.org/10.3390/ma18102183

APA StyleLiu, Y., Huang, C., Guo, J., Zu, H., Shen, J., Zhang, P., & Chen, W. (2025). Superspreading-Based Fabrication of Poly(methyl methacrylate) Films with High Toughness for Ultra-Wideband Flexible Transparent Antenna. Materials, 18(10), 2183. https://doi.org/10.3390/ma18102183