Performance of Nanotechnology in Cementitious Materials: Synthesis and Application

Abstract

1. Introduction

2. Nanotechnology

2.1. Nanomaterials and Their Morphology

2.1.1. Characterization of Nanomaterials

2.1.2. Top–Down/Bottom–Up

2.2. Synthesis of Nanoparticles

2.2.1. Lithography

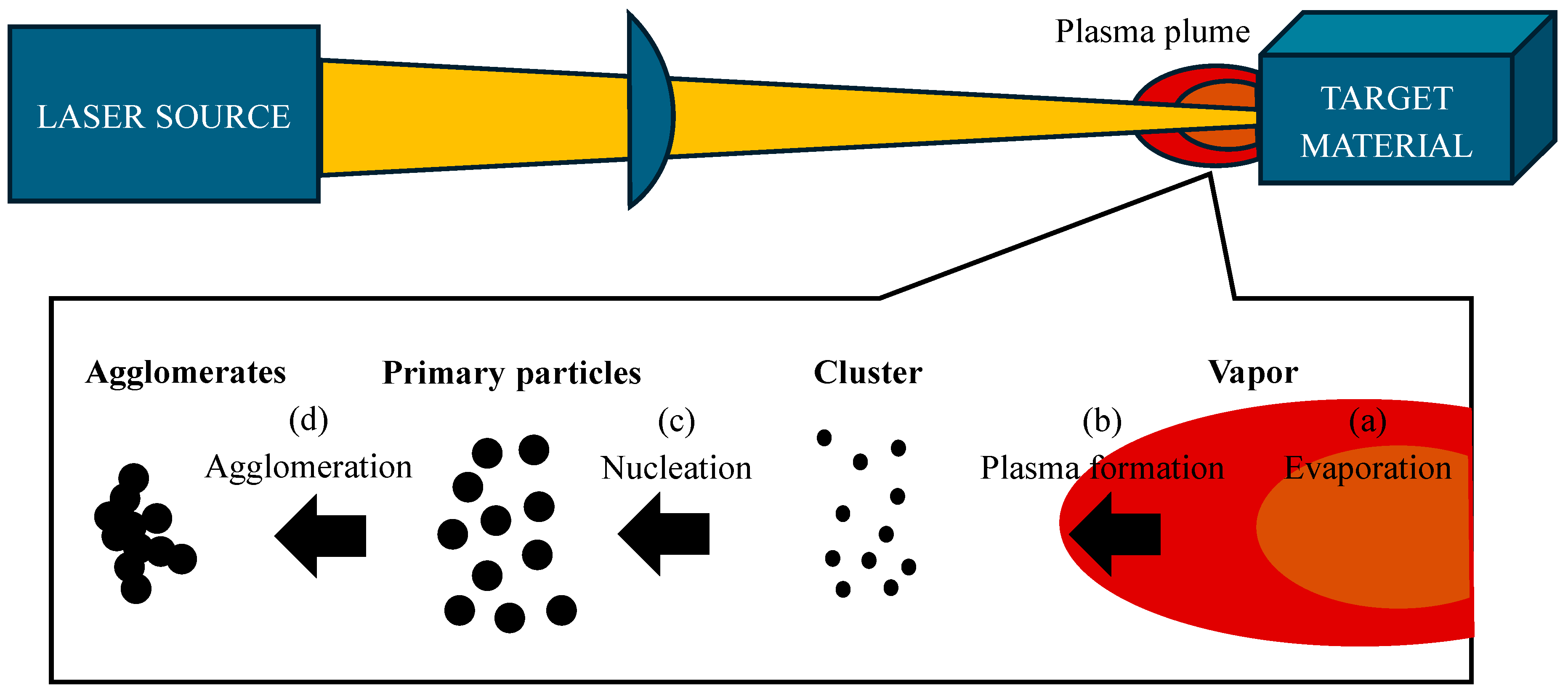

2.2.2. Laser Ablation

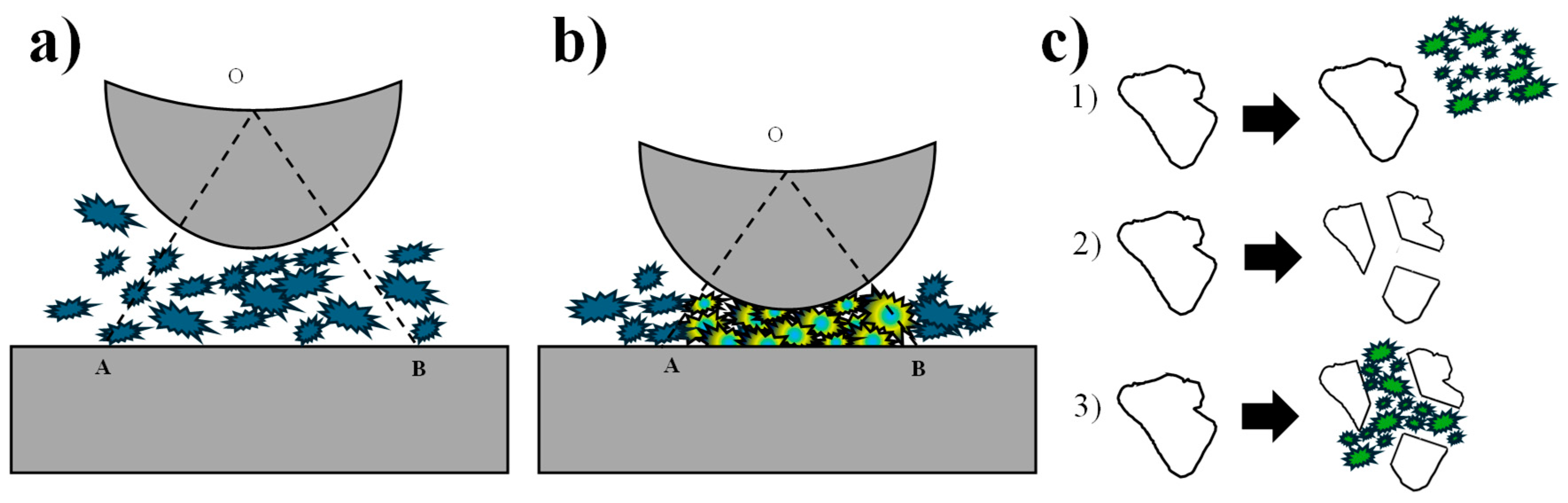

2.2.3. Mechanical Milling

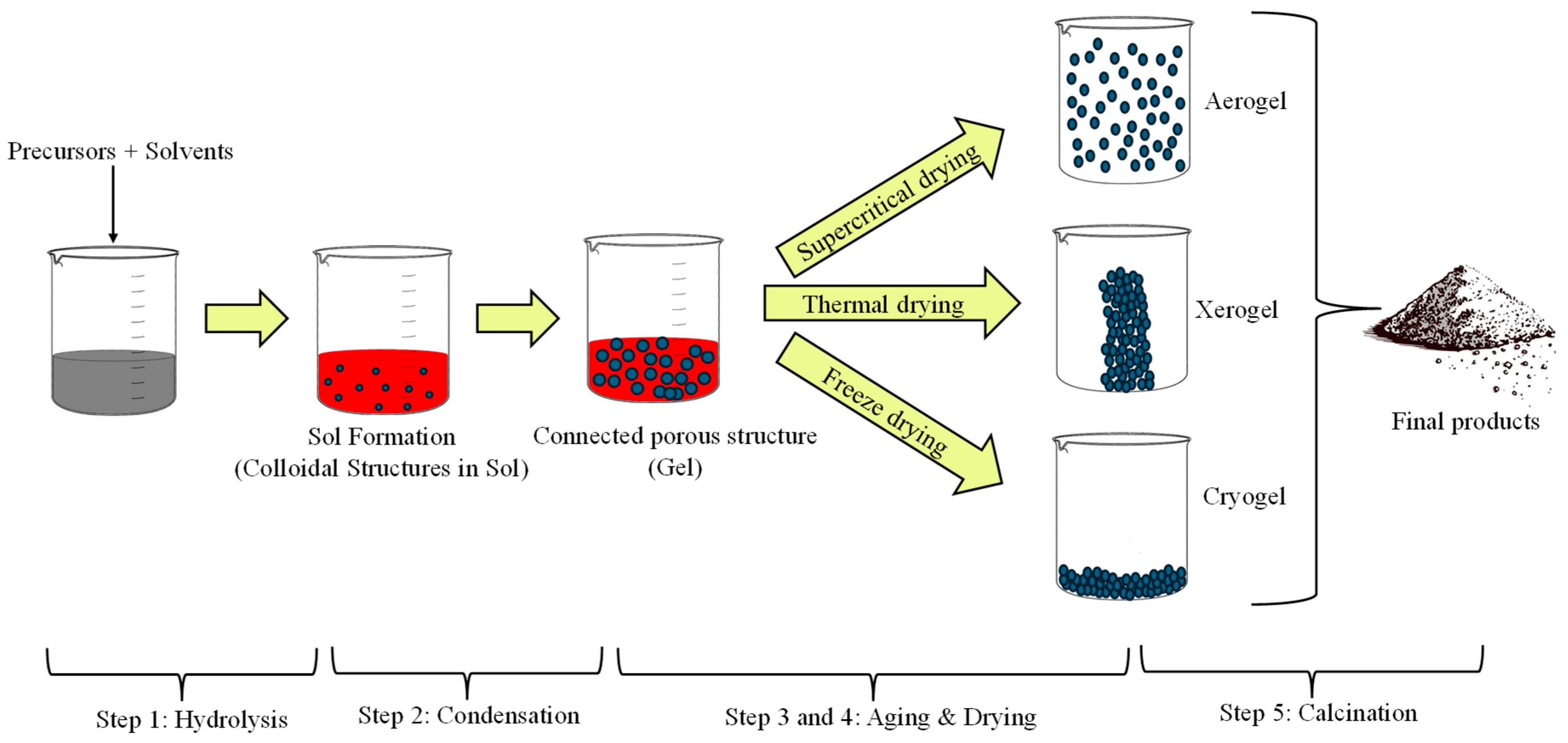

2.2.4. Sol-Gel

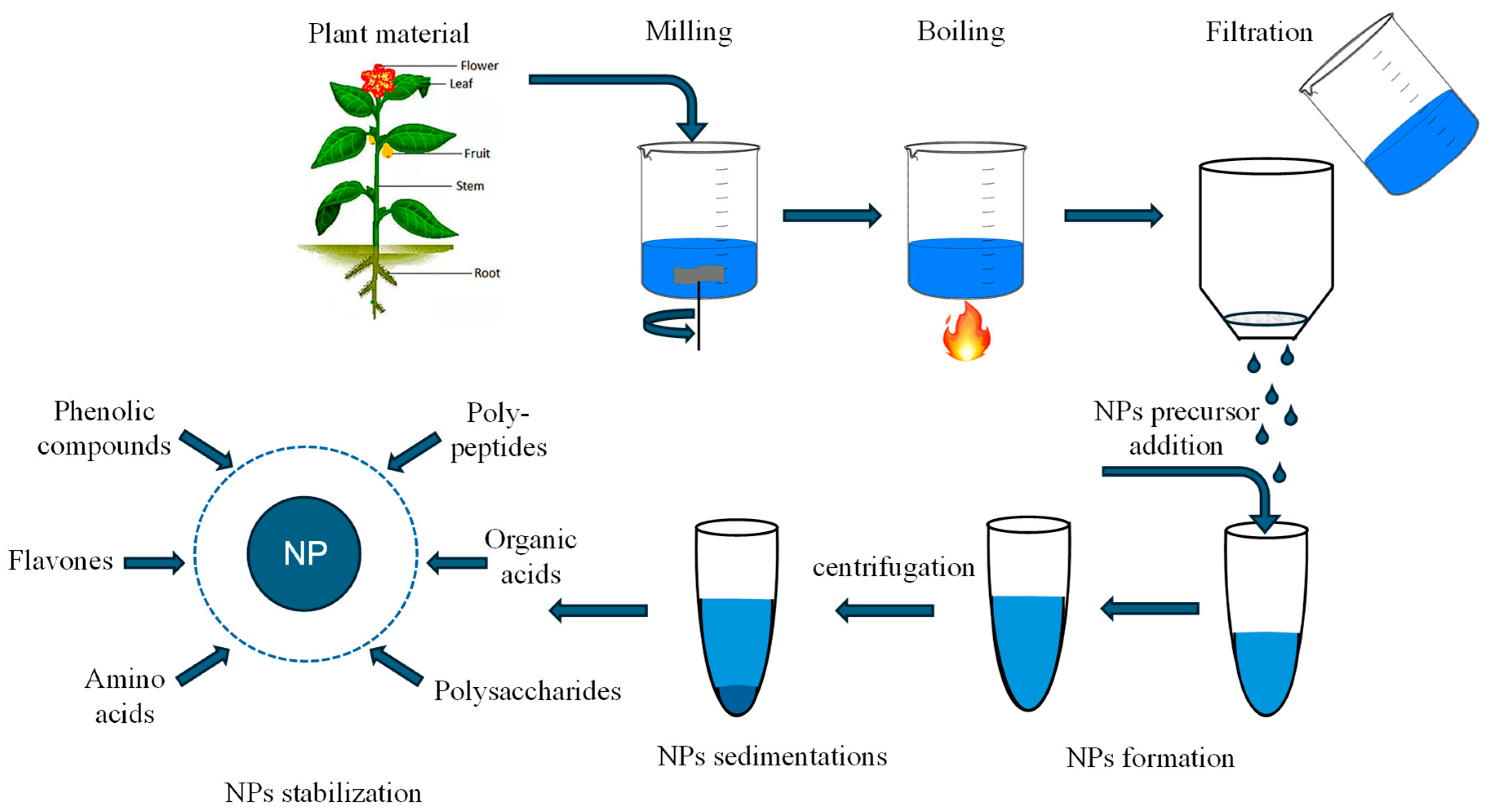

2.2.5. Biosynthesis

2.3. Synthesis of Nanofibers

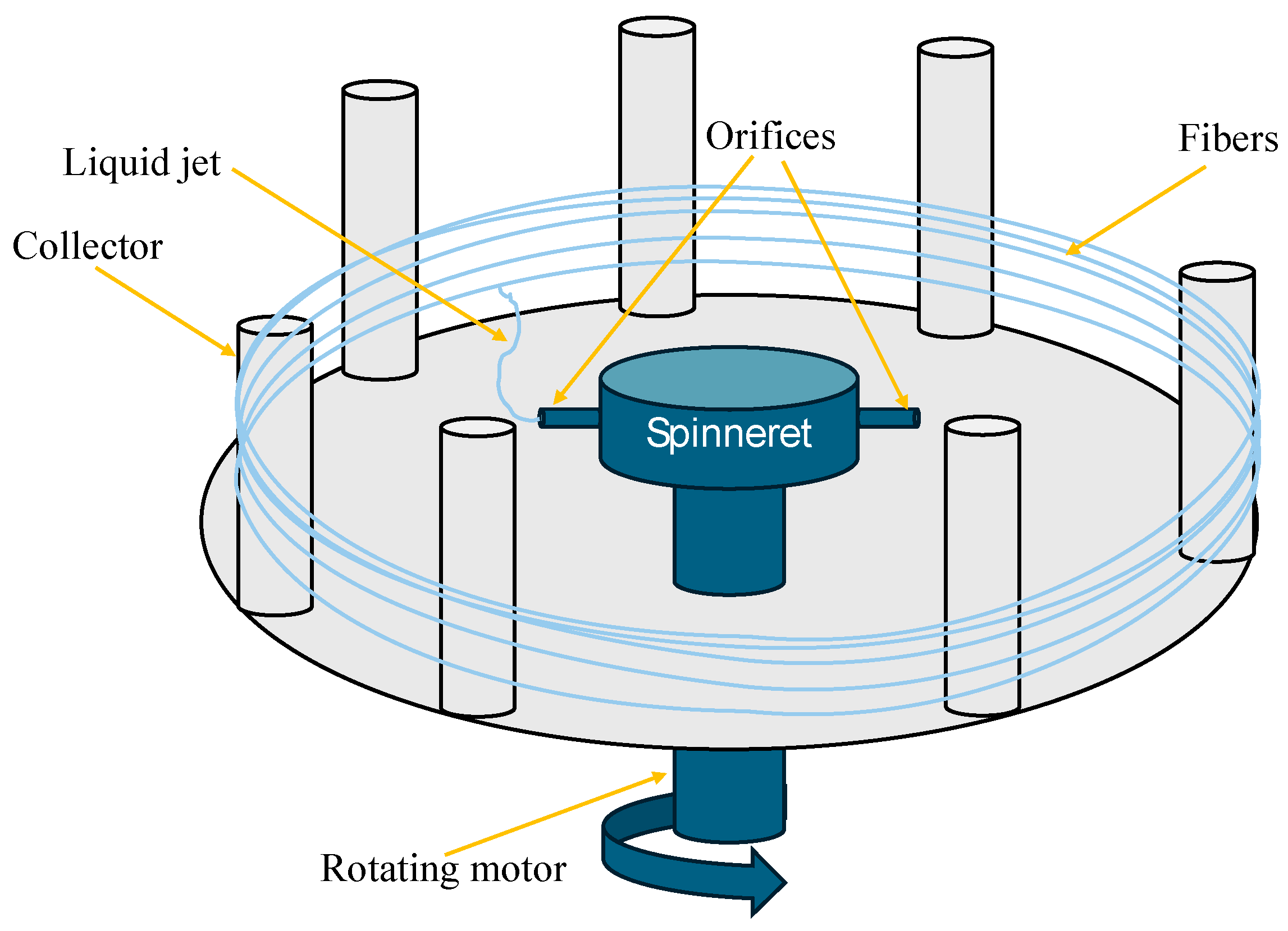

2.3.1. Centrifugal Jet Spinning

2.3.2. CO2 Laser Supersonic Drawing

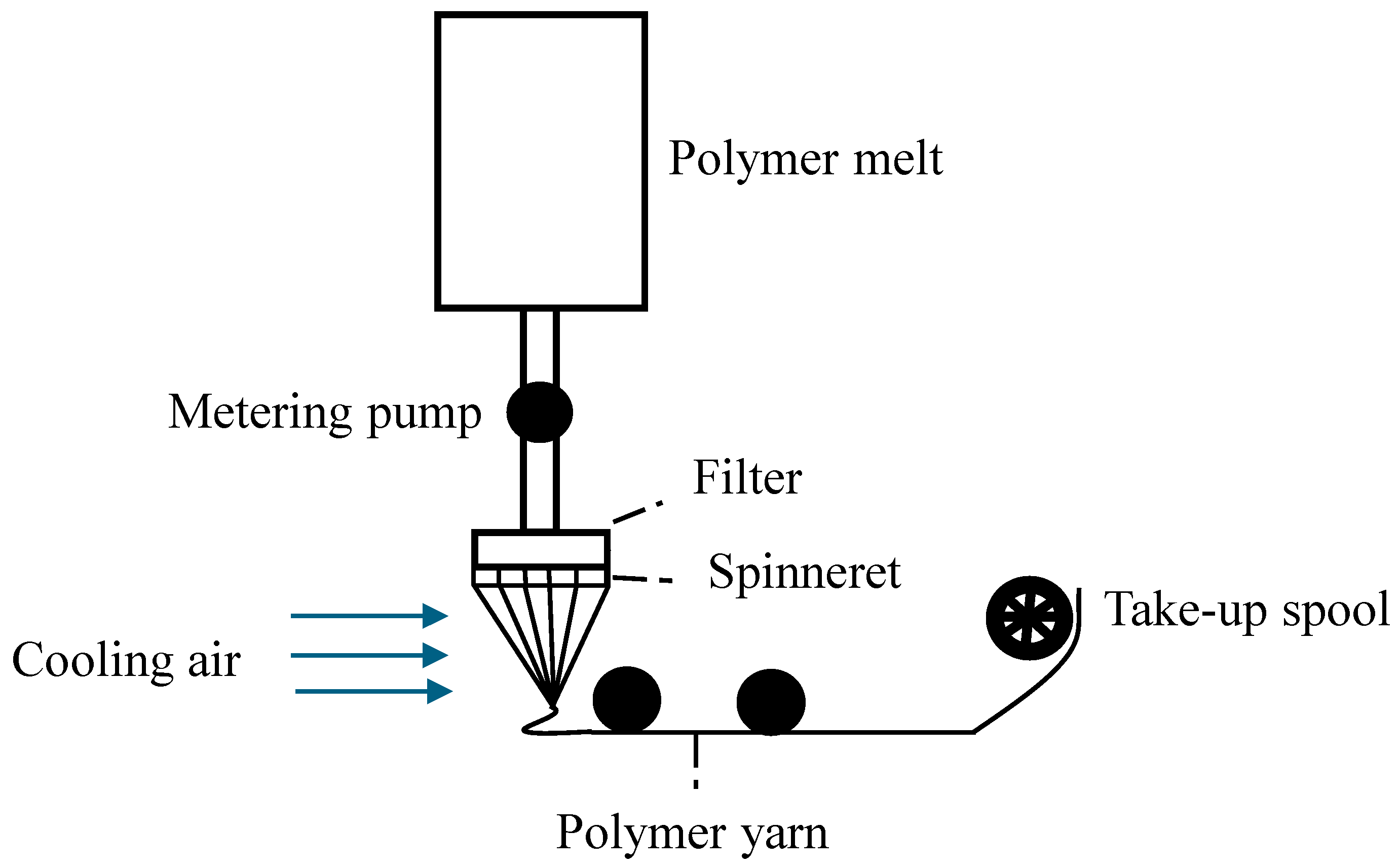

2.3.3. Melt Spinning

2.3.4. Blow Spinning

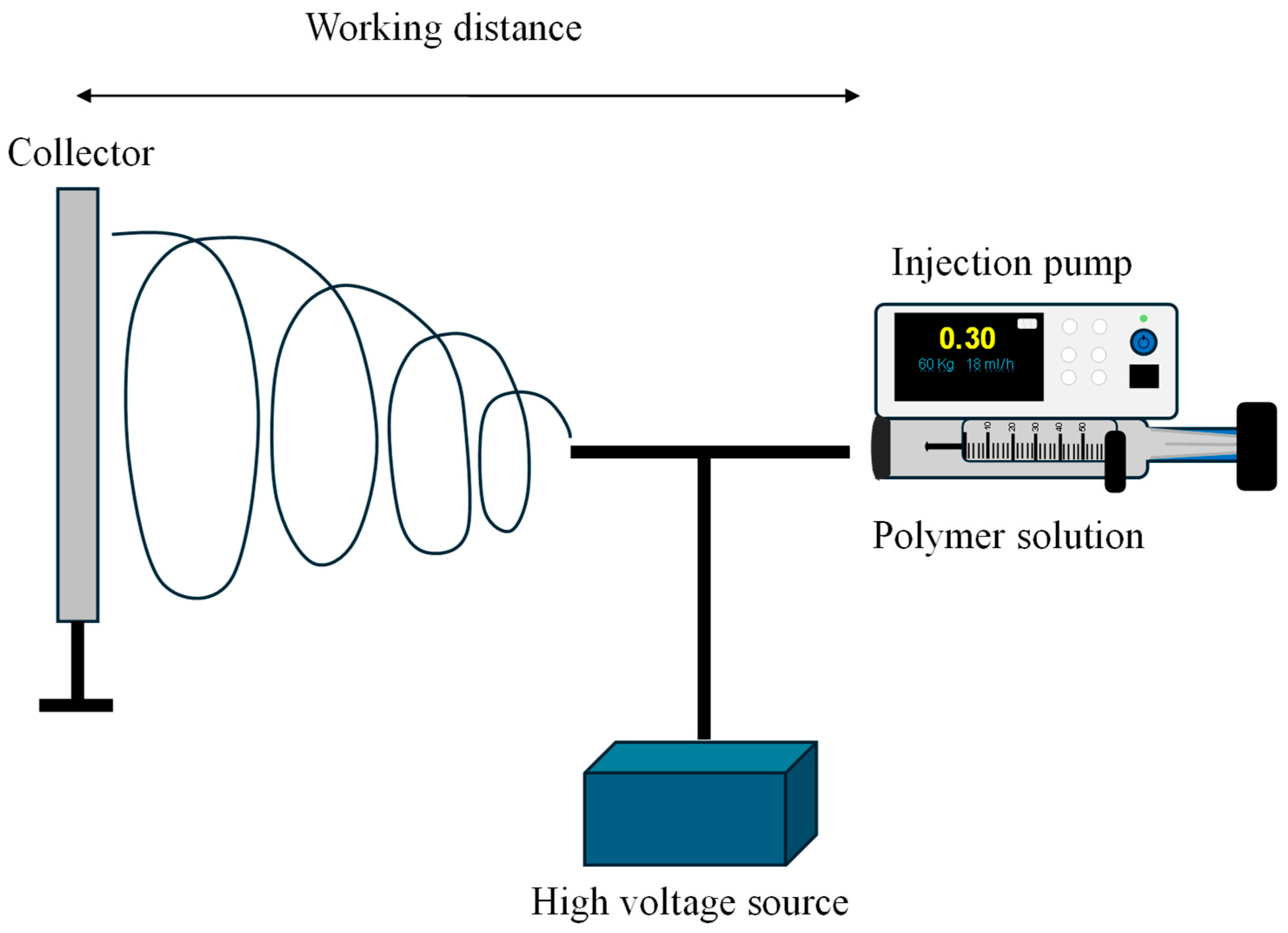

2.3.5. Electrospinning

3. Nanotechnology Applied to Cementitious Materials

3.1. Mechanical Properties

| Nanomateriales en Materiales Cementantes | Size | w/c | % | F’C | M.R. | Reference |

|---|---|---|---|---|---|---|

| Carbon Nanotubes in mortar | 8–15 nm | 0.4 | 0.10% | 18.40% | 22.23% | [140] |

| Cellulose NPs in mortar | 5–100 nm | 0.4 | 0.50% | 23.40% | 30.46% | [140] |

| SiO2 NPs in mortar | 20–30 nm | 0.4 | 2% | 23.09% | 14.91% | [140] |

| Carbon Nanotubes in concrete | >50 nm | 0.55 | 0.10% | 22.30% | NE | [138] |

| Carbon NPs in concrete | 150 nm | 0.4 | 1.20% | 1.00% | NE | [146] |

| SiO2 NPs in concrete | 15–20 nm | 0.4 | 0.60% | 17.58% | NE | [146] |

| (SiO2 + Ca) NPs in concrete | Two previous | 0.45 | 0.4% NC + 0.6 NS | 9.16% | NE | [146] |

| Fe2O3 NPs in concrete | 15 nm | 0.4 | 1.00% | 15.49% | NE | [142] |

| SiO2 NPs + fly ash in concrete | 116 m2/g * | 0.25 | 2% | 30.00% | 23% | [134] |

| SiO2 NPs in concrete | 200 m2/g * | 0.4 | 2% | 15.00% | NE | [147] |

| Al2Si2O5(OH)4 (Halloysite) Nanotubes in concrete | 29 m2/g * | 0.4 | 3% | 13.10% | NE | [147] |

| Al2H2O12Si4 (Montmorillonite) NPs in concrete | 27 m2/g * | 0.4 | 3% | 23.10% | NE | [147] |

| SiO2 NPs in concrete | 10–20 nm | 0.42 | 4% | 7.90% | 2.80% | [136] |

| TiO2 NPs in concrete | <25 nm | 0.42 | 2% | 2.70% | 3.90% | [136] |

| Al2O3 NPs in concrete | <50 nm | 0.42 | 0.50% | 4.50% | −2.20% | [136] |

| Carbon Nanotubes in concrete | 149 nm | 0.2 | 0.50% | 14.20% | 10.40% | [139] |

| SiO2 NPs in concrete | 15 nm | 0.4 | 4% | NE | 45% | [141] |

3.2. Durability

3.3. Shrinkage

4. Nanotechnology Applied to Sustainable Cementitious Materials

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tai, Y.S.; Chu, T.L.; Hu, H.T.; Wu, J.Y. Dynamic Response of a Reinforced Concrete Slab Subjected to Air Blast Load. Theor. Appl. Fract. Mech. 2011, 56, 140–147. [Google Scholar] [CrossRef]

- ACI. Definition of Concrete, Hydraulic Cement, Mortar, and Grout. Available online: https://www.concrete.org/tools/frequentlyaskedquestions.aspx?faqid=640 (accessed on 10 January 2025).

- Tayeh, B.A.; Hamada, H.M.; Almeshal, I.; Bakar, B.H.A. Durability and Mechanical Properties of Cement Concrete Comprising Pozzolanic Materials with Alkali-Activated Binder: A Comprehensive Review. Case Stud. Constr. Mater. 2022, 17, e01429. [Google Scholar] [CrossRef]

- Dhanalakshmi, M.; Sowmya, N.J.; Chandrashekar, A. A Comparative Study on Egg Shell Concrete with Partial Replacement of Cement by Fly Ash. Int. J. Res. Appl. Sci. Eng. Technol. 2015, 3, 12–20. [Google Scholar] [CrossRef]

- Xiao, J.; Lv, Z.; Duan, Z.; Zhang, C. Pore Structure Characteristics, Modulation and Its Effect on Concrete Properties: A Review. Constr. Build. Mater. 2023, 397, 132430. [Google Scholar] [CrossRef]

- Zhao, Z.; Qi, T.; Zhou, W.; Hui, D.; Xiao, C.; Qi, J.; Zheng, Z.; Zhao, Z. A Review on the Properties, Reinforcing Effects, and Commercialization of Nanomaterials for Cement-Based Materials. Nanotechnol. Rev. 2020, 9, 303–322. [Google Scholar] [CrossRef]

- Xiao, H.; Zhang, F.; Liu, R.; Zhang, R.; Liu, Z.; Liu, H. Effects of Pozzolanic and Non-Pozzolanic Nanomaterials on Cement-Based Materials. Constr. Build. Mater. 2019, 213, 1–9. [Google Scholar] [CrossRef]

- Sharma, P.; Bhargava, M. Applications and Characteristics of Nanomaterials in Industrial Environment. Res. Dev. 2013, 3, 63–72. [Google Scholar]

- Hulla, J.E.; Sahu, S.C.; Hayes, A.W. Nanotechnology: History and Future. Hum. Exp. Toxicol. 2015, 34, 1318–1321. [Google Scholar] [CrossRef]

- Besley, J.C.; Kramer, V.L.; Priest, S.H. Expert Opinion on Nanotechnology: Risks, Benefits, and Regulation. J. Nanoparticle Res. 2008, 10, 549–558. [Google Scholar] [CrossRef]

- Sudha, P.N.; Sangeetha, K.; Vijayalakshmi, K.; Barhoum, A. Nanomaterials History, Classification, Unique Properties, Production and Market. In Emerging Applications of Nanoparticles and Architecture Nanostructures; Elsevier: Amsterdam, The Netherlands, 2018; pp. 341–384. [Google Scholar]

- Pokropivny, V.V.; Skorokhod, V.V. Classification of Nanostructures by Dimensionality and Concept of Surface Forms Engineering in Nanomaterial Science. Mater. Sci. Eng. C 2007, 27, 990–993. [Google Scholar] [CrossRef]

- Mekuye, B.; Abera, B. Nanomaterials: An Overview of Synthesis, Classification, Characterization, and Applications. Nano Sel. 2023, 4, 486–501. [Google Scholar] [CrossRef]

- Barhoum, A.; García-Betancourt, M.L.; Jeevanandam, J.; Hussien, E.A.; Mekkawy, S.A.; Mostafa, M.; Omran, M.M.; Abdalla, M.S.; Bechelany, M. Review on Natural, Incidental, Bioinspired, and Engineered Nanomaterials: History, Definitions, Classifications, Synthesis, Properties, Market, Toxicities, Risks, and Regulations. Nanomaterials 2022, 12, 177. [Google Scholar] [CrossRef] [PubMed]

- Baig, N.; Kammakakam, I.; Falath, W. Nanomaterials: A Review of Synthesis Methods, Properties, Recent Progress, and Challenges. Mater. Adv. 2021, 2, 1821–1871. [Google Scholar] [CrossRef]

- Prasad, R.D.; Shrivastav, R.; Sinha, P.; Sinha, A.D.; Sinha, S.B.; Prasad, N.R.; Prasad, R.R.; Prasad, R.B.; Prasad, N.; Karhu, B.G. A Critical Review on Electron, X-Ray, Probe Microscopic Techniques for Analysis of Biomaterials and Nanomaterials. Int. J. Nanomater. Nanostructures 2024, 10, 1–32. [Google Scholar]

- Malatesta, M. Transmission Electron Microscopy as a Powerful Tool to Investigate the Interaction of Nanoparticles with Subcellular Structures. Int. J. Mol. Sci. 2021, 22, 12789. [Google Scholar] [CrossRef]

- Escalante, J.; Chen, W.-H.; Tabatabaei, M.; Hoang, A.T.; Kwon, E.E.; Lin, K.-Y.A.; Saravanakumar, A. Pyrolysis of Lignocellulosic, Algal, Plastic, and Other Biomass Wastes for Biofuel Production and Circular Bioeconomy: A Review of Thermogravimetric Analysis (TGA) Approach. Renew. Sustain. Energy Rev. 2022, 169, 112914. [Google Scholar] [CrossRef]

- Mangam, V.T.; Narla, D.; Konda, R.K.; Sarella, P.N.K. Beyond the Spectrum: Exploring Unconventional Applications of Fourier Transform Infrared (FTIR) Spectroscopy. Asian J. Pharm. Anal. 2024, 14, 86–94. [Google Scholar] [CrossRef]

- Fatimah, S.; Ragadhita, R.; Al Husaeni, D.F.; Nandiyanto, A.B.D. How to Calculate Crystallite Size from X-Ray Diffraction (XRD) Using Scherrer Method. ASEAN J. Sci. Eng. 2022, 2, 65–76. [Google Scholar] [CrossRef]

- Krishna, D.N.G.; Philip, J. Review on Surface-Characterization Applications of X-Ray Photoelectron Spectroscopy (XPS): Recent Developments and Challenges. Appl. Surf. Sci. Adv. 2022, 12, 100332. [Google Scholar] [CrossRef]

- Alshehawy, A.M.; Mansour, D.-E.A.; Ghali, M.; Lehtonen, M.; Darwish, M.M.F. Photoluminescence Spectroscopy Measurements for Effective Condition Assessment of Transformer Insulating Oil. Processes 2021, 9, 732. [Google Scholar] [CrossRef]

- Khan, W.A.; Varanusupakul, P.; Haq, H.U.; Arain, M.B.; Boczkaj, G. Applications of Nanosorbents in Dispersive Solid Phase Extraction/Microextraction Approaches for Monitoring of Synthetic Dyes in Various Types of Samples: A Review. Microchem. J. 2025, 208, 112419. [Google Scholar] [CrossRef]

- El-Khawaga, A.M.; Zidan, A.; El-Mageed, A.I.A.A. Preparation Methods of Different Nanomaterials for Various Potential Applications: A Review. J. Mol. Struct. 2023, 1281, 135148. [Google Scholar] [CrossRef]

- Tripathy, S.; Rodrigues, J.; Shimpi, N.G. Top-down and Bottom-up Approaches for Synthesis of Nanoparticles. Nanobiomater. Perspect. Med. Appl. Diagn. Treat. Dis. 2023, 145, 92–130. [Google Scholar]

- Ealia, S.A.M.; Saravanakumar, M.P. A Review on the Classification, Characterisation, Synthesis of Nanoparticles and Their Application. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 263, p. 32019. [Google Scholar]

- Zain Ul Abidin, M.; Ikram, M.; Moeen, S.; Nazir, G.; Kanoun, M.B.; Goumri-Said, S. A Comprehensive Review on the Synthesis of Ferrite Nanomaterials via Bottom-up and Top-down Approaches Advantages, Disadvantages, Characterizations and Computational Insights. Coord. Chem. Rev. 2024, 520, 216158. [Google Scholar] [CrossRef]

- Banjara, R.A.; Kumar, A.; Aneshwari, R.K.; Satnami, M.L.; Sinha, S.K. A Comparative Analysis of Chemical vs. Green Synthesis of Nanoparticles and Their Various Applications. Environ. Nanotechnol. Monit. Manag. 2024, 22, 100988. [Google Scholar] [CrossRef]

- Ali, A.; Aasim, M.; Çelik, K.; Nadeem, M.A.; Baloch, F.S. Frontiers in Bacterial-Based Green Synthesized Nanoparticles (NPs): A Sustainable Strategy for Combating Infectious Plant Pathogens. Biocatal. Agric. Biotechnol. 2024, 60, 103293. [Google Scholar] [CrossRef]

- Ghareeb, O.A.; Ali, Q.A. Pathological Disorders Caused by Atmospheric Nanoparticles. Peerian J. 2024, 26, 44–51. [Google Scholar]

- Mohanraj, V.J.; Chen, Y. Nanoparticles—A Review. Trop. J. Pharm. Res. 2006, 5, 561–573. [Google Scholar] [CrossRef]

- Maganti, M. Nanoparticles Using Speedometer. Int. J. Health Care Biol. Sci. 2024, 13–17. [Google Scholar] [CrossRef]

- Meena, K.P.; Sahu, B.K.; Karri, T.; Samal, P.; Yadav, S.; Jaiswal, D. Development and Characterization Pioglitazone Hydrochloride Loaded Nanoparticle for Management of Diabetes Mellitus. Res. J. Pharm. Technol. 2024, 17, 1748–1752. [Google Scholar] [CrossRef]

- Jeevanandam, J.; Barhoum, A.; Chan, Y.S.; Dufresne, A.; Danquah, M.K. Review on Nanoparticles and Nanostructured Materials: History, Sources, Toxicity and Regulations. Beilstein J. Nanotechnol. 2018, 9, 1050–1074. [Google Scholar] [CrossRef] [PubMed]

- Stark, W.J.; Stoessel, P.R.; Wohlleben, W.; Hafner, A. Industrial Applications of Nanoparticles. Chem. Soc. Rev. 2015, 44, 5793–5805. [Google Scholar] [CrossRef]

- Khan, I.; Saeed, K.; Khan, I. Nanoparticles: Properties, Applications and Toxicities. Arab. J. Chem. 2019, 12, 908–931. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Kumar, V.; Thomas, S. Nanoparticles Reinforced Metal Nanocomposites: Mechanical Performance and Durability; Springer Nature: Berlin/Heidelberg, Germany, 2023; ISBN 9811997292. [Google Scholar]

- Kusada, K.; Mukoyoshi, M.; Wu, D.; Kitagawa, H. Chemical Synthesis, Characterization, and Properties of Multi-Element Nanoparticles. Angew. Chem. 2022, 134, e202209616. [Google Scholar] [CrossRef]

- Mughal, B.; Zaidi, S.Z.J.; Zhang, X.; Hassan, S.U. Biogenic Nanoparticles: Synthesis, Characterisation and Applications. Appl. Sci. 2021, 11, 2598. [Google Scholar] [CrossRef]

- Bouafia, A.; Laouini, S.E.; Ahmed, A.S.A.; Soldatov, A.V.; Algarni, H.; Feng Chong, K.; Ali, G.A.M. The Recent Progress on Silver Nanoparticles: Synthesis and Electronic Applications. Nanomaterials 2021, 11, 2318. [Google Scholar] [CrossRef] [PubMed]

- Seitkalieva, M.M.; Samoylenko, D.E.; Lotsman, K.A.; Rodygin, K.S.; Ananikov, V.P. Metal Nanoparticles in Ionic Liquids: Synthesis and Catalytic Applications. Coord. Chem. Rev. 2021, 445, 213982. [Google Scholar] [CrossRef]

- Bustamante-Torres, M.; Romero-Fierro, D.; Estrella-Nuñez, J.; Arcentales-Vera, B.; Chichande-Proaño, E.; Bucio, E. Polymeric Composite of Magnetite Iron Oxide Nanoparticles and Their Application in Biomedicine: A Review. Polymers 2022, 14, 752. [Google Scholar] [CrossRef] [PubMed]

- Sajid, M.; Płotka-Wasylka, J. Nanoparticles: Synthesis, Characteristics, and Applications in Analytical and Other Sciences. Microchem. J. 2020, 154, 104623. [Google Scholar] [CrossRef]

- Khan, Y.; Sadia, H.; Ali Shah, S.Z.; Khan, M.N.; Shah, A.A.; Ullah, N.; Ullah, M.F.; Bibi, H.; Bafakeeh, O.T.; Khedher, N.B.; et al. Classification, Synthetic, and Characterization Approaches to Nanoparticles, and Their Applications in Various Fields of Nanotechnology: A Review. Catalysts 2022, 12, 1386. [Google Scholar] [CrossRef]

- Sharma, E.; Rathi, R.; Misharwal, J.; Sinhmar, B.; Kumari, S.; Dalal, J.; Kumar, A. Evolution in Lithography Techniques: Microlithography to Nanolithography. Nanomaterials 2022, 12, 2754. [Google Scholar] [CrossRef]

- Chiang, N.; Scarabelli, L.; Vinnacombe-Willson, G.A.; Pérez, L.A.; Dore, C.; Mihi, A.; Jonas, S.J.; Weiss, P.S. Large-Scale Soft-Lithographic Patterning of Plasmonic Nanoparticles. ACS Mater. Lett. 2021, 3, 282–289. [Google Scholar] [CrossRef]

- McGrath, F.; Qian, J.; Gwynne, K.; Kumah, C.; Daly, D.; Hrelescu, C.; Zhang, X.; O’Carroll, D.M.; Bradley, A.L. Structural, Optical, and Electrical Properties of Silver Gratings Prepared by Nanoimprint Lithography of Nanoparticle Ink. Appl. Surf. Sci. 2021, 537, 147892. [Google Scholar] [CrossRef]

- Miura, S.; Yamagishi, R.; Sugino, N.; Yokoyama, Y.; Miyazaki, R.; Yasuda, K.; Ando, M.; Hachikubo, Y.; Murashita, T.; Kameda, T.; et al. Nanoimprint Lithography and Microinjection Molding Using Gas-Permeable Hybrid Mold for Antibacterial Nanostructures. J. Photopolym. Sci. Technol. 2023, 36, 183–190. [Google Scholar] [CrossRef]

- Semaltianos, N.G. Nanoparticles by Laser Ablation. Crit. Rev. Solid State Mater. Sci. 2010, 35, 105–124. [Google Scholar] [CrossRef]

- Kim, M.; Osone, S.; Kim, T.; Higashi, H.; Seto, T. Synthesis of Nanoparticles by Laser Ablation: A Review. KONA Powder Part. J. 2017, 34, 80–90. [Google Scholar] [CrossRef]

- Rashid, T.M.; Nayef, U.M.; Jabir, M.S.; Mutlak, F.A.-H. Synthesis and Characterization of Au: ZnO (Core: Shell) Nanoparticles via Laser Ablation. Optik 2021, 244, 167569. [Google Scholar] [CrossRef]

- Khashan, K.S.; Sulaiman, G.M.; Abdulameer, F.A.; Albukhaty, S.; Ibrahem, M.A.; Al-Muhimeed, T.; AlObaid, A.A. Antibacterial Activity of TiO2 Nanoparticles Prepared by One-Step Laser Ablation in Liquid. Appl. Sci. 2021, 11, 4623. [Google Scholar] [CrossRef]

- Elsayed, K.A.; Alomari, M.; Drmosh, Q.A.; Alheshibri, M.; Al Baroot, A.; Kayed, T.S.; Manda, A.A.; Al-Alotaibi, A.L. Fabrication of ZnO-Ag Bimetallic Nanoparticles by Laser Ablation for Anticancer Activity. Alex. Eng. J. 2022, 61, 1449–1457. [Google Scholar] [CrossRef]

- Gorrasi, G.; Sorrentino, A. Mechanical Milling as a Technology to Produce Structural and Functional Bio-Nanocomposites. Green Chem. 2015, 17, 2610–2625. [Google Scholar] [CrossRef]

- DeCastro, C.L.; Mitchell, B.S. Nanoparticles from Mechanical Attrition. In Synthesis, Functionalization, and Surface Treatment of Nanoparticles; American Scientific Publishers: Stevenson Ranch, CA, USA, 2002; Volume 5. [Google Scholar]

- Arbain, R.; Othman, M.; Palaniandy, S. Preparation of Iron Oxide Nanoparticles by Mechanical Milling. Miner. Eng. 2011, 24, 1–9. [Google Scholar] [CrossRef]

- Shojaei, M.; Shokuhfar, A.; Zolriasatein, A. Synthesis and Characterization of CuAlS2 Nanoparticles by Mechanical Milling. Mater. Today Commun. 2021, 27, 102243. [Google Scholar] [CrossRef]

- Velásquez, A.A.; Urquijo, J.P. Synthesis and Characterization of Magnetite-Maghemite Nanoparticles in Presence of Polyethylene Glycol Obtained by Mechanical Milling. Mater. Sci. Eng. B 2021, 263, 114873. [Google Scholar] [CrossRef]

- Wirunchit, S.; Gansa, P.; Koetniyom, W. Synthesis of ZnO Nanoparticles by Ball-Milling Process for Biological Applications. Mater. Today Proc. 2021, 47, 3554–3559. [Google Scholar] [CrossRef]

- Danks, A.E.; Hall, S.R.; Schnepp, Z. The Evolution of ‘Sol–Gel’ Chemistry as a Technique for Materials Synthesis. Mater. Horiz. 2016, 3, 91–112. [Google Scholar] [CrossRef]

- Bokov, D.; Turki Jalil, A.; Chupradit, S.; Suksatan, W.; Javed Ansari, M.; Shewael, I.H.; Valiev, G.H.; Kianfar, E. Nanomaterial by Sol-gel Method: Synthesis and Application. Adv. Mater. Sci. Eng. 2021, 2021, 5102014. [Google Scholar] [CrossRef]

- Parashar, M.; Shukla, V.K.; Singh, R. Metal Oxides Nanoparticles via Sol–Gel Method: A Review on Synthesis, Characterization and Applications. J. Mater. Sci. Mater. Electron. 2020, 31, 3729–3749. [Google Scholar] [CrossRef]

- Eslami, A.; Lachini, S.A.; Shaterian, M.; Karami, M.; Enhessari, M. Sol-Gel Synthesis, Characterization, and Electrochemical Evaluation of Magnesium Aluminate Spinel Nanoparticles for High-Capacity Hydrogen Storage. J. Sol-Gel Sci. Technol. 2024, 109, 215–225. [Google Scholar] [CrossRef]

- Kistan, A.; Mohan, S.; Mahalakshmi, S.; Jayanthi, A.; Ramya, A.J.; Karthik, P.S. Sol-Gel Technique, Characterization and Photocatalytic Degradation Activity of Manganese Doped ZnO Nanoparticles. Main Group Chem. 2024, 23, 17–30. [Google Scholar] [CrossRef]

- Renganathan, B.; Gopakumar, C.K.; Priya, A.K.; Rao, S.K.; Sastikumar, D.; Silambarasan, M.; Kannapiran, N. Optimizing Gas Sensing Performance of CuO Nanoparticles via Sol-Gel Synthesis Approach for Efficient Detection of Ammonia Gas. Mater. Res. Bull. 2024, 170, 112556. [Google Scholar] [CrossRef]

- Hulkoti, N.I.; Taranath, T.C. Biosynthesis of Nanoparticles Using Microbes—A Review. Colloids Surf. B Biointerfaces 2014, 121, 474–483. [Google Scholar] [CrossRef] [PubMed]

- Chopra, H.; Bibi, S.; Singh, I.; Hasan, M.M.; Khan, M.S.; Yousafi, Q.; Baig, A.A.; Rahman, M.M.; Islam, F.; Emran, T.B.; et al. Green Metallic Nanoparticles: Biosynthesis to Applications. Front. Bioeng. Biotechnol. 2022, 10, 874742. [Google Scholar] [CrossRef]

- Letchumanan, D.; Sok, S.P.M.; Ibrahim, S.; Nagoor, N.H.; Arshad, N.M. Plant-Based Biosynthesis of Copper/Copper Oxide Nanoparticles: An Update on Their Applications in Biomedicine, Mechanisms, and Toxicity. Biomolecules 2021, 11, 564. [Google Scholar] [CrossRef] [PubMed]

- Karunakaran, G.; Sudha, K.G.; Ali, S.; Cho, E.-B. Biosynthesis of Nanoparticles from Various Biological Sources and Its Biomedical Applications. Molecules 2023, 28, 4527. [Google Scholar] [CrossRef]

- Singh, S.; Ghosh, C.; Roy, P.; Pal, K. Biosynthesis of Folic Acid Appended PHBV Modified Copper Oxide Nanorods for PH Sensitive Drug Release in Targeted Breast Cancer Therapy. Int. J. Pharm. 2022, 622, 121831. [Google Scholar] [CrossRef]

- Maity, D.; Gupta, U.; Saha, S. Biosynthesized Metal Oxide Nanoparticles for Sustainable Agriculture: Next-Generation Nanotechnology for Crop Production, Protection and Management. Nanoscale 2022, 14, 13950–13989. [Google Scholar] [CrossRef]

- Rabee, M.; Elmogy, S.A.; Morsy, M.; Lawandy, S.; Zahran, M.A.H.; Moustafa, H. Biosynthesis of MgO Nanoparticles and Their Impact on the Properties of the PVA/Gelatin Nanocomposites for Smart Food Packaging Applications. ACS Appl. Bio Mater. 2023, 6, 5037–5051. [Google Scholar] [CrossRef] [PubMed]

- Kashyap, P.; Shirkot, P.; Das, R.; Pandey, H.; Singh, D. Biosynthesis and Characterization of Copper Nanoparticles from Stenotrophomonas Maltophilia and Its Effect on Plant Pathogens and Pesticide Degradation. J. Agric. Food Res. 2023, 13, 100654. [Google Scholar] [CrossRef]

- Nguyen, D.T.C.; Nguyen, N.T.T.; Nguyen, T.T.T.; Van Tran, T. Recent Advances in the Biosynthesis of ZnO Nanoparticles Using Floral Waste Extract for Water Treatment, Agriculture and Biomedical Engineering. Nanoscale Adv. 2024, 6, 4047–4061. [Google Scholar] [CrossRef]

- Koul, B.; Poonia, A.K.; Yadav, D.; Jin, J.-O. Microbe-Mediated Biosynthesis of Nanoparticles: Applications and Future Prospects. Biomolecules 2021, 11, 886. [Google Scholar] [CrossRef]

- Fagier, M.A. Plant-mediated Biosynthesis and Photocatalysis Activities of Zinc Oxide Nanoparticles: A Prospect towards Dyes Mineralization. J. Nanotechnol. 2021, 2021, 6629180. [Google Scholar] [CrossRef]

- Albert, H.M.; Mendam, K.; Bansod, P.G.; Rao, M.S.S.; Asatkar, A.; Chakravarthi, M.K.; Mallesh, M.P. Biosynthesis, Spectroscopic, and Antibacterial Investigations of Silver Nanoparticles. J. Fluoresc. 2024, 34, 2009–2017. [Google Scholar] [CrossRef] [PubMed]

- Ohiduzzaman, M.; Khan, M.N.I.; Khan, K.A.; Paul, B. Biosynthesis of Silver Nanoparticles by Banana Pulp Extract: Characterizations, Antibacterial Activity, and Bioelectricity Generation. Heliyon 2024, 10, e25520. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Maksoud, G.; Abdel-Nasser, M.; Hassan, S.E.-D.; Eid, A.M.; Abdel-Nasser, A.; Fouda, A. Biosynthesis of Titanium Dioxide Nanoparticles Using Probiotic Bacterial Strain, Lactobacillus Rhamnosus, and Evaluate of Their Biocompatibility and Antifungal Activity. Biomass Convers. Biorefinery 2024, 14, 23961–23983. [Google Scholar] [CrossRef]

- Rasouli, R.; Barhoum, A.; Bechelany, M.; Dufresne, A. Nanofibers for Biomedical and Healthcare Applications. Macromol. Biosci. 2019, 19, 1800256. [Google Scholar] [CrossRef]

- Huang, Z.-M.; Zhang, Y.-Z.; Kotaki, M.; Ramakrishna, S. A Review on Polymer Nanofibers by Electrospinning and Their Applications in Nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar] [CrossRef]

- de Castro Monsores, K.G.; da Silva, A.O.; Oliveira, S.d.S.; Weber, R.P.; Dias, M.L. Production of Nanofibers from Solution Blow Spinning (SBS). J. Mater. Res. Technol. 2022, 16, 1824–1831. [Google Scholar] [CrossRef]

- Chamanehpour, E.; Thouti, S.; Rubahn, H.; Dolatshahi-Pirouz, A.; Mishra, Y.K. Smart Nanofibers: Synthesis, Properties, and Scopes in Future Advanced Technologies. Adv. Mater. Technol. 2024, 9, 2301392. [Google Scholar] [CrossRef]

- Huang, Y.; Song, J.; Yang, C.; Long, Y.; Wu, H. Scalable Manufacturing and Applications of Nanofibers. Mater. Today 2019, 28, 98–113. [Google Scholar] [CrossRef]

- Badrossamay, M.R.; McIlwee, H.A.; Goss, J.A.; Parker, K.K. Nanofiber Assembly by Rotary Jet-Spinning. Nano Lett. 2010, 10, 2257–2261. [Google Scholar] [CrossRef]

- Gholipour-Kanani, A.; Daneshi, P. A Review on Centrifugal and Electro-Centrifugal Spinning as New Methods of Nanofibers Fabrication. J. Text. Polym. 2022, 10, 41–55. [Google Scholar]

- Ren, L.; Kotha, S.P. Centrifugal Jet Spinning for Highly Efficient and Large-Scale Fabrication of Barium Titanate Nanofibers. Mater. Lett. 2014, 117, 153–157. [Google Scholar] [CrossRef]

- Ren, L.; Pandit, V.; Elkin, J.; Denman, T.; Cooper, J.A.; Kotha, S.P. Large-Scale and Highly Efficient Synthesis of Micro-and Nano-Fibers with Controlled Fiber Morphology by Centrifugal Jet Spinning for Tissue Regeneration. Nanoscale 2013, 5, 2337–2345. [Google Scholar] [CrossRef]

- Ye, P.; Guo, Q.; Zhang, Z.; Xu, Q. High-Speed Centrifugal Spinning Polymer Slip Mechanism and PEO/PVA Composite Fiber Preparation. Nanomaterials 2023, 13, 1277. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Yagi, S.; Ashour, S.; Du, L.; Hoque, M.E.; Tan, L. A Review on Current Nanofiber Technologies: Electrospinning, Centrifugal Spinning, and Electro-centrifugal Spinning. Macromol. Mater. Eng. 2023, 308, 2200502. [Google Scholar] [CrossRef]

- Xu, J.; Li, X.; Hou, T.; Zhou, J.; Zhang, Z.; Yang, B. Fabrication of Low-Cost, Self-Floating, and Recyclable Janus Nanofibrous Membrane by Centrifugal Spinning for Photodegradation of Dyes. Colloids Surfaces A Physicochem. Eng. Asp. 2024, 685, 133181. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, J.; Xu, J.; Ye, H.; Zhao, M.; Li, W.; Yang, B.; Li, X. Centrifugal Spinning of PVDF Micro/Nanofibrous Membrane for Oil–Water Separation. ACS Appl. Nano Mater. 2024, 7, 25665–25674. [Google Scholar] [CrossRef]

- Mei, S.; Xu, B.; Wan, J.; Chen, J. Preparation of CNT/CNF/PDMS/TPU Nanofiber-Based Conductive Films Based on Centrifugal Spinning Method for Strain Sensors. Sensors 2024, 24, 4026. [Google Scholar] [CrossRef]

- Lim, C.T. Nanofiber Technology: Current Status and Emerging Developments. Prog. Polym. Sci. 2017, 70, 1–17. [Google Scholar]

- Koyama, H.; Watanabe, Y.; Suzuki, A. Poly (P-phenylene Sulfide) Nanofibers Prepared by CO2 Laser Supersonic Drawing. J. Appl. Polym. Sci. 2014, 131, 40922. [Google Scholar] [CrossRef]

- Suzuki, A.; Ohta, K. Mechanical Properties of Poly (Ethylene Terephthalate) Nanofiber Three-dimensional Structure Prepared by CO2 Laser Supersonic Drawing. J. Appl. Polym. Sci. 2018, 135, 45763. [Google Scholar] [CrossRef]

- Suzuki, A.; Oshiro, Y. Preparation of Poly (Ethylene-2,6-Naphthalate) Nanofibers by CO2 Laser Supersonic Drawing. Polym. J. 2021, 53, 593–601. [Google Scholar] [CrossRef]

- Ueta, I.; Sekiguchi, N.; Suzuki, A.; Kobayashi, Y.; Kuwabara, T.; Saito, Y. Carbon Dioxide Laser Supersonic Drawing Nanofiber Sheet for Extraction of Polycyclic Aromatic Hydrocarbons in Water Samples. Chromatography 2020, 41, 85–89. [Google Scholar] [CrossRef]

- Koyama, H.; Watanabe, Y.; Suzuki, A. Preparation and Mechanical Properties of Poly (p-Phenylene Sulfide) Nanofiber Sheets Obtained by CO2 Laser Supersonic Multi-Drawing. J. Polym. Eng. 2017, 37, 53–60. [Google Scholar] [CrossRef]

- McCulloch, J.G. The History of the Development of Melt Blowing Technology. Int. Nonwovens J. 1999, 8, 139–149. [Google Scholar] [CrossRef]

- Rong, C.; Shen, B. Nanocrystalline and Nanocomposite Permanent Magnets by Melt Spinning Technique. Chin. Phys. B 2018, 27, 117502. [Google Scholar] [CrossRef]

- Schmidt, J.; Shenvi Usgaonkar, S.; Kumar, S.; Lozano, K.; Ellison, C.J. Advances in Melt Blowing Process Simulations. Ind. Eng. Chem. Res. 2021, 61, 65–85. [Google Scholar] [CrossRef]

- González-Sánchez, A.; Rosas-Macías, R.; Hernández-Bautista, J.E.; Valdez-Garza, J.A.; Rodríguez-Fuentes, N.; Soriano-Corral, F.; Ledezma-Pérez, A.S.; Ávila-Orta, C.A.; Cruz-Delgado, V.J. Antimicrobial Properties of Polyester/Copper Nanocomposites by Melt-Spinning and Melt-Blowing Techniques. Textiles 2023, 4, 1–16. [Google Scholar] [CrossRef]

- Ji, D.; Gao, Y.; Wang, W.; Feng, H.; Chen, K.; Xiao, C. Green Preparation of PVDF Hollow Fiber Membranes with Multiple Pore Structure via Melt Spinning Method for Oil/Water Separation. J. Environ. Chem. Eng. 2022, 10, 108337. [Google Scholar] [CrossRef]

- Qu, H.; Skorobogatiy, M. Conductive Polymer Yarns for Electronic Textiles. In Electronic Textiles; Elsevier: Amsterdam, The Netherlands, 2015; pp. 21–53. [Google Scholar]

- Daristotle, J.L.; Behrens, A.M.; Sandler, A.D.; Kofinas, P. A Review of the Fundamental Principles and Applications of Solution Blow Spinning. ACS Appl. Mater. Interfaces 2016, 8, 34951–34963. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, J.; Su, Y.; Wang, H.; Wang, X.-X.; Huang, L.-P.; Yu, M.; Ramakrishna, S.; Long, Y.-Z. Recent Progress and Challenges in Solution Blow Spinning. Mater. Horiz. 2021, 8, 426–446. [Google Scholar] [CrossRef] [PubMed]

- Medeiros, E.S.; Glenn, G.M.; Klamczynski, A.P.; Orts, W.J.; Mattoso, L.H.C. Solution Blow Spinning: A New Method to Produce Micro-and Nanofibers from Polymer Solutions. J. Appl. Polym. Sci. 2009, 113, 2322–2330. [Google Scholar] [CrossRef]

- Behrens, A.M.; Casey, B.J.; Sikorski, M.J.; Wu, K.L.; Tutak, W.; Sandler, A.D.; Kofinas, P. In Situ Deposition of PLGA Nanofibers via Solution Blow Spinning. ACS Macro Lett. 2014, 3, 249–254. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, N.; Han, S.; Jensen, M.; Li, X.; Zhang, X. Synthesis of Layered SnOX Nanostructure Composite Carbon Hybrid Nanofiber Mats by Blow-Spinning for High Performance Pseodocapacitors. Electrochim. Acta 2021, 383, 138240. [Google Scholar] [CrossRef]

- Du, Z.; Chen, Y.; Jensen, M.; Wang, N.; Li, X.; Zhang, X. Preparation of 3D Crimped ZnO/PAN Hybrid Nanofiber Mats with Photocatalytic Activity and Antibacterial Properties by Blow-spinning. J. Appl. Polym. Sci. 2021, 138, 49908. [Google Scholar] [CrossRef]

- Alinezhad Sardareh, E.; Shahzeidi, M.; Salmanifard Ardestani, M.T.; Mousavi-Khattat, M.; Zarepour, A.; Zarrabi, A. Antimicrobial Activity of Blow Spun PLA/Gelatin Nanofibers Containing Green Synthesized Silver Nanoparticles against Wound Infection-Causing Bacteria. Bioengineering 2022, 9, 518. [Google Scholar] [CrossRef]

- Rutledge, G.C.; Fridrikh, S.V. Formation of Fibers by Electrospinning. Adv. Drug Deliv. Rev. 2007, 59, 1384–1391. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A Fascinating Fiber Fabrication Technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef]

- Cooley, J.F. Apparatus for Electrically Dispersing Fluids. U.S. Patent No. 692,631A, 4 February 1902. [Google Scholar]

- Morton, W.J. Method of Dispersing Fluids. U.S. Patent No. 705,691A, 29 July 1902. [Google Scholar]

- Formhals, A. Method and Apparatus for the Production of Artificial Fibers. U.S. Patent No. 2,158,416A, 16 May 1939. [Google Scholar]

- Formhals, A. Artificial Fiber Construction. U.S. Patent No. 2,109,333A, 22 February 1938. [Google Scholar]

- Formhals, A. Process and Apparatus for Preparing Artificial Threads. U.S. Patent No. 1,975,504A, 2 October 1934. [Google Scholar]

- Subbiah, T.; Bhat, G.S.; Tock, R.W.; Parameswaran, S.; Ramkumar, S.S. Electrospinning of Nanofibers. J. Appl. Polym. Sci. 2005, 96, 557–569. [Google Scholar] [CrossRef]

- Teo, W.E.; Ramakrishna, S. A Review on Electrospinning Design and Nanofibre Assemblies. Nanotechnology 2006, 17, R89. [Google Scholar] [CrossRef]

- Gong, W.; Wang, M.-L.; Liu, Y.; Yu, D.-G.; Bligh, S.W.A. Shell Distribution of Vitamin K3 within Reinforced Electrospun Nanofibers for Improved Photo-Antibacterial Performance. Int. J. Mol. Sci. 2024, 25, 9556. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.; Gong, W.; Guo, Q.; Liu, H.; Yu, D.-G. Synergistic Effects of Radical Distributions of Soluble and Insoluble Polymers within Electrospun Nanofibers for an Extending Release of Ferulic Acid. Polymers 2024, 16, 2614. [Google Scholar] [CrossRef] [PubMed]

- Alshaya, H.A.; Alfahad, A.J.; Alsulaihem, F.M.; Aodah, A.H.; Alshehri, A.A.; Almughem, F.A.; Alfassam, H.A.; Aldossary, A.M.; Halwani, A.A.; Bukhary, H.A.; et al. Fast-Dissolving Nifedipine and Atorvastatin Calcium Electrospun Nanofibers as a Potential Buccal Delivery System. Pharmaceutics 2022, 14, 358. [Google Scholar] [CrossRef]

- Alharbi, A.R.; Alarifi, I.M.; Khan, W.S.; Asmatulu, R. Highly Hydrophilic Electrospun Polyacrylonitrile/Polyvinypyrrolidone Nanofibers Incorporated with Gentamicin as Filter Medium for Dam Water and Wastewater Treatment. J. Membr. Sep. Technol. 2016, 5, 38–56. [Google Scholar] [CrossRef]

- Oke, A.E.; Aliu, J.; Ebekozien, A.; Akinpelu, T.M.; Olatunde, T.M.; Ogunsanya, O.A. Strategic Drivers for the Deployment of Energy Economics Principles in the Developing Construction Industry: A Nigerian Perspective. Environ. Prog. Sustain. Energy 2024, 43, e14351. [Google Scholar] [CrossRef]

- Liu, X.; Yang, L.; Du, J.; Zhang, H.; Hu, J.; Chen, A.; Lv, W. Carbon and Air Pollutant Emissions Forecast of China’s Cement Industry from 2021 to 2035. Resour. Conserv. Recycl. 2024, 204, 107498. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Bani-Hani, K.A.; Malkawi, D.A.H.; Albatayneh, O. Suitability of Sustainable Sand for Concrete Manufacturing-A Complete Review of Recycled and Desert Sand Substitution. Results Eng. 2024, 23, 102478. [Google Scholar] [CrossRef]

- Raghav, M.; Park, T.; Yang, H.-M.; Lee, S.-Y.; Karthick, S.; Lee, H.-S. Review of the Effects of Supplementary Cementitious Materials and Chemical Additives on the Physical, Mechanical and Durability Properties of Hydraulic Concrete. Materials 2021, 14, 7270. [Google Scholar] [CrossRef]

- Zhang, P.; Li, X.; Guo, J.; Gao, Z. Fracture Properties of Cementitious Composites Containing Nano-Materials: A Comprehensive Review. Theor. Appl. Fract. Mech. 2024, 133, 104586. [Google Scholar] [CrossRef]

- Singh, L.P.; Goel, A.; Bhattachharyya, S.K.; Ahalawat, S.; Sharma, U.; Mishra, G. Effect of Morphology and Dispersibility of Silica Nanoparticles on the Mechanical Behaviour of Cement Mortar. Int. J. Concr. Struct. Mater. 2015, 9, 207–217. [Google Scholar] [CrossRef]

- Abdullah, G.M.S.; Chohan, I.M.; Ali, M.; Bheel, N.; Ahmad, M.; Najeh, T.; Gamil, Y.; Almujibah, H.R. Effect of Titanium Dioxide as Nanomaterials on Mechanical and Durability Properties of Rubberised Concrete by Applying RSM Modelling and Optimizations. Front. Mater. 2024, 11, 1357094. [Google Scholar] [CrossRef]

- Rahimzadeh, C.Y.; Barzinjy, A.A.; Mohammed, A.S.; Hamad, S.M. Green Synthesis of SiO2 Nanoparticles from Rhus Coriaria L. Extract: Comparison with Chemically Synthesized SiO2 Nanoparticles. PLoS ONE 2022, 17, e0268184. [Google Scholar] [CrossRef]

- Palla, R.; Karade, S.R.; Mishra, G.; Sharma, U.; Singh, L.P. High Strength Sustainable Concrete Using Silica Nanoparticles. Constr. Build. Mater. 2017, 138, 285–295. [Google Scholar] [CrossRef]

- Liu, J.; Li, Q.; Xu, S. Influence of Nanoparticles on Fluidity and Mechanical Properties of Cement Mortar. Constr. Build. Mater. 2015, 101, 892–901. [Google Scholar] [CrossRef]

- Niewiadomski, P.; Hoła, J.; Ćwirzeń, A. Study on Properties of Self-Compacting Concrete Modified with Nanoparticles. Arch. Civ. Mech. Eng. 2018, 18, 877–886. [Google Scholar] [CrossRef]

- Rattan, A.; Sachdeva, P.; Chaudhary, A. Use of Nanomaterials in Concrete. Int. J. Latest Res. Eng. Technol. 2016, 2, 81–84. [Google Scholar]

- Hawreen, A.; Bogas, J.A.; Kurda, R. Mechanical Characterization of Concrete Reinforced with Different Types of Carbon Nanotubes. Arab. J. Sci. Eng. 2019, 44, 8361–8376. [Google Scholar] [CrossRef]

- Wang, H.; Gao, X.; Liu, J.; Ren, M.; Lu, A. Multi-Functional Properties of Carbon Nanofiber Reinforced Reactive Powder Concrete. Constr. Build. Mater. 2018, 187, 699–707. [Google Scholar] [CrossRef]

- Fu, C.; Xie, C.; Liu, J.; Wei, X.; Wu, D. A Comparative Study on the Effects of Three Nano-Materials on the Properties of Cement-Based Composites. Materials 2020, 13, 857. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. Microstructural, Thermal, Physical and Mechanical Behavior of the Self Compacting Concrete Containing SiO2 Nanoparticles. Mater. Sci. Eng. A 2010, 527, 7663–7672. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S.; Riahi, S.; Shamekhi, S.F.; Khademno, A. Benefits of Fe2O3 Nanoparticles in Concrete Mixing Matrix. J. Am. Sci. 2010, 6, 102–106. [Google Scholar]

- Li, W.; Guo, Y.; Zhang, X.; Dong, W.; Li, X.; Yu, T.; Wang, K. Development of Self-Sensing Ultra-High-Performance Concrete Using Hybrid Carbon Black and Carbon Nanofibers. Cem. Concr. Compos. 2024, 148, 105466. [Google Scholar] [CrossRef]

- Zhang, J.; Zhuge, Y.; Liu, Y. Fracture Properties of Nanofiber Reinforced Cementitious Material: A Review. Case Stud. Constr. Mater. 2024, 20, e03371. [Google Scholar] [CrossRef]

- Rajendran, N.; Runge, T.; Bergman, R.D.; Nepal, P.; Nair, N.; Ashraf, W. Economic and Environmental Impact Analysis of Cellulose Nanofiber-Reinforced Concrete Mixture Production. Resour. Conserv. Recycl. 2025, 212, 107917. [Google Scholar] [CrossRef]

- Rezania, M.; Panahandeh, M.; Razavi, N.; Berto, F. Experimental Study of the Simultaneous Effect of Nano-Silica and Nano-Carbon Black on Permeability and Mechanical Properties of the Concrete. Theor. Appl. Fract. Mech. 2019, 104, 102391. [Google Scholar] [CrossRef]

- Ghoddousi, P.; Zareechian, M.; Javid, A.A.S.; Korayem, A.H. Microstructural Study and Surface Properties of Concrete Pavements Containing Nanoparticles. Constr. Build. Mater. 2020, 262, 120103. [Google Scholar] [CrossRef]

- Li, S.; Jiang, J.; Geng, Y.; Hu, J.; Sui, S.; Liu, A.; Hu, M.; Shan, Y.; Liu, Z. Application of Silane Protective Materials in the Concrete Durability Improvement in Recent Years: A Review. Eng. Fail. Anal. 2024, 160, 108140. [Google Scholar] [CrossRef]

- Nodehi, M.; Aguayo, F.; Madey, N.; Zhou, L. A Comparative Review of Polymer, Bacterial-Based, and Alkali-Activated (Also Geopolymer) Binders: Production, Mechanical, Durability, and Environmental Impacts (Life Cycle Assessment (LCA)). Constr. Build. Mater. 2024, 422, 135816. [Google Scholar] [CrossRef]

- Khan, S.A.; Amjad, H.; Ahmad, F.; Khan, H.A. A Scientometric Review Summarizing the Impact of Nanomaterials on the Fresh, Hardened, and Durability Properties of Cement-Based Materials. Adv. Civ. Eng. 2024, 2024, 8639483. [Google Scholar] [CrossRef]

- Zhang, M.; Xie, F.; Sun, Y.; Han, Y. Durability of Concrete with Nanoparticles under the Action of Both Cl− Penetration and Freeze–Thaw Cycles. J. Cold Reg. Eng. 2024, 38, 4023024. [Google Scholar] [CrossRef]

- Sridhar, R.; Aosai, P.; Imjai, T.; Setkit, M.; Shirkol, A.; Laory, I. Influence of Nanoparticles and PVA Fibers on Concrete and Mortar on Microstructural and Durability Properties. Fibers 2024, 12, 54. [Google Scholar] [CrossRef]

- Adebanjo, A.U.; Abbas, Y.M.; Shafiq, N.; Khan, M.I.; Farhan, S.A.; Masmoudi, R. Optimizing Nano-TiO2 and ZnO Integration in Silica-Based High-Performance Concrete: Mechanical, Durability, and Photocatalysis Insights for Sustainable Self-Cleaning Systems. Constr. Build. Mater. 2024, 446, 138038. [Google Scholar] [CrossRef]

- Yazdchi, M.; Foroughi Asl, A.; Talatahari, S.; Gandomi, A.H. Evaluation of the Mechanical Properties of Normal Concrete Containing Nano-MgO under Freeze–Thaw Conditions by Evolutionary Intelligence. Appl. Sci. 2021, 11, 2529. [Google Scholar] [CrossRef]

- Zhong, C.; Yu, Z.; Zhou, J.; Long, Y.; Tian, P.; Chen, J. Effect of Nano-TiO2 on Capillary Water Absorption of Recycled Aggregate Concrete. Coatings 2022, 12, 1833. [Google Scholar] [CrossRef]

- Zhang, A.; Yang, W.; Ge, Y.; Du, Y.; Liu, P. Effects of Nano-SiO2 and Nano-Al2O3 on Mechanical and Durability Properties of Cement-Based Materials: A Comparative Study. J. Build. Eng. 2021, 34, 101936. [Google Scholar] [CrossRef]

- Gamal, H.A.; El-Feky, M.S.; Alharbi, Y.R.; Abadel, A.A.; Kohail, M. Enhancement of the Concrete Durability with Hybrid Nano Materials. Sustainability 2021, 13, 1373. [Google Scholar] [CrossRef]

- Faried, A.S.; Mostafa, S.A.; Tayeh, B.A.; Tawfik, T.A. Mechanical and Durability Properties of Ultra-High Performance Concrete Incorporated with Various Nano Waste Materials under Different Curing Conditions. J. Build. Eng. 2021, 43, 102569. [Google Scholar] [CrossRef]

- Zaheer, M.M.; Hasan, S.D. Mechanical and Durability Performance of Carbon Nanotubes (CNTs) and Nanosilica (NS) Admixed Cement Mortar. Mater. Today Proc. 2021, 42, 1422–1431. [Google Scholar]

- Liu, C.; Su, X.; Wu, Y.; Zheng, Z.; Yang, B.; Luo, Y.; Yang, J.; Yang, J. Effect of Nano-Silica as Cementitious Materials-Reducing Admixtures on the Workability, Mechanical Properties and Durability of Concrete. Nanotechnol. Rev. 2021, 10, 1395–1409. [Google Scholar] [CrossRef]

- Saliani, M.; Honarbakhsh, A.; Zhiani, R.; Movahedifar, S.M.; Motavalizadehkakhky, A. Effects of GO/Al2O3 and Al2O3 Nanoparticles on Concrete Durability against High Temperature, Freeze-thaw Cycles, and Acidic Environments. Adv. Civ. Eng. 2021, 2021, 4555802. [Google Scholar] [CrossRef]

- Mostafa, F.E.-Z.M.; Smarzewski, P.; El Hafez, G.M.A.; Farghali, A.A.; Morsi, W.M.; Faried, A.S.; Tawfik, T.A. Analyzing the Effects of Nano-Titanium Dioxide and Nano-Zinc Oxide Nanoparticles on the Mechanical and Durability Properties of Self-Cleaning Concrete. Materials 2023, 16, 6909. [Google Scholar] [CrossRef] [PubMed]

- Bheel, N.; Mohammed, B.S.; Liew, M.S.; Zawawi, N.A.W.A. Effect of Graphene Oxide as a Nanomaterial on the Durability Behaviors of Engineered Cementitious Composites by Applying RSM Modelling and Optimization. Buildings 2023, 13, 2026. [Google Scholar] [CrossRef]

- Qureshi, T.; Ootim, S. Multifunctional Concrete with Graphene-Based Nanomaterials and Superabsorbent Polymer. J. Mater. Civ. Eng. 2023, 35, 4023046. [Google Scholar] [CrossRef]

- Antolín-Rodríguez, A.; Merino-Maldonado, D.; González-Domínguez, J.M.; Fernández-Raga, M.; Morán-del Pozo, J.M.; García-González, J.; Juan-Valdés, A. Performance of Graphene Oxide as a Water-Repellent Coating Nanomaterial to Extend the Service Life of Concrete Structures. Heliyon 2024, 10, e23969. [Google Scholar] [CrossRef]

- Zhou, B.; Ma, Y.; Sha, S.; Wang, Y.; Liu, Y.; Xiao, Y.; Shi, C. Synthesis, Performance and Mechanism of Shrinkage-Reducing Agents with Water-Reducing Function for Cement-Based Materials. Constr. Build. Mater. 2024, 425, 135994. [Google Scholar] [CrossRef]

- Ge, H.; Sun, Z.; Lu, Z.; Yang, H.; Zhang, T.; He, N. Influence and Mechanism Analysis of Different Types of Water Reducing Agents on Volume Shrinkage of Cement Mortar. J. Build. Eng. 2024, 82, 108204. [Google Scholar] [CrossRef]

- Jiang, L.; Wu, M.; Du, F.; Chen, D.; Xiao, L.; Chen, W.; Du, W.; Ding, Q. State-of-the-Art Review of Microcapsule Self-Repairing Concrete: Principles, Applications, Test Methods, Prospects. Polymers 2024, 16, 3165. [Google Scholar] [CrossRef]

- Zhang, J.; Shen, C.; Diao, G. Application and Microstructure Properties of Nanomaterials in New Concrete Materials. J. Nanomater. 2022, 2022, 7396295. [Google Scholar] [CrossRef]

- Ikhlasi, Z.; Gholampour, A.; Vincent, T. Drying Shrinkage of Waste-Based Concrete Reinforced with Pristine Graphene (PRG) Nanomaterial. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Wang, J.; Cheng, Y.; Yuan, L.; Xu, D.; Du, P.; Hou, P.; Zhou, Z.; Cheng, X.; Liu, S.; Wang, Y. Effect of Nano-Silica on Chemical and Volume Shrinkage of Cement-Based Composites. Constr. Build. Mater. 2020, 247, 118529. [Google Scholar] [CrossRef]

- Hong, X.; Lee, J.C.; Ng, J.L.; Abdulkareem, M.; Yusof, Z.M.; Li, Q.; He, Q. Prediction Model and Mechanism for Drying Shrinkage of High-Strength Lightweight Concrete with Graphene Oxide. Nanomaterials 2023, 13, 1405. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Bheel, N.; Zardari, S.; Alraeeini, A.S.; Almaliki, A.H.; Benjeddou, O. Effect of Graphene Oxide on Mechanical, Deformation and Drying Shrinkage Properties of Concrete Reinforced with Fly Ash as Cementitious Material by Using RSM Modelling. Sci. Rep. 2024, 14, 18675. [Google Scholar] [CrossRef] [PubMed]

- Hua, Y.; Wang, G.; Liu, F.; Huang, B.; Zhu, M.; Qu, F. Investigation on Strength, Drying Shrinkage and Photocatalytic Efficiency of TiO2 Cement Composite Mortar by the Layered Method. KSCE J. Civ. Eng. 2025, 100198. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, G.; Yun, W.; Li, J.; Xie, J.; Wu, W.; Deng, Z. Combined Impact of Nano-SiO2 and Superabsorbent Polymers on Early-Age Concrete Engineering Properties for Water-Related Structures. Buildings 2025, 15, 374. [Google Scholar] [CrossRef]

- Jing, Y.; Lee, J.C.; Moon, W.C.; Ng, J.L.; Yew, M.K.; Jin, Y. Durability and Environmental Evaluation of Rice Husk Ash Sustainable Concrete Containing Carbon Nanotubes. Sci. Rep. 2025, 15, 4352. [Google Scholar] [CrossRef] [PubMed]

- Park, K.-Y.; Lee, T.; Wang, W.; Li, H.; Chen, F. High-Performance Ruddlesden–Popper Perovskite Oxide with in Situ Exsolved Nanoparticles for Direct CO2 Electrolysis. J. Mater. Chem. A 2023, 11, 21354–21364. [Google Scholar] [CrossRef]

- Khaiyum, M.Z.; Sarker, S.; Kabir, G. Evaluation of Carbon Emission Factors in the Cement Industry: An Emerging Economy Context. Sustainability 2023, 15, 15407. [Google Scholar] [CrossRef]

- Hanifa, M.; Agarwal, R.; Sharma, U.; Thapliyal, P.C.; Singh, L.P. A Review on CO2 Capture and Sequestration in the Construction Industry: Emerging Approaches and Commercialised Technologies. J. CO2 Util. 2023, 67, 102292. [Google Scholar] [CrossRef]

- Singh, N.B. Clays and Clay Minerals in the Construction Industry. Minerals 2022, 12, 301. [Google Scholar] [CrossRef]

- Wang, D.; Lu, C.; Zhu, Z.; Zhang, Z.; Liu, S.; Ji, Y.; Xing, Z. Mechanical Performance of Recycled Aggregate Concrete in Green Civil Engineering. Case Stud. Constr. Mater. 2023, 19, e02384. [Google Scholar] [CrossRef]

- Wang, C.; Du, Z. Microscopic Interface Deterioration Mechanism and Damage Behavior of High-Toughness Recycled Aggregate Concrete Based on 4D in-Situ CT Experiments. Cem. Concr. Compos. 2024, 153, 105720. [Google Scholar] [CrossRef]

- Xiao, J.; Tang, Y.; Chen, H.; Zhang, H.; Xia, B. Effects of Recycled Aggregate Combinations and Recycled Powder Contents on Fracture Behavior of Fully Recycled Aggregate Concrete. J. Clean. Prod. 2022, 366, 132895. [Google Scholar] [CrossRef]

- Zhang, H.; Xiao, J.; Tang, Y.; Duan, Z.; Poon, C. Long-Term Shrinkage and Mechanical Properties of Fully Recycled Aggregate Concrete: Testing and Modelling. Cem. Concr. Compos. 2022, 130, 104527. [Google Scholar] [CrossRef]

- Sabău, M.; Remolina Duran, J. Prediction of Compressive Strength of General-Use Concrete Mixes with Recycled Concrete Aggregate. Int. J. Pavement Res. Technol. 2022, 15, 73–85. [Google Scholar] [CrossRef]

- Kishore, K.; Pandey, A.; Wagri, N.K.; Saxena, A.; Patel, J.; Al-Fakih, A. Technological Challenges in Nanoparticle-Modified Geopolymer Concrete: A Comprehensive Review on Nanomaterial Dispersion, Characterization Techniques and Its Mechanical Properties. Case Stud. Constr. Mater. 2023, 19, e02265. [Google Scholar] [CrossRef]

- Saleem, H.; Zaidi, S.J.; Alnuaimi, N.A. Recent Advancements in the Nanomaterial Application in Concrete and Its Ecological Impact. Materials 2021, 14, 6387. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Wang, L.; Wei, H.; Wang, J. A Critical Review on Effect of Nanomaterials on Workability and Mechanical Properties of High-performance Concrete. Adv. Civ. Eng. 2021, 2021, 8827124. [Google Scholar] [CrossRef]

- Chinchillas-Chinchillas, M.J.; Cortez-Rodríguez, H.; Fajardo-San Miguel, G.J.; Pellegrini-Cervantes, M.J.; Rodriguez-Rodriguez, M.; Corral-Higuera, R.; Arredondo-Rea, S.P.; Gaxiola, A.; Castro-Beltrán, A. Recycled Cement Mortars Reinforced with PVDF Nanofibers Synthesized by Electrospinning. J. Build. Eng. 2024, 86, 108663. [Google Scholar] [CrossRef]

- Deng, F.; Cao, C.; Chi, Y.; Xu, L. Effect of Cellulose Nanofiber Addition on the Microstructure Characterization and Nano-Mechanical Behavior of Interfacial Transition Zones in Recycled Concrete. J. Mater. Res. Technol. 2024, 33, 7572–7585. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J.; Jweihan, Y.S.; Rabi, M.; Ghaffar, S.H. Durability Enhancement of Concrete with Recycled Concrete Aggregate: The Role of Nano-ZnO. Buildings 2024, 14, 353. [Google Scholar] [CrossRef]

- Amin, M.; Hakeem, I.Y.; Zeyad, A.M.; Tayeh, B.A.; Maglad, A.M.; Agwa, I.S. Influence of Recycled Aggregates and Carbon Nanofibres on Properties of Ultra-High-Performance Concrete under Elevated Temperatures. Case Stud. Constr. Mater. 2022, 16, e01063. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, B.; Xie, J.; Xue, Z.; Huang, K.; Tan, J. Effects of Recycled Sand and Nanomaterials on Ultra-High Performance Concrete: Workability, Compressive Strength and Microstructure. Constr. Build. Mater. 2023, 378, 131180. [Google Scholar] [CrossRef]

- Ting, W.; Qingshan, W.; Shenao, C.U.I.; Haihe, Y.I.; Tian, S.U.; Zhenyu, T.A.N. Effects of Nanomaterials Reinforced Aggregate on Mechanical Properties and Microstructure of Recycled Brick Aggregate Concrete. Mater. Sci. 2023, 29, 347–355. [Google Scholar]

- Luo, J.; Wang, S.; Quan, X.; Xu, J.; Li, J.; Liu, K.; Xu, F.; Hong, Z. Nano-SiO2 Recycled Concrete Anti-Sulfate Performance and Damage Mechanism Research. Buildings 2023, 13, 1429. [Google Scholar] [CrossRef]

- Fan, C.; Zheng, Y.; Zhuo, J.; Du, C.; Hu, S. Study on Mechanical and Bonding Properties of Nano-SiO2 Reinforced Recycled Concrete: Macro Test and Micro Analysis. J. Build. Eng. 2024, 94, 109877. [Google Scholar] [CrossRef]

- Gholampour, A.; Sofi, M.; Alipooramirabad, H.; Tang, Y. Performance of Concrete Containing Pristine Graphene-Treated Recycled Concrete Aggregates. Resour. Conserv. Recycl. 2023, 199, 107266. [Google Scholar] [CrossRef]

- Allujami, H.M.; Abdulkareem, M.; Jassam, T.M.; Al-Mansob, R.A.; Ibrahim, A.; Ng, J.L.; Yam, H.C. Mechanical Properties of Concrete Containing Recycle Concrete Aggregates and Multi-Walled Carbon Nanotubes under Static and Dynamic Stresses. Case Stud. Constr. Mater. 2022, 17, e01651. [Google Scholar] [CrossRef]

| Classification Parameter | Classification | Examples |

|---|---|---|

| Dimension | 0D | Nanoparticles |

| 1D | Nanofibers, nanotubes | |

| 2D | Graphene, phosphorene | |

| 3D | Bulk solids, Nanostructures films | |

| Phase composition | Single-phase solids | Sigle metal or oxide nanoparticles |

| Multi-phase solids | Core shell | |

| Origin | Engineered | “Top–down” and “bottom–up” methods |

| Incidental | Storm, cosmic dust, volcanic activity | |

| Natural | Micro and higher organisms | |

| Composition | Carbonaceous | All allotropic forms |

| Organic | Molecular self-assembled | |

| Inorganic | Metal nanoparticles, QD | |

| Composites | Bimetallic, core–shell | |

| Dispersion | Dispersed nanomaterials | Isometric, inhomogeneous |

| Aggregated nanomaterials | Isometric, inhomogeneous |

| Year | Nanomaterial | Test | Results | Reference |

|---|---|---|---|---|

| 2021 | Al2O3 NPs (3%) in concrete | Resistance ion Cl− | +14.5% | [156] |

| 2021 | SiO2 NPs (0.5%) in concrete | Electrical resistivity | +61.5% | [156] |

| 2021 | Al2O3 NPs (1%) in concrete | Water absorption | −6% | [156] |

| 2021 | Carbon nanotubes (0.01%) + Nano clay (5%) in concrete | Water penetration test | +150% | [157] |

| 2021 | Carbon Nanotubes (0.01%) in concrete | Resistance ion Cl− | +82.3% | [157] |

| 2021 | SiO2 NPs (1%) in concrete | Sorptivity | −84.8% | [158] |

| 2021 | SiO2 NPs (1%) + Carbon Nanotubes (0.3%) in mortar | Length expansion | −14.3% | [159] |

| 2021 | SiO2 NPs (1%) + Carbon Nanotubes (0.3%) in mortar | Abrasion | −29.2% | [159] |

| 2021 | SiO2 NPs (1%) + Carbon Nanotubes (0.3%) in mortar | Resistivity | +5.1% | [159] |

| 2021 | SiO2 NPs (1%) + Carbon Nanotubes (0.3%) in mortar | Ultrasonic pulse velocity | +25% | [159] |

| 2021 | SiO2 NPs (2%) in concrete | Resistance ion Cl− | −14.7% | [160] |

| 2021 | GO + Al2O3 NPs (2%) | Compressive strength under freeze–thaw | −10.8% | [161] |

| 2021 | Al2O3 NPs (2%) | Compressive strength under freeze–thaw | −12.9% | [161] |

| 2023 | TiO2 NPs (2.5%) in concrete | Corrosion rate (6 months) | −86.5% | [162] |

| 2023 | PVA fibers (2%) + Graphene Oxide NPs (0.05%) in mortar | pH test | −8.3% | [163] |

| 2023 | PVA fibers (2%) + Graphene Oxide NPs (0.05%) in mortar | Resistance ion Cl− | −17.3% | [163] |

| 2023 | Graphene nanoplatelet (0.05%) + Sodium polyacrylate (0.11%) | Chloride ion penetration depth under freeze–thaw | −42% | [164] |

| 2024 | Al2O3 NPs (1%) + PVA fibers (0.3%) in mortar | Resistance ion Cl− | −35.9% | [152] |

| 2024 | Graphene oxide NPs (Surface treatment with 31.5 µg cm−2) in concrete | Water absorption by capillary action. | −21.4% | [165] |

| 2024 | Graphene oxide NPs (Surface treatment with 31.5 µg cm−2) in concrete | Water absorption by immersion. | −41.8% | [165] |

| 2024 | TiO2 NPs (2%) + Crumb rubber aggregate (10%) in concrete | Sorptivity | −25.5% | [132] |

| 2024 | TiO2 NPs (2%) + Crumb rubber aggregate (10%) in concrete | Apparent Porosity | −37.8% | [132] |

| Year | Nanomaterial (%) | Test | Results | Reference |

|---|---|---|---|---|

| 2020 | SiO2 NPs (1.2%) in cement paste | Chemical shrinkage | +57.5% | [171] |

| 2021 | SiO2 NPs (3%) in concrete | Drying | +13.3% | [156] |

| 2022 | SiO2 NPs (0.4%) in cement paste | Chemical Shrinkage | +3.5% | [169] |

| 2023 | Pristine Graphene NPs (0.1%) in concrete | Drying shrinkage | −66% | [170] |

| 2023 | Graphene oxide NPs (0.01%) in concrete | Drying shrinkage | +1.3% | [172] |

| 2024 | Graphene oxide NPs (0.08%) + fly ash (15%) in concrete | Drying shrinkage | −45.7% | [173] |

| 2024 | TiO2 NPs (2%) + Crumb rubber aggregate (10%) in concrete | Drying shrinkage | +12.5% | [132] |

| 2025 | TiO2 NPs (8%) in mortar | Drying shrinkage | +68.18% | [174] |

| 2025 | SiO2 NPs (1.5%) in concrete | Autogenous shrinkage | +37.87% | [175] |

| 2025 | Carbon nanotubes (0.2%) + Rice husk ash (15%) in concrete | Drying shrinkage | −5.04% | [176] |

| Year | Nanomaterial (%) | Recycled Aggregate | Test | Results | Reference |

|---|---|---|---|---|---|

| 2022 | Carbon NFs (0.25%) + Steel Fibers (2%) in concrete | Recycled coarse aggregate (100%) | Compressive strength | Increase 23.1%, but decrease workability | [192] |

| 2024 | PVDF NFs (0.1%) in mortar | Recycled fine aggregate (25%) | Compressive strength | Increase 12% | [189] |

| 2024 | PVDF NFs (0.1%) in mortar | Recycled fine aggregate (25%) | Flexural strength | Increase 23% | [189] |

| 2024 | PVDF NFs (0.1%) in mortar | Recycled fine aggregate (25%) | Porosity | Decrease 3% | [189] |

| 2024 | PVDF NFs (0.1%) in mortar | Recycled fine aggregate (25%) | Chloride ion permeability | Increase 20% | [189] |

| 2023 | SiO2 NPs (1%) in concrete | Recycled fine aggregate (25%) | Compressive strength | Increase 14% | [193] |

| 2023 | Al2O3 NPs (1%) in concrete | Brick aggregate (30%) | Water absorption | Decrease 24.2% | [194] |

| 2023 | SiO2 NPs (1%) in concrete | Brick aggregate (30%) | Water absorption | Decrease 27.9% | [194] |

| 2023 | Al2O3 NPs (2%) in concrete | Brick aggregate (30%) | Compressive strength | Increase 43.4% | [194] |

| 2023 | SiO2 NPs (2%) in concrete | Brick aggregate (30%) | Compressive strength | Increase 33.1% | [194] |

| 2023 | SiO2 NPs (4%) in concrete | Recycled coarse aggregate (30%) | Dry wet cycle | Decrease 9.4% | [195] |

| 2024 | SiO2 NPs (3%) in concrete | Recycled coarse aggregate (100%) | Compressive strength | Increase 20.6% | [196] |

| 2024 | SiO2 NPs (3%) in concrete | Recycled coarse aggregate (100%) | Split Tensile Strength | Increase 23.8% | [196] |

| 2024 | SiO2 NPs (3%) in concrete | Recycled coarse aggregate (100%) | Bond Strength | Increase 20.92% | [196] |

| 2022 | TiO2 NPs (1.2%) in concrete | Recycled coarse aggregate (25%) | Freeze–thaw | Decrease 25.52% water absorption and 14.57% porosity | [155] |

| 2024 | TiO2 NPs (2%) in concrete | Crumb rubber concrete (10%) | Sorptivity | Decrease 25.5% | [132] |

| 2024 | TiO2 NPs (2%) in concrete | Crumb rubber concrete (10%) | Apparent Porosity | Decrease 37.8% | [132] |

| 2023 | Pristine graphene (0.2%) in concrete | Recycled coarse aggregate (50%) | Workability | Increase 13% | [197] |

| 2023 | Pristine graphene (0.2%) in concrete | Recycled coarse aggregate (50%) | Compressive strength | Increase 21% | [197] |

| 2023 | Pristine graphene (0.2%) in concrete | Recycled coarse aggregate (50%) | Tensile strength | Increase 12% | [197] |

| 2023 | Pristine graphene (0.2%) in concrete | Recycled coarse aggregate (50%) | Water absorption | Decrease 22% | [197] |

| 2023 | Pristine graphene (0.2%) in concrete | Recycled coarse aggregate (50%) | Drying shrinkage | Decrease 20% | [197] |

| 2022 | Carbon NTs (0.1%) in concrete | Recycled coarse aggregate (50%) | Compressive strength | Increase 46.7% | [198] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montes Rubio, T.; Rosas Casarez, C.A.; Orozco Carmona, V.M.; Ahumada Cervantes, R.; Luna Valenzuela, A.; Cervantes Rosas, M.d.l.A.; Chinchillas Chinchillas, M.d.J. Performance of Nanotechnology in Cementitious Materials: Synthesis and Application. Materials 2025, 18, 2171. https://doi.org/10.3390/ma18102171

Montes Rubio T, Rosas Casarez CA, Orozco Carmona VM, Ahumada Cervantes R, Luna Valenzuela A, Cervantes Rosas MdlA, Chinchillas Chinchillas MdJ. Performance of Nanotechnology in Cementitious Materials: Synthesis and Application. Materials. 2025; 18(10):2171. https://doi.org/10.3390/ma18102171

Chicago/Turabian StyleMontes Rubio, Thalia, Carlos Antonio Rosas Casarez, Victor Manuel Orozco Carmona, Ramiro Ahumada Cervantes, Analila Luna Valenzuela, Maria de los Angeles Cervantes Rosas, and Manuel de Jesus Chinchillas Chinchillas. 2025. "Performance of Nanotechnology in Cementitious Materials: Synthesis and Application" Materials 18, no. 10: 2171. https://doi.org/10.3390/ma18102171

APA StyleMontes Rubio, T., Rosas Casarez, C. A., Orozco Carmona, V. M., Ahumada Cervantes, R., Luna Valenzuela, A., Cervantes Rosas, M. d. l. A., & Chinchillas Chinchillas, M. d. J. (2025). Performance of Nanotechnology in Cementitious Materials: Synthesis and Application. Materials, 18(10), 2171. https://doi.org/10.3390/ma18102171