Tribomechanical Properties of Glazes for Ceramic Tiles: A Novel Protocol for Their Characterization

Abstract

1. Introduction

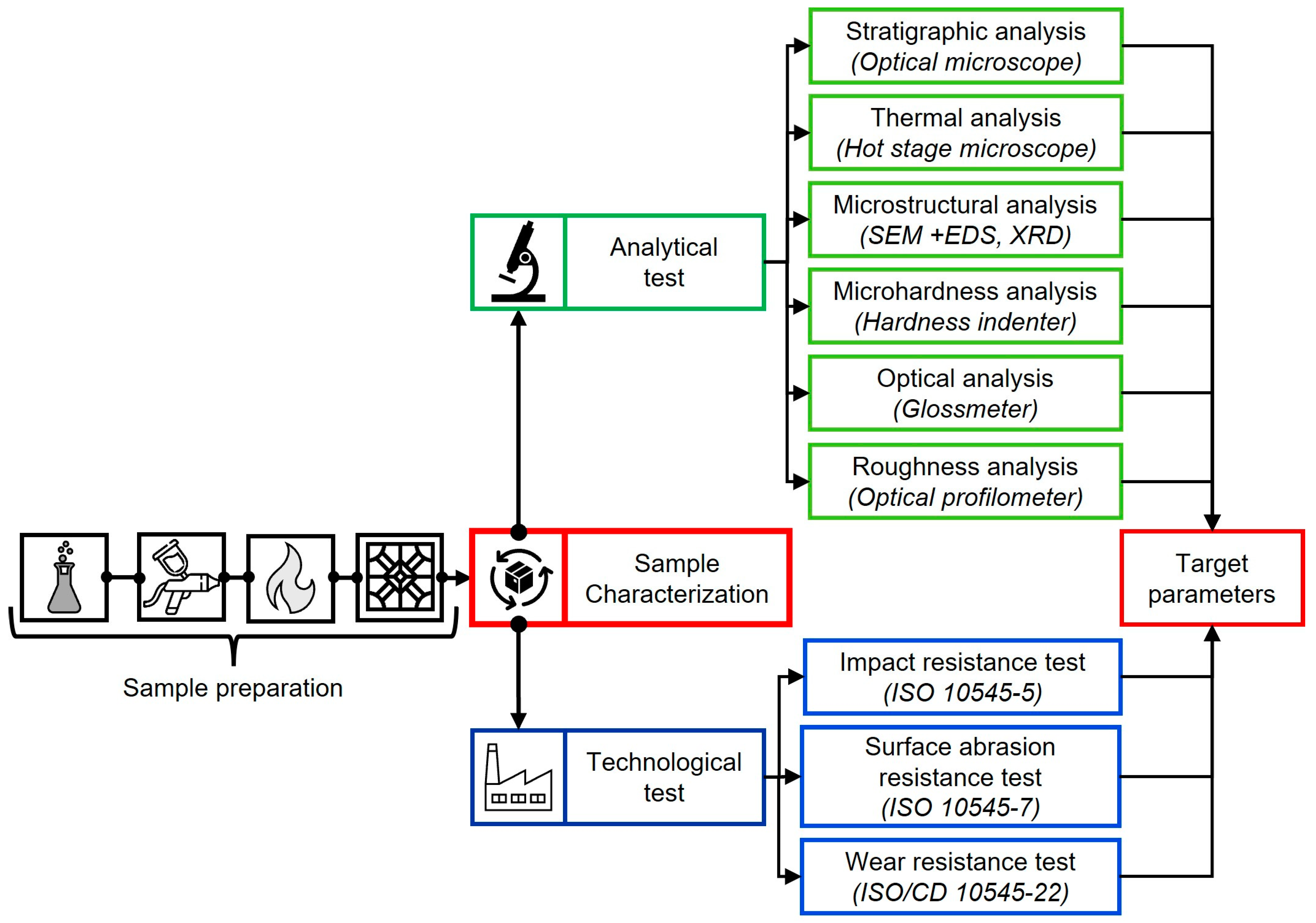

2. Glaze Characterization Protocol (GCP) Design

3. Materials and Methods

3.1. Glazes and Samples Preparation

3.2. Characterization Methods

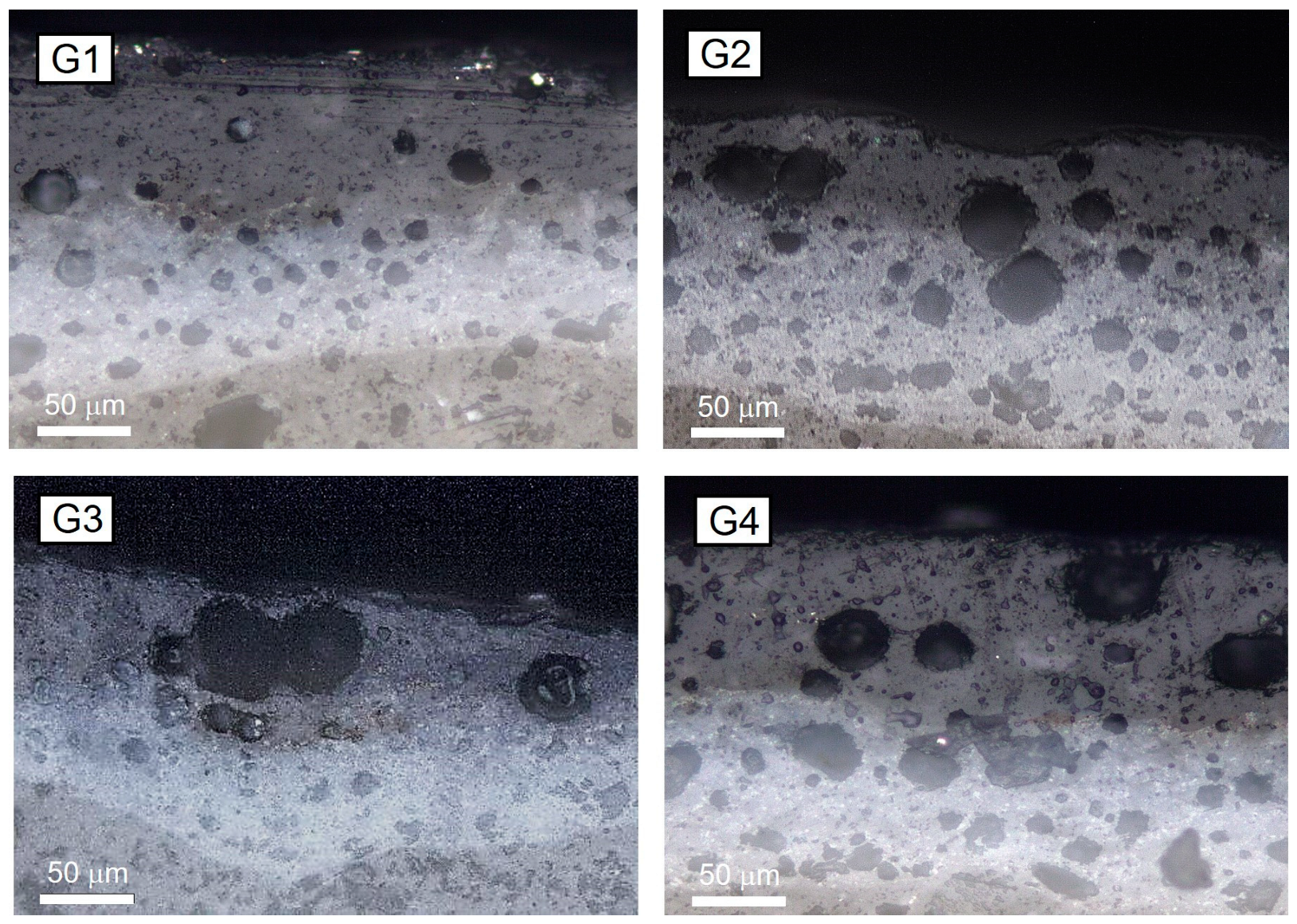

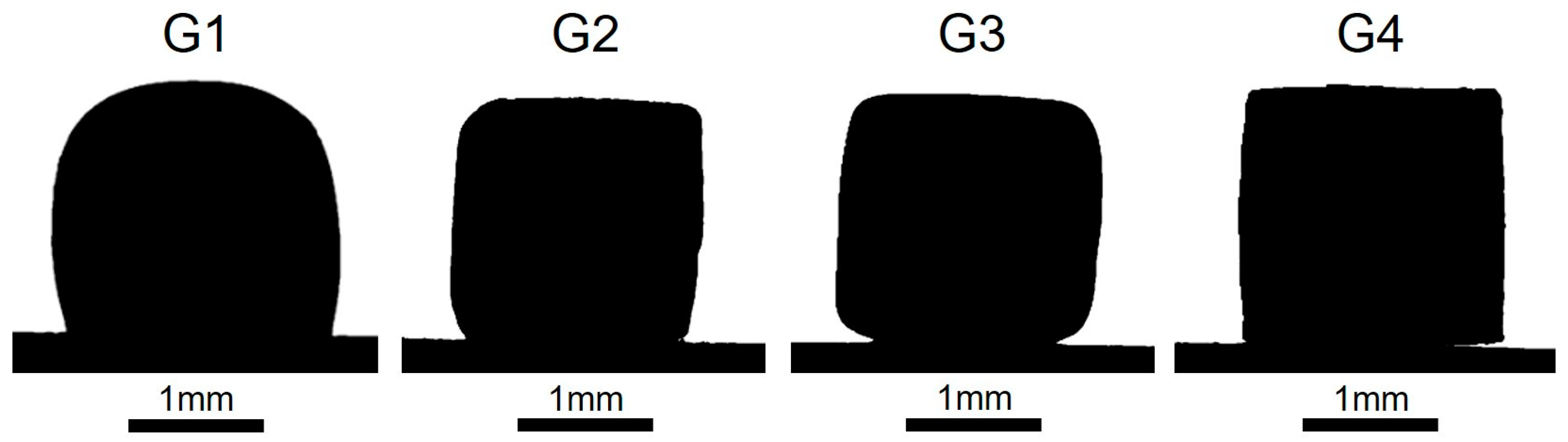

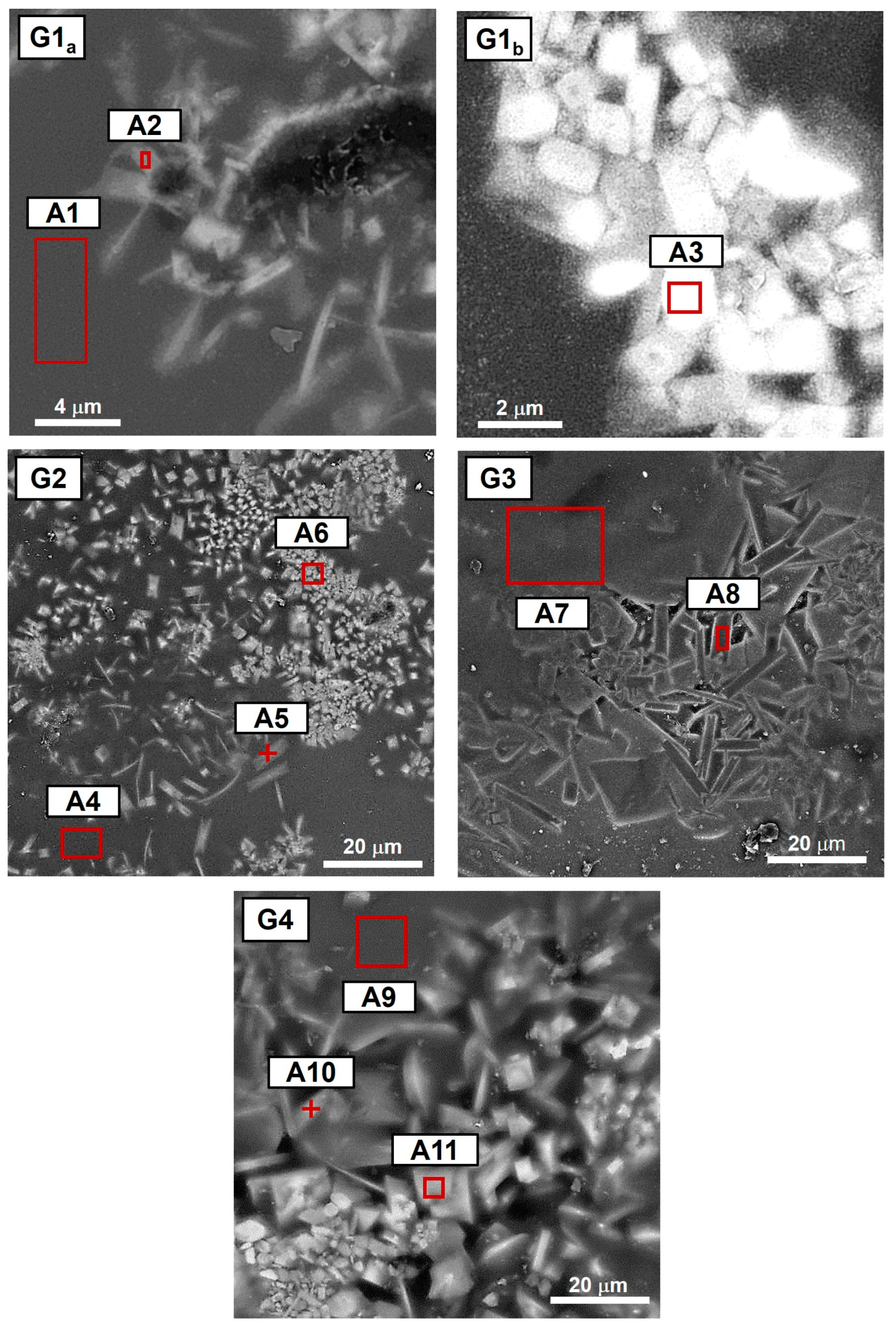

4. Results and Discussion

5. Conclusions

- ⮚

- Analytical tests provide fundamental information that is strongly related with the chemical composition of the glaze and the crystalline phases formed during firing. A complete microstructural analysis involving the techniques listed in the protocol allows for the determination of characteristics that are strongly connected to the nature, shape, and distribution of the crystalline phases;

- ⮚

- Technological tests give different results, as some of them (e.g., impact resistance and surface abrasion resistance tests) are not able to differentiate between the investigated glazes, whereas others, such as the combination of tests present in the wear resistance test, seem very effective in highlighting the difference between the various surface properties of the glazes;

- ⮚

- A good correlation between the analytical tests and wear resistance test has been found, highlighting that for ceramic tile glaze formulation purposes, all these tests can be largely adopted.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barrachina, E.; Esquinas, M.; Llop, J.; Notari, M.D.; Carda, J.B. Development of a glass-ceramic glaze formulated from industrial residues to improve the mechanical properties of the porcelain stoneware tiles. Mater. Lett. 2018, 220, 226–228. [Google Scholar] [CrossRef]

- Boschi, G.; Masi, G.; Bonvicini, G.; Bignozzi, M.C. Sustainability in Italian ceramic tile production: Evaluation of the environmental impact. Appl. Sci. 2020, 10, 9063. [Google Scholar] [CrossRef]

- Boschi, G.; Bonvicini, G.; Masi, G.; Bignozzi, M.C. Recycling insight into the ceramic tile manufacturing industry. Open Ceram. 2023, 16, 100471. [Google Scholar] [CrossRef]

- Vieira, A.W.; Rosso, L.S.; Demarch, A.; Pasini, D.; Ruzza, S.P.; Arcaro, S.; Ribeiro, M.J.; Angioletto, E. Life cycle assessment in the ceramic tile industry: A review. J. Mater. Res. Technol. 2023, 23, 3904–3915. [Google Scholar] [CrossRef]

- Casasola, R.; Rincón, J.M.; Romero, M. Glass-ceramic glazes for ceramic tiles: A review. J. Mater. Sci. 2012, 47, 553–582. [Google Scholar] [CrossRef]

- Romero, M.; Pérez, J.M. Relation between the microstructure and technological properties of porcelain stoneware: A review. Mater. Constr. 2015, 65. [Google Scholar] [CrossRef]

- Sánchez, E.; García-Ten, J.; Sanz, V.; Moreno, A. Porcelain tile: Almost 30 years of steady scientific-technological evolution. Ceram. Int. 2010, 36, 831–845. [Google Scholar] [CrossRef]

- Ghosh, S.; Pal, K.S.; Dandapat, N.; Ghosh, J.; Datta, S. Glass-ceramic glazes for future generation floor tiles. J. Eur. Ceram. Soc. 2013, 33, 935–942. [Google Scholar] [CrossRef]

- Yekta, B.E.; Alizadeh, P.; Rezazadeh, L. Floor tile glass-ceramic glaze for improvement of glaze surface properties. J. Eur. Ceram. Soc. 2006, 26, 3809–3812. [Google Scholar] [CrossRef]

- Da Cunha, T.B.; Wu, J.P.; Peitl, O.; Fokin, V.M.; Zanotto, E.D.; Iannucci, L.; Boccaccini, A.R. Mechanical properties and impact resistance of a new transparent glass-ceramic. Adv. Eng. Mater. 2007, 9, 191–196. [Google Scholar] [CrossRef]

- Gajek, M.; Rapacz-Kmita, A.; Stodolak-Zych, E.; Zarzecka-Napierała, M.; Wilk, M.; Magdziarz, A.; Dudek, M. Microstructure and mechanical properties of diopside and anorthite glazes with high abrasion resistance. Ceram. Int. 2022, 48, 6792–6798. [Google Scholar] [CrossRef]

- Yu, Y.; Su, H.; Xiao, J.; Yuan, F.; Gu, X.; Peng, C.; Wu, J. Study of a quantitative method to evaluate the wear resistance of glazed tiles. Int. J. Appl. Ceram. Technol. 2020, 17, 1063–1070. [Google Scholar] [CrossRef]

- Rossi, S.; Russo, F.; Calovi, M. Durability of vitreous enamel coatings and their resistance to abrasion, chemicals, and corrosion: A review. J. Coat. Technol. Res. 2021, 18, 39–52. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.; Wang, C.; Bai, M.; Zhou, X.; Zhang, X.; Wang, Y. Anorthite-based transparent glass-ceramic glaze for ceramic tiles: Preparation and crystallization mechanism. J. Eur. Ceram. Soc. 2022, 42, 1132–1140. [Google Scholar] [CrossRef]

- Pasiut, K.; Partyka, J.; Lesniak, M.; Jelen, P.; Olejniczak, Z. Raw glass-ceramics glazes from SiO2–Al2O3–CaO–MgO–Na2O–K2O system modified by ZrO2 addition—Changes of structure, microstructure and surface properties. Open Ceram. 2021, 8, 100188. [Google Scholar] [CrossRef]

- Altindal, F.; Anil, U.E.; Varisli, S.O.; Ozturk, B. Investigation of the effect of BaO–Al2O3 variations for BAS glass-ceramic glaze: Insights into thermal, phase, microstructural and surface features. J. Eur. Ceram. Soc. 2024, 44, 3200–3209. [Google Scholar] [CrossRef]

- Cannillo, V.; Esposito, L.; Rambaldi, E.; Sola, A.; Tucci, A. Microstructural and mechanical changes by chemical ageing of glazed ceramic surfaces. J. Eur. Ceram. Soc. 2009, 29, 1561–1569. [Google Scholar] [CrossRef]

- Deubener, J.; Allix, M.; Davis, M.J.; Duran, A.; Höche, T.; Honma, T.; Komatsu, T.; Krüger, S.; Mitra, I.; Müller, R.; et al. Updated definition of glass-ceramics. J. Non-Cryst. Solids 2018, 501, 3–10. [Google Scholar] [CrossRef]

- Gajek, M.; Partyka, J.; Rapacz-Kmita, A.; Gasek, K. Development of anorthite based white porcelain glaze without ZrSiO4 content. Ceram. Int. 2017, 43, 1703–1709. [Google Scholar] [CrossRef]

- Pradell, T.; Molera, J. Ceramic technology. How to characterise ceramic glazes. Archaeol. Anthropol. Sci. 2020, 12, 189. [Google Scholar] [CrossRef]

- Cedillo-González, E.I.; Chierici, P.; Buttazzo, M.; Siligardi, C.; Blasi, E.; Ardizzoni, A. Correlating the physico-chemical properties of two conventional glazed porcelain stoneware tiles in relation to cleanability and sanitization. Mater. Today Commun. 2023, 34, 105191. [Google Scholar] [CrossRef]

- ISO 13006:2018; Ceramic Tiles—Definitions, Classification, Characteristics and Marking. International Organization for Standardization: Geneva, Switzerland, 2018.

- EN 14411:2016; Ceramic Tiles—Definition, Classification, Characteristics, Assessment and Verification of Constancy of Performance and Marking. European Committee for Standardization: Brussels, Belgium, 2016.

- Dondi, M.; Guarini, G.; Melandri, C.; Raimondo, M.; Zanelli, C. Resistance to impact of porcelain stoneware tiles. Ceram. Int. 2016, 42, 5731–5736. [Google Scholar] [CrossRef]

- Enríquez, E.; Fuertes, V.; Cabrera, M.J.; Seores, J.; Muñoz, D.; Fernández, J.F. Absence of surface flaking in hierarchical glass-ceramic coating: High impact resistant ceramic tiles. J. Eur. Ceram. Soc. 2019, 39, 4450–4456. [Google Scholar] [CrossRef]

- Pasiut; Partyka, J.; Bućko, M.M.; Grandys, M.; Kurpaska, Ł.; Piekarczyk, W. An impact of the molar ratio of Na2O/K2O on nanomechanical properties of glaze materials containing zirconium oxide. J. Alloys Compd. 2020, 815, 152411. [Google Scholar] [CrossRef]

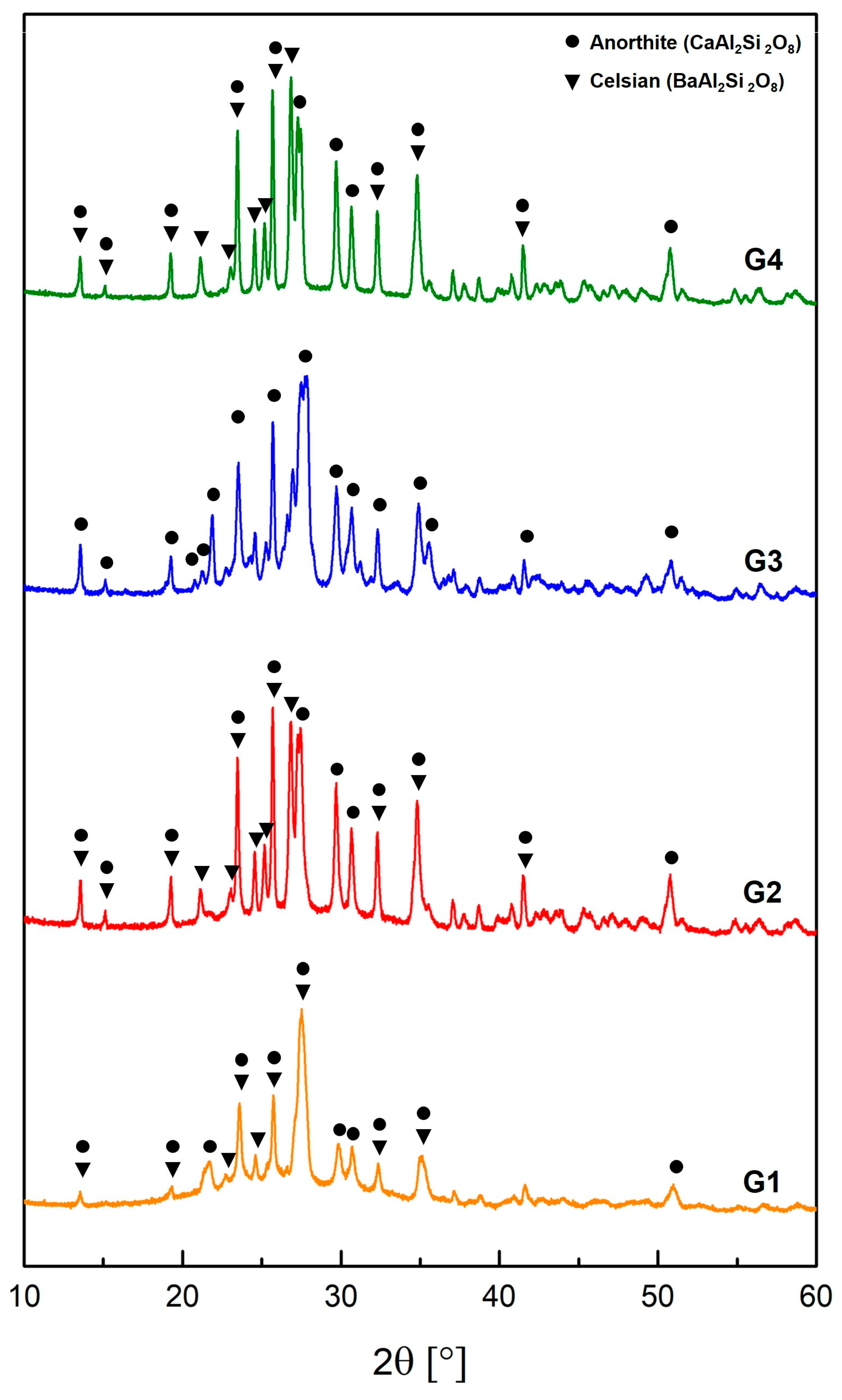

- Partyka, J.; Gasek, K.; Pasiut, K.; Gajek, M. Effect of addition of BaO on sintering of glass–ceramic materials from SiO2–Al2O3–Na2O–K2O–CaO/MgO system. J. Therm. Anal. Calorim. 2016, 125, 1095–1103. [Google Scholar] [CrossRef]

- Partyka, J. Effect of BaO addition on the structure and microstructure of SiO2–Al2O3–Na2O–K2O–MgO glass-ceramic composites. Ceram. Int. 2015, 41, 14013–14020. [Google Scholar] [CrossRef]

- Tunali, A.; Ozel, E.; Turan, S. Production and characterisation of granulated frit to achieve anorthite based glass-ceramic glaze. J. Eur. Ceram. Soc. 2015, 35, 1089–1095. [Google Scholar] [CrossRef]

- Demarch, A.; Waterkemper, A.; Pasini, D.; Ruzza, S.; Montedo, O.R.K.; Angioletto, E. Effects of roughness parameters on slip resistance for different methods used to determine the coefficient of friction for ceramic floor tiles. Ceram. Int. 2021, 47, 24281–24286. [Google Scholar] [CrossRef]

- Pasiut, K.; Partyka, J.; Kozień, D.; Kronberg, T. Impact of barium oxide on the structure and surface properties of glass-crystalline glazes. Ceram. Int. 2024, 50, 47980–47990. [Google Scholar] [CrossRef]

- Bao, Z.; Wang, S.; Miao, L.; Xu, Y.; Cheng, Z.; Wang, X. Preparation, properties and formation mechanism of transparent anorthite-based glass-ceramic glaze with high hardness. Ceram. Int. 2024, 50, 26182–26192. [Google Scholar] [CrossRef]

- Cai, J.; Lv, M.; Guan, K.; Sun, Q.; Peng, C.; Wu, J.; Liu, Y. Development of spinel opaque glazes for ceramic tiles. J. Eur. Ceram. Soc. 2018, 38, 297–302. [Google Scholar] [CrossRef]

- Li, R.; Lv, M.; Cai, J.; Guan, K.; He, F.; Li, W.; Peng, C.; Rao, P.; Wu, J. Development of sapphirine opaque glazes for ceramic tiles. J. Eur. Ceram. Soc. 2018, 38, 5632–5636. [Google Scholar] [CrossRef]

- ISO 10545-5:2000; Determination of Impact Resistance by Measurement of Coefficient of Restitution. International Organization for Standardization: Geneva, Switzerland, 2000.

- ISO 10545-7:2000; Determination of Resistance to Surface Abrasion for Glazed Tiles. International Organization for Standardization: Geneva, Switzerland, 2000.

- ISO/CD 10545-22; ISO Standards Determination of Resistance to Wear with a Multi-Attribute Method, (Ongoing). International Organization for Standardization: Geneva, Switzerland, 2019.

- Fabris, R.; Masi, G.; Mazzini, D.; Sanseverino, L.; Bignozzi, M.C. Application of different test methods to assess the wear resistance of ceramic tiles ceramic tile manufacture. In Qualicer, Castellón de la Plana; 2024; p. 9. Available online: https://www.qualicer.org/programa/2024/ING/Ponencias/B/35%20paper%20ing.pdf (accessed on 14 November 2024).

- CSTB 3778_V3; 2020 Annexe 10: Méthode D’usure “Mazaud” des Carreaux Céramiques Avec Décors Superficiels sur Tesson en Grès Cérame. Centre Scientifique et Technique du Bâtiment: Paris, France, 2020.

- ASTM C1870-18; Test Method for Determination of Impact Diameter from Falling Ball on Ceramic Tile. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C1327-15; Standard Test Method for Vickers Indentation Hardness of Advanced Ceramics. ASM International: Detroit, MI, USA, 2019.

- ISO 2813-2014; Paints and Varnishes—Determination of Gloss Value at 20 Degrees, 60 Degrees and 85 Degrees. International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 21920-2:2022; Geometrical Product Specifications (GPS)—Surface Texture: Profile. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 10545-14:2015; Determination of Resistance to Stains. International Organization for Standardization: Geneva, Switzerland, 2015.

- ASTM C1895-20; Standard Test Method for Determination of Mohs Scratch Hardness. ASM International: Detroit, MI, USA, 2020.

- Melchiades, F.G.; Rego, B.T.; Higa, S.M.; Alves, H.J.; Boschi, A.O. Factors affecting glaze transparency of ceramic tiles manufactured by the single firing technique. J. Eur. Ceram. Soc. 2010, 30, 2443–2449. [Google Scholar] [CrossRef]

- Nieves, L.J.J.; Nastri, S.; Lot, A.V.; Melchiades, F.G.; Marsola, G.A.; Flauzino, I.S.; Innocentini, M.D.M.; Boschi, A.O. Influence of engobe and glaze layers on the evolution of porosity and permeability of single-fired porcelain tiles. Appl. Clay Sci. 2022, 228, 106635. [Google Scholar] [CrossRef]

- Pasiut, K.; Partyka, J. Thermal properties of glass-ceramic glazes with zirconium oxide added to multicomponent system SiO2–Al2O3–CaO–MgO–Na2O. J. Therm. Anal. Calorim. 2023, 148, 1867–1874. [Google Scholar] [CrossRef]

- Lu, J.; Li, Y.; Zou, C.; Liu, Z.; Wang, C. Effect of heating rate on the sinterability, crystallization, and mechanical properties of sintered glass–ceramics from granite waste. J. Therm. Anal. Calorim. 2019, 135, 1977–1985. [Google Scholar] [CrossRef]

- Stábile, F.M.; Piccico, M.; Serra, M.F.; Rafti, M.; Súarez, G.; Rendtorff, N.M. Viscosity and Thermal Evolution of Density and Wetting Angle of a Commercial Glaze by Means of Hot Stage Microscopy. Procedia Mater. Sci. 2015, 9, 563–570. [Google Scholar] [CrossRef]

- Amorós, J.L.; Blasco, E.; Moreno, A.; Gómez-Tena, M.P.; Feliu, C. Non-isothermal sinter-crystallisation of satin glazes: A kinetic model. Ceram. Int. 2018, 44, 7780–7787. [Google Scholar] [CrossRef]

- Kaczmarczyk, K.; Partyka, J. Effect of ZrSiO4 addition on sintering and selected physicochemical parameters of glass-ceramic materials from the SiO2–Al2O3–Na2O–K2O–CaO–MgO system in the presence of barium oxide. Ceram. Int. 2019, 45, 22813–22820. [Google Scholar] [CrossRef]

- Gajek, M.; Leśniak, M.; Sitarz, M.; Stodolak-Zych, E.; Rapacz-Kmita, A. The crystallization and structure features of glass within the K2O–MgO–CaO–Al2O3–SiO2–(BaO) system. J. Mol. Struct. 2020, 1220, 128747. [Google Scholar] [CrossRef]

- Li, H.; Wu, L.; Wang, X.; Xu, D.; Teng, Y.; Li, Y. Crystallization behavior and microstructure of barium borosilicate glass–ceramics. Ceram. Int. 2015, 41, 15202–15207. [Google Scholar] [CrossRef]

- Rowe, M.C.; Brewer, B.J. AMORPH: A statistical program for characterizing amorphous materials by x-ray diffraction. Comput. Geosci. 2018, 120, 21–31. [Google Scholar] [CrossRef]

- Taskiran, M.U.; Demirkol, N.; Capoglu, A. A new porcelainised stoneware material based on anorthite. J. Eur. Ceram. Soc. 2005, 25, 293–300. [Google Scholar] [CrossRef]

- Lee, H.K.; Zerbetto, S.; Colombo, P.; Pantano, C.G. Glass-ceramics and composites containing aluminum borate whiskers. Ceram. Int. 2010, 36, 1589–1596. [Google Scholar] [CrossRef]

- Wang, C.; Wang, S.; Li, X.; Chen, W.; Bai, M.; Li, X.; Wang, Y.; CaF, E.O. TiO2– and P2O5– on crystallization and properties of CaO–Al2O3–SiO2–ZrO2-based glass-ceramic glaze. Ceram. Int. 2024, 50, 14139–14150. [Google Scholar] [CrossRef]

- Son, S.; Kim, K. Effect of TiO2 content on crystallization behavior of CaO–Al2O3–SiO2–ZnO glass-ceramic glaze. Ceram. Int. 2023, 49, 13677–13686. [Google Scholar] [CrossRef]

- Kaczmarczyk, K.; Partyka, J.; Pasiut, K.; Michałek, J. Strontium carbonate in glazes from the SiO2–Al2O3–CaO–MgO–Na2O–K2O system, sintering and surface properties. Open Ceram. 2022, 9, 100233. [Google Scholar] [CrossRef]

- Cheng, X.; Ke, S.; Wang, Q.; Wang, H.; Shui, A.; Liu, P. Fabrication and characterization of anorthite-based ceramic using mineral raw materials. Ceram. Int. 2012, 38, 3227–3235. [Google Scholar] [CrossRef]

| Frits/Raw Materials | G1 | G2 | G3 | G4 |

|---|---|---|---|---|

| F1 | 30–40 | - | 30–40 | 10–20 |

| F2 | - | 20–30 | - | 10–20 |

| F3 | 10–20 | 20–30 | - | |

| F4 | - | 1–5 | 5–10 | |

| Clay | 5–10 | 5–10 | - | 5–10 |

| Kaolin | 10–20 | 5–10 | 5–10 | - |

| Dolomite | 5–10 | - | 1–5 | 5–10 |

| Feldspar | 10–20 | 10–20 | 5–10 | 10–20 |

| Nepheline | - | 10–20 | 10–20 | 10–20 |

| Quartz | 10–20 | - | 5–10 | 1–5 |

| BaCO3 | 5–10 | 1–5 | - | 5–10 |

| ZnO | 1–5 | 1–5 | - | 1–5 |

| Frit/Raw Material | SiO2 | Al2O3 | MgO | CaO | Na2O | K2O | BaO | B2O3 | ZnO | TiO2 | L.O.I. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| F1 | 50–60 | 10–20 | - | 10–20 | - | 1–5 | - | - | 5–10 | - | - |

| F2 | 30–40 | 10–20 | - | 20–30 | - | 1–5 | 30–40 | - | - | - | - |

| F3 | 40–50 | 10–20 | - | 20–30 | 1–5 | - | - | - | - | - | - |

| F4 | 30–40 | 10–20 | - | 10–20 | - | 1–5 | - | 1–5 | - | - | - |

| Clay | 58 | 29 | 0.3 | 0.3 | 0.2 | 1.1 | - | - | - | 0.7 | 10.5 |

| Kaolin | 47 | 38.5 | 0.2 | 0.1 | - | 1.6 | - | - | - | 0.2 | 12.4 |

| Dolomite | - | - | 21.6 | 31.8 | - | - | - | - | - | - | 47.6 |

| Feldspar | 70 | 18 | 0.3 | 0.3 | 10.5 | 0.5 | - | - | - | - | 0.4 |

| Nepheline | 60.8 | 23.4 | - | 0.4 | 9.8 | 5 | - | - | - | - | 0.6 |

| Quartz | 99.3 | 0.4 | - | 0.05 | - | 0.05 | - | - | - | - | 0.2 |

| BaCO3 | - | - | - | - | - | - | 76.5 | - | - | - | 23.5 |

| Samples | SiO2 | Al2O3 | Na2O | K2O | MgO | CaO | BaO | ZnO | B2O3 | TiO2 | L.O.I |

|---|---|---|---|---|---|---|---|---|---|---|---|

| G1 | 50–55 | 16–18 | 3–5 | 1–3 | 1–3 | 6–10 | 6–8 | 1–3 | - | <1 | 5–7 |

| G2 | 45–50 | 12–16 | 3–5 | 1–3 | 1–3 | 5–8 | 15–20 | 1–3 | - | <1 | 1–3 |

| G3 | 50–55 | 17–20 | 3–5 | 1–3 | 1–3 | 8–12 | - | 3–5 | 0.5–1 | <1 | 2–4 |

| G4 | 45–50 | 18–21 | 3–5 | 1–3 | 1–3 | 4–7 | 9–12 | 3–5 | - | <1 | 5–7 |

| Test Method | Wear Resistance Class | ||

|---|---|---|---|

| H | HH | HHH | |

| ΔWLS [mg/cm2] (@ 6000) | 0.035 < ΔWLS < 0.045 | 0.028 ≤ ΔWLS < 0.035 | ΔWLS < 0.028 |

| ΔG [GU] | @ 600 cycles 36 ≤ ΔG ≤ 50 | @ 600 cycles 6 < ΔG ≤ 35 | @ 6000 cycles ΔG ≤ 5 |

| Stain resistance | Minimum class: 3 | ||

| SR | Hardness point ≥ 4 | Hardness point ≥ 5 | Hardness point ≥ 7 |

| Samples | TSI | TSO | TSP |

|---|---|---|---|

| [°C] | [°C] | [°C] | |

| G1 | 1138 | 1160 | 1203 |

| G2 | 1150 | 1180 | 1232 |

| G3 | 1146 | 1170 | 1210 |

| G4 | 1197 | 1240 | 1256 |

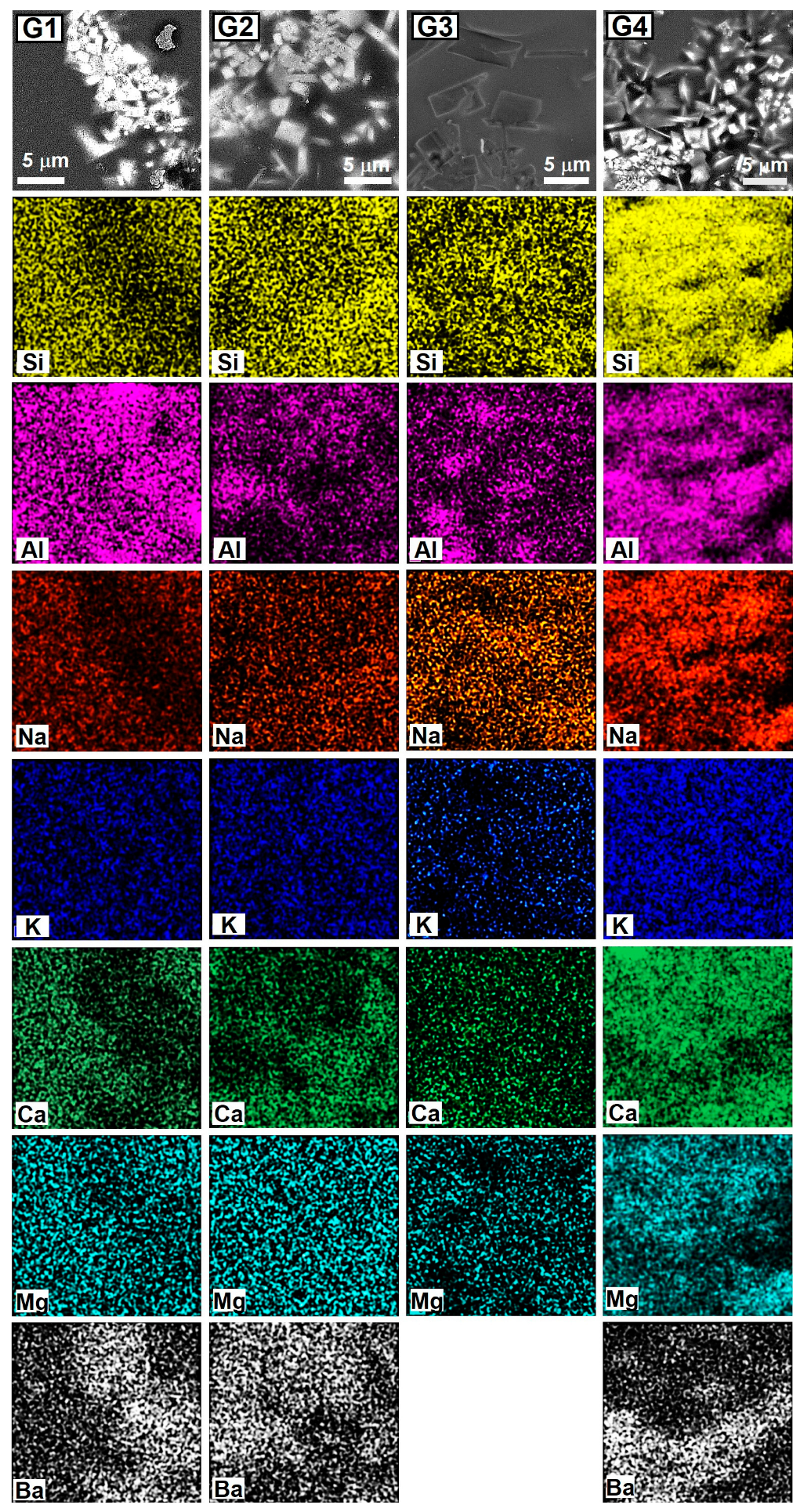

| Sample | Area | O | Na | K | Ca | Mg | Zn | Ba | Al | Si |

|---|---|---|---|---|---|---|---|---|---|---|

| G1 | A1 | 58.3 ± 2.3 | 5.9 ± 0.4 | 1.1 ± 0.2 | 5.7 ± 0.6 | 1.8 ± 0.1 | 1.0 ± 0.1 | 1.3 ± 0.2 | 10.4 ± 1.3 | 10.4 ± 0.8 |

| A2 | 59.3 ± 2.3 | 4.0 ± 0.7 | 0.7 ± 0.2 | 3.4 ± 1.2 | 0.6 ± 0.2 | 0.3 ± 0.1 | 2.6 ± 1.2 | 14.6 ± 2.3 | 14.6 ± 2.3 | |

| A3 | 58.4 ± 2.8 | 2.9 ± 0.7 | 0.7 ± 0.2 | 2.2 ± 0.6 | 0.4 ± 0.1 | 0.3 ± 0.1 | 4.0 ± 1.3 | 12.0 ± 1.2 | 19.1 ± 1.7 | |

| G2 | A4 | 55.7 ± 2.8 | 4.6 ± 0.1 | 0.6 ± 0.1 | 7.5 ± 0.3 | 0.3 ± 0.1 | 1.2 ± 0.1 | 2.1 ± 0.1 | 7.1 ± 0.6 | 20.9 ± 1.1 |

| A5 | 62.6 ± 1.3 | 3.5 ± 0.2 | 0.7 ± 0.1 | 6.0 ± 1.4 | 0.2 ± 0.1 | 1.0 ± 0.3 | 2.7 ± 0.2 | 7.0 ± 1.8 | 16.5 ± 1.2 | |

| A6 | 59.1 ± 1.2 | 3.0 ± 0.2 | 1.0 ± 0.1 | 3.7 ± 0.7 | 0.1 ± 0.1 | 0.7 ± 0.1 | 4.4 ± 0.4 | 10.2 ± 0.5 | 17.9 ± 1.1 | |

| G3 | A7 | 58.4 ± 1.1 | 4.5 ± 0.2 | 1.4 ± 0.5 | 5.7 ± 0.6 | 1.4 ± 0.5 | 1.6 ± 0.2 | - | 6.7 ± 0.4 | 20.3 ± 0.8 |

| A8 | 56.9 ± 1.2 | 4.2 ± 0.5 | 0.4 ± 0.1 | 6.5 ± 0.6 | 0.9 ± 0.2 | 0.7 ± 0.2 | - | 11.2 ± 1.1 | 19.3 ± 1.1 | |

| G4 | A9 | 43.7 ± 2.2 | 5.0 ± 0.3 | 1.3 ± 0.2 | 4.4 ± 0.9 | 2.6 ± 0.7 | 3.2 ± 0.8 | 3.7 ± 1.2 | 9.6 ± 0.2 | 26.5 ± 1.2 |

| A10 | 40.6 ± 3.4 | 5.0 ± 0.2 | 0.8 ± 0.1 | 4.5 ± 0.8 | 2.6 ± 0.7 | 2.9 ± 1.2 | 6.0 ± 1.1 | 11.4 ± 0.3 | 26.1 ± 1.3 | |

| A11 | 49.0 ± 2.1 | 3.9 ± 0.3 | 0.9 ± 0.2 | 3.6 ± 1.1 | 1.5 ± 0.7 | 1.9 ± 1.1 | 9.2 ± 2.5 | 9.6 ± 0.5 | 20.5 ± 2.6 |

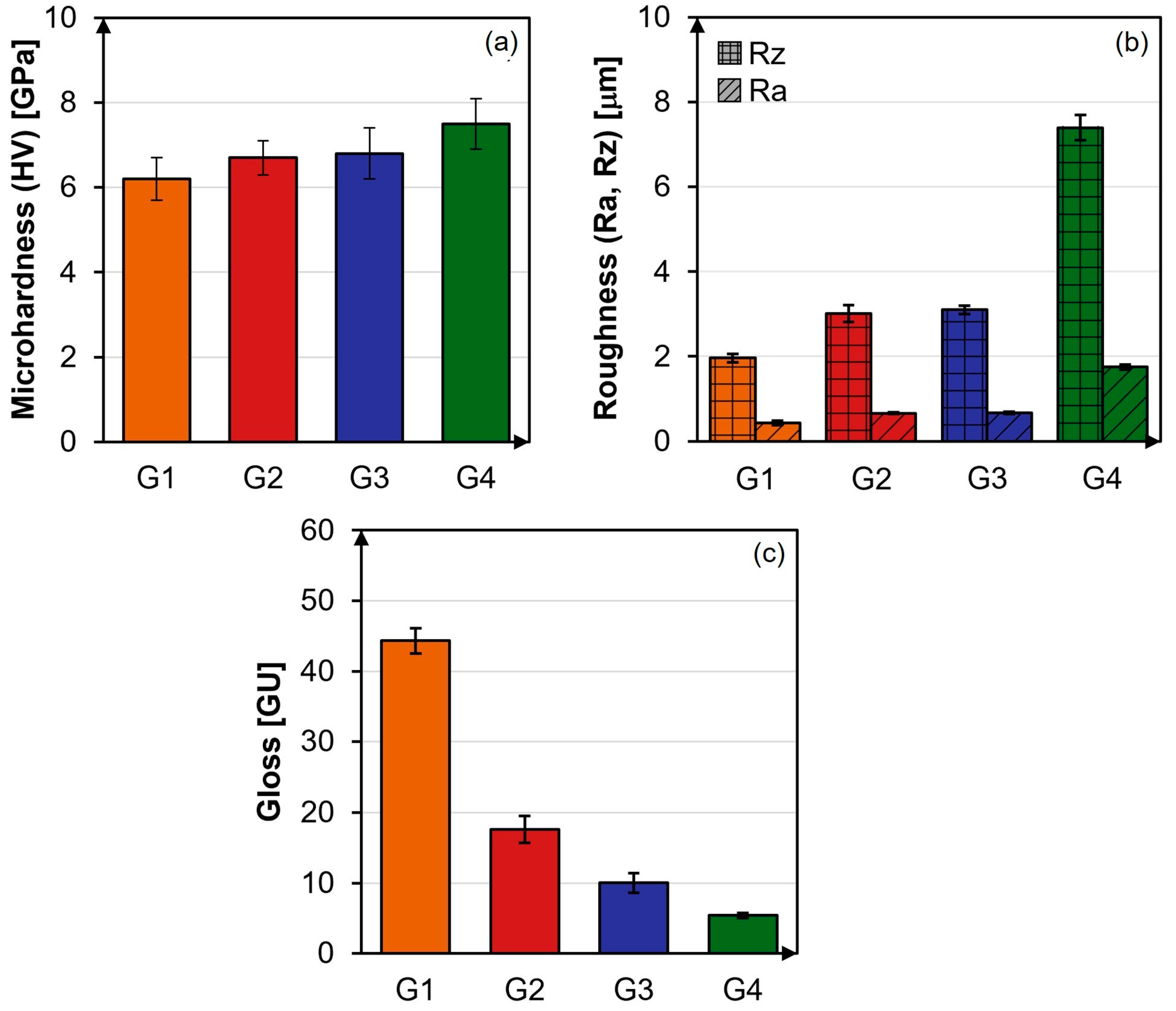

| Sample | G1 | G2 | G3 | G4 |

|---|---|---|---|---|

| ΔWLS [g/cm2] | 0.025 ± 0.001 | 0.018 ± 0.001 | 0.025 ± 0.001 | 0.017 ± 0.001 |

| ΔG (@ 600) [GU] | 38.7 ± 0.9 | 12.8 ± 0.8 | 14.1 ± 1.2 | - |

| ΔG (@ 6000) [GU] | - | - | - | 2.5 ± 1.3 |

| Stain resistance | 5 | 5 | 5 | 5 |

| Scratch resistance | 6 | 6 | 6 | 7 |

| Wear resistance class | H | HH | HH | HHH |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fabris, R.; Masi, G.; Mazzini, D.; Sanseverino, L.; Bignozzi, M.C. Tribomechanical Properties of Glazes for Ceramic Tiles: A Novel Protocol for Their Characterization. Materials 2025, 18, 60. https://doi.org/10.3390/ma18010060

Fabris R, Masi G, Mazzini D, Sanseverino L, Bignozzi MC. Tribomechanical Properties of Glazes for Ceramic Tiles: A Novel Protocol for Their Characterization. Materials. 2025; 18(1):60. https://doi.org/10.3390/ma18010060

Chicago/Turabian StyleFabris, Riccardo, Giulia Masi, Denia Mazzini, Leonardo Sanseverino, and Maria Chiara Bignozzi. 2025. "Tribomechanical Properties of Glazes for Ceramic Tiles: A Novel Protocol for Their Characterization" Materials 18, no. 1: 60. https://doi.org/10.3390/ma18010060

APA StyleFabris, R., Masi, G., Mazzini, D., Sanseverino, L., & Bignozzi, M. C. (2025). Tribomechanical Properties of Glazes for Ceramic Tiles: A Novel Protocol for Their Characterization. Materials, 18(1), 60. https://doi.org/10.3390/ma18010060