Research on Quantitative Characterization Model of Compressive Strength or Elastic Modulus of Recycled Concrete Based on Pore Grading

Abstract

1. Introduction

2. Establishing Quantitative Characterization Model of Compressive Strength or Elastic Modulus

3. Test Study of Recycled Concrete

3.1. Test Material

- (1)

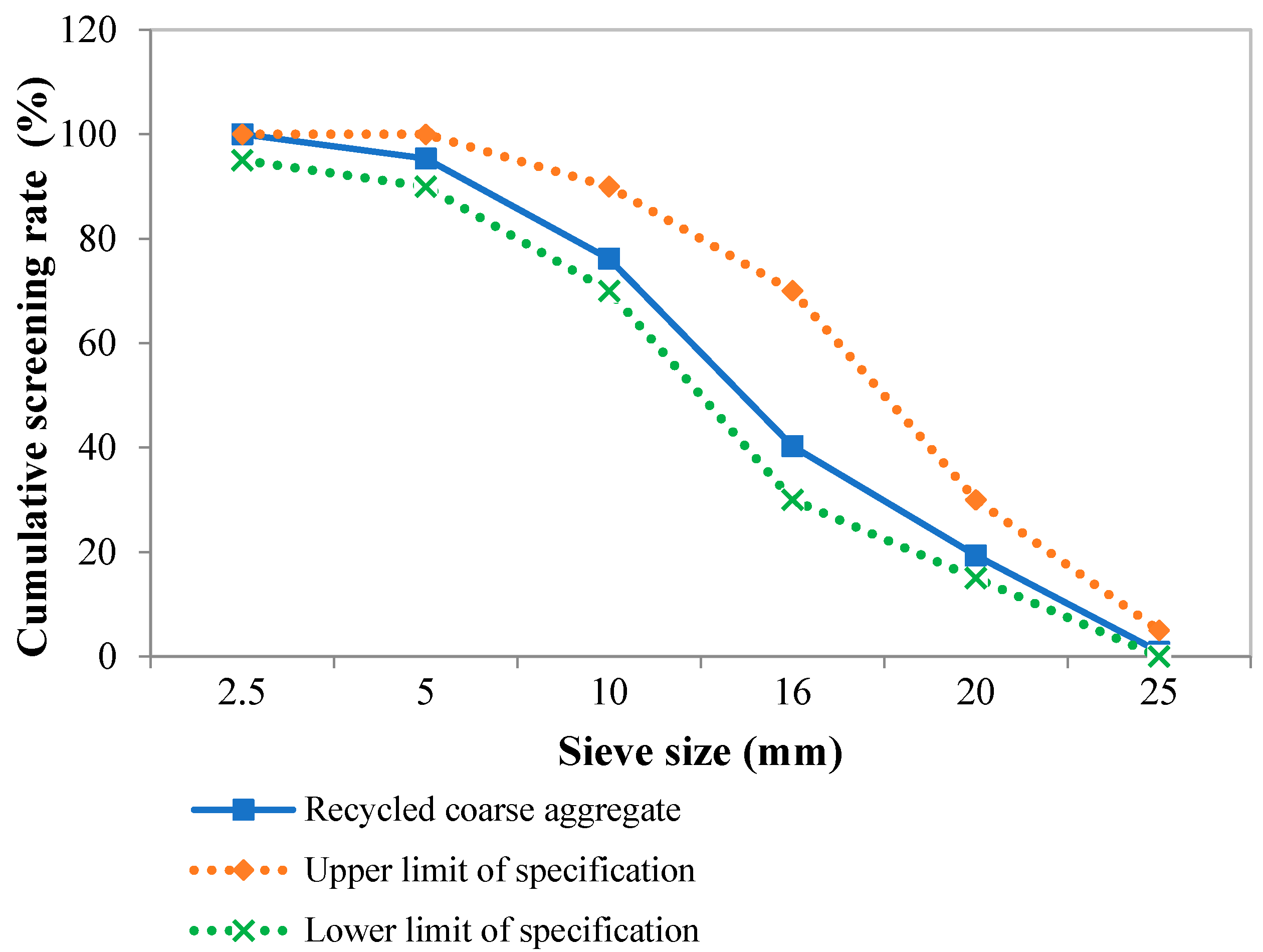

- Coarse aggregate

- (2)

- Fine aggregate

- (3)

- Test cement

- (4)

- Test water

3.2. Mix of Recycled Concrete

3.3. Production of Recycled Concrete Test Blocks

3.4. Test Machine and Scheme of Recycled Concrete Compressive Strength and Elastic Modulus

3.4.1. Test Machine

3.4.2. The Test Scheme of Compressive Strength and Elastic Modulus

3.5. Testing Machine and Scheme of Recycled Concrete Pore Grading

3.5.1. Test Instrument

3.5.2. The Test Scheme of Pore Structure

4. Results and Discussion

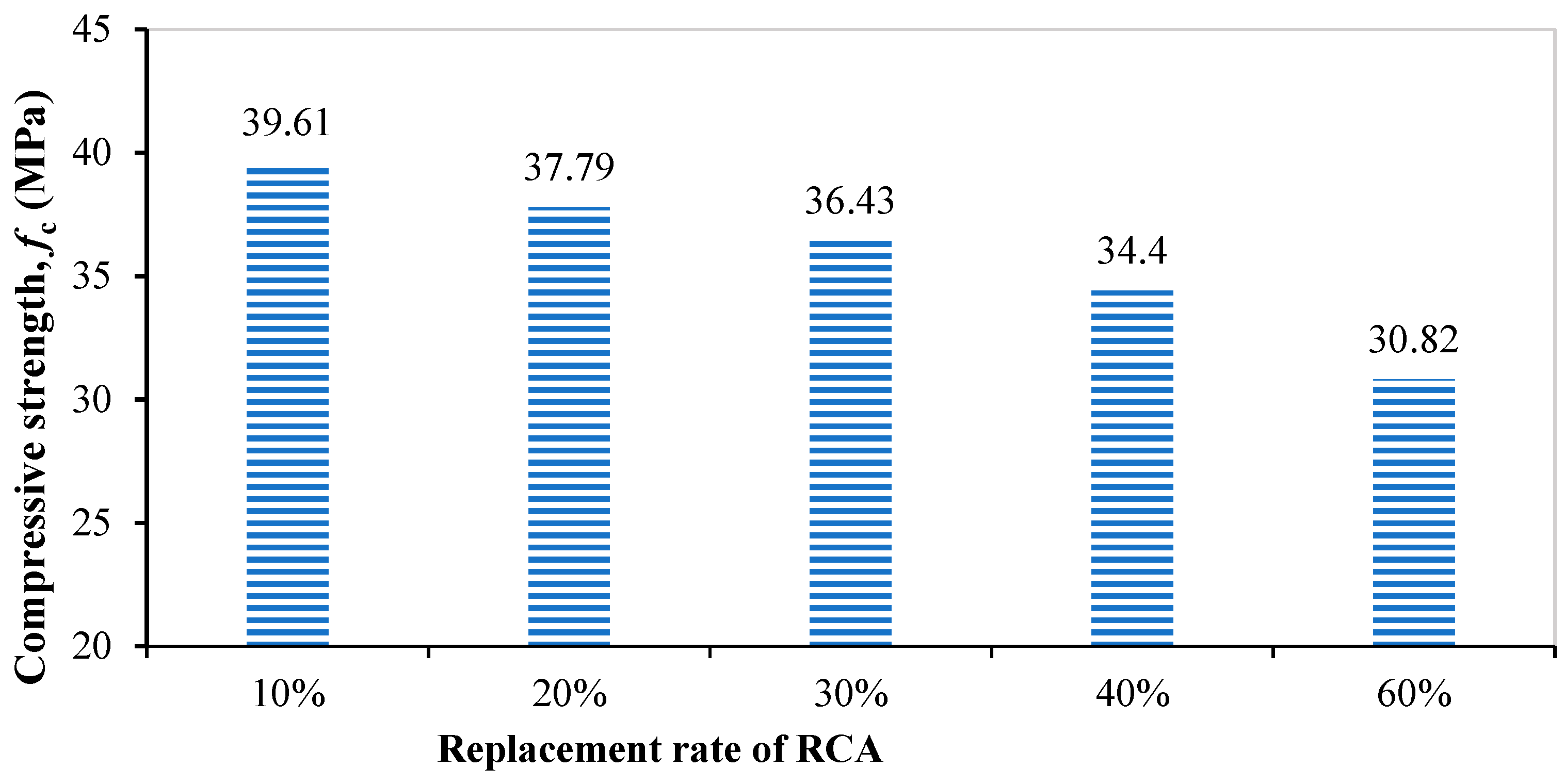

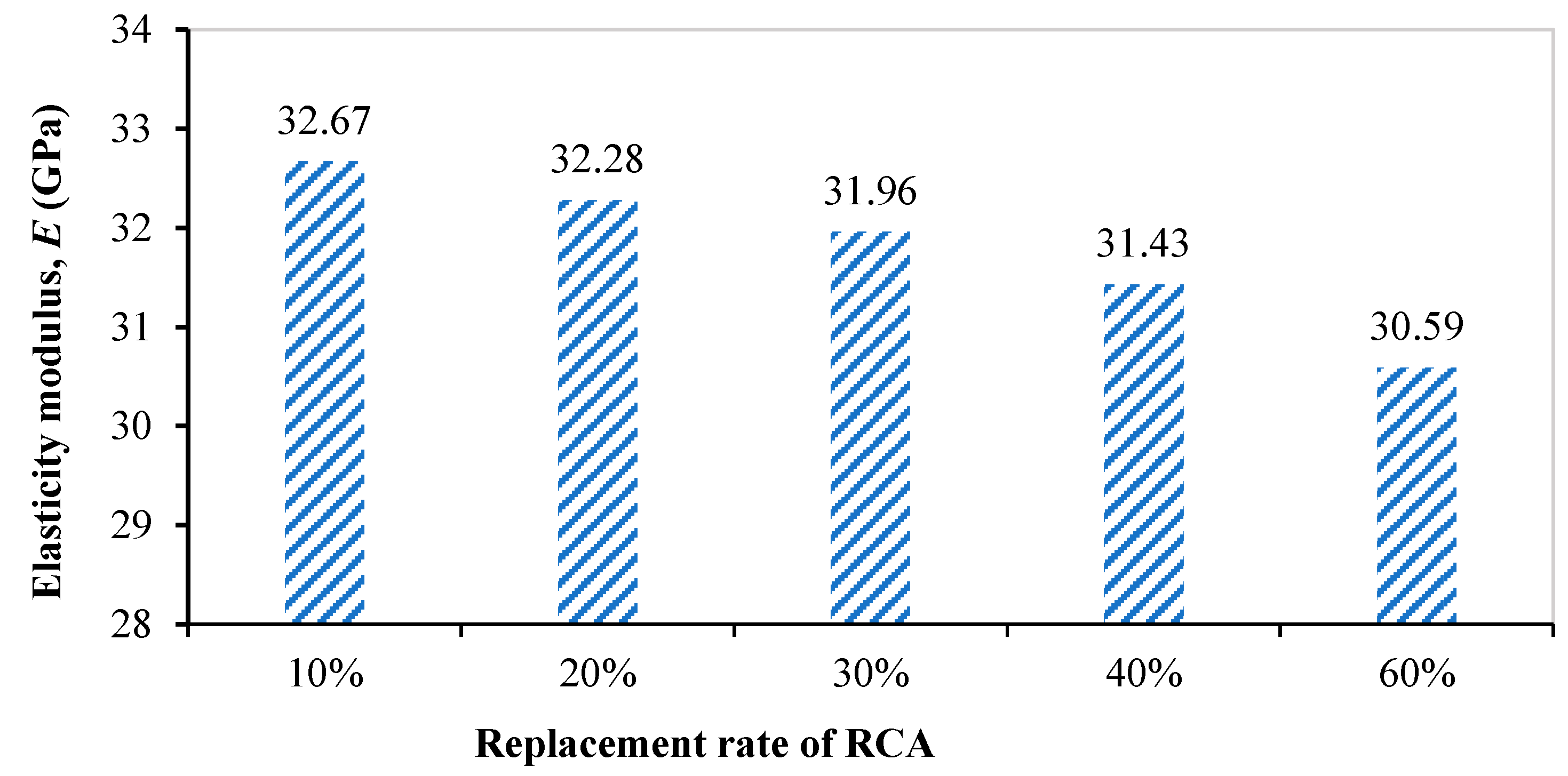

4.1. Test Results and Discussion of Compressive Strength or Elastic Modulus

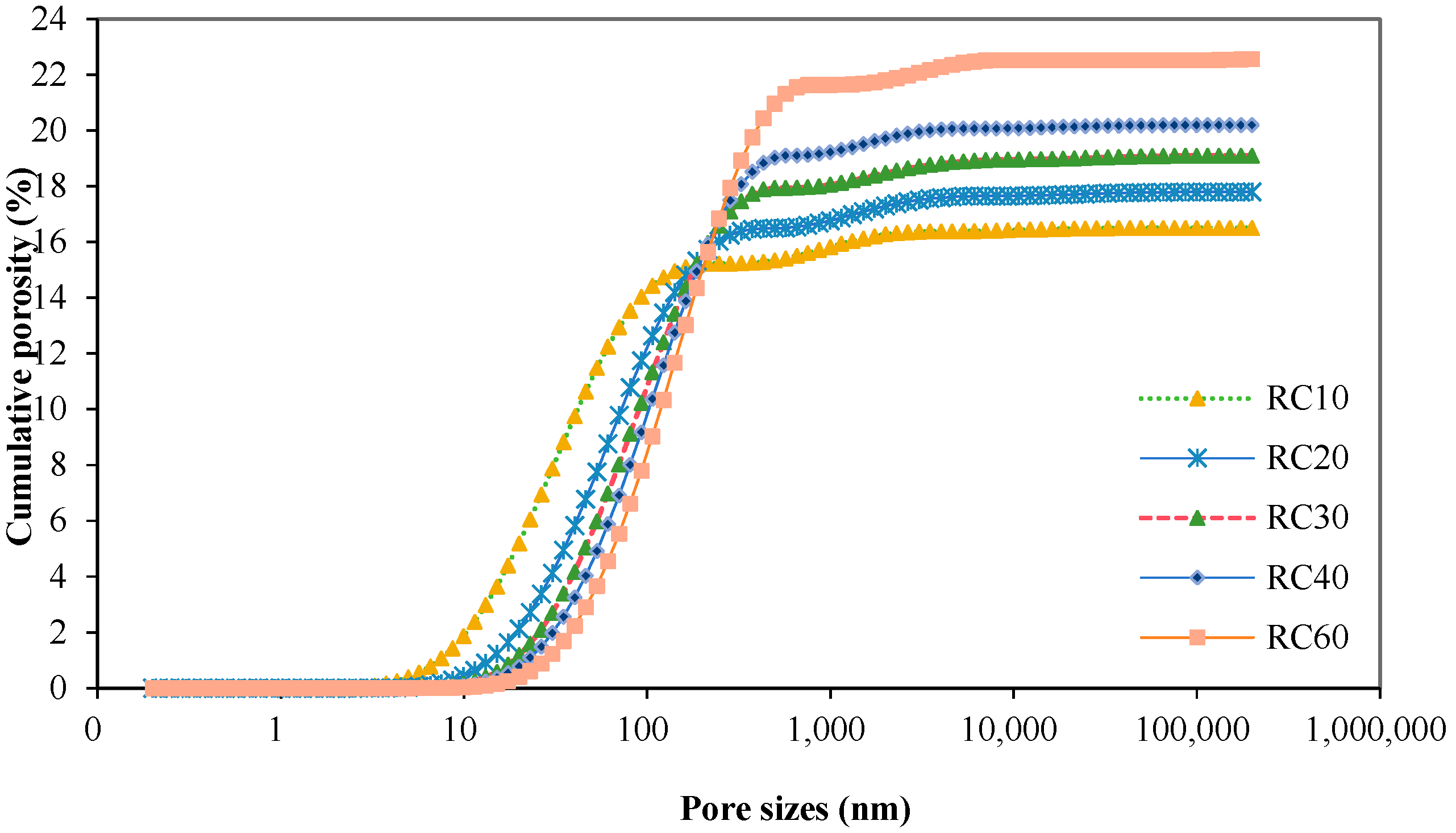

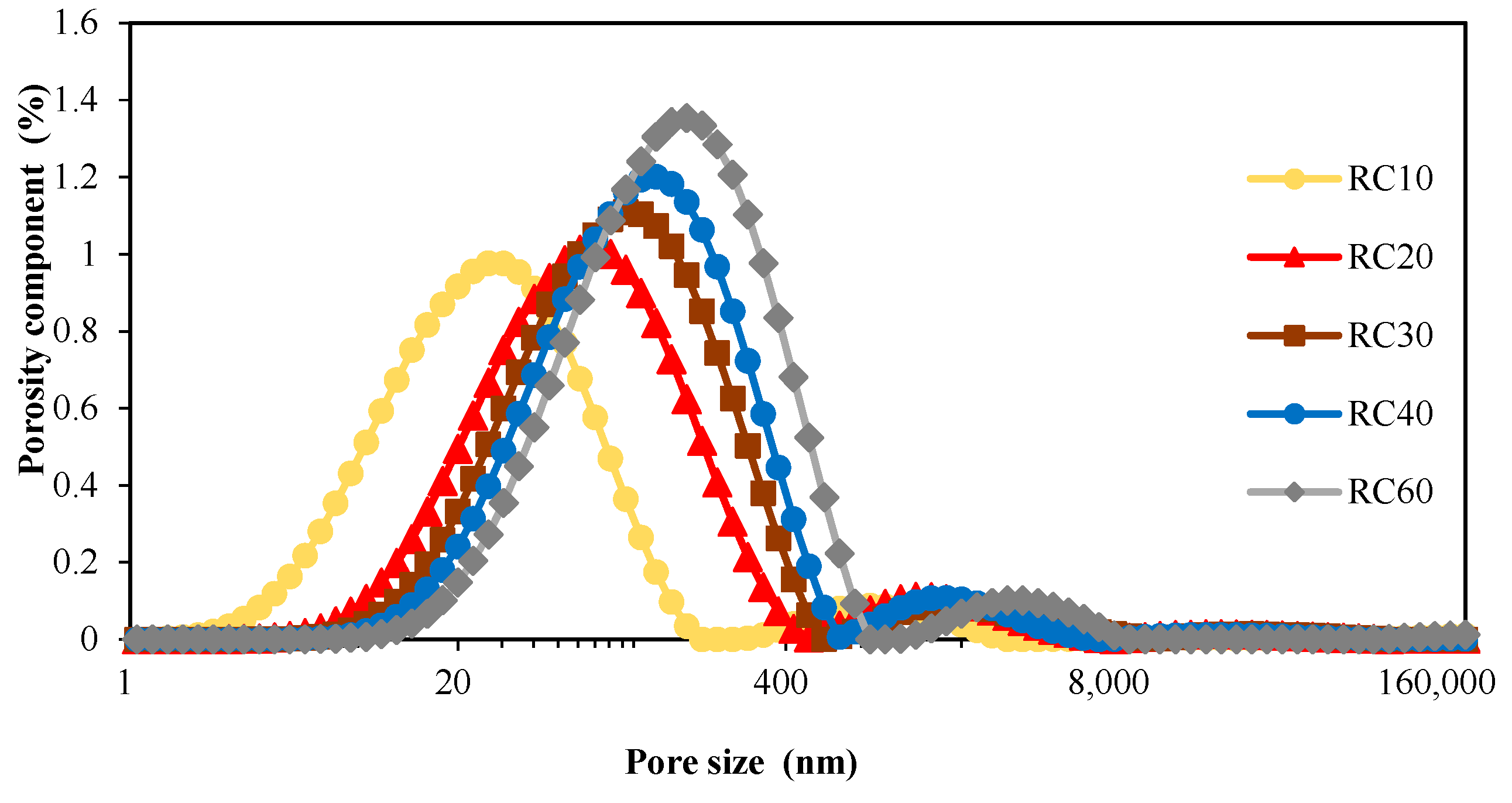

4.2. Test Results and Discussion of Pore Grading

5. Influence Analysis Between Different Pore Sizes and Compressive Strength or Elastic Modulus of Recycled Concrete

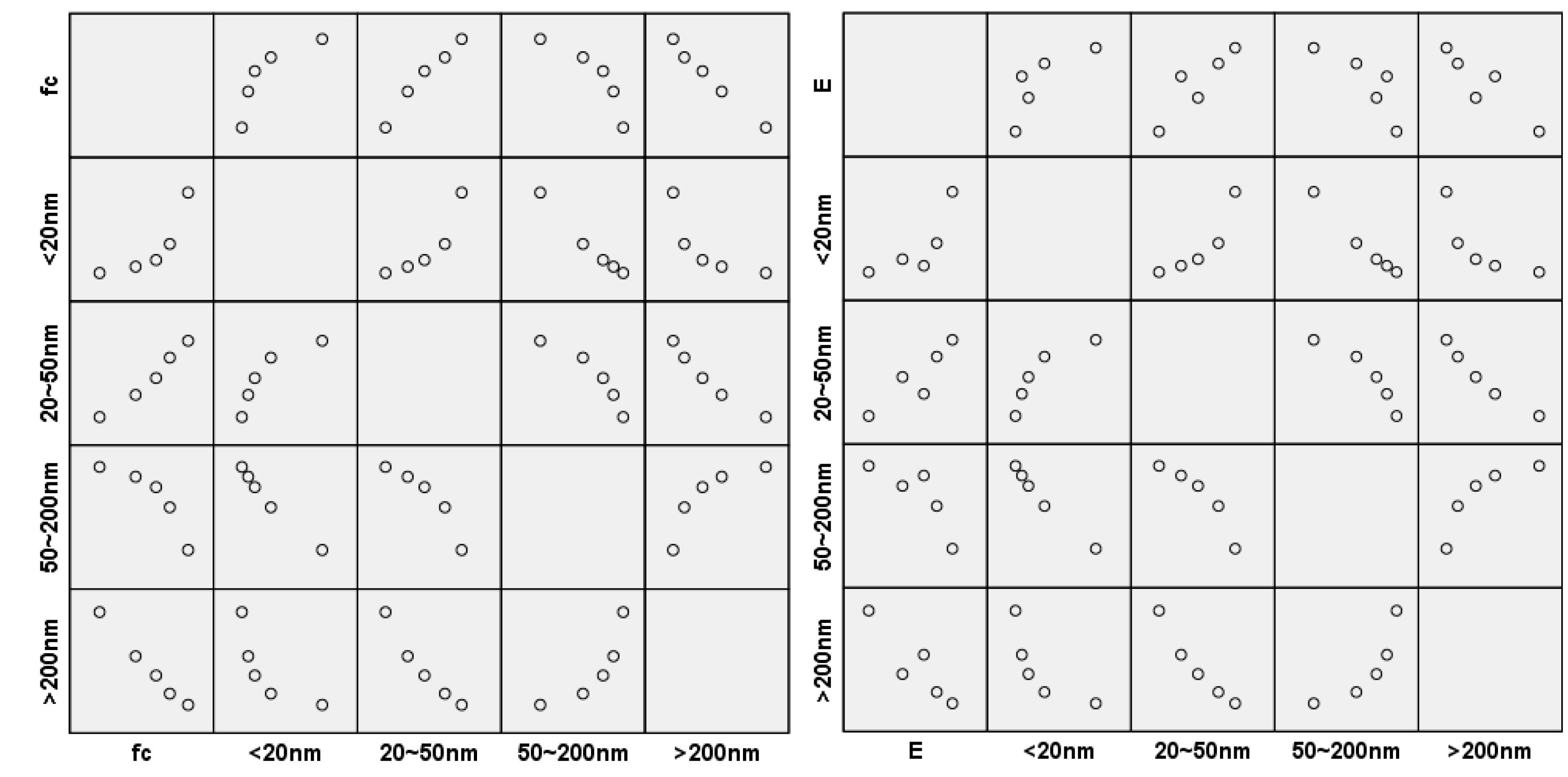

5.1. Correlation Analysis

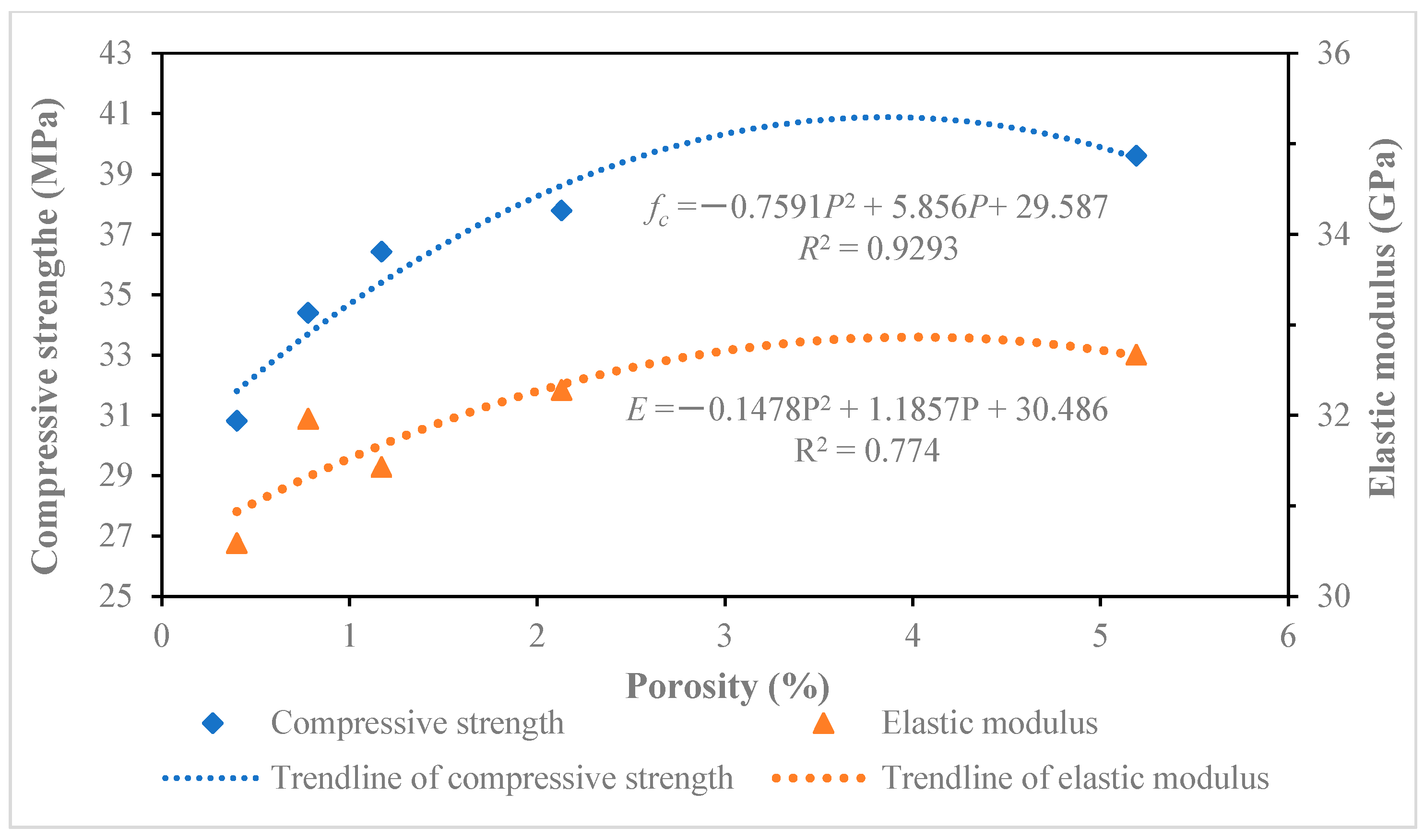

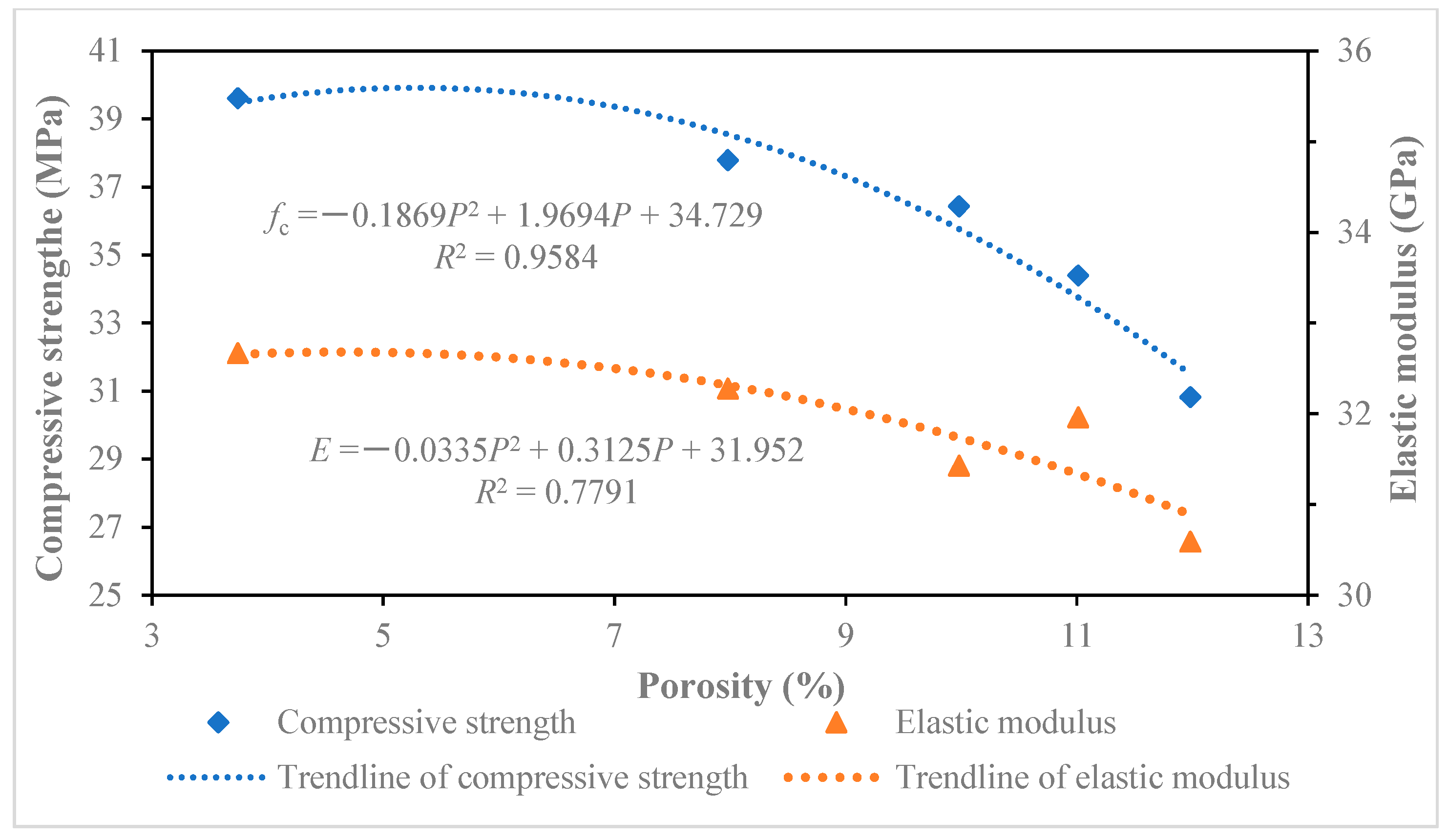

5.2. Influence Analysis Between Pore Size and Compressive Strength or Elastic Modulus

6. Quantitative Characterization of Compressive Strength or Elastic Modulus of Recycled Concrete Based on Pore Grading

6.1. Establishment of Quantitative Model

6.2. Error Analysis Between Test Results and Predicted Results

6.3. Comparative Analysis Between Quantitative Characterization Model and Existing Models

7. Conclusions

- (1)

- With the increase in the replacement rate of recycled coarse aggregate, the compressive strength and elastic modulus of recycled concrete decreased, and the greater the replacement rate, the more obvious the decrease.

- (2)

- With the increase in the replacement rate of recycled coarse aggregate, the peak pore size in the pore size distribution curve of recycled concrete increased continuously, and the proportion of pore size above 50~200 nm and 200 nm also increased continuously.

- (3)

- The pore size below 20 nm and 20~50 nm had a positive correlation with the compressive strength and elastic modulus of recycled concrete, while the pore size above 50~200 nm and 200 nm had a negative correlation with the compressive strength and elastic modulus of recycled concrete. The test results of recycled concrete verify that the quantitative characterization model could better characterize the compressive strength and elastic modulus of recycled concrete.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, J.F. The Theoretical Research of the Pore Structure and Strength of Concrete; Zhejiang University Press: Hangzhou, China, 2004. (In Chinese) [Google Scholar]

- Rao, G.A. Generalization of Abrams’ law for cement mortars. Cem. Concr. Res. 2001, 31, 495–502. [Google Scholar] [CrossRef]

- Wittmann, F.H. Structure of concrete with respect to crack growth. In Fracture Mechanics of Concrete; Springer: Dordrecht, The Netherlands, 1983; pp. 56–69. [Google Scholar]

- Wu, Z.-W. An Approach to the Recent Trends of Concrete Science and Technology. J. Chin. Ceram. Soc. 1979, 7, 262–270. (In Chinese) [Google Scholar]

- Atize, C.; Massidda, L. Effect of pore size distribution on strength of hardened cement paste. Cem. Concr. Res. 1986, 56–62. [Google Scholar]

- Lian, H.-Z. Research Basis of the Phase of Building Materials; Tsinghua University Press: Beijing, China, 1996. (In Chinese) [Google Scholar]

- Zhang, J.; Wu, Y.; Sun, K.; Guo, Y. Experimental study on pore structure of recycled aggregate concrete. Bull. Silic. 2011, 30, 239–244. (In Chinese) [Google Scholar]

- Zhang, J.-X.; Zhang, J.-H.; Wu, C.-S. Study on Properties and Pore Structure of Recycled Concrete. J. Build. Mater. 2006, 142–147. (In Chinese) [Google Scholar]

- Xue, C.; Shen, A.-Q.; Guo, Y.-C. Prediction Model for the Compressive Strength of Concrete Mixed with CWCPM Based on Pore Structure Parameters. Mater. Rep. 2019, 33, 1348–1353. (In Chinese) [Google Scholar]

- Yin, Z.-G.; Zhang, K.; Zhao, Y. Bulletin of the Chinese Ceramic Society. Bull. Chin. Ceram. Soc. 2020, 39, 756–761+778. (In Chinese) [Google Scholar]

- Chen, H.; Xu, F. Quantitative Characterization Model of Macroscopic Mechanical Properties of Recycled Concrete Based on Porosity and Pore Sizes. Adv. Mater. Sci. Eng. 2024, 2024, 5261052. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Jia, J.; Li, X.; Huo, G.; Xie, L.; Meng, Z.; Gao, Y.; Cao, Z. Analysis of Pore Structure and Mechanical Properties of Recycled Concrete with Full Replacement of Coarse Aggregate. Bull. Chin. Ceram. Soc. 2024, 43, 3005–3016+3033. (In Chinese) [Google Scholar]

- GB/T 14865-2022; Pebbles and Crushed Stone for Construction. People’s Republic of China: Beijing, China, 2022.

- JGJ52-2016; Standard for the Quality and Inspection Methods of Sand and Stone for Ordinary Concrete. People’s Republic of China: Beijing, China, 2016.

- GB/175-2020; Ordinary Portland Cement. People’s Republic of China: Beijing, China, 2020.

- JGJ63-2006; Concrete Mixing Water Standard. People’s Republic of China: Beijing, China, 2006.

- GB8076-2008; Concrete Admixture. People’s Republic of China: Beijing, China, 2008.

- JGJ55-2019; Common Concrete Mix Design Code. People’s Republic of China: Beijing, China, 2019.

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. People’s Republic of China: Beijing, China, 2016.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. People’s Republic of China: Beijing, China, 2019.

- Ozturk, A.U.; Baradan, B. A comparison study of porosity and compressive strength mathematical models with image analysis. Cem. Concr. Res. 2008, 43, 974–979. [Google Scholar] [CrossRef]

- Shi, C. Strength, pore structure and permeability of alkali-activated slag mortars. Cem. Concr. Res. 1996, 24, 1789–1799. [Google Scholar] [CrossRef]

- Kumar, R.; Bhattacharjee, B. Porosity, pore size distribution and in situ strength of concrete. Cem. Concr. Res. 2003, 33, 155–164. [Google Scholar] [CrossRef]

| Coarse Aggregate | Bulk Density (kg/m3) | Apparent Density (kg/m3) | Crush Value (%) | Water Absorption (%) |

|---|---|---|---|---|

| NCA | 1257 | 2673 | 6.4 | 0.85 |

| RCA | 1123 | 2492 | 13.2 | 3.75 |

| Specific Surface Area (m2/kg) | Firing Loss (%) | Fineness (μm) | Standard Consistency (%) | Setting Time (h:min) | Compressive Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|

| Initial Set | Final Set | 3d | 7d | 28d | ||||

| 333.3 | 2.14 | 32 | 27.9 | 2:35 | 3:56 | 25.9 | 34.1 | 51.4 |

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | TiO2 | P2O5 |

|---|---|---|---|---|---|---|---|---|---|

| 24.61 | 7.64 | 2.8 | 56.27 | 2.39 | 2.17 | 1.45 | 0.42 | 0.3 | 0.05 |

| Specimen | Replacement Rate | Water | Cement | RCA | NCA | Sand | Water Reducing Agent | Additional Water | Slump/mm |

|---|---|---|---|---|---|---|---|---|---|

| RC10 | 10% | 140 | 348 | 1202 | 134 | 580 | 0.976 | 0 | 63 |

| RC20 | 20% | 140 | 348 | 1068 | 267 | 580 | 1.114 | +4.0 | 61 |

| RC30 | 30% | 140 | 348 | 935 | 401 | 580 | 1.198 | +7.0 | 60 |

| RC40 | 40% | 140 | 348 | 801 | 534 | 580 | 1.375 | +11.0 | 59 |

| RC60 | 60% | 140 | 348 | 534 | 803 | 580 | 1.537 | +19.0 | 56 |

| System Parameter | Parameter Value | System Parameter | Parameter Value |

|---|---|---|---|

| SF | 21 MHz | O1 | 275,415.9 Hz |

| RFD | 0.100 ms | P1 | 17.00 μs |

| TW | 2000 ms | P2 | 32.48 μs |

| TD | 44,994 | NS | 2 |

| SW | 100 kHz | TE | 0.300 ms |

| RG1 | 10 db | NE | 1500 |

| DRG1 | 3 | Pore type | Cylindrical or tubular |

| PRG | 1 | Permeation model | Coates model |

| Recycled Concrete | Compressive Strength | Elastic Modulus | ||

|---|---|---|---|---|

| Average Value (MPa) | Standard Deviation | Average Value (GPa) | Standard Deviation | |

| RC10 | 39.61 | 1.55 | 32.67 | 1.58 |

| RC20 | 37.79 | 0.64 | 32.28 | 0.72 |

| RC30 | 36.43 | 0.54 | 31.43 | 0.52 |

| RC40 | 34.4 | 0.78 | 31.96 | 0.65 |

| RC60 | 30.82 | 1.15 | 30.59 | 1.21 |

| Recycled Concrete | Compressive Strength (MPa) | Elastic Modulus (GPa) | Porosity of Different Pore Sizes (%) | |||

|---|---|---|---|---|---|---|

| <20 nm | 20~50 nm | 50~200 nm | >200 nm | |||

| RC10 | 39.61 | 32.67 | 5.19 | 6.29 | 3.74 | 1.39 |

| RC20 | 37.79 | 32.28 | 2.13 | 5.62 | 7.98 | 2.06 |

| RC30 | 36.43 | 31.43 | 1.17 | 4.81 | 9.98 | 3.14 |

| RC40 | 34.40 | 31.96 | 0.78 | 4.14 | 11.01 | 4.29 |

| RC60 | 30.82 | 30.59 | 0.40 | 3.26 | 11.98 | 6.92 |

| Item | Different Pore Size | |||

|---|---|---|---|---|

| <20 nm | 20~50 nm | 50~200 nm | >200 nm | |

| Compressive strength | 0.827 | 0.987 ** | −0.887 * | −0.995 ** |

| Elastic modulus | 0.782 | 0.893 * | −0.827 | −0.910 * |

| Compressive Strength (MPa) | Elastic Modulus (GPa) | ||||

|---|---|---|---|---|---|

| Test Results | Predicted Results | Error | Test Results | Predicted Results | Error |

| 39.61 | 39.65 | 0.10% | 32.67 | 32.71 | 0.12% |

| 37.79 | 37.89 | 0.26% | 32.28 | 32.09 | −0.59% |

| 36.43 | 36.25 | −0.49% | 31.43 | 31.78 | 1.10% |

| 34.4 | 34.61 | 0.61% | 31.96 | 31.43 | −1.66% |

| 30.82 | 30.71 | −0.36% | 30.59 | 30.40 | −0.62% |

| Proposer | Equation After Calibration | R2 |

|---|---|---|

| Model in this paper | 0.9954 0.9962 | |

| Hensselmann | 0.6944 | |

| Schille | 0.6872 | |

| Ryshkewitch | 0.6896 | |

| Powers | 0.6782 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, F.; Pan, H. Research on Quantitative Characterization Model of Compressive Strength or Elastic Modulus of Recycled Concrete Based on Pore Grading. Materials 2025, 18, 3. https://doi.org/10.3390/ma18010003

Xu F, Pan H. Research on Quantitative Characterization Model of Compressive Strength or Elastic Modulus of Recycled Concrete Based on Pore Grading. Materials. 2025; 18(1):3. https://doi.org/10.3390/ma18010003

Chicago/Turabian StyleXu, Fuwei, and Hongke Pan. 2025. "Research on Quantitative Characterization Model of Compressive Strength or Elastic Modulus of Recycled Concrete Based on Pore Grading" Materials 18, no. 1: 3. https://doi.org/10.3390/ma18010003

APA StyleXu, F., & Pan, H. (2025). Research on Quantitative Characterization Model of Compressive Strength or Elastic Modulus of Recycled Concrete Based on Pore Grading. Materials, 18(1), 3. https://doi.org/10.3390/ma18010003