Structure and Properties of Al–CNT-Based Composites Manufactured by Different Methods: A Brief Review

Abstract

1. Introduction

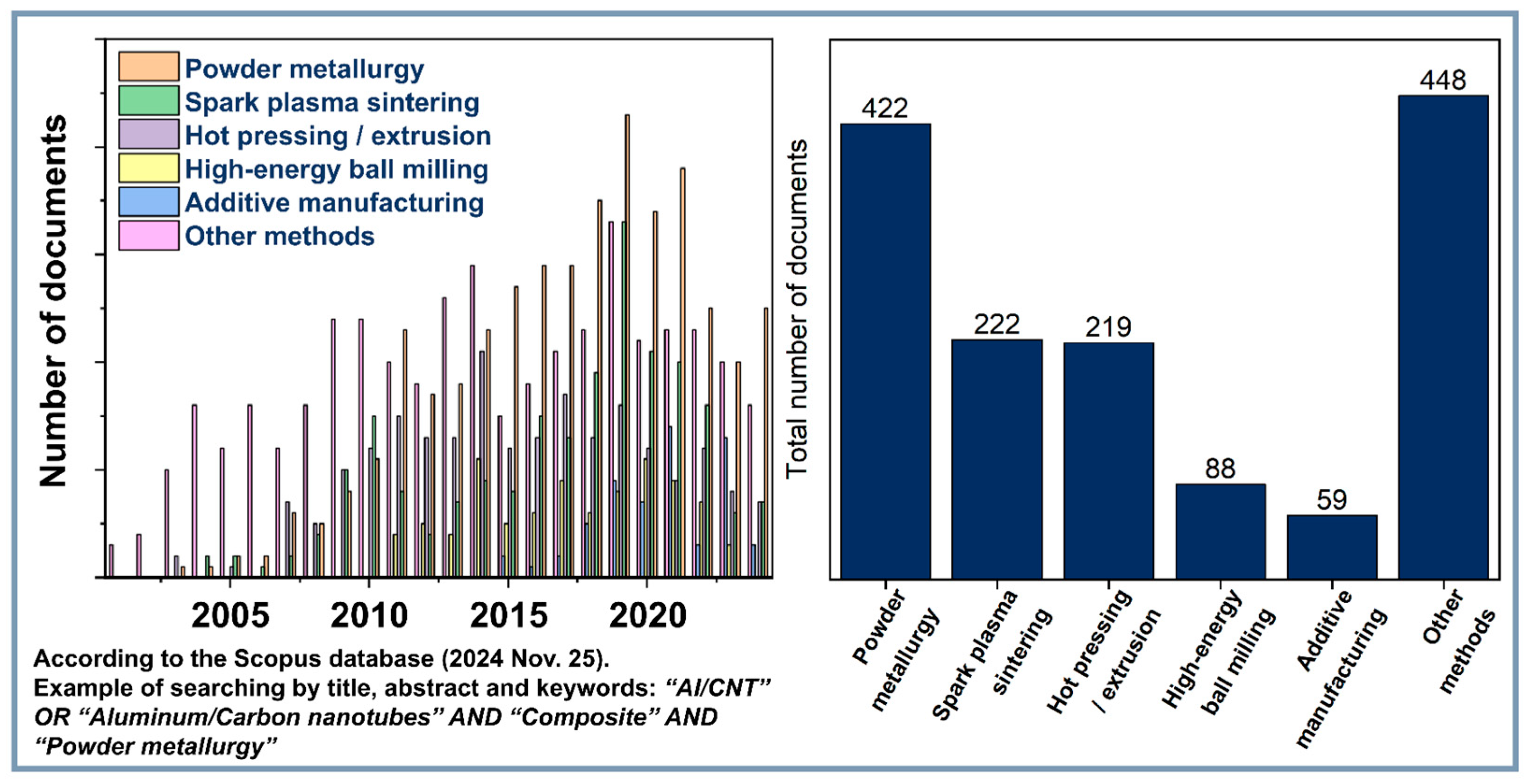

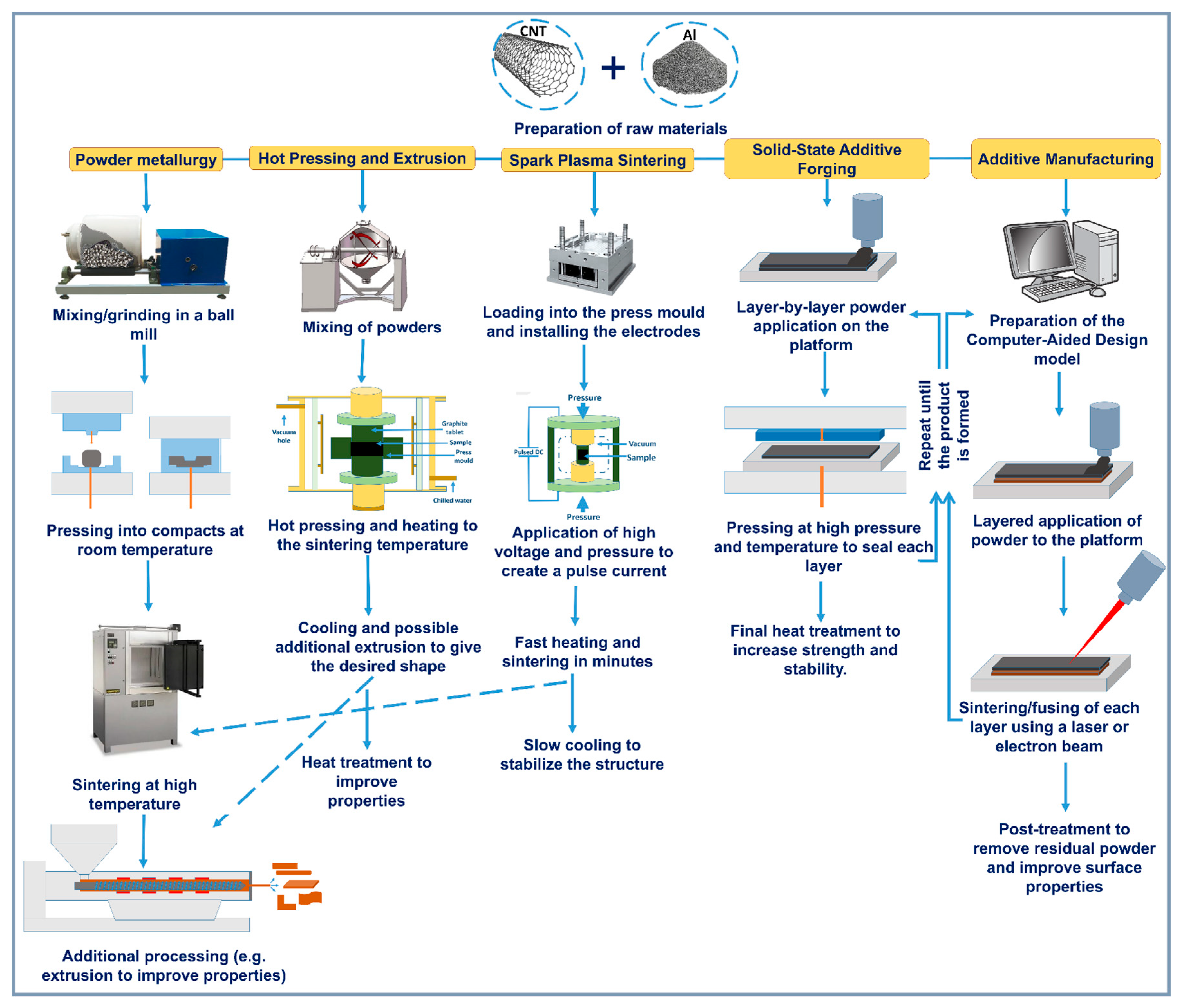

2. Fabrication Methods of Al-CNT Composites and Their Impact on Structure

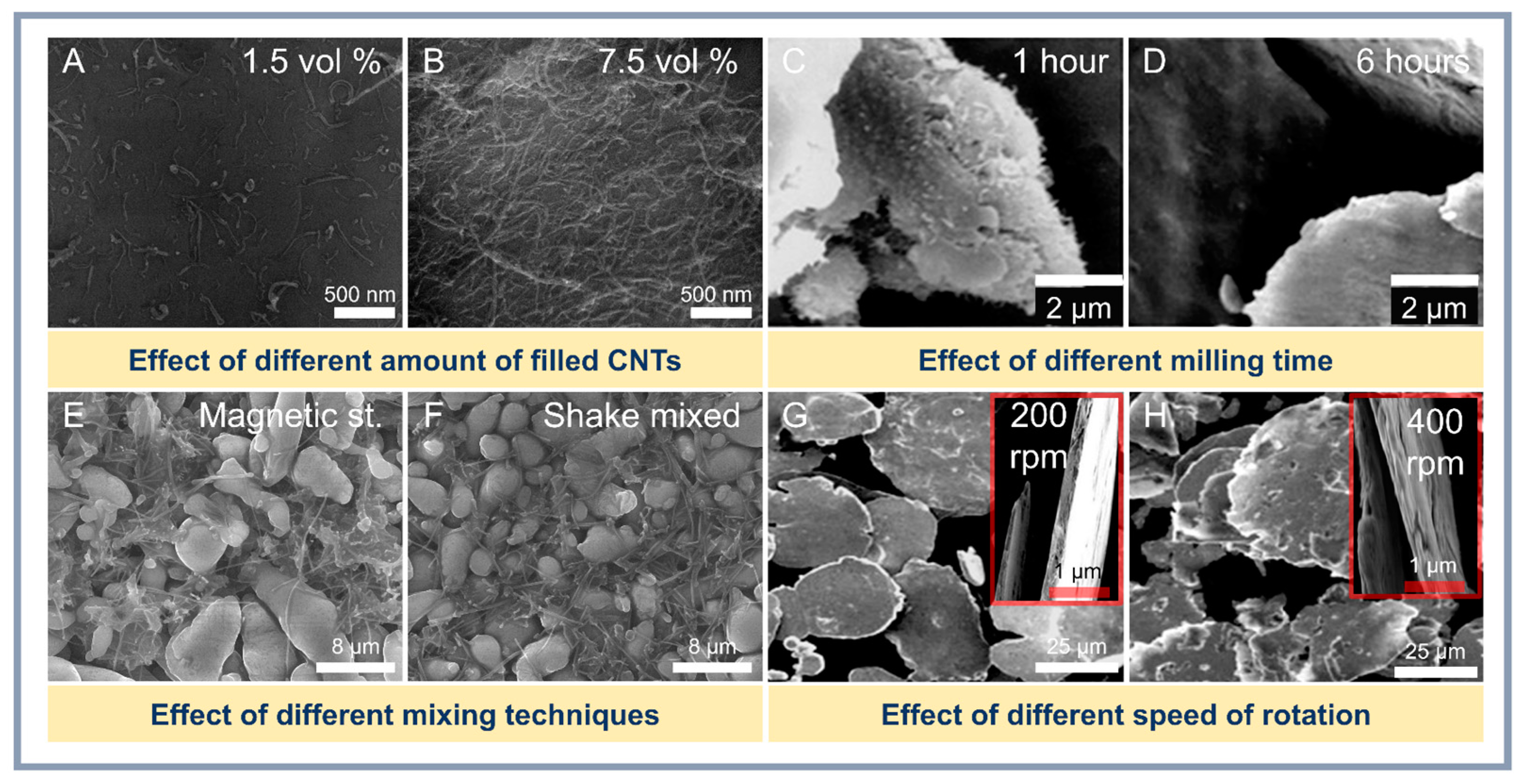

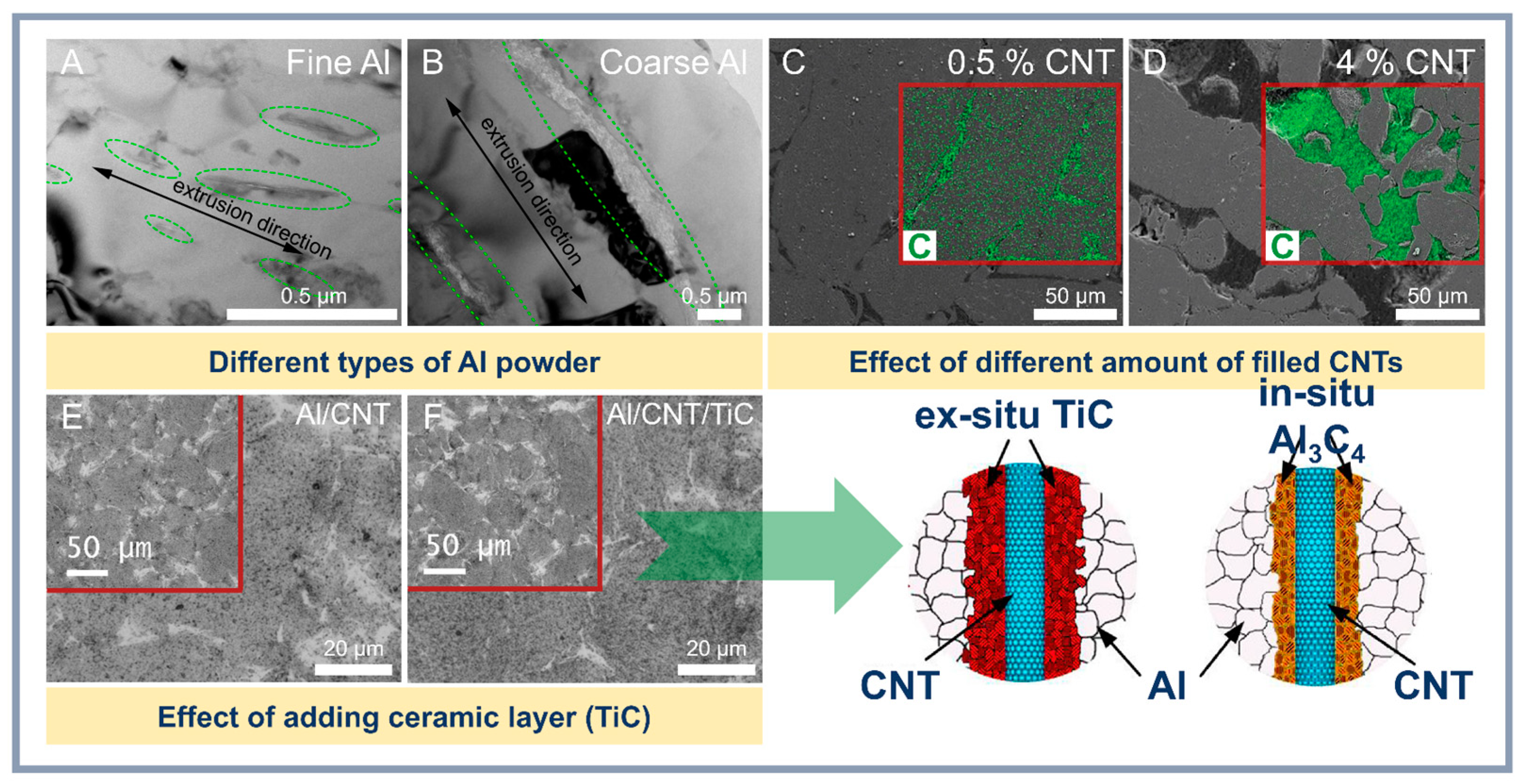

2.1. Conventional Powder Metallurgy Techniques

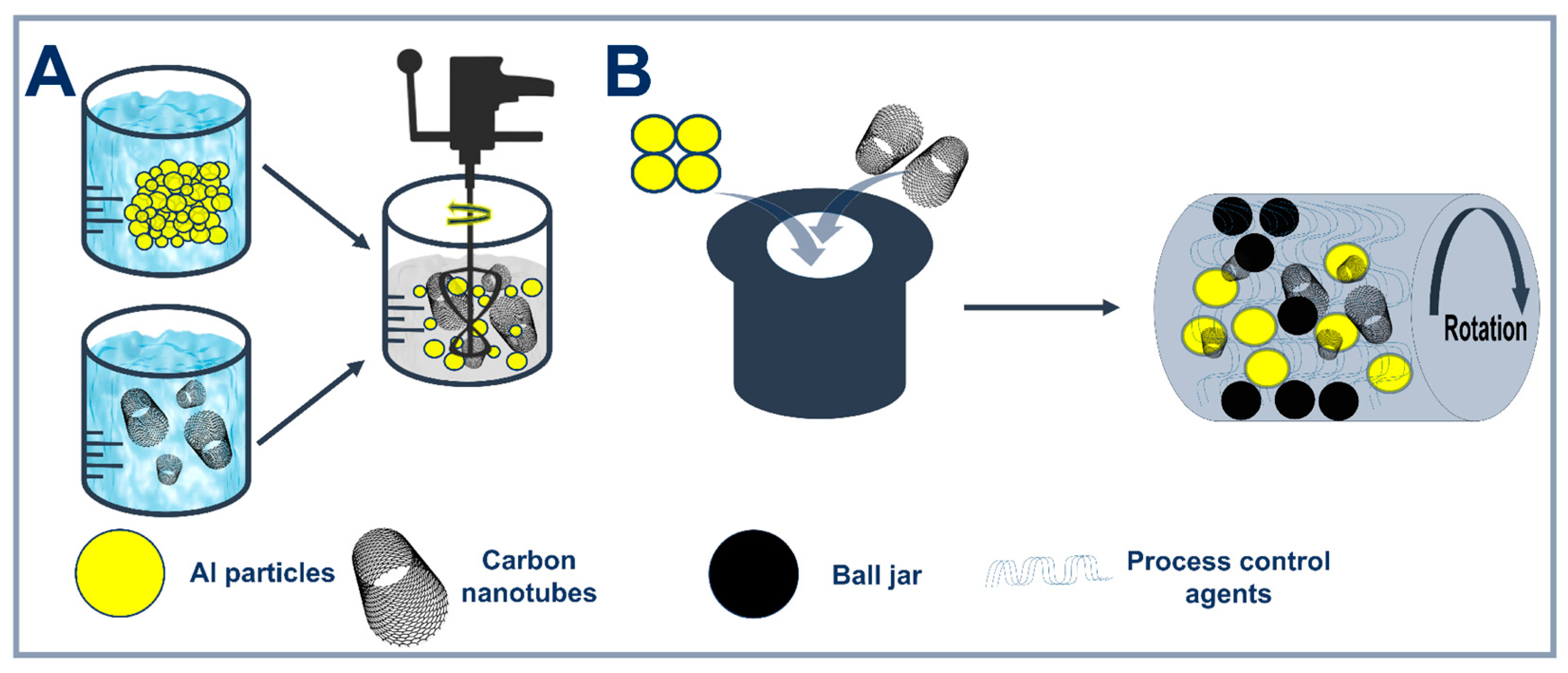

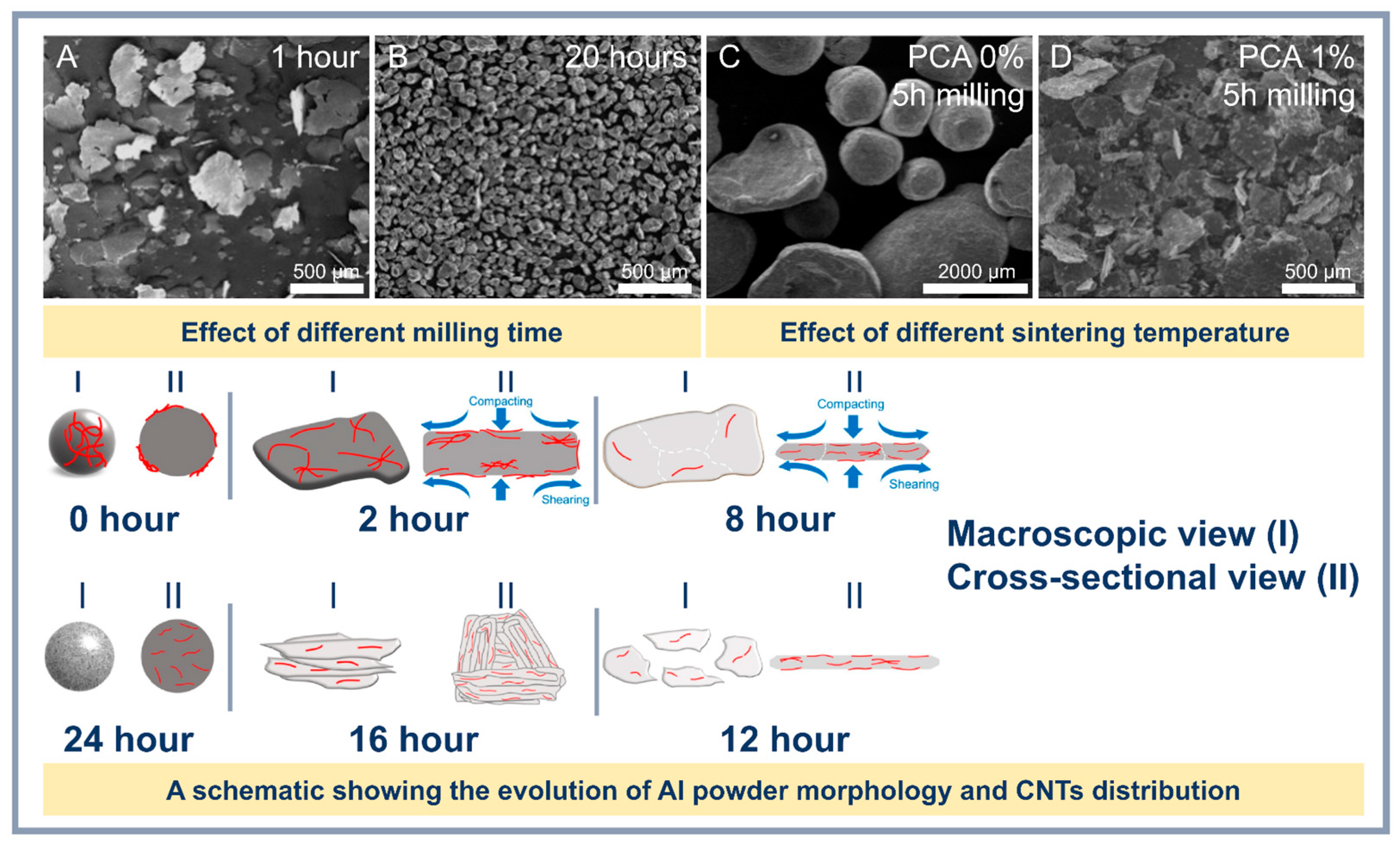

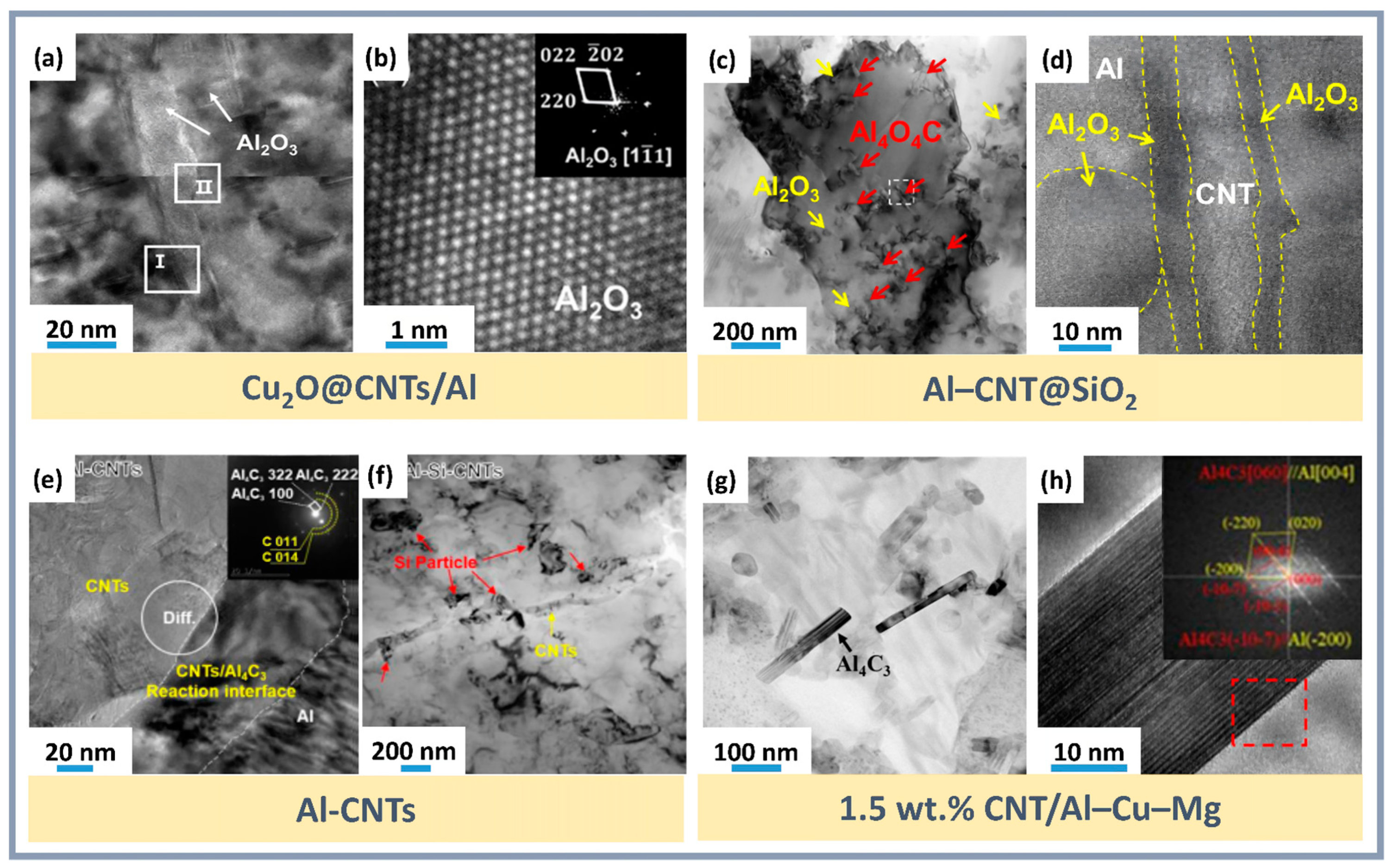

2.1.1. Powder Metallurgy (PM)

2.1.2. Friction Stirring Bonding (FSP)

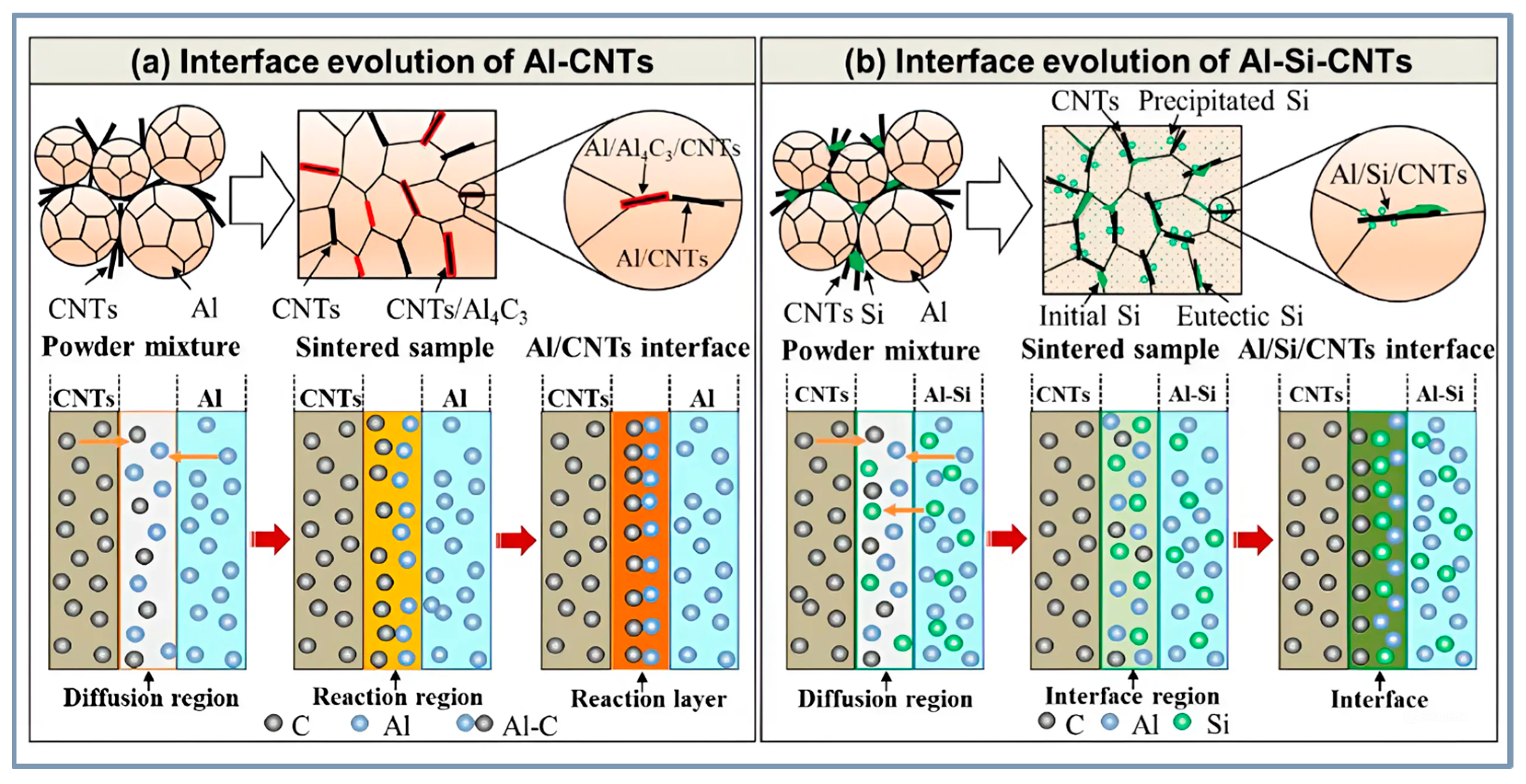

2.2. Diffusion and Reaction Coupling

2.2.1. Spark Plasma Sintering (SPS)

2.2.2. Hot Pressing and Extrusion (HP and HE)

2.2.3. Die Casting

2.3. Adhesive and Reactive Bonding

Deposition Methods

2.4. A Brief Review of the Methods for Producing Al-CNT Composites

3. Properties of Al-CNT Composites

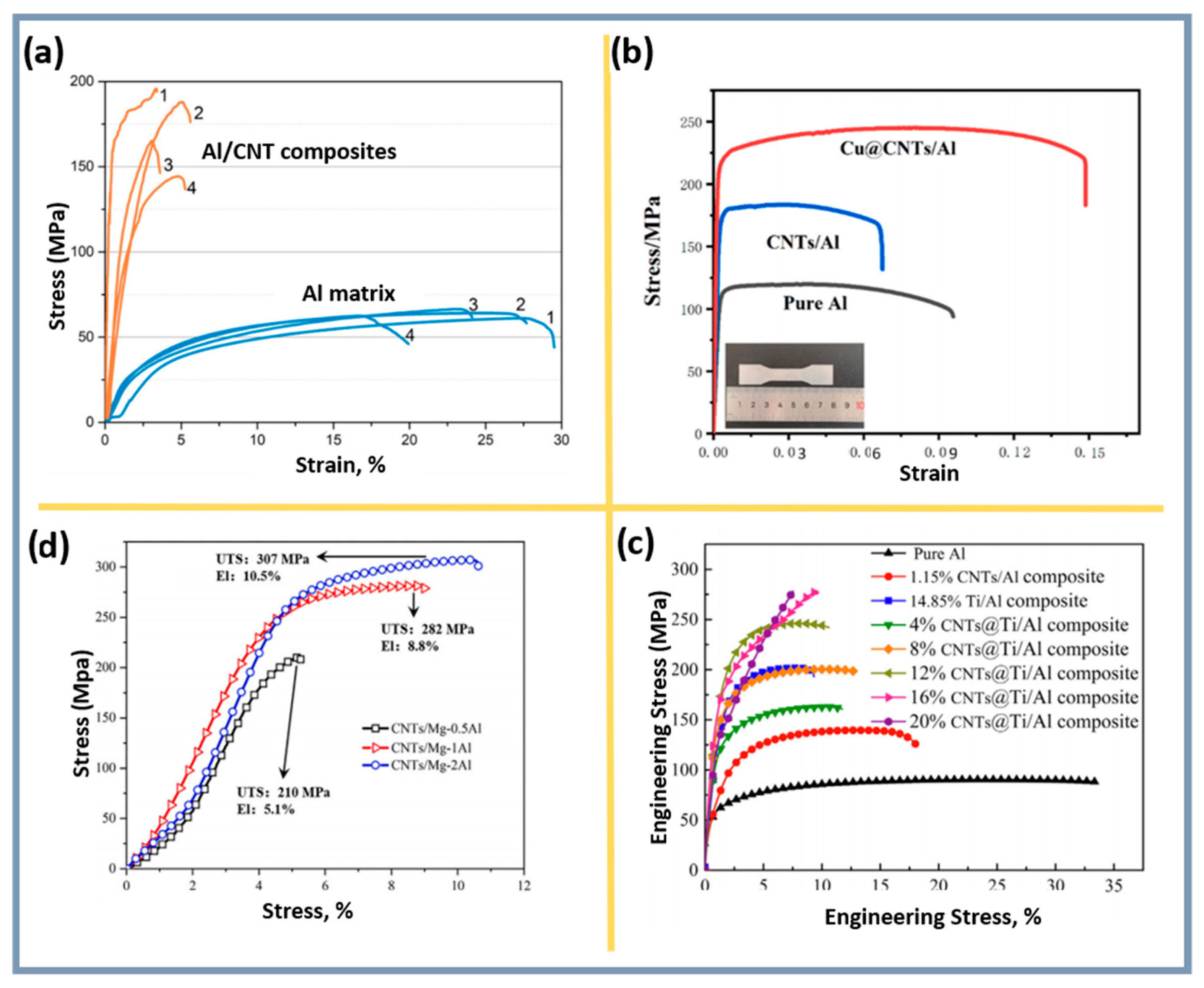

3.1. Mechanical Properties

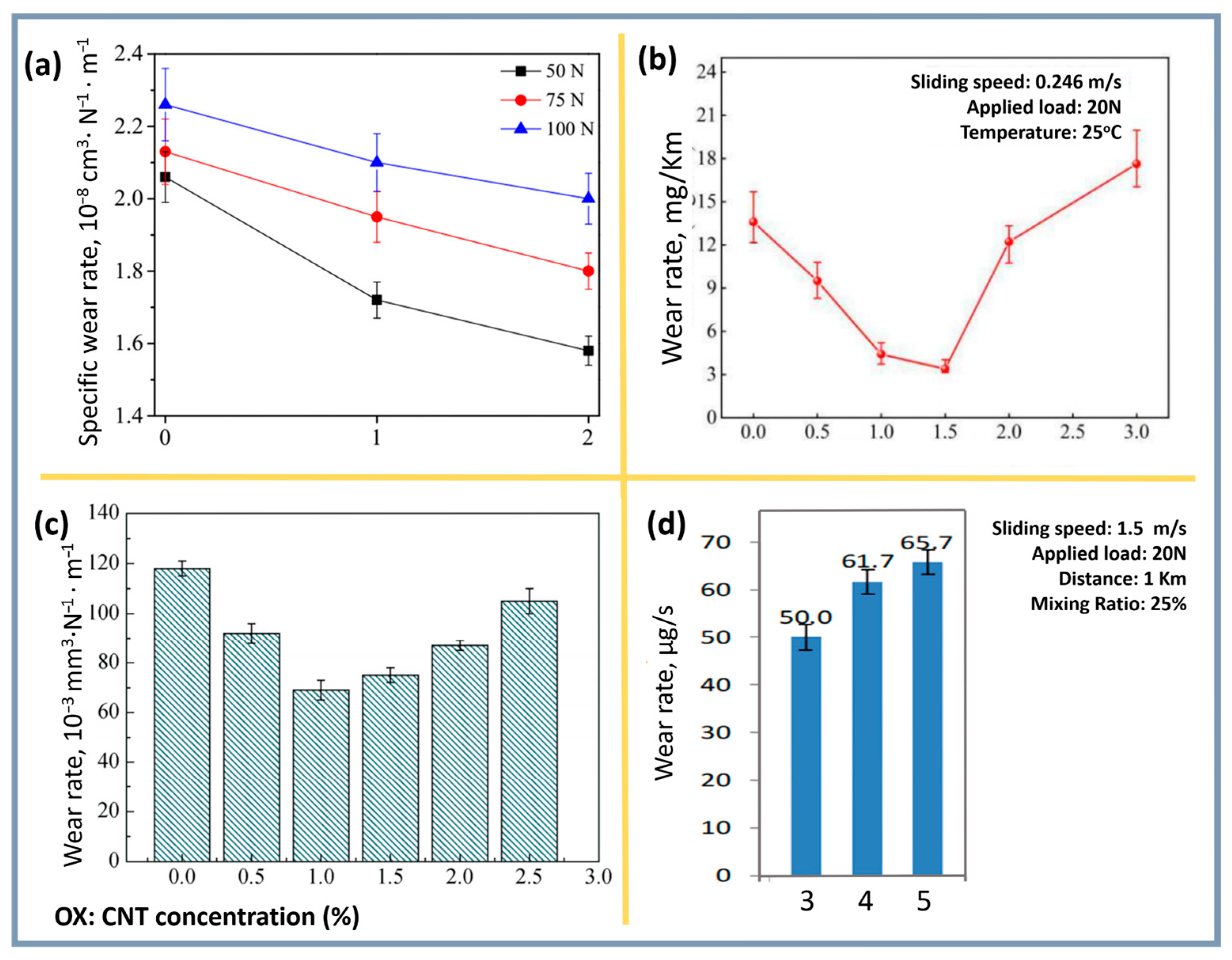

3.2. Wear Resistance

| Composite | PM1 | SP2 | WV3 | WR4 | COF5 | Comms | R6 |

|---|---|---|---|---|---|---|---|

| Al2O3-ZrO2/CNT | Atmospheric plasma spraying | 40 KW, 57.20 V | - | 0.9·10−6 | 0.57 | Synergistic effect of ZrO2, CNT and bimodality helps in enhancing wear resistance. | [150] |

| AA6061-0.5 wt% CNT | Squeeze-casting | 750 °C, 2 min, 100 MPa | n/a | 9.2·10−4 | 0.19 | When the load was increased to 10 N, COF increased to 0.41, but at 15 N, it decreased to 0.34, and SWR decreased to 7.9·10−4 mm3·N−1·m−1 due to the self-lubricating effect of CNT. | [155] |

| Al71Ni14.5Co14.5/CNT poly-quasicrystal | MA and SPS | 950 °C, 10 min, 80 MPa | n/a | 1.0·10−4 | n/a | 21.5% reduction in compressive strength, although the compressive strength remained above 1.1 GPa at 600 °C. | [157] |

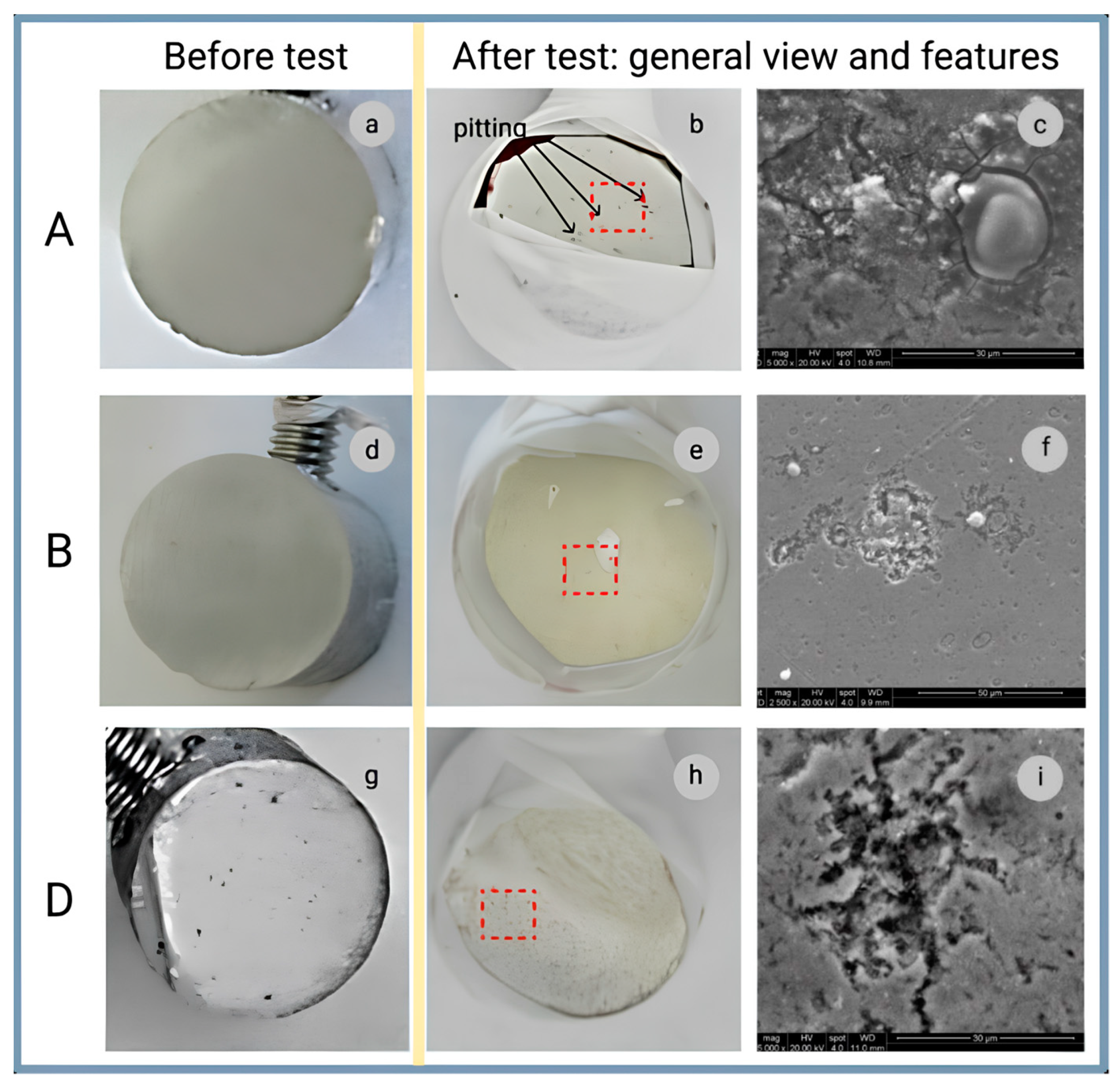

3.3. Corrosion and Erosion Resistance

| Composite | PM1 | SP2 | CP3 | CD4 | CR5 | Comms | R6 |

|---|---|---|---|---|---|---|---|

| Al-Si10-Mg/0.8%CNT | SPS | 540 °C, 18 min, 40 MPa | −324 | −6.34 | n/a | Composite has the large radius of circle and large polarization resistance, | [110] |

| Al1070-0.5%MWCNTs | HP die casting | 760 °C, 200 MPa | −787 (0.5 h) | 0.02 | n/a | Yield strength is 104 MPa, tensile strength is 132.2 MPa | [120] |

| 6Al-Ti−4V/CNT | Taguchi | Dielectric liquid treatment | 3.51 | 1.83 | 0.03 | Improved surface hardness to 10 times (4452.5 HV), | [131] |

| Al71Ni14.5Co14.5/CNT poly-quasicrystal | MA and SPS | 950 °C, 10 min, 80 MPa | −324 | 0.20 | n/a | The QC sample exhibited the lowest Icorr at 0.12 µA·cm−2 | [157] |

| Al-2GAg,NPs/4%CNTs | SPS | 580 °C, 50 MPa, 5 V, 300 amps | −170 | 43.27 | 0.25 | Corrosion resistance is 163.7 Ω.cm2 | [171] |

3.4. Electrical and Thermal Conductivity

4. Challenges and Further Prospects of Al–CNT Composites

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Marques, A.; Guimarães, B.; Bartolomeu, F.; Miranda, G.; Silva, F.S.; Carvalho, O. Multi-Material Inconel 718—Aluminium Parts Targeting Aerospace Applications: A Suitable Combination of Low-Weight and Thermal Properties. Opt. Laser Technol. 2023, 158, 108913. [Google Scholar] [CrossRef]

- Soni, R.; Verma, R.; Garg, R.K.; Singh, H. Progress in Aerospace Materials and Ablation Resistant Coatings: A Focused Review. Opt. Laser Technol. 2024, 177, 111160. [Google Scholar] [CrossRef]

- Zheng, X.; Zhang, H.; Liu, Z.; Jiang, R.; Zhou, X. Functional Composite Electromagnetic Shielding Materials for Aerospace, Electronics and Wearable Fields. Mater. Today Commun. 2022, 33, 104498. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Linul, E. A Review on Synthetic Fibers for Polymer Matrix Composites: Performance, Failure Modes and Applications. Materials 2022, 15, 4790. [Google Scholar] [CrossRef]

- Paladugu, S.R.M.; Sreekanth, P.S.R.; Sahu, S.K.; Naresh, K.; Karthick, S.A.; Venkateshwaran, N.; Ramoni, M.; Mensah, R.A.; Das, O.; Shanmugam, R. A Comprehensive Review of Self-Healing Polymer, Metal, and Ceramic Matrix Composites and Their Modeling Aspects for Aerospace Applications. Materials 2022, 15, 8521. [Google Scholar] [CrossRef] [PubMed]

- Sarmah, P.; Gupta, K. Recent Advancements in Fabrication of Metal Matrix Composites: A Systematic Review. Materials 2024, 17, 4635. [Google Scholar] [CrossRef] [PubMed]

- Fu, W.; Xue, Y.; Song, X.; Tian, X.; Wu, G.; Bian, H.; Hu, S. Microstructural Evolution and Mechanical Properties of Al2O3/Al Joint Bonded by Bi2O3-B2O3-SiO2-ZnO-Al2O3 Glass. Ceram. Int. 2024, 51, 612–622. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, M.; Jiang, T.; Xie, Y.; Sun, Z.; Li, W. Additive Friction Stir Deposition of an Al-Cu-Mg Alloy: Microstructure Evolution and Mechanical Properties. Mater. Charact. 2024, 218, 114562. [Google Scholar] [CrossRef]

- Verma, P.K.; Singh, A.; Kumar, A.; Malik, N. Microstructure, Mechanical, and Wear Characteristics of Heat-Treated Aerospace-Grade Aluminium Composite Reinforced with HEA Particles. Mater. Chem. Phys. 2025, 331, 130195. [Google Scholar] [CrossRef]

- Prasad, J.; Sonwani, R.K. Optimize Chemical Milling of Aluminium Alloys to Achieve Minimum Surface Roughness in Aerospace and Defense Industry. J. Indian Chem. Soc. 2024, 102, 101537. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent Developments in Advanced Aircraft Aluminium Alloys. Mater. Des. 1980–2015 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Agarwal, I. Composites, Metals, and Ceramics Used in the Boeing 787—A Material Overview. Int. J. Sci. Res. IJSR 2024, 13, 1661–1666. [Google Scholar] [CrossRef]

- Zhu, L.; Li, N.; Childs, P.R.N. Light-Weighting in Aerospace Component and System Design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Vadivel, M.; Seenivasan, S.; Satishkumar, P.; Gomkale, S.; Saminathan, R. Enhancement of Mechanical Properties in AA5083 Aluminum Metal Matrix Composites through Alumina and Titanium Carbide Reinforcement. Interactions 2024, 245, 365. [Google Scholar] [CrossRef]

- Muribwathoho, O.; Msomi, V.; Mabuwa, S. An Analysis Comparing the Taguchi Method for Optimizing the Process Parameters of AA5083/Silicon Carbide and AA5083/Coal Composites That Are Fabricated via Friction Stir Processing. Appl. Sci. 2024, 14, 9616. [Google Scholar] [CrossRef]

- Krishnan, B.R.; Viravel, D.K.; Sundaram, C.M.; Ramkumaresh, H. Wear Analysis of Al-SiC-Jute Ash Hybrid Composite via Stir Casting Process. Interactions 2024, 245, 205. [Google Scholar] [CrossRef]

- Lucas, J.P.; Stephens, J.J.; Greulich, F.A. The Effect of Reinforcement Stability on Composition Redistribution in Cast Aluminum Metal Matrix Composites. Mater. Sci. Eng. A 1991, 131, 221–230. [Google Scholar] [CrossRef]

- Farid, W.; Li, H.; Wang, Z.; Cui, H.; Kong, C.; Yu, H. Integrating Experimental and Computational Analyses for Mechanical Characterization of Titanium Carbide/Aluminum Metal Matrix Composites. Materials 2024, 17, 2093. [Google Scholar] [CrossRef]

- Andilab, B.; Emadi, P.; Sydorenko, M.; Ravindran, C. Influence of GNP Additions on the Microstructure, Mechanical Properties, and Electrical Conductivity of Cast A319 Aluminum Alloy. Int. J. Met. 2024, 18, 3047–3061. [Google Scholar] [CrossRef]

- Zhu, M.; Shao, Y.; Zhao, Y.; Chua, B.W.; Du, Z.; Gan, C.L. Interface Engineering in CF/Al Matrix Composites for Enhancement in Mechanical Strength and Anti-Corrosion Properties. Mater. Charact. 2024, 212, 113990. [Google Scholar] [CrossRef]

- Kundu, S.; Mondal, S. Electro-Thermal and Mechanical Property Analysis of Powder Metallurgy Processed, Multi-Stage Ball Milled Aluminium-Copper-Multi Walled Carbon Nanotube Composite. Eng. Res. Express 2024, 6, 025574. [Google Scholar] [CrossRef]

- Devadiga, U.; Fernandes, P.; Buradi, A.; Emma, A.F. Significance of Addition of Carbon Nanotubes and Fly Ash on the Wear and Frictional Performance of Aluminum Metal Matrix Composites. Eng. Rep. 2024, 6, e12865. [Google Scholar] [CrossRef]

- Yao, N.; Lordi, V. Young’s Modulus of Single-Walled Carbon Nanotubes. J. Appl. Phys. 1998, 84, 1939–1943. [Google Scholar] [CrossRef]

- George, R.; Kashyap, K.T.; Rahul, R.; Yamdagni, S. Strengthening in Carbon Nanotube/Aluminium (CNT/Al) Composites. Scr. Mater. 2005, 53, 1159–1163. [Google Scholar] [CrossRef]

- Li, L.; Jiang, H.; Liu, Y.; Zhao, Q.; Tao, J.; Fan, Y.; Liu, Y.; Li, C.; Yi, J. Improvement of Thermal Conductivity and Wear Property of Gr/EP Composites with CNTs/Cu Foam as 3-Dimensional Reinforcing Skeleton. J. Mater. Res. Technol. 2024, 29, 1172–1182. [Google Scholar] [CrossRef]

- Kumar, N.; Soren, S.; Prasad, R.; Singh, Y.; Nautiyal, H.; Sharma, A.; Tiang, S.S.; Lim, W.H. Optimization of Sintering Process Parameters by Taguchi Method for Developing Al-CNT-Reinforced Powder Composites. Crystals 2023, 13, 1352. [Google Scholar] [CrossRef]

- Cao, L.; Chen, B.; Wan, J.; Kondoh, K.; Guo, B.; Shen, J.; Li, J.S. Superior High-Temperature Tensile Properties of Aluminum Matrix Composites Reinforced with Carbon Nanotubes. Carbon 2022, 191, 403–414. [Google Scholar] [CrossRef]

- Adara, P.P.; Oyinbo, S.T.; Jen, T.-C. Electrical and Mechanical Properties Variation of Al2O3–CaO-CNT(3,3) Nanomaterial Due to Al Vacancy and Temperature: DFT Approach. Results Mater. 2024, 22, 100571. [Google Scholar] [CrossRef]

- Yang, K.; Yang, X.; Liu, E.; Shi, C.; Ma, L.; He, C.; Li, Q.; Li, J.; Zhao, N. Elevated Temperature Compressive Properties and Energy Absorption Response of In-Situ Grown CNT-Reinforced Al Composite Foams. Mater. Sci. Eng. A 2017, 690, 294–302. [Google Scholar] [CrossRef]

- Hussein, M.A.; Shahzad, H.K.; Patel, F.; Atieh, M.A.; Al-Aqeeli, N.; Baroud, T.N.; Laoui, T. Porous Al2O3-CNT Nanocomposite Membrane Produced by Spark Plasma Sintering with Tailored Microstructure and Properties for Water Treatment. Nanomaterials 2020, 10, 845. [Google Scholar] [CrossRef]

- Kuzumaki, T.; Miyazawa, K.; Ichinose, H.; Ito, K. Processing of Carbon Nanotube Reinforced Aluminum Composite. J. Mater. Res. 1998, 13, 2445–2449. [Google Scholar] [CrossRef]

- Shivaramu, H.T.; Nayak, U.V.; Neelakantha, V.L.; Umashankar, K.S. Production of Al/MWCNT Nanocomposite by Powder Metallurgy to Enhance Dry Sliding Wear Performance Aided by Design of Experiment. In Structural Composite Materials: Fabrication, Properties, Applications and Challenges; Boppana, S.B., Ramachandra, C.G., Kumar, K.P., Ramesh, S., Eds.; Springer Nature: Singapore, 2024; pp. 223–241. ISBN 978-981-9959-82-2. [Google Scholar]

- Deng, C.F.; Wang, D.Z.; Zhang, X.X.; Li, A.B. Processing and Properties of Carbon Nanotubes Reinforced Aluminum Composites. Mater. Sci. Eng. A 2007, 444, 138–145. [Google Scholar] [CrossRef]

- Doğan, K.; Özgün, M.İ.; Sübütay, H.; Salur, E.; Eker, Y.; Kuntoğlu, M.; Aslan, A.; Gupta, M.K.; Acarer, M. Dispersion Mechanism-Induced Variations in Microstructural and Mechanical Behavior of CNT-Reinforced Aluminum Nanocomposites. Arch. Civ. Mech. Eng. 2022, 22, 55. [Google Scholar] [CrossRef]

- Ujah, C.; Popoola, P.; Popoola, O.; Aigbodion, V. Enhanced Mechanical, Electrical and Corrosion Characteristics of Al-CNTs-Nb Composite Processed via Spark Plasma Sintering for Conductor Core. J. Compos. Mater. 2019, 53, 3775–3786. [Google Scholar] [CrossRef]

- Ujah, C.O.; Popoola, A.P.I.; Popoola, O.M.; Aigbodion, V.S. Enhanced Tribology, Thermal and Electrical Properties of Al-CNT Composite Processed via Spark Plasma Sintering for Transmission Conductor. J. Mater. Sci. 2019, 54, 14064–14073. [Google Scholar] [CrossRef]

- Krishna, A.; Aravinda, L.S.; Murugan, A.; Kumar, N.S.; Sankar, M.R.; Nagahanumaiah; Reddy, K.N.; Balashanmugam, N. A Study on Wafer Scalable, Industrially Applicable CNT Based Nanocomposites of Al-CNT, Cu-CNT, Ti-CNT, and Ni-CNT as Thermal Interface Materials Synthesised by Thin Film Techniques. Surf. Coat. Technol. 2022, 429, 127926. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Z.; Peng, Y.; Yan, D.; Tan, Z.; Zhou, Q.; Wang, K.; Zhou, M. Microstructure and Mechanical Properties of Underwater Friction Stir Welding of CNT/Al-Cu-Mg Composites. J. Mater. Res. Technol. 2022, 18, 405–415. [Google Scholar] [CrossRef]

- Soni, S.; Thomas, B.; Kar, V. A Comprehensive Review on CNTs and CNT-Reinforced Composites: Syntheses, Characteristics and Applications. Mater. Today Commun. 2020, 25, 101546. [Google Scholar] [CrossRef]

- Zuo, G.; Bai, Y.; Shi, S.; Tan, Z.; Fan, W.; Li, Z.; Hao, H. Interfacial Healing Behavior of CNTs/Al Composites in Solid-State Additive Forging. J. Manuf. Process. 2024, 125, 143–154. [Google Scholar] [CrossRef]

- Akbarpour, M.R.; Pouresmaeil, A. The Influence of CNTs on the Microstructure and Strength of Al-CNT Composites Produced by Flake Powder Metallurgy and Hot Pressing Method. Diam. Relat. Mater. 2018, 88, 6–11. [Google Scholar] [CrossRef]

- Li, P.Y.; Li, X.N.; Dong, Z.Y.; Liu, Z.Y.; Chen, L.Q.; Xiao, B.L.; Ma, Z.Y. Microstructure Evolution and Strength-Ductility Improving Mechanism Change of Heterogeneous CNT/2009Al Composite after Hot Rolling. J. Alloys Compd. 2023, 948, 169764. [Google Scholar] [CrossRef]

- bin Ariffin, M.A.; bin Muhamad, M.R.; Raja, S.; Jamaludin, M.F.; Yusof, F.; Suga, T.; Liu, H.; Morisada, Y.; Fujii, H. Friction Stir Alloying of AZ61 and Mild Steel with Cu-CNT Additive. J. Mater. Res. Technol. 2022, 21, 2400–2415. [Google Scholar] [CrossRef]

- Zuo, G.; Bai, Y.; Tan, Z.; Fan, W.; Shi, S.; Hao, H. Temperature Effects on Solid State Bonding Joints of Ultrafine-Grained CNT/Al–Cu–Mg Composites. Compos. Part B Eng. 2024, 284, 111681. [Google Scholar] [CrossRef]

- Yuan, C.; Zhang, Z.; Tan, Z.; Xu, L.; Zhang, S.; Fan, G.; Zhang, P.; Li, Z. Enhanced Ductility by Mg Addition in the CNT/Al-Cu Composites via Flake Powder Metallurgy. Mater. Today Commun. 2021, 26, 101854. [Google Scholar] [CrossRef]

- Cao, L.; Chen, B.; Wan, J.; Shen, J.; Li, S.; Liu, S.; Li, J. Unraveling the Dispersion Mechanism of Carbon Nanotubes in Aluminum Powder Particles during High Energy Ball Milling by FIB-TEM Study. Powder Technol. 2023, 419, 118339. [Google Scholar] [CrossRef]

- Wang, T.; Xu, F.; Sun, L.; Miao, L.; Liao, L.; Wei, S.; Yin, Q.; Zhang, K.; Li, Y.; Wu, Y.; et al. Improved Performance of Hydrogen Generation for Al–Bi-CNTs Composite by Spark Plasma Sintering. J. Alloys Compd. 2021, 860, 157925. [Google Scholar] [CrossRef]

- Ramachandran, K.; Gnanasagaran, C.L.; Pazhani, A.; Kumar, V.H.; Xavior, M.A.; Subramani, R.R.; Arunkumar, T. Impact Behaviour of MWCNTs Reinforced YSZ and Al2O3 Ceramic-Nanocomposites Prepared via Vacuum Hot-Pressing Technique. J. Mater. Res. Technol. 2023, 24, 6595–6603. [Google Scholar] [CrossRef]

- Ma, K.; Liu, Z.Y.; Liu, B.S.; Xiao, B.L.; Ma, Z.Y. Improving Ductility of Bimodal Carbon Nanotube/2009Al Composites by Optimizing Coarse Grain Microstructure via Hot Extrusion. Compos. Part Appl. Sci. Manuf. 2021, 140, 106198. [Google Scholar] [CrossRef]

- Dhore, V.G.; Rathod, W.S.; Patil, K.N. Investigation of Mechanical Properties of Carbon Nanotubes Reinforced Aluminium Composite by Metal Injection Molding. Mater. Today Proc. 2018, 5, 20690–20698. [Google Scholar] [CrossRef]

- Zhong, K.; Zhou, J.; Zhao, C.; Yun, K.; Qi, L. Effect of Interfacial Transition Layer with CNTs on Fracture Toughness and Failure Mode of Carbon Fiber Reinforced Aluminum Matrix Composites. Compos. Part Appl. Sci. Manuf. 2022, 163, 107201. [Google Scholar] [CrossRef]

- Guan, H.D.; Li, C.J.; Peng, Y.Z.; Gao, P.; Feng, Z.X.; Liu, Y.C.; Li, J.N.; Tao, J.M.; Yi, J.H. Fe-Based Metallic Glass Particles Carry Carbon Nanotubes to Reinforce Al Matrix Composites. Mater. Charact. 2022, 189, 112006. [Google Scholar] [CrossRef]

- Liu, L.; Li, S.; Zhang, X.; Pan, D.; Gao, L.; Chen, B.; Umeda, J.; Kondoh, K. Syntheses, Microstructure Evolution and Performance of Strength-Ductility Matched Aluminum Matrix Composites Reinforced by Nano SiC-Cladded CNTs. Mater. Sci. Eng. A 2021, 824, 141784. [Google Scholar] [CrossRef]

- Saba, F.; Chen, M.; Ziaei, H.; Fan, G.; Tan, Z.; Li, Z. Fabrication of High-Content Hybrid-Reinforced Al Nanocomposites by in-Situ Reaction of TiO2-Decorated CNTs and Matrix. Diam. Relat. Mater. 2023, 138, 110228. [Google Scholar] [CrossRef]

- Geng, H.; Chen, B.; Cao, L.; Wan, J.; Shen, J.; Kondoh, K.; Li, J. Aging Behavior, Microstructure and Mechanical Properties of Al-Cu-Mg Alloy Matrix Composites Reinforced with Carbon Nanotubes. Mater. Sci. Eng. A 2024, 915, 147174. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiao, Y.; Xu, J.; He, M.; Luo, Y.; Xiang, J. Understanding the Influencing Mechanism of CNTs on the Microstructure and Mechanical Properties of Semi-Solid Stir Casting Al-Cu-Mg Alloys. J. Mater. Res. Technol. 2022, 18, 3949–3960. [Google Scholar] [CrossRef]

- Zhu, W.; Liu, H.; Xing, S.; Jiang, C.; Ji, V. Surface Mechanical Property and Residual Stress Stability of Nanostructured CNT/Al-Cu-Mg Composites Induced by Shot Peening. Mater. Charact. 2024, 218, 114515. [Google Scholar] [CrossRef]

- Sasani, F.; Taheri, A.K.; Pouranvari, M. Correlation between Microstructure and Mechanical Properties of AlMg6/CNT-Al Composite Produced by Accumulative Roll Bonding Process: Experimental and Modelling Analysis. Mater. Sci. Eng. A 2022, 850, 143559. [Google Scholar] [CrossRef]

- Zhang, B.; Huang, Y.; Dou, Z.; Wang, J.; Huang, Z. Refractory High-Entropy Alloys Fabricated by Powder Metallurgy: Progress, Challenges and Opportunities. J. Sci. Adv. Mater. Devices 2024, 9, 100688. [Google Scholar] [CrossRef]

- Wei, Y.; Luo, L.-M.; Liu, H.-B.; Zan, X.; Song, J.-P.; Xu, Q.; Zhu, X.-Y.; Wu, Y.-C. A Powder Metallurgy Route to Fabricate CNT-Reinforced Molybdenum-Hafnium-Carbon Composites. Mater. Des. 2020, 191, 108635. [Google Scholar] [CrossRef]

- Fan, G.; Xu, R.; Tan, Z.; Zhang, D.; Li, Z. Development of Flake Powder Metallurgy in Fabricating Metal Matrix Composites: A Review. Acta Metall. Sin. Engl. Lett. 2014, 27, 806–815. [Google Scholar] [CrossRef]

- Xu, R.; Tan, Z.; Xiong, D.; Fan, G.; Guo, Q.; Zhang, J.; Su, Y.; Li, Z.; Zhang, D. Balanced Strength and Ductility in CNT/Al Composites Achieved by Flake Powder Metallurgy via Shift-Speed Ball Milling. Compos. Part Appl. Sci. Manuf. 2017, 96, 57–66. [Google Scholar] [CrossRef]

- Sattari, S.; Jahani, M.; Atrian, A. Effect of Volume Fraction of Reinforcement and Milling Time on Physical and Mechanical Properties of Al7075–SiC Composites Fabricated by Powder Metallurgy Method. Powder Metall. Met. Ceram. 2017, 56, 283–292. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Zhao, K.; Xiao, B.L.; Wang, W.G.; Ma, Z.Y. Fabrication of CNT/Al Composites with Low Damage to CNTs by a Novel Solution-Assisted Wet Mixing Combined with Powder Metallurgy Processing. Mater. Des. 2016, 97, 424–430. [Google Scholar] [CrossRef]

- Choi, H.; Shin, J.; Min, B.; Park, J.; Bae, D. Reinforcing Effects of Carbon Nanotubes in Structural Aluminum Matrix Nanocomposites. J. Mater. Res. 2009, 24, 2610–2616. [Google Scholar] [CrossRef]

- Peng, T.; Chang, I. Uniformly Dispersion of Carbon Nanotube in Aluminum Powders by Wet Shake-Mixing Approach. Powder Technol. 2015, 284, 32–39. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.; Perrone, A.; Castro, M.M. Optimizing Ball Milling Parameters for Controlling the Internal Microstructure and Tensile Characteristics of a Laminated Carbon Nanotube/Aluminum–Copper–Magnesium Composite. Results Mater. 2024, 21, 100520. [Google Scholar] [CrossRef]

- Kim, D.; Hirayama, Y.; Liu, Z.; Takagi, K.; Kobashi, M. Fabrication of Al-CNT Composite with High Hardness and Electrical Conductivity by Controlling Al4C3 Formation. J. Alloys Compd. 2023, 942, 169102. [Google Scholar] [CrossRef]

- Ardila-Rodríguez, L.A.; Menezes, B.R.C.; Pereira, L.A.; Oliveira, A.C.; Travessa, D.N. Titanium Dioxide Protection against Al4C3 Formation during Fabrication of Aluminum-TiO2 Coated MWCNT Composite. J. Alloys Compd. 2019, 780, 772–782. [Google Scholar] [CrossRef]

- Toozandehjani, M.; Ostovan, F.; Jamaludin, K.R.; Amrin, A.; Matori, K.A.; Shafiei, E. Process−microstructure−properties Relationship in Al−CNTs−Al2O3 Nanocomposites Manufactured by Hybrid Powder Metallurgy and Microwave Sintering Process. Trans. Nonferrous Met. Soc. China 2020, 30, 2339–2354. [Google Scholar] [CrossRef]

- Zhang, X.; Li, X.; Liu, L.; Li, B.; Hou, X.; Pan, D.; Gao, L.; Li, S. Interface Regulation Strategy of Al-CNTs Composite Induced by Al-Si Eutectic Reaction and Its Strengthening Mechanism. J. Mater. Sci. Technol. 2023, 151, 1–9. [Google Scholar] [CrossRef]

- Wan, J.; Chen, B.; Feng, D.; Cao, L.; Shen, J.; Guo, B.; Li, J.S. Strengthening Efficiency Competition between Carbon Nanotubes (CNTs) and in-Situ Al4C3 Nanorods in CNTs/Al Composites Influenced by Alumina Characteristics. Compos. Part Appl. Sci. Manuf. 2022, 152, 106704. [Google Scholar] [CrossRef]

- Peng, T.; Chang, I. Mechanical Alloying of Multi-Walled Carbon Nanotubes Reinforced Aluminum Composite Powder. Powder Technol. 2014, 266, 7–15. [Google Scholar] [CrossRef]

- Payandehpeyman, J.; Hedayatian, M.; Mazaheri, M. Predicting Effective Elastic Modulus of CNT Metal Matrix Nanocomposites: A Developed Micromechanical Model with Agglomeration and Interphase Effects. Compos. Struct. 2024, 344, 118317. [Google Scholar] [CrossRef]

- Yi, C.; Chen, X.; Gou, F.; Dmuchowski, C.M.; Sharma, A.; Park, C.; Ke, C. Direct Measurements of the Mechanical Strength of Carbon Nanotube—Aluminum Interfaces. Carbon 2017, 125, 93–102. [Google Scholar] [CrossRef]

- Awotunde, M.A.; Olubambi, P.A.; Chen, D. Compressive Deformation Behaviour and Toughening Mechanisms of Spark Plasma Sintered NiAl-CNT Composites. Ceram. Int. 2022, 48, 16072–16084. [Google Scholar] [CrossRef]

- Carneiro, Í.; Viana, F.; Vieira, M.; Fernandes, J.; Simões, S. EBSD Analysis of Metal Matrix Nanocomposite Microstructure Produced by Powder Metallurgy. Nanomaterials 2019, 9, 878. [Google Scholar] [CrossRef]

- Liu, Y.; Ning, Y.; Zekun, Y.; Li, H.; Miao, X.; Li, Y.; Zhao, Z. Plastic Deformation and Dynamic Recrystallization of a Powder Metallurgical Nickel-Based Superalloy. J. Alloys Compd. 2016, 675, 73–80. [Google Scholar] [CrossRef]

- Li, B.; Chen, H.; Li, G.; Wei, G.; Xie, W. Strengthening and Toughening Mechanisms of CNTs/Mg–Al Composites Prepared via Powder Metallurgy Combined with Hot Extrusion. Vacuum 2023, 214, 112210. [Google Scholar] [CrossRef]

- Wang, S.; Yuan, T.; Liu, L.; Wang, L.; Jiang, X.; Shan, H.; Chen, S.; Zhao, P. Microstructure and Strengthening Mechanism of TIG Welded Joint of AZ31 Alloy Based on FSP Technique. J. Manuf. Process. 2024, 124, 551–565. [Google Scholar] [CrossRef]

- Sharma, A.; Fujii, H.; Paul, J. Influence of Reinforcement Incorporation Approach on Mechanical and Tribological Properties of AA6061-CNT Nanocomposite Fabricated via FSP. J. Manuf. Process. 2020, 59, 604–620. [Google Scholar] [CrossRef]

- Jain, V.K.S.; Yazar, K.U.; Muthukumaran, S. Development and Characterization of Al5083-CNTs/SiC Composites via Friction Stir Processing. J. Alloys Compd. 2019, 798, 82–92. [Google Scholar] [CrossRef]

- Izadi, H.; Gerlich, A.P. Distribution and Stability of Carbon Nanotubes during Multi-Pass Friction Stir Processing of Carbon Nanotube/Aluminum Composites. Carbon 2012, 50, 4744–4749. [Google Scholar] [CrossRef]

- Parikh, V.K.; Badgujar, A.D.; Ghetiya, N.D. Effect of Friction Stir Processing Parameters on Microstructure and Microhardness of Aluminium Based Metal Matrix Composites. Mater. Today Proc. 2022, 62, 7455–7460. [Google Scholar] [CrossRef]

- Khan, M.; Rehman, A.; Aziz, T.; Naveed, K.; Ahmad, I.; Subhani, T. Cold Formability of Friction Stir Processed Aluminum Composites Containing Carbon Nanotubes and Boron Carbide Particles. Mater. Sci. Eng. A 2017, 701, 382–388. [Google Scholar] [CrossRef]

- Pragada, V.; Soni, V.; Ghetiya, N.D.; Bharti, S. Influence of Tool Travel Direction on Microhardness and Tribological Properties of AA2014/SiC-CNT Hybrid Surface Composites Produced by Multi-Pass Friction Stir Processing. Mater. Today Proc. 2022, 56, 150–156. [Google Scholar] [CrossRef]

- Dinesh Kumar, D.; Balamurugan, A.; Suresh, K.C.; Suresh Kumar, R.; Jayanthi, N.; Ramakrishnan, T.; Hasane Ahammad, S.K.; Mayakannan, S.; Venkatesa Prabhu, S. Study of Microstructure and Wear Resistance of AA5052/B4C Nanocomposites as a Function of Volume Fraction Reinforcement to Particle Size Ratio by ANN. J. Chem. 2023, 2023, 2554098. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, T.; Jiang, Z. Carbon Nanotubes/Aluminum Interface Structure and Its Effects on the Strength and Electrical Conductivity of Aluminum. J. Mater. Res. Technol. 2023, 27, 7037–7046. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Xiao, B.L.; Wang, W.G.; Ma, Z.Y. Developing High-Performance Aluminum Matrix Composites with Directionally Aligned Carbon Nanotubes by Combining Friction Stir Processing and Subsequent Rolling. Carbon 2013, 62, 35–42. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Z.; Peng, Y.; Yan, D.; Tan, Z.; Zhou, Q.; Wang, K. In Situ Synthesized Nano-Al4C3 Reinforced Aluminum Matrix Composites via Friction Stir Processing. J. Mater. Res. Technol. 2021, 14, 2658–2664. [Google Scholar] [CrossRef]

- Du, Z.; Tan, M.J.; Guo, J.F.; Bi, G.; Wei, J. Fabrication of a New Al-Al2O3-CNTs Composite Using Friction Stir Processing (FSP). Mater. Sci. Eng. A 2016, 667, 125–131. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, J.; Sharma, S.; Li, C.; Królczyk, G.; Wojciechowski, S. Neutrosophic Entropy-Based Ingenious Measurement for Fast Fourier Transforms Based Classification of Process-Parameters and Wear Resistance of Friction-Stir Processed Hybrid AA7075-B4C Aluminium Metal-Matrix Composites. J. Mater. Res. Technol. 2022, 20, 720–739. [Google Scholar] [CrossRef]

- Pasha, S.A.; Reddy, P.R.; Laxmi Narayana, P. Wear Behavior and Microstructural Characterization of AA7075/MWCNT Surface Composites Fabricated through Friction Stir Processing. IOSR J. Mech. Civ. Eng. 2017, 14, 140–146. [Google Scholar] [CrossRef]

- Golla, C.B.; Babar Pasha, M.; Rao, R.N.; Ismail, S.; Gupta, M. Influence of TiC Particles on Mechanical and Tribological Characteristics of Advanced Aluminium Matrix Composites Fabricated through Ultrasonic-Assisted Stir Casting. Crystals 2023, 13, 1360. [Google Scholar] [CrossRef]

- Ekhlasiosgouei, O.; Ebrahimi, R.; Hasheminiasari, M.; Molin, S. An Investigation of Microstructural Basis for Corrosion Behavior of Al-CNT Composites Fabricated by SPS. Diam. Relat. Mater. 2023, 140, 110422. [Google Scholar] [CrossRef]

- Liao, Z.; He, Q.; Zhang, W.; Zhang, F.; Wang, W.; Fu, Z. B4C Ceramics with Increased Dislocation Density Fabricated by Reactive Spark Plasma Sintering via Carbon Nanotubes–Boron Mixture. Ceram. Int. 2024, 50, 22443–22455. [Google Scholar] [CrossRef]

- Tsukamoto, H. Chemical and Mechanical Treatments for Enhancement of Carbon Nanotube Reinforced Aluminum Matrix Composites. Mater. Sci. Eng. A 2023, 867, 144749. [Google Scholar] [CrossRef]

- Chen, D.; Chen, G.; Deng, M.; Wang, H.; Huang, Z.; Qi, J.; Lu, T. Fabrication and Mechanical Properties of Multi-Walled Carbon Nanotubes Doped AlN Ceramics Prepared by Spark Plasma Sintering. Ceram. Int. 2022, 48, 4505–4511. [Google Scholar] [CrossRef]

- Heydari, S.; Sajjadi, S.A.; Babakhani, A.; Eskandari, H.; Nateq, B. An Investigation on the Effect of Al4C3 on Microstructure and Mechanical Properties of Carbon Nanotube Reinforced Aluminum Composite. Ceram. Int. 2023, 49, 14024–14034. [Google Scholar] [CrossRef]

- Suslova, E.; Savilov, S.; Egorov, A.; Shumyantsev, A.; Lunin, V. Carbon Nanotube Frameworks by Spark Plasma Sintering. Microporous Mesoporous Mater. 2019, 293, 109807. [Google Scholar] [CrossRef]

- Wan, J. CNT-Induced Heterogeneous Matrix Grain Structure in CNTs/Al Composites. Carbon 2024, 216, 118529. [Google Scholar] [CrossRef]

- Huang, L.; Liu, B.; Wang, Z.; Yuan, J. Effect of Carbon Nanotube Content on the Microstructure and Mechanical Properties of CNTs/TiAl Alloys. Ceram. Int. 2023, 49, 8196–8203. [Google Scholar] [CrossRef]

- Trinh, P.V.; Lee, J.; Kang, B.; Minh, P.N.; Phuong, D.D.; Hong, S.H. Mechanical and Wear Properties of SiCp/CNT/Al6061 Hybrid Metal Matrix Composites. Diam. Relat. Mater. 2022, 124, 108952. [Google Scholar] [CrossRef]

- Yang, C.M.Y.; Li, X.; Li, C.J.; Peng, Y.Z.; Xing, Y.; Feng, Z.X.; Tan, J.; Tao, J.M.; Li, Z.L.; Wang, Y.R.; et al. Interface and Strengthening Mechanisms of Al Matrix Composites Reinforced with In-Situ CNTs Grown on Ti Particles. Mater. Des. 2023, 229, 111923. [Google Scholar] [CrossRef]

- Guo, B.; Ni, S.; Yi, J.; Shen, R.; Tang, Z.; Du, Y.; Song, M. Microstructures and Mechanical Properties of Carbon Nanotubes Reinforced Pure Aluminum Composites Synthesized by Spark Plasma Sintering and Hot Rolling. Mater. Sci. Eng. A 2017, 698, 282–288. [Google Scholar] [CrossRef]

- Jagannatham, M.; Sankaran, S.; Haridoss, P. Microstructure and Mechanical Behavior of Copper Coated Multiwall Carbon Nanotubes Reinforced Aluminum Composites. Mater. Sci. Eng. A 2015, 638, 197–207. [Google Scholar] [CrossRef]

- Yu, M.; Kim, M.; Yoon, B.; Oh, S.; Nam, D.-H.; Kwon, H. Carbon Nanotubes/Aluminum Composite as a Hydrogen Source for PEMFC. Int. J. Hydrogen Energy 2014, 39, 19416–19423. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, Y.; Wang, Z.; Li, H. Microstructure and Mechanical Properties of Aluminum Matrix Composites Reinforced by One-Dimensional/Two-Dimensional Hybrid Carbon Nanophases. Chin. J. Nonferrous Met. 2022, 32, 800–815. [Google Scholar]

- Yang, S.; Luo, H.; Wang, L.; Guang, Z.; Zhang, P.; Liu, Y. Interface Structure and Bonding Strength of Metallurgical Bonded Aluminum Foam Sandwich (AFS) Fabricated by Hot-Pressing. Vacuum 2023, 211, 111987. [Google Scholar] [CrossRef]

- Chang, J.-M.; Yadav, B.N.; Mandal, A.; Tiwari, J.K.; Kam, K.-H.; Liu, D.-S.; Lin, P.C. Carbon Nanotubes Used to Enhance the Wear Properties of AlSi10Mg/CNTs Nanocomposites Prepared through Additive Manufacturing. Diam. Relat. Mater. 2024, 144, 110993. [Google Scholar] [CrossRef]

- Wang, X. Effect of the CNTs into SiCp-Al Interfacial Micro-Zones on Ageing Precipitation Behavior, Microstructure and Mechanical Properties of SiCp(CNT)/Al–Zn–Mg–Cu Composites. Compos. Part B 2023, 259, 110708. [Google Scholar] [CrossRef]

- Wang, X.; Wang, S.; Wang, X.; Su, Y.; Yue, Z.; Cao, H.; Zhang, D.; Ouyang, Q. Synergistic Strengthening-Toughening Effect of SiCp(CNT) Hybrid Reinforcements on Mg-Compensated SiCp(CNT)/Al–Zn–Mg–Cu Composites. Mater. Sci. Eng. A 2024, 892, 145999. [Google Scholar] [CrossRef]

- Xiang, J.; Zheng, Y.; Li, J.; Tan, Z. Mechanical Response of CNT/2024Al Composite to Compression and Tension at Different Strain Rates. Metals 2023, 13, 254. [Google Scholar] [CrossRef]

- Sha, J.; Li, J.; Wang, S.; Zhang, Z.; Wang, Y.; Dai, J. Microstructure and Mechanical Properties of Hot-Pressed ZrC–Ti–CNTs Composites. Mater. Des. 2016, 107, 520–528. [Google Scholar] [CrossRef]

- Guo, B.; Song, M.; Yi, J.; Ni, S.; Shen, T.; Du, Y. Improving the Mechanical Properties of Carbon Nanotubes Reinforced Pure Aluminum Matrix Composites by Achieving Non-Equilibrium Interface. Mater. Des. 2017, 120, 56–65. [Google Scholar] [CrossRef]

- Yildirim, M.; Özyürek, D.; Gürü, M. Investigation of Microstructure and Wear Behaviors of al Matrix Composites Reinforced by Carbon Nanotube. Fuller. Nanotub. Carbon Nanostruct. 2016, 24, 467–473. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Elkin, A.I.; Reshetniak, V.V.; Ob’edkov, A.M.; Sytschev, A.E.; Leontiev, V.G.; Titov, D.D.; Alymov, M.I. Thermal Expansion of Aluminum Matrix Composites Reinforced by Carbon Nanotubes with In-Situ and Ex-Situ Designed Interfaces Ceramics Layers. J. Alloys Compd. 2021, 872, 159593. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Jin, Q.; Li, Z.; Li, L.; Sun, Y. Study on the Mechanism of CNTs Regulating the Microstructures and Properties of Al–Cu–Mg Alloy. Crystals 2024, 14, 165. [Google Scholar] [CrossRef]

- Oh, S.-H.; Kang, H.-J.; Yoon, P.-H.; Lee, G.-H.; Shin, S.-M.; Choi, Y.-S.; Park, J.-Y. Feasibility Study on the Fabricating of Carbon-Nanotube-Reinforced Al-Si-Cu Alloy Matrix Composites Using Oxygen-Replacing Die Casting Process. Metals 2023, 13, 730. [Google Scholar] [CrossRef]

- Popov, V.V.; Pismenny, A.; Larianovsky, N.; Lapteva, A.; Safranchik, D. Corrosion Resistance of Al–CNT Metal Matrix Composites. Materials 2021, 14, 3530. [Google Scholar] [CrossRef]

- Usef, A.P.; Bhajantri, V.; Kannoth, V.; Jambagi, S.C. Influence of Carbon Nanotube Reinforcement on the Heat Transfer Coefficient, Microstructure, and Mechanical Properties of a Die Cast Al-7Si-0.35Mg Alloy. J. Alloys Compd. 2021, 888, 160844. [Google Scholar] [CrossRef]

- Zhang, J.; Cinkilic, E.; Huang, X.; Wang, G.G.; Liu, Y.C.; Weiler, J.P.; Luo, A.A. Optimization of T5 Heat Treatment in High Pressure Die Casting of Al–Si–Mg–Mn Alloys by Using an Improved Kampmann-Wagner Numerical (KWN) Model. Mater. Sci. Eng. A 2023, 865, 144604. [Google Scholar] [CrossRef]

- Maniraj, S.; Anand, K.; Anbarasu, R.; Aravindan, A.A.; Gokul, G.; Logendran, R. Impacts of Carbon Nano Tubes (CNT) and Boron Carbide (B4C) Particles on Material Properties of al 6061. Mater. Today Proc. 2022, 66, 738–742. [Google Scholar] [CrossRef]

- Larianovsky, N.; Popov, V.; Katz-Demyanetz, A.; Fleisher, A.; Meyers, D.E.; Chaudhuri, R.S. Production of Al Metal Matrix Composites Reinforced With Carbon Nanotubes by Two-Stage Melt-Based HPDC-CE Method. J. Eng. Mater. Technol. 2019, 141, 011002. [Google Scholar] [CrossRef]

- Sarkar, S.; Ray, S.; Dey, U.; Kumar, C.; Chakraborti, P.C.; Mukhopadhyay, G.; Kumar, C.S.; Roy, S. Establishment of a Facile Technique to Fabricate Bulk AA6061/CNT Composite with Improved Mechanical Properties Using Combined Stir-Casting and Squeeze-Casting. Mater. Today Commun. 2023, 37, 107471. [Google Scholar] [CrossRef]

- Li, Q.; Rottmair, C.A.; Singer, R.F. CNT Reinforced Light Metal Composites Produced by Melt Stirring and by High Pressure Die Casting. Compos. Sci. Technol. 2010, 70, 2242–2247. [Google Scholar] [CrossRef]

- Morovvati, M.R.; Mollaei-Dariani, B.; Lalehpour, A.; Toghraie, D. Fabrication and Finite Element Simulation of Aluminum/Carbon Nanotubes Sheet Reinforced with Thermal Chemical Vapor Deposition (TCVD). J. Mater. Res. Technol. 2023, 23, 1887–1902. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Q.; Chen, G.; Ramachandran, C.S. Mechanical, Tribological and Corrosion Physiognomies of CNT-Al Metal Matrix Composite (MMC) Coatings Deposited by Cold Gas Dynamic Spray (CGDS) Process. Surf. Coat. Technol. 2020, 403, 126380. [Google Scholar] [CrossRef]

- Liu, X.; Li, J.; Liu, E.; Li, Q.; He, C.; Shi, C.; Zhao, N. Effectively Reinforced Load Transfer and Fracture Elongation by Forming Al4C3 for In-Situ Synthesizing Carbon Nanotube Reinforced Al Matrix Composites. Mater. Sci. Eng. A 2018, 718, 182–189. [Google Scholar] [CrossRef]

- Tang, J.; Fan, G.; Li, Z.; Li, X.; Xu, R.; Li, Y.; Zhang, D.; Moon, W.-J.; Kaloshkin, S.D.; Churyukanova, M. Synthesis of Carbon Nanotube/Aluminium Composite Powders by Polymer Pyrolysis Chemical Vapor Deposition. Carbon 2013, 55, 202–208. [Google Scholar] [CrossRef]

- Liu, Y.; Li, S.; Misra, R.D.K.; Geng, K.; Yang, Y. Planting Carbon Nanotubes within Ti-6Al-4V to Make High-Quality Composite Powders for 3D Printing High-Performance Ti-6Al-4V Matrix Composites. Scr. Mater. 2020, 183, 6–11. [Google Scholar] [CrossRef]

- Huang, Y.; Su, Y.; Guo, X.; Guo, Q.; Ouyang, Q.; Zhang, G.; Zhang, D. Fabrication and Thermal Conductivity of Copper Coated Graphite Film/Aluminum Composites for Effective Thermal Management. J. Alloys Compd. 2017, 711, 22–30. [Google Scholar] [CrossRef]

- Meng, L.; Wang, X.; Ning, J.; Hu, X.; Fan, G.; Wu, K. Beyond the Dimensional Limitation in Bio-Inspired Composite: Insertion of Carbon Nanotubes Induced Laminated Cu Composite and the Simultaneously Enhanced Strength and Toughness. Carbon 2018, 130, 222–232. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, H.; Hu, X.; Ju, D. A Novel Processing for CNT-Reinforced Mg-Matrix Laminated Composites to Enhance the Electromagnetic Shielding Property. Coatings 2021, 11, 1030. [Google Scholar] [CrossRef]

- Bhat, A.; Balla, V.K.; Bysakh, S.; Basu, D.; Bose, S.; Bandyopadhyay, A. Carbon Nanotube Reinforced Cu–10Sn Alloy Composites: Mechanical and Thermal Properties. Mater. Sci. Eng. A 2011, 528, 6727–6732. [Google Scholar] [CrossRef]

- Eren, O.; Kamara, A.M.; Sezer, H.K.; Marimuthu, S. Synthesis of Aluminium Nitride-Based Coatings on Mild Steel Substrates Utilising an Integrated Laser/Sol–Gel Method. Photonics 2024, 11, 382. [Google Scholar] [CrossRef]

- Shen, H.-Z.; Wang, Y.; Chen, S.-M.; Shen, P. Wettability and Reactivity between Molten Aluminum and Randomly Aligned Carbon Nanotubes. J. Mater. Sci. 2021, 56, 7799–7810. [Google Scholar] [CrossRef]

- Rong, X.; Chen, X.; Zhao, D.; Zhang, X.; He, C.; Shi, C.; Zhao, N. High Mechanical Strengthened CNTs/Al Composite Concepts with Robust Interface and Intragranular Reinforcement Achieved via Interfacial Thermite Reaction. Compos. Part Appl. Sci. Manuf. 2023, 173, 107630. [Google Scholar] [CrossRef]

- Qiu, C.; Su, Y.; Yang, J.; Wang, X.; Chen, B.; Ouyang, Q.; Zhang, D. Microstructural Characteristics and Mechanical Behavior of SiC(CNT)/Al Multiphase Interfacial Micro-Zones via Molecular Dynamics Simulations. Compos. Part B Eng. 2021, 220, 108996. [Google Scholar] [CrossRef]

- Herzallah, H.; Elsayd, A.; Shash, A.; Adly, M. Effect of Carbon Nanotubes (CNTs) and Silicon Carbide (SiC) on Mechanical Properties of Pure Al Manufactured by Powder Metallurgy. J. Mater. Res. Technol. 2020, 9, 1948–1954. [Google Scholar] [CrossRef]

- Ziaei, H.; Fan, G.; Tan, Z.; Zhang, Y.; Zhao, L.; Li, Z.; Li, Z. SiO2 Coating on CNTs to Fabricate the Al4O4C-Al Composite with Superior Young’s Modulus. Mater. Charact. 2024, 207, 113597. [Google Scholar] [CrossRef]

- Ramesh, R.; Thirugnanasambantham, K.G.; Ravi, L.; Sivakumar, P.; Giridhar, D. Effect of Agglomeration in Carbon Nanotube (CNT) Reinforced Aluminum (Al) Composites: A Review. AIP Conf. Proc. 2024, 3161, 020090. [Google Scholar] [CrossRef]

- Wang, M.; Li, Y.; Chen, B.; Shi, D.; Umeda, J.; Kondoh, K.; Shen, J. The Rate-Dependent Mechanical Behavior of CNT-Reinforced Aluminum Matrix Composites under Tensile Loading. Mater. Sci. Eng. A 2021, 808, 140893. [Google Scholar] [CrossRef]

- Chen, J.; Yan, L.; Liang, S.; Cui, X.; Liu, C.; Wang, B.; Zou, L. Remarkable Improvement of Mechanical Properties of Layered CNTs/Al Composites with Cu Decorated on CNTs. J. Alloys Compd. 2022, 901, 163404. [Google Scholar] [CrossRef]

- Shen, M.; Hao, Z.; Song, J.; An, M.; Ying, T.; Xue, X.; Gao, Y.; Yang, Z. Architectural and Component Design of CNTs/Al Hierarchical Composite for Enhanced Mechanical/Thermal Properties. J. Mater. Res. Technol. 2024, 30, 120–133. [Google Scholar] [CrossRef]

- Chowdhury, H.; Masud, A. Stress Distribution in CNT-Aluminum Matrix Composite by Changing Distances between CNT Bundles. J. Nav. Archit. Mar. Eng. 2016, 13, 125. [Google Scholar] [CrossRef]

- Carneiro, Í.; Simões, S. Investigation of Mechanical Properties of Al/CNT Nanocomposites Produced by Powder Metallurgy. Appl. Sci. 2022, 13, 54. [Google Scholar] [CrossRef]

- Luo, S.; Wu, Y.; Chen, B.; Song, M.; Yi, J.; Guo, B.; Wang, Q.; Yang, Y.; Li, W.; Yu, Z. Effects of Cu Content on Microstructures and Compressive Mechanical Properties of CNTs/Al-Cu Composites. Trans. Nonferrous Met. Soc. China 2022, 32, 3860–3872. [Google Scholar] [CrossRef]

- Pan, J.; Zou, L.; Liao, Z.; Lin, Z.; Chen, J. Study on the Properties of Carbon Nanotube (CNTs) Reinforced AlSi10Mg Composites Fabricated by Powder Metallurgy. Materials 2023, 16, 3905. [Google Scholar] [CrossRef] [PubMed]

- Kushwaha, S.; Bhadauria, A.; Bajpai, S.; Tiwari, A.; Pandey, K.K.; Keshri, A.K.; Balani, K. Mechanical, Microstructural, and Fretting Wear Behaviour of Al2O3–ZrO2-CNT Based Bimodal Composite Coatings. Wear 2023, 532–533, 205127. [Google Scholar] [CrossRef]

- Abdeltawab, N.M.; Esawi, A.M.K.; Wifi, A. Investigation of the Wear Behavior of Dual-Matrix Aluminum–(Aluminum–Carbon Nanotube) Composites. Metals 2023, 13, 1167. [Google Scholar] [CrossRef]

- Zhu, W.; Liu, H.; Xing, S.; Jiang, C.; Ji, V. Effect of Dual Shot Peening on Microstructure and Wear Performance of CNT/Al-Cu-Mg Composites. Materials 2024, 17, 5066. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Z.; Luo, Y.; Xiao, Y.; Tan, F.; Liu, K. Understanding the Influencing Mechanism of CNTs on the Microstructures and Wear Characterization of Semi-Solid Stir Casting Al-Cu-Mg-Si Alloys. Metals 2022, 12, 2171. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Wu, J.; Zhang, X. Mechanical Properties and Friction Behaviors of CNT/AlSi10Mg Composites Produced by Spark Plasma Sintering. Int. J. Miner. Met. Mater. 2017, 24, 584–593. [Google Scholar] [CrossRef]

- Sarkar, S.; Dam, B.; Dey, U.; Mandal, N.; Kumar, C.S.; Manna, I.; Roy, S. Effect of Dispersion Technique and Applied Load on the Dry Sliding Wear Behavior of Combined Stir-Squeeze-Cast AA6061–0.5 Wt % CNT Composite against a Steel Counter Body at Both Room Temperature and Elevated Temperature. Wear 2025, 562–563, 205656. [Google Scholar] [CrossRef]

- Sharma, R.; Sasikumar, C.; Baral, J. Wear Behaviour of Al-MWCNT Composites by Varying MWCNTs Concentration. J. Alloys Metall. Syst. 2024, 7, 100104. [Google Scholar] [CrossRef]

- Hosseini, S.; Novák, P.; Alishahi, M.; Kačenka, Z.; Šittner, P. Trade-Off Between Wear/Corrosion Performance and Mechanical Properties in D-AlNiCo Poly-Quasicrystals Through CNT Addition to the Microstructure. Metals 2024, 14, 1269. [Google Scholar] [CrossRef]

- Al-Ashwan, Z.H.; Hayat, U.; Toor, I.H.; Hassan, S.F.; Saheb, N. Corrosion Behavior of Spark Plasma Sintered Alumina and Al2O3-SiC-CNT Hybrid Nanocomposite. Mater. Res. 2020, 23, e20190496. [Google Scholar] [CrossRef]

- Arora, G.S.; Saxena, K.K.; Mohammed, K.A.; Prakash, C.; Dixit, S. Manufacturing Techniques for Mg-Based Metal Matrix Composite with Different Reinforcements. Crystals 2022, 12, 945. [Google Scholar] [CrossRef]

- Yan, H.; Li, L.; Hu, H.; Huang, W. Influence of Al2O3 and H-BN on Wear and Corrosion Performance of IN625 Nickel-Based Coating. Coatings 2024, 14, 1359. [Google Scholar] [CrossRef]

- Li, N.; Liu, W.; Wang, Y.; Zhao, Z.; Yan, T.; Zhang, G.; Xiong, H. Laser Additive Manufacturing on Metal Matrix Composites: A Review. Chin. J. Mech. Eng. 2021, 34, 38. [Google Scholar] [CrossRef]

- Chen, Y.; Shen, J.; Hu, S.; Zhen, Y.; Zhao, H. Corrosion Behavior of CMT Cladding Layer of AZ91 Magnesium Alloy Subjected to Friction Stir Processing. Materials 2024, 17, 2875. [Google Scholar] [CrossRef] [PubMed]

- Ananiadis, E.A.; Karantzalis, A.E.; Sfikas, A.K.; Georgatis, E.; Matikas, T.E. Aluminium Matrix Composites Reinforced with AlCrFeMnNi HEA Particulates: Microstructure, Mechanical and Corrosion Properties. Materials 2023, 16, 5491. [Google Scholar] [CrossRef]

- Ammisetti, D.K.; Kruthiventi, S.S.H.; Vinjavarapu, S.; Babu, N.N.; Gandepudi, J.R.; Battula, S.K. A Review on Reinforcements, Fabrication Methods, and Mechanical and Wear Properties of Titanium Metal Matrix Composites. J. Eng. Appl. Sci. 2024, 71, 60. [Google Scholar] [CrossRef]

- Singh, G.; Ablyaz, T.R.; Shlykov, E.S.; Muratov, K.R.; Bhui, A.S.; Sidhu, S.S. Enhancing Corrosion and Wear Resistance of Ti6Al4V Alloy Using CNTs Mixed Electro-Discharge Process. Micromachines 2020, 11, 850. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z. Micro-Electrolysis Based Nitrate Reduction from Aqueous Solution by CNTs-Al-Cu Composite under Alkaline Environment. Chemosphere 2023, 313, 137563. [Google Scholar] [CrossRef] [PubMed]

- Kumar, G.; Jyotheender, K.; Srivastava, C. Effect of Grain Boundary Constitution on Corrosion Behaviour in Cobalt-Carbon Nanotube Composite Coatings. Materialia 2022, 24, 101500. [Google Scholar] [CrossRef]

- Burleigh, T. Corrosion of Aluminum and Its Alloys. In Shreir’s Corrosion; Elsevier: Amsterdam, The Netherlands, 2003; pp. 1974–2010. ISBN 978-0-8247-0896-2. [Google Scholar]

- Okokpujie, I.P.; Nakpoberuo, D.O.; Emojeya, D.O.; Azeez, T.M.; Tartibu, L.K. Investigating Corrosion and Surface Hardness of Al6061 in Machining Fluids with Variable CNT Concentrations. Rev. Compos. Matér. Avancés 2024, 34, 9–18. [Google Scholar] [CrossRef]

- Ujah, C.; Popoola, P.; Popoola, O.; Aigbodion, V.S. Influence of CNTs Addition on the Mechanical, Microstructural, and Corrosion Properties of Al Alloy Using Spark Plasma Sintering Technique. Int. J. Adv. Manuf. Technol. 2020, 106, 2961–2969. [Google Scholar] [CrossRef]

- Aigbodion, V.S. Microstructural Evolution, Electrical Conductivity, and Electrochemical Analysis of α-Al-CNTs-GAg.NPs High-Conductor Nanocomposite. Chem. Data Collect. 2021, 33, 100707. [Google Scholar] [CrossRef]

- Rondineau, A.; Gaillet, L.; Dieng, L.; Langlois, S. Degradation of Steel Wires in Bimetallic Aluminum–Steel Conductors Exposed to Severe Corrosion Conditions. Corros. Mater. Degrad. 2022, 3, 646–660. [Google Scholar] [CrossRef]

- Alraddadi, S.; Assaedi, H. Phase Evolution, Mechanical, and Electrical Properties of Lightweight Ceramic Prepared Using Scoria at Low Temperature. Crystals 2024, 14, 929. [Google Scholar] [CrossRef]

- Devesa, S.; Amorim, C.O.; Belo, J.H.; Araújo, J.P.; Teixeira, S.S.; Graça, M.P.F.; Costa, L.C. Comprehensive Characterization of Bi1.34Fe0.66Nb1.34O6.35 Ceramics: Structural, Morphological, Electrical, and Magnetic Properties. Magnetochemistry 2024, 10, 79. [Google Scholar] [CrossRef]

- Rodrigues, F.; Pinheiro, P.; Sousa, M.; Angélica, R.; Paz, S.; Reis, M. Electrical Properties of Iodine-Doped Cu/f-CNT Coated Aluminum Wires by Electrophoresis with Copper Sulfate Solution. Metals 2022, 12, 787. [Google Scholar] [CrossRef]

- Zhou, W.; Zhou, Z.; Kubota, K.; Ono, H.; Nomura, N.; Kawasaki, A. Design of High-Performance Al4C3/Al Matrix Composites for Electric Conductor. Mater. Sci. Eng. A 2020, 798, 140331. [Google Scholar] [CrossRef]

- Jin, Y.; Wei, S.; Yang, Z.; Cui, C.; Wang, J.; Li, D.; Qian, W. Li-Ion Batteries with a Binder-Free Cathode of Carbon Nanotubes-LiFePO4-Al Foam. Batteries 2024, 10, 261. [Google Scholar] [CrossRef]

- Ding, C.; Lu, Z.; Li, S.; Wang, Z.; Yu, P.; Ye, S. Microstructures, Thermal and Mechanical Properties of Al–Si-CNT Composites for Thermal Management Applications. Mater. Chem. Phys. 2023, 297, 127368. [Google Scholar] [CrossRef]

- Ding, C.; Yu, K.; Nodooshan, H.R.J.; Ye, S.; Yu, P. Effect of Powder Microstructure on the Thermal and Mechanical Properties of Hot Extruded Al-CNT Composite. J. Alloys Compd. 2022, 891, 162059. [Google Scholar] [CrossRef]

- Geng, K.; Li, S.; Yang, Y.F.; Misra, R.D.K. 3D Printing of Al Matrix Composites through in Situ Impregnation of Carbon Nanotubes on Al Powder. Carbon 2020, 162, 465–474. [Google Scholar] [CrossRef]

- Li, X.X.; Zhang, H.M.; Mu, X.N.; Fan, Q.B.; Cheng, X.W.; Cui, Z.S.; Chang, S. Achieving High Thermal Conductivity in CNTs@GF/Al Laminates via a Rapid and Simple Strategy. Vacuum 2024, 222, 112990. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, K.; Yuan, T.; Liu, Z.; Wang, Q.; Xiao, B.; Ma, Z. Investigation into the Influence of CNTs Configuration on the Thermal Expansion Coefficient of CNT/Al Composites. J. Mater. Res. Technol. 2022, 18, 3478–3491. [Google Scholar] [CrossRef]

- Chen, B.; Kondoh, K. Sintering Behaviors of Carbon Nanotubes—Aluminum Composite Powders. Metals 2016, 6, 213. [Google Scholar] [CrossRef]

- Zhang, Z.-C.; Zhang, G.-W.; Hu, Y.-L.; Lv, W.-Z.; Yu, H.; Ren, X.-Y. Al-Ti-C (CNTs) Master Alloys Improve Room Temperature and High-Temperature Mechanical Properties of ZL205A Alloy. Mater. Today Commun. 2024, 41, 110689. [Google Scholar] [CrossRef]

- Parveez, B.; Kittur, M.I.; Badruddin, I.A.; Kamangar, S.; Hussien, M.; Umarfarooq, M.A. Scientific Advancements in Composite Materials for Aircraft Applications: A Review. Polymers 2022, 14, 5007. [Google Scholar] [CrossRef]

- Guo, M.; Du, J.; Zhang, Y. Effect of CNT Content and Size on the High-Temperature Particle-Erosion Resistance of Ablative Materials for Thermal Protection Systems. Compos. Sci. Technol. 2023, 235, 109969. [Google Scholar] [CrossRef]

- Nguyen-Tran, H.-D.; Hoang, V.-T.; Do, V.-T.; Chun, D.-M.; Yum, Y.-J. Effect of Multiwalled Carbon Nanotubes on the Mechanical Properties of Carbon Fiber-Reinforced Polyamide-6/Polypropylene Composites for Lightweight Automotive Parts. Materials 2018, 11, 429. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Zhao, S.; Huang, T.; He, W.; Zhou, X.; Wang, G.; Guo, M.; Luo, X.; Cao, M.; Yue, Y.; et al. Self-Charging V2CTx/CNT-Based Zinc Ion Micro-Supercapacitor for Wearable Electronics. Chem. Eng. J. 2024, 490, 151589. [Google Scholar] [CrossRef]

- Benali, H.; Hartiti, B.; Lmai, F.; Batan, A.; Fadili, S.; Thevenin, P. Enhancing the Efficiency of the Organic-Inorganic Hybrid Perovskite Cells Using Al-Doped ZnO as an Electron Transport Layer and CNTs as a Hole Transport Layer: An Experimental and Numerical Study. Optik 2024, 304, 171733. [Google Scholar] [CrossRef]

| Method | Influence on Morphology and Structure | Advantages | Limitations |

|---|---|---|---|

| PM | Uniform CNT distribution in the aluminum matrix; low temperatures prevent CNT agglomeration; oxide formation on powder surfaces may reduce Al-CNT bonding but can enhance properties in some cases. | Low-temperature processing; excellent microstructure control; low cost and flexibility; scalable for large-scale production. | Oxide layers may weaken composite strength; diffusion issues at high temperatures; inefficiency with high CNT content. |

| SPS | Enhanced strength via carbon “nails”; formation of barriers preventing CNT degradation but reducing interfacial bonding with aluminum; fine-grained microstructures with controlled porosity. | Reduced processing time; preservation of CNT properties; ability to create various microstructures; improved densification at lower temperatures. | Requires meticulous preparation; equipment demands (vacuum and inert atmospheres); formation of oxide films. |

| HEBM | Improved dispersion uniformity; reduced agglomeration; increased aluminum surface area for effective CNT interaction; potential for nanostructured composites. | Enhanced mechanical properties; customizable milling conditions; effective for breaking down CNT clusters. | High energy consumption; risk of CNT damage; requires precise parameter adjustment to avoid agglomeration. |

| HP/HE | Grain elongation increases anisotropy; improved toughness by crack redirection; formation of hybrid phases (SiCp/CNT) enhances fracture energy. | Increased yield strength and toughness; grain growth suppression; suitable for producing dense bulk components. | Mechanical anisotropy; formation of Al4C3 phases may weaken CNTs; high energy demands; precise control required. |

| EPD | Uniform CNT coating on metallic particles or substrates; formation of thin films with controlled thickness and dispersion. | Simple and scalable process; low-cost equipment; good control over coating thickness and uniformity. | Requires conductive substrates; adhesion issues without post-treatment; potential agglomeration. |

| CVD | Direct growth of CNTs on metallic powders; strong interfacial bonding through controlled reactions; uniform CNT distribution. | High purity and crystallinity of CNTs; controlled growth parameters; suitable for hybrid reinforcement strategies. | Requires high temperatures and vacuum; risk of CNT degradation; formation of unwanted carbide phases (Al4C3). |

| PVD | Thin metallic coatings on CNTs or substrates; improved interfacial bonding and wettability; controlled coating thickness. | High precision and purity; good adhesion; minimal thermal damage to CNTs; suitable for creating interfaces. | Requires vacuum; limited scalability for bulk production; high equipment cost; difficulty coating complex shapes. |

| Laser deposition | Dense, defect-free coatings; enhanced bonding between CNTs and matrix; minimal heat-affected zone. | Rapid processing; high precision; minimal thermal distortion; suitable for surface repairs and reinforcements. | High equipment cost; risk of porosity and cracks; requires precise control of laser parameters. |

| Composite | PM1 | SP2 | YS3 | TS4 | E5 | YM6 | HV7 | Comms | R8 |

|---|---|---|---|---|---|---|---|---|---|

| Al-Al-Mg/CNT | ARB | 375 °C,1 h | 462.0 | - | - | - | 126.0 (10 kg) | Energy absorption capability is 19.2 MPa | [58] |

| Al-5Si-0.5CNTs | SPS | 577 °C, 1 h, 30 MPa (a vacuum of 5 Pa) | 320.0 | 391.0 | 7.5 | 91.5 | - | Load transfer is 86 MPa | [71] |

| Al-10%SiCp/2%CNT | SPS | 560 °C, 5 min, 50 MPa | 178.5 | 249.5 | 6.5 | - | 159.5 | The relative density is 99.1% | [103] |

| Al-CNT@ Ti | SPS | 590 °C, 40 min, 50 MPa | - | 284.0 | 10 | - | ~145 | Increased efficiency of Al-CNT activities | [104] |

| Al-Cu-Mg/CNT | HP/HE | 520 °C, 1 cm | 456.7 | 480.4 | 11.9 | - | - | Load transfer of 1.5% CNT is 7.0 MPa | [118] |

| Al-Si-Cu/CNT | ORDC | 200–680 °C, 80 MPa, 32%, 20 mm | 150.1 | 258.5 | ~1.8 | - | 157.9 | The wettability has increased due to the improved reaction between molten Al and O2 when using a polymer gate | [119] |

| Al-CNTs@Cu2O | HE | At 520 °C, extrusion coefficient is 16:1 | 236.0 | 415.0 | 11.6 | - | - | Strengthening contribution of Cu2O@CNT is 236 MPa | [138] |

| Al-Cu/CNT | SPS | 600 °C (100 °C/min—10 min) | 221.9 | 245.0 | 14.8 | - | - | Improved wettability of the interface of composites and “Al-Cu-CNT” interlocking effect | [144] |

| Mg-2Al/CNT | HE/HP | 500 °C, 180 s/550 °C, 2 h, 30 MPa | - | 307.0 | 10.5 | - | - | Exhibited strength–ductility synergy | [79] |

| Al-CNT@ SiO2 changed to Al–Al4O4C | SPS | 610 °C | 370.0 | 472.0 | 9.6 | 86.8 | - | No degrading of ductility | [141] |

| Al-Cu/CNT | PM | 300 r/min, 3 h, ball/powder mass ratio of 5:1 | 368.0 | 495.14 | - | 78.3 | 107.7 | Density is 2.7 g·cm3 Compression strain/is 19.9% | [148] |

| 7075Al-SiCp/0.5CNT | HP/HE | 550 °C, 30 min, 300 MPa/400 °C, 1 h | 504.6 | 575.9 | 5.4 | 101.3 | 191.1 | The introduction of a hybrid SiCp reinforcing material (CNT) can help reduce the deposition of composites during aging | [111] |

| Al-Si-10Mg/1.5%CNT | SPS | 540 °C, 18 min, 40 MPa | 241.0 | 337.0 | 4.0 | - | - | The uniform dispersion of 0.8 wt.% CNTs on the surface of the matrix improves the mechanical properties of the composites | [149] |

| Al2O3-ZrO2/CNT | Atmos-pheric plasma spraying | 40 KW, 57.20 V | - | - | - | 102.7 | 14.1 GPa | Plasticity index is 0.17 Shared stress is 332.0 MPa | [150] |

| Composite | PM1 | SP2 | DD3 | EC4 | Comms | R5 |

|---|---|---|---|---|---|---|

| Al-CNT | PM | Al:CNT is 95:5, 400 °C, 1 min | - | 1.52·107 | No change in the hardness level, compared with Al | [68] |

| Al-4%CNTs/2GAg,NPs | SPS | 580 °C, 50 MPa, 5 V, 300 amps | 1.98·104 | 4.21·105 | 91.08 and 95.56% protection efficiency were obtained over that of the α-Al Matrix at Al-4%CNTs and Al-4%CNTs + 2%GAgNPs | [171] |

| Al-Cu/f-CNT | *EP | 0.5 V, 5 min | - | 72.93% for wire (coated by electrophoresis at 1.2 A) | Electrical resistivity is 3.29·10−9 Ωm | [175] |

| Composite | PM1 | SP2 | TE3 | TC4 | Comms | R5 |

|---|---|---|---|---|---|---|

| Al-0.5CNTs/L3 | HP | 150 rpm, 600 °C, 20 MPa, vacuum 10 Pa, 50 min | - | 148.0 | Molecular dynamics simulations revealed the heat transfer mechanism through the electron–phonon coupling effect | [145] |

| Al-Si/CNT | HE | 550 °C, 1 mm/s, 16:1 | 16.8 × 10−6 (at 50–400 °C) | 102.0 | Yield strength is 235 MPa | [178] |

| Al-CNT | CVD/HE | 550 °C, 30 min/400 °C, 16:1 | - | 246.6 (400 °C) | Ultimate strength is 186.2 MPa; minimum CTE is 25 × 10−6 K−1 (400 °C) | [179] |

| Al-3.7%CNT | 3D printing | 350 W, scan speed of 1250 mm/s, layerthickness of 30 mm and hatch spacing of 60 mm. | - | 400.0 | Detected the effect of the interface and thermal loading direction on the thermal conductivity of the composites | [180] |

| Al-Graphite Film/CNT | PM | 570 °C, 50 MPa, 30 min | - | 897.0 | The in-plane TC improved due to the heat conduction pathway formed by CNTs on the interface | [181] |

| Al-5%CNT | 3D RVE model | - | 5.12 × 10−6 °C−1 | n/a | The effect of increasing the volume fraction of CNTs leads to a remarkable decrease in the CTE of Al/CNT composites | [182] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nurguzhin, M.; Janikeyev, M.; Omarbayev, M.; Yermakhanova, A.; Meiirbekov, M.; Zhumakhanov, M.; Keneshbekova, A.; Atamanov, M.; Akylbayeva, A.; Lesbayev, A.; et al. Structure and Properties of Al–CNT-Based Composites Manufactured by Different Methods: A Brief Review. Materials 2025, 18, 214. https://doi.org/10.3390/ma18010214

Nurguzhin M, Janikeyev M, Omarbayev M, Yermakhanova A, Meiirbekov M, Zhumakhanov M, Keneshbekova A, Atamanov M, Akylbayeva A, Lesbayev A, et al. Structure and Properties of Al–CNT-Based Composites Manufactured by Different Methods: A Brief Review. Materials. 2025; 18(1):214. https://doi.org/10.3390/ma18010214

Chicago/Turabian StyleNurguzhin, Marat, Marat Janikeyev, Myrzakhan Omarbayev, Azira Yermakhanova, Mohammed Meiirbekov, Miras Zhumakhanov, Aruzhan Keneshbekova, Meiram Atamanov, Aigerim Akylbayeva, Aidos Lesbayev, and et al. 2025. "Structure and Properties of Al–CNT-Based Composites Manufactured by Different Methods: A Brief Review" Materials 18, no. 1: 214. https://doi.org/10.3390/ma18010214

APA StyleNurguzhin, M., Janikeyev, M., Omarbayev, M., Yermakhanova, A., Meiirbekov, M., Zhumakhanov, M., Keneshbekova, A., Atamanov, M., Akylbayeva, A., Lesbayev, A., & Yerezhep, D. (2025). Structure and Properties of Al–CNT-Based Composites Manufactured by Different Methods: A Brief Review. Materials, 18(1), 214. https://doi.org/10.3390/ma18010214