Effect of Stress Aging on Strength, Toughness and Corrosion Resistance of Al-10Zn-3Mg-3Cu Alloy

Abstract

1. Introduction

2. Material and Experiments

2.1. Material and Aging Treatment

2.2. Properties Testing

2.3. Microstructural Investigations

2.4. Corrosion Testing

3. Results

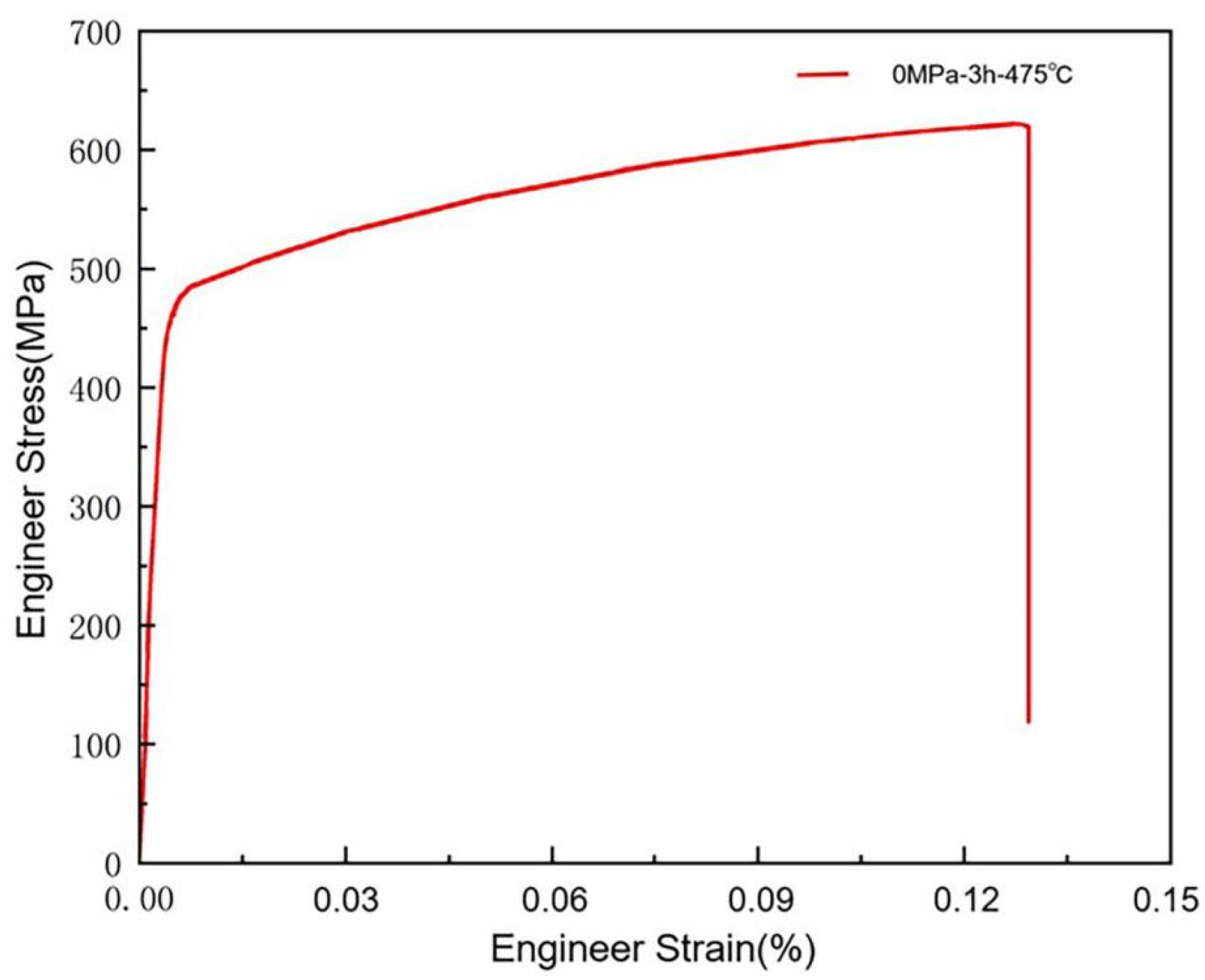

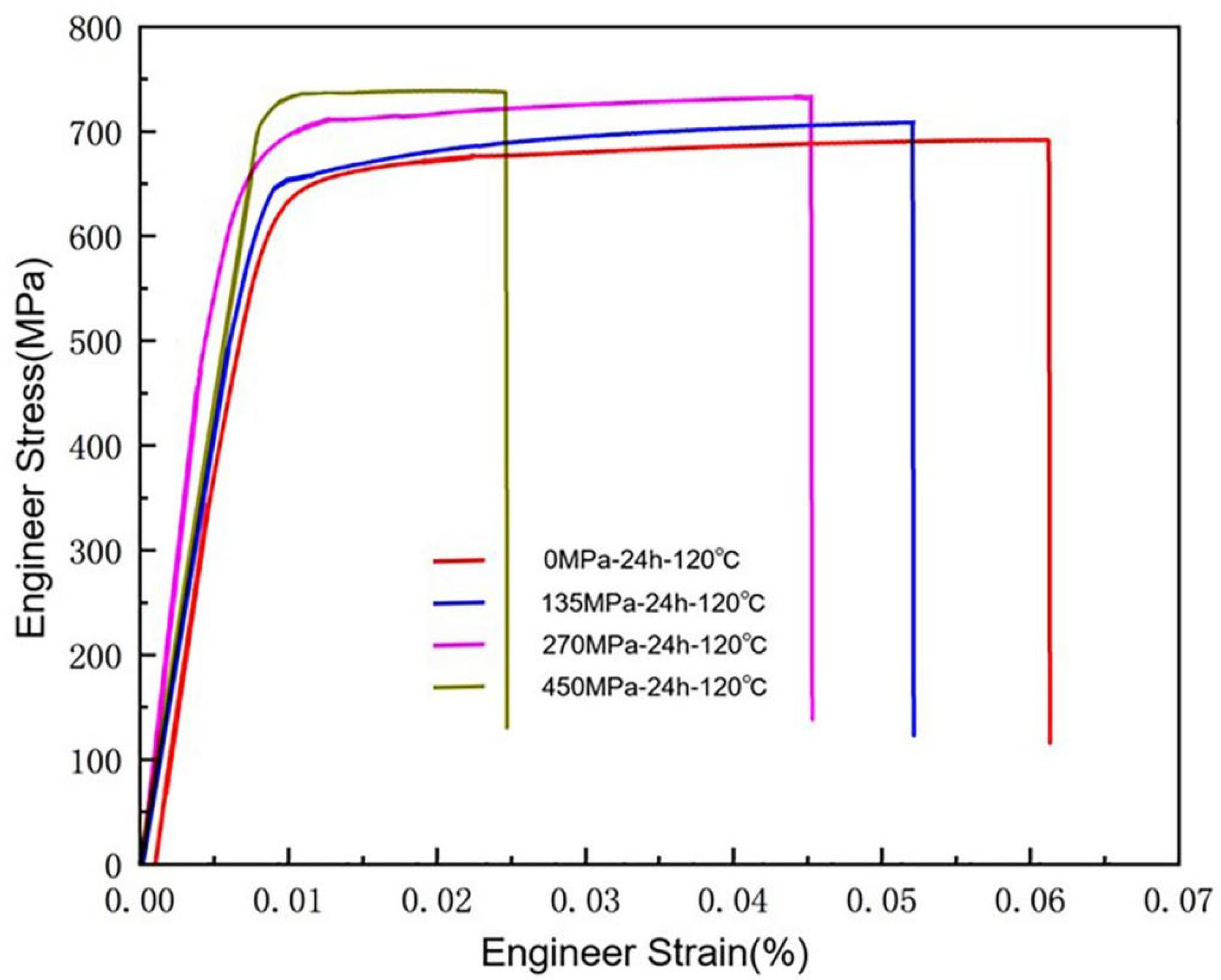

3.1. Tensile Property

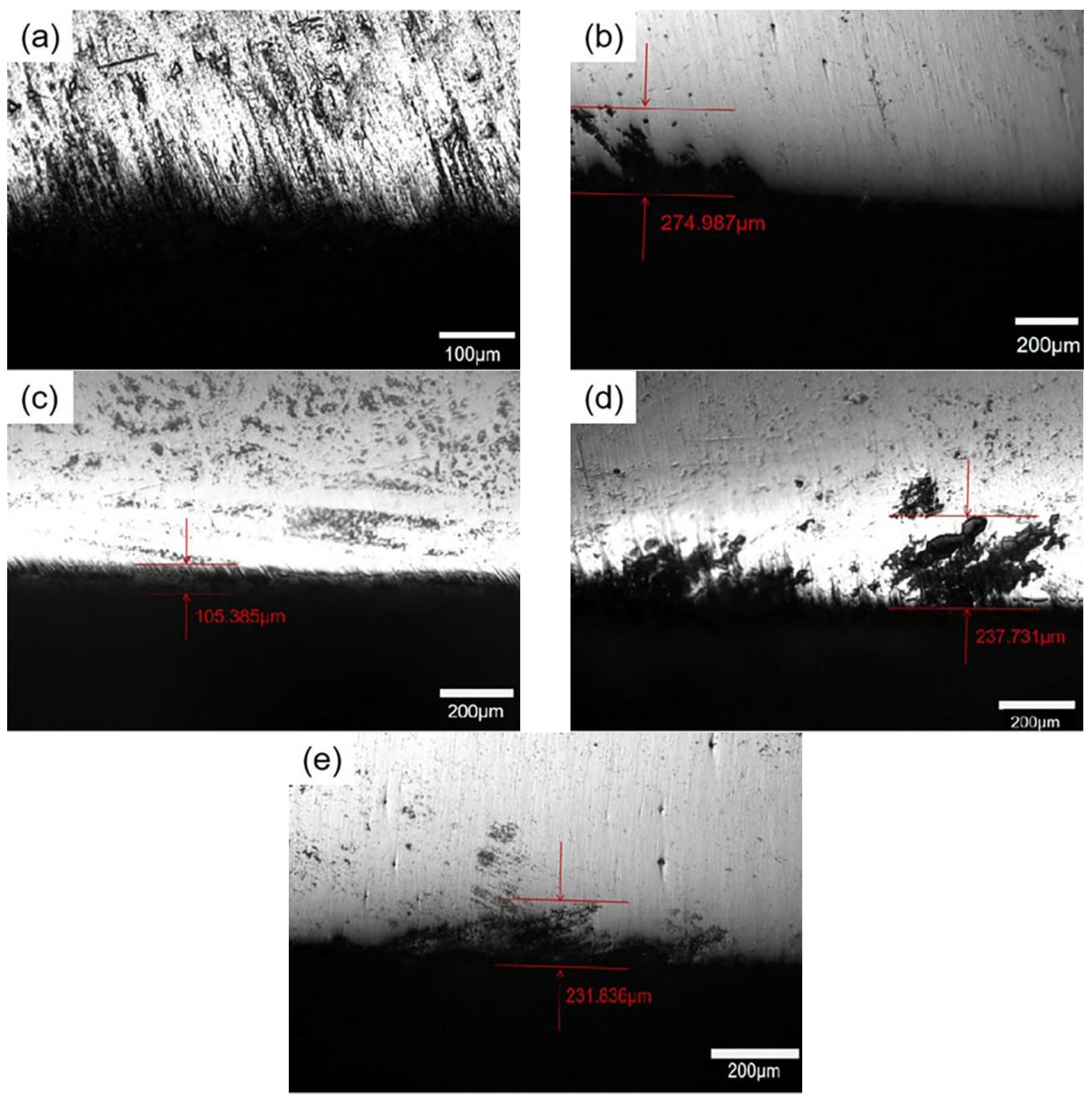

3.2. Intergranular Corrosion Resistance

3.3. Electrochemical Corrosion Behavior

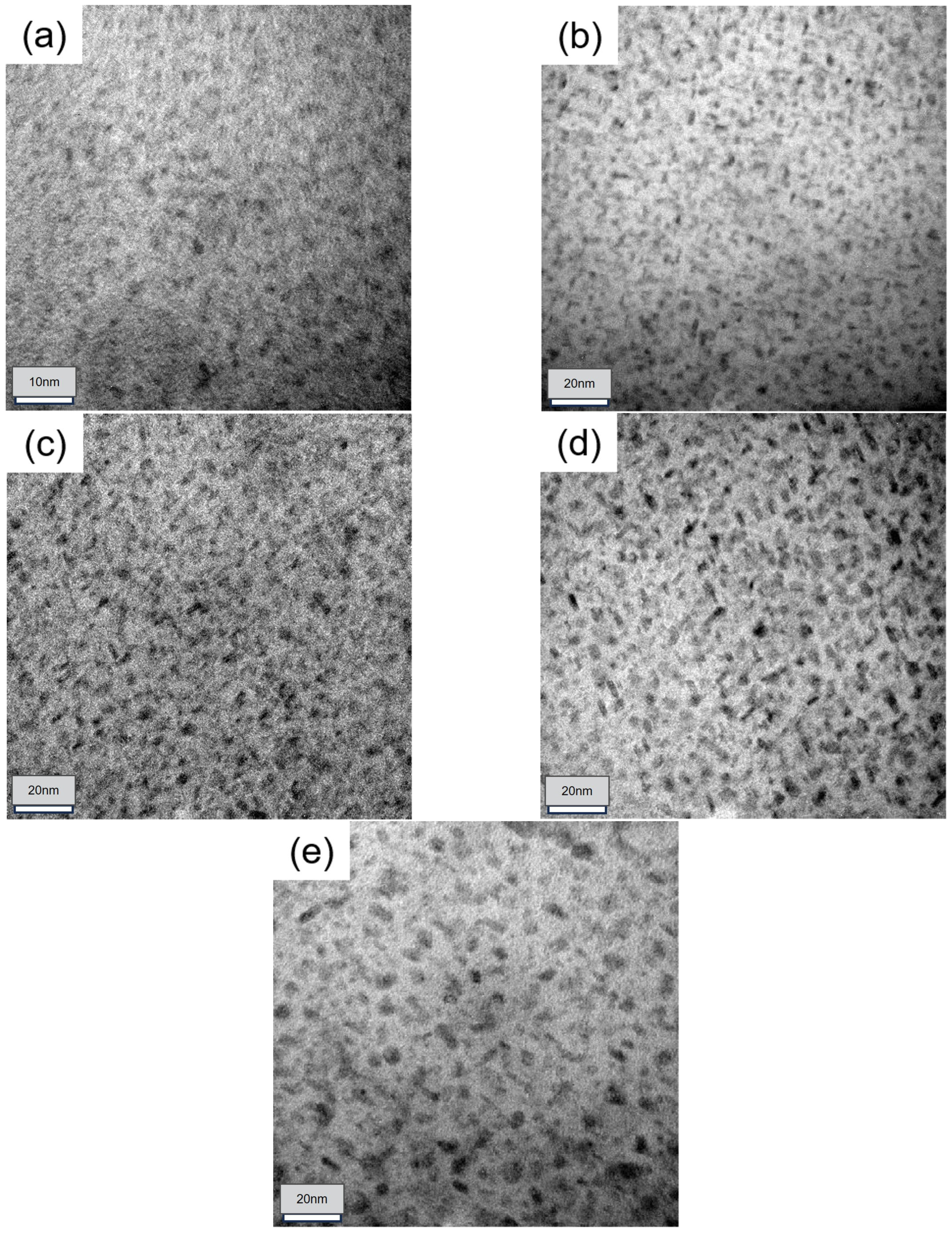

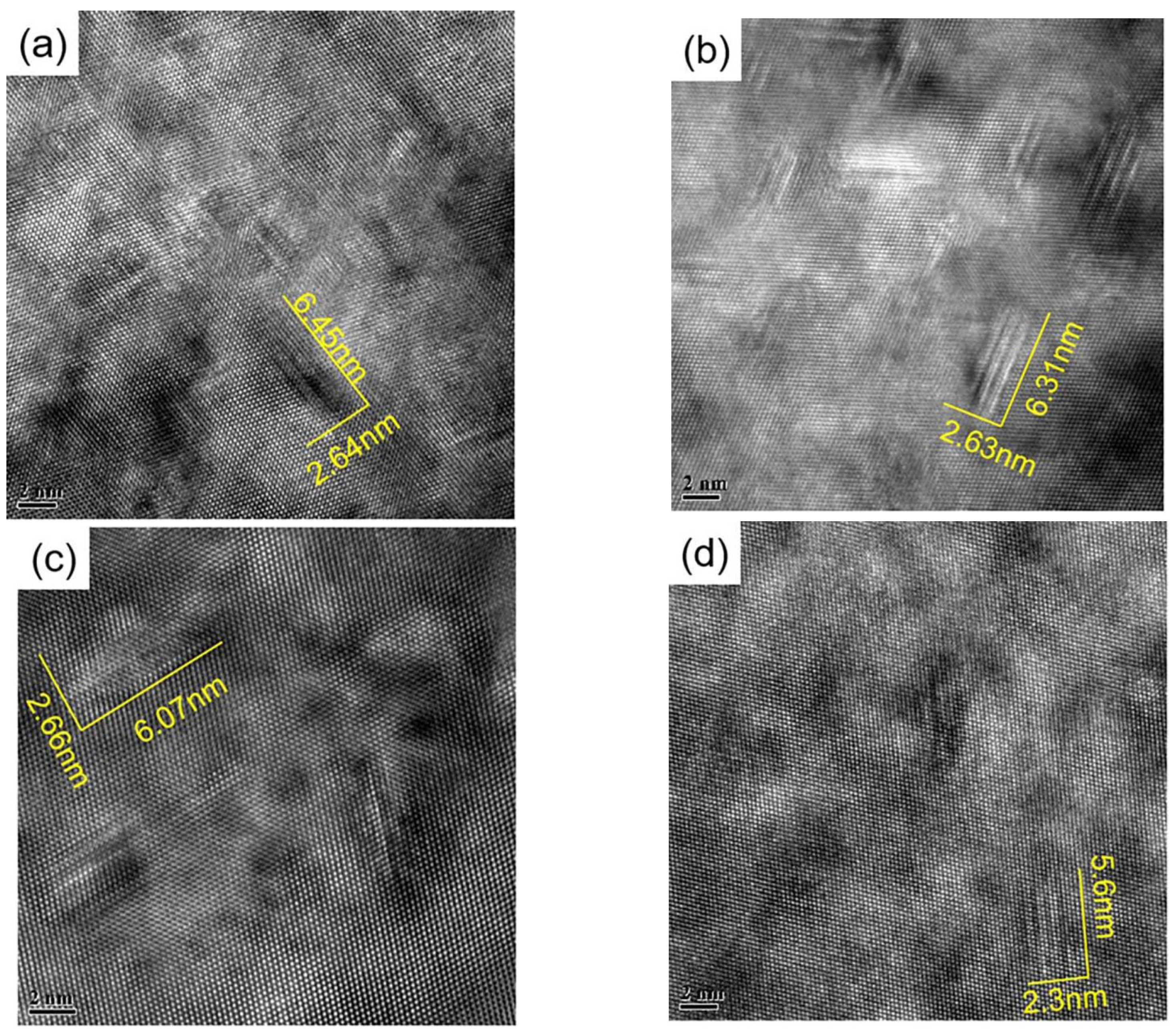

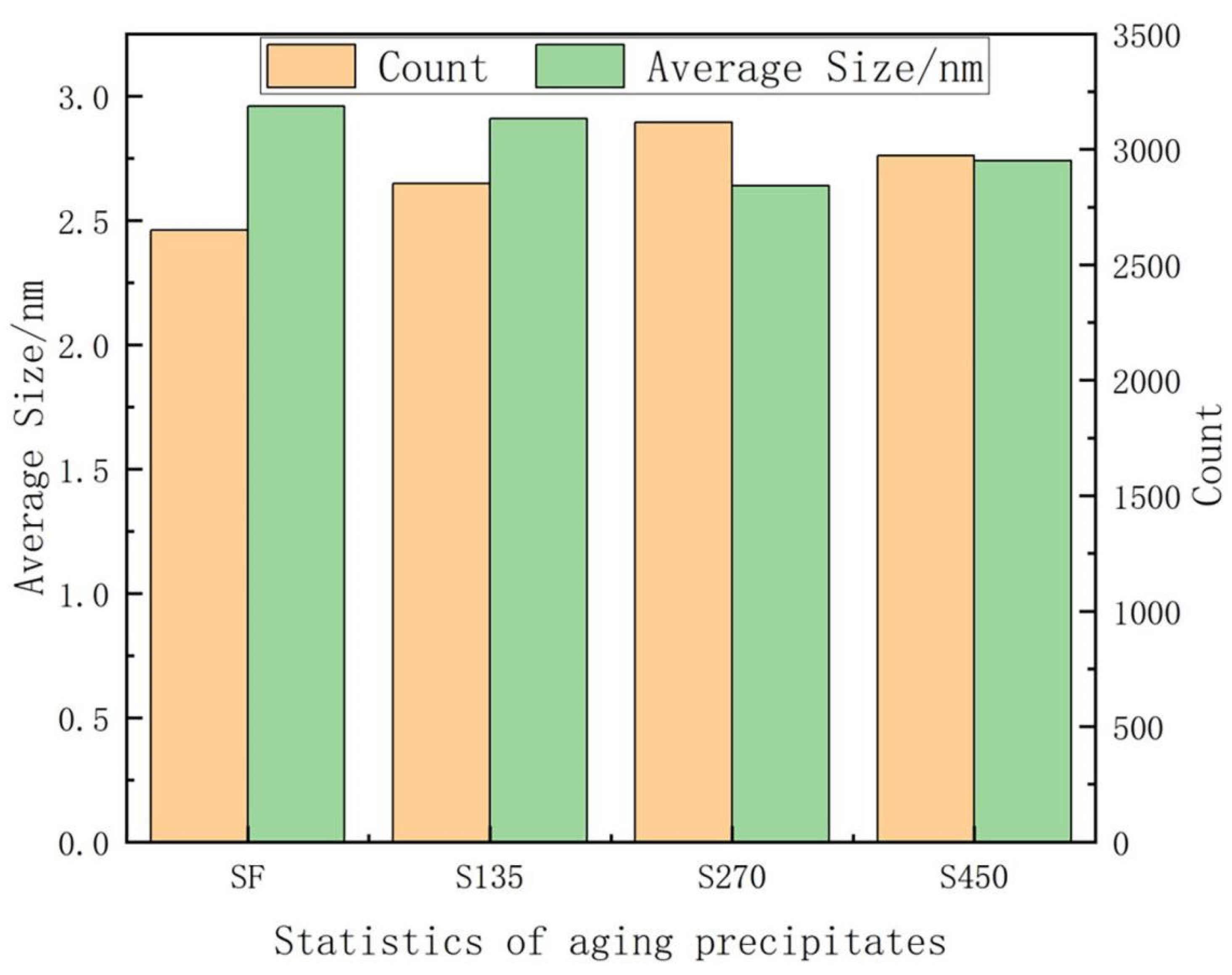

3.4. Precipitated Phase Characterization

4. Discussion

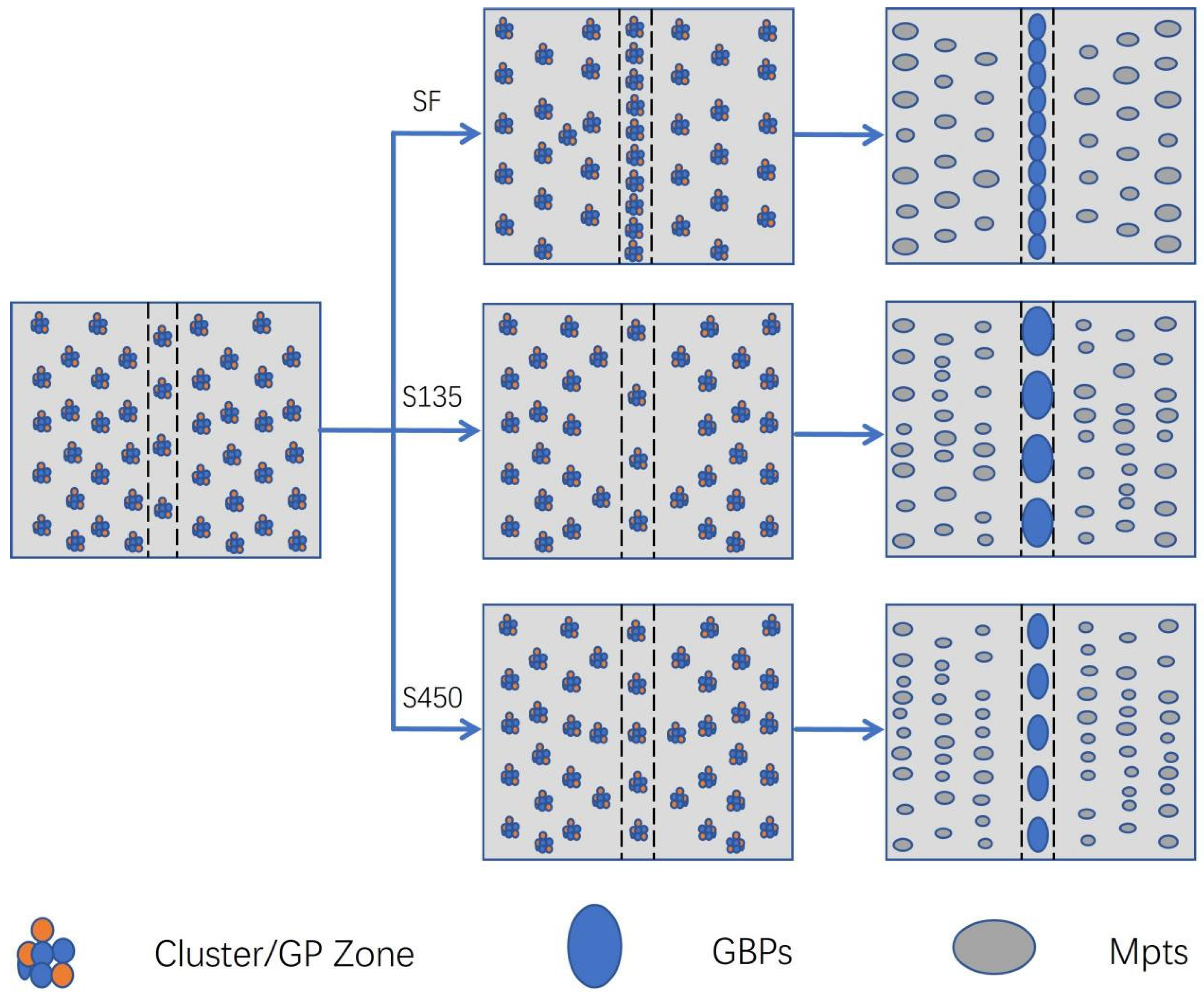

4.1. Aging Stress Field Affects Sample Strengthening Mechanism

4.2. Aging Stress Field Affects the Corrosion Resistance Mechanism of the Sample

5. Conclusions

- (1)

- The mechanical properties of the alloy improve progressively with the increase in the applied stress, though its ductility decreases. Both the yield strength (YS) and ultimate tensile strength (UTS) reach the peak values (YS: 713 MPa, UTS: 740 MPa) when the applied stress is 450 MPa. In the absence of stress, the YS and UTS are 640 MPa and 691 MPa, respectively. This is due to the external stress inducing alloy lattice defects, reducing the solubility of solute atoms, which combine with matrix precipitates (MPts) to produce a strong competitive relationship, and inhibiting the coarsening of MPts and the η’ → η phase transition, thereby improving the mechanical properties of the alloy.

- (2)

- With the application and gradual increase in external stress, the overall Icorr of the alloy shows a downward trend. The Icorr values for stress conditions of SF, S135, S270 and S450 are 1.508 × 10−4, 2.962 × 10−6, 1.999 × 10−5 and 8.892 × 10−6, respectively. The alloy achieves the balance of mechanical properties and corrosion resistance when the applied stress is 270 MPa. This is because the applied stress limits the motion of the vacancy and solute atoms. This results in the rapid growth of a grain boundary precipitated phase (GBP) and the formation of a precipitation-free zone (PFZ). When a discontinuous GBP is formed, corrosion can be prevented to a certain extent, while a narrower PFZ within a certain range will also improve the corrosion resistance of the alloy. This phenomenon is more obvious at lower stresses.

- (3)

- The improvement of mechanical properties is inevitably accompanied by the decrease in elongation. When the applied stress is 270 MPa, the strength, toughness and corrosion resistance of the alloy reach a relative balance in which the mechanism study of stress on mechanical properties and corrosion resistance can guide the engineering application of the material, making its application field more extensive.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, B.; Wang, X.; Chen, H.; Hu, J.; Huang, C.; Gou, G.Q. Influence of heat treatment on the strength and fracture toughness of 7N01 aluminum alloy. J. Alloys Compd. 2016, 678, 160–166. [Google Scholar] [CrossRef]

- Cao, F.H.; Zheng, J.X.; Jiang, Y.; Cheng, B.; Wang, Y.R.; Hu, T. Experimental and DFT characterization of η′ nano-phase and its interfaces in Al-Zn-Mg-Cu alloys. Acta Mater. 2019, 164, 207–219. [Google Scholar] [CrossRef]

- Yang, X.B.; Chen, J.H.; Liu, J.Z.; Qin, F.; Xie, J.; Wu, C.L. A high-strength Al-Zn-Mg alloy hardened by the T-phase precipitates. J. Alloys Compd. 2014, 610, 69–73. [Google Scholar] [CrossRef]

- Li, Z.M.; Jiang, H.C.; Wang, Y.L.; Zhang, D.; Yan, D.S.; Rong, L.J. Effect of minor Sc addition on microstructure and stress corrosion cracking behavior of medium strength Al-Zn-Mg alloy. J. Mater. Sci. Technol. 2018, 34, 1172–1179. [Google Scholar] [CrossRef]

- Wang, Y.L.; Jiang, H.C.; Li, Z.M.; Yan, D.S.; Zhang, D.; Rong, L.J. Two-stage double peaks ageing and its effect on stress corrosion cracking susceptibility of Al-Zn-Mg alloy. J. Mater. Sci. Technol. 2018, 34, 1250–1257. [Google Scholar] [CrossRef]

- Ren, X.; Zhang, J.; Zhang, Z.; Wang, Q.; Xue, Y.; Liu, H.; Meng, M.; Zhao, X.; Liu, H. Influence of the solid solution duration on the microstructure and mechanical properties of the Al-10.0Zn-3.0Mg-2.5Cu alloy. Mater 2024, 896, 146299. [Google Scholar] [CrossRef]

- Fu, Z.L.; Zhao, X.; Jiao, M.H.; Ren, X.W.; Zhao, H.B.; Liu, H.L. Study on the Aging Precipitation Behavior and Kinetics of Al-10.0Zn-3.0Mg-2.8Cu Alloy by Pre-Deformation Treatment. Mater 2024, 17, 3729. [Google Scholar] [CrossRef]

- Xiao, F.; Shu, D.; Wang, D.H.; Zhu, G.L.; Wang, S.B.; Sun, B.D. Effect of Zn content on the formability and aging precipitation of Al-Zn-Mg-Cu-Nb alloys prepared by LPBF. J. Mater. Sci. Technol. 2023, 25, 6338–6355. [Google Scholar] [CrossRef]

- Liu, X.Y.; Pan, Q.L.; Zhang, X.L.; Liang, S.X.; Zheng, L.Y.; Gao, F.; Xie, H.L. Effects of stress-aging on the microstructure and properties of an aging forming Al-Cu-Mg-Ag alloy. Mater. Des. 2014, 58, 247–251. [Google Scholar] [CrossRef]

- Guo, W.; Guo, J.; Wang, J.; Yang, M.; Li, H.; Wen, X.; Zhang, J. Evolution of precipitate microstructure during stress aging of an Al–Zn–Mg–Cu alloy. Mater. Sci. Eng. A 2015, 634, 167–175. [Google Scholar] [CrossRef]

- Wang, R.; Wang, D.T.; Nagaumi, H.; Wu, Z.B.; Zhang, X.Z.; Li, X.Z. Effect of Zn content on corrosion resistance of as-cast Al-6Si-3Cu alloy. Mater. Lett. 2022, 312, 131658. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Shi, L.; Su, R.M.; Liu, T.Y.; Li, G.L. Effect of Variable Rate Non-isothermal Aging on the Microstructure and Properties of Al-Zn-Mg-Cu Alloy. JOM 2024, 76, 4683–4697. [Google Scholar] [CrossRef]

- Zhu, Z.; Jiang, X.; Wei, G.; Fang, X.; Zhong, Z.; Song, K.; Han, J.; Jiang, Z. Influence of Zn Content on Microstructures, Mechanical Properties and Stress Corrosion Behavior of AA5083 Aluminum Alloy. Acta Metall. Sin. 2020, 33, 1369–1378. [Google Scholar] [CrossRef]

- Wei, Q.Y.; Zhao, Y.L.; Liu, H.; He, W.X.; Wang, M.M.; Sun, Z.Z. Effect of heat treatment on the deformation behavior of an Al-Cu alloy studied by in-situ synchrotron X-ray diffraction. Mater 2024, 914, 147138. [Google Scholar] [CrossRef]

- Li, Y.; Xu, G.F.; Peng, X.Y.; Wang, F.X.; Deng, Y.; Liang, X.P. Effect of different aging treatment on high temperature properties of die-forged Al-5.87Zn-2.07Mg-2.42Cu alloy. Mater. Charact. 2020, 164, 110239. [Google Scholar] [CrossRef]

- Yu, Z.; Li, H.; Cai, P.; Fu, X.; Feng, Z.; Zhang, L.; Wang, J.; Xiao, N. Effect of aging route on the precipitation behavior and thermal stability of Al-Cu-Mg-Ag alloy. J. Mater. Sci. Technol. 2023, 23, 2010–2019. [Google Scholar] [CrossRef]

- Xiong, Y.; Robson, J.D.; Cao, Z.; Deng, Y.; Yao, Y.; Zhong, X.; Bendo, A.; Jinlong, L.; Guarracino, F.; Donoghue, J.; et al. Mitigation effects of over-aging (T73) induced intergranular corrosion on stress corrosion cracking of AA7075 aluminum alloy and behaviors of η phase grain boundary precipitates during the intergranular corrosion formation. Corros. Sci. 2023, 225, 111570. [Google Scholar] [CrossRef]

- Liu, L.; Hou, Y.; Ye, T.; Zhang, L.; Huang, X.; Gong, Y.; Liu, C.; Wu, Y.; Duan, S. Effects of Aging Treatments on the Age Hardening Behavior and Microstructures in an Al-Mg-Si-Cu Alloy. Metals 2024, 14, 238. [Google Scholar] [CrossRef]

- Sanyal, S.; Chatterjee, S.; Chabri, S.; Bhowmik, N.; Sinha, A. Influence of over-aging and sub-zero temperature rolling on strength-ductility balance in AA6061 alloy. Eng. Sci. Technol. Int. J. 2019, 22, 359–369. [Google Scholar] [CrossRef]

- Ren, J.; Wang, R.; Peng, C.; Zhang, H.; Xu, C.; Wu, Y.; Feng, Y. Effect of repetitious retrogression and re-aging treatment on the microstructure, strength and corrosion behavior of powder hot-extruded 7055 Al alloy. Mater. Charact 2020, 162, 110190. [Google Scholar] [CrossRef]

- Xie, P.; Chen, S.; Chen, K.; Jiao, H.; Huang, L.; Zhang, Z.; Yang, Z. Enhancing the stress corrosion cracking resistance of a low-Cu containing Al-Zn-Mg-Cu aluminum alloy by step-quench and aging heat treatment. Corros. Sci. 2019, 161, 108184. [Google Scholar] [CrossRef]

- Su, H.; Toda, H.; Shimizu, K.; Uesugi, K.; Takeuchi, A.; Watanabe, Y. Assessment of hydrogen embrittlement via image-based techniques in Al-Zn-Mg-Cu aluminum alloy. Acta Mater. 2019, 176, 96–108. [Google Scholar] [CrossRef]

- Guo, X.B.; Zhang, J.; Deng, Y.L.; Zhang, X.M.; Zhang, Y. Effect of grain boundaries on the preferential orientation distribution of θ′ precipitates in stress-aged Al-2Cu alloy bicrystals. J. Alloys Compd. 2019, 794, 501–508. [Google Scholar] [CrossRef]

- Wu, X.T.; Zhan, L.H.; Guan, C.L.; Yang, X.B.; He, J.Y. Effect of creep aging parameters on creep resistance behavior of Al-Cu-Mg alloy. Mater. Res. Express 2019, 6, 1265a7. [Google Scholar] [CrossRef]

- Chen, F.; Zhan, L.-H.; Xu, Y.-Q.; Liu, C.-H.; Ma, B.-L.; Zeng, Q.-Q.; Hu, Z.-G.; Zhu, W.-L.; Yan, D.-Y. Regulation mechanism of aging behavior and mechanical properties of 2195-T34 Al-Li alloy at different stress levels. J. Cent. S. Univ. 2024, 31, 11–24. [Google Scholar] [CrossRef]

- Zhu, A.W.; Starke, E.A. Stress aging of Al-xCu alloys: Experiments. Acta Mater. 2001, 49, 2285–2295. [Google Scholar] [CrossRef]

- Guo, W.; Yang, M.; Zheng, Y.; Zhang, X.; Li, H.; Wen, X.; Zhang, J. Influence of elastic tensile stress on aging process in an Al-Zn-Mg-Cu alloy. Mater. Lett. 2013, 106, 14–17. [Google Scholar] [CrossRef]

- Guo, X.B.; Zhang, J.; Chen, J.Q.; Deng, Y.L. Effect of edge dislocations on the distribution of θ′ precipitates in stress-aged Al-Cu single crystal. J. Alloys Compd. 2020, 812, 152173. [Google Scholar] [CrossRef]

- Quan, L.-W.; Zhao, G.; Tian, N.; Huang, M.-L. Effect of stress on microstructures of creep-aged 2524 alloy. Trans. Nonferrous Met. Soc. China 2013, 23, 2209–2214. [Google Scholar] [CrossRef]

- Lin, Y.C.; Zhang, J.L.; Chen, M.S. Evolution of precipitates during two-stage stress-aging of an Al-Zn-Mg-Cu alloy. J. Alloys Compd. 2016, 684, 177–187. [Google Scholar] [CrossRef]

- Lin, Y.C.; Peng, X.B.; Jiang, Y.Q.; Shuai, C.J. Effects of creep-aging parameters on aging precipitates of a two-stage creep-aged Al-Zn-Mg-Cu alloy under the extra compressive stress. J. Alloys Compd. 2018, 743, 448–455. [Google Scholar] [CrossRef]

- Zhang, D.; Jiang, H.C.; Cui, Z.J.; Yan, D.S.; Song, Y.Y.; Rong, L.J. Precipitation kinetics in an Al-Zn-Mg alloy during stress-aging. J. Alloys Compd. 2021, 862, 158680. [Google Scholar] [CrossRef]

- Liu, Y.X.; Li, J.M.; Gao, F.; Liang, S.X.; Zhang, X.L.; Cui, H.X. Effects of aging treatment on the intergranular corrosion behavior of Al-Cu-Mg-Ag alloy. J. Alloys Compd. 2015, 639, 263–267. [Google Scholar] [CrossRef]

- Li, S.; Dong, H.G.; Li, P.; Chen, S. Effect of repetitious non-isothermal heat treatment on corrosion behavior of Al-Zn-Mg alloy. Corros. Sci. 2018, 131, 278–289. [Google Scholar] [CrossRef]

- Zhang, Z.; Ma, X.; Zhang, C.; Chu, G.; Meng, Z.; Zhao, G.; Chen, L. Effect of stress-aging treatment on the mechanical and corrosion properties of Al-Zn-Mg-Cu alloy. Mater. Sci. Eng. A 2022, 838, 142791. [Google Scholar] [CrossRef]

- Clouet, E.; Nastar, M.; Sigli, C. Nucleation of Al3Zr and Al3Sc in aluminum alloys: From kinetic Monte Carlo simulations to classical theory. Phys. Rev. B 2004, 69, 064109. [Google Scholar] [CrossRef]

- Guo, F.; Duan, S.; Pan, Y.; Wu, D.; Matsuda, K.; Wang, T.; Zou, Y. Stress corrosion behavior and microstructure analysis of Al-Zn-Mg-Cu alloys friction stir welded joints under different aging conditions. Corros. Sci. 2023, 210, 110821. [Google Scholar] [CrossRef]

- Ren, Y.; Wan, T.; Xu, Y.; Zhang, K.; Zhang, M.; Li, J. Effects of stress aging treatment on the microstructure, mechanical properties and electrochemical corrosion behavior of Al-Zn-Mg-Cu alloy. J. Alloys Compd. 2024, 997, 174686. [Google Scholar] [CrossRef]

- Shang, F.U.; Yi, D.Q.; Liu, H.Q.; Jiang, Y.; Wang, B.; Hu, Z. Effects of external stress aging on morphology and precipitation behavior of θ″ phase in Al-Cu alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 2282–2288. [Google Scholar] [CrossRef]

- Zhang, D.; Jiang, H.C.; Cui, Z.J.; Yan, D.S.; Song, Y.Y.; Rong, L.J. Synchronous improvement of mechanical properties and stress corrosion resistance by stress-aging coupled with natural aging pre-treatment in an Al-Zn-Mg alloy with high recrystallization fraction. J. Mater. Sci. Technol. 2022, 121, 40–51. [Google Scholar] [CrossRef]

- Feng, Y.; Liu, M.; Shi, Y.; Ma, H.; Li, D.; Li, Y.; Lu, L.; Chen, X. High-throughput modeling of atomic diffusion migration energy barrier of fcc metals. Prog. Nat. Sci. Mater. Int. 2019, 29, 341–348. [Google Scholar] [CrossRef]

- Tan, P.; Liu, Z.Q.; Qin, J.; Wei, Q.R.; Wang, B.; Yi, D.Q. Enhanced corrosion performance by controlling grain boundary precipitates in a novel crossover Al-Cu-Zn-Mg alloy by optimizing Zn content. Mater. Charact. 2024, 208, 113615. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, H.; Huang, R.; Sun, P.; Zheng, S.; Li, M.; Wang, X.; Du, Q. Investigation of microstructure and corrosion resistance of an Al-Zn-Mg-Cu alloy under various ageing conditions. Corros. Sci. 2024, 227, 111719. [Google Scholar] [CrossRef]

- Tang, J.; Wang, Y.; Fujihara, H.; Shimizu, K.; Hirayama, K.; Ebihara, K.; Takeuchi, A.; Uesugi, M.; Toda, H. Stress corrosion cracking induced by the combination of external and internal hydrogen in Al-Zn-Mg-Cu alloy. Scr. Mater. 2024, 239, 115804. [Google Scholar] [CrossRef]

- Song, F.X.; Zhang, X.M.; Liu, S.D.; Tan, Q.; Li, D.F. The effect of quench rate and overageing temper on the corrosion behaviour of AA7050. Corros. Sci. 2014, 78, 276–286. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, B.; Lin, H.; Zhou, Y.; Sun, L.; Wang, J.; Han, E.-H.; Ke, W. Correlations between stress corrosion cracking susceptibility and grain boundary microstructures for an Al-Zn-Mg alloy. Corros. Sci. 2013, 77, 103–112. [Google Scholar] [CrossRef]

- Knight, S.P.; Birbilis, N.; Muddle, B.C.; Trueman, A.R.; Lynch, S.P. Correlations between intergranular stress corrosion cracking, grain-boundary microchemistry, and grain-boundary electrochemistry for Al-Zn-Mg-Cu alloys. Corros. Sci. 2010, 52, 4073–4080. [Google Scholar] [CrossRef]

- Xiao, Q.; Xu, Y.; Huang, J.; Li, B.; Wang, B.; Liu, S.; Fu, L. Effects of quenching agents, two-step aging and microalloying on tensile properties and stress corrosion cracking of Al-Zn-Mg-Cu alloys. J. Mater. Sci. Technol. 2020, 9, 10198–10208. [Google Scholar] [CrossRef]

- Qiu, Y.; Liu, R.; Zou, L.; Chi, H.; Wang, C.; Wang, B.; Chen, J. Influence of Grain Boundary Precipitates on Intergranular Corrosion Behavior of 7050 Al Alloys. Coatings 2022, 12, 249. [Google Scholar] [CrossRef]

- Metalnikov, P.; Ben-Hamu, G.; Shin, S.K. Relation Between Zn Additions, Microstructure and Corrosion Behavior of New Wrought Mg-5Al Alloys. Met. Mater. Int. 2019, 27, 1493–1505. [Google Scholar] [CrossRef]

- Li, Z.G.; Chen, L.; Tang, J.W.; Zhao, G.Q.; Zhang, C.S. Response of mechanical properties and corrosion behavior of Al-Zn-Mg alloy treated by aging and annealing: A comparative study. J. Alloys Compd. 2020, 848, 156561. [Google Scholar] [CrossRef]

- Zhang, Y.; Jin, S.; Trimby, P.W.; Liao, X.; Murashkin, M.Y.; Valiev, R.Z.; Liu, J.; Cairney, J.M.; Ringer, S.P.; Sha, G. Dynamic precipitation, segregation and strengthening of an Al-Zn-Mg-Cu alloy (AA7075) processed by high-pressure torsion. Acta Mater. 2019, 162, 19–32. [Google Scholar] [CrossRef]

| Mg | Si | Cu | Zn | Zr | Fe | Al |

|---|---|---|---|---|---|---|

| 3.0 | 0.03 | 3.0 | 10.0 | 0.15 | 0.06 | Bal. |

| Sample | Solution Treatment | Aging Parameter | ||

|---|---|---|---|---|

| Aging Time/h | Aging Temperature/°C | Aging Stress/MPa | ||

| S0 | 475 °C × 3 h | 0 | 0 | 0 |

| SF | 24 | 120 | 0 | |

| S135 | 24 | 120 | 135 | |

| S270 | 24 | 120 | 270 | |

| S450 | 24 | 120 | 450 | |

| Sample | Yield Strength/MPa | Ultimate Tensile Strength/MPa | Elongation/% |

|---|---|---|---|

| SF | 640 | 691 | 6.1% |

| S135 | 637 | 710 | 5.2% |

| S270 | 695 | 733 | 4.52% |

| S450 | 713 | 740 | 2.56% |

| Sample | Ecorr/V | Icorr/(A∙cm−2) |

|---|---|---|

| S0 | −0.762 | 2.583 × 10−5 |

| SF | −0.737 | 1.508 × 10−4 |

| S135 | −0.894 | 2.962 × 10−6 |

| S270 | −1.178 | 1.999 × 10−5 |

| S450 | −0.781 | 8.892 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.; Zhao, X.; Ren, X.; Yan, S.; Gao, Y.; Liu, H. Effect of Stress Aging on Strength, Toughness and Corrosion Resistance of Al-10Zn-3Mg-3Cu Alloy. Materials 2025, 18, 181. https://doi.org/10.3390/ma18010181

Yang D, Zhao X, Ren X, Yan S, Gao Y, Liu H. Effect of Stress Aging on Strength, Toughness and Corrosion Resistance of Al-10Zn-3Mg-3Cu Alloy. Materials. 2025; 18(1):181. https://doi.org/10.3390/ma18010181

Chicago/Turabian StyleYang, Dongchu, Xi Zhao, Xianwei Ren, Shiliang Yan, Yihan Gao, and Hongbin Liu. 2025. "Effect of Stress Aging on Strength, Toughness and Corrosion Resistance of Al-10Zn-3Mg-3Cu Alloy" Materials 18, no. 1: 181. https://doi.org/10.3390/ma18010181

APA StyleYang, D., Zhao, X., Ren, X., Yan, S., Gao, Y., & Liu, H. (2025). Effect of Stress Aging on Strength, Toughness and Corrosion Resistance of Al-10Zn-3Mg-3Cu Alloy. Materials, 18(1), 181. https://doi.org/10.3390/ma18010181