Statistical Reliability Analysis of Ultrasonic Velocity Method for Predicting Residual Strength of High-Strength Concrete under High-Temperature Conditions

Abstract

:1. Introduction

2. Experimental Plan and Methods

2.1. Experimental Plan

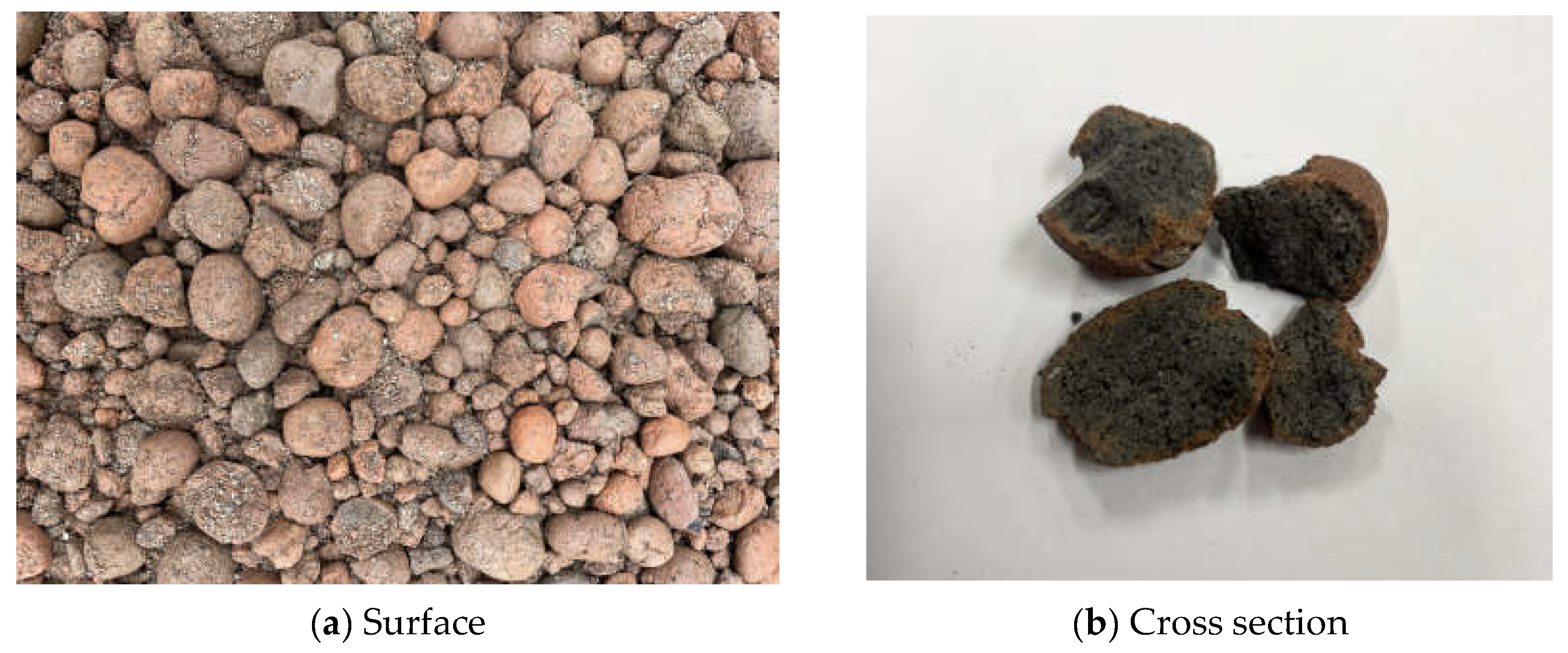

2.2. Materials

2.3. Mix Proportion and Specimen Preparation

2.4. Test Method

3. Results and Discussion

3.1. Mechanical Properties of Concrete

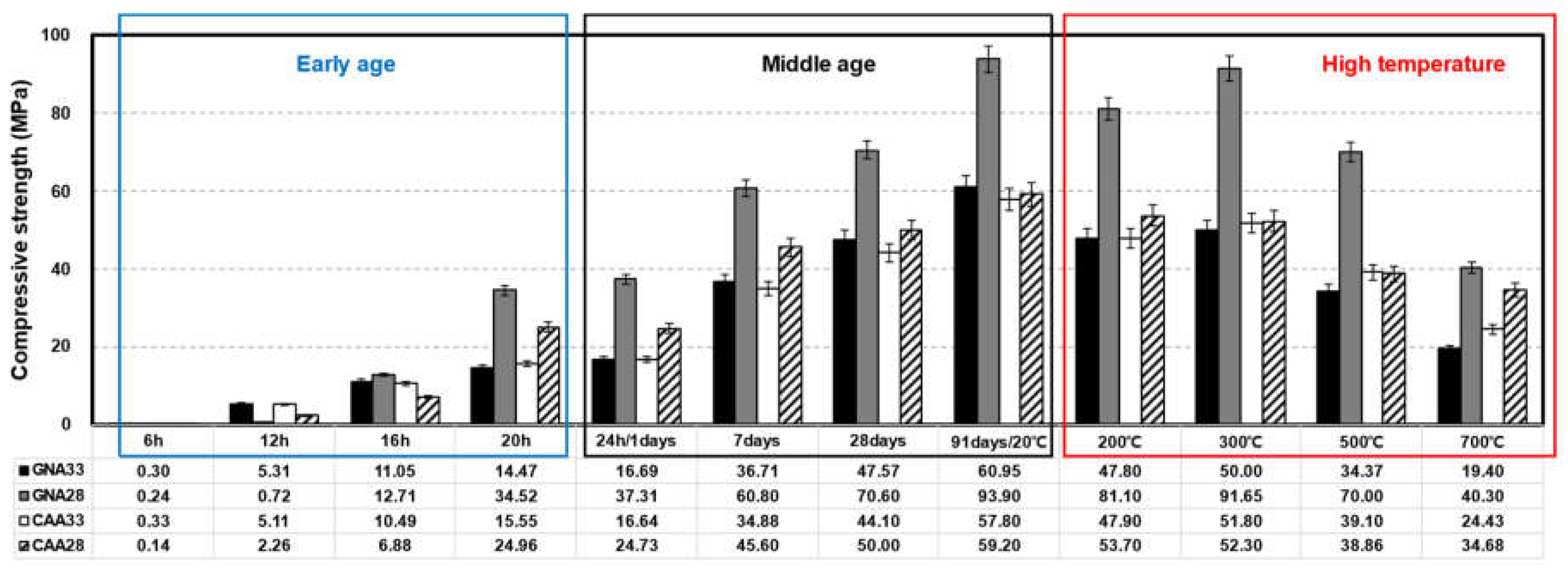

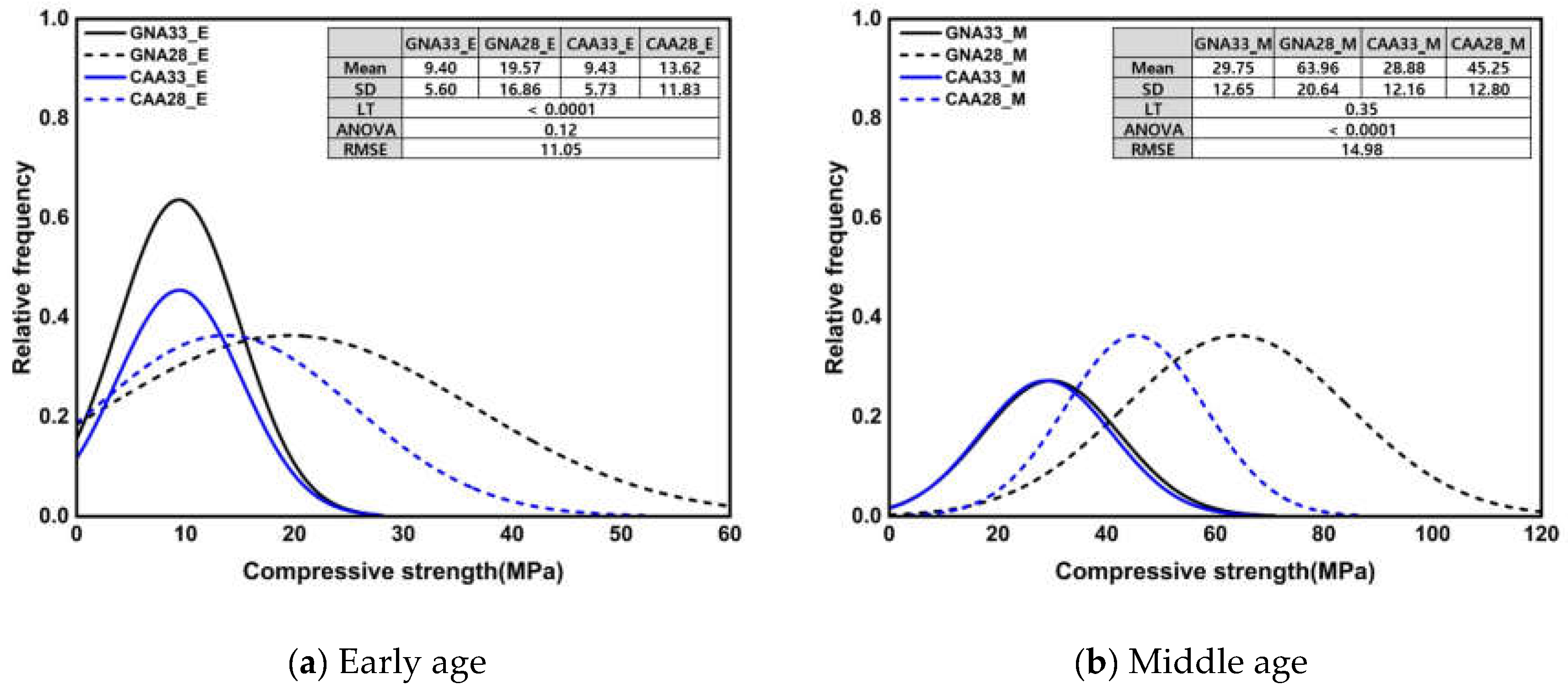

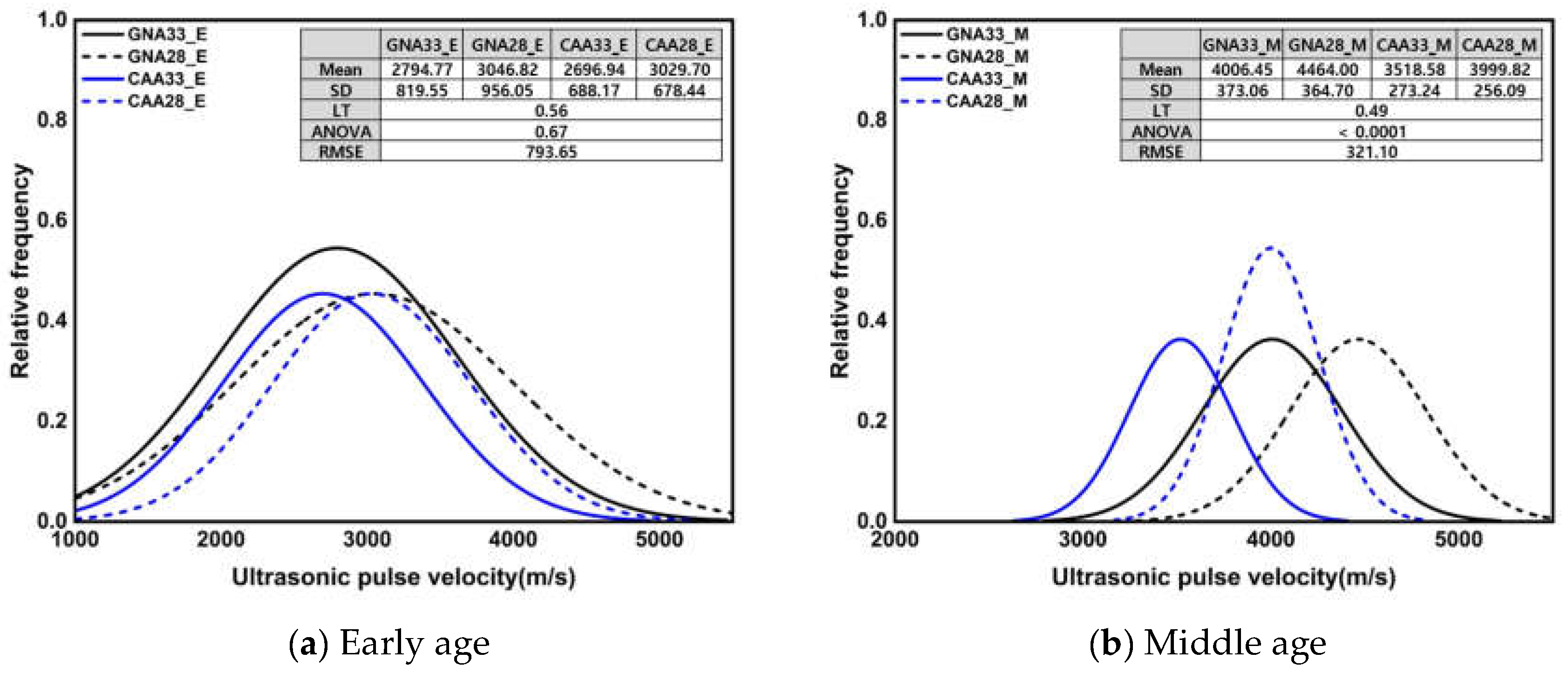

3.1.1. Compressive Strength

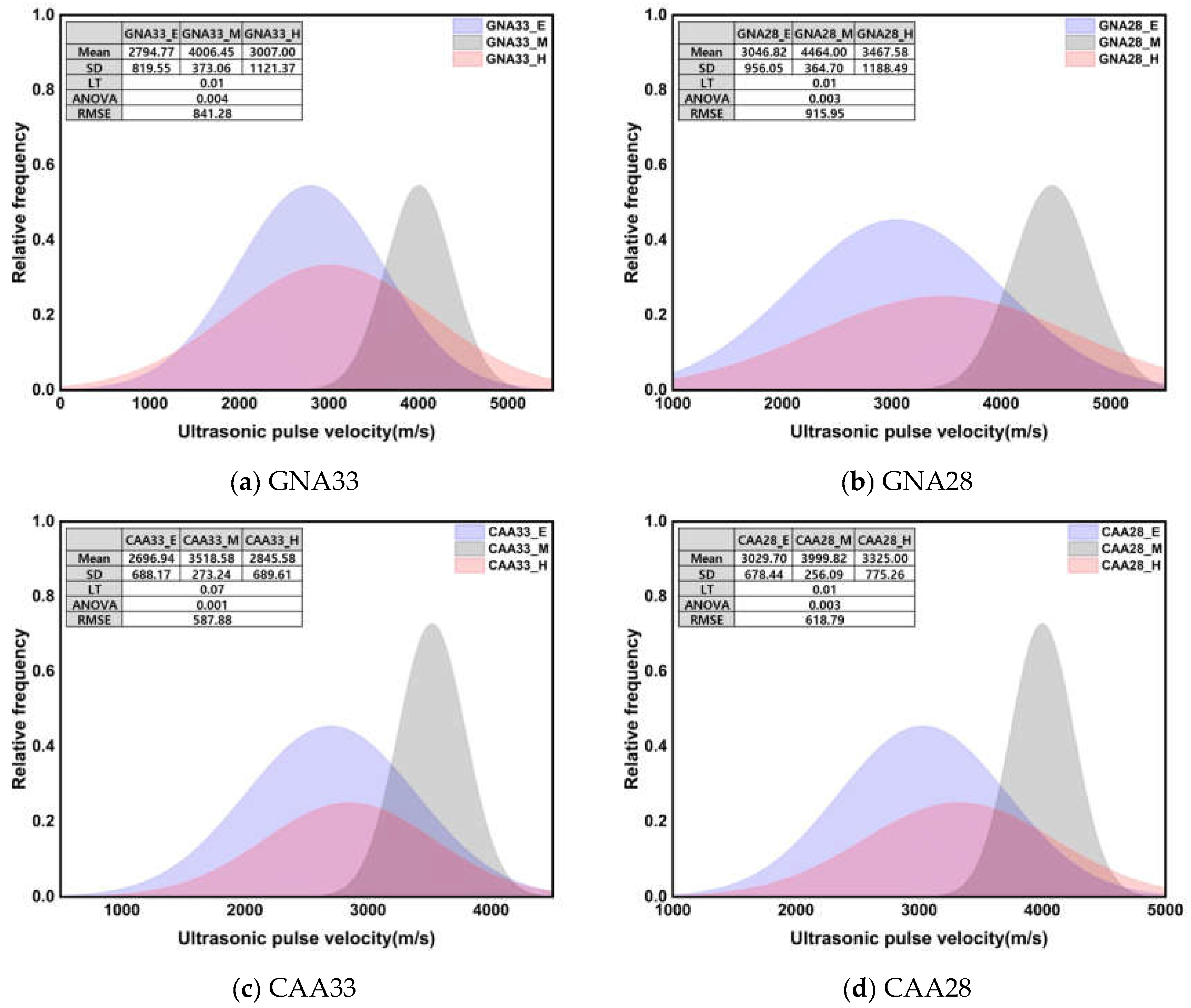

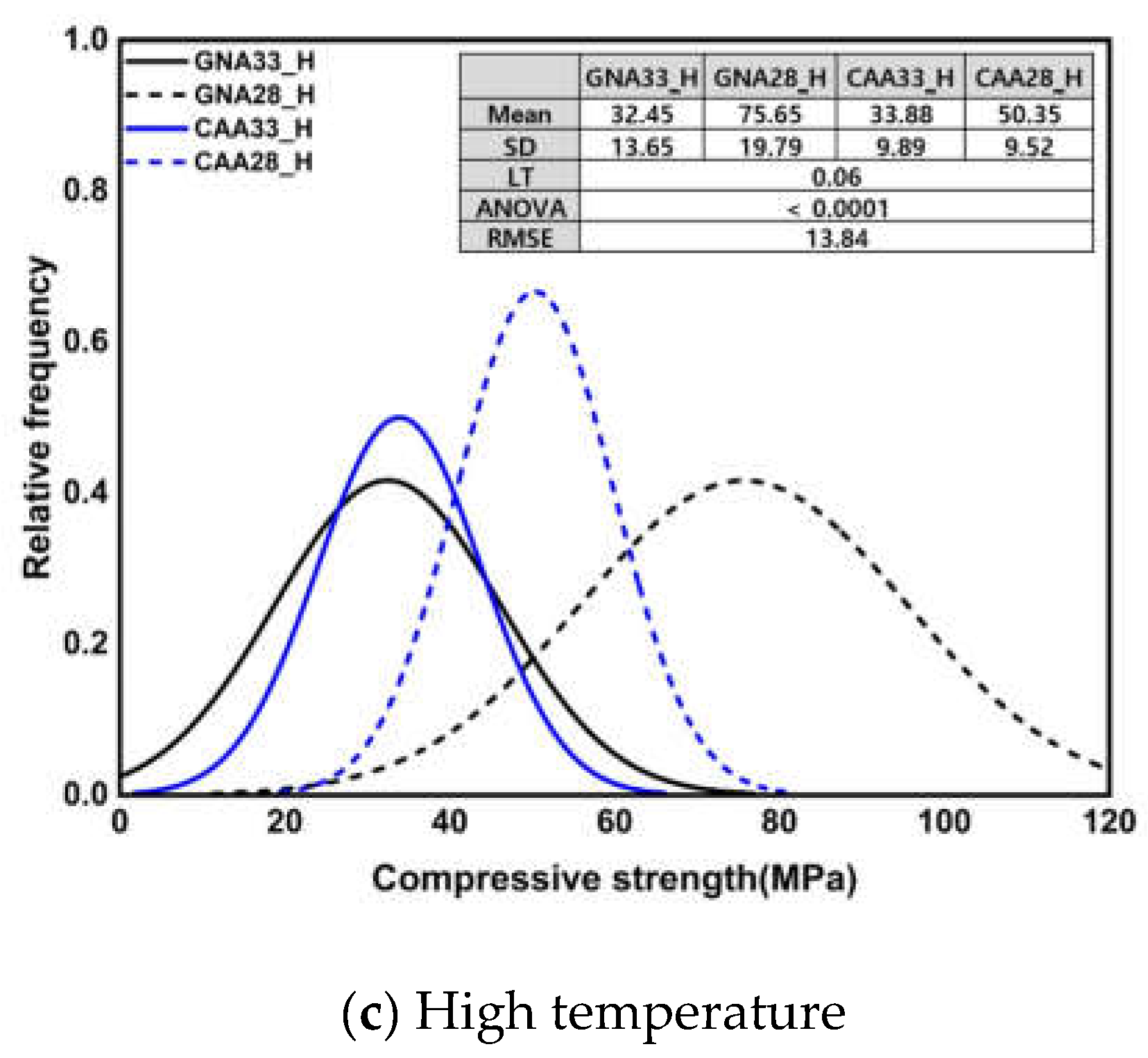

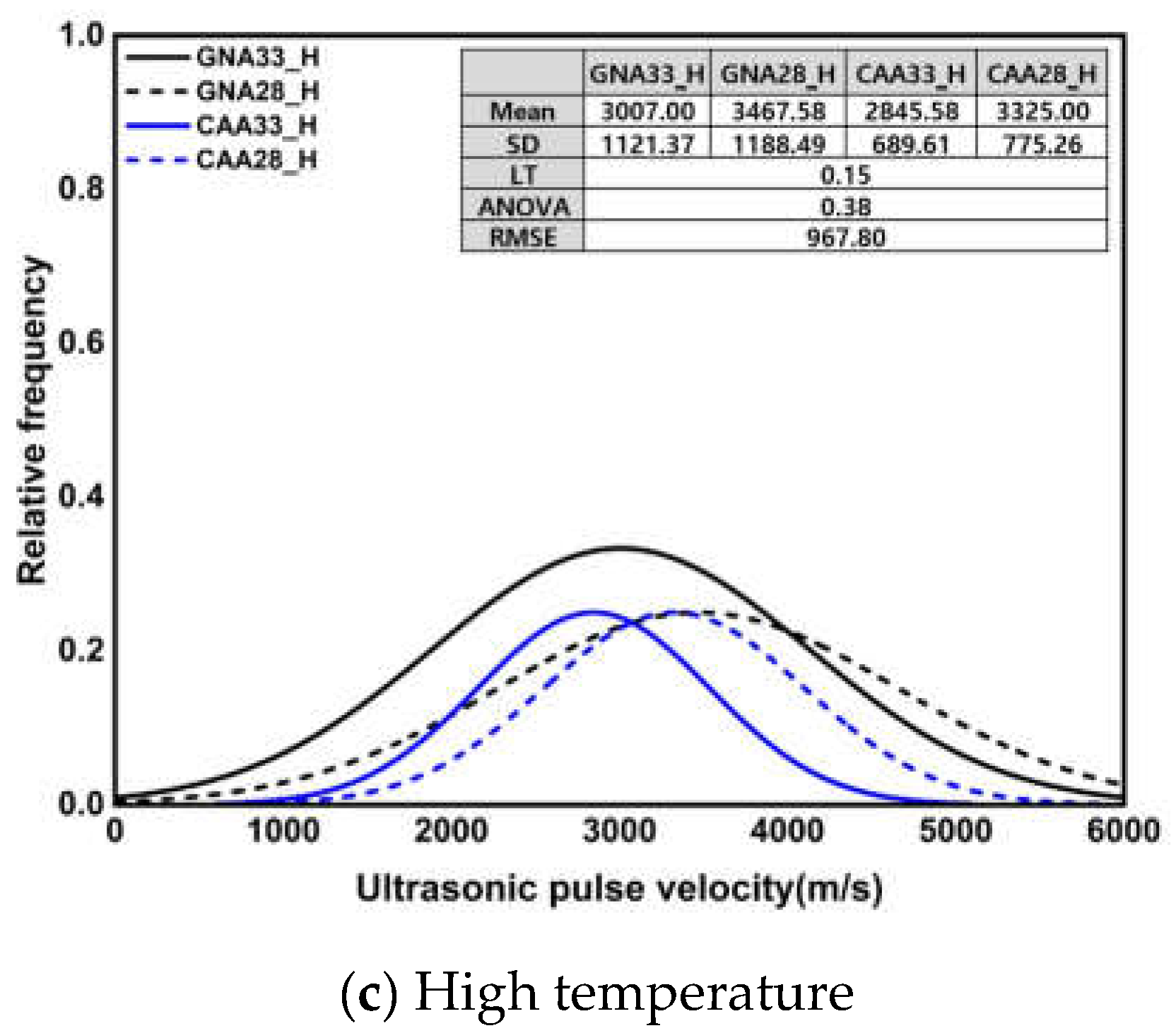

3.1.2. Ultrasonic Pulse Velocity

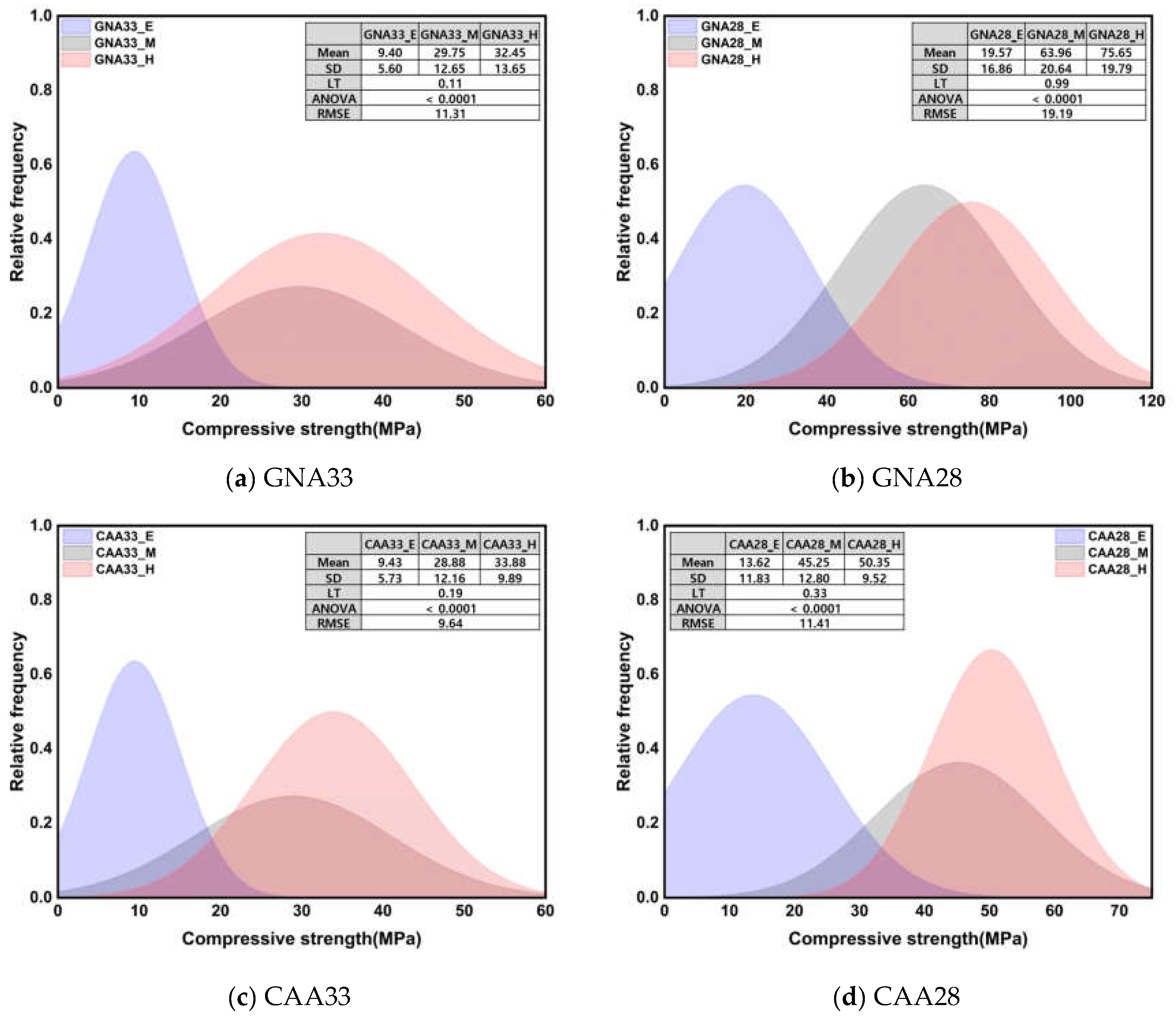

3.2. Statistical Analysis

3.2.1. Statistical Significance Test for 3 Conditions

3.2.2. Statistical Significance Test according to W/C Ratio and Coarse Aggregate

3.2.3. Regression Analysis Results

4. Conclusions

- (1)

- During the early age of 16 h, all specimens exhibited similar compressive strengths. However, from 1 to 91 d of age, GNA28 showed approximately 72.93% higher strength than GNA33, and CAA28 showed approximately 23.79% higher strength than CAA33. After high-temperature exposure, the lightweight aggregate exhibited a higher residual rate than normal concrete, owing to the influence of small thermal expansion deformation.

- (2)

- At approximately 16 h, at an early age, the specimen with a W/C ratio of 0.28 showed a higher UPV than the specimen with a W/C ratio of 0.33; by 91 d of age, GNA showed approximately 8.72% higher UPV owing to the influence of the porous lightweight aggregate mixed with CAA. After high-temperature exposure, CAA showed a residual rate approximately 10.35% higher than that of GNA.

- (3)

- The compressive strength of all specimens showed a very low mean at an early age, with no significant difference between strength at middle age, and that after high-temperature exposure. UPV showed the highest mean at middle age among the three conditions, while also showing a similar average at early age and after high-temperature exposure; therefore, it was inferred as a statistically identical group.

- (4)

- In the ANOVA result of the compressive strength at an early age, the p-value was 0.05 or more, indicating insignificance. However, in middle age, all compressive strengths were significant except for GNA28. The compressive strengths of the specimens after high-temperature exposure exhibited significant differences between the groups, except for GNA33 and CAA33. On the contrary, UPV did not show a significant difference for concrete at an early age or after high-temperature exposure, except for the middle-age condition.

- (5)

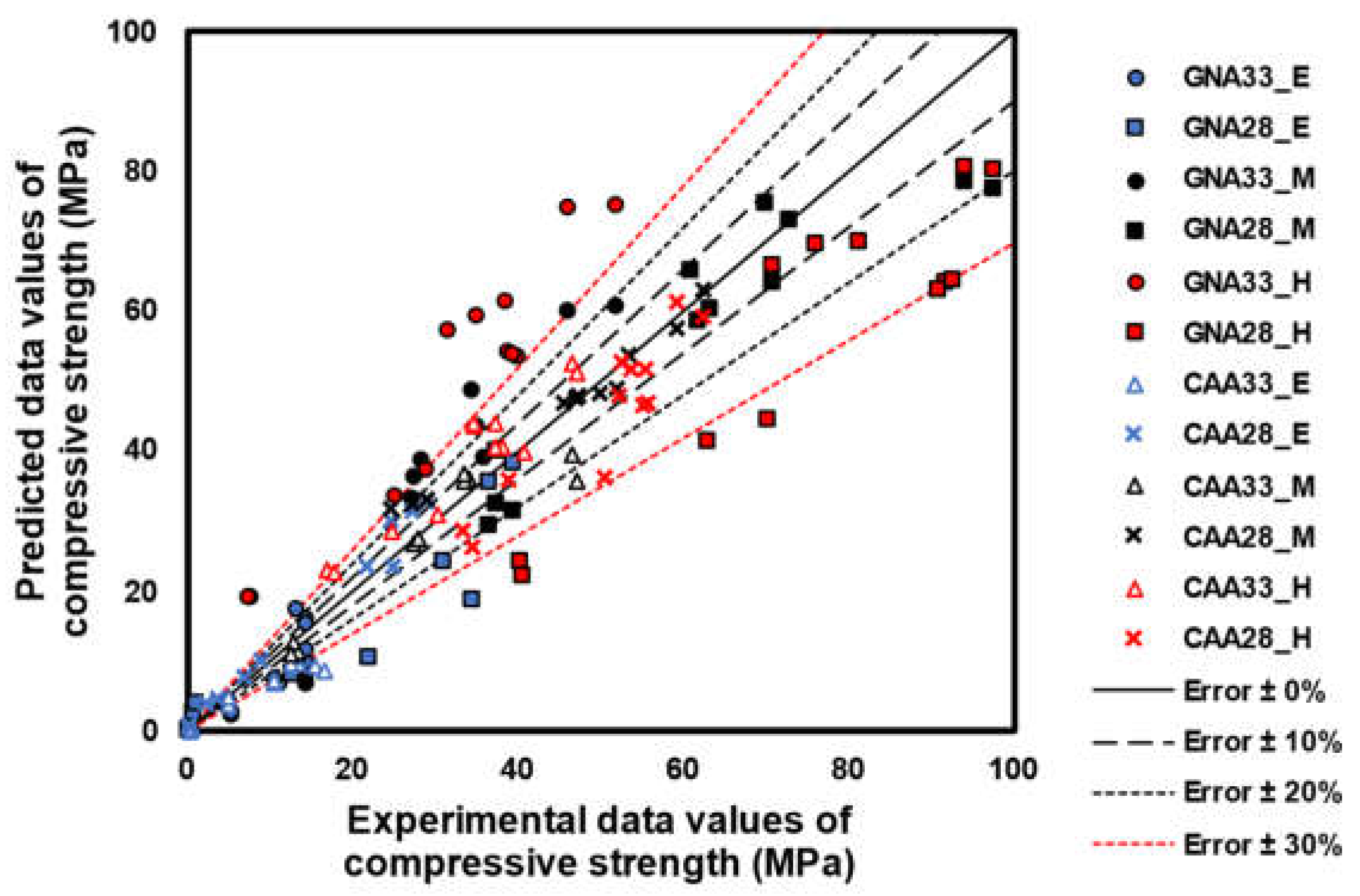

- Regression analyses revealed that the exponential function forms were suitable for GNA and CAA at the early stage, and GNA at middle age. On the contrary, the linear functional forms showed optimal suitability for CAA and GNA after high-temperature exposure, and CAA at middle age. However, after high-temperature exposure, the GNA and CAA groups showed very low R-square values, primarily attributed to their dependence on the W/C ratio; as such, it is generally acknowledged that the W/C ratio of lightweight concrete assumes higher importance in model consideration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baehaki; Andi, M.; Yohanes, G.R. Experimental study of crack depth measurement of concrete with ultrasonic pulse velocity (UPV). IOP Conf. Ser. Mater. Sci. Eng. 2019, 673, 012047. [Google Scholar] [CrossRef]

- Kim, S.D.; Shin, D.H.; Lim, L.M.; Lee, J.; Kim, S.H. Designed Strength Identification of Concrete by Ultrasonic Signal Processing Based on Artificial Intelligence Techniques. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2005, 52, 1145–1151. [Google Scholar]

- Bonamy, D.; Bounchaud, E. Failure of heterogeneous materials: A dynamic phase transition? Phys. Rep. 2011, 498, 1–44. [Google Scholar] [CrossRef]

- Al-Mufti, R.L.; Fried, A.N. Non-destructive evaluation of reclaimed asphalt cement concrete. Eur. J. Environ. Civ. Eng. 2018, 22, 770–782. [Google Scholar] [CrossRef]

- Lawson, I.; Danso, K.A.; Odoi, H.C.; Adjei, C.A.; Quashie, F.K. Non-Destructive Evaluation of Concrete using Ultrasonic Pulse Velocity. Res. J. Appl. Sci. Eng. Technol. 2011, 3, 499–504. [Google Scholar]

- Lee, T.; Lee, J. Setting time and compressive strength prediction model of concrete by nondestructive ultrasonic pulse velocity testing at early age. Constr. Build. Mater. 2020, 252, 119027. [Google Scholar] [CrossRef]

- Majhi, R.K.; Padhy, A.; Nayak, A.N. Performance of structural lightweight concrete produced by utilizing high volume of fly ash cenosphere and sintered fly ash aggregate with silica fume. Clean. Eng. Technol. 2021, 3, 100121. [Google Scholar] [CrossRef]

- Shafigh, P.; Nomeli, M.A.; Alengaram, U.J.; Mahmud, H.B.; Jumaat, M.Z. Engineering properties of lightweight aggregate concrete containing limestone powder and high volume fly ash. J. Clean. Prod. 2016, 135, 148–157. [Google Scholar] [CrossRef]

- Sua-iam, G.; Sokrai, P.; Makul, N. Novel ternary blends of Type 1 Portland cement, residual rice husk ash, and limestone powder to improve the properties of self-compacting concrete. Constr. Build. Mater. 2016, 125, 1028–1034. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Wan, H.W. Properties of concrete prepared with low-grade recycled aggregates. Constr. Build. Mater. 2012, 36, 881–889. [Google Scholar] [CrossRef]

- Kumar, V.S.; Ram, K.S.S. Performance of Concrete At Elevated Temperatures Made With Crushed Rock Dust As Filler Material. Mater. Today Proc. 2019, 18, 2270–2278. [Google Scholar] [CrossRef]

- Saha, A.K.; Sarker, P.K.; Majhi, S. Effect of elevated temperatures on concrete incorporating ferronickel slag as fine aggregate. Fire Mater. 2019, 43, 8–21. [Google Scholar] [CrossRef]

- Islam, M.Z.; Sohel, K.M.A.; Al-Jabri, K.; Harthy, A.A. Properties of concrete with ferrochrome slag as a fine aggregate at elevated temperatures. Case Stud. Constr. Mater. 2021, 15, e00599. [Google Scholar] [CrossRef]

- Dolinar, U.; Trtnik, G.; Turk, G.; Hozjan, T. The feasibility of estimation of mechanical properties of limestone concrete after fire using nondestructive methods. Constr. Build. Mater. 2019, 228, 116786. [Google Scholar] [CrossRef]

- Sevim, O.; Alakara, E.H.; Demir, I.; Bayer, I.R. Effect of magnetic water on properties of slag-based geopolymer composites incorporating ceramic tile waste from construction and demolition waste. Arch. Civ. Mech. Eng. 2023, 23, 107. [Google Scholar] [CrossRef]

- Sevim, O.; Alakara, E.H.; Guzelkucuk, S. Fresh and Hardened Properties of Cementitious Composites Incorporating Firebrick Powder from Construction and Demolition Waste. Buildings 2023, 13, 45. [Google Scholar] [CrossRef]

- Nam, Y.; Jeong, K.; Kim, W.; Choi, H.; Lee, T. Evaluation on Early Strength Development of Concrete Mixed with Non-Sintered Hwangto Using Ultrasonic Pulse Velocity. Materials 2023, 16, 6850. [Google Scholar] [CrossRef]

- Zhang, Y.; Aslani, F. Compressive strength prediction models of lightweight aggregate concretes using ultrasonic pulse velocity. Constr. Build. Mater. 2021, 292, 123419. [Google Scholar] [CrossRef]

- Khan, K.; Amin, M.N.; Sahar, U.U.; Ahmad, W.; Shah, K.; Mohamed, A. Machine learning techniques to evaluate the ultrasonic pulse velocity of hybrid fiber-reinforced concrete modified with nano-silica. Front. Mater. 2022, 9, 1098304. [Google Scholar] [CrossRef]

- Tenza-Abril, A.J.; Villacampa, Y.; Solak, A.B.; Baeza-Brotons, F. Prediction and sensitivity analysis of compressive strength in segregated lightweight concrete based on artificial neural network using ultrasonic pulse velocity. Constr. Build. Mater. 2018, 189, 1173–1183. [Google Scholar] [CrossRef]

- Kim, W.; Lee, T. A Study to Improve the Reliability of High-Strength Concrete Strength Evaluation Using an Ultrasonic Velocity Method. Materials 2023, 16, 6800. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.K.; Lee, K.M.; Kim, Y.H.; Yim, H.; Bae, D.B. Ultrasonic in-situ monitoring of setting process of high-performance concrete. Cem. Concr. Res. 2004, 34, 631–640. [Google Scholar] [CrossRef]

- Ji, G.B.; Mun, J.H.; Yang, K.H. Evaluation of Mechanical Properties of Lightweight Concrete Using Bottom Ash Aggregates and Foam. J. Korea Concr. Inst. 2019, 31, 375–384. [Google Scholar] [CrossRef]

- Lee, K.H.; Yang, K.H. Proposal for Compressive Strength Development Model of Lightweight Aggregate Concrete Using Expanded Bottom Ash and Dredged Soil Granules. Archit. Inst. Korea 2018, 34, 19–26. [Google Scholar]

- Choi, S.J.; Kim, D.B.; Lee, K.S.; Kim, Y.U. The Study on the Physical and Strength Properties of Lightweight Concrete by Replacement Ratio of Artificial Lightweight Aggregate. J. Korea Inst. Build. Constr. 2019, 19, 313–322. [Google Scholar]

- ASTM C873/C873M; Standard Test Method for Compressive Strength of Concrete Cylinders Cast in Place in Cylindrical Molds. American Society of Testing and Materials (ASTM): West Conshohocken, PA, USA, 2015; pp. 1–4.

- ASTM C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. American Society of Testing and Materials (ASTM): West Conshohocken, PA, USA, 2018; pp. 1–8.

- ASTM C597-16; Standard Test Method for Pulse Velocity Through Concrete. American Society of Testing and Materials: West Conshohocken, PA, USA, 2016; pp. 1–4.

- Ali, F.; Khan, M.A.; Qurashi, M.A.; Shah, S.A.; Khan, N.M.; Khursheed, Z.; Rahim, H.S.; Arshad, H.; Farhan, M.; Waseem, M. Utilization of Pyrolytic Carbon Black Waste for the development of Sustainable Materials. Processe 2020, 8, 174. [Google Scholar] [CrossRef]

- Hwang, E.; Kim, G.; Choe, G.; Yoon, M.; Gucunski, N.; Nam, J. Evaluation of concrete degradation depending on heating conditions by ultrasonic pulse velocity. Constr. Build. Mater. 2018, 171, 511–520. [Google Scholar] [CrossRef]

- Ali, Z.; Bhaskar, S.B. Basic statistical tools in research and data analysis. Indian J. Anaesth. 2016, 60, 662. [Google Scholar] [CrossRef]

- Voigt, T.; Malonn, T.; Shah, S.P. Green and early age compressive strength of extruded cement mortar monitored with compression tests and ultrasonic techniques. Cem. Concr. Res. 2006, 36, 858–867. [Google Scholar] [CrossRef]

- Bentz, P. Influence of internal curing using lightweight aggregates on interfacial transition zone percolation and chloride ingress in mortars. Cem. Concr. Compos. 2009, 31, 285–289. [Google Scholar]

- Kumar, S.; Kapoor, K.; Singh, S.P.; Singh, P.; Sharma, V. A review on the properties of natural and recycled coarse aggregates concrete made with different coal ashes. Clean. Mater. 2022, 5, 100109. [Google Scholar] [CrossRef]

- Vargas, P.; Baena, O.R.; Tobón, J.I. Microstructural analysis of interfacial transition zone (ITZ) and its impact on the compressive strength of lightweight concretes. Constr. Build. Mater. 2017, 137, 381–389. [Google Scholar] [CrossRef]

- Gündüz, L. The effects of pumice aggregate/cement ratios on the low-strength concrete properties. Constr. Build. Mater. 2008, 22, 721–728. [Google Scholar] [CrossRef]

- Newman, J.; Owens, P. Properties of lightweight concrete. Adv. Concr. Technol. 2003, 3, 1–29. [Google Scholar]

- Lo, T.Y.; Cui, H.Z.; Tang, W.C.; Leung, W.M. The effect of aggregate absorption on pore area at interfacial zone of lightweight concrete. Constr. Build. Mater. 2008, 22, 623–628. [Google Scholar] [CrossRef]

- Alonso, C.; Femandez, L. Dehydration and rehydration processes of cement paste exposed to high temperature environments. J. Mater. Sci. 2004, 39, 3015–3024. [Google Scholar] [CrossRef]

- Kim, G.Y.; Kang, Y.W.; Lee, T.G.; Choe, G.C.; Yoon, M.H. An Experimental Study on the Mechanical Properties of Concrete with High Temperatures and Cooling Conditions. J. Korea Inst. Build. Constr. 2012, 12, 323–331. [Google Scholar] [CrossRef]

- Roufael, G.; Beaucour, A.; Eslami, J.; Hoxha, D.; Noumowé, A. Influence of lightweight aggregates on the physical and mechanical residual properties of concrete subjected to high temperatures. Constr. Build. Mater. 2021, 268, 121221. [Google Scholar] [CrossRef]

- Zhang, J.; Shen, Y.; Yang, G.; Zhang, G.; Wang, Y.; Hou, X.; Sun, Q.; Li, G. Inconsistency of changes in uniaxial compressive strength and P-wave velocity of sandstone after temperature treatments. J. Rock Mech. Geotech. Eng. 2021, 13, 143–153. [Google Scholar] [CrossRef]

- Hossain, K.M.A. Properties of volcanic pumice based cement and lightweight concrete. Cem. Concr. Res. 2004, 34, 283–291. [Google Scholar] [CrossRef]

- Torić, N.; Boko, I.; Juradin, S.; Baloević, G. Mechanical properties of lightweight concrete after fire exposure. Struct. Concr. 2016, 17, 1071–1081. [Google Scholar] [CrossRef]

- Rao, S.K.; Sravana, P.; Rao, T.C. Experimental studies in Ultrasonic Pulse Velocity of roller compacted concrete pavement containing fly ash and M-sand. Int. J. Pavement Res. Technol. 2016, 9, 289–301. [Google Scholar] [CrossRef]

- Lee, T.; Lee, J.; Choi, H. Assessment of Strength Development at Hardened Stage on High-Strength Concrete Using NDT. Appl. Sci. 2020, 10, 6261. [Google Scholar] [CrossRef]

- Abed, M.; Brito, J. Evaluation of high-performance self-compacting concrete using alternative materials and exposed to elevated temperatures by non-destructive testing. J. Build. Eng. 2020, 32, 101720. [Google Scholar] [CrossRef]

| Type | Researchers | Equations of Model |

|---|---|---|

| Early age | R. L. Al-Mufti | |

| I. Lawson | ||

| T. Lee | ||

| Middle age | R. K. Majhi | |

| P. Shafigh | ||

| G. Sua-iam | ||

| S. Kou | ||

| High temperature | N. V. S. Kumar | |

| A. K. Saha | ||

| M. Z. Islam | ||

| U. Dolinar |

| Item | Details |

|---|---|

| Types of concrete | GNA (Granite aggregate) CAA (Coal-ash aggregate) |

| Water–cement ratio | 0.33, 0.28 |

| Elapsed time at early age | 6, 12, 16, 20, 24 h |

| Curing age | 1, 7, 28, 91 d |

| Heating temperature | 20, 200, 300, 500, 700 °C |

| Mechanical properties | Compressive strength UPV (Ultrasonic pulse velocity) |

| Statistical analysis | Levene’s test, ANOVA (or Welch’s ANOVA), Post hoc test, Regression analysis, Error test |

| Item | Details |

|---|---|

| Cement | ASTM Type-I ordinary Portland cement Density: 3150 kg/m3, fineness: 320 m2/kg |

| Coarse aggregate | Granite aggregate Density: 2680 kg/m3, fineness modulus: 7.03, absorption: 0.68%, Sizemax: 20 mm |

| Coal-ash aggregate Density: 1470 kg/m3, fineness modulus: 6.39, absorption: 8.68%, Sizemax: 20 mm | |

| Fine aggregate | River sand Density: 2540 kg/m3, fineness modulus: 2.54, absorption: 1.60% |

| Super plasticizer (SP) | Polycarboxylic-based super plasticizer |

| Materials | Chemical Compositions (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | K2O | Others | L.O.I | |

| OPC (1) | 60.30 | 19.80 | 4.90 | 3.30 | 3.80 | 2.90 | 1.10 | 0.90 | 3.00 |

| Mix ID | Ratio | Unit Weight (kg/m3) | |||||

|---|---|---|---|---|---|---|---|

| W/C (1) | S/a (2) | Water | Cement | River Sand | Granite Aggregate | Coal-Ash Aggregate | |

| GNA33 | 0.33 | 0.43 | 165 | 500 | 711 | 762 | - |

| GNA28 | 0.28 | 500 | 711 | - | 533 | ||

| CAA33 | 0.33 | 600 | 676 | 896 | - | ||

| CAA28 | 0.28 | 600 | 676 | - | 507 | ||

| ID | Mean Difference | p-Value | ID | Grouping Letters Table | |||

|---|---|---|---|---|---|---|---|

| Comp. | UPV | Comp. | UPV | Comp. | UPV | ||

| GNA33_E & GNA33_M | 20.35 | 1211.68 | 0.001 | 0.006 | GNA33_E | A | A |

| GNA33_E & GNA33_H | 23.06 | 212.23 | <0.001 | 1.000 | GNA33_M | A | B |

| GNA33_M & GNA33_H | 2.70 | 999.45 | 1.000 | 0.023 | GNA33_H | B | B |

| GNA28_E & GNA28_M | 44.39 | 1417.18 | <0.001 | 0.003 | GNA28_E | A | A |

| GNA28_E & GNA28_H | 56.08 | 420.77 | <0.001 | 0.84 | GNA28_M | A | B |

| GNA28_M & GNA28_H | 11.69 | 996.42 | 0.46 | 0.04 | GNA28_H | B | B |

| CAA33_E & CAA33_M | 19.45 | 821.64 | <0.001 | 0.007 | CAA33_E | A | A |

| CAA33_E & CAA33_H | 24.45 | 148.64 | <0.001 | 0.818 | CAA33_M | A | B |

| CAA33_M & CAA33_H | 5.00 | 672.99 | 0.67 | 0.026 | CAA33_H | B | B |

| CAA28_E & CAA28_M | 31.63 | 970.12 | <0.001 | 0.003 | CAA28_E | A | A |

| CAA28_E & CAA28_H | 36.73 | 295.30 | <0.001 | 0.785 | CAA28_M | A | B |

| CAA28_M & CAA28_H | 5.10 | 674.82 | 0.539 | 0.041 | CAA28_H | B | B |

| ID | Mean Difference | p-Value | ID | Grouping Letters Table | |||

|---|---|---|---|---|---|---|---|

| Comp. | UPV | Comp. | UPV | Comp. | UPV | ||

| GNA33_E & GNA28_E | 10.17 | 252.05 | 0.221 | 1.000 | GNA33_E | A | A |

| GNA33_E & CAA33_E | 0.04 | 97.86 | 1.000 | 1.000 | GNA28_E | A | A |

| GNA28_E & CAA33_E | 10.13 | 349.88 | 0.226 | 1.000 | CAA33_E | A | A |

| GNA33_E & CAA28_E | 4.22 | 234.92 | 1.000 | 1.000 | CAA28_E | A | A |

| GNA28_E & CAA28_E | 5.95 | 17.12 | 1.000 | 1.000 | - | ||

| CAA33_E & CAA28_E | 4.19 | 332.76 | 1.000 | 1.000 | - | ||

| GNA33_M & GNA28_M | 34.20 | 457.55 | <0.001 | 0.011 | GNA33_M | B | B |

| GNA33_M & CAA33_M | 0.87 | 487.88 | 1.000 | 0.006 | GNA28_M | A | A |

| GNA28_M & CAA33_M | 35.07 | 945.42 | <0.001 | <0.001 | CAA33_M | B | C |

| GNA33_M & CAA28_M | 15.50 | 6.64 | 0.119 | 1.000 | CAA28_M | B | B |

| GNA28_M & CAA28_M | 18.70 | 464.18 | 0.034 | 0.009 | - | ||

| CAA33_M & CAA28_M | 16.37 | 481.24 | 0.086 | 0.007 | - | ||

| GNA33_H & GNA28_H | 43.19 | 460.58 | <0.001 | 1.000 | GNA33_H | C | A |

| GNA33_H & CAA33_H | 1.43 | 161.42 | 1.000 | 1.000 | GNA28_H | A | A |

| GNA28_H & CAA33_H | 41.76 | 622.00 | <0.001 | 0.736 | CAA33_H | C | A |

| GNA33_H & CAA28_H | 17.89 | 318.00 | 0.017 | 1.000 | CAA28_H | B | A |

| GNA28_H & CAA28_H | 25.30 | 142.58 | <0.001 | 1.000 | - | ||

| CAA33_H & CAA28_H | 16.46 | 479.42 | 0.034 | 1.000 | - | ||

| ID | Model | p-Value | Pearson’s r | R-Square | RMSE |

|---|---|---|---|---|---|

| GNA_E | Linear | <0.0010 | 0.82 | 0.67 | 7.89 |

| Exponential | <0.0001 | - | 0.89 | 4.52 | |

| GNA_M | Linear | <0.0001 | 0.92 | 0.85 | 9.49 |

| Exponential | <0.0001 | - | 0.91 | 7.36 | |

| GNA_H | Linear | 0.0001 | 0.70 | 0.49 | 20.09 |

| Exponential | 1.0000 | - | −3.99 | 63.13 | |

| CAA_E | Linear | <0.0001 | 0.84 | 0.71 | 5.16 |

| Exponential | <0.0001 | - | 0.93 | 2.50 | |

| CAA_M | Linear | <0.0001 | 0.96 | 0.93 | 4.03 |

| Exponential | <0.0001 | - | 0.90 | 4.85 | |

| CAA_H | Linear | <0.0001 | 0.88 | 0.77 | 6.26 |

| Exponential | 1.0000 | - | −11.51 | 45.86 |

| ID | Types of Models | Equation | Regression Coefficient (R2) | |

|---|---|---|---|---|

| Early age | GNA | Exponential function | 0.89 | |

| CAA | 0.93 | |||

| Middle age | GNA | 0.91 | ||

| CAA | Linear function | 0.93 | ||

| High temperature | GNA | 0.49 | ||

| CAA | 0.77 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, W.; Jeong, K.; Lee, T. Statistical Reliability Analysis of Ultrasonic Velocity Method for Predicting Residual Strength of High-Strength Concrete under High-Temperature Conditions. Materials 2024, 17, 1406. https://doi.org/10.3390/ma17061406

Kim W, Jeong K, Lee T. Statistical Reliability Analysis of Ultrasonic Velocity Method for Predicting Residual Strength of High-Strength Concrete under High-Temperature Conditions. Materials. 2024; 17(6):1406. https://doi.org/10.3390/ma17061406

Chicago/Turabian StyleKim, Wonchang, Keesin Jeong, and Taegyu Lee. 2024. "Statistical Reliability Analysis of Ultrasonic Velocity Method for Predicting Residual Strength of High-Strength Concrete under High-Temperature Conditions" Materials 17, no. 6: 1406. https://doi.org/10.3390/ma17061406