Effect of Scanning Strategy on the Manufacturing Quality and Performance of Printed 316L Stainless Steel Using SLM Process

Abstract

1. Introduction

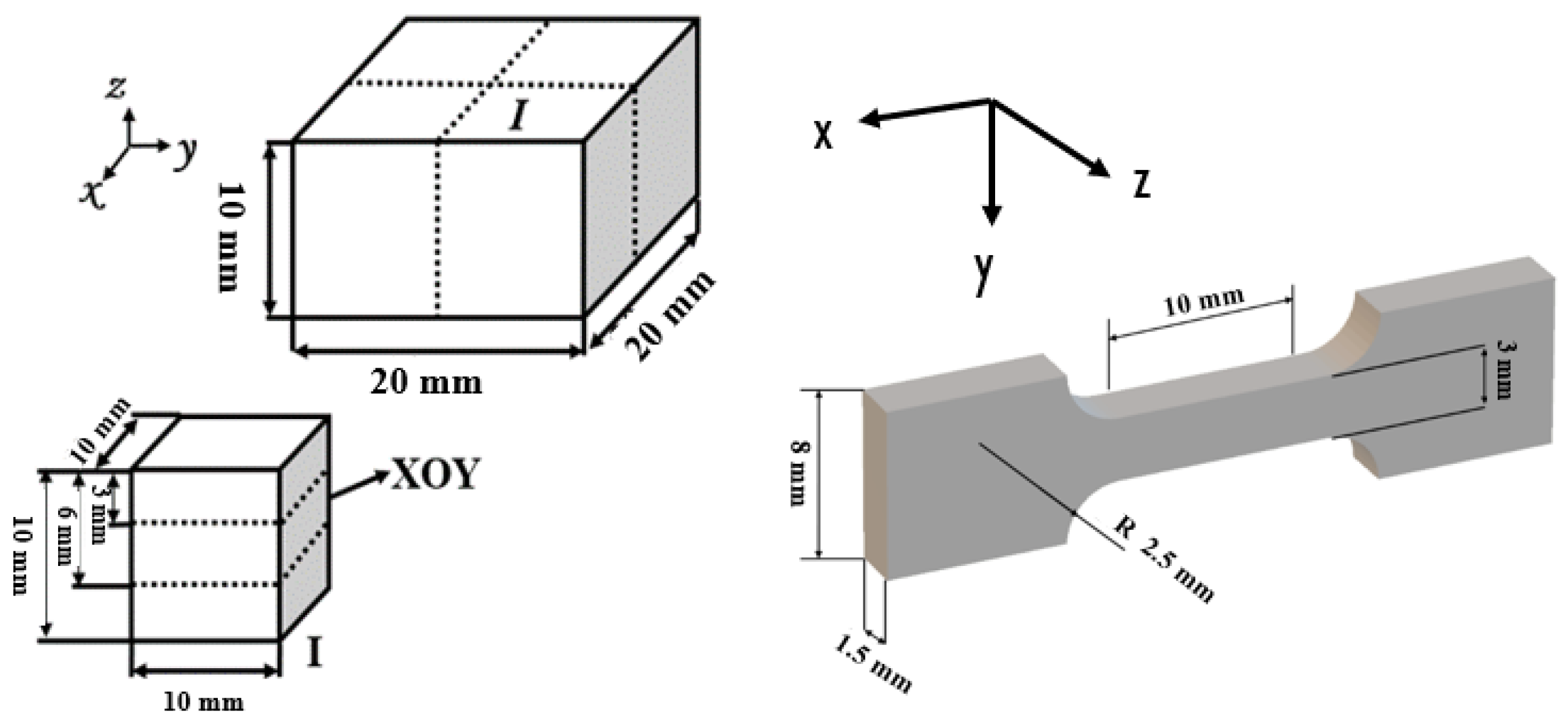

2. Materials and Methods

3. Results and Discussion

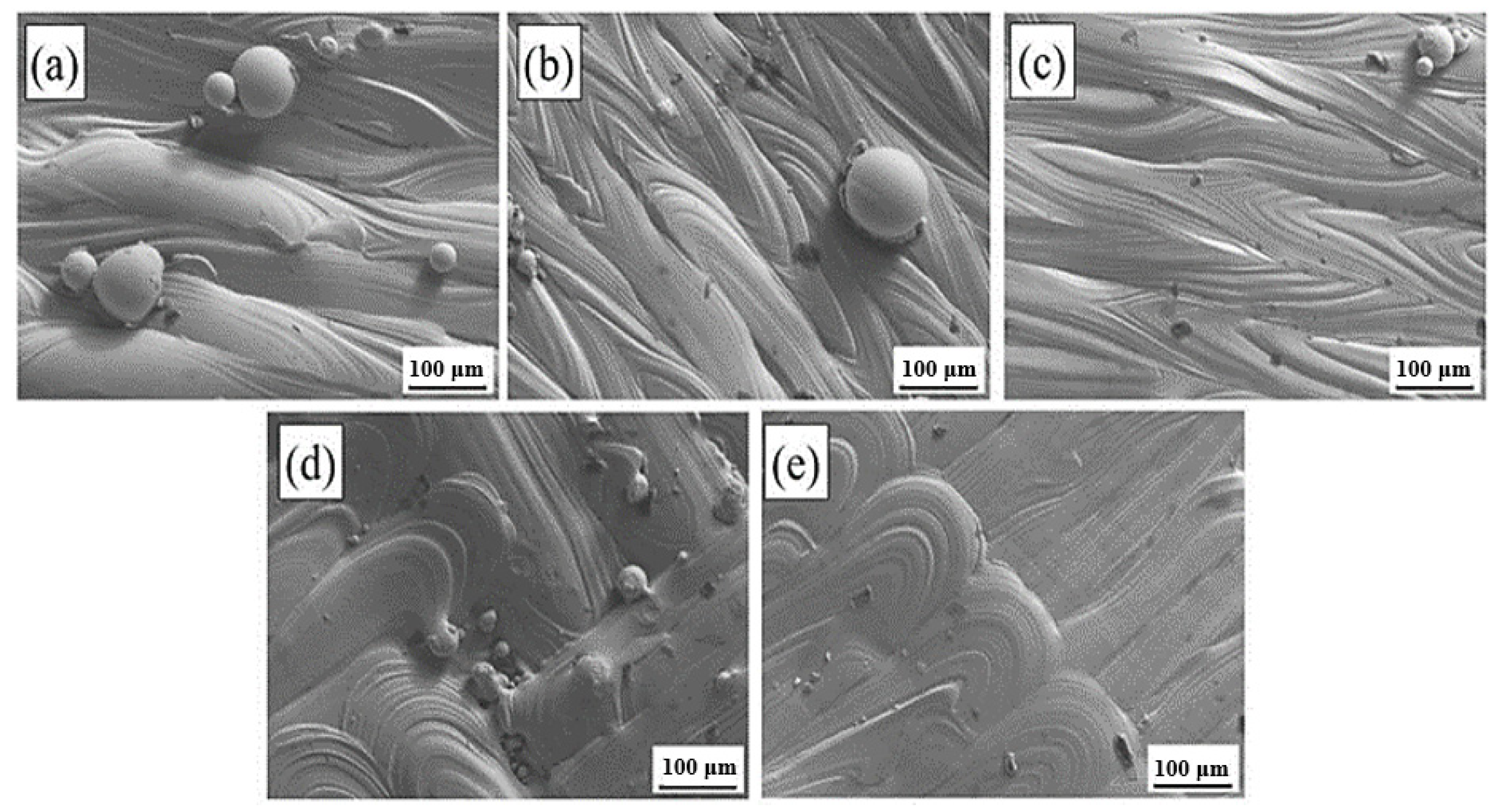

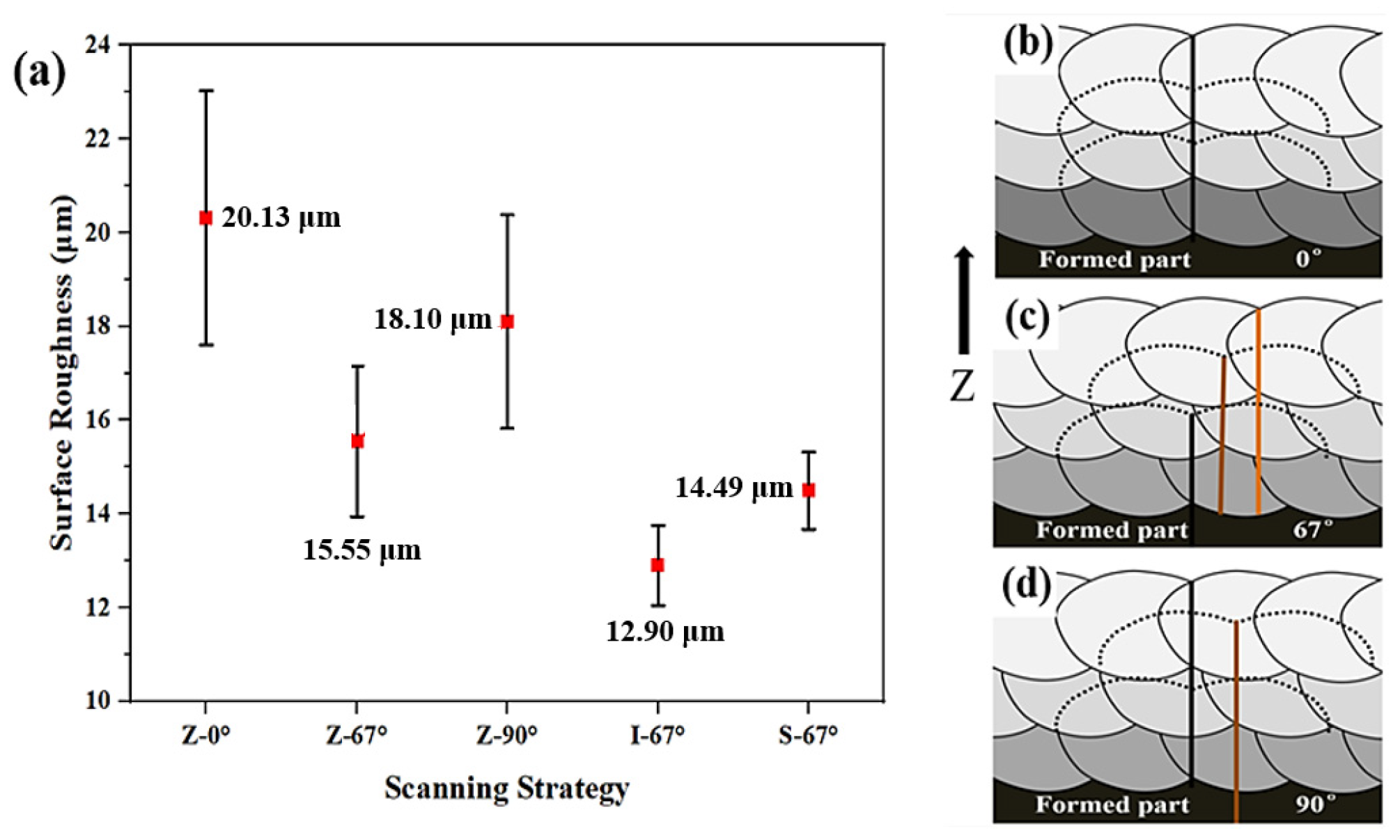

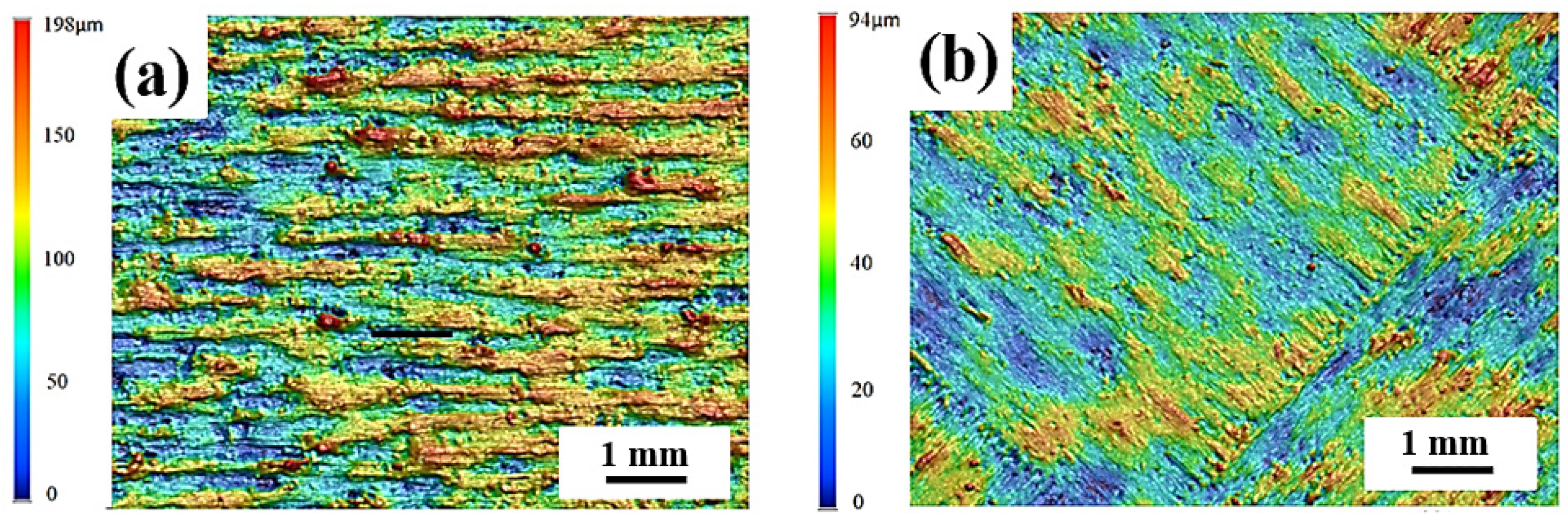

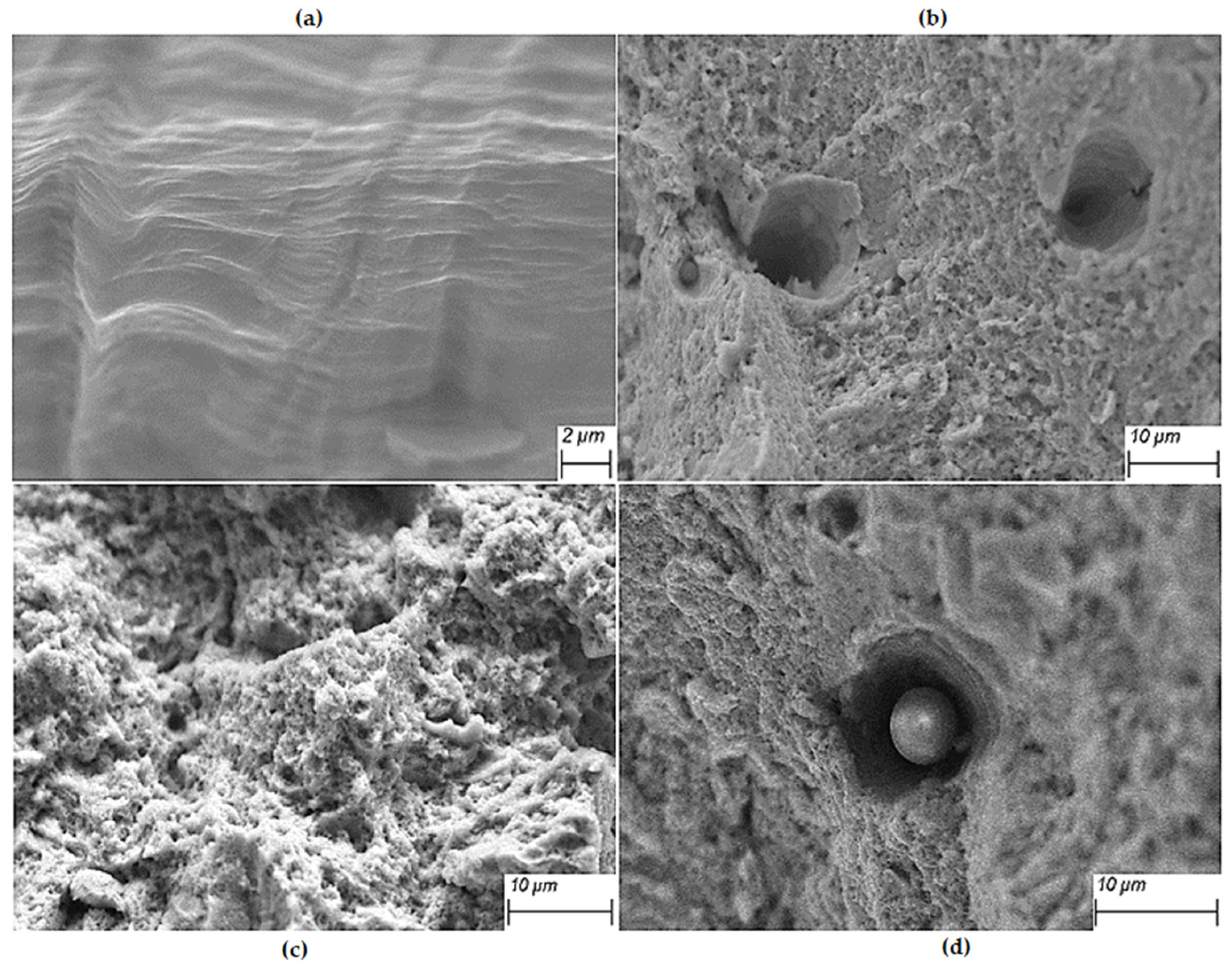

3.1. Surface Topography and Roughness Analysis

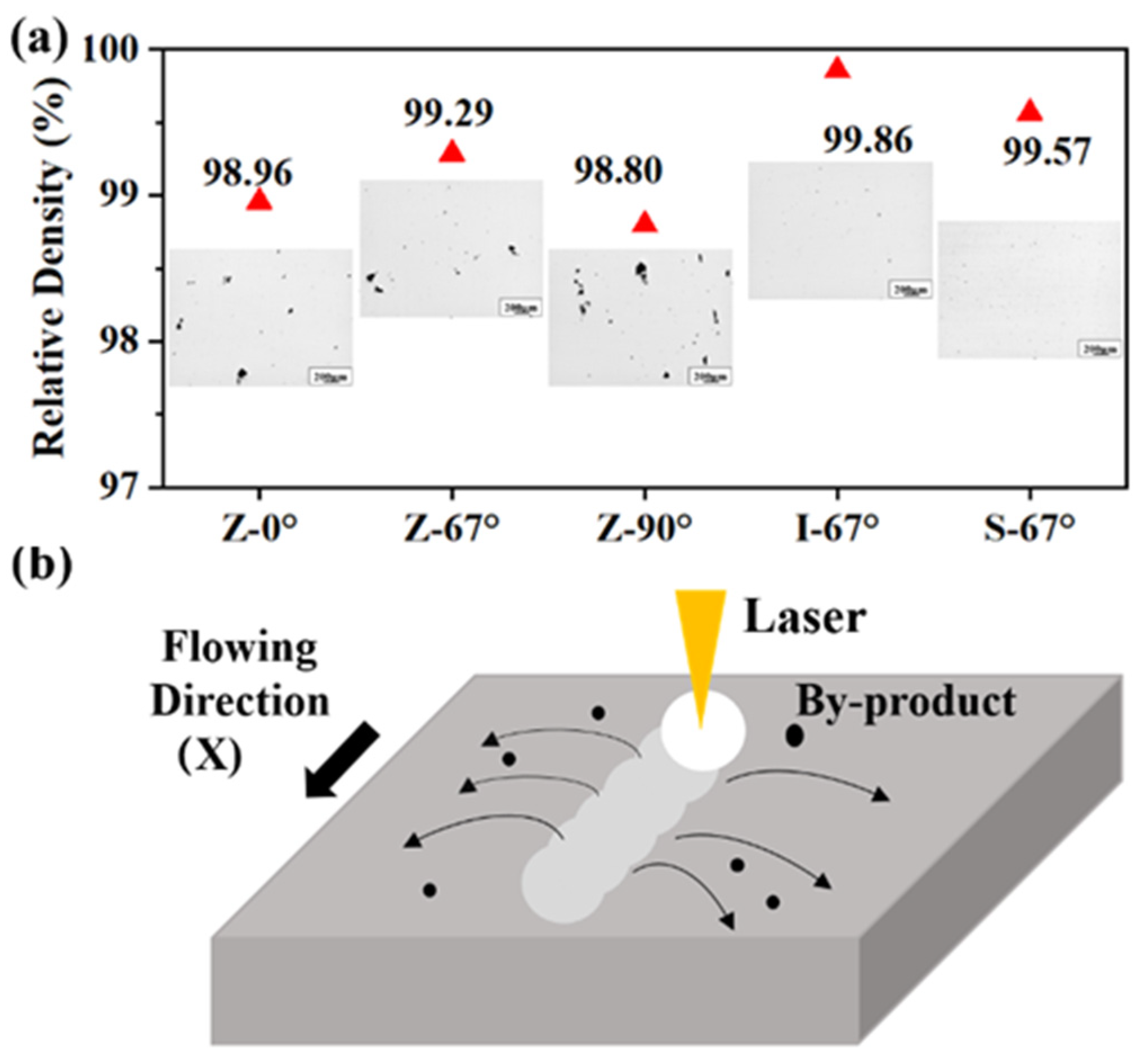

3.2. Density Analysis

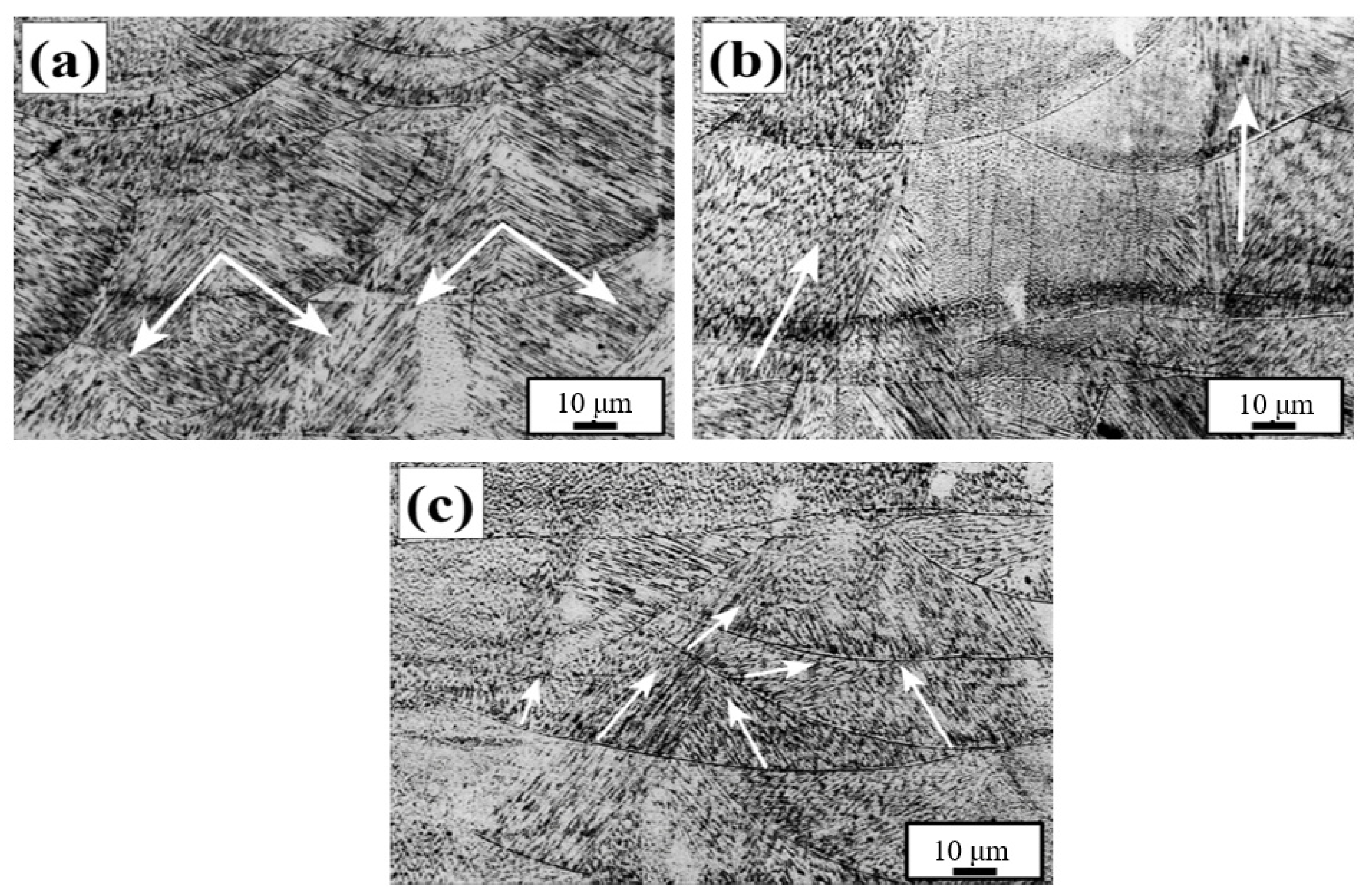

3.3. Microstructure and Phase Analysis

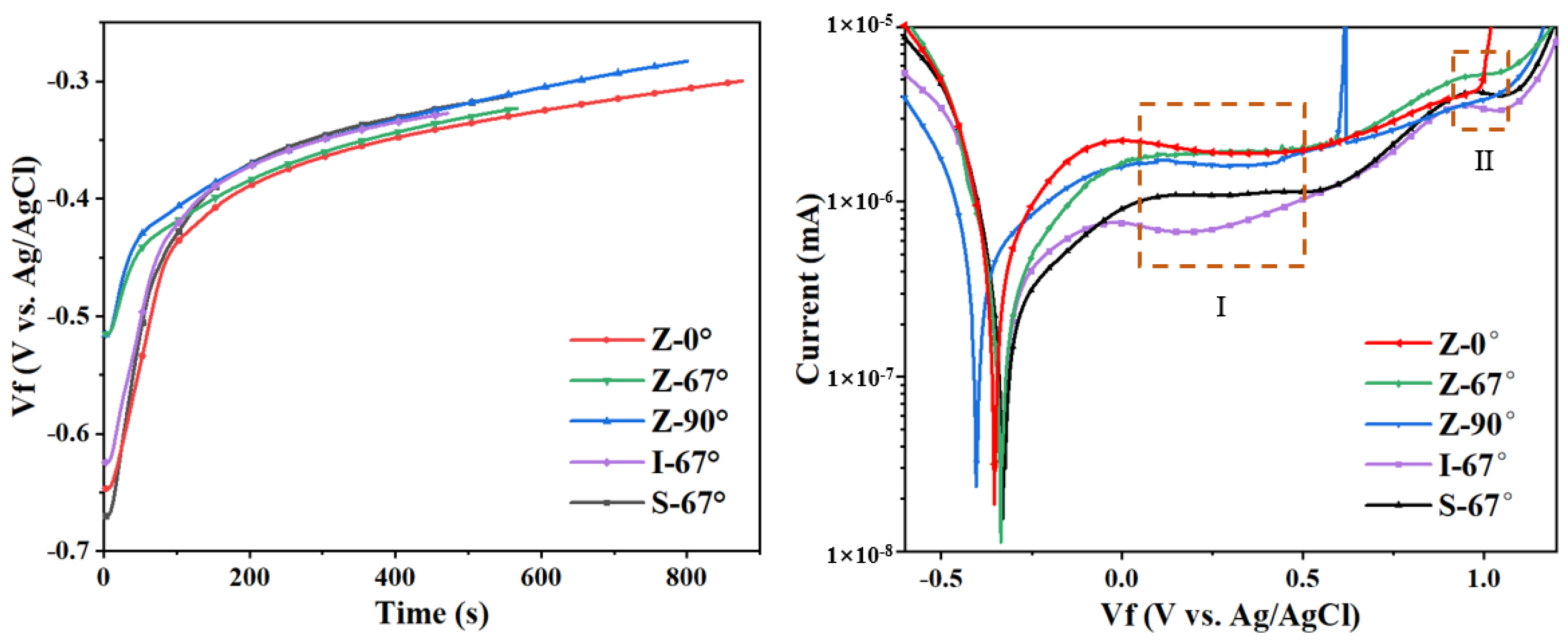

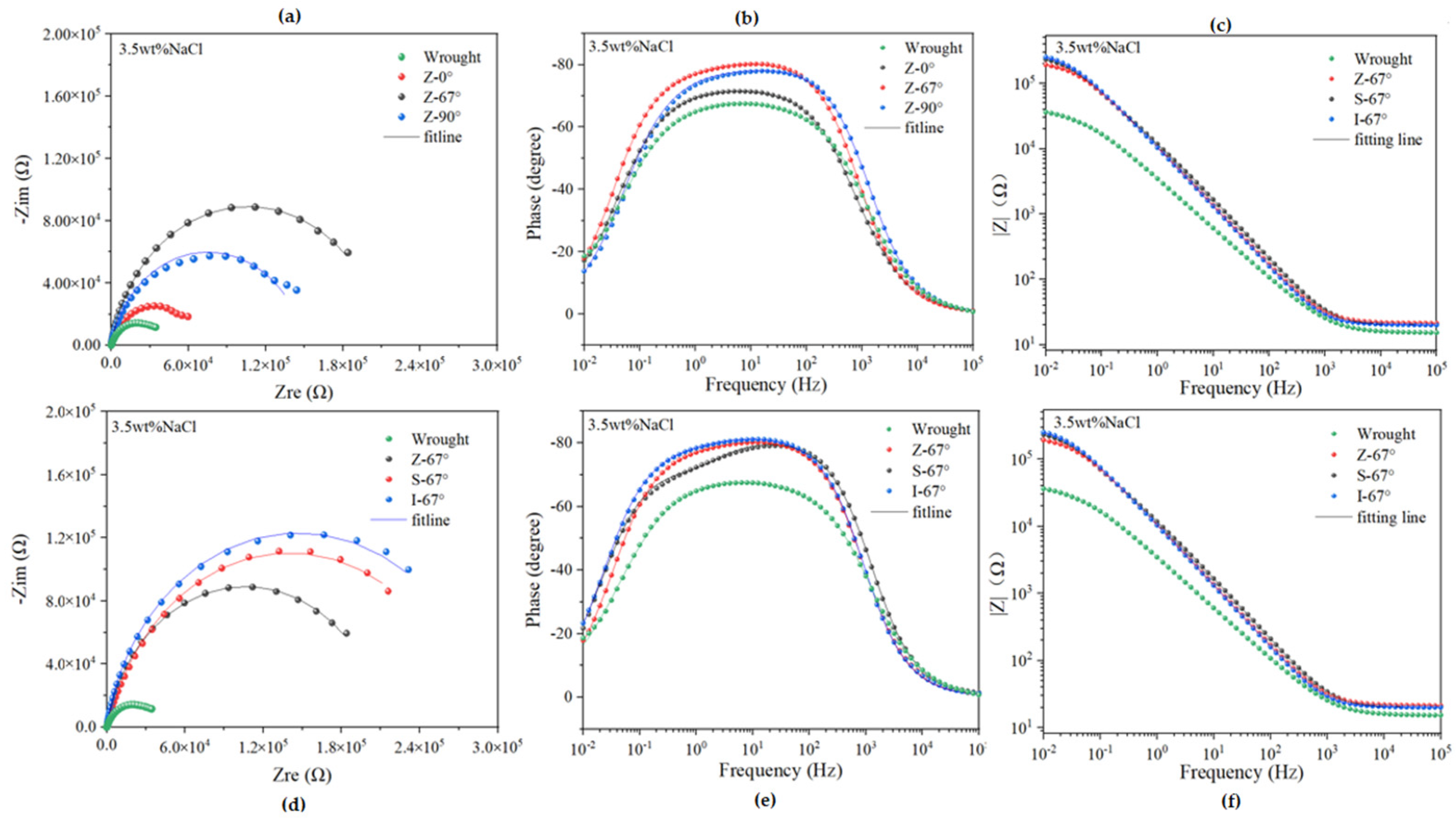

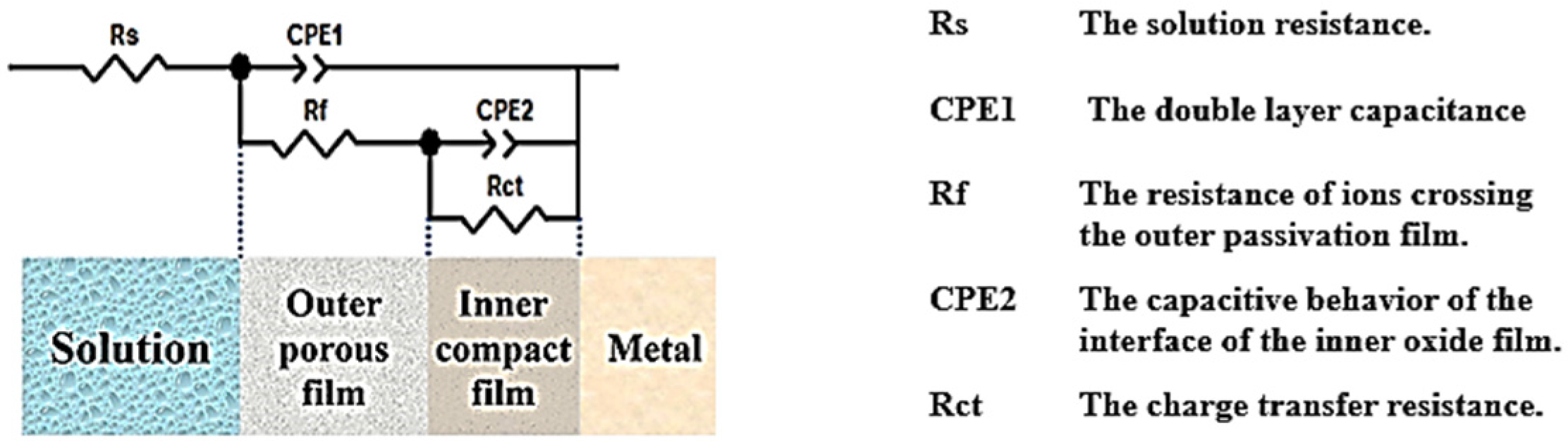

3.4. Corrosion Resistance

3.5. Mechanical Properties

| Sample | Z-0° | Z-67° | Z-90° | S-67° | I-67° | ISO | S.J. [10] | C.P. [44] |

|---|---|---|---|---|---|---|---|---|

| YS (MPa) | 471.7 | 512.4 | 457.0 | 498.1 | 533.0 | ≥205 | 511.6 | 569 |

| UTS (MPa) | 663.0 | 739.1 | 669.6 | 693.7 | 807.7 | ≥515 | 621.7 | 667 |

| E (%) | 43.9 | 48.6 | 48.3 | 52.5 | 52.4 | ≥35 | 20.4 | 33 |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ali, H.; Ghadbeigi, H.; Mumtaz, K. Effect of scanning strategies on residual stress and mechanical properties of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A 2018, 712, 175–187. [Google Scholar] [CrossRef]

- Debroy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Reza, A.; Lo, Y.L.; Raza, M. 3D Multi-T rack and Multi-Layer Epitaxy Grain Growth Simulations of Selective Laser Melting. Materials 2021, 14, 7346. [Google Scholar]

- Huang, M.; Zhang, Z.; Chen, P. Effect of selective laser melting process parameters on microstructure and mechanical properties of 316L stainless steel helical micro-diameter spring. Int. J. Adv. Manuf. Technol. 2019, 104, 2117–2131. [Google Scholar] [CrossRef]

- Bi, Z.; Li, Y.; Qian, B. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar]

- Bertoli, U.S.; Wolfer, A.J.; Matthews, M.J.; Delplanque JP, R.; Schoenung, J.M. On the limitations of Volumetric Energy Density as a design parameter for Selective Laser Melting. Mater. Des. 2017, 113, 331–340. [Google Scholar] [CrossRef]

- Shen, L.L.; Ma, G.F.; Li, J.Q. Optimization of relative density for SLM forming 304L austenitic stainless steel. Die Mould. Ind. 2021, 47, 66–69. [Google Scholar]

- Liu, C.; Ma, X.C.; Ma, H.B. Effect of Process Parameters on Density of 316L Stainless Steel by SLM and Defects Manifestation Methods. Hot Work. Technol. 2021, 50, 44–49. [Google Scholar]

- Song, J.F.; Song, Y.N.; Wang, W.W.; Lang, Y.D.; Dong, Y.G.; Yang, R.X. Prediction and Control on the Surface Roughness of Metal Powder using Selective Laser Melting. Chin. J. Lasers 2022, 49, 81–94. [Google Scholar]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Mechanical behavior of selective laser melted 316L stainless steel. Mater. Sci. Eng. A 2017, 696, 113–121. [Google Scholar] [CrossRef]

- Liang, Y. Microstructure and Anisotropy of the Mechanical Properties of 316L Stainless Steel Fabricated by Selective Laser Melting. Metals 2021, 11, 775. [Google Scholar]

- Ni, M.; Chen, C.; Wang, X.J.; Zhang, X. Anisotropic tensile behavior of in situ precipitation strengthened Inconel 718 fabricated by additive manufacturing. Mater. Sci. Eng. 2017, 701, 344–351. [Google Scholar] [CrossRef]

- Tucho, W.M.; Lysne, V.H.; Austbø, H. Investigation of effects of process parameters on microstructure and hardness of SLM manufactured SS316L. J. Alloys Compd. 2018, 740, 910–925. [Google Scholar] [CrossRef]

- Li, H.; Ramezani, M.; Li, M.; Ma, C.; Wang, J. Effect of process parameters on tribological performance of 316L stainless steel parts fabricated by selective laser melting. Manuf. Lett. 2018, 16, 36–39. [Google Scholar] [CrossRef]

- Zhang, Z.; Chu, B.; Wang, L.; Lu, Z. Comprehensive effects of placement orientation and scanning angle on mechanical properties and behavior of 316L stainless steel based on the selective laser melting process. J. Alloys Compd. 2019, 791, 166–175. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, M.; Li, X.; Zeng, X. Effects of processing parameters on tensile properties of selective laser melted 304 stainless steel. Mater. Des. 2013, 50, 581–586. [Google Scholar]

- Saboori, A.; Aversa, A.; Marchese, G.; Fino, P. Microstructure and Mechanical Properties of AISI 316L Produced by Directed Energy Deposition-Based Additive Manufacturing: A Review. Appl. Sci. 2020, 10, 3310. [Google Scholar] [CrossRef]

- Li, B.Q.; Li, Z.H.; Liu, B.; Kuai, Z. Liang, M. Generation and Reduction of Porosity in AlSi10Mg Fabricated by Selective Laser Melting. Appl. Laser 2018, 38, 742–747. [Google Scholar]

- El Magri, A.; Hsissou, R.; Hmada, A.; Berisha, A.; Dkhireche, N.; Vaudreuil, S. Development of new polymer composites formulated by glass as a potential protective coating for 3D printed H13 steel in acidic medium: DFT, MC and MD computational. J. Mol. Liq. 2023, 387, 122690. [Google Scholar] [CrossRef]

- Zhang, J.Q.; Wang, M.J.; Liu, J.Y.; Niu, L.H.; Wang, J.H. Influence of scanning strategy on printing quality and properties of selective laser melted 18Ni300 maraging steel. J. Mater. Eng. 2020, 48, 105–113. [Google Scholar]

- Ge, Y.N.; Wu, M.P.; Mao, Y.Y.; Han, J.Y. Effect of Scanning Strategy on Forming Precision of Titanium Alloy by Selective Laser Melting. Laser Optoelectron. Prog. 2018, 55, 262. [Google Scholar]

- Yakout, M.; Elbestawi, M.A.; Veldhuis, S.C. Density and mechanical properties in selective laser melting of Invar 36 and stainless steel 316L. J. Mater. Process. Technol. 2018, 266, 397–420. [Google Scholar] [CrossRef]

- Li, J.; Lin, B.; Zheng, H.; Wang, H.; Zhang, H.; Zhang, Y.; Nie, Z.; Tang, J. Study on pitting corrosion behavior and semi in-situ pitting corrosion growth model of 304 L SS with elastic stress in NaCl corrosion environment. Corros. Sci. 2023, 211, 110862. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, W.; Liu, Y.; Zhong, L.; Wang, J. Study of localized corrosion of 304 stainless steel under chloride solution droplets using the wire beam electrode. Corros. Sci. 2011, 53, 2963–2968. [Google Scholar] [CrossRef]

- Yin, Y.; Niu, L.; Lu, M.; Guo, W.; Chen, S. In situ characterization of localized corrosion of stainless steel by scanning electrochemical microscope. Appl. Surf. Sci. 2009, 255, 9193–9199. [Google Scholar] [CrossRef]

- Pardo, A.; Merino, M.C.; Coy, A.E.; Viejo, F.; Arrabal, R.; Matykina, E. Pitting corrosion behaviour of austenitic stainless steels—Combining effects of Mn and Mo additions. Corros. Sci. 2008, 50, 1796–1806. [Google Scholar] [CrossRef]

- Xie, Y.J.; Yang, H.C.; Wang, X.B.; Kuang, C.J.; Han, W. Effects of laser parameters and scanning strategy on the forming properties of selective laser melting TC11 alloy. Powder Metall. Ind. 2018, 28, 18–24. [Google Scholar]

- Gao, M.X.; Wang, J.H.; Ren, J. Effects of scanning strategies on microstructure and properties of selective laser melted cobalt–chromium alloy. Laser J. 2020, 41, 133–136. [Google Scholar]

- Diepold, B.; Palm, M.S.; Wimmer, A. Rotating Scan Strategy Induced Anisotropic Microstructural and Mechanical Behavior of Selective Laser Melted Materials and Their Reduction by Heat Treatments. Adv. Eng. Mater. 2021, 23, 2100622. [Google Scholar] [CrossRef]

- Gunenthiram, V.; Peyre, P.; Schneider, M.; Dal, M.; Coste, F.; Koutiri, I.; Fabbro, R. Experimental analysis of spatter generation and melt-pool behavior during the powder bed laser beam melting process. J. Mater. Process. Technol. 2018, 251, 376–386. [Google Scholar] [CrossRef]

- Ladewig, A.; Schlick, G.; Fisser, M.; Schulze, V.; Glatzel, U. Influence of the shielding gas flow on the removal of process by-products in the selective laser melting process. Addit. Manuf. 2016, 10, 1–9. [Google Scholar] [CrossRef]

- Scholz, T.; Dickmann, K.; Ostendorf, A.; Uphoff, H.; Michalewicz, M. Effect of process parameters on the formation of laser-induced nanoparticles during material processing with continuous solid-state lasers. J. Laser Appl. 2015, 27, 032001. [Google Scholar] [CrossRef]

- Andreau, O.; Koutiri, I.; Peyre, P.; Penot, J.; Saintier, N.; Pessard, E.; De Terris, T.; Dupuy, C.; Baudin, T. Texture control of 316L parts by modulation of the melt pool morphology in selective laser melting. J. Mater. Process. Technol. 2019, 264, 21–31. [Google Scholar] [CrossRef]

- Keshavarzkermani, A.; Marzbanrad, E.; Esmaeilizadeh, R.; Mahmoodkhani, Y.; Ali, U.; Enrique, P.D.; Zhou, N.Y.; Bonakdar, A.; Toyserkani, E. An investigation into the effect of process parameters on melt pool geometry, cell spacing, and grain refinement during laser powder bed fusion. Opt. Laser Technol. 2019, 116, 83–91. [Google Scholar] [CrossRef]

- Leicht, A.; Yu, C.H.; Luzin, V.; Klement, U.; Hryha, E. Effect of scan rotation on the microstructure development and mechanical properties of 316L parts produced by laser powder bed fusion. Mater. Charact. 2020, 163, 110309. [Google Scholar] [CrossRef]

- Duan, Z.W.; Cheng, M.; Dong, C.F.; Cui, Z.Y.; Kong, D.C.; Wang, L.; Wang, X. Pitting behavior of SLM 316L stainless steel exposed to chloride environments with different aggressiveness: Pitting mechanism induced by gas pores. Corros. Sci. 2020, 167, 10852. [Google Scholar] [CrossRef]

- Brewick, P.T.; Kota, N.; Lewis, A.C.; DeGiorgi, V.G.; Geltmacher, A.B.; Qidwai, S.M. Microstructure-sensitive modeling of pitting corrosion: Effect of the crystallographic orientation. Corrosionence 2017, 129, 54–56. [Google Scholar] [CrossRef]

- Fu, J.; Li, F.; Sun, J.; Cui, K.; Du, X.; Wu, Y. Effect of crystallographic orientations on the corrosion resistance of Fe-17Cr ferritic stainless steel. J. Electroanal. Chem. 2019, 841, 56–62. [Google Scholar] [CrossRef]

- Jinlong, L.; Tongxiang, L.; Chen, W.; Ting, G. Effect of in site strain on passivated property of the 316L stainless steels. Mater. Sci. Eng. C 2016, 61, 32–36. [Google Scholar] [CrossRef] [PubMed]

- Dong, S.; Chen, X.; La Plante, E.C.; Gussev, M.; Leonard, K.; Sant, G. Elucidating the grain-orientation dependent corrosion rates of austenitic stainless steels. Mater. Des. 2020, 191, 108583. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Ni, X.; Zhang, L.; Luo, H.; Li, R.; Wang, L.; Man, C.; Li, X. The passivity of selective laser melted 316L stainless steel. Appl. Surf. Sci. 2020, 504, 144495. [Google Scholar] [CrossRef]

- Wu, J.H.; Xu, F.; Meng, F.Y. Microstructure and properties of 316L stainless steel manufactured by selective laser melting. Ordnance Mater. Sci. Eng. 2022, 45, 8. [Google Scholar]

- Nezhadfar, P.D.; Wedge, K.A.; Daniewicz, S.R.; Phan, N.; Shao, S.; Shamsaei, N. Improved high cycle fatigue performance of additively manufactured 17-4 PH stainless steel via in-process refining micro-/defect-structure—ScienceDirect. Addit. Manuf. 2020, 36, 101604. [Google Scholar]

- Pauzon, C.; Hryha, E.; Forêt, P.; Nyborg, L. Effect of argon and nitrogen atmospheres on the properties of stainless steel 316 L parts produced by laser-powder bed fusion. Mater. Des. 2019, 179, 107873. [Google Scholar] [CrossRef]

- Zhu, H.; Pan, Q.; Zhang, K.; Zhou, C.; Zhang, W.; Yao, Y.; Ying, D.; He, Y.; Zheng, J.; Zhang, L. The difference in fatigue crack growth induced by internal and external hydrogen in selective laser melted 304L stainless steel. Int. J. Fatigue 2022, 163, 107052. [Google Scholar] [CrossRef]

| Material | C | Cr | Ni | Mo | Mn | Si | P | S | O | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Powder | 0.008 | 16.73 | 10.95 | 2.62 | 0.88 | 0.56 | 0.01 | 0.004 | 0.052 | Bal. |

| Samples | Rs (Ω) | Rf (Ω) | Rct (Ω) | CPE1 | CPE2 | ||

|---|---|---|---|---|---|---|---|

| Q1 (Ω·sn) | n1 | Q2 (Ω·sn) | n2 | ||||

| Wrought | 15.14 | 4.6 × 102 | 4.28 × 104 | 5.19 × 10−5 | 0.82 | 1.03 × 10−7 | 0.66 |

| Z-0° | 19.16 | 4.11 × 104 | 2.70 × 104 | 4.6 × 10−5 | 0.82 | 6.7 × 10−6 | 0.78 |

| Z-67° | 21.37 | 6.68 × 104 | 1.46 × 105 | 1.69 × 10−5 | 0.91 | 4.32 × 10−6 | 0.75 |

| Z-90° | 18.37 | 1.55 × 104 | 1.37 × 105 | 1.6 × 10−5 | 0.90 | 3.5 × 10−6 | 0.64 |

| S-67° | 20.06 | 3.44 × 104 | 2.44 × 105 | 1.36 × 10−5 | 0.91 | 7.76 × 10−6 | 0.78 |

| I-67° | 20.1 | 7.01 × 104 | 2.25 × 105 | 1.68 × 10−5 | 0.92 | 3.82 × 10−6 | 0.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Z.; Sun, B.; Mao, L. Effect of Scanning Strategy on the Manufacturing Quality and Performance of Printed 316L Stainless Steel Using SLM Process. Materials 2024, 17, 1189. https://doi.org/10.3390/ma17051189

Zheng Z, Sun B, Mao L. Effect of Scanning Strategy on the Manufacturing Quality and Performance of Printed 316L Stainless Steel Using SLM Process. Materials. 2024; 17(5):1189. https://doi.org/10.3390/ma17051189

Chicago/Turabian StyleZheng, Zhijun, Bing Sun, and Lingyan Mao. 2024. "Effect of Scanning Strategy on the Manufacturing Quality and Performance of Printed 316L Stainless Steel Using SLM Process" Materials 17, no. 5: 1189. https://doi.org/10.3390/ma17051189

APA StyleZheng, Z., Sun, B., & Mao, L. (2024). Effect of Scanning Strategy on the Manufacturing Quality and Performance of Printed 316L Stainless Steel Using SLM Process. Materials, 17(5), 1189. https://doi.org/10.3390/ma17051189