Mechanical and Microstructural Investigation of Geopolymer Concrete Incorporating Recycled Waste Plastic Aggregate

Abstract

:1. Introduction

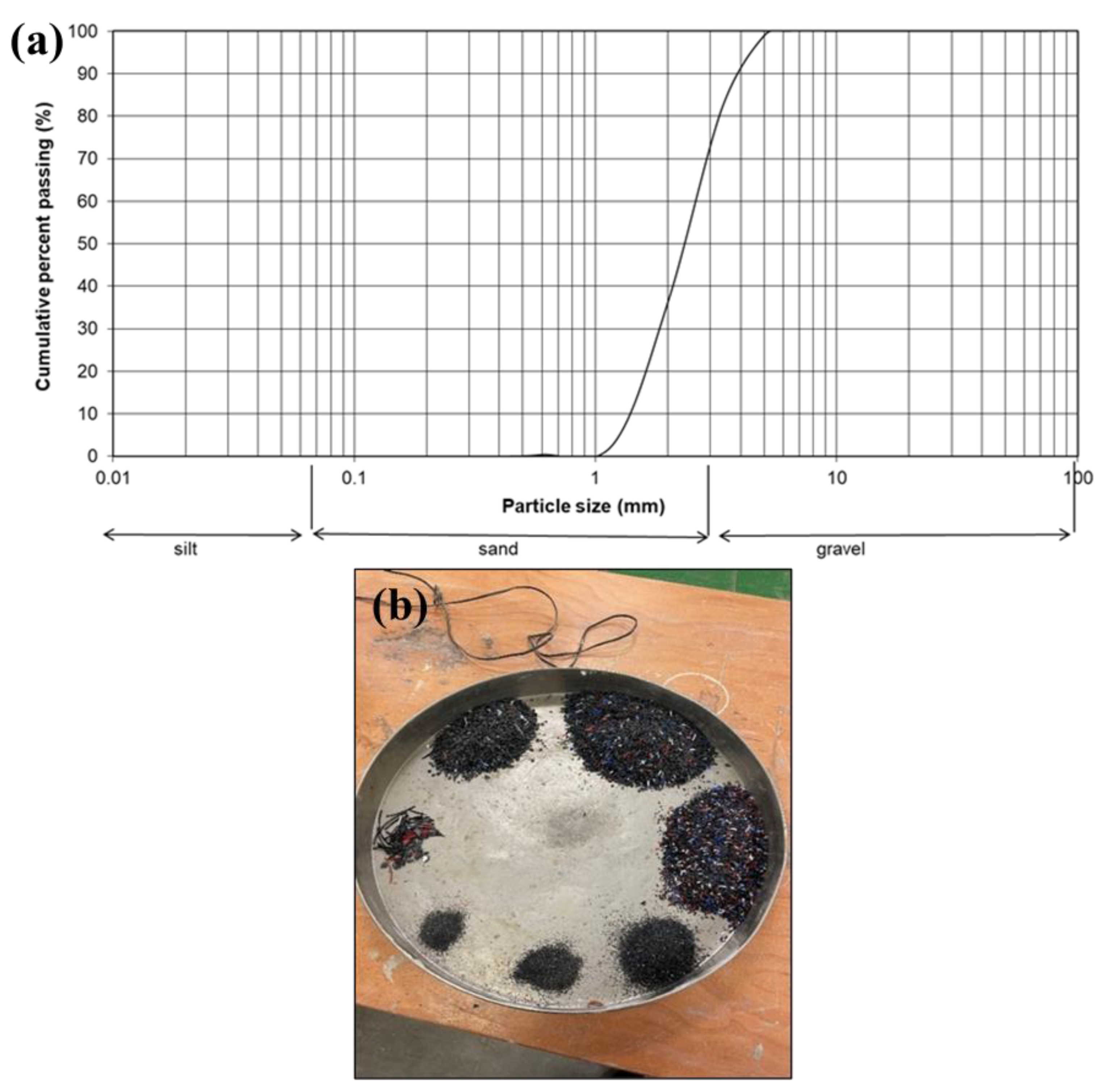

2. Materials

3. Methodology

3.1. Mix Design

3.2. Concrete Specimen Preparation and Testing Methods

4. Results and Discussions

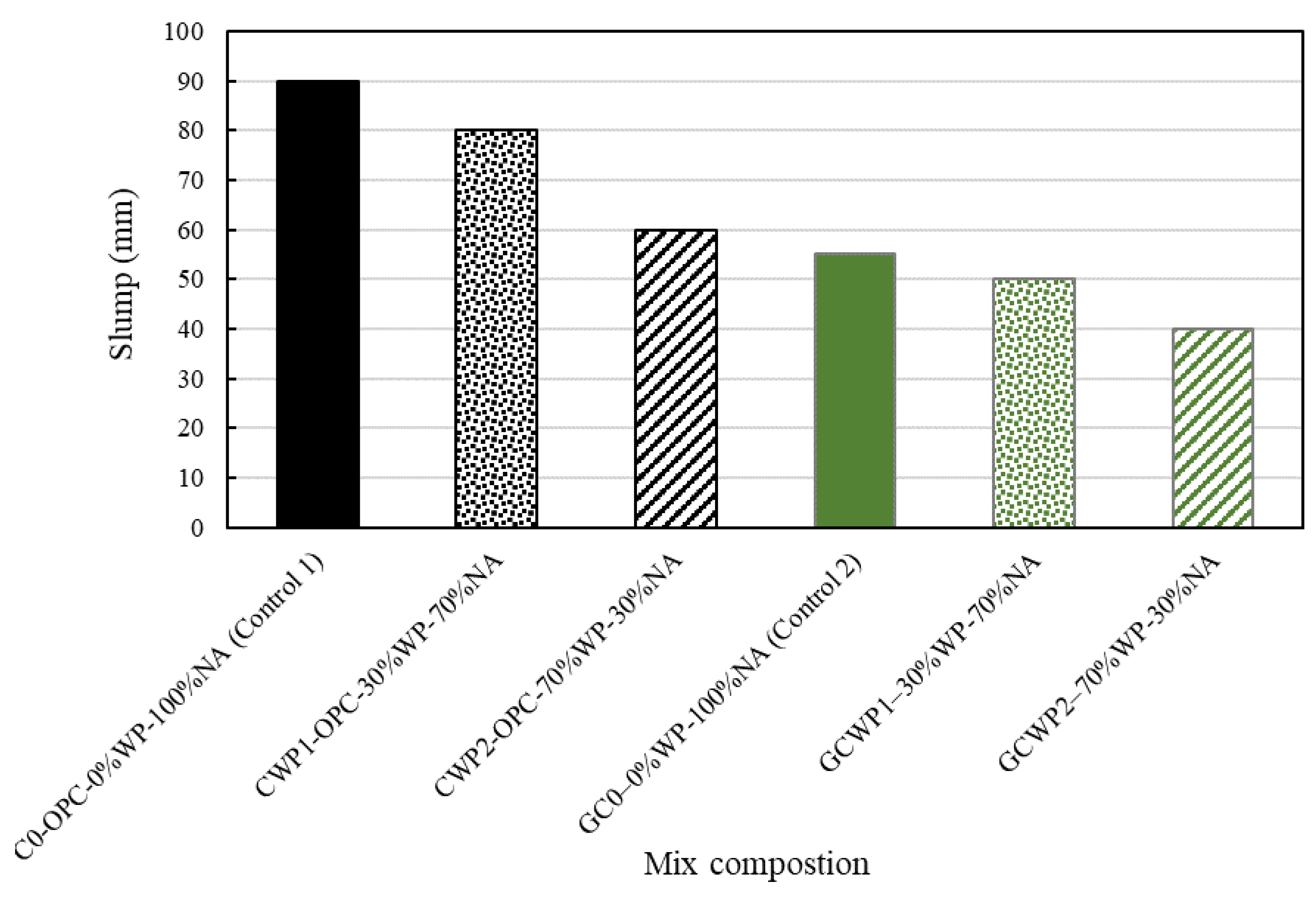

4.1. Consistency of Fresh Concrete

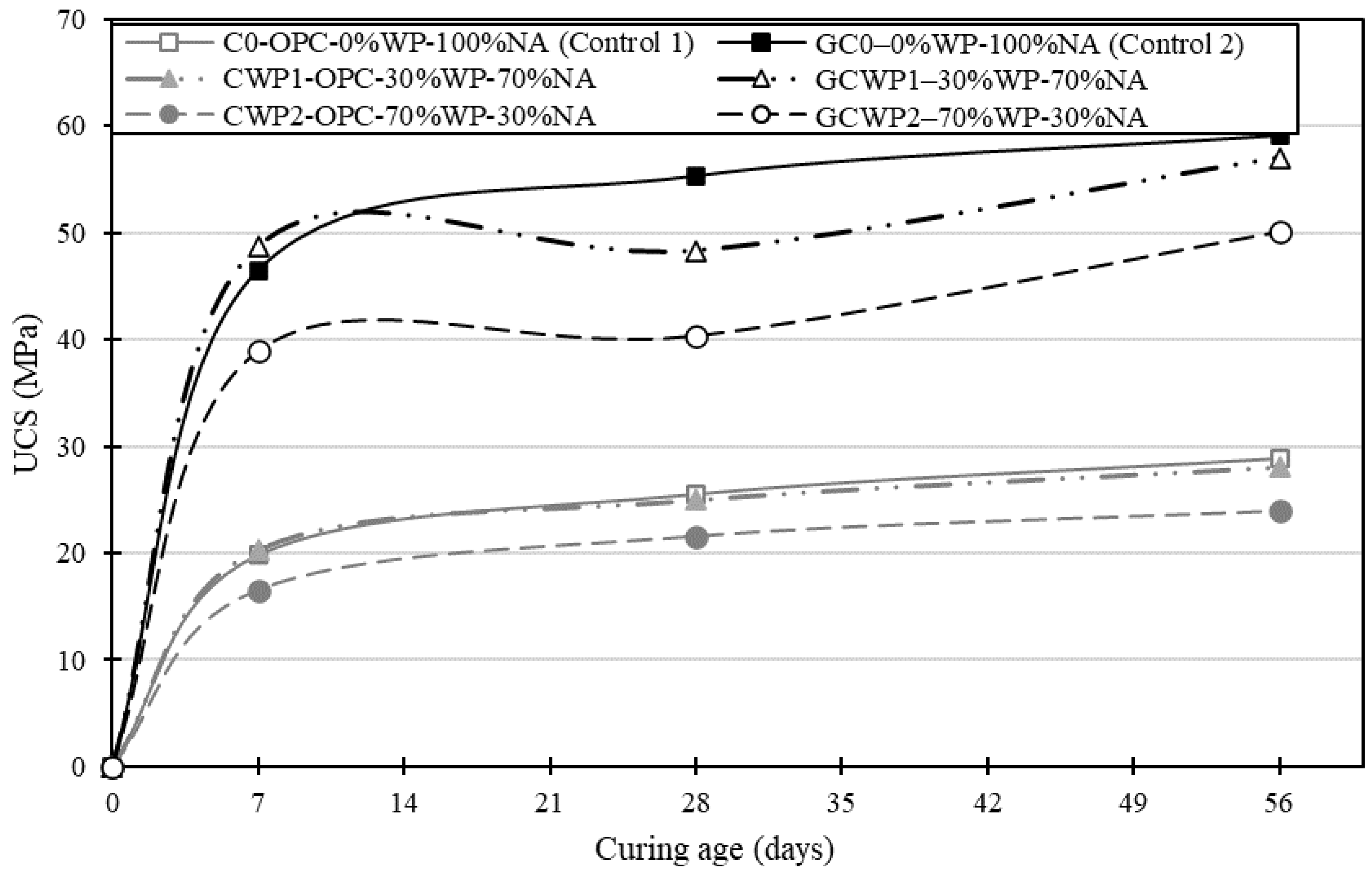

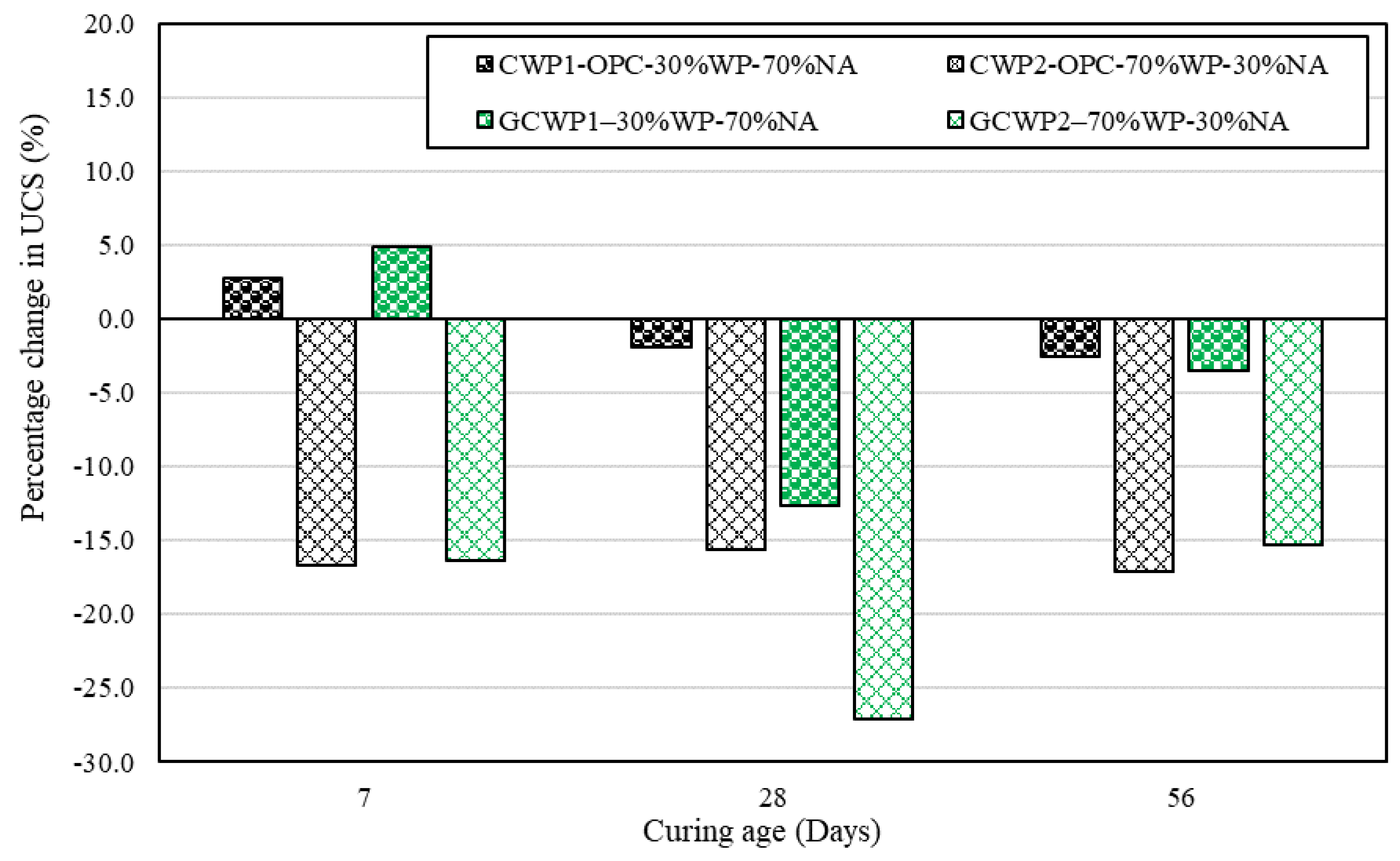

4.2. Concrete Strength Development

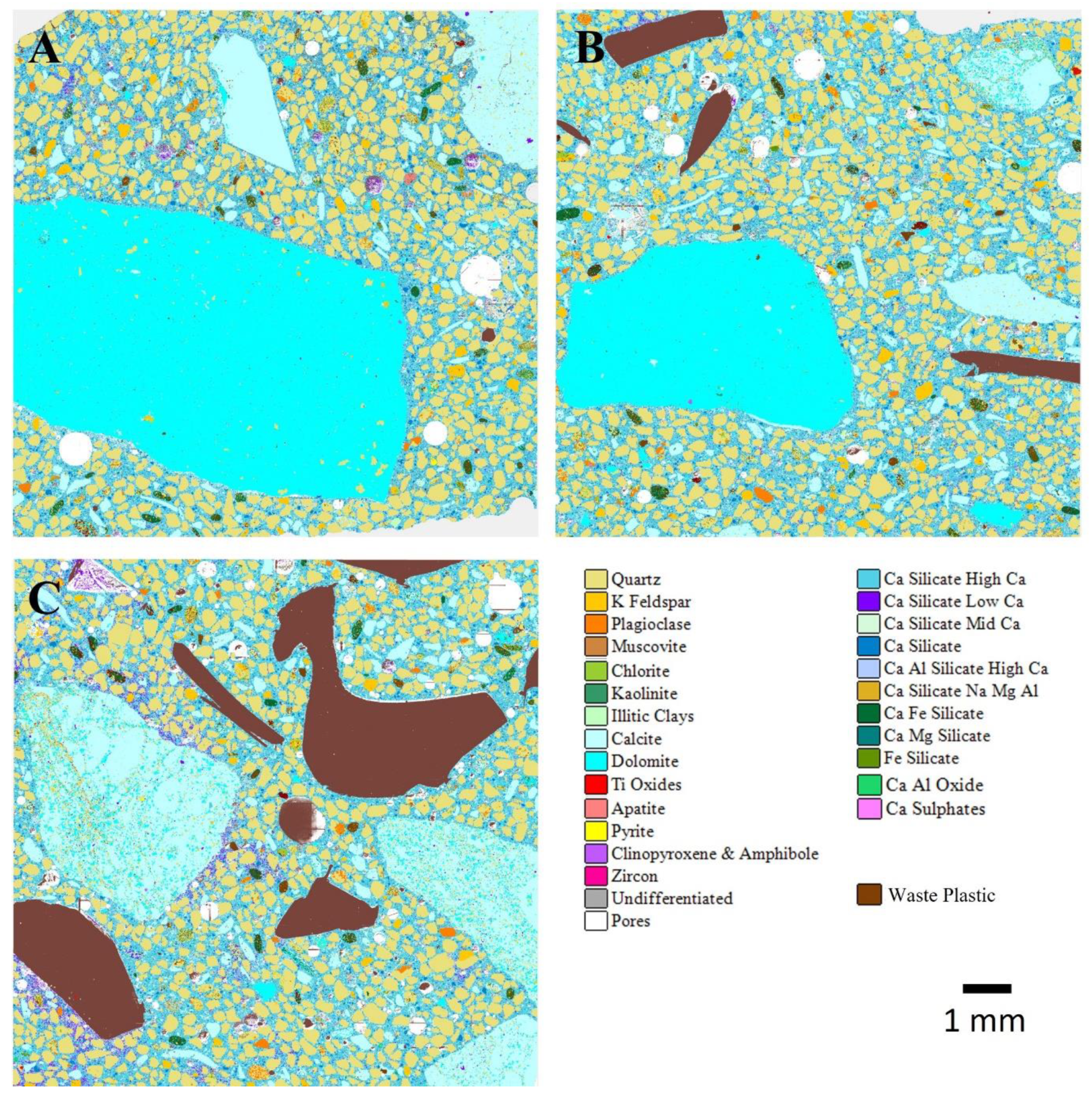

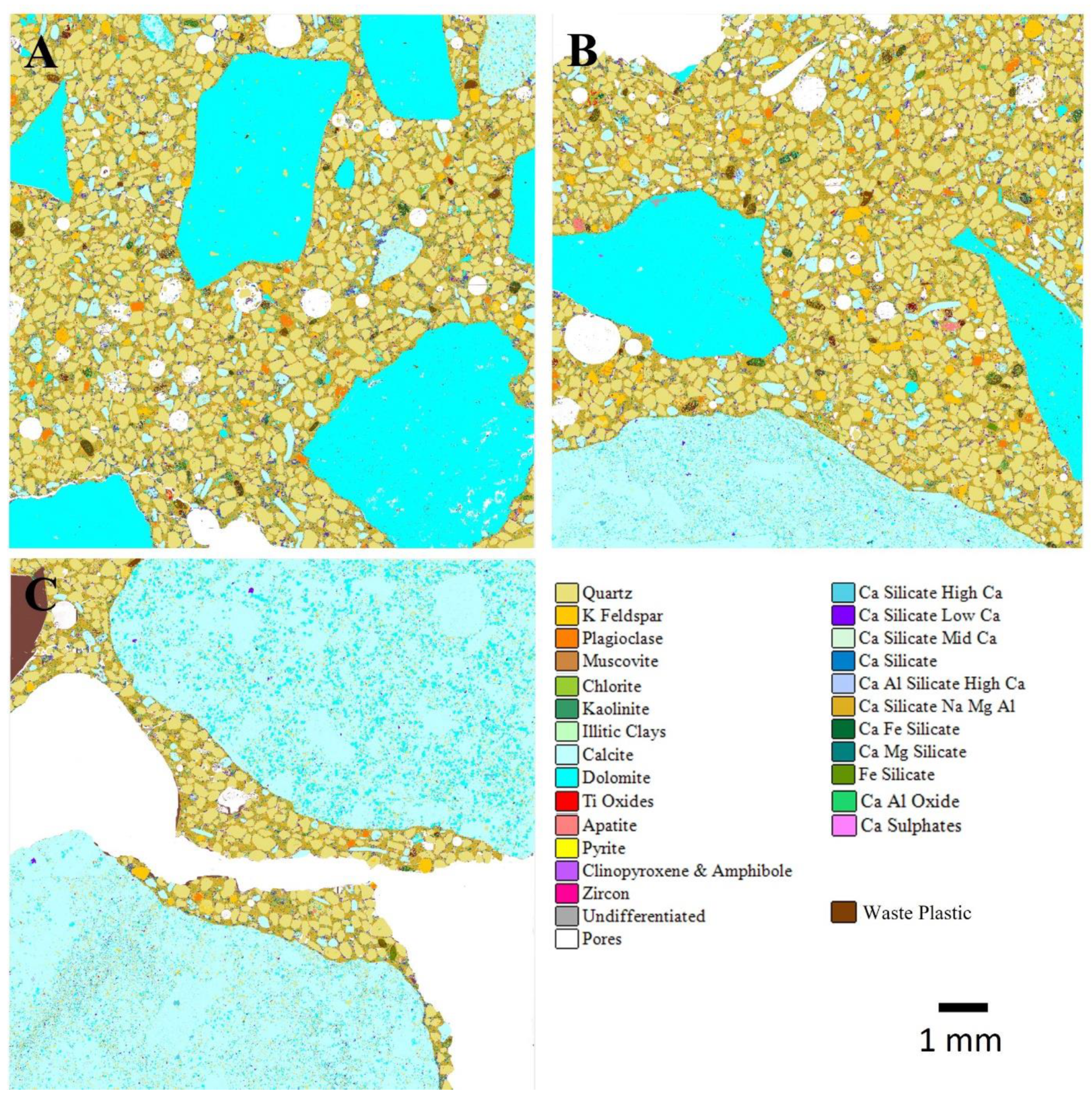

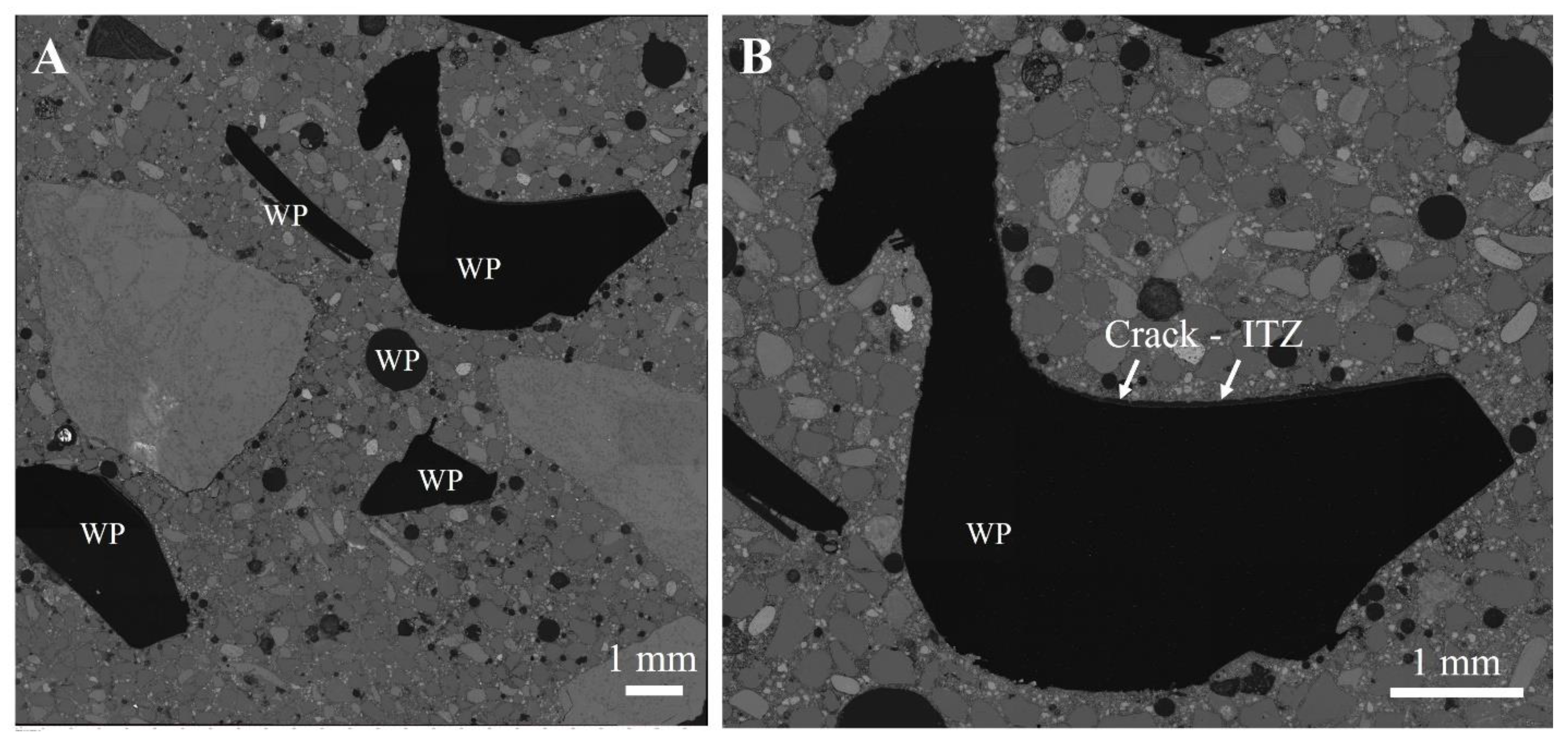

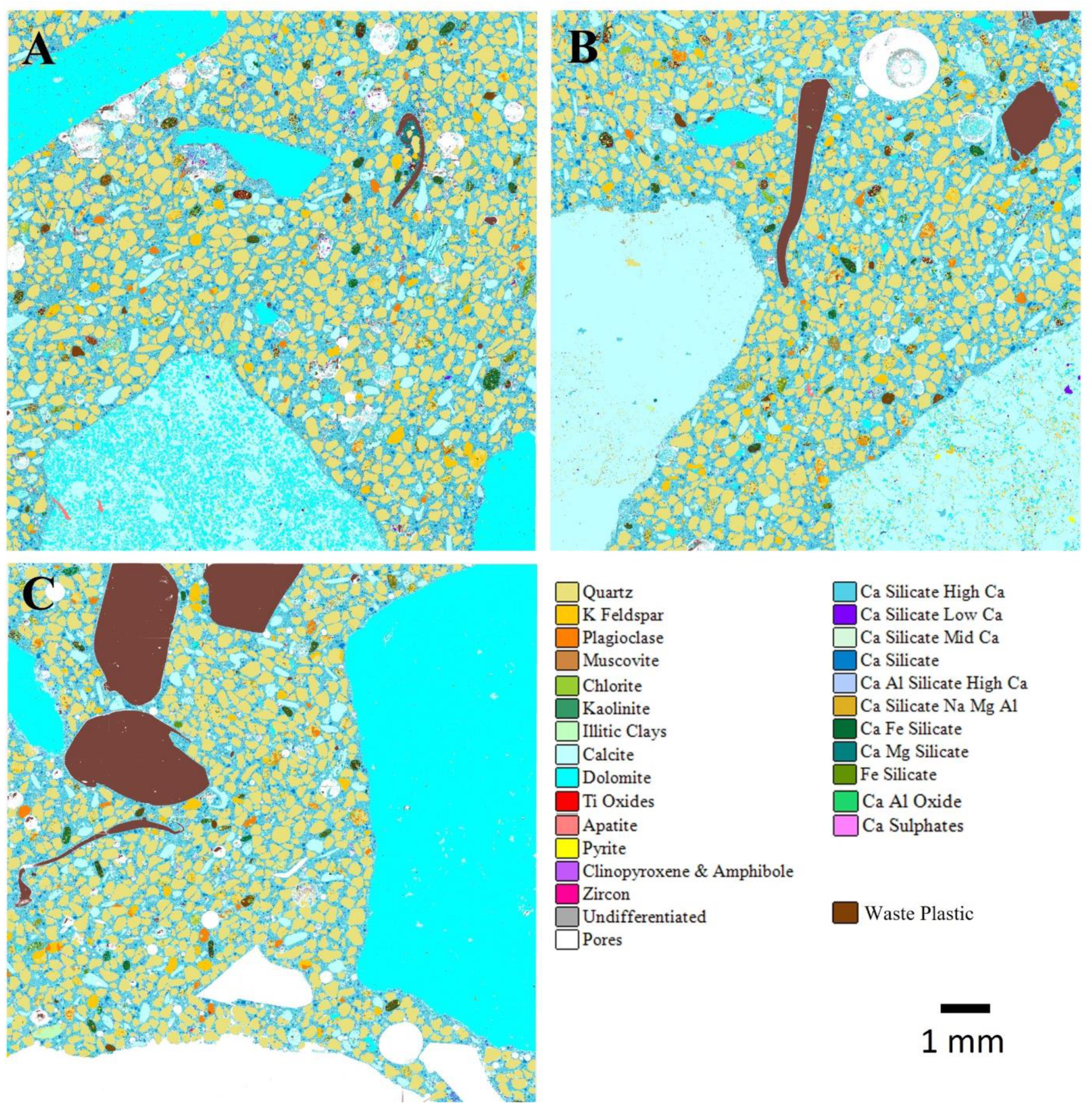

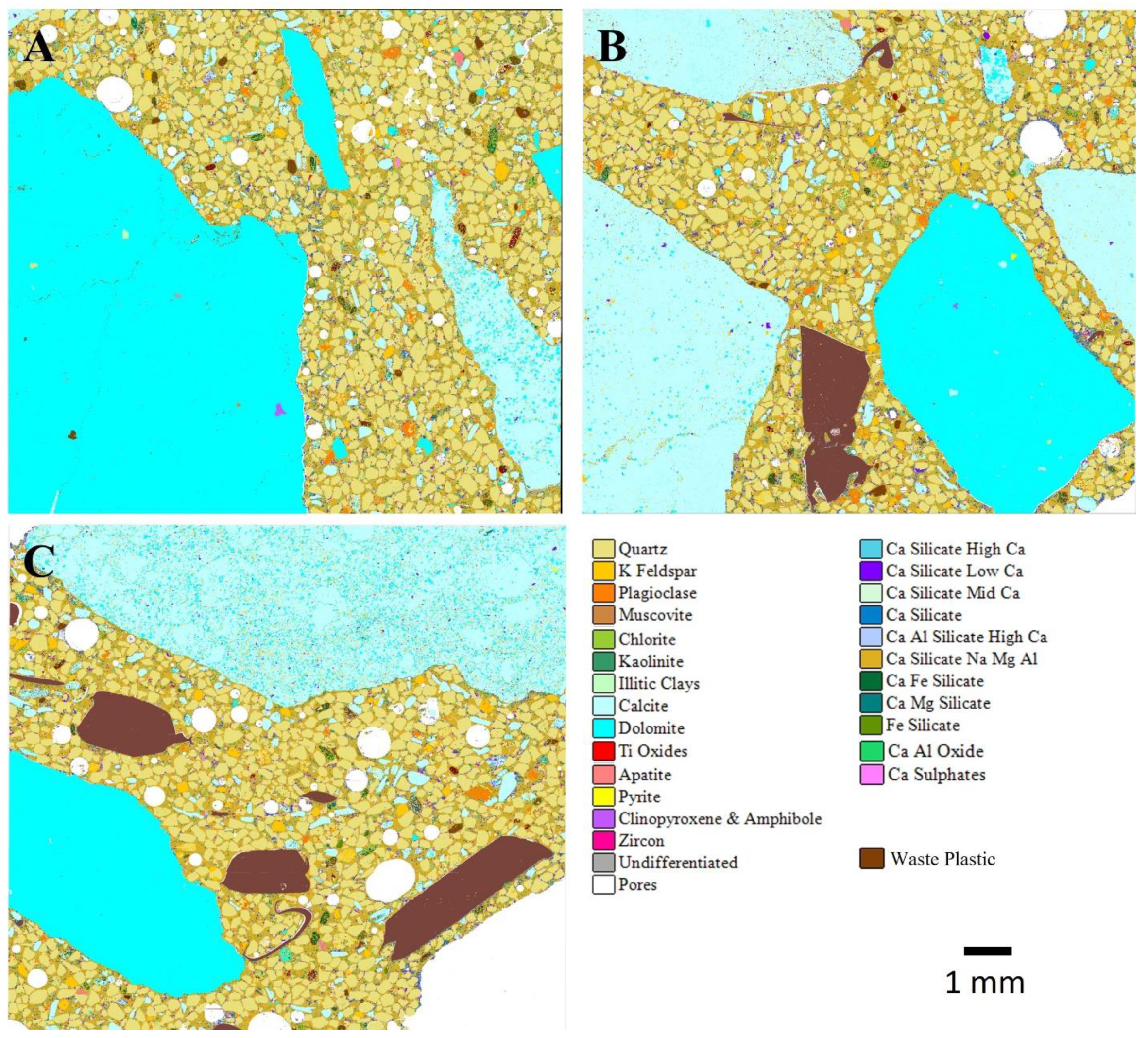

4.3. Compositional and Microstructural Analysis

5. Conclusions

- The consistency results indicated a gradual decline in slump values for every increase in the quantity of WP for both geopolymer and ordinary concrete mixes. This behaviour is more pronounced in geopolymer formulations due to the high viscosity of the developed geopolymer paste and the non-uniformity in the shape of WP. Therefore, any WP replacement of more than 70 wt% could impact the overall workability of the concrete produced. However, appropriate admixtures (superplasticiser) could be applied to improve the workability further.

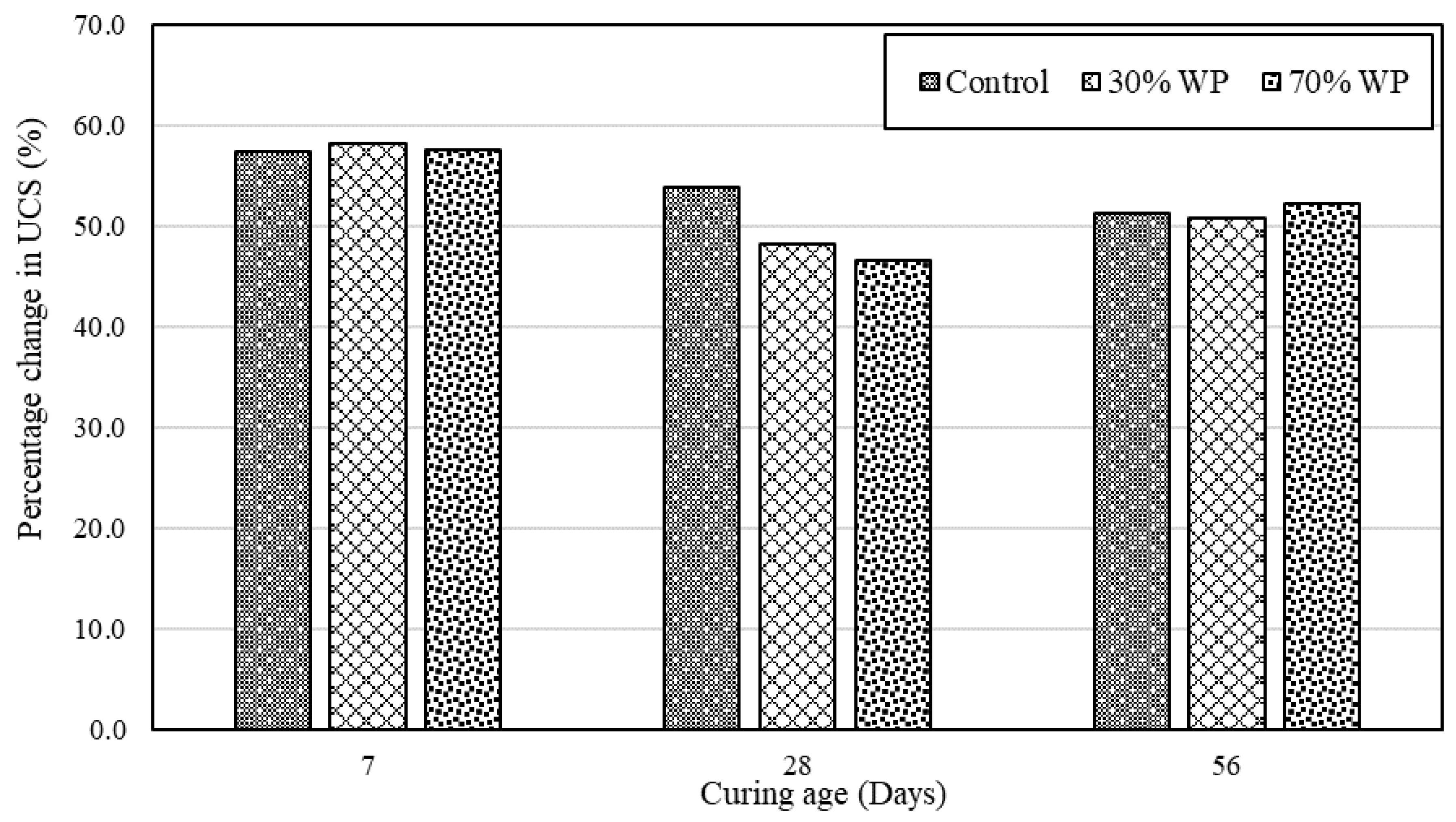

- A UCS comparison between geopolymer and ordinary concrete with and without the inclusion of WP, indicated superior strength development for the geopolymer concrete within the range of 46.7–58.3% at each curing age duration, indicating the robustness of the geopolymerisation reaction in concrete. Mix C0 and GC0 without WP achieved the highest UCS of 25.5 MPa and 55.4 MPa, respectively, while mix CWP2 and GWP2 with 70% WP replacement levels, performed the lowest with a UCS of 21.5 and 40.4 MPa at 28 days. In addition, the compressive strength of the ordinary and geopolymer concrete formulations declined with increasing dosages of WP (30% and 70%) due to the weak interfacial bonds between WP and the binder matrix. Moreover, this was more pronounced in ordinary concrete mixes, while the binder matrix in geopolymer concrete showed more interaction with WP.

- An SEM analysis indicates that adding WP in both ordinary and geopolymer concrete reduced the presence of pores within the microstructure. However, this was detrimental to the ordinary concrete due to the low ITZ between the CSH gel and WP, resulting in the formation of cracks. The observation justifies the significant reduction in strength for ordinary concrete compared with geopolymer concrete. In contrast to the ordinary concrete mix, the presence of pores in the geopolymer mixes (GC0, GCWP2, and GCWP2), which reduced over the duration of the curing period, did not significantly impact the UCS due to the robustness of the geopolymer gel (Na-bearing aluminosilicates) and improved ITZ with both the WP and the natural aggregates.

- Automated SEM-EDS quantifies the natural aggregates, waste plastics, and cementitious hydrates such as CSH and Na-bearing aluminosilicates (geopolymer) gel present.

- Although a concrete mix with 70% WP showed a significant reduction in UCS in both concrete formulations, geopolymer concrete can still be applied to construction practice depending on the required design strength.

- Further research can be carried out to improve the consistency and strength of geopolymer concrete incorporated with other types of plastic for its use in structural applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ponmalar, S.; Revathi, P. Waste recycled plastic granules substitute for aggregate in concrete—Review. Mater. Today Proc. 2022, 65, 1441–1448. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.S.; Mohammed, A.A. Engineering properties of geopolymer concrete composites incorporated recycled plastic aggregates modified with nano-silica. J. Build. Eng. 2023, 75, 106942. [Google Scholar] [CrossRef]

- PlasticsEurope. Plastics—The Facts 2020. An Analysis of European Plastics Production, Demand and Waste Data. 2020. Available online: https://www.plasticseurope.org/application/files/5716/0752/4286/AF_Plastics_the_facts-WEB-2020-ING_FINAL.pdf (accessed on 16 January 2024).

- Brahney, J.; Hallerud, M.; Heim, E.; Hahnenberger, M.; Sukumaran, S. Plastic rain in protected areas of the United States. Science 2020, 368, 1257. [Google Scholar] [CrossRef] [PubMed]

- Adeleke, B.O.; Kinuthia, J.M.; Oti, J.; Ebailila, M. Physico-Mechanical Evaluation of Geopolymer Concrete Activated by Sodium Hydroxide and Silica Fume-Synthesised Sodium Silicate Solution. Materials 2023, 16, 2400. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A.; Fini, E.H. Sustainable construction via novel geopolymer composites incorporating waste plastic of different sizes and shapes. Constr. Build. Mater. 2022, 324, 126697. [Google Scholar] [CrossRef]

- Zhang, K.; Hamidian, A.H.; Tubic, A.; Zhang, Y.; Fang, J.K.H.; Wu, C.; Lam, P.K.S. Understanding plastic degradation and microplastic formation in the environment: A review. Environ. Pollut. 2021, 274, 116554. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Y.; Jiang, L.; Zhou, Y.; Luo, Z.; Zhi, D.; Yang, J.; Lam, S.S. Microplastics and environmental pollutants: Key interaction and toxicology in aquatic and soil environments. J. Hazard. Mater. 2022, 422, 126843. [Google Scholar] [CrossRef]

- Sridharan, S.; Kumar, M.; Singh, L.; Bolan, N.S.; Saha, M. Microplastics as an emerging source of particulate air pollution: A critical review. J. Hazard. Mater. 2021, 418, 126245. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, M.; Almeida, M.; Miguel, I. A micro(nano)plastic boomerang tale: A never ending story? TrAC Trends Anal. Chem. 2019, 112, 196–200. [Google Scholar] [CrossRef]

- Bridson, J.H.; Gaugler, E.C.; Smith, D.A.; Northcott, G.L.; Gaw, S. Leaching and extraction of additives from plastic pollution to inform environmental risk: A multidisciplinary review of analytical approaches. J. Hazard. Mater. 2021, 414, 125571. [Google Scholar] [CrossRef]

- Wang, L.; Wu, W.M.; Bolan, N.S.; Tsang, D.C.W.; Qin YLi, M.; Hou, D. Environmental fate, toxicity and risk management strategies of nanoplastics in the environment: Current status and future perspectives. J. Hazard. Mater. 2021, 401, 123415. [Google Scholar] [CrossRef]

- Horton, A.A. Plastic pollution: When do we know enough? J. Hazard. Mater. 2022, 422, 126885. [Google Scholar] [CrossRef]

- Mofijur, M.; Ahmed, S.F.; Rahman, S.M.A.; Arafat Siddiki, S.Y.; Islam, A.; Shahabuddin, M.; Ong, H.C.; Mahlia TM, I.; Djavanroodi, F.; Show, P.L. Source, distribution and emerging threat of micro- and nanoplastics to marine organism and human health: Socio-economic impact and management strategies. Environ. Res. 2021, 195, 110857. [Google Scholar] [CrossRef]

- Borrelle, S.B.; Ringma, J.; Law, K.L.; Monnahan, C.C.; Lebreton, L.; McGivern, A.; Murphy, E.; Jambeck, J.; Leonard, G.H.; Hilleary, M.A.; et al. Predicted growth in plastic waste exceeds efforts to mitigate plastic pollution. Science 2020, 369, 1515–1518. [Google Scholar] [CrossRef] [PubMed]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Yang, Z.; Lu, F.; Zhang, H.; Wang, W.; Shao, L.; Ye, J.; He, P. Is incineration the terminator of plastics and microplastics? J. Hazard. Mater. 2021, 401, 123429. [Google Scholar] [CrossRef]

- Koley, S. Sustainability appraisal of arsenic mitigation policy innovations in West Bengal, India. Infrastruct. Asset Manag. 2023, 10, 17–37. [Google Scholar] [CrossRef]

- Bayiha, B.N.; Yamb, E.; Metekong, J.S.; Billong, N.; Nzengwa, R. Optimizing the Choice of Limestone Deposits for the Production of Portland Cement in Cameroon. Int. J. Mater. Sci. Appl. 2018, 7, 174–185. [Google Scholar] [CrossRef]

- Billong, N.; Oti, J.; Kinuthia, J. Using silica fume based activator in sustainable geopolymer binder for building application. Constr. Build. Mater. 2021, 275, 122177. [Google Scholar] [CrossRef]

- Adeleke, B.O.; Kinuthia, J.M.; Oti, J.E. Impacts of MgO waste:GGBS formulations on the performance of a stabilised natural high sulphate bearing soil. Constr. Build. Mater. 2022, 15, 125745. [Google Scholar] [CrossRef]

- Thorneycroft, J.; Orr, J.; Savoikar, P.; Ball, R.J. Performance of structural concrete with recycled plastic waste as a partial replacement for sand. Constr. Build. Mater. 2018, 161, 63–69. [Google Scholar] [CrossRef]

- Tota-Maharaj, K.; Adeleke, B.O.; Nounu, G. Effects of waste plastics as partial fine-aggregate replacement for reinforced low-carbon concrete pavements. Int. J. Sustain. Eng. 2022, 15, 192–207. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A. Geopolymer additive manufacturing: A review. Addit. Manuf. 2022, 55, 102782. [Google Scholar] [CrossRef]

- Sun, K.; Peng, X.; Wang, S.; Zeng, L.; Ran, P.; Ji, G. Effect of nano-SiO2 on the efflorescence of an alkali-activated metakaolin mortar. Constr. Build. Mater. 2020, 253, 118952. [Google Scholar] [CrossRef]

- Simão, L.; Fernandes, E.; Hotza, D.; Ribeiro, M.J.; Montedo, O.R.K.; Raupp-Pereira, F. Controlling efflorescence in geopolymers: A new approach. Case Stud. Constr. Mater. 2021, 15, e00740. [Google Scholar] [CrossRef]

- Skariah Thomas, B.; Yang, J.; Bahurudeen, A.; Chinnu, S.N.; Abdalla, J.A.; Hawileh, R.A.; Hamada, H.M. Geopolymer concrete incorporating recycled aggregates: A comprehensive review. Clean. Mater. 2022, 3, 100056. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef]

- Provis, J.L. Geopolymers and other alkali activated materials: Why, how, and what? Mater. Struct. 2014, 47, 11–25. [Google Scholar] [CrossRef]

- Hama, S.M.; Hilal, N.N. Fresh properties of self-compacting concrete with plastic waste as partial replacement of sand. Int. J. Sustain. Built Environ. 2017, 6, 299–308. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F. Introduction to the use of recycled plastics in eco-efficient concrete. In Use of Recycled Plastics in Eco-Efficient Concrete; Woodhead: Sawston, UK, 2019; pp. 1–8. [Google Scholar]

- Shaikh, F.U.A. Tensile and flexural behaviour of recycled polyethylene terephthalate (PET) fibre reinforced geopolymer composites. Constr. Build. Mater. 2020, 245, 118438. [Google Scholar] [CrossRef]

- Chithambar Ganesh, A.; Deepak, N.; Deepak, V.; Ajay, S.; Pandian, A.; Karthik. Utilization of PET bottles and plastic granules in geopolymer concrete. Mater. Today Proc. 2021, 42, 444–449. [Google Scholar] [CrossRef]

- BS EN 197-1:2011; “Cement”, Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardisation: London, UK, 2011.

- BS EN 15167-1:2006; “Ground Granulated Blast Furnace slag for Use in Concrete, Mortar and Grout”, Part 1: Definitions, Specifications and Conformity Criteria. European Committee for Standardisation: London, UK, 2006.

- BS EN 12620:2002+A1:2008; Aggregates for Concrete. ASRO: Bucharest, Romania, 2008.

- Gutierrez, R. All You Need to Know About PLA Plastic/Material. 2020. Available online: https://www.wjoffice.com/blog/all-you-need-know-about-pla-plasticmaterial (accessed on 25 November 2023).

- BS EN ISO 17892-4:2016; “Geotechnical Investigation and Testing—Laboratory Testing of Soil”, Part 4: Determination of Particle Size Distribution. European Committee for Standardisation: London, UK, 2016.

- BS EN 12350-2:2019; “Testing Fresh Concrete”, Part 1: Slump Test. European Committee for Standardisation: London, UK, 2019.

- BS EN 206:2013+A2:2021; “Concrete” Specification, Performance, Production and Conformity. European Committee for Standardisation: London, UK, 2021.

- BS EN 12390-2:2019; “Testing Hardened Concrete”, Part 2: Making and Curing Specimens for Strength Tests. European Committee for Standardisation: London, UK, 2019.

- BS EN 12390-3:2019; “Testing Hardened Concrete”, Part 3: Compressive Strength of Test Specimens. European Committee for Standardisation: London, UK, 2019.

- Pirrie, D.; Rollinson, G.K. Unlocking the applications of automated mineral analysis. Geol. Today 2011, 27, 226–235. [Google Scholar] [CrossRef]

- Schulz, B.; Sandmann, D.; Gilbricht, S. SEM-Based Automated Mineralogy and Its Application in Geo- and Material Sciences. Minerals 2020, 10, 1004. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmuş, H.İ. Utilization and efficiency of ground granulated blast furnace slag on concrete properties—A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Swathi, B.; Vidjeapriya, R. Influence of precursor materials and molar ratios on normal, high, and ultra-high performance geopolymer concrete—A state of art review. Constr. Build. Mater. 2023, 392, 132006. [Google Scholar] [CrossRef]

- Belmokaddem, M.; Mahi, A.; Senhadji, Y.; Pekmezci, B.Y. Mechanical and physical properties and morphology of concrete containing plastic waste as aggregate. Constr. Build. Mater. 2020, 257, 119559. [Google Scholar] [CrossRef]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Khan, T.M.Y.; Dawood Abdul Khadar, S. Molarity activity effect on mechanical and microstructure properties of geopolymer concrete: A review. Case Stud. Constr. Mater. 2022, 16, e01014. [Google Scholar] [CrossRef]

| Oxides | Compositions (%) | ||

|---|---|---|---|

| Cement | GGBS | SF | |

| CaO | 61.49 | 37.99 | 0.2 |

| MgO | 3.54 | 8.78 | 0.1 |

| SiO2 | 18.84 | 35.54 | 97.1 |

| Al2O3 | 4.77 | 11.46 | 0.2 |

| Na2O | 0.02 | 0.37 | - |

| P2O5 | 0.1 | 0.02 | 0.03 |

| Fe2O3 | 2.87 | 0.42 | 0.01 |

| Mn2O3 | 0.05 | 0.43 | - |

| K2O | 0.57 | 0.43 | 0.2 |

| TiO2 | 0.26 | 0.7 | - |

| V2O5 | 0.06 | 0.04 | - |

| BaO | 0.05 | 0.09 | - |

| SO3 | 3.12 | 1.54 | 0.1 |

| Loss on ignition | 4.3 | 2 | 0.5 |

| Other Properties | Cement | GGBS | SF |

|---|---|---|---|

| Insoluble residue | 0.5 | 0.3 | - |

| Bulk density (kg/m3) | 1400 | 1200 | 300 |

| Specific gravity | 3.15 | 2.9 | 3.15 |

| Glass content (%) | - | 90 | - |

| Blaine fineness (m2/kg) | 365 | 450 | - |

| Alkalinity value (pH) | 13.41 | 10.4 | 7 |

| Colour | Grey | Off-white | Grey |

| Physical form | Fine powder | Fine powder | Powder |

| Physical Properties | Coarse Aggregates | Fine Aggregates (Sand) | Waste Plastics (WP) | |

|---|---|---|---|---|

| 20 mm | 10 mm | |||

| Uniformity coefficient (CU) | 1.3 | 3.3 | 0.11 | - |

| Curvature coefficient (CC) | 7.5 | 1.5 | 1.75 | - |

| Flakiness index (%) | 23 | 30–35 | - | - |

| Elongation index (%) | 12 | 17–22 | - | - |

| Shape index (%) | 7 | 12 | - | - |

| Impact value | 15 | 23 | - | - |

| Fineness modulus (mm) | - | 4 | 1.54 | - |

| 2570 | 1350 | 1500 | - | |

| Pre-dried particle density | - | 2690 | 2600 | - |

| Water absorption (%) | 1.1 | 2 | 21 | - |

| Heat Deflection Temperature—Hdt (°C) | - | - | - | 52 |

| Density (g/cm³) | - | - | - | 1.24 |

| Tensile strength (MPa) | - | - | - | 50 |

| Flexural strength (MPa) | 80 | |||

| Impact strength (Unnotched) Izod (J/m) | - | - | - | 96.1 |

| Shrink rate %(in/in) | - | - | - | 0.37–0.41 (0.0037–0.0041) |

| Mix Code | Elaborated Abbreviation | Concrete Binder | W (L) | Aggregates (kg) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OPC (kg) | Geopolymer Binder | NFA | WP | Natural Coarse Aggregate | ||||||||

| GGBS (kg) | A/P | SS:SH | Activator (mL) | |||||||||

| Ratio | SS | SH | 10 mm | 20 mm | ||||||||

| C0 | C0-OPC-0%WP-100%NA (Control 1) | 3.9 | - | - | - | - | - | 2.2 | 7.9 | - | 3.9 | 7.9 |

| CWP1 | CWP1-OPC-30%WP-70%NA | 3.9 | - | - | - | - | - | 2.2 | 7.9 | 1.2 | 2.7 | 7.9 |

| CWP2 | CWP2-OPC-70%WP-30%NA | 3.9 | - | - | - | - | - | 2.2 | 7.9 | 2.7 | 1.2 | 7.9 |

| GC0 | GC0–0%WP-100%NA (Control 2) | - | 2.6 | 0.5 | 1.2:0.8 | 540 | 360 | 1.1 | 7.9 | - | 3.9 | 7.9 |

| GCWP1 | GCWP1–30%WP-70%NA | - | 2.6 | 0.5 | 1.2:0.8 | 540 | 360 | 1.1 | 7.9 | 1.2 | 2.7 | 7.9 |

| GCWP2 | GCWP2–70%WP-30%NA | - | 2.6 | 0.5 | 1.2:0.8 | 540 | 360 | 1.1 | 7.9 | 2.7 | 1.2 | 7.9 |

| Minerals | Area (%) | |||||

|---|---|---|---|---|---|---|

| OPC-0%WP-100%NA | OPC-30%WP-70%NA | OPC-70%WP-30%NA | GC-0%WP100%NA | GC-30%WP70%NA | GC-70%WP30%NA | |

| Plastic | 1.58 | 3.52 | 16.28 | 0.23 | 0.19 | 1.91 |

| Quartz | 23.28 | 29.92 | 29.11 | 28.64 | 30.37 | 12.67 |

| K Feldspar | 1.04 | 1.30 | 1.05 | 0.95 | 1.54 | 0.53 |

| Plagioclase | 0.57 | 0.60 | 0.64 | 0.68 | 0.64 | 0.14 |

| Muscovite | 0.13 | 0.20 | 0.29 | 0.12 | 0.13 | 0.25 |

| Biotite | 0.19 | 0.29 | 0.28 | 0.28 | 0.34 | 0.05 |

| Chlorite | 0.26 | 0.28 | 0.29 | 0.27 | 0.34 | 0.06 |

| Kaolinite | 0.09 | 0.09 | 0.07 | 0.04 | 0.06 | 0.03 |

| Illitic Clays | 0.42 | 0.49 | 0.55 | 0.33 | 0.39 | 0.31 |

| Calcite | 12.50 | 13.76 | 28.42 | 6.22 | 19.59 | 66.97 |

| Dolomite | 34.97 | 17.50 | 4.03 | 33.88 | 16.57 | 8.18 |

| Fe Oxides and Siderite | 0.21 | 0.25 | 0.30 | 0.37 | 0.30 | 0.08 |

| Ti Oxides | 0.14 | 0.04 | 0.03 | 0.02 | 0.04 | 0.03 |

| Apatite | 0.09 | 0.01 | 0.00 | 0.00 | 0.08 | 0.01 |

| Pyrite | 0.09 | 0.00 | 0.02 | 0.00 | 0.01 | 0.01 |

| Clinopyroxene and Amphibole | 0.17 | 0.03 | 0.05 | 0.03 | 0.05 | 0.03 |

| Zircon | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Ca Silicate High Ca | 2.23 | 2.21 | 1.76 | 0.02 | 0.01 | 0.00 |

| Ca Silicate Mid Ca | 16.87 | 24.16 | 23.47 | 0.52 | 0.75 | 1.03 |

| Ca Silicate Low Ca | 1.37 | 1.74 | 2.30 | 0.25 | 0.20 | 0.14 |

| Ca Silicate | 1.00 | 1.28 | 2.50 | 2.08 | 2.12 | 0.93 |

| Ca Al Silicate High Ca | 0.63 | 0.87 | 0.88 | 0.04 | 0.10 | 0.32 |

| Ca Silicate Na Mg Al | 0.01 | 0.01 | 0.01 | 21.43 | 23.05 | 6.64 |

| Ca Fe Silicate | 0.49 | 0.53 | 0.58 | 0.29 | 0.31 | 0.06 |

| Ca Mg Silicate | 2.12 | 3.04 | 2.26 | 3.26 | 2.70 | 1.42 |

| Fe Silicate | 0.14 | 0.14 | 0.13 | 0.19 | 0.20 | 0.08 |

| Ca Al Oxide | 0.38 | 0.46 | 0.55 | 0.00 | 0.01 | 0.00 |

| Ca Sulphates | 0.49 | 0.71 | 0.32 | 0.02 | 0.01 | 0.00 |

| Undifferentiated | 0.10 | 0.07 | 0.09 | 0.06 | 0.10 | 0.04 |

| Minerals | Area (%) | |||||

|---|---|---|---|---|---|---|

| OPC-0%WP-100%NA | OPC-30%WP-70%NA | OPC-70%WP-30%NA | GC-0%WP100%NA | GC-30%WP70%NA | GC-70%WP30%NA | |

| Plastic | 2.00 | 2.80 | 10.31 | 0.06 | 3.66 | 6.82 |

| Quartz | 28.86 | 25.64 | 26.56 | 25.21 | 21.88 | 26.11 |

| K Feldspar | 1.12 | 1.06 | 1.19 | 0.55 | 0.82 | 1.16 |

| Plagioclase | 0.46 | 0.51 | 0.71 | 0.57 | 0.57 | 0.51 |

| Muscovite | 0.09 | 0.21 | 0.09 | 0.12 | 0.09 | 0.14 |

| Biotite | 0.25 | 0.26 | 0.14 | 0.29 | 0.18 | 0.30 |

| Chlorite | 0.19 | 0.25 | 0.23 | 0.29 | 0.23 | 0.29 |

| Kaolinite | 0.03 | 0.05 | 0.04 | 0.05 | 0.03 | 0.03 |

| Illitic Clays | 0.32 | 0.42 | 0.36 | 0.38 | 0.24 | 0.38 |

| Calcite | 17.92 | 38.85 | 7.99 | 8.01 | 32.24 | 28.46 |

| Dolomite | 16.32 | 2.64 | 36.35 | 42.66 | 20.08 | 18.72 |

| Fe Oxides and Siderite | 0.32 | 0.27 | 0.24 | 0.35 | 0.20 | 0.18 |

| Ti Oxides | 0.02 | 0.02 | 0.01 | 0.02 | 0.01 | 0.02 |

| Apatite | 0.06 | 0.03 | 0.00 | 0.05 | 0.04 | 0.04 |

| Pyrite | 0.00 | 0.02 | 0.00 | 0.00 | 0.02 | 0.01 |

| Clinopyroxene and Amphibole | 0.02 | 0.02 | 0.01 | 0.05 | 0.03 | 0.04 |

| Zircon | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Ca Silicate High Ca | 1.94 | 1.78 | 1.21 | 0.01 | 0.01 | 0.01 |

| Ca Silicate Mid Ca | 24.05 | 22.60 | 19.22 | 0.41 | 0.54 | 0.83 |

| Ca Silicate Low Ca | 1.88 | 0.59 | 0.92 | 0.16 | 0.18 | 0.20 |

| Ca Silicate | 1.16 | 0.86 | 0.72 | 1.49 | 1.98 | 1.85 |

| Ca Al Silicate High Ca | 0.56 | 0.62 | 0.62 | 0.05 | 0.08 | 0.16 |

| Ca Silicate Na Mg Al | 0.02 | 0.01 | 0.01 | 16.50 | 18.20 | 18.11 |

| Ca Fe Silicate | 0.50 | 0.43 | 0.43 | 0.28 | 0.18 | 0.30 |

| Ca Mg Silicate | 2.50 | 1.55 | 1.80 | 2.24 | 2.01 | 1.93 |

| Fe Silicate | 0.16 | 0.18 | 0.17 | 0.16 | 0.09 | 0.15 |

| Ca Al Oxide | 0.45 | 0.40 | 0.49 | 0.00 | 0.00 | 0.00 |

| Ca Sulphates | 0.27 | 0.31 | 0.40 | 0.02 | 0.01 | 0.01 |

| Undifferentiated | 0.52 | 0.41 | 0.05 | 0.07 | 0.05 | 0.06 |

| Minerals | Area (%) | |||||

|---|---|---|---|---|---|---|

| OPC-0%WP-100%NA | OPC-30%WP-70%NA | OPC-70%WP-30%NA | GC-0%WP100%NA | GC-30%WP70%NA | GC-70%WP30%NA | |

| Plastic | 0.10 | 9.89 | 10.10 | 0.19 | 2.47 | 11.30 |

| Quartz | 14.76 | 20.37 | 27.43 | 13.07 | 38.80 | 19.24 |

| K Feldspar | 0.57 | 0.76 | 1.07 | 0.53 | 1.54 | 0.76 |

| Plagioclase | 0.27 | 0.32 | 0.63 | 0.40 | 0.86 | 0.50 |

| Muscovite | 0.07 | 0.15 | 0.14 | 0.09 | 0.20 | 0.15 |

| Biotite | 0.16 | 0.12 | 0.23 | 0.06 | 0.36 | 0.20 |

| Chlorite | 0.15 | 0.11 | 0.21 | 0.11 | 0.32 | 0.24 |

| Kaolinite | 0.05 | 0.04 | 0.04 | 0.03 | 0.05 | 0.03 |

| Illitic Clays | 0.19 | 0.32 | 0.32 | 0.19 | 0.47 | 0.36 |

| Calcite | 17.06 | 54.96 | 39.58 | 69.77 | 15.90 | 53.76 |

| Dolomite | 50.33 | 0.54 | 0.79 | 2.72 | 2.62 | 1.42 |

| Fe Oxides and Siderite | 0.22 | 0.22 | 0.30 | 0.08 | 0.36 | 0.19 |

| Ti Oxides | 0.02 | 0.03 | 0.02 | 0.02 | 0.03 | 0.02 |

| Apatite | 0.01 | 0.00 | 0.01 | 0.01 | 0.02 | 0.01 |

| Pyrite | 0.02 | 0.12 | 0.00 | 0.10 | 0.01 | 0.01 |

| Clinopyroxene and Amphibole | 0.01 | 0.01 | 0.01 | 0.02 | 0.05 | 0.03 |

| Zircon | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Ca Silicate High Ca | 0.59 | 1.20 | 1.66 | 0.01 | 0.03 | 0.01 |

| Ca Silicate Mid Ca | 12.03 | 15.72 | 21.44 | 0.86 | 0.82 | 0.97 |

| Ca Silicate Low Ca | 0.37 | 0.49 | 0.92 | 0.27 | 0.42 | 0.35 |

| Ca Silicate | 0.66 | 1.18 | 1.11 | 1.31 | 2.95 | 1.95 |

| Ca Al Silicate High Ca | 0.49 | 0.81 | 0.80 | 0.13 | 0.09 | 0.22 |

| Ca Silicate Na Mg Al | 0.01 | 0.00 | 0.01 | 8.67 | 29.82 | 17.06 |

| Ca Fe Silicate | 0.30 | 0.28 | 0.32 | 0.07 | 0.29 | 0.19 |

| Ca Mg Silicate | 1.04 | 1.31 | 2.00 | 1.34 | 3.61 | 2.09 |

| Fe Silicate | 0.07 | 0.09 | 0.10 | 0.06 | 0.27 | 0.12 |

| Ca Al Oxide | 0.34 | 0.33 | 0.40 | 0.00 | 0.00 | 0.00 |

| Ca Sulphates | 0.12 | 0.20 | 0.35 | 0.01 | 0.02 | 0.00 |

| Undifferentiated | 0.08 | 0.32 | 0.13 | 0.07 | 0.10 | 0.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adeleke, B.O.; Kinuthia, J.M.; Oti, J.; Pirrie, D.; Power, M. Mechanical and Microstructural Investigation of Geopolymer Concrete Incorporating Recycled Waste Plastic Aggregate. Materials 2024, 17, 1340. https://doi.org/10.3390/ma17061340

Adeleke BO, Kinuthia JM, Oti J, Pirrie D, Power M. Mechanical and Microstructural Investigation of Geopolymer Concrete Incorporating Recycled Waste Plastic Aggregate. Materials. 2024; 17(6):1340. https://doi.org/10.3390/ma17061340

Chicago/Turabian StyleAdeleke, Blessing O., John M. Kinuthia, Jonathan Oti, Duncan Pirrie, and Matthew Power. 2024. "Mechanical and Microstructural Investigation of Geopolymer Concrete Incorporating Recycled Waste Plastic Aggregate" Materials 17, no. 6: 1340. https://doi.org/10.3390/ma17061340