Wet–Dry Cycles and Microstructural Characteristics of Expansive Subgrade Treated with Sustainable Cementitious Waste Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation and Experimental Design

3. Results and Discussion

3.1. Wetting and Drying Cycles

3.2. The California Bearing Ratio (CBR)

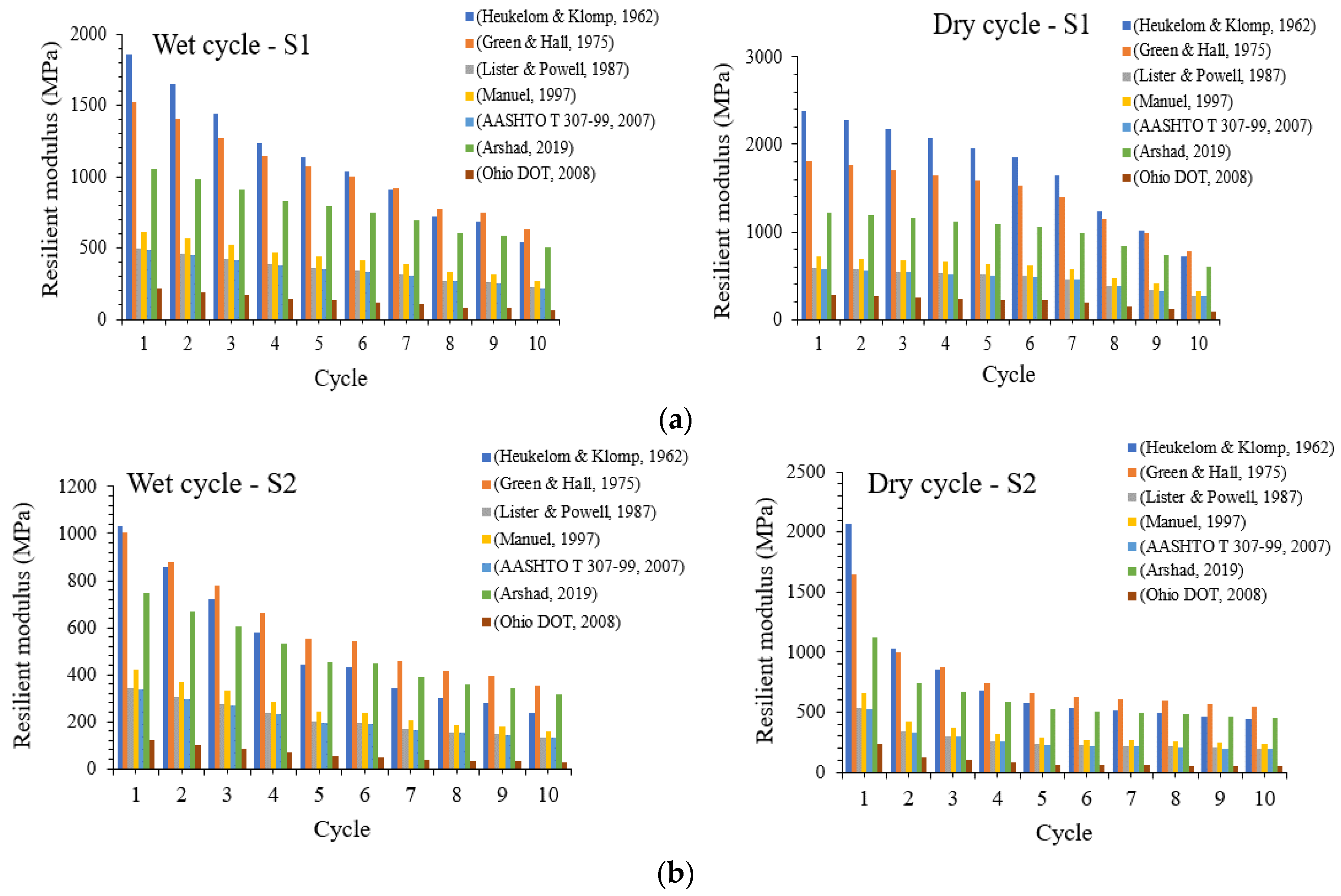

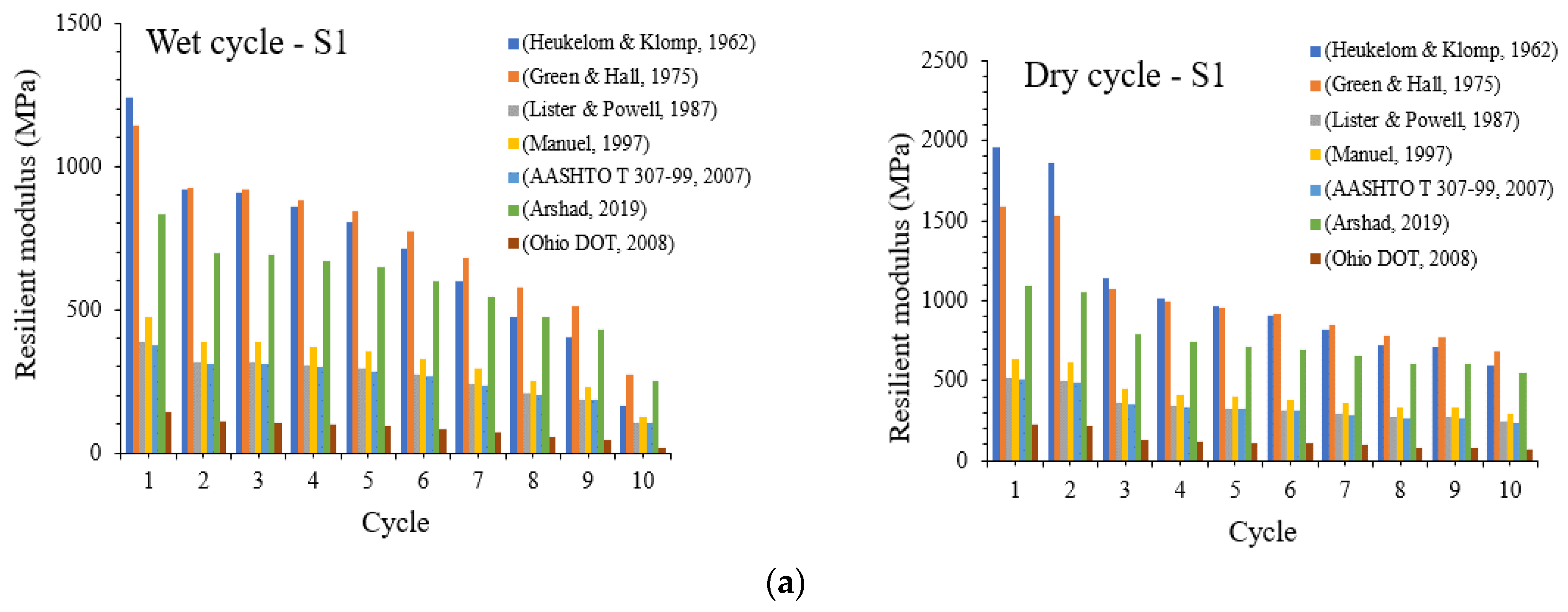

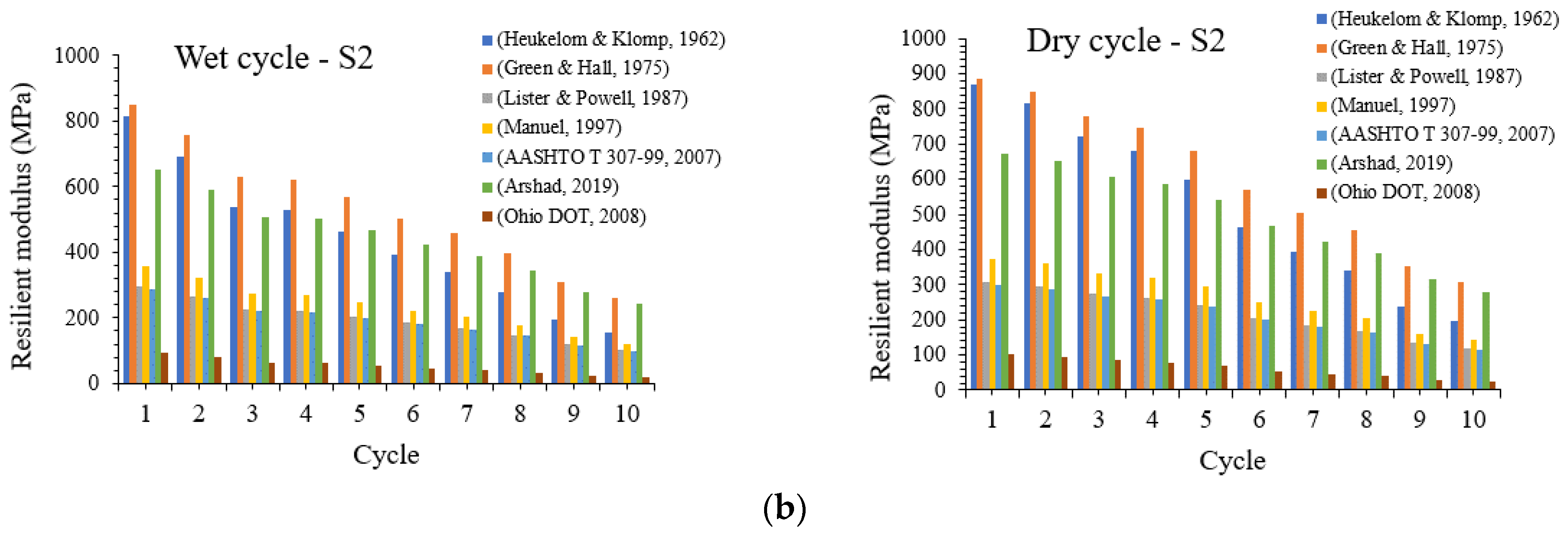

3.3. The Resilient Modulus

3.4. Microstructural Properties

4. Conclusions

- Expansive subgrade materials treated with a blend of GGBS and BDW showed higher resistance against degradation at the end of 10 cycles of wetting and drying. The higher strength at the end of the wetting–drying periods indicates that the addition of 11.75% BDW to the binder mix enhanced the resistance of the treated soils against expansion and shrinkage cracks.

- The strength reduction over the wet–dry cycles was lower for samples treated with a blend of BDW. The addition of BDW increase the production of CHS gels due to the additional pozzolanic activity which increased interparticle bond under the wet–dry cycles.

- The result of mass loss analysis of the treated soils aligns with the bearing capacity results and the microstructural characteristics indicates that the addition of 11.75% BDW blends into the binder mix is a useful means of lowering the mass loss which occurs through constant swelling and shrinking leading to the breakdown of the bonds. Lower mass loss indicates that subgrade treatment with a blend of BDW has higher resilience and could maintain strength in the event of rapidly fluctuating environmental conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, Z.; Peng, K.; Li, L.; Ma, Q.; Xiao, H.; Li, Z.; Ai, P. Effect of Wetting-Drying Cycles on Mechanical Behaviour and Electrical Resistivity of Unsaturated Subgrade Soil. Adv. Civ. Eng. 2019, 2019, 3465327. [Google Scholar] [CrossRef]

- Chen, R.; Ng, C. Impact of wetting–drying cycles on hydro-mechanical behavior of an unsaturated compacted clay. Appl. Clay Sci. 2013, 86, 38–46. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, Q.; Zhang, Y.; Dai, L.; Wu, H. Nondestructive Measurement of Water Content and Moisture Migration of Unsaturated Red Clays in South China. Adv. Mater. Sci. Eng. 2015, 2015, 542538. [Google Scholar] [CrossRef]

- Farulla, C.A.; Ferrari, A.; Romero, E. Mechanical Behaviour of Compacted Scaly Clay During Cyclic Controlled-Suction Testing. In Experimental Unsaturated Soil Mechanics; Schanz, T., Ed.; Springer Proceedings in Physics; Springer: Berlin/Heidelberg, Germany, 2007; Volume 112. [Google Scholar] [CrossRef]

- Holtz, W.G. Expansive Clays—Properties and Problems. Q. Colo. Sch. Mines 1973, 54, 89–125. [Google Scholar]

- Soltani, A.; Deng, A.; Taheri, A.; O’Kelly, B. Intermittent swelling and shrinkage of a highly expansive soil treated with polyacrylamide. J. Rock Mech. Geotech. Eng. 2022, 14, 252–261. [Google Scholar] [CrossRef]

- Zhang, M.; Tian, Z.; Zhu, Q.; Chen, J. In-situ assessment of soil shrinkage and swelling behavior and hydro-thermal regimes with a thermo-time domain reflectometry technique. Soil Tillage Res. 2023, 227, 105617. [Google Scholar] [CrossRef]

- Gens, A.; Sánchez, M.; Sheng, D. On constitutive modelling of unsaturated soils. Acta Geotech. 2006, 1, 137–147. [Google Scholar] [CrossRef]

- Kim, J.; Hwang, W.; Kim, Y. Effects of hysteresis on hydro-mechanical behavior of unsaturated soil. Eng. Geol. 2018, 245, 1–9. [Google Scholar] [CrossRef]

- Chertkov, V. Physical modeling of the soil swelling curve vs. the shrinkage curve. Adv. Water Resour. 2012, 44, 66–84. [Google Scholar] [CrossRef]

- Fernandes, M.; Denis, A.; Fabre, R.; Lataste, J.-F.; Chrétien, M. In situ study of the shrinkage-swelling of a clay soil over several cycles of drought-rewetting. Eng. Geol. 2015, 192, 63–75. [Google Scholar] [CrossRef]

- Amakye, S.Y.O.; Abbey, S.J.; Booth, C.A.; Oti, J. Road Pavement Thickness and Construction Depth Optimization Using Treated and Untreated Artificially-Synthesized Expansive Road Subgrade Materials with Varying Plasticity Index. Materials 2022, 15, 2773. [Google Scholar] [CrossRef]

- Jeremiah, J.J.; Abbey, S.J.; Booth, C.A.; Kashyap, A. Behaviour and Microstructural Characteristics of Lime-GGBS-Treated Kaolin Clay Contaminated with Gypsum. Materials 2023, 16, 874. [Google Scholar] [CrossRef]

- Tripathy, S.; Rao, K.S.S. Cyclic Swell–Shrink Behaviour of a Compacted Expansive Soil. Geotech. Geol. Eng. 2009, 27, 89–103. [Google Scholar] [CrossRef]

- Navagire, O.P.; Sharma, S.K.; Rambabu, D. Stabilization of black cotton soil with coal bottom ash. Mater. Today Proc. 2022, 52, 979–985. [Google Scholar] [CrossRef]

- Amakye, S.Y.; Abbey, S.J.; Booth, C.A.; Mahamadu, A. Enhancing the engineering properties of subgrade materials using processed waste: A review. Geotechnics 2021, 1, 307–329. [Google Scholar] [CrossRef]

- Tiwari, N.; Satyam, N.; Puppala, A.J. Strength and durability assessment of expansive soil stabilized with recycled ash and natural fibers. Transp. Geotech. 2021, 29, 100556. [Google Scholar] [CrossRef]

- Abbey, S.J.; Eyo, E.U.; Oti, J.; Amakye, S.Y.; Ngambi, S. Mechanical Properties and Microstructure of Fibre-Reinforced Clay Blended with By-Product Cementitious Materials. Geosciences 2020, 10, 241. [Google Scholar] [CrossRef]

- Khadka, S.D.; Jayawickrama, P.W.; Senadheera, S.; Segvic, B. Stabilization of highly expansive soils containing sulfate using metakaolin and fly ash based geopolymer modified with lime and gypsum. Transp. Geotech. 2020, 23, 100327. [Google Scholar] [CrossRef]

- Pandey, A.; Schwab, P.; Little, D.N. Optimization of magnesium phosphate cement: Stabilization of a kaolinitic soil. Transp. Geotech. 2022, 37, 100854. [Google Scholar] [CrossRef]

- Mohanty, S.; Roy, N.; Singh, S.P.; Sihag, P. Strength and durability of flyash, GGBS and cement clinker stabilized dispersive soil. Cold Reg. Sci. Technol. 2021, 191, 103358. [Google Scholar] [CrossRef]

- Jiang, N.; Du, Y.; Liu, K. Durability of lightweight alkali-activated ground granulated blast furnace slag (GGBS) stabilized clayey soils subjected to sulfate attack. Appl. Clay Sci. 2018, 161, 70–75. [Google Scholar] [CrossRef]

- Peethamparan, S.; Olek, J.; Lovell, J. Influence of chemical and physical characteristics of cement kiln dusts (CKDs) on their hydration behavior and potential suitability for soil stabilization. Cem. Concr. Res. 2008, 38, 803–815. [Google Scholar] [CrossRef]

- Eyo, E.U.; Ng’ambi, S.; Abbey, S.J. Incorporation of a nanotechnology-based additive in cementitious products for clay stabilisation. J. Rock Mech. Geotech. Eng. 2020, 12, 1056–1069. [Google Scholar] [CrossRef]

- Miller, G.A.; Azad, S. Influence of soil type on stabilization with cement kiln dust. Constr. Build. Mater. 2000, 14, 89–97. [Google Scholar] [CrossRef]

- Abbey, S.J.; Ngambi, S.; Coakley, E. Effect of cement and by-product material inclusion on plasticity of deep mixing improved soils. Int. J. Civ. Eng. Technol. 2016, 7, 265–274. [Google Scholar]

- Abbey, S.J.; Ngambi, S.; Olubanwo, A.O.; Tetteh, F.K. Strength and hydraulic conductivity of cement and by-product cementitious materials improved soil. Int. J. Appl. Eng. Res. 2018, 13, 8684–8694. [Google Scholar]

- Eyo, E.U.; Ng’Ambi, S.; Abbey, S.J. Performance of clay stabilized by cementitious materials and inclusion of zeolite/alkaline metals-based additive. Transp. Geotech. 2020, 23, 100330. [Google Scholar] [CrossRef]

- Rao, S.M.; Reddy, B.V.V.; Muttharam, M. The impact of cyclic wetting and drying on the swelling behaviour of stabilized expansive soils. Eng. Geol. 2001, 60, 223–233. [Google Scholar] [CrossRef]

- Consoli, N.C.; Samaniego, Q.R.A.; Gonz´alez, L.E.; Bittar, E.J.; Cuisinier, O. Impact of Severe Climate Conditions on Loss of Mass, Strength, and Stiffness of Compacted Fine-Grained Soils-Portland Cement Blends. J. Mater. Civ. Eng. 2018, 30, 04018174. [Google Scholar] [CrossRef]

- Wassermann, A.; Abdallah, A.; Cuisinier, O. Impact of wetting and drying cycles on the mechanical behaviour of a cement-treated soil. Transp. Geotech. 2022, 36, 100804. [Google Scholar] [CrossRef]

- Ying, Z.; Benahmed, N.; Cui, Y.; Duc, M. Wetting-drying cycle effect on the compressibility of lime-treated soil accounting for wetting fluid nature and aggregate size. Eng. Geol. 2022, 307, 106778. [Google Scholar] [CrossRef]

- ASTM D559/D559M-15; Standard Test Methods for Wetting and Drying Compacted Soil-Cement Mixture1. ASTM: West Conshohocken, PA, USA, 2016.

- BS EN 13286-47; Unbound and Hydraulically Bound Mixtures—Test Methods for the Determination of California Bearing Ratio, Immediate Bearing Index and Linear Swelling. British Standards Institution: London, UK, 2021.

- BS EN 197-1; Cement Composition, Specifications and Conformity Criteria for Common Cements. British Standards Institution: London, UK, 2011.

- BS EN 459-1; Building Lime Definitions, Specifications and Conformity Criteria. British Standards Institution: London, UK, 2015.

- BS EN 771-1:2011+A1:2015; Specification for Masonry Units. Clay Masonry Units. British Standards Institution: London, UK, 2015.

- BS EN 15167-1:2006; Ground Granulated Blast Furnace Slag for Use in Concrete, Mortar and Grout Definitions, Specifications and Conformity Criteria. British Standards Institution: London, UK, 2006.

- BS EN 13286-2-2012; Unbound and Hydraulically Bound Mixtures—Test Methods for Laboratory Reference Density and Water Content. Proctor Compaction. British Standards Institution: London, UK, 2012.

- BS EN ISO 17892-1-2021; Geotechnical Investigation and Testing. Laboratory Testing of Soil—Determination of Water Content. British Standards Institution: London, UK, 2021.

- BS 1377-4:1990; Methods of Test for Soils for Civil Engineering Purposes—Compaction—Related Tests. British Standards Institution: London, UK, 1990.

- Amakye, S.Y.O.; Abbey, S.J.; Booth, C.A. DMRB Flexible Road Pavement Design Using Re-Engineered Expansive Road Subgrade Materials with Varying Plasticity Index. Geotechnics 2022, 2, 395–411. [Google Scholar] [CrossRef]

- Amakye, S.Y.O.; Abbey, S.J.; Booth, C.A.; Oti, J. Performance of Sustainable Road Pavements Founded on Clay Subgrades Treated with Eco-Friendly Cementitious Materials. Sustainability 2022, 14, 12588. [Google Scholar] [CrossRef]

- Harichane, K.; Ghrici, M.; Khebizi, W.; Missoum, W. Effect of the Combination of Lime and Natural Pozzolana on the Durability of Clayey Soils. Electron. J. Geotech. Eng. 2010, 15, 1194–1210. Available online: https://www.researchgate.net/publication/228501953_Effect_of_the_Combination_of_Lime_and_Natural_Pozzolana_on_the_Durability_of_Clayey_Soils (accessed on 8 July 2022).

- Ahmadi, S.; Ghasemzadeh, H.; Changizi, F. Effects of Thermal Cycles on Microstructural and Functional Properties of nano Treated Clayey Soil. Eng. Geol. 2021, 280, 105929. [Google Scholar] [CrossRef]

- Zihms, S.G.; Switzer, C.; Karstunen, M.; Tarantino, A. Understanding the effect of high temperature processes on the engineering properties of soils. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 2–6 September 2013; Available online: https://www.cfms-sols.org/sites/default/files/Actes/3427-3430.pdf (accessed on 8 July 2022).

- Tu, Y.; Zhang, R.; Zhong, Z.; Chai, H. The strength behaviour and desiccation crack development of silty clay subjected to wetting-drying cycles. Front. Earth Sci. Sec. Geohazard Georisks 2022, 10, 852820. [Google Scholar] [CrossRef]

- British Lime Association. Soil Stabilisation with Lime, Cement and Other Binders. 2015. Available online: https://britishlime.org/documents/Plantworx_Presentation_Britpave_Plantworx_Stabilisation_Chemistry_Presentation_2015_2.pdf (accessed on 8 July 2022).

- Kinuthia, J.M.; Nidzam, R.M. Towards zero industrial waste: Utilisation of brick dust waste in sustainable construction. Waste Manag. 2011, 31, 1867–1878. [Google Scholar] [CrossRef]

- Amakye, S.Y.O.; Abbey, S.J.; Booth, C.A. Road pavement defect investigation using treated and untreated expansive road subgrade materials with varying plasticity index. Transp. Eng. 2022, 9, 100123. [Google Scholar] [CrossRef]

- Rogers, S.B. Evaluation and Testing of Brick Dust as a Pozzolanic Additive LIME Mortars for Architectural Conservation. Master’s Thesis, University of Pennsylvania, Philadelphia, PA, USA, 2011. Available online: https://repository.upenn.edu/cgi/viewcontent.cgi?article=1178&context=hp_theses (accessed on 16 July 2022).

- Hewlett, P. Lea’s Chemistry of Cement and Concrete, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2003; pp. 637–678. ISBN 978-0-7506-6256-7. [Google Scholar]

- Amakye, S.Y.; Abbey, S.J.; Olubanwo, A.O. Consistency and mechanical properties of sustainable concrete blended with brick dust waste cementitious materials. SN Appl. Sci. 2021, 3, 420. [Google Scholar] [CrossRef]

- Hidalgo, C.; Carvajal, G.; Muñoz, F. Laboratory Evaluation of Finely Milled Brick Debris as a Soil Stabilizer. Sustainability 2019, 11, 967. [Google Scholar] [CrossRef]

- Manuel, A. Development of a Rational Probabilistic Approach for Flexible Pavement Analysis; University of Maryland: College Park, MD, USA, 1997; Volume 2. [Google Scholar]

- van Til, C.J.; Mccullough, B.F.; Vallerga, B.A.; Hick, R.G. Evaluation of AASHTO Interim Guide for the Design of Pavement Structures; National Cooperative Highway Research Program: Washington, DC, USA, 1972. [Google Scholar]

- Shaqlaih, A.; White, L.; Zaman, M. Resilient Modulus Modeling with Information Theory Approach. Int. J. Géoméch. 2013, 13, 384–389. [Google Scholar] [CrossRef]

- Zaman, M.; Solanki, P.; Ebrahimi, A.; White, L. Neural Network Modeling of Resilient Modulus Using Routine Subgrade Soil Properties. Int. J. Géoméch. 2010, 10, 1–12. [Google Scholar] [CrossRef]

- AASHTO T 307-99; Standard Method of Test for Determining the Resilient Modulus of Soils and Aggregate Materials. American Association of State and Highway Transportation Officials: Washington, DC, USA, 2007.

- Arshad, M. Development of a Correlation between the Resilient Modulus and CBR Value for Granular Blends Containing Natural Aggregates and RAP/RCA Materials. Adv. Mater. Sci. Eng. 2019, 2019, 1–16. [Google Scholar] [CrossRef]

- Green, J.L.; Hall, J.W. Nondestructive Vibratory Testing of Airport Pavements. Volume 1. Experimental Test Results and Development of Evaluation Methodology and Procedure; U.S. Department of Transportation: Washington, DC, USA, 1975. [Google Scholar]

- Heukelom, W.; Klomp, A. Dynamic Testing as a Means of Controlling Pavements during and after Construction. In Proceedings of the International Conference on the Structural Design of Asphalt Pavements, University of Michigan, Ann Arbor, MI, USA, 20–24 August 1962. [Google Scholar]

- Lister, N.W.; Powell, D. Design practices for bituminous pavements in the United Kingdom. In Proceedings of the 6th International Conference on the Structural Design of Asphalt Pavements, Ann Arbor, MI, USA, 13–17 July 1987. [Google Scholar]

- Ohio Department of Transportation. Pavement Design Manual; Ohio Department of Transportation: Columbus, OH, USA, 2008. [Google Scholar]

- Abbey, S.J.; Eyo, E.U.; Jeremiah, J.J. Experimental Study on Early Age Characteristics of Lime-GGBS-Treated Gypseous Clays under Wet–Dry Cycles. Geotechnics 2021, 1, 402–415. [Google Scholar] [CrossRef]

| Oxide (%) | SiO2 | Al2O3 | Fe2O3 | FeO | MgO | CaO | K2O | SO3 | TiO2 | Na2O | Trace | L.O.I |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bentonite | 63.02 | 21.08 | 3.25 | 0.35 | 2.67 | 0.65 | - | - | - | 2.57 | 0.72 | 5.64 |

| Kaolinite | 48.5 | 36.0 | 1.00 | - | 0.30 | 0.05 | 2.15 | - | 0.06 | 0.15 | - | 11.7 |

| Cement | 20 | 6.0 | 3.0 | - | 4.21 | 63 | - | 2.30 | - | - | - | 0.80 |

| GGBS | 35.35 | 11.59 | 0.35 | - | 8.04 | 41.99 | - | 0.23 | - | - | - | - |

| Lime | 3.25 | 0.19 | 0.16 | - | 0.45 | 89.2 | 0.01 | 2.05 | - | - | - | - |

| BDW | 52 | 41 | 0.7 | - | 0.12 | 4.32 | 0.53 | 0.33 | 0.65 | 0.05 | - | 2.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbey, S.J.; Amakye, S.Y.O.; Eyo, E.U.; Booth, C.A.; Jeremiah, J.J. Wet–Dry Cycles and Microstructural Characteristics of Expansive Subgrade Treated with Sustainable Cementitious Waste Materials. Materials 2023, 16, 3124. https://doi.org/10.3390/ma16083124

Abbey SJ, Amakye SYO, Eyo EU, Booth CA, Jeremiah JJ. Wet–Dry Cycles and Microstructural Characteristics of Expansive Subgrade Treated with Sustainable Cementitious Waste Materials. Materials. 2023; 16(8):3124. https://doi.org/10.3390/ma16083124

Chicago/Turabian StyleAbbey, Samuel J., Samuel Y. O. Amakye, Eyo U. Eyo, Colin A. Booth, and Jeremiah J. Jeremiah. 2023. "Wet–Dry Cycles and Microstructural Characteristics of Expansive Subgrade Treated with Sustainable Cementitious Waste Materials" Materials 16, no. 8: 3124. https://doi.org/10.3390/ma16083124

APA StyleAbbey, S. J., Amakye, S. Y. O., Eyo, E. U., Booth, C. A., & Jeremiah, J. J. (2023). Wet–Dry Cycles and Microstructural Characteristics of Expansive Subgrade Treated with Sustainable Cementitious Waste Materials. Materials, 16(8), 3124. https://doi.org/10.3390/ma16083124