Influence of the Second-Phase Resin Structure on the Interfacial Shear Strength of Carbon Fiber/Epoxy Resin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation

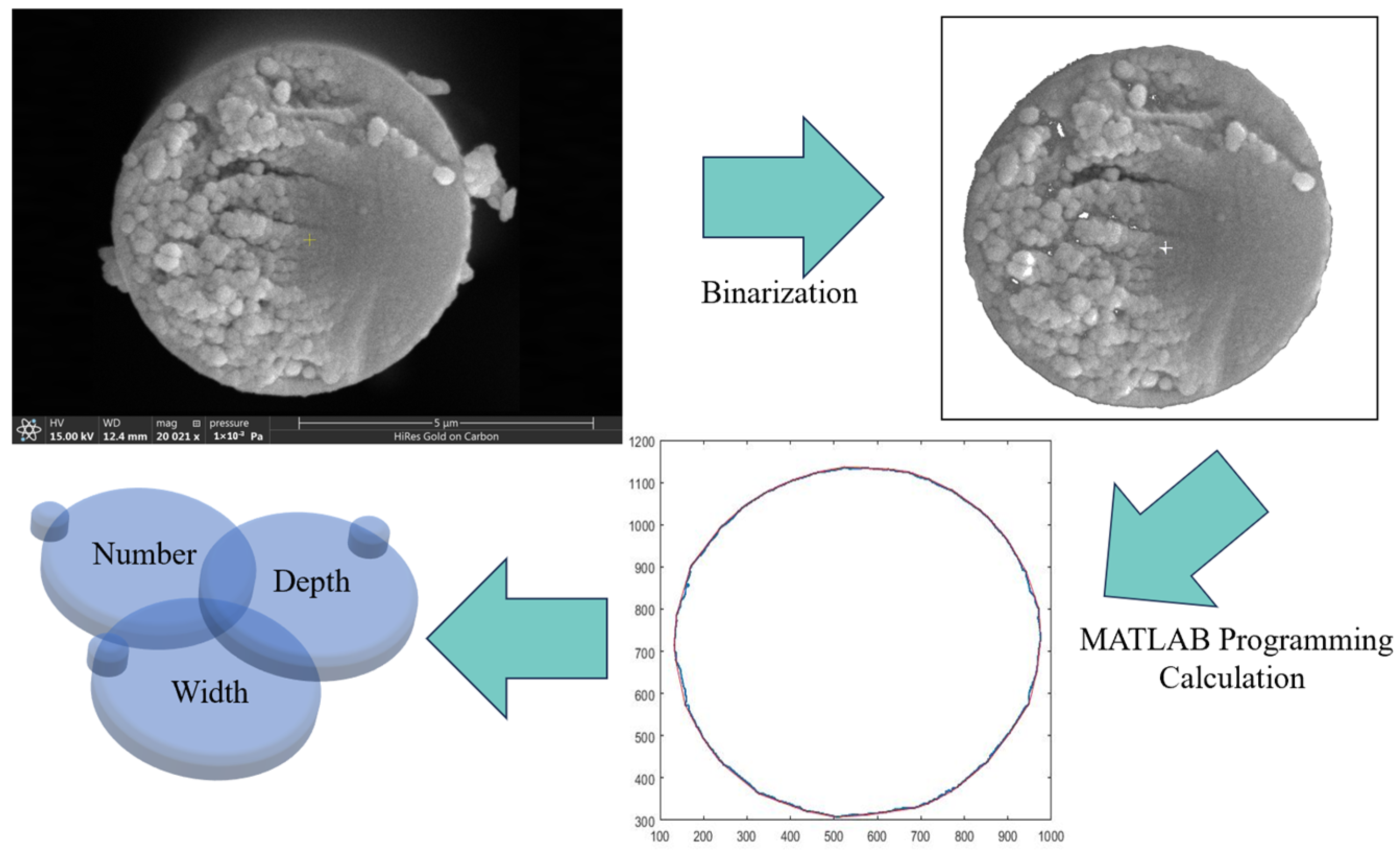

2.3. Tests and Measurements

3. Results and Discussion

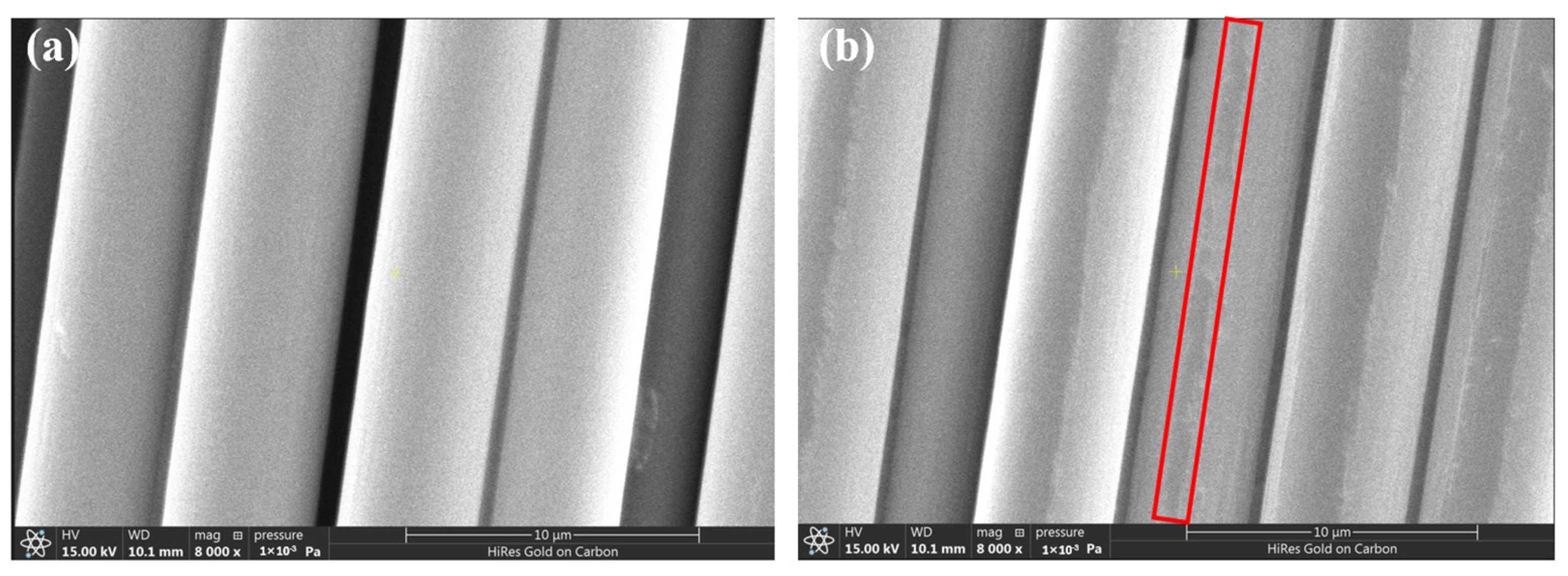

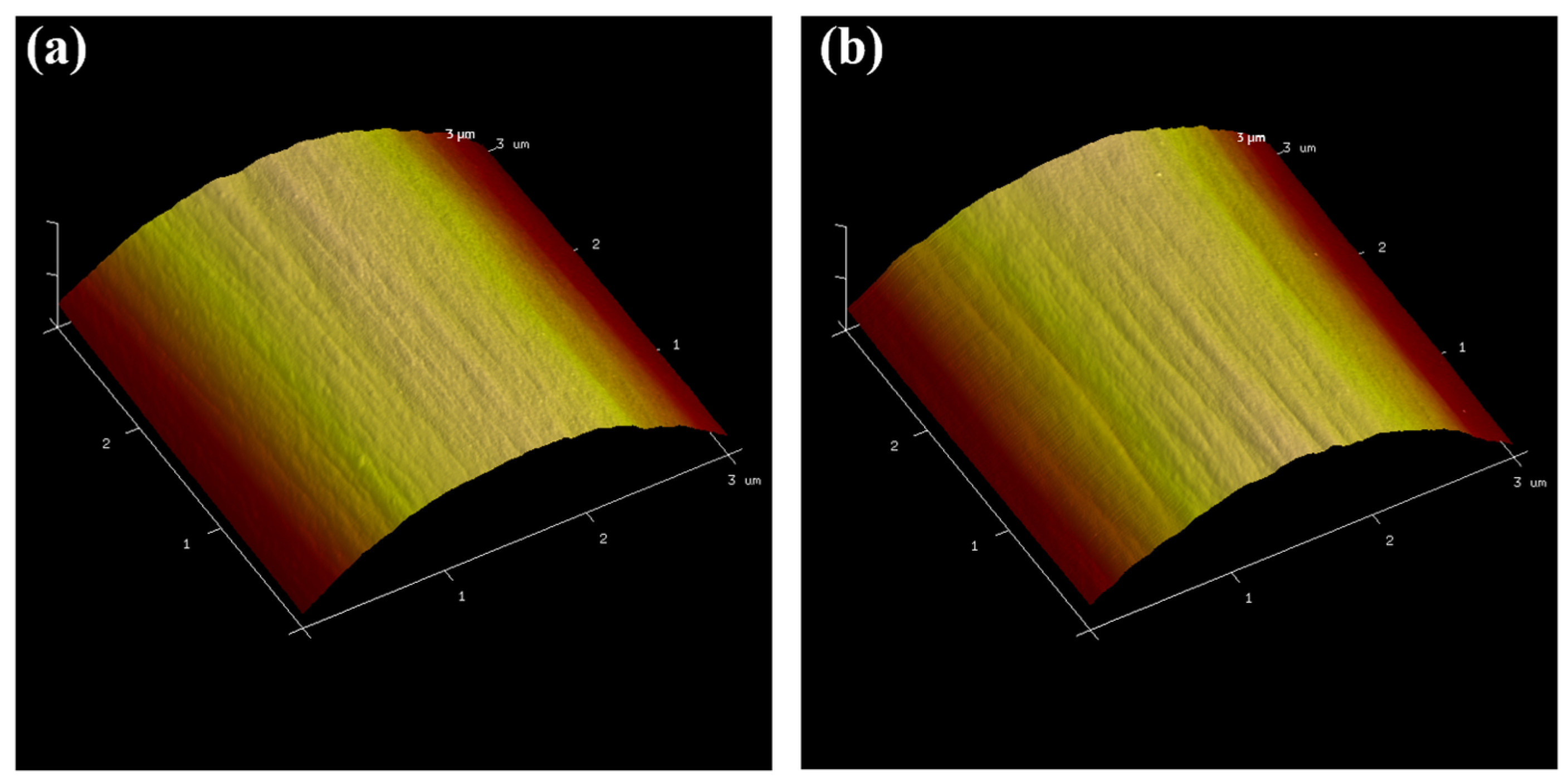

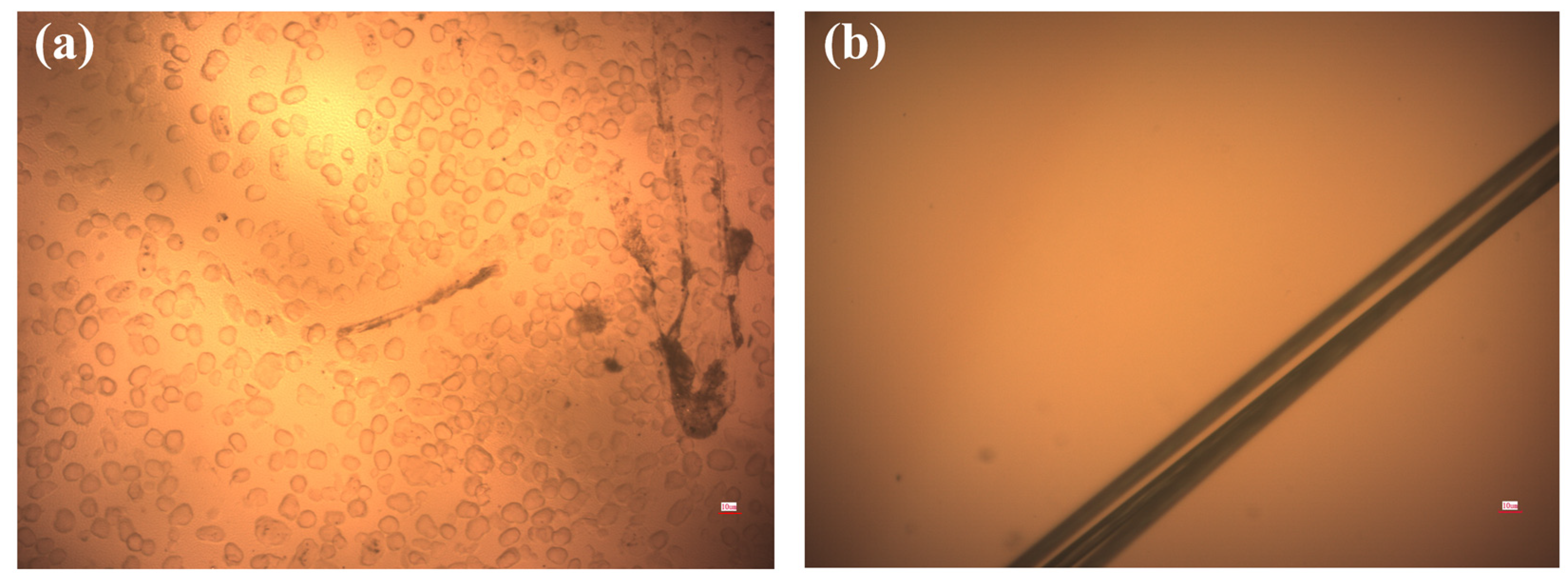

3.1. Surface Microstructure of CFs

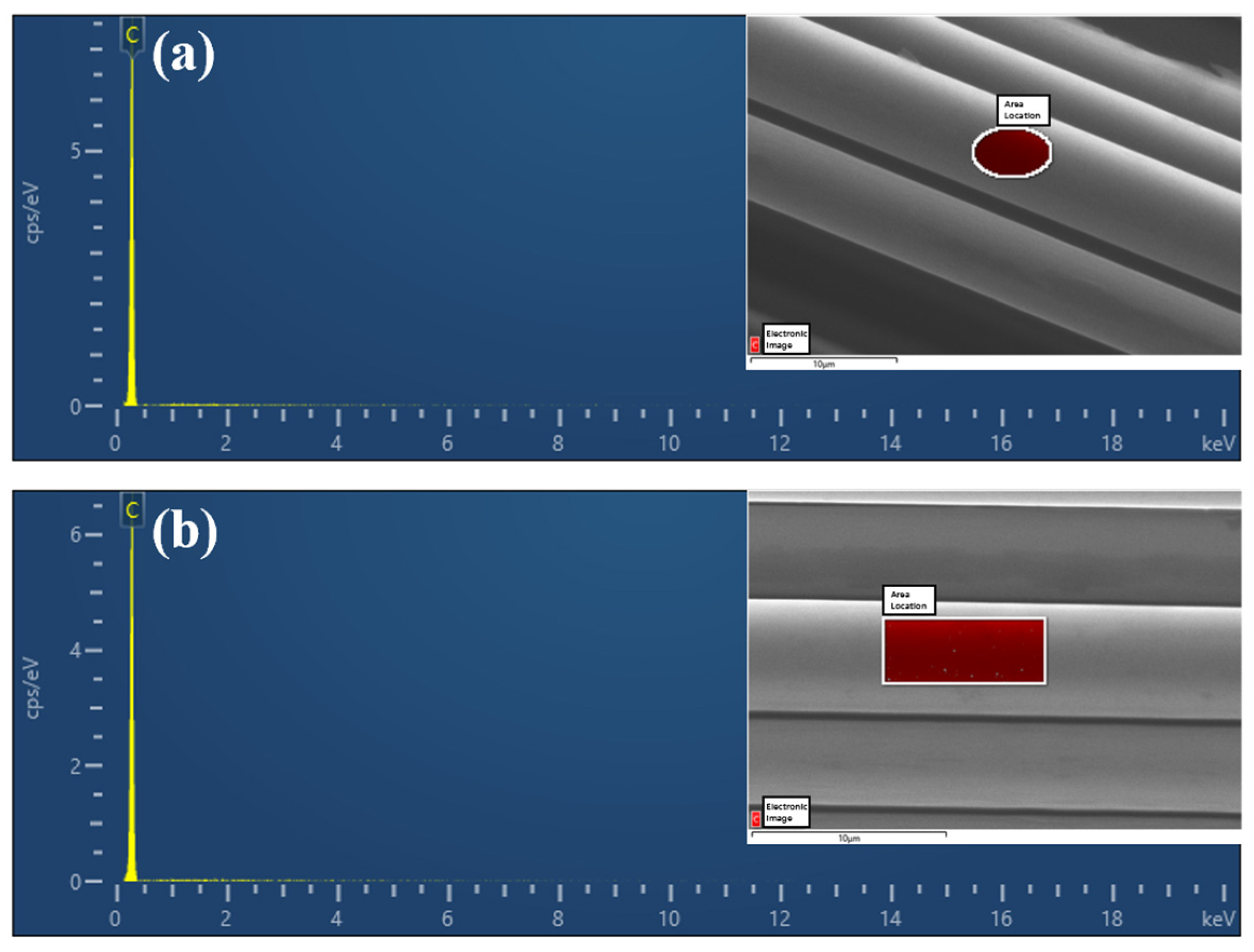

3.2. Physicochemical Characterization and Surface Energy of CFs

3.3. Microphase Structure of AC53X

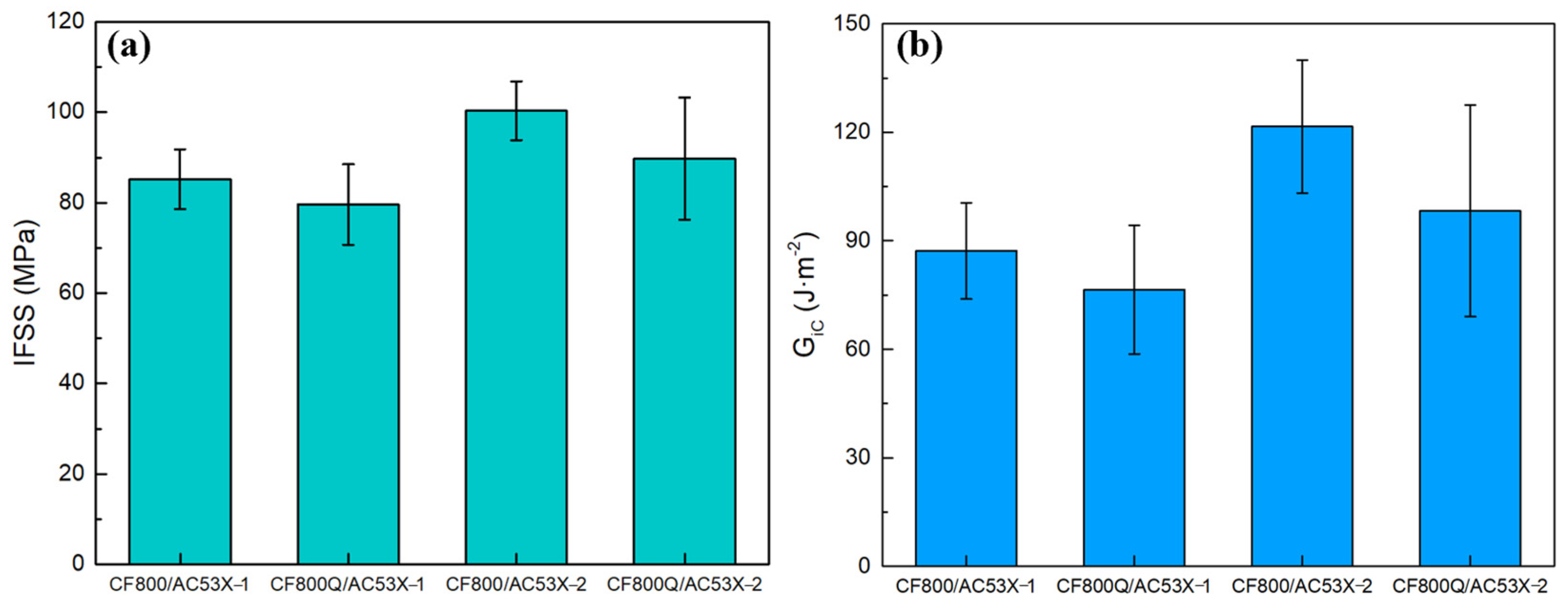

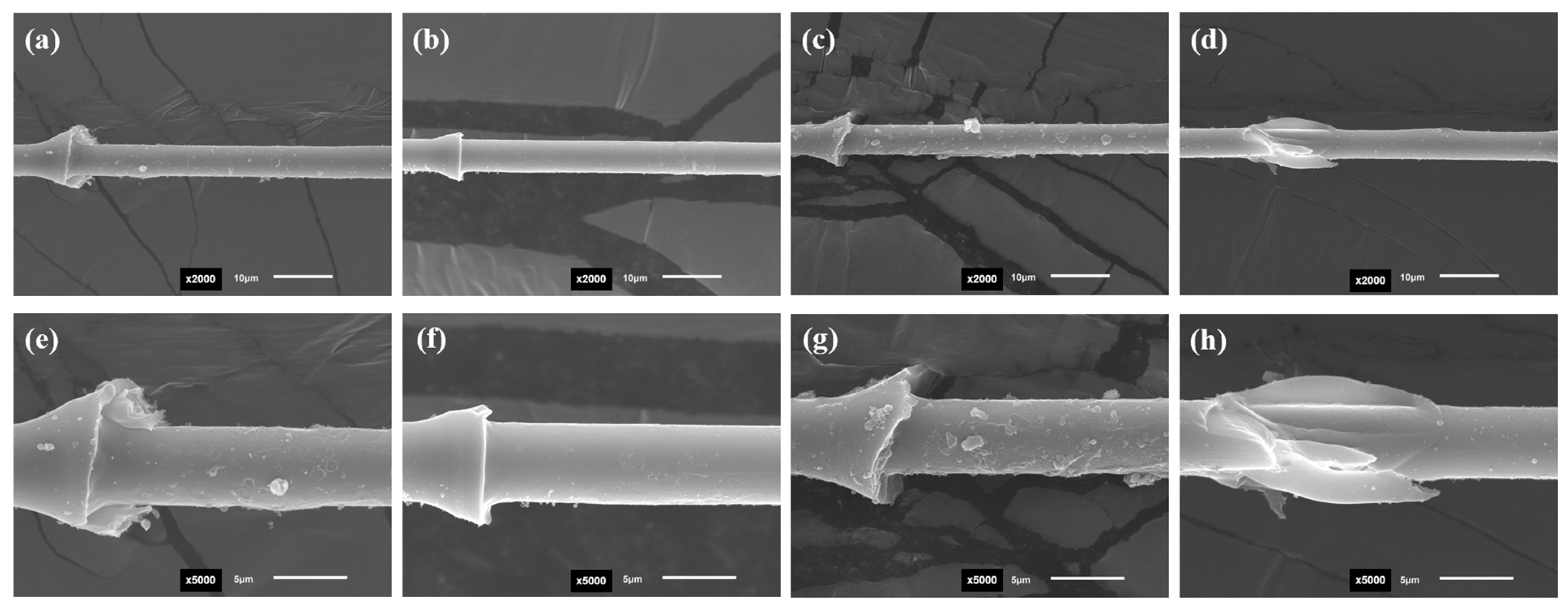

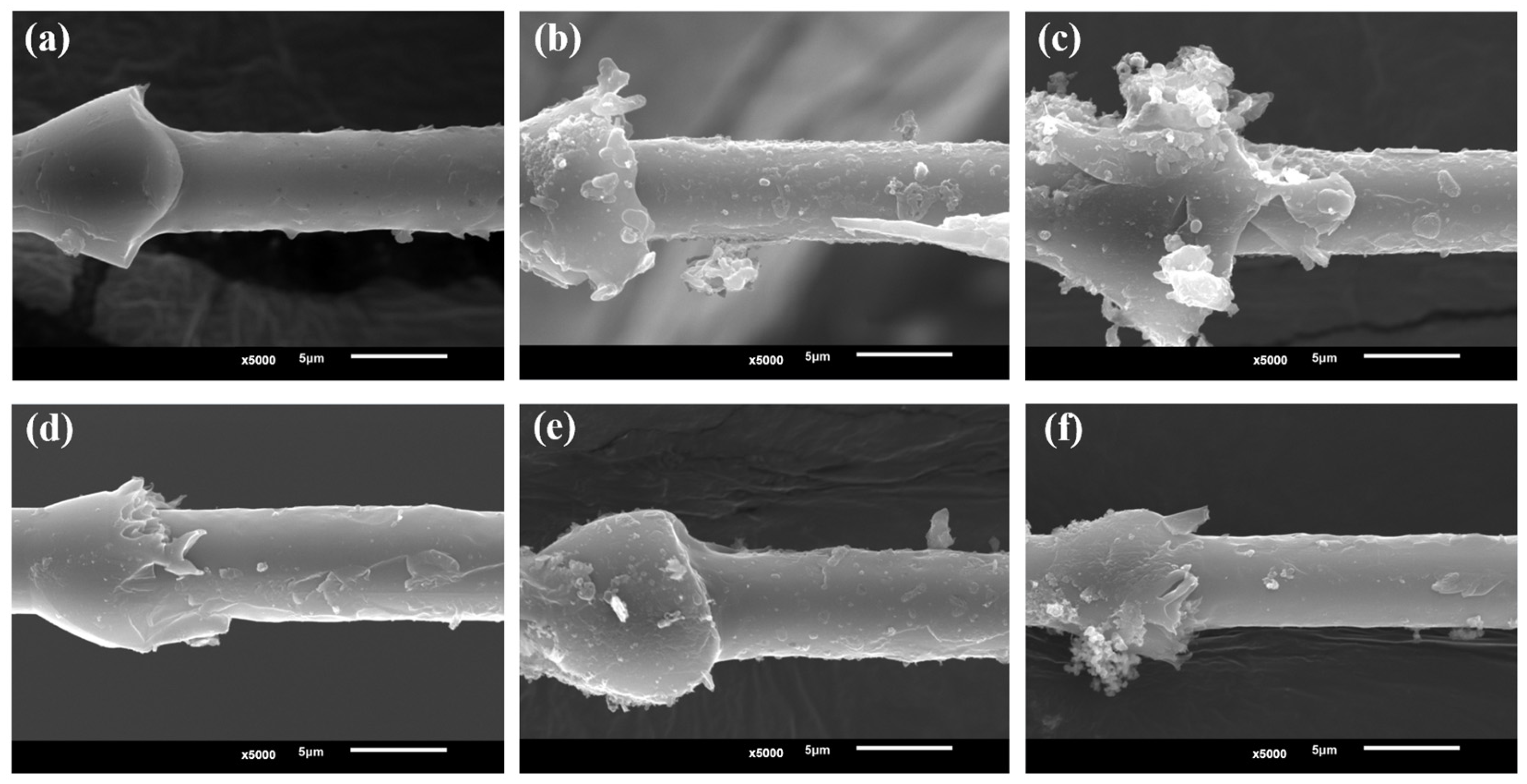

3.4. Micro-Interfacial Performance of CF/Epoxy Composites

3.5. IFSS after Hygrothermal Treatment

4. Conclusions

- (1)

- The surface of CF800 shows a smooth characterization; after desizing, the surface roughness shows no difference, the number of grooves decreases, and the width and depth of the grooves slightly increase.

- (2)

- The C content of CF800 rises after desizing, the ratio of inactive -C-C/-C-H rises, decreases, and the sizing process has the positive effect of increasing the interfacial bonding properties of the CF/epoxy.

- (3)

- The microphase structure of the resin samples shows that AC53X-1 has a double-phase structure and AC53X-2 has a single-phase structure.

- (4)

- The IFSS of CF800Q/AC53X-1 is lower than that of the corresponding sizing system, indicating that the presence of the sizing agent is beneficial to the interfacial bonding between CF and epoxy. The IFSS of CF800Q/AC53X-2 is higher than that of CF800Q/AC53X-1, showing that the introduction of the second phase in the resin reduces the interfacial bonding performance between the CF and epoxy.

- (5)

- After hygrothermal treatment, the IFSS value and property retention of CF800/AC53X-2 show a high level. The introduction of the second-phase resin brings about more hidden defect sources, allowing water molecules to diffuse along the interfacial paths between the two resins, which in turn creates defects and brings about a consequent reduction in the interfacial performance of the composite.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rafique, I.; Kausar, A.; Muhammad, B. Epoxy resin composite reinforced with carbon fiber and inorganic filler: Overview on preparation and properties. Polym.-Plast. Technol. Eng. 2016, 55, 1653–1672. [Google Scholar] [CrossRef]

- Chung, D.D.L. Processing-structure-property relationships of continuous carbon fiber polymer-matrix composites. Mater. Sci. Eng. R 2017, 113, 1–29. [Google Scholar] [CrossRef]

- Sprenger, S. Epoxy resin composites with surface-modified silicon dioxide nanoparticles: A review. J. Appl. Polym. Sci. 2013, 130, 1421–1428. [Google Scholar] [CrossRef]

- Tian, Z.; Wang, Y.; Hou, X. Review of chemical recycling and reuse of carbon fiber reinforced epoxy resin composites. New Carbon Mater. 2022, 37, 1021–1041. [Google Scholar] [CrossRef]

- Bai, T.; Wang, D.; Yan, J.; Cheng, W.; Han, G. Wetting mechanism and interfacial bonding performance of bamboo fiber reinforced epoxy resin composites. Compos. Sci. Technol. 2021, 213, 108951. [Google Scholar] [CrossRef]

- Hamerton, I.; Kratz, J. The Use of Thermosets in Modern Aerospace Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 303–340. [Google Scholar]

- Matykiewicz, D.; Skórczewska, K. Characteristics and application of eugenol in the production of epoxy and thermosetting resin composites: A review. Materials 2022, 15, 4824. [Google Scholar] [CrossRef] [PubMed]

- Ligoda-Chmiel, J.; Śliwa, R.E.; Potoczek, M. Flammability and acoustic absorption of alumina foam/tri-functional epoxy resin composites manufactured by the infiltration process. Compos. Part B Eng. 2017, 112, 196–202. [Google Scholar] [CrossRef]

- Hernandez Michelena, A.; Summerscales, J.; Graham-Jones, J.; Hall, W. Sustainable manufacture of natural fibre reinforced epoxy resin composites with coupling agent in the hardener. J. Compos. Sci. 2022, 6, 97. [Google Scholar] [CrossRef]

- Fellahi, S.; Chikhi, N.; Bakar, M. Modification of epoxy resin with kaolin as a toughening agent. J. Appl. Polym. Sci. 2001, 82, 861–878. [Google Scholar] [CrossRef]

- Unnikrishnan, K.P.; Thachil, E.T. Toughening of epoxy resins. Des. Monomers Polym. 2006, 9, 129–152. [Google Scholar] [CrossRef]

- Ramos, V.D.; Da Costa, H.M.; Soares, V.L.P.; Nascimento, R.S.V. Modification of epoxy resin: A comparison of different types of elastomer. Polym. Test. 2005, 24, 387–394. [Google Scholar] [CrossRef]

- Chikhi, N.; Fellahi, S.; Bakar, M. Modification of epoxy resin using reactive liquid (ATBN) rubber. Eur. Polym. J. 2002, 38, 251–264. [Google Scholar] [CrossRef]

- Mohan, P. A critical review: The modification, properties, and applications of epoxy resins. Polym.-Plast. Technol. Eng. 2013, 52, 107–125. [Google Scholar] [CrossRef]

- Ricciardi, M.R.; Papa, I.; Langella, A.; Langella, T.; Lopresto, V.; Antonucci, V. Mechanical properties of glass fibre composites based on nitrile rubber toughened modified epoxy resin. Compos. Part B Eng. 2018, 139, 259–267. [Google Scholar] [CrossRef]

- Mathew, V.S.; George, S.C.; Parameswaranpillai, J.; Thomas, S. Epoxidized natural rubber/epoxy blends: Phase morphology and thermomechanical properties. J. Appl. Polym. Sci. 2014, 131, 1001–1007. [Google Scholar] [CrossRef]

- Barcia, F.L.; Amaral, T.P.; Soares, B.G. Synthesis and properties of epoxy resin modified with epoxy-terminated liquid polybutadiene. Polymer 2003, 44, 5811–5819. [Google Scholar] [CrossRef]

- Eissa, M.M.; Youssef, M.S.A.; Ramadan, A.M.; Amin, A. Poly(ester-amine) hyperbranched polymer as toughening and co-curing agent for epoxy/clay nanocomposite. Polym. Eng. Sci. 2013, 53, 1011–1020. [Google Scholar] [CrossRef]

- Cheng, Y.; Xiao, K.; Lin, Y.; Mai, Y.W. Numerical and experimental studies on the fracture behavior of rubber-toughened epoxy in bulk specimen and laminated composites. J. Mater. Sci. 2002, 37, 921–927. [Google Scholar]

- Gui, D.; Gao, X.; Hao, J.; Liu, J. Preparation and characterization of liquid crystalline polyurethane-imide modified epoxy resin composites. Polym. Eng. Sci. 2014, 54, 1704–1711. [Google Scholar] [CrossRef]

- Farooq, U.; Teuwen, J.; Dransfeld, C. Toughening of epoxy systems with interpenetrating polymer network (IPN): A review. Polymers 2020, 12, 1908. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, B.; Sun, M.; Li, L.; Wang, L.; Qin, C. Miscibility, morphology, mechanical, and thermodynamic properties of epoxy resins toughened with functionalized core-shell nanoparticles containing epoxy groups on the surface. Pigm. Resin Technol. 2013, 43, 181–189. [Google Scholar] [CrossRef]

- Brocks, T.; Ascione, L.; Ambrogi, V. Efficiency comparison of hyperbranched polymers as toughening agents for a one—Part epoxy resin. J. Mater. Res. 2015, 30, 869–878. [Google Scholar] [CrossRef]

- Girard-Reydet, E.; Sautereau, H.; Pascault, J.P.; Keates, P.; Navard, P.; Thollet, G.; Vigier, G. Reaction—Induced phase separation mechanisms in modified thermosets. Polymer 1998, 39, 2269–2280. [Google Scholar] [CrossRef]

- Mimura, K.; Ito, H.; Fujioka, H. Improvement of thermal and mechanical properties by control of morphologies in PES—Modified epoxy resins. Polymer 2000, 41, 4451–4459. [Google Scholar] [CrossRef]

- Li, J.; Xiang, Y.; Zheng, S. Hyperbranched block copolymer from AB(2) macromonomer: Synthesis and its reaction-induced microphase separation in epoxy thermosets. J. Polym. Sci. Part A Polym. Chem. 2016, 54, 368–380. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, S.; Chen, X.; Lu, Y.; Miao, M.; Zhang, D. Controllability of epoxy equivalent weight and performance of hyperbranched epoxy resins. Compos. Part B Eng. 2019, 160, 615–625. [Google Scholar] [CrossRef]

- Cai, W.; Yuan, Z.; Wang, Z.; Guo, Z.; Zhang, L.; Wang, J.; Liu, W.; Tang, T. Enhancing the toughness of epoxy resin by using a novel hyperbranched benzoxazine. React. Funct. Polym. 2021, 164, 104920. [Google Scholar] [CrossRef]

- Inoue, T. Reaction-induced phase decomposition in polymer blends. Prog. Polym. Sci. 1995, 20, 119–153. [Google Scholar] [CrossRef]

- Woo, E.M.; Mao, K.L. Interlaminar morphology effects on fracture resistance of amorphous polymer-modified epoxy /carbon fiber composites. Compos. Part A Appl. Sci. Manuf. 1996, 27, 625–631. [Google Scholar] [CrossRef]

- Venderbosch, R.W.; Peijst, T.; Meijer, H.E.H.; Lemstra, P.L. Fiber-reinforced composites with tailored interphases using PPE/epoxy blends as a matrix system. Compos. Part A Appl. Sci. Manuf. 1996, 27, 895–905. [Google Scholar] [CrossRef]

- Oyanguren, P.A.; Galante, M.J.; Andromaque, K.; Frontini, P.M.; Williams, R.J.J. Development of bicontinuous morphologies in polysulfone-epoxy blends. Polymer 1999, 40, 5249–5255. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, C.; Zhang, S.; Lin, X. Effect of surface modification on carbon fiber and its reinforced phenolic matrix composite. Appl. Surf. Sci. 2012, 259, 288–293. [Google Scholar] [CrossRef]

- Vedrtnam, A.; Sharma, S.P. Study on the performance of different nano-species used for surface modification of carbon fiber for interface strengthening. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105509. [Google Scholar] [CrossRef]

- Liu, H.; Ma, X.; Wang, K.; Zhong, X.; Bao, J. Preparation and properties of aminated MXene cross-linked polyimide aerogels. High Perform. Polym. 2023, 35, 923–935. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, X.; Song, C.; Zhang, Y.; Fang, Y.; Yang, B.; Wang, X. An effective surface modification of carbon fiber for improving the interfacial adhesion of polypropylene composites. Mater. Des. 2015, 88, 810–819. [Google Scholar] [CrossRef]

- Liu, H.; Sun, J.; Duan, Z.; Liu, Z.; Ma, X.; Lu, W.; Sun, T.; Li, Z.; Zhang, P.; Zhong, X.; et al. Study on properties influence of carbon fiber reinforced polyimide composites via surface modification using metal mesh. Polym. Compos. 2023, 44, 971–979. [Google Scholar] [CrossRef]

- Lee, E.; Lee, C.; Chun, Y.S.; Han, C.; Lim, D. Effect of hydrogen plasma-mediated surface modification of carbon fibers on the mechanical properties of carbon-fiber-reinforced polyetherimide composites. Compos. Part B Eng. 2017, 116, 451–458. [Google Scholar] [CrossRef]

- Chukov, D.; Nematulloev, S.; Torokhov, V.; Stepashkin, A.; Sherif, G.; Tcherdyntsev, V. Effect of carbon fiber surface modification on their interfacial interaction with polysulfone. Results Phys. 2019, 15, 102634. [Google Scholar] [CrossRef]

- Ilyin, S.O.; Brantseva, T.V.; Kotomin, S.V.; Antonov, S.V. Epoxy nanocomposites as matrices for aramid fiber-reinforced plastics. Polym. Compos. 2018, 39, E2167–E2174. [Google Scholar] [CrossRef]

- Ilyin, S.O.; Kotomin, S.V. Effect of nanoparticles and their anisometry on adhesion and strength in hybrid carbon-fiber-reinforced epoxy nanocomposites. J. Compos. Sci. 2023, 7, 147. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, Y.; Li, N.; Li, S.; Li, X.; Liu, Z.; Cheng, S.; Wang, K.; Du, S. Effect of polyetherimide sizing on surface properties of carbon fiber and interfacial strength of carbon fiber/polyetheretherketone composites. Polym. Compos. 2021, 42, 931–943. [Google Scholar] [CrossRef]

- Wu, Q.; Zhao, R.; Liu, Q.; Jiao, T.; Zhu, J.; Wang, F. Simultaneous improvement of interfacial strength and toughness between carbon fiber and epoxy by introducing amino functionalized ZrO2 on fiber surface. Mater. Des. 2018, 149, 15–24. [Google Scholar] [CrossRef]

- Dilsiz, N.; Wightman, J.P. Surface analysis of unsized and sized carbon fibers. Carbon 1999, 37, 1105. [Google Scholar] [CrossRef]

- Fowkes, F.M. Additivity of intermolecular forces at interfaces. I. determination of the contribution to surface and interfacial tensions of dispersion forces in various liquids. J. Phys. Chem. 1963, 67, 2538. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741. [Google Scholar] [CrossRef]

- Hoecker, F.; Karger Kocsis, J. Surface energetics of carbon fibers and its effects on the mechanical performance of CF/EP composites. J. Appl. Polym. Sci. 1996, 59, 139. [Google Scholar] [CrossRef]

| Sample | Rq/nm |

|---|---|

| CF800 | 11.06 ± 7.11 |

| CF800Q | 11.19 ± 6.83 |

| Sample | Number of Grooves | Width of Grooves (nm) | Depth of Grooves (nm) |

|---|---|---|---|

| CF800 | 122 | 135 | 12 |

| CF800Q | 96 | 176 | 15 |

| Name | Atomic % | |

|---|---|---|

| CF800 | CF800Q | |

| C 1s | 80.87 | 83.25 |

| O 1s | 16.48 | 11.72 |

| N 1s | 0.98 | 3.34 |

| Si 2p | 1.59 | 1.65 |

| S 2p | 0.07 | 0.04 |

| Name | Peak | B.E./eV | C 1 s Peaks in Different States B.E. (P.C., %) | |

|---|---|---|---|---|

| CF800 | CF800Q | |||

| -C-C/-C-H | 1 | 284.39 | 70.25 | 74.48 |

| -C-O | 2 | 285.8 | 21.34 | 23.70 |

| -C=O | 3 | 286.7 | 2.20 | 1.00 |

| -COOH | 4 | 288 | 6.21 | 0.82 |

| Sample | θ Water/° | θ Ethylene Glycol/° | θ Formamide/° | /mJ·m−2 | /mJ·m−2 | /mJ·m−2 |

|---|---|---|---|---|---|---|

| CF800 | 75.86 | 61.95 | 57.45 | 29.95 | 10.17 | 19.79 |

| CF800Q | 81.76 | 62.31 | 68.96 | 26.02 | 14.66 | 11.36 |

| Performance Retention/% | 1 Day | 3 Days | 5 Days |

|---|---|---|---|

| CF800/AC53X-1 | 91.3 | 76.3 | 73.2 |

| CF800/AC53X-2 | 98.6 | 91.2 | 77.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Sun, J.; Zhang, L.; Liu, Z.; Huang, C.; Sun, M.; Duan, Z.; Wang, W.; Zhong, X.; Bao, J. Influence of the Second-Phase Resin Structure on the Interfacial Shear Strength of Carbon Fiber/Epoxy Resin. Materials 2024, 17, 1323. https://doi.org/10.3390/ma17061323

Liu H, Sun J, Zhang L, Liu Z, Huang C, Sun M, Duan Z, Wang W, Zhong X, Bao J. Influence of the Second-Phase Resin Structure on the Interfacial Shear Strength of Carbon Fiber/Epoxy Resin. Materials. 2024; 17(6):1323. https://doi.org/10.3390/ma17061323

Chicago/Turabian StyleLiu, Hansong, Jinsong Sun, Lianwang Zhang, Zhaobo Liu, Chengyu Huang, Mingchen Sun, Ziqi Duan, Wenge Wang, Xiangyu Zhong, and Jianwen Bao. 2024. "Influence of the Second-Phase Resin Structure on the Interfacial Shear Strength of Carbon Fiber/Epoxy Resin" Materials 17, no. 6: 1323. https://doi.org/10.3390/ma17061323