Fire Resistance of Foamed Concrete for Discontinuous Partition Filling

Abstract

1. Introduction

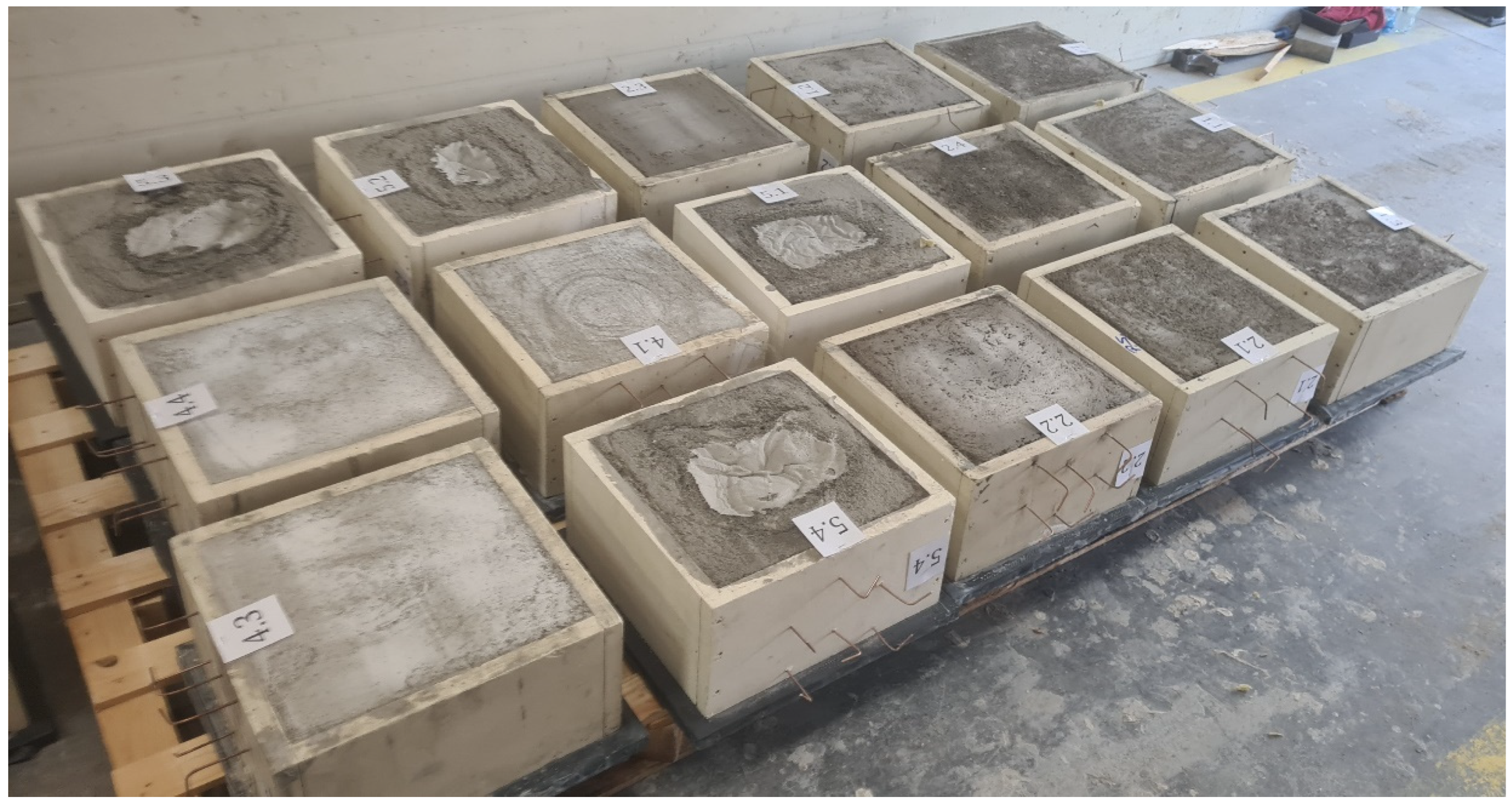

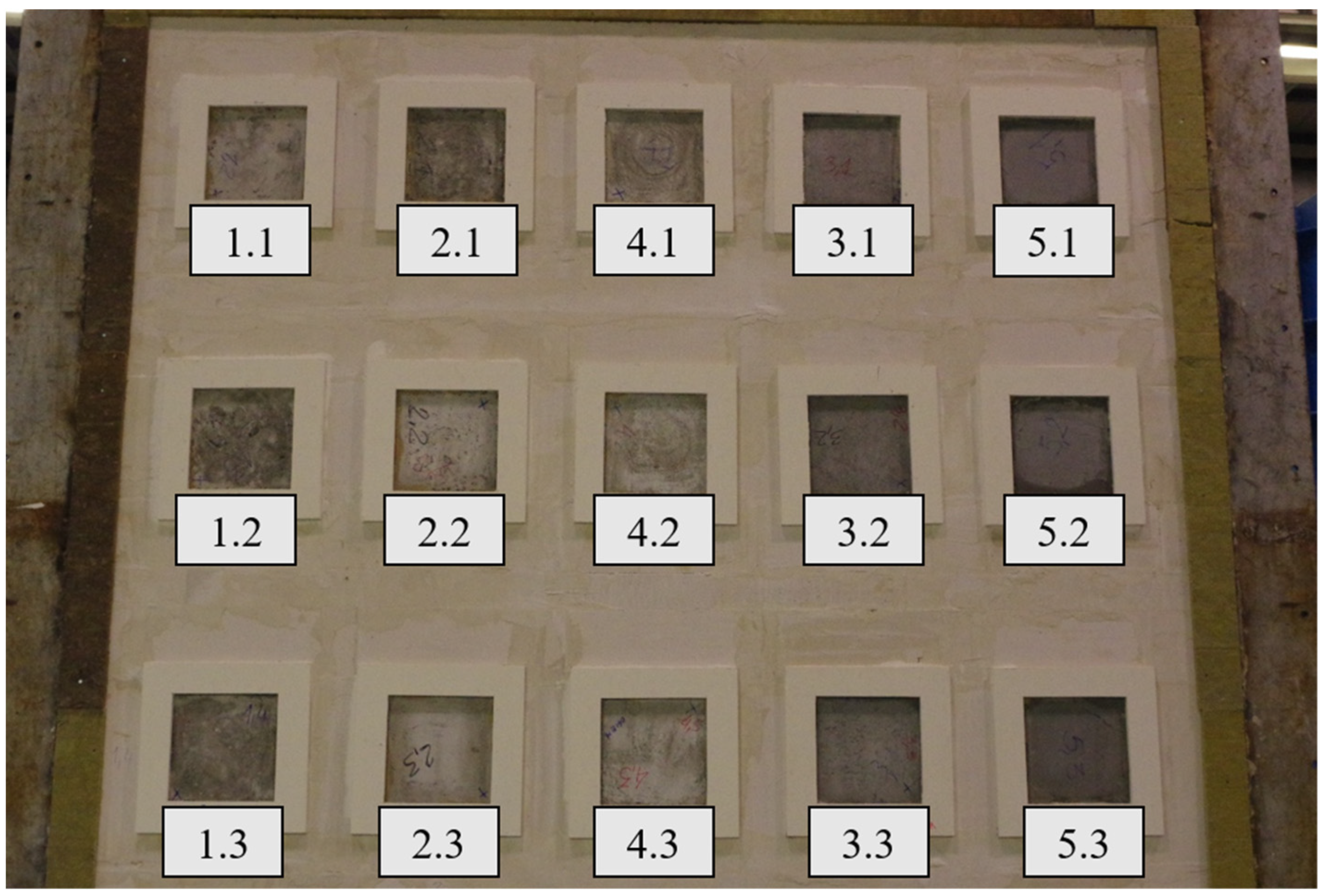

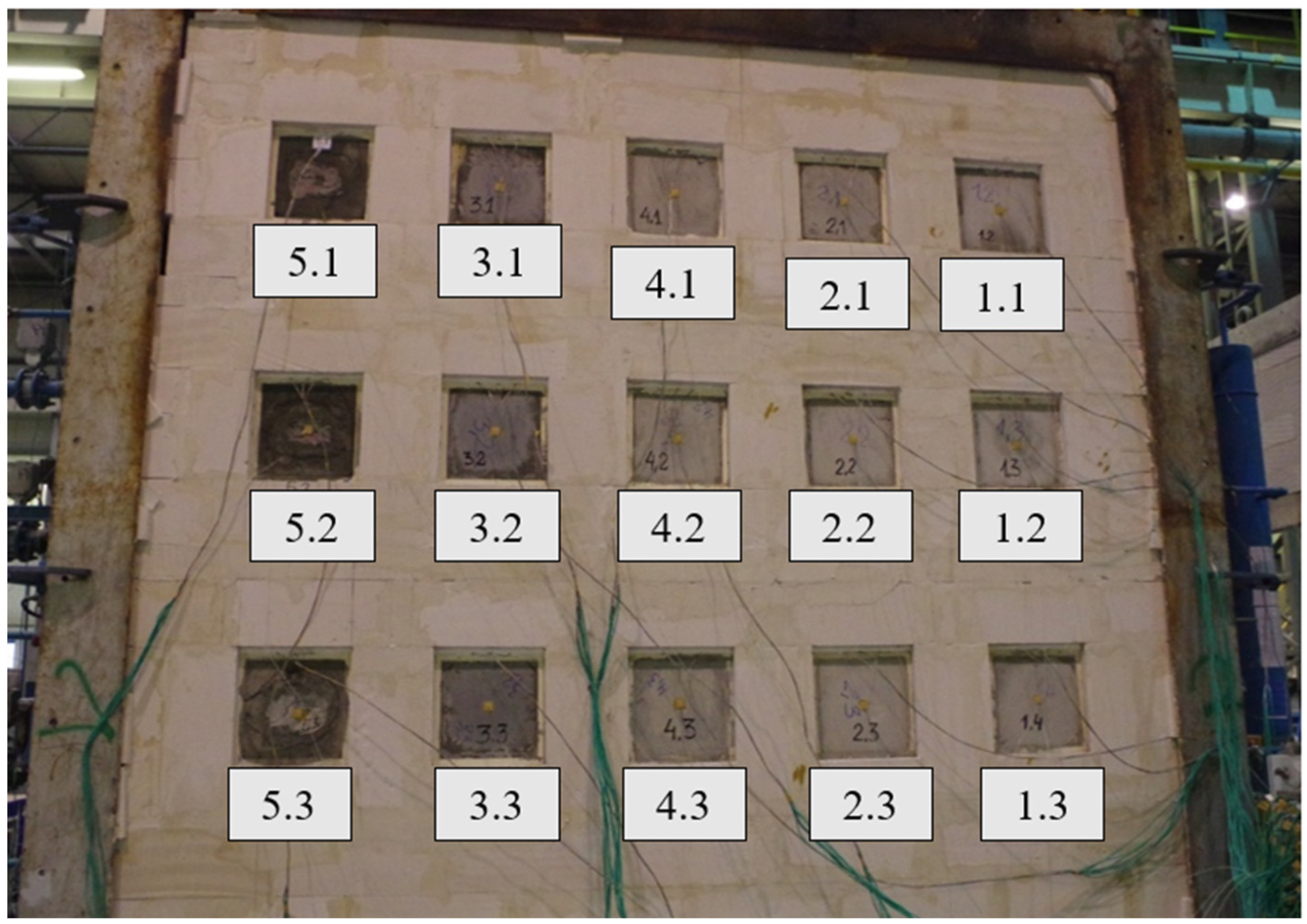

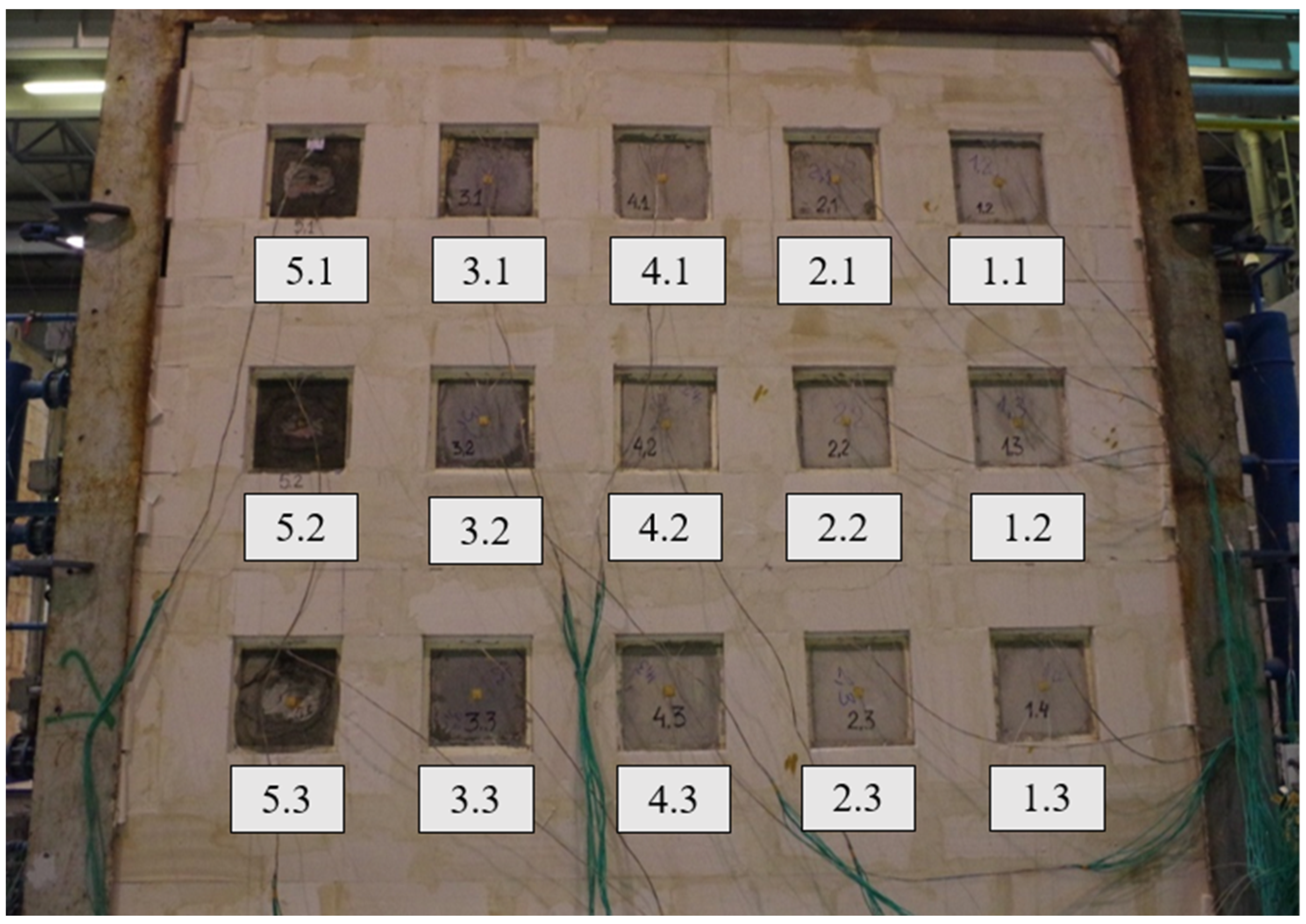

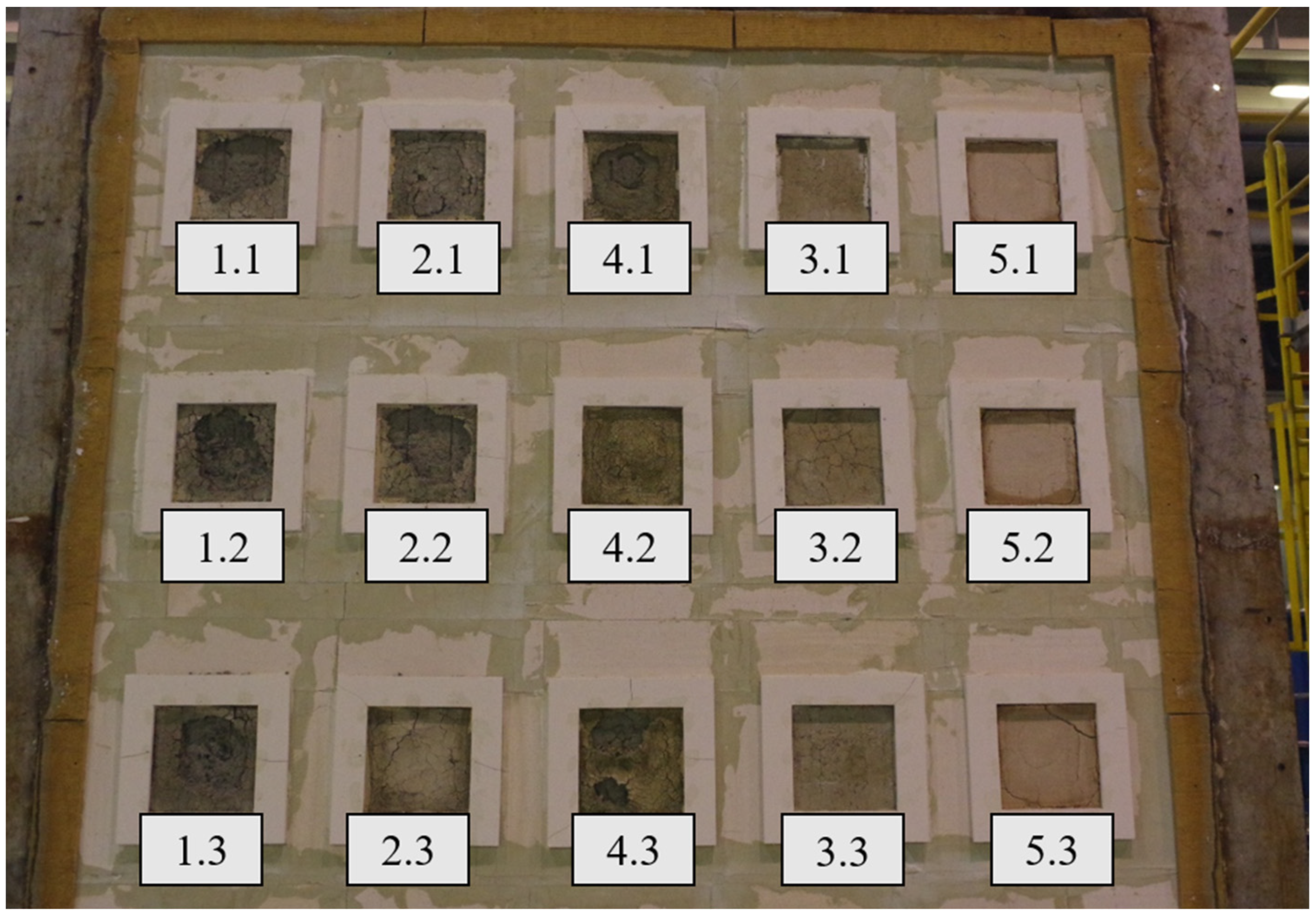

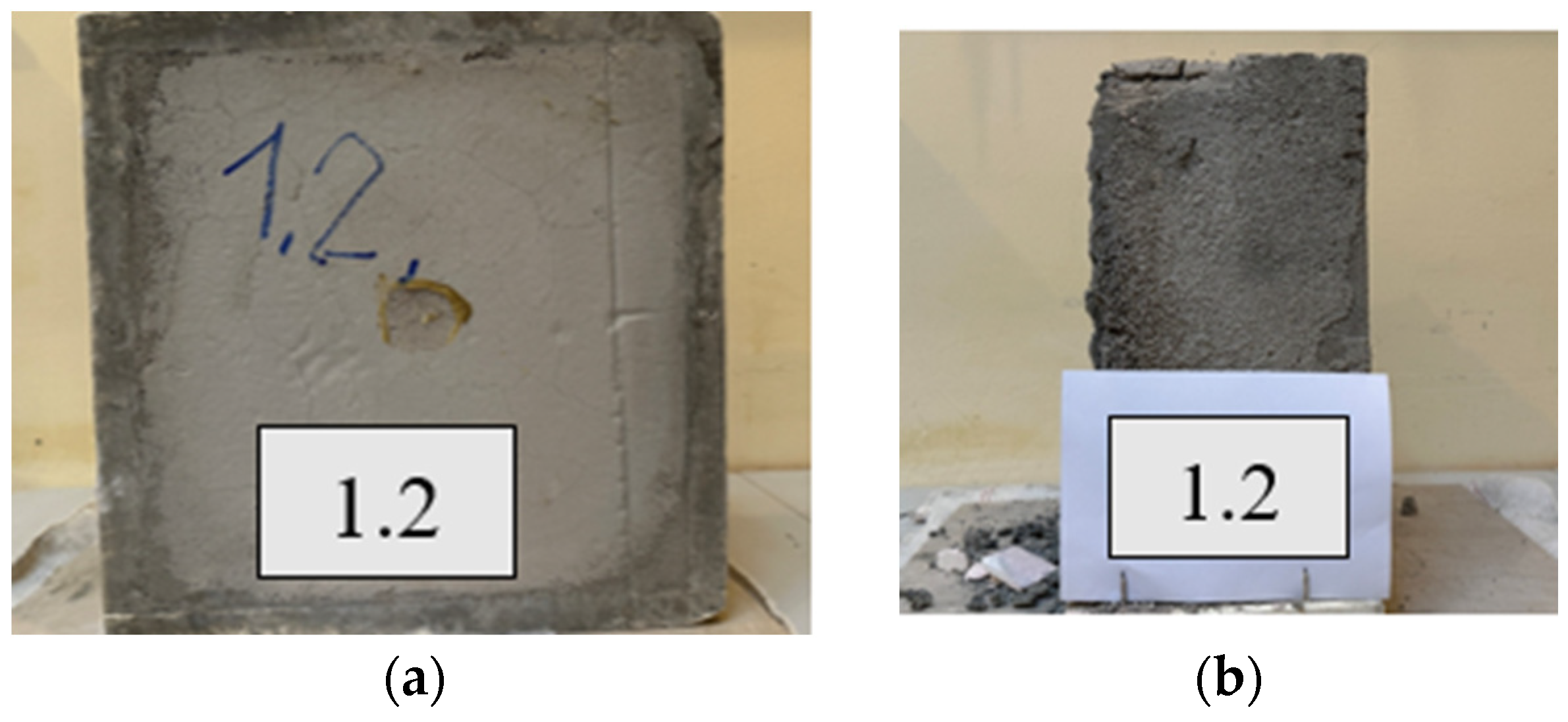

2. Materials and Methods

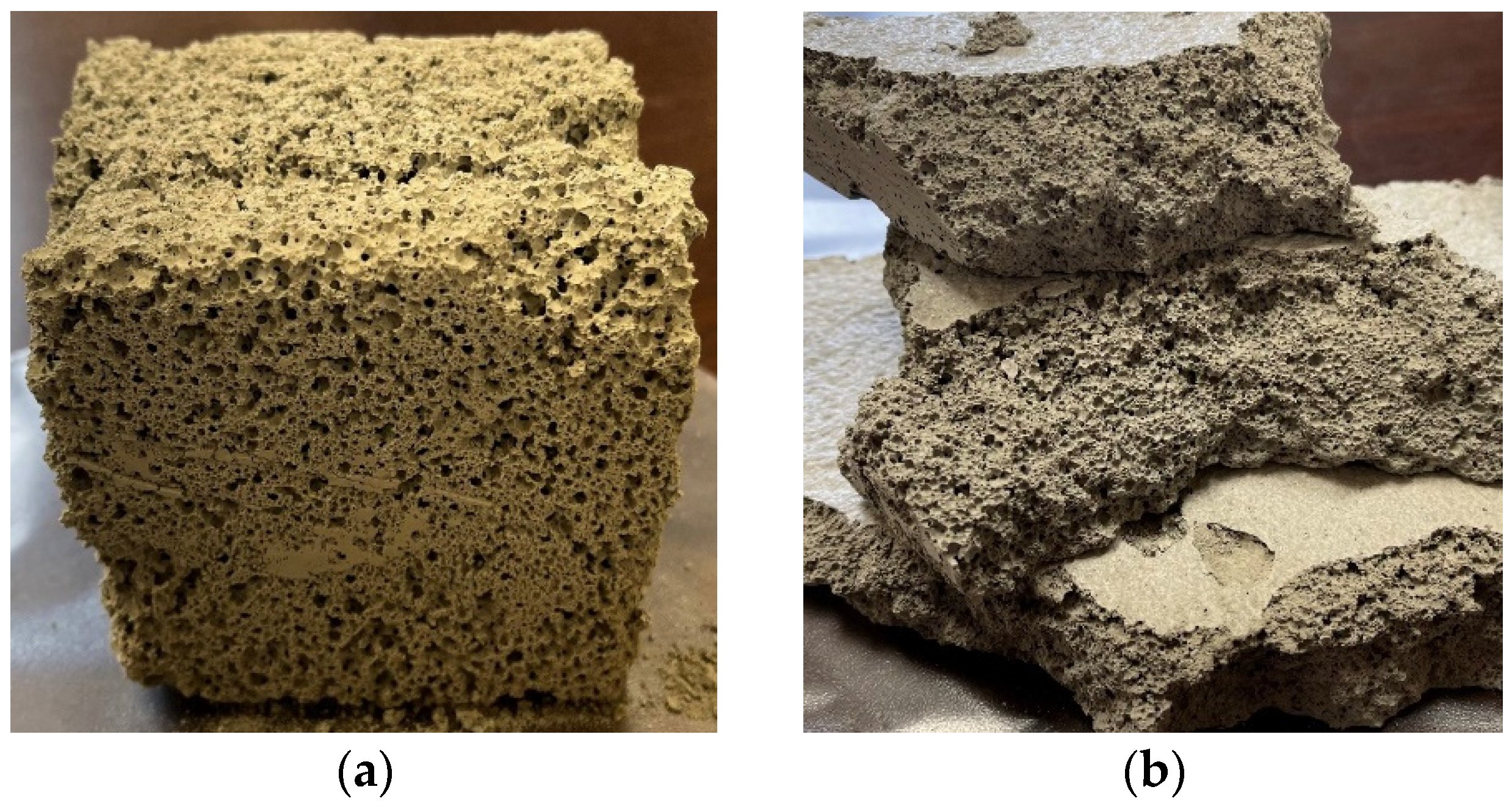

2.1. Materials

2.2. Methods

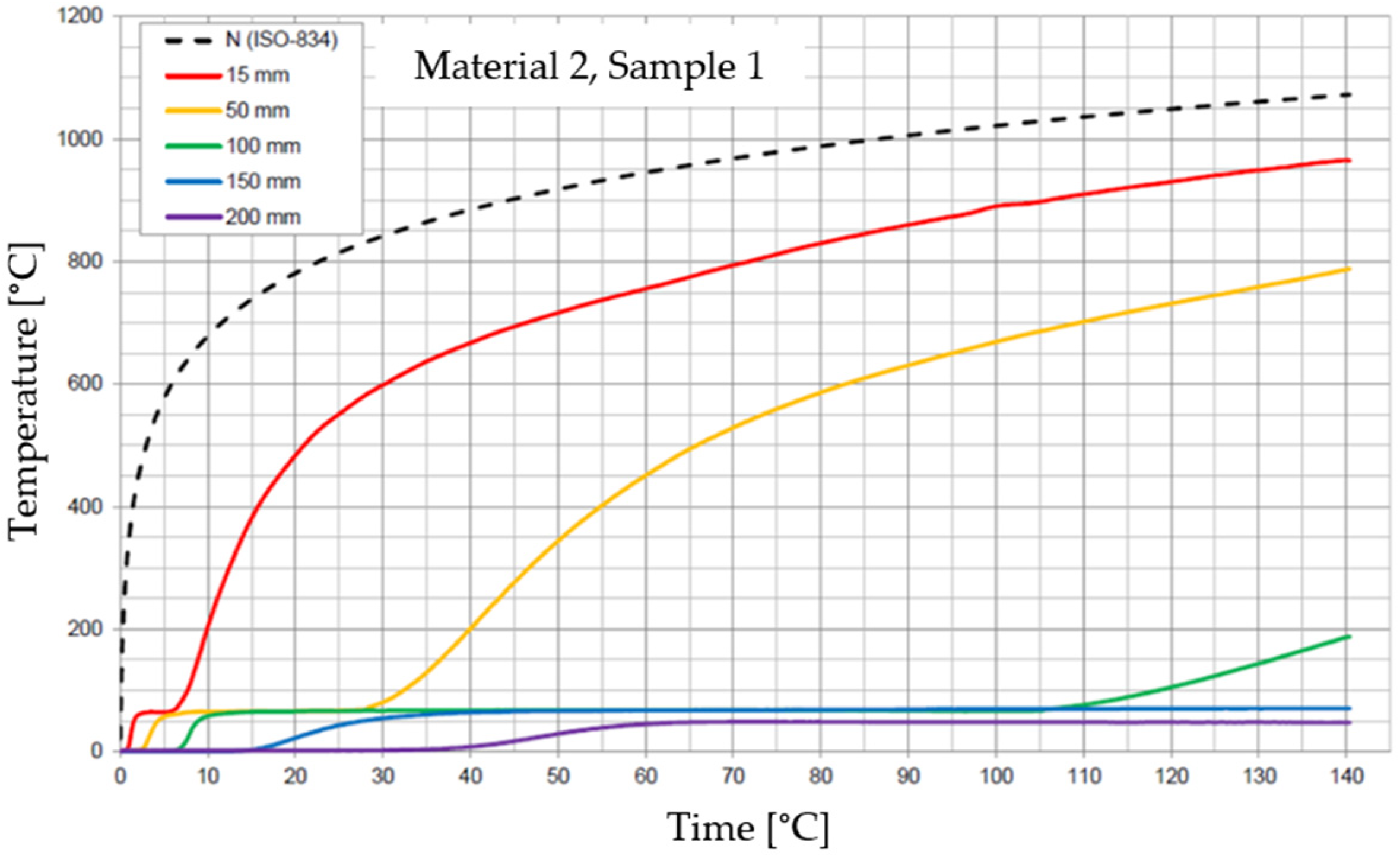

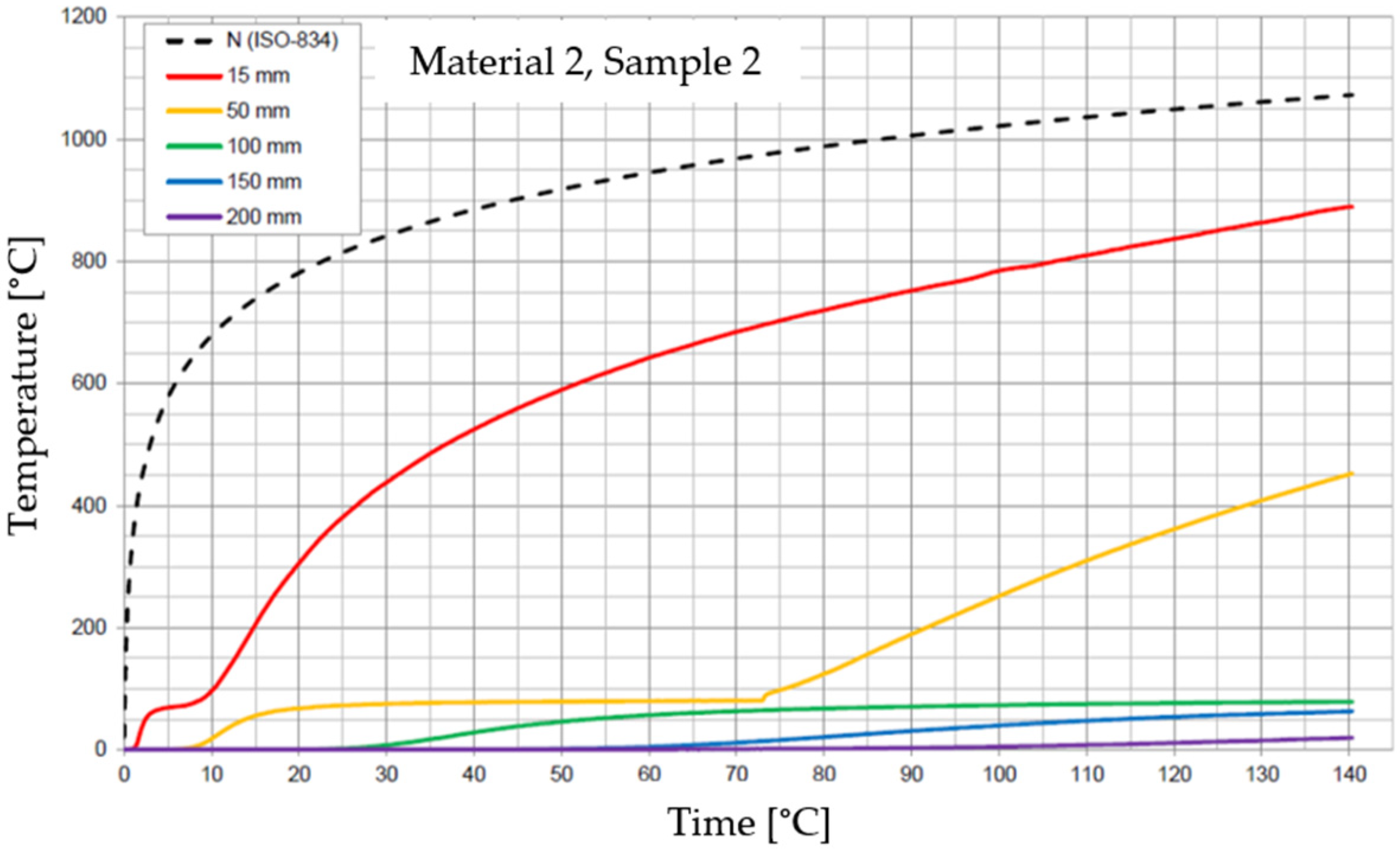

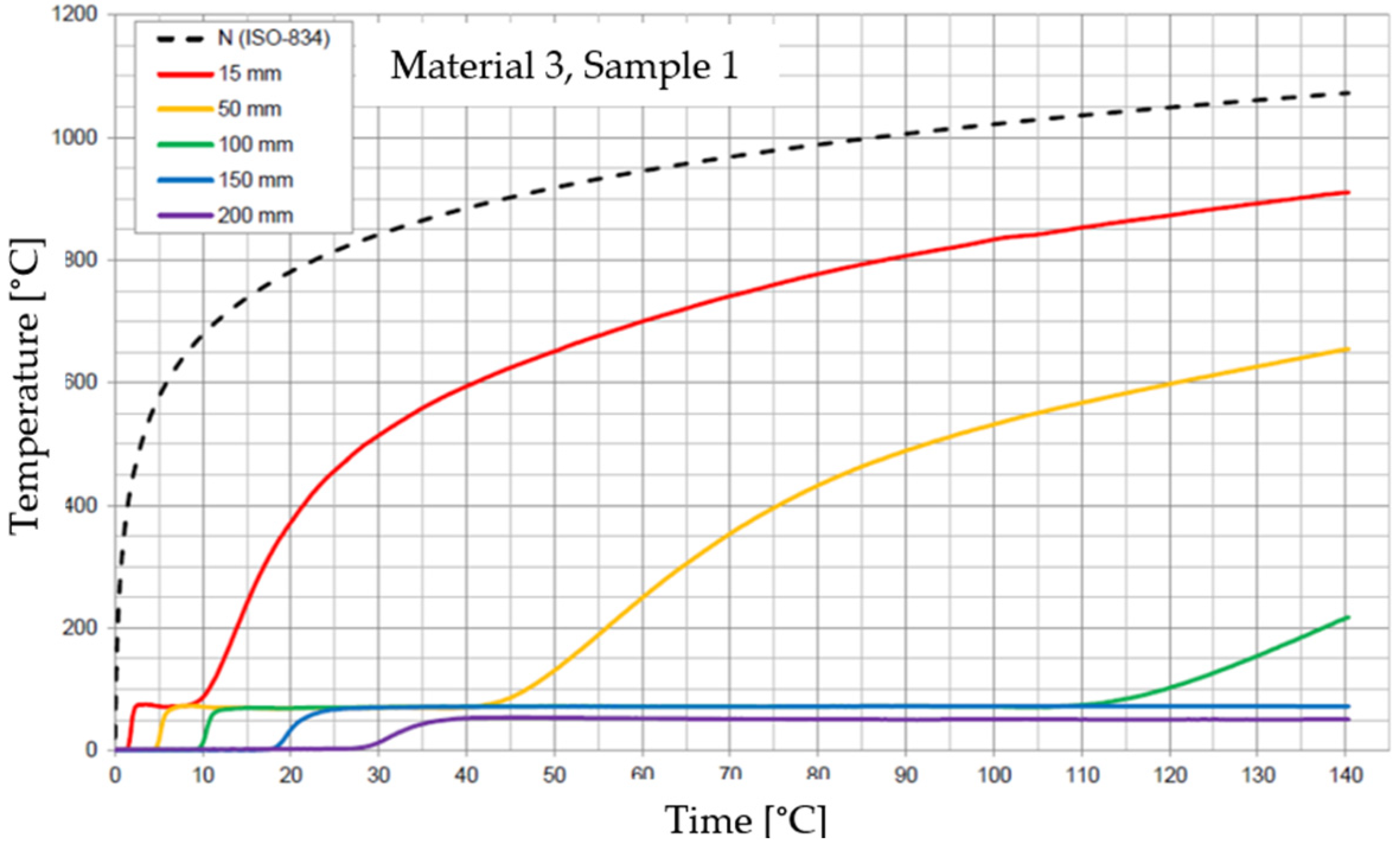

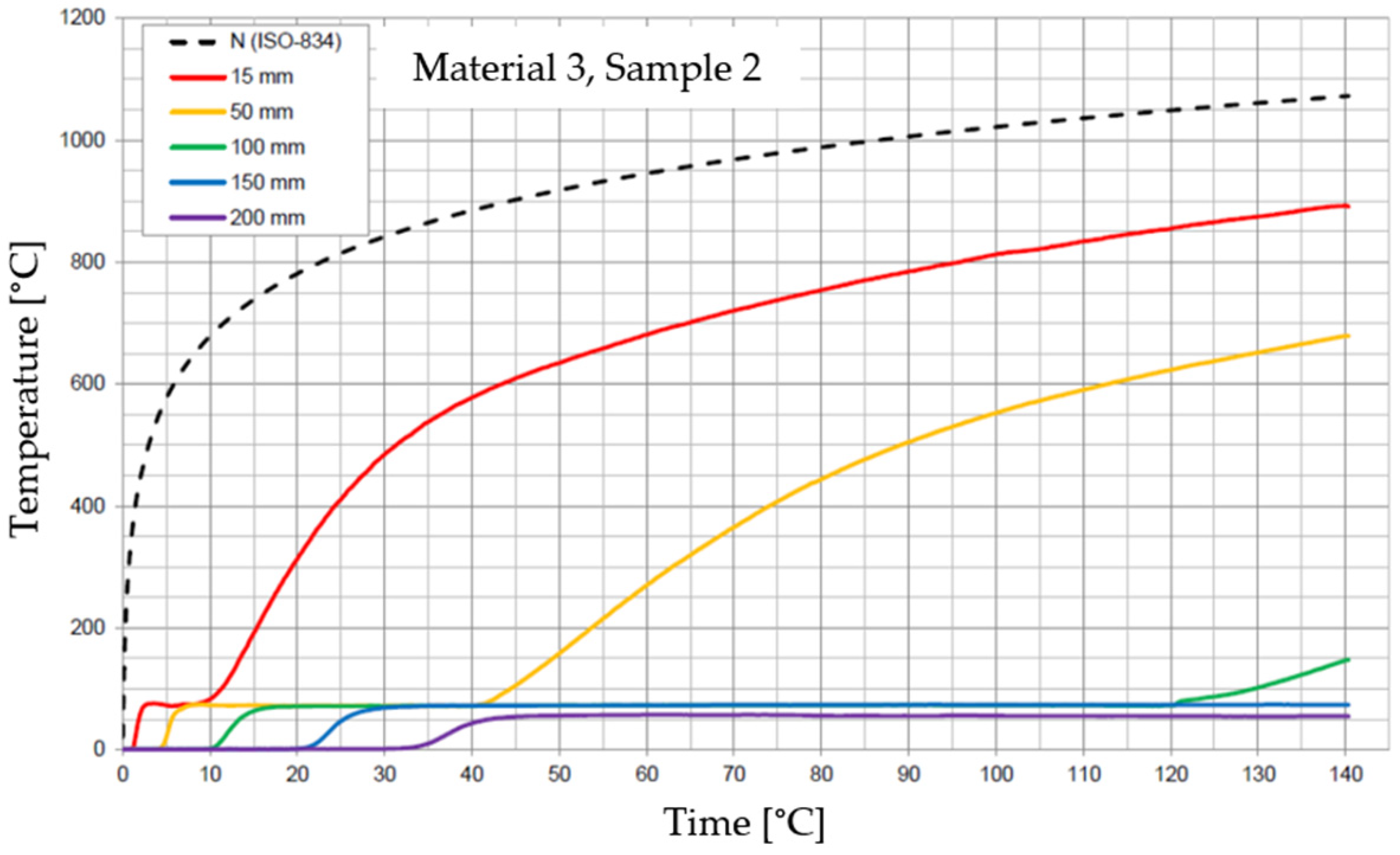

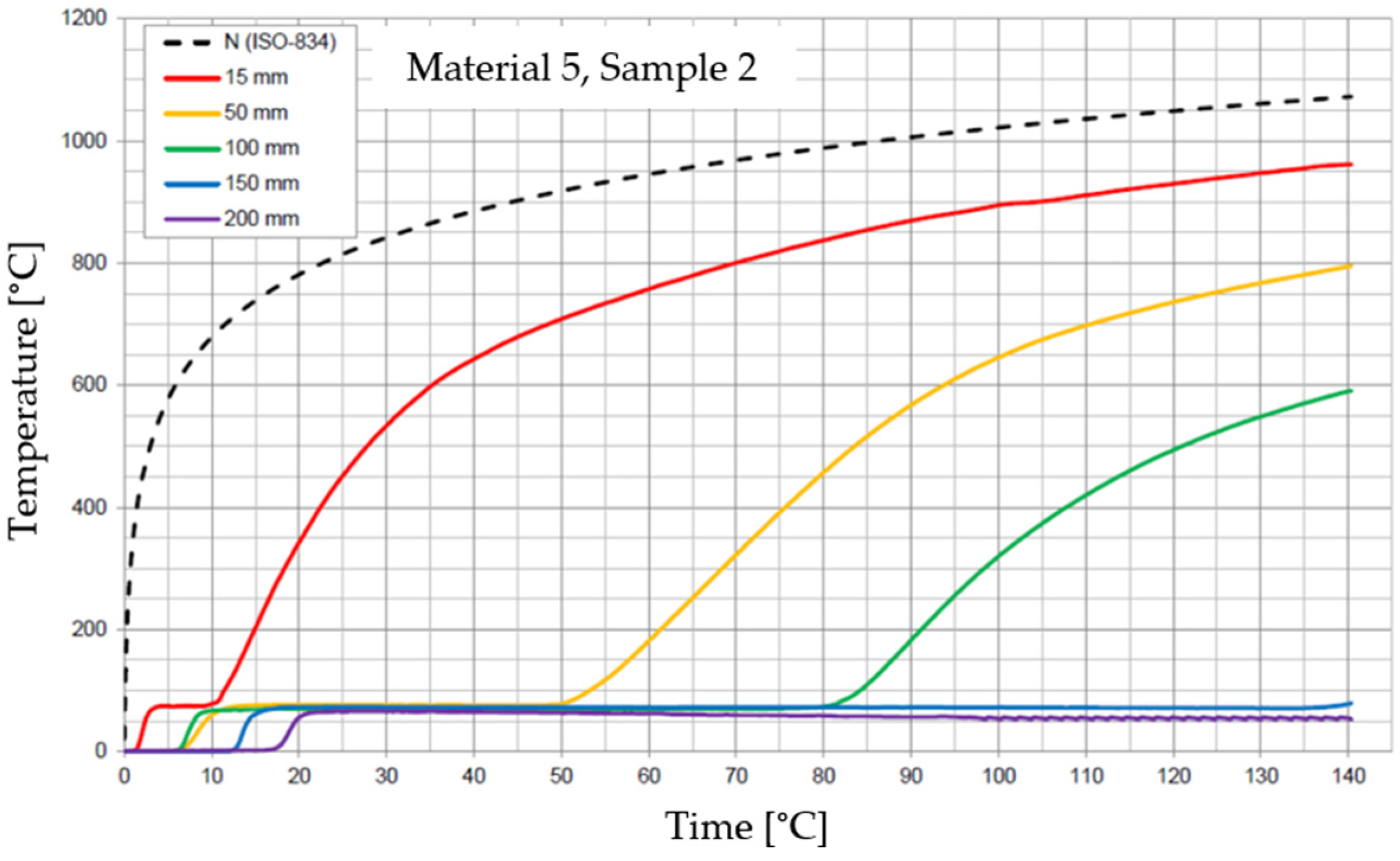

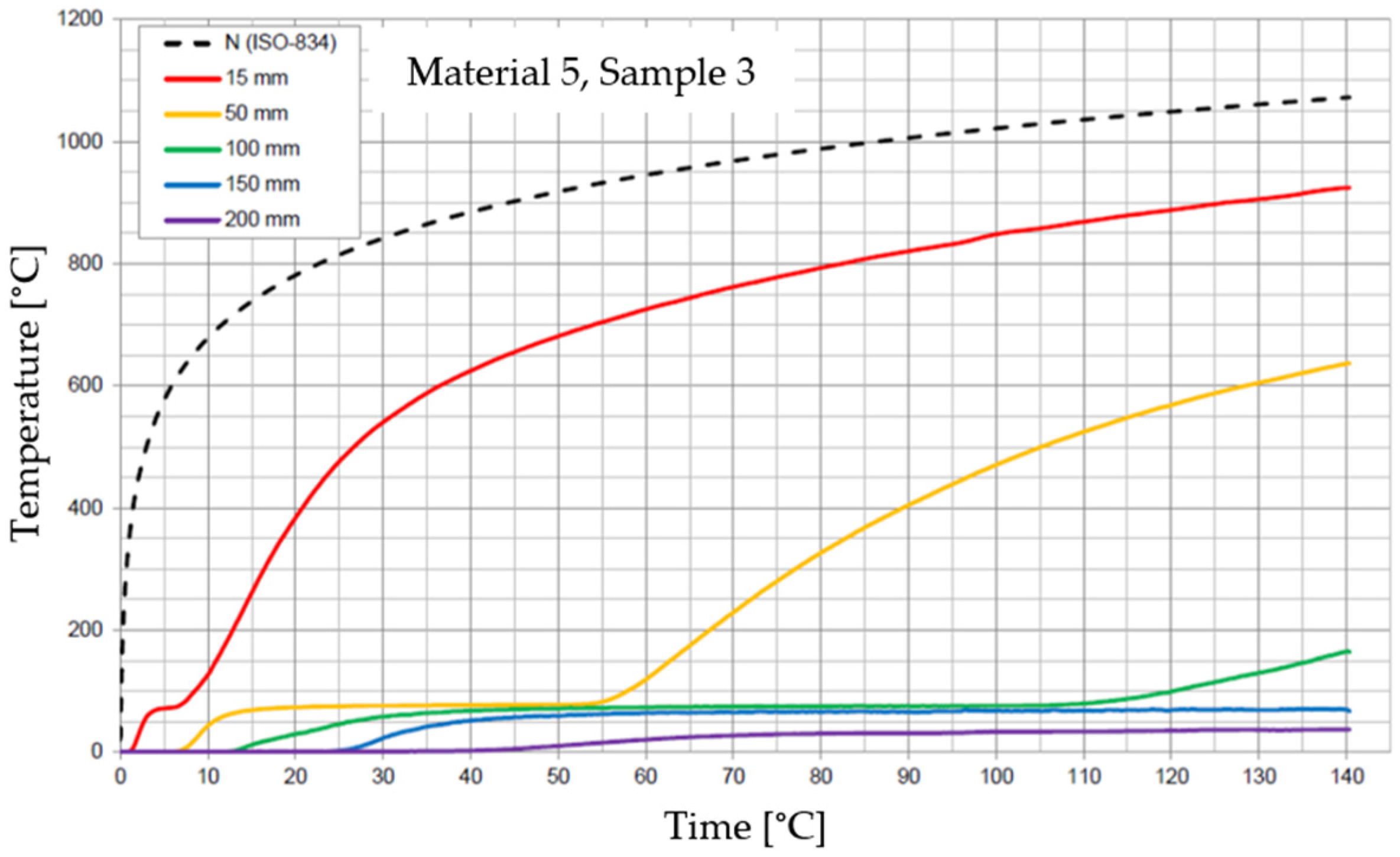

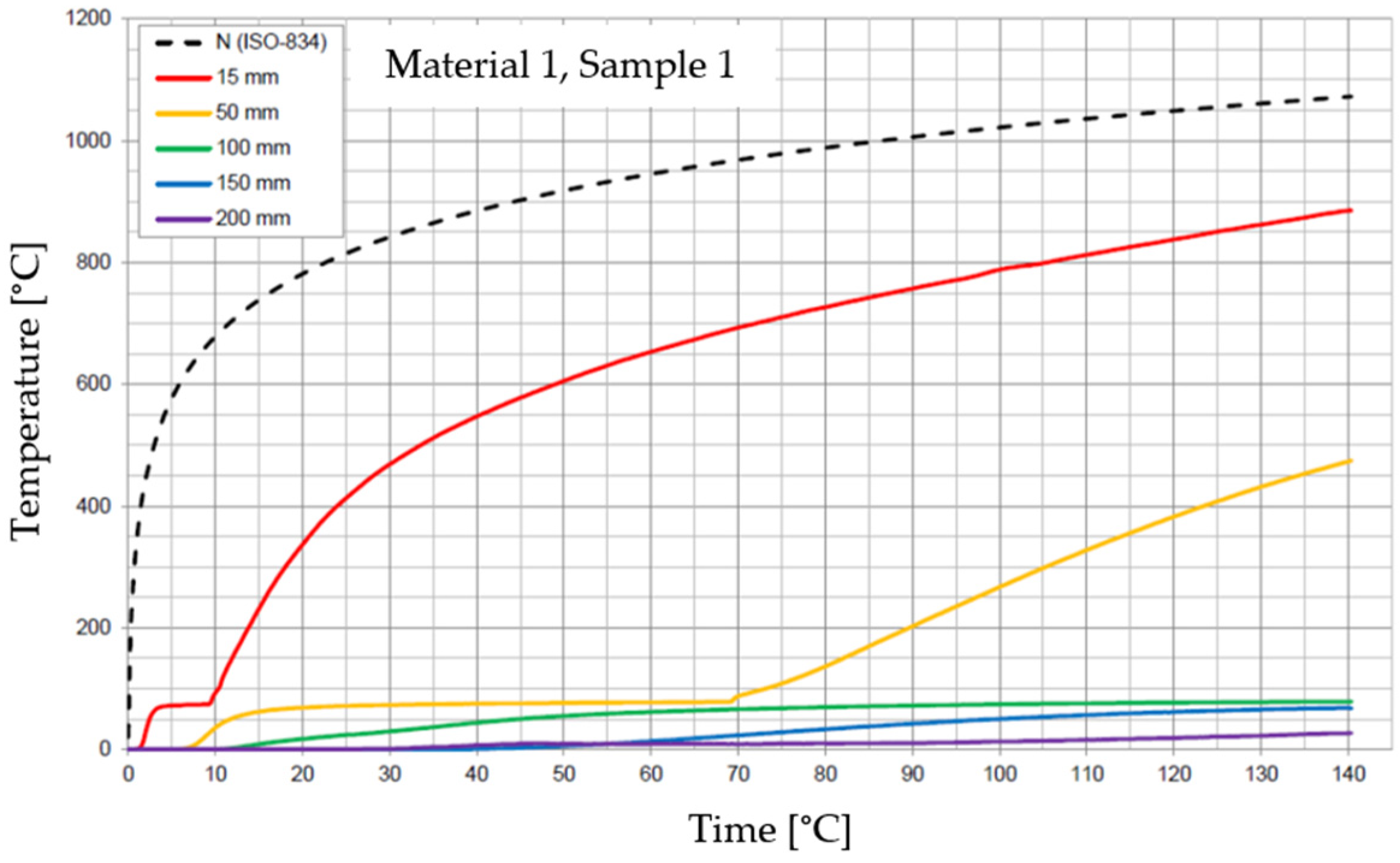

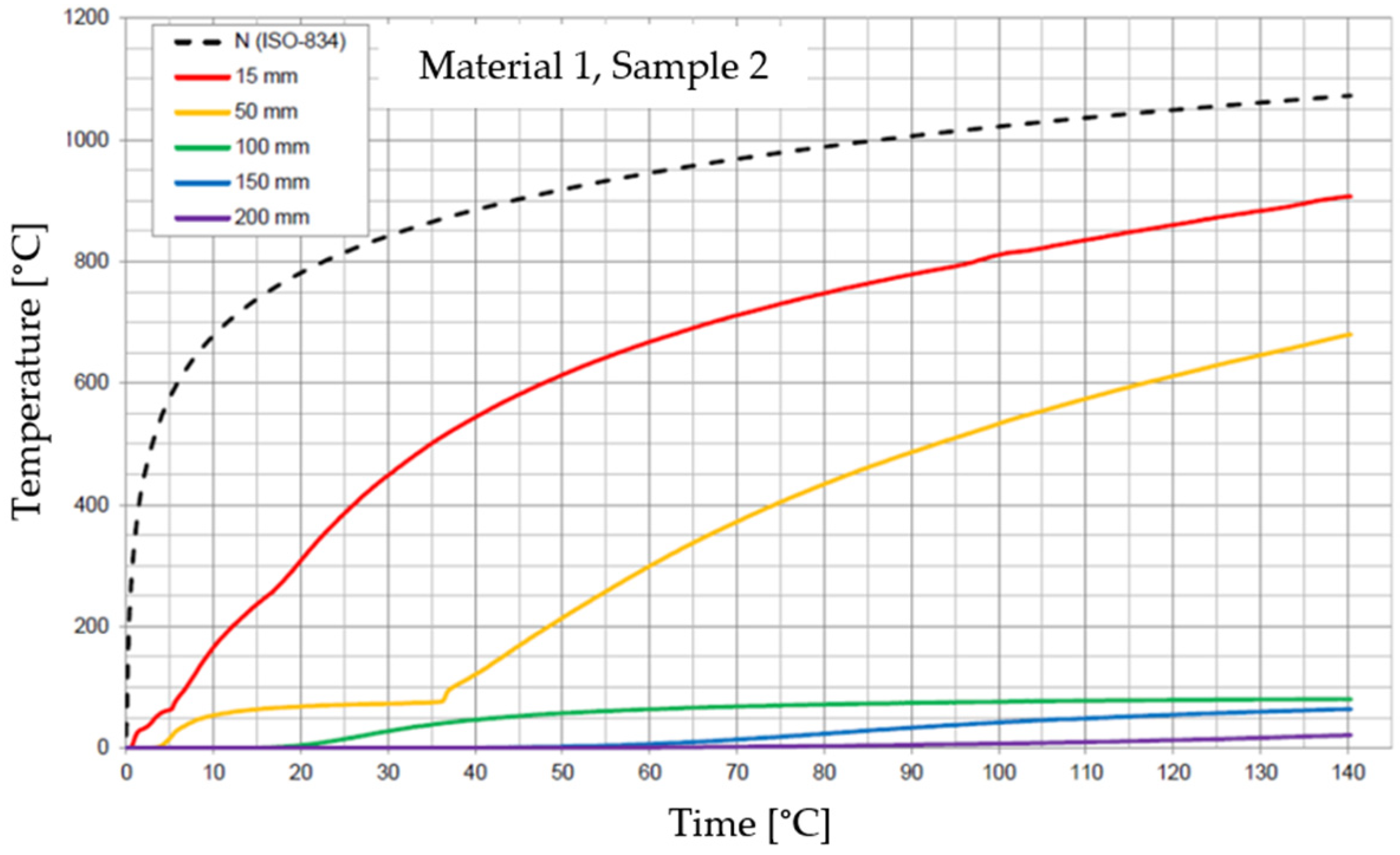

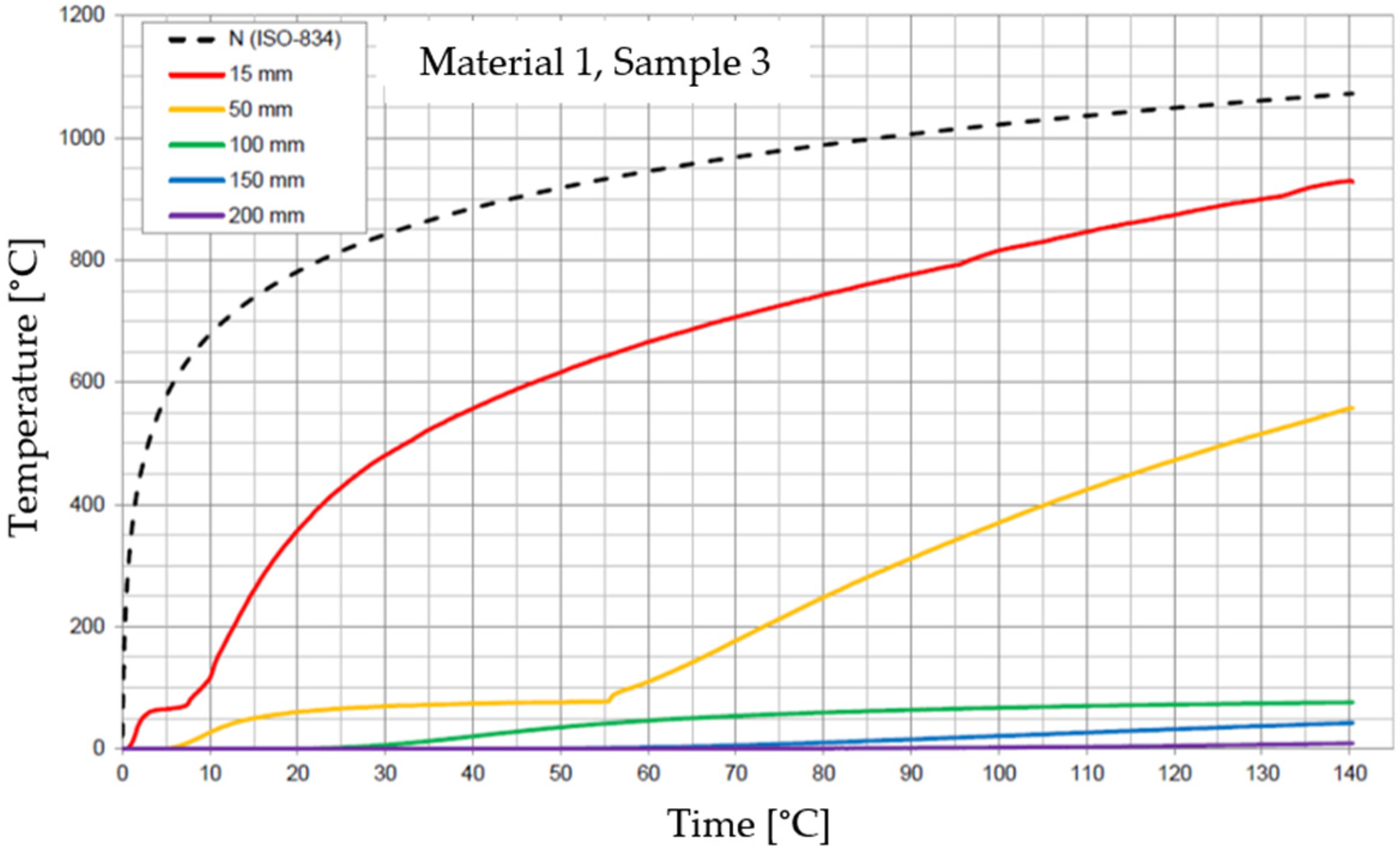

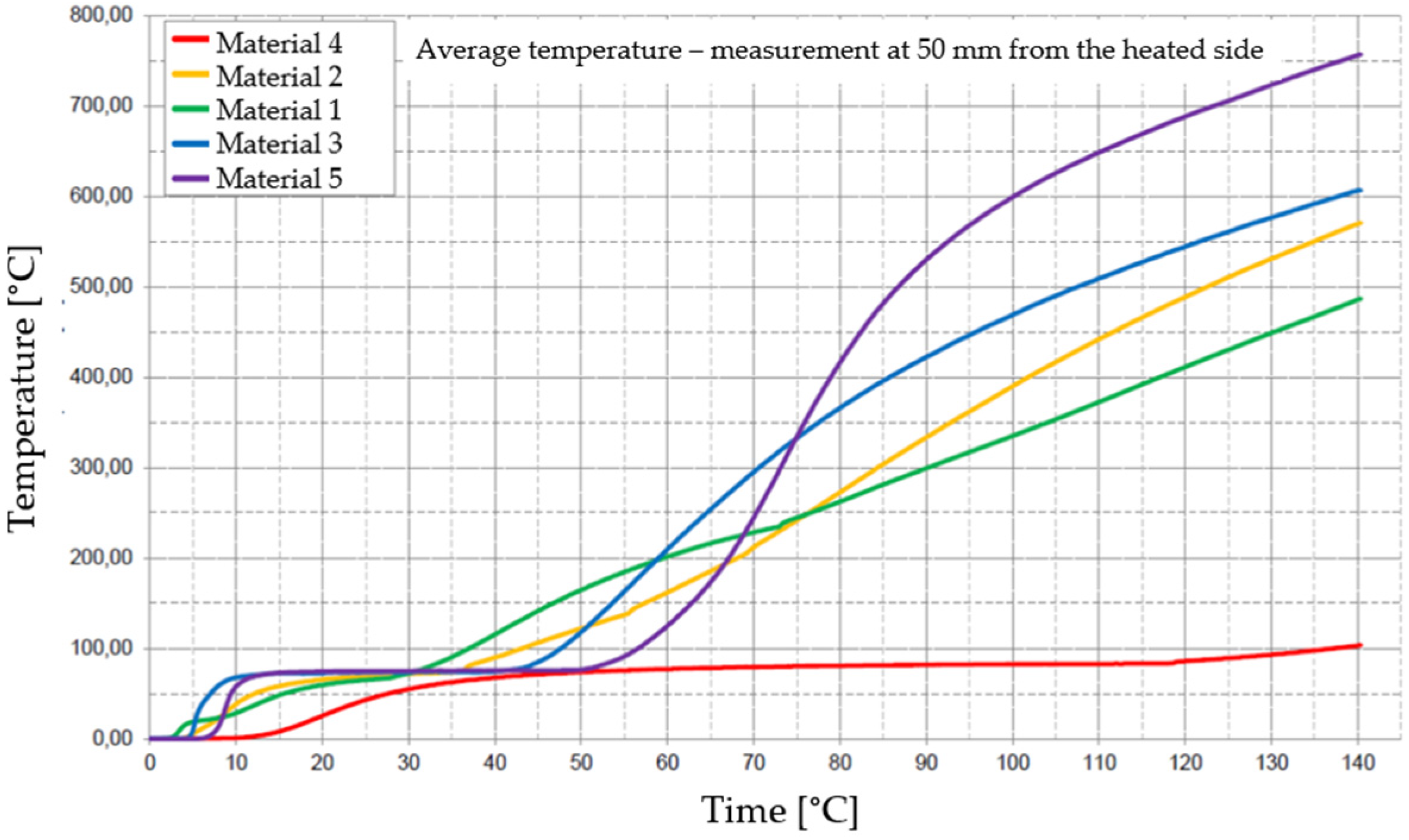

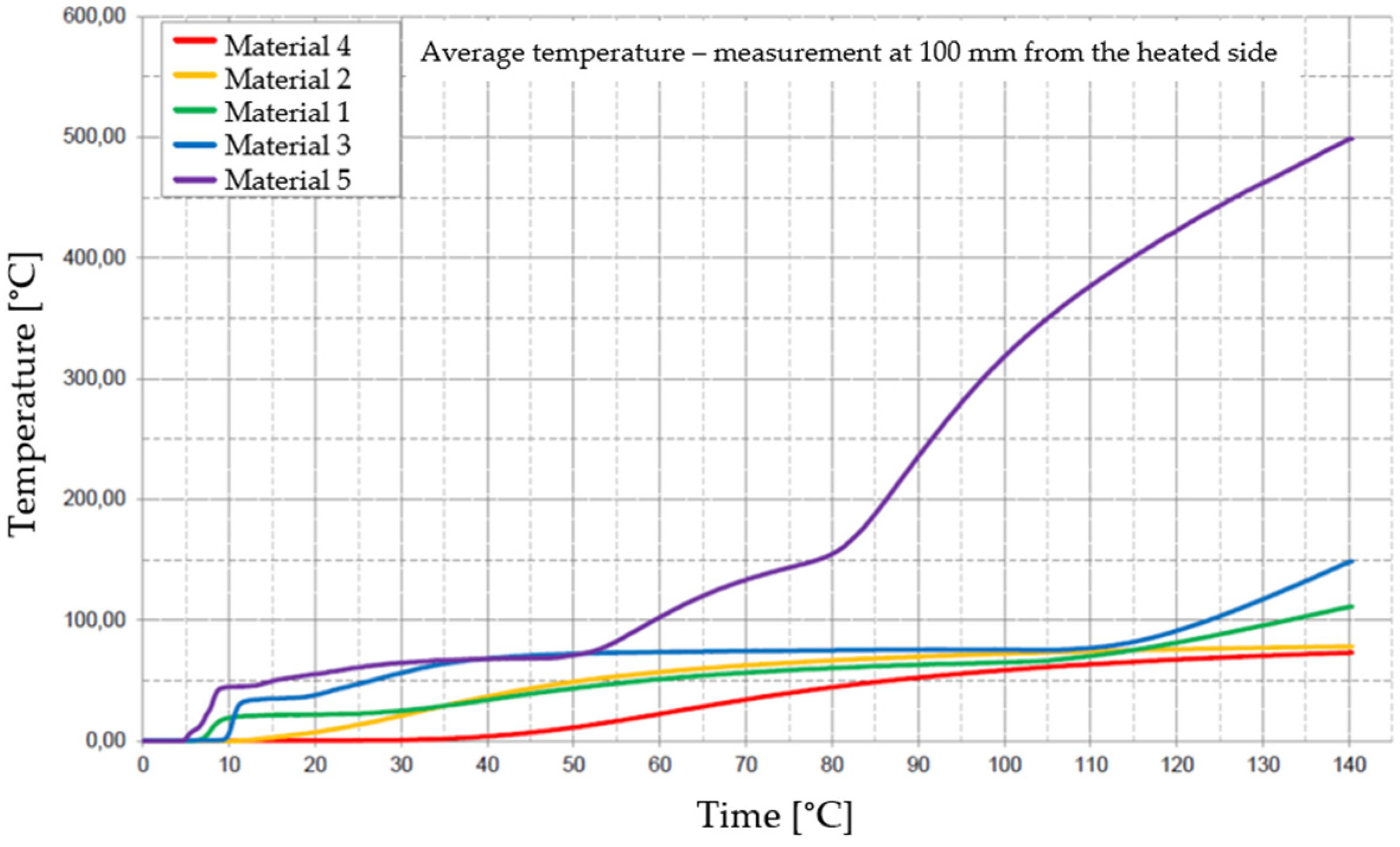

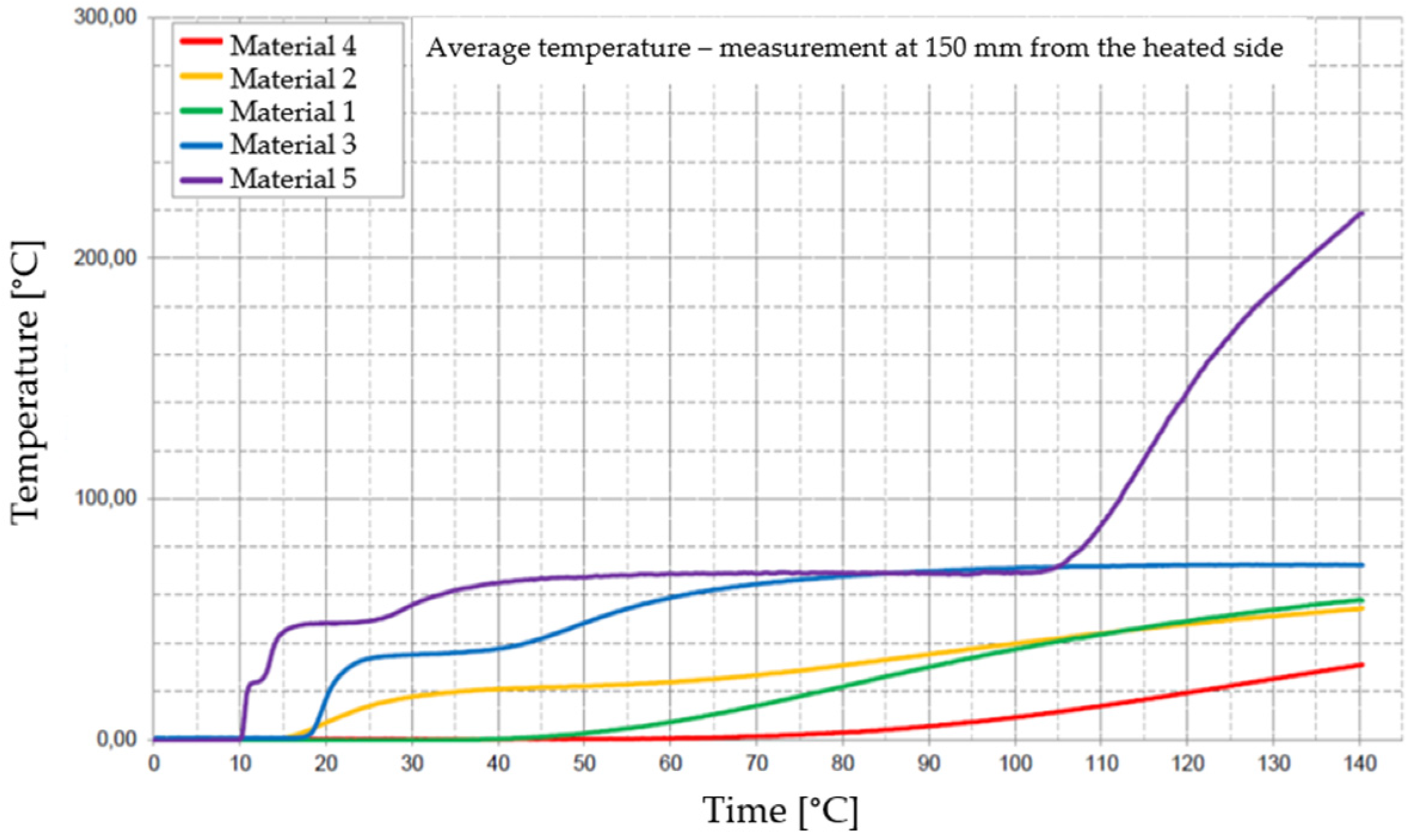

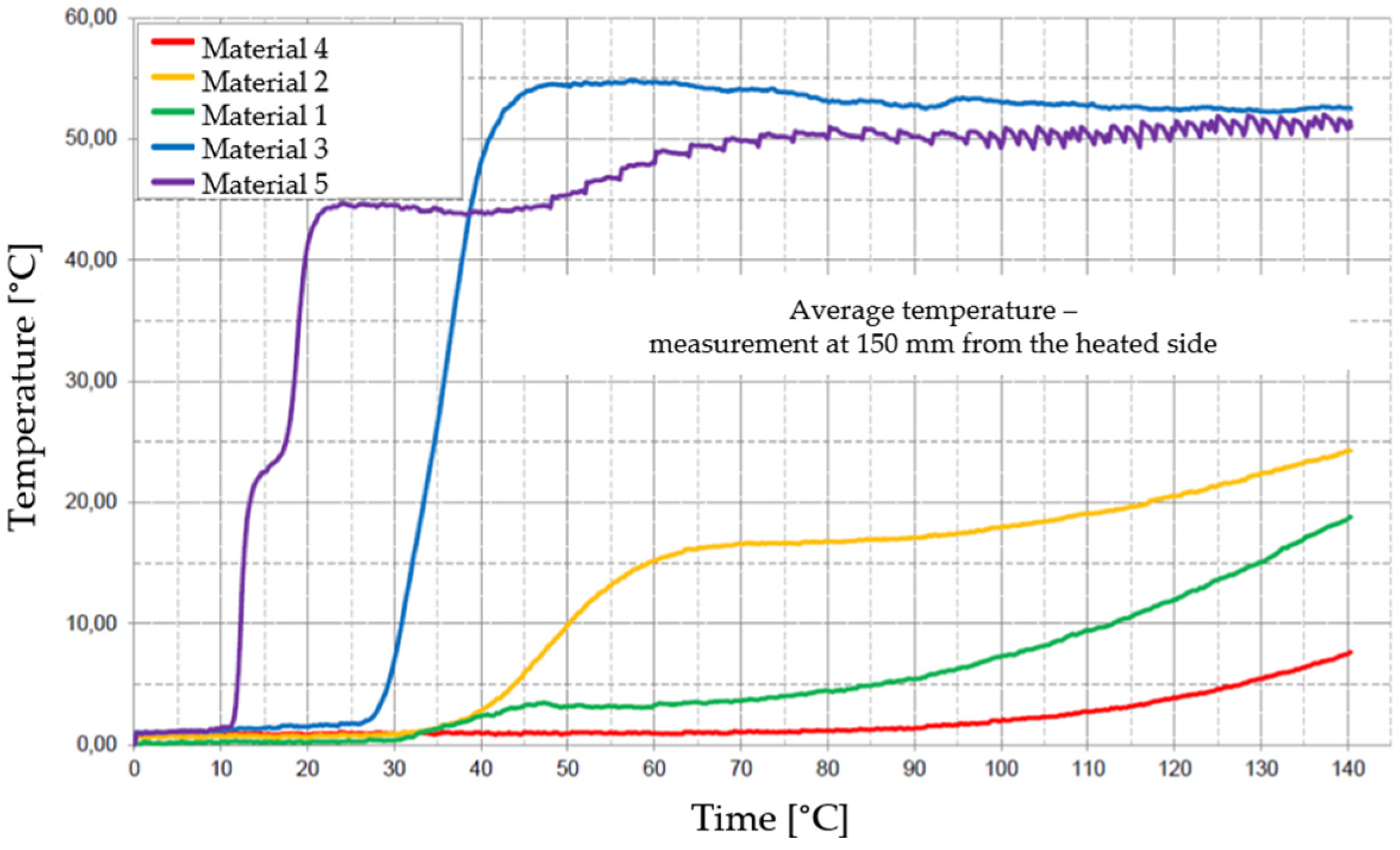

3. Results

4. Conclusions

- For all materials, the effectiveness of insulating fire temperatures for the entire duration test was confirmed for material thicknesses of 150 and 200 mm.

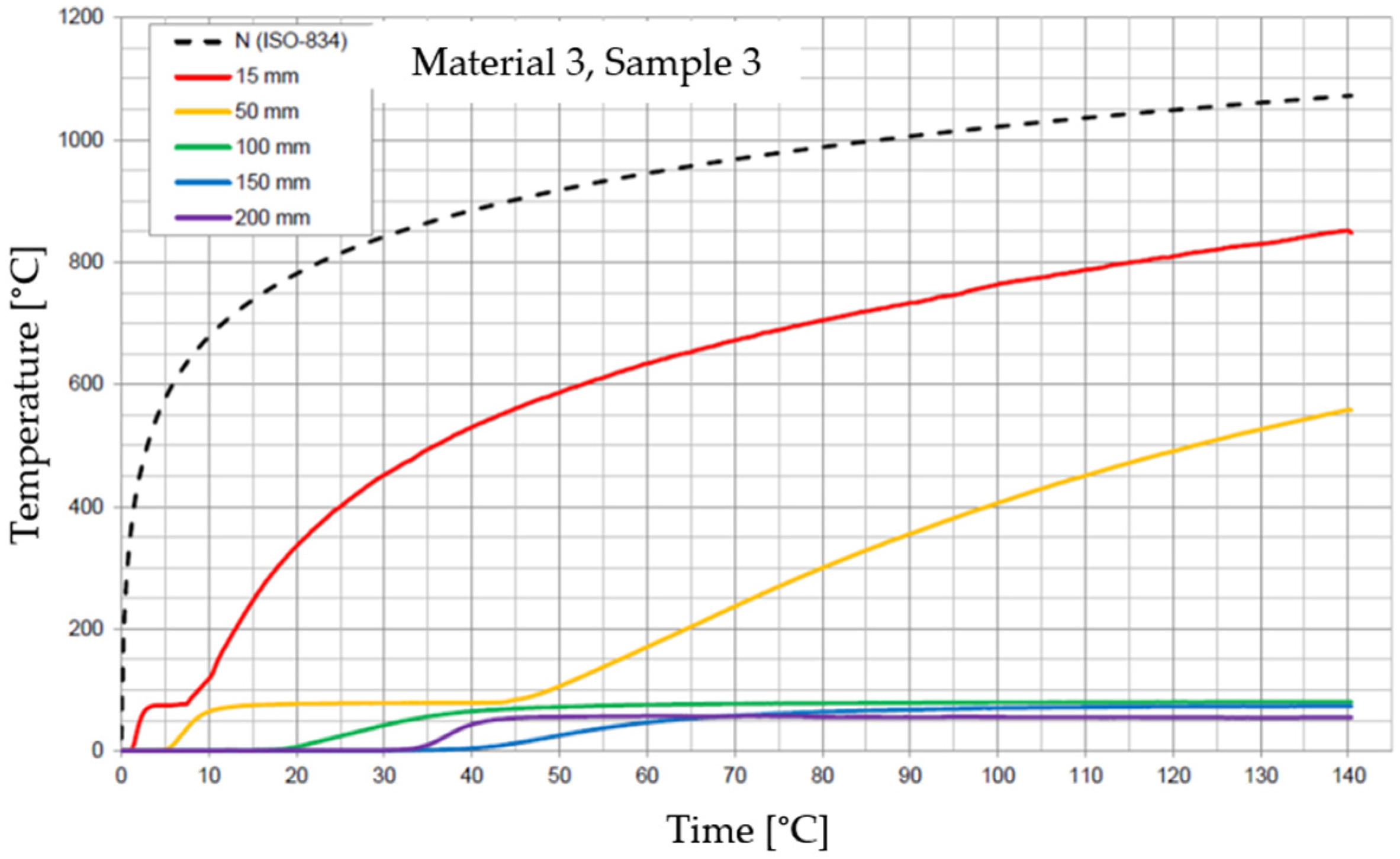

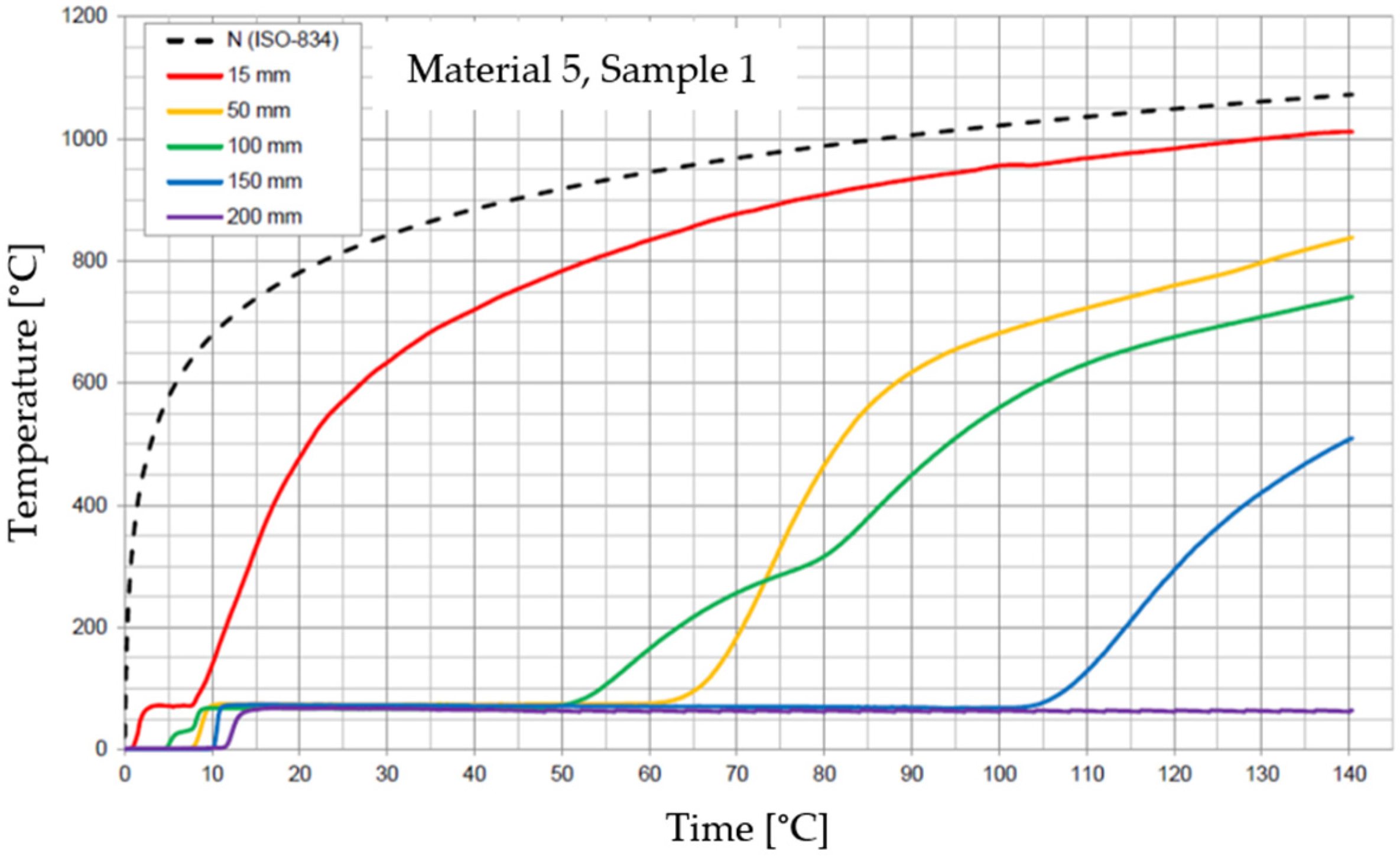

- Considering materials with a thickness of 100 mm, confirmation of effectiveness throughout the test was obtained for Materials 1 and 4. At the same thickness, Materials 2 and 3 maintained their effectiveness up to a time range of 138 min to 140 min and of 135 to 140 min, respectively. Material 5 exhibited the lowest insulating fire temperature range of 62 to 140 min at a thickness of 100 mm.

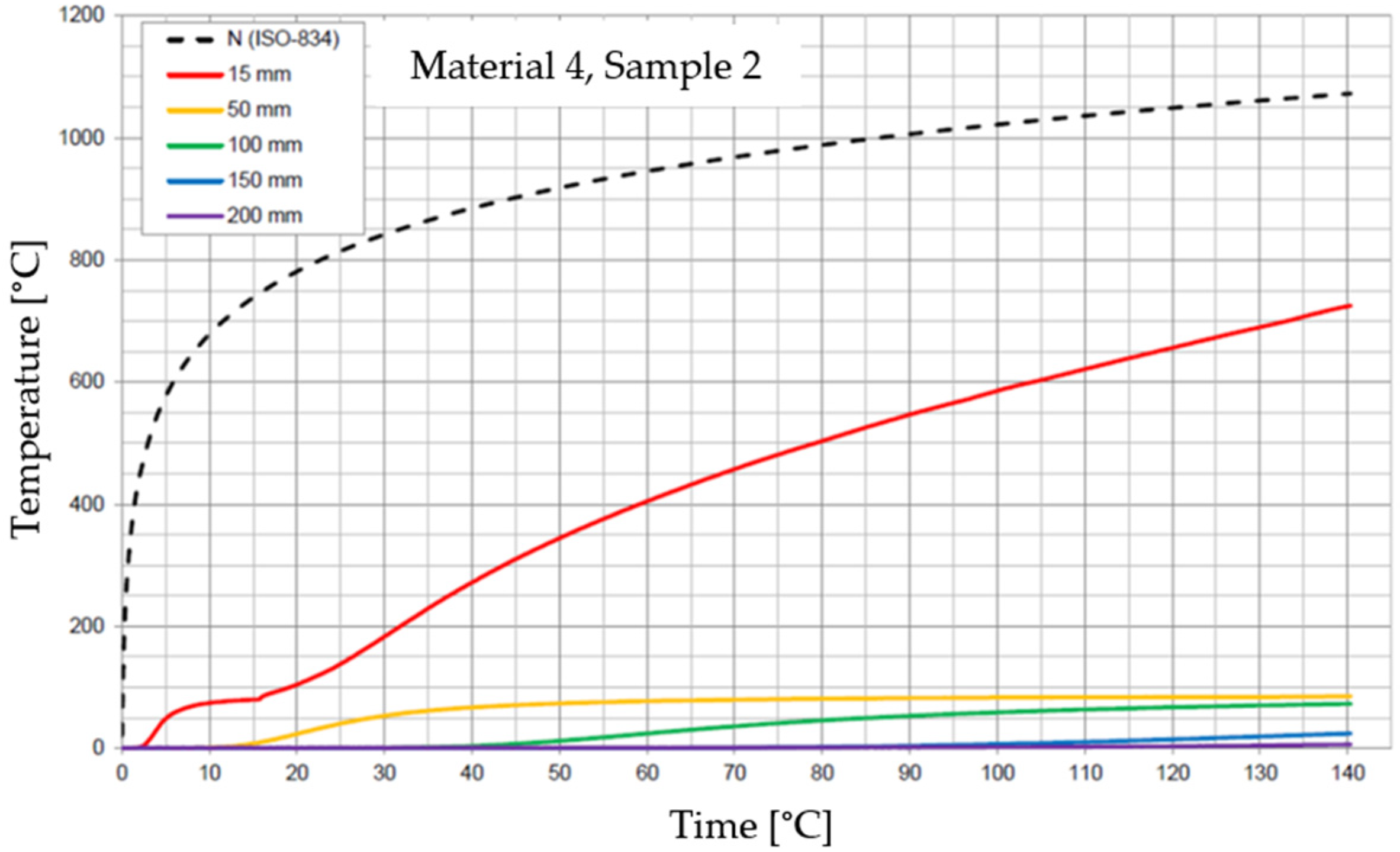

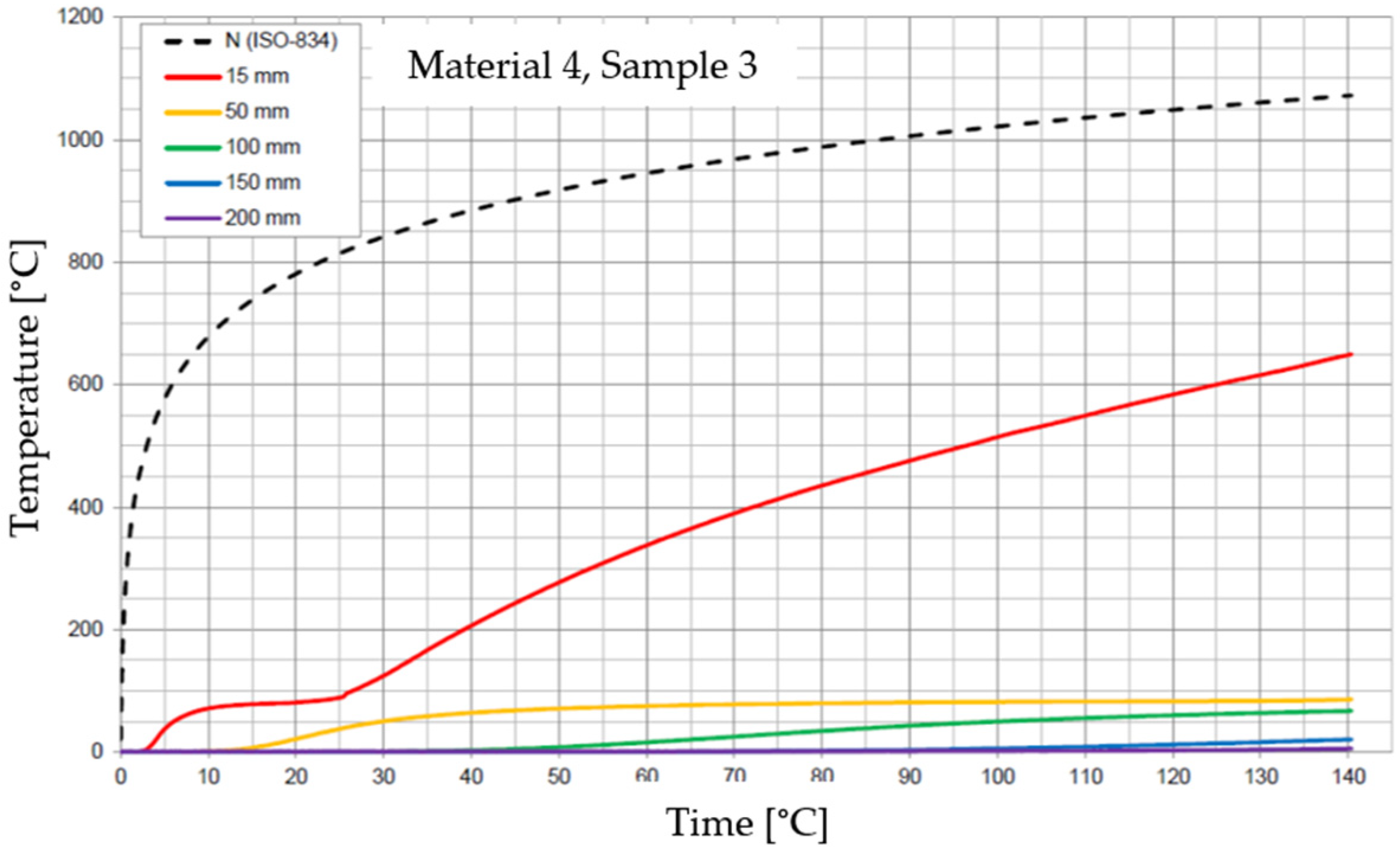

- The best results for the material thickness of 50 mm were obtained for Material 4. Moreover, at a thickness of 15 mm, Material 4 exhibited the longest time in maintaining the effectiveness of insulating against fire temperatures (from 30 to 38 min). This may be due to the fact that Material 4 exhibits the greatest density (826.94 ± 31.37 kg/m3) of all the tested materials.

- However, based on the results, the fire resistance of foamed concrete does not only depend on the density of the material. A change in the manufacturing process to continuous foam feeding may provide similar results in most of the thicknesses studied.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, Y.; Yang, Z.; You, Z.; Wang, X.; Chen, K.; Guo, B.; Wu, K. Experimental Study on Fire Resistance of Concrete Beams Made with Iron Tailings Sand. Buildings 2022, 12, 1816. [Google Scholar] [CrossRef]

- Hull, T.R. Challenges in fire testing: Reaction to fire tests and assessment of fire toxicity. In Advances in Fire Retardant Materials; Horrocks, A.R., Price, D., Eds.; Woodhead Publishing: Sawston, UK, 2008; pp. 255–290. [Google Scholar]

- Oliveira, P.N.; Fonseca, E.M.M.; Campilho, R.D.S.G.; Piloto, P.A.G. Analytical Equations Applied to the Study of Steel Profiles under Fire According to Different Nominal Temperature-Time Curves. Math. Comput. Appl. 2021, 26, 48. [Google Scholar] [CrossRef]

- Arioz, O. Effects of elevated temperatures on properties of concrete. Fire Saf. J. 2007, 42, 516–522. [Google Scholar] [CrossRef]

- Dowbysz, A.; Samsonowicz, M.; Kukfisz, B.; Koperniak, P. Recent Developments of Nano Flame Retardants for Unsaturated Polyester Resin. Materials 2024, 17, 852. [Google Scholar] [CrossRef]

- Kanagaraj, B.; Nammalvar, A.; Andrushia, A.D.; Gurupatham, B.G.; Roy, K. Influence of Nano Composites on the Impact Resistance of Concrete at Elevated Temperatures. Fire 2023, 6, 135. [Google Scholar] [CrossRef]

- Li, L.; Wang, H.; Wu, J.; Du, X.; Zhang, X.; Yao, Y. Experimental and numerical investigation on impact dynamic performance of steel fiber reinforced concrete beams at elevated temperatures. J. Build. Eng. 2022, 47, 103841. [Google Scholar] [CrossRef]

- Issa, C.A.; Izadifard, R.A. Numerical simulation of the experimental behavior of RC beams at elevated temperatures. Adv. Model. Simul. Eng. Sci. 2021, 8, 12. [Google Scholar] [CrossRef]

- Schabowicz, K.; Sulik, P.; Gorzelańczyk, T.; Zawiślak, Ł. Numerical analysis of storey-to-storey fire spreading. Arch. Civ. Eng. 2022, 68, 91–109. [Google Scholar] [CrossRef]

- Compaoré, A.; Sawadogo, M.; Sawadogo, Y.; Ouedraogo, M.; Sorgho, B.; Seynou, M.; Blanchart, P.; Zerbo, L. Preparation and characterization of foamed concrete using a foaming agent and local mineral resources from Burkina Faso. Results Mater. 2023, 17, 100365. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Farzadnia, N.; Abang Ali, A.A. Properties and applications of foamed concrete; a review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Upasiri, I.R.; Konthesingha, K.M.C.; Poologanathan, K.; Nanayakkara, S.M.A.; Nagaratnam, B. Review on Fire Performance of Cellular Lightweight Concrete. In Proceedings of the ICSBE 2018: 9th International Conference on Sustainable Built Environment, Kandy, Sri Lanka, 13–15 December 2018; Springer: Singapore, 2020; pp. 470–478. [Google Scholar]

- Raj, A.; Sathyan, D.; Mini, K.M. Physical and functional characteristics of foam concrete: A review. Constr. Build. Mater. 2019, 221, 787–799. [Google Scholar] [CrossRef]

- Chaipanich, A.; Chindaprasirt, P. The properties and durability of autoclaved aerated concrete masonry blocks. In Eco-Efficient Masonry Bricks and Blocks; Pacheco-Torgal, F., Lourenço, P.B., Labrincha, J.A., Kumar, S., Chindaprasirt, P., Eds.; Woodhead Publishing: Oxford, UK, 2015; pp. 215–230. [Google Scholar]

- Thorat, V.M.; Papal, M.; Kacha, V.; Sarnobat, T.; Gaikwad, S. Hollow Concrete Blocks-A New Trend. Int. J. Eng. Res. 2015, 5, 19–26. [Google Scholar]

- Wong, R.W.M.; Loo, B.P.Y. Sustainability implications of using precast concrete in construction: An in-depth project-level analysis spanning two decades. J. Clean. Prod. 2022, 378, 134486. [Google Scholar] [CrossRef]

- Fudge, C.; Fouad, F.; Klingner, R. Autoclaved aerated concrete. In Developments in the Formulation and Reinforcement of Concrete, 2nd ed.; Mindess, S., Ed.; Woodhead Publishing: Oxford, UK, 2019; pp. 345–363. [Google Scholar]

- Salami, B.A.; Iqbal, M.; Abdulraheem, A.; Jalal, F.E.; Alimi, W.; Jamal, A.; Tafsirojjaman, T.; Liu, Y.; Bardhan, A. Estimating compressive strength of lightweight foamed concrete using neural, genetic and ensemble machine learning approaches. Cem. Concr. Compos. 2022, 133, 104721. [Google Scholar] [CrossRef]

- Fakharian, P.; Rezazadeh Eidgahee, D.; Akbari, M.; Jahangir, H.; Ali Taeb, A. Compressive strength prediction of hollow concrete masonry blocks using artificial intelligence algorithms. Structures 2023, 47, 1790–1802. [Google Scholar] [CrossRef]

- Kodur, V. Properties of Concrete at Elevated Temperatures. ISRN Civ. Eng. 2014, 2014, 468510. [Google Scholar] [CrossRef]

- Ninu, S.; Nisthar, A.; Sahil, R.; Najeeb, M. Study on Performance of Polystyrene Concrete Building Blocks. Int. J. Innov. Res. Sci. Eng. Technol. 2020, 9, 4787–4793. [Google Scholar]

- Yoon, H.; Kim, Y.J.; Kim, H.S.; Kang, J.W.; Koh, H.-M. Evaluation of Early-Age Concrete Compressive Strength with Ultrasonic Sensors. Sensors 2017, 17, 1817. [Google Scholar] [CrossRef]

- Jain, D.; Hindoriya, A.K.; Bhadauria, S.S. Evaluation of properties of cellular light weight concrete. AIP Conf. Proc. 2019, 2158, 020034. [Google Scholar] [CrossRef]

- Narayanan, N.; Ramamurthy, K. Structure and properties of aerated concrete: A review. Cem. Concr. Compos. 2000, 22, 321–329. [Google Scholar] [CrossRef]

- Jhatial, A.A.; Goh, W.I.; Mohamad, N.; Alengaram, U.J.; Mo, K.H. Effect of Polypropylene Fibres on the Thermal Conductivity of Lightweight Foamed Concrete. MATEC Web Conf. 2018, 150, 03008. [Google Scholar] [CrossRef]

- Fogiatto; Santos, G.H.D.; Mendes, N. Thermal transmittance evaluation of concrete hollow blocks. In Proceedings of the 12th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics, Costa del Sol, Spain, 11–13 July 2016; pp. 1291–1296. [Google Scholar]

- Fediuk, R.A.-O.; Amran, M.; Vatin, N.A.-O.; Vasilev, Y.; Lesovik, V.; Ozbakkaloglu, T. Acoustic Properties of Innovative Concretes: A Review. Materials 2021, 14, 398. [Google Scholar] [CrossRef] [PubMed]

- Hillier, S.R.; Sangha, C.M.; Plunkett, B.A.; Walden, P.J. Long-term leaching of toxic trace metals from Portland cement concrete. Cem. Concr. Res. 1999, 29, 515–521. [Google Scholar] [CrossRef]

- Gencel, O.; Bilir, T.; Bademler, Z.; Ozbakkaloglu, T. A Detailed Review on Foam Concrete Composites: Ingredients, Properties, and Microstructure. Appl. Sci. 2022, 12, 5752. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J.; Zhang, L.; Liu, Z.; Jiang, Z. Dynamic Performance of Foam Concrete with Recycled Coir Fiber. Front. Mater. 2020, 7, 567655. [Google Scholar] [CrossRef]

- Fu, Y.; Wang, X.; Wang, L.; Li, Y. Foam Concrete: A State-of-the-Art and State-of-the-Practice Review. Adv. Mater. Sci. Eng. 2020, 2020, 6153602. [Google Scholar] [CrossRef]

- Galal, M.; Youssef, T.; Abdel-Aziz, A. Factors Influencing the Physical and Mechanical Properties of Foamed Concrete–Modelling and Optimization. Int. J. Sci. Eng. Res. 2018, 8, 860–867. [Google Scholar]

- Britez, C.; Carvalho, M.; Helene, P. Fire impacts on concrete structures. A brief review. Revista ALCONPAT 2019, 10, 1–21. [Google Scholar] [CrossRef]

- Rybakov, V.; Seliverstov, A.; Usanova, K.; Rayimova, I. Combustibility of lightweight foam concrete based on natural protein foaming agent. In Proceedings of the International Scientific Conference “Construction Mechanics, Hydraulics and Water Resources Engineering” (CONMECHYDRO–2021), Tashkent, Uzbekistan, 1–3 April 2021; p. 8. [Google Scholar]

- Yew, M.K.; Yew, M.C.; Beh, J.H.; Saw, L.H.; Lee, Y.L.; Lim, J.H. Fire resistance of lightweight foam concrete by incorporating lightweight bio-based aggregate. IOP Conf. Ser. Earth Environ. Sci. 2021, 920, 9. [Google Scholar] [CrossRef]

- Awoyera, P.; Onoja, E.; Adesina, A. Fire resistance and thermal insulation properties of foamed concrete incorporating pulverized ceramics and mineral admixtures. Asian J. Civ. Eng. 2019, 1, 147–156. [Google Scholar] [CrossRef]

- Othuman Mydin, M.A. Evaluation of the Mechanical Properties of Lightweight Foamed Concrete at Varying Elevated Temperatures. Fire 2023, 6, 53. [Google Scholar] [CrossRef]

- Vilches, J.; Ramezani, M.; Neitzert, T. Experimental investigation of the fire resistance of ultra lightweight foam concrete. Int. J. Adv. Eng. Appl. 2012, 1, 15–22. [Google Scholar]

- EN 1363-1; Fire Resistance Tests–Part 1: General Requirements. iTeh Standards: Etobicoke, ON, Canada, 2019.

- Gales, J.; Chorlton, B.; Jeanneret, C. The Historical Narrative of the Standard Temperature–Time Heating Curve for Structures. Fire Technol. 2021, 57, 529–558. [Google Scholar] [CrossRef]

- IS0-834; Fire-Resistance Tests—Elements of Building Construction. International Organization for Standardization: Geneva, Switzerland, 1975.

- EN 13501-2; Fire Classification of Construction Products and Building Elements—Part 2: Classification Using Data from Fire Resistance and/or Smoke Control Tests, Excluding Ventilation Services. CEN: Brussels, Belgium, 2023.

| Keyword | Links | Total Link Strength | Occurrences |

|---|---|---|---|

| Elevated temperatures | 40 | 233 | 90 |

| Beam | 36 | 135 | 66 |

| Columns | 31 | 140 | 62 |

| High-performance concrete | 34 | 222 | 61 |

| Compressive strength | 33 | 200 | 59 |

| Polypropylene fibers | 36 | 220 | 56 |

| Fire | 31 | 101 | 53 |

| Steel | 35 | 125 | 50 |

| Microstructure | 36 | 187 | 48 |

| Fire resistance | 29 | 110 | 47 |

| Concrete Type | Foam Concrete | Autoclaved Cellular Concrete | Hollow Concrete Blocks | Plain Concrete |

|---|---|---|---|---|

| Composition | Water, sand, cement, and foaming agents + aggregates [13] | Lime, cement, sand, aluminum powder + energy stimulus [14] | Sand, water, cement + mold [15] | Sand, water, cement + mold [16] |

| Manufacturing method; equipment | Prefabrication or in situ; mortar mixer and foam generator [13] | Prefabrication; high pressure autoclave [17] | Prefabrication [15] | Prefabrication or in situ [16] |

| Compressive strength, MPa | <51.18 [18] | <12 [14] | <40.5 [19] | 20–50 [20] |

| Density, kg/m3 | • Grouting, thermal insulation: 300–600 • Non-load bearing structures: 600–1200 • Load-bearing structures: 1200–1600 [13] | Non-structural elements: 700 [14] | Structural and non-structural elements: 1700–2000 [21] | Structural elements: 2400 [22] |

| Shape and size of element | Any shape [23] | Any shape in a prepared mold [17] | Different sizes in block forms [15] | Any shape [16] |

| Concrete compaction | Not required [13] | Not required [24] | Required [15] | Required [16] |

| Thermal conductivity, W/mK | 0.1–0.7 [25] | 0.07–0.17 [24] | <1.75 [26] | 1.4–3.6 [20] |

| Acoustic properties | Enhanced [13] | Enhanced [14] | Good [27] | Good [27] |

| Ease of manufacturing and processing | Enhanced; ease of drilling and cutting [23] | Enhanced [17] | Normal [15] | Normal [16] |

| Environmental impact | Pollution-free; lower energy consumption [23] | High energy consumption [14] | Pollution-free [15] | Pollution-free if well cured [28] |

| Element | Material 1 | Material 2 | Material 3 | Material 4 | Material 5 |

|---|---|---|---|---|---|

| Water (L) | 7.5 | 7.5 | 6 | 7.5 | - |

| Cement 42.5 R (kg) | 14 | 14 | - | 14 | - |

| Cement 32.5 R (kg) | - | - | 13.5 | - | - |

| Cement grout (m3) | - | - | - | - | 2 |

| Foam (0.4 MPa/3% conc.) | 30 | 24 | 24 | 12 | - |

| Foam (g/L) 1 | - | - | - | - | 80 |

| Ash (kg) | - | - | - | - | 80 |

| Material | Sample | Weight, kg | Density, kg/m3 | Average Density, kg/m3 |

|---|---|---|---|---|

| 1 | 1 | 15.13 | 617.55 | 624.08 ± 11.31 |

| 2 | 15.13 | 617.55 | ||

| 3 | 15.61 | 637.14 | ||

| 2 | 1 | 16.38 | 668.57 | 659.86 ± 8.57 |

| 2 | 15.96 | 651.43 | ||

| 3 | 16.16 | 659.59 | ||

| 3 | 1 | 11.39 | 464.90 | 490.75 ± 22.69 |

| 2 | 12.43 | 507.35 | ||

| 3 | 12.25 | 500.00 | ||

| 4 | 1 | 19.38 | 791.02 | 826.94 ± 31.37 |

| 2 | 20.60 | 840.82 | ||

| 3 | 20.80 | 848.98 | ||

| 5 | 1 | 7.16 | 292.24 | 302.04 ± 8.53 |

| 2 | 7.54 | 307.76 | ||

| 3 | 7.50 | 306.12 |

| Thickness, mm | 15 | 50 | 100 | 150 | 200 | |

|---|---|---|---|---|---|---|

| Material | Average Density, kg/m3 | Effectiveness of Insulating Fire Temperatures, min | ||||

| 1 | 624.08 ± 11.31 | 11–13 | 47–87 | 140 | 140 | 140 |

| 2 | 659.86 ± 8.57 | 9–24 | 38–130 | 138–140 | 140 | 140 |

| 3 | 490.75 ± 22.69 | 12–14 | 53–63 | 135–140 | 140 | 140 |

| 4 | 826.94 ± 31.37 | 30–38 | 140 | 140 | 140 | 140 |

| 5 | 302.04 ± 8.53 | 11–13 | 60–70 | 62–140 | 140 | 140 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sulik, P.; Kukfisz, B.; Dowbysz, A.; Oszczak-Nowińska, A. Fire Resistance of Foamed Concrete for Discontinuous Partition Filling. Materials 2024, 17, 1315. https://doi.org/10.3390/ma17061315

Sulik P, Kukfisz B, Dowbysz A, Oszczak-Nowińska A. Fire Resistance of Foamed Concrete for Discontinuous Partition Filling. Materials. 2024; 17(6):1315. https://doi.org/10.3390/ma17061315

Chicago/Turabian StyleSulik, Paweł, Bożena Kukfisz, Adriana Dowbysz, and Agata Oszczak-Nowińska. 2024. "Fire Resistance of Foamed Concrete for Discontinuous Partition Filling" Materials 17, no. 6: 1315. https://doi.org/10.3390/ma17061315

APA StyleSulik, P., Kukfisz, B., Dowbysz, A., & Oszczak-Nowińska, A. (2024). Fire Resistance of Foamed Concrete for Discontinuous Partition Filling. Materials, 17(6), 1315. https://doi.org/10.3390/ma17061315