Zirconia Toughened Alumina Ceramics via Forming Intragranular Structure

Abstract

:1. Introduction

2. Materials and Experimental Methods

3. Characterization Methods

4. Results and Discussion

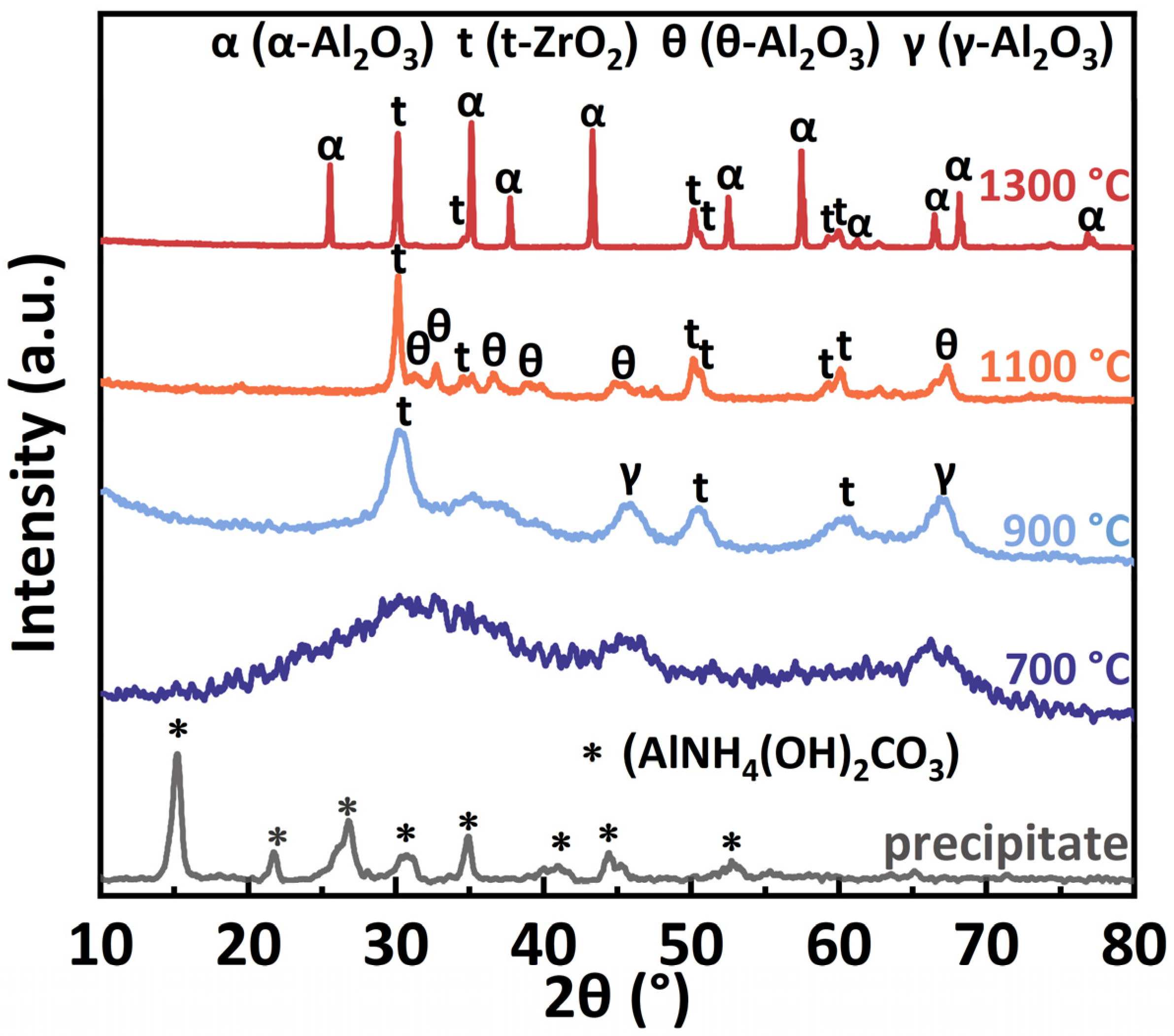

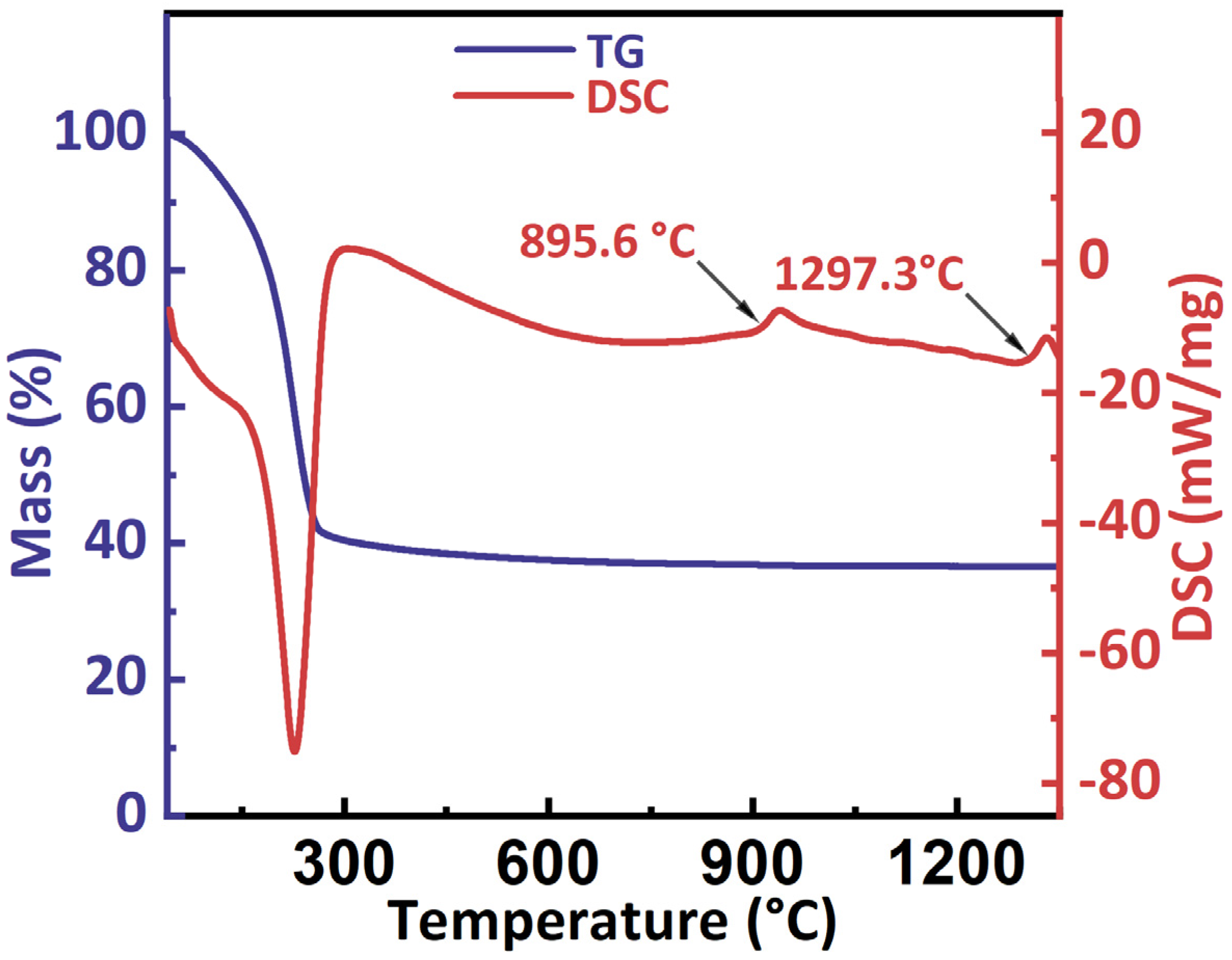

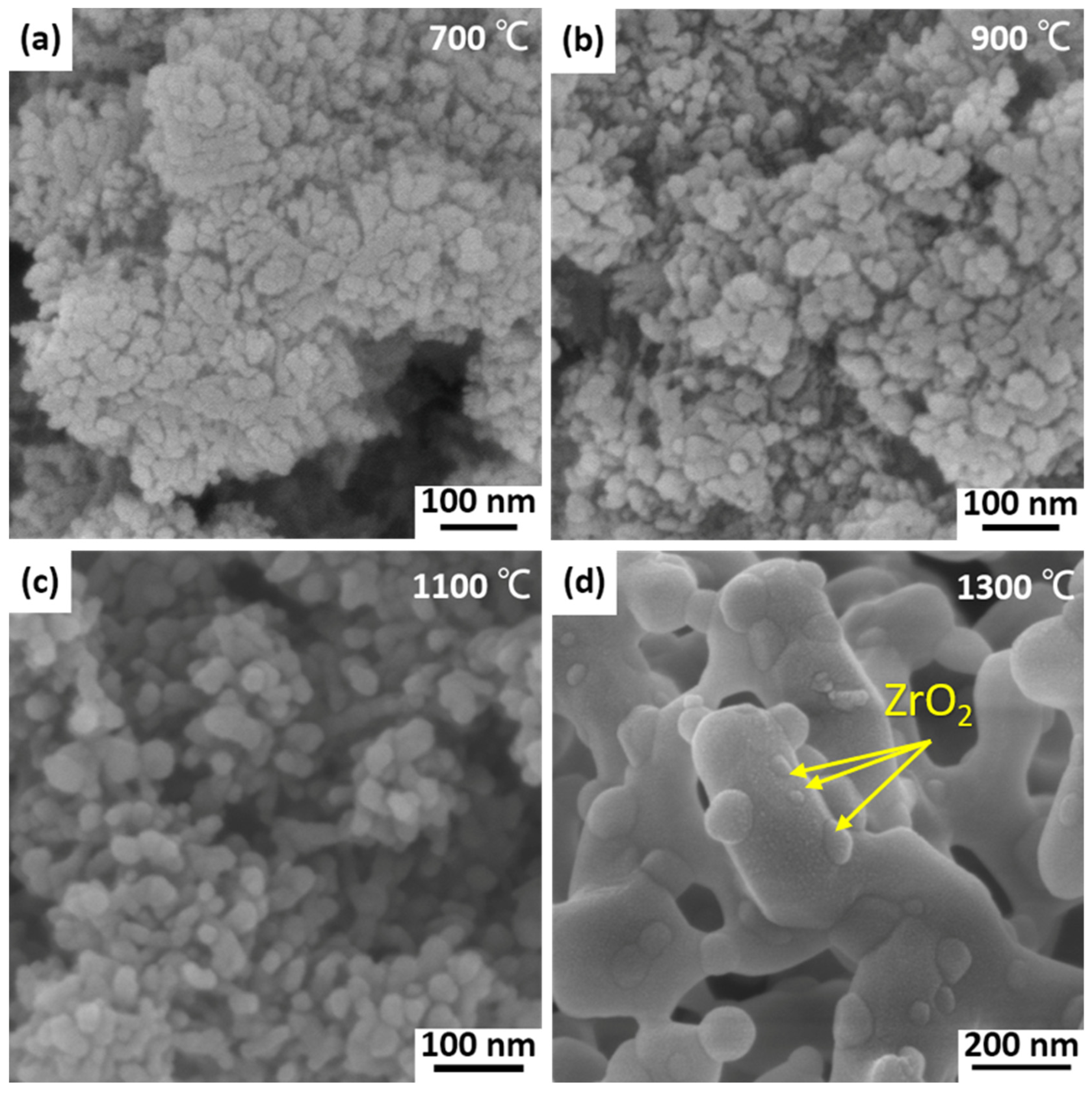

4.1. Powder Preparation

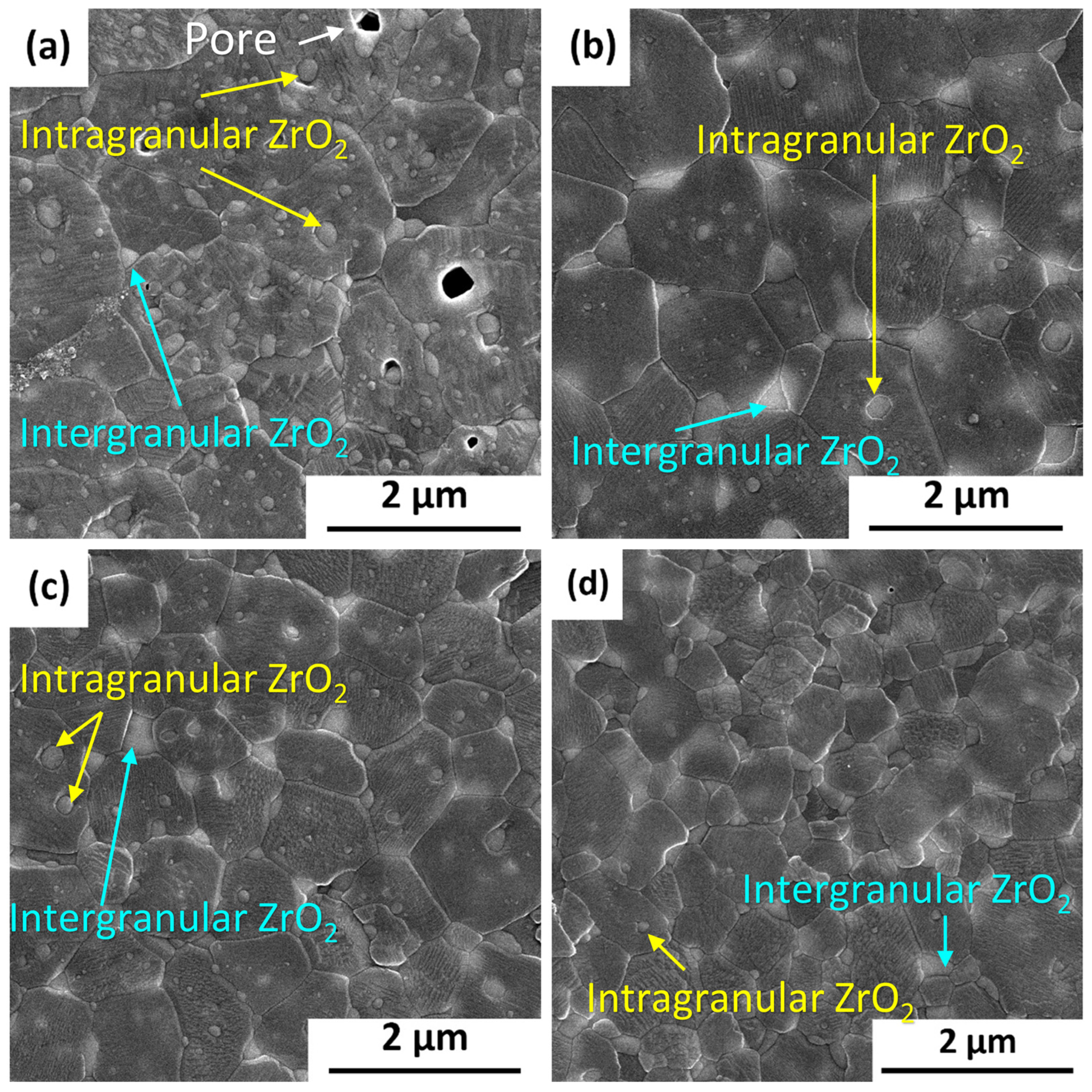

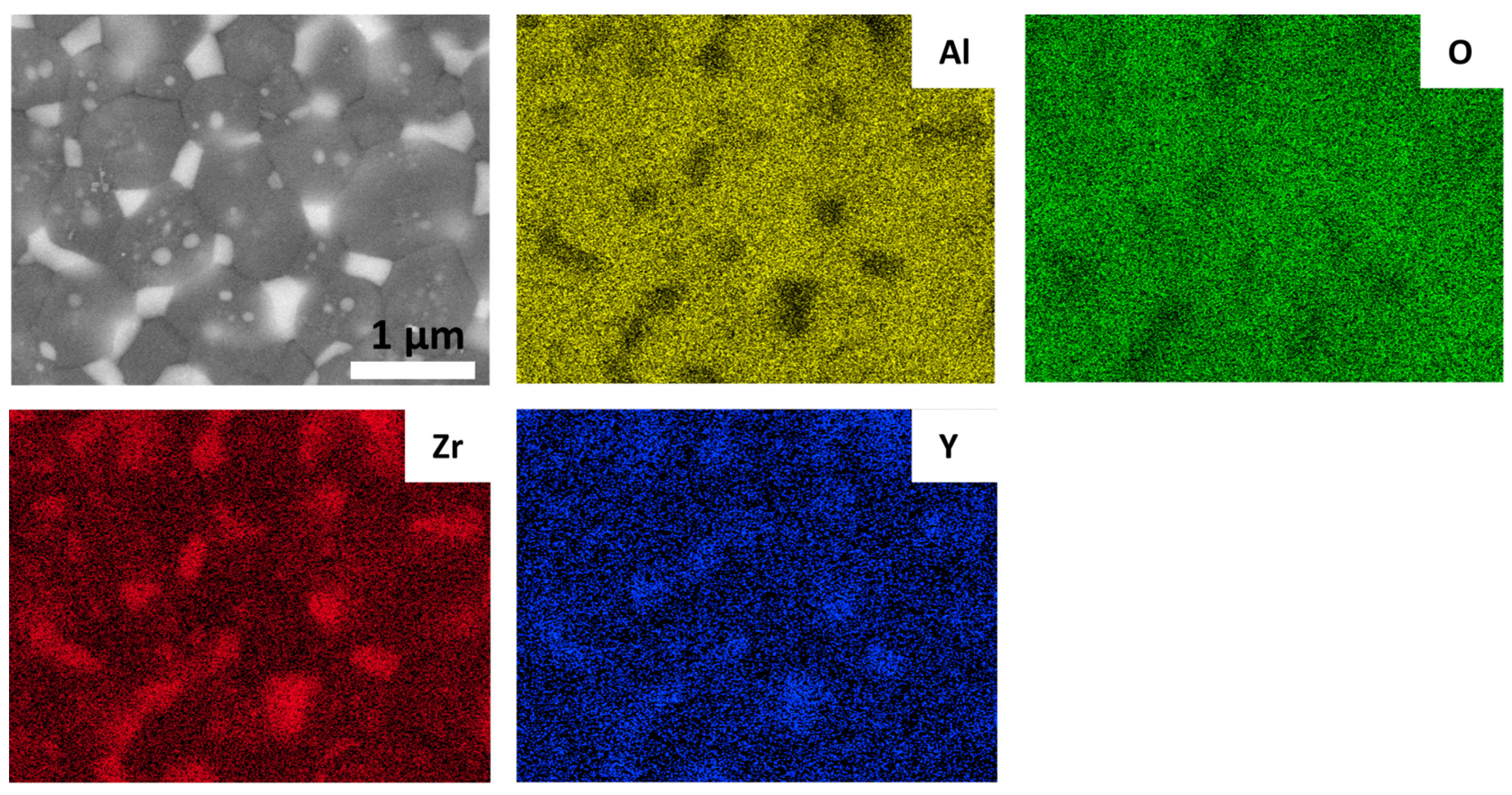

4.2. Microstructure of the ZTA Ceramics

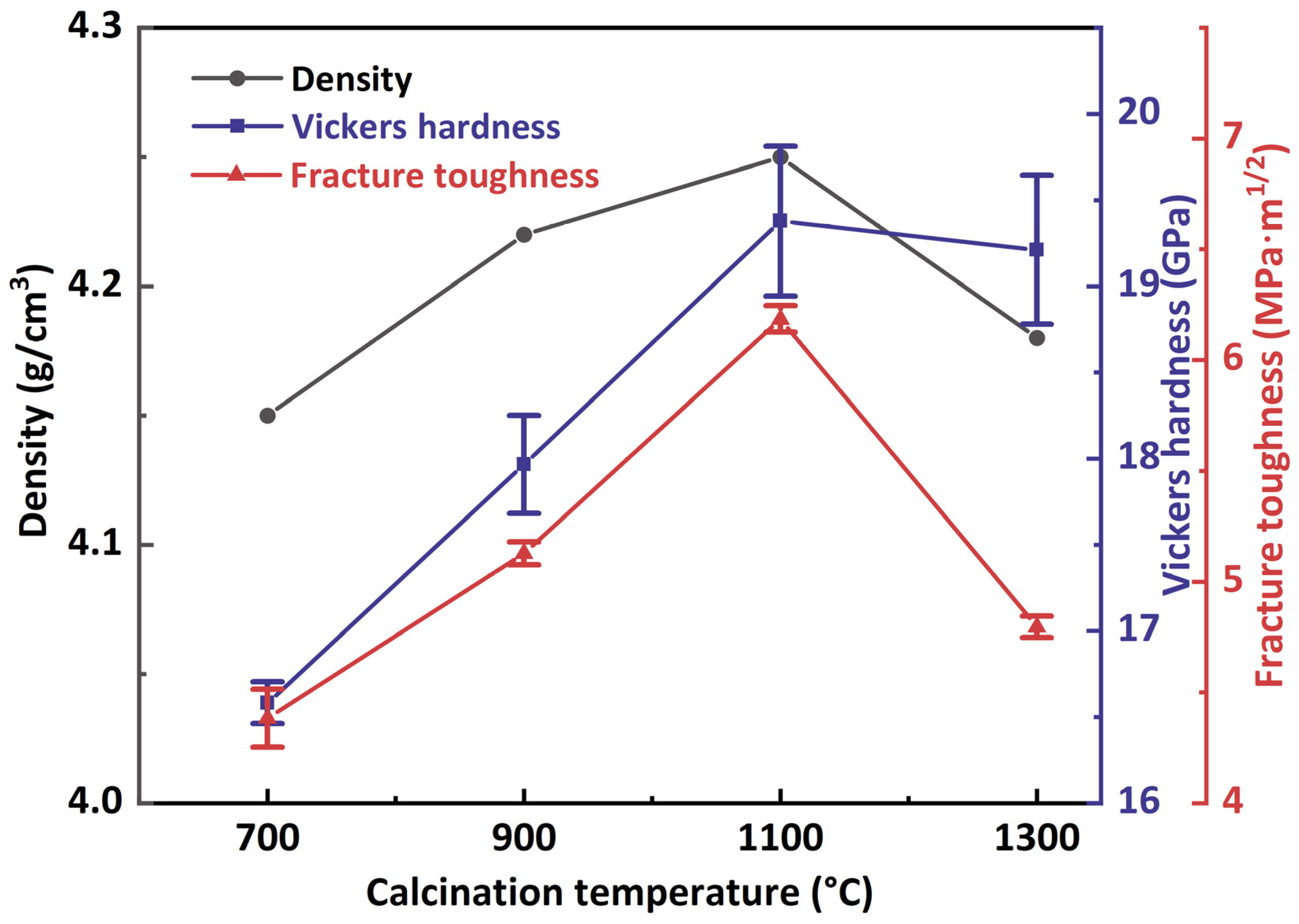

4.3. Mechanical Properties of the ZTA Ceramics

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abyzov, A.M. Aluminum Oxide and Alumina Ceramics (Review). Part 1. Properties of Al2O3 and Commercial Production of Dispersed Al2O3. Refract. Ind. Ceram. 2019, 60, 24–32. [Google Scholar] [CrossRef]

- Khalid, M.W.; Kim, Y.I.; Haq, M.A.; Lee, D.; Kim, B.S.; Lee, B. Microwave Hybrid Sintering of Al2O3 and Al2O3–ZrO2 Composites, and Effects of ZrO2 Crystal Structure on Mechanical Properties, Thermal Properties, and Sintering Kinetics. Ceram. Int. 2020, 46, 9002–9010. [Google Scholar] [CrossRef]

- Chai, J.; Zhu, Y.; Gao, X.; Shen, T.; Niu, L.; Li, S.; Jin, P.; Cui, M.; Wang, Z. Effects of Residual Stress and Intragranular Particles on Mechanical Properties of Hot-Pressed Al2O3/SiC Ceramic Composites. Ceram. Int. 2022, 48, 23258–23265. [Google Scholar] [CrossRef]

- Kosyanov, D.Y.; Liu, X.; Vornovskikh, A.A.; Zavjalov, A.P.; Zakharenko, A.M.; Kosianova, A.A.; Fedorets, A.N.; Shichalin, O.O.; Leonov, A.A.; Li, W.; et al. Al2O3–Ce:YAG Composite Ceramics for High Brightness Lighting: Cerium Doping Effect. J. Alloys Compd. 2021, 887, 161486. [Google Scholar] [CrossRef]

- Khalile, N.; Petit, C.; Meunier, C.; Valdivieso, F. Microwave Sintering of Zirconia Toughened Alumina—Influence of the Type and Content of Doping in Zirconia. Ceram. Int. 2023, 49, 36218–36224. [Google Scholar] [CrossRef]

- Pligovka, A.; Lazavenka, A.; Zakhlebayeva, A. Electro-Physical Properties of Niobia Columnlike Nanostructures via the Anodizing of Al/Nb Layers. In Proceedings of the 2018 IEEE 18th International Conference on Nanotechnology (IEEE-NANO), Cork, Ireland, 23–26 July 2018; pp. 1–5. [Google Scholar]

- Liu, L.; Maeda, K.; Onda, T.; Chen, Z.-C. Effect of YSZ with Different Y2O3 Contents on Toughening Behavior of Al2O3/Ba-β-Al2O3/ZrO2 Composites. Ceram. Int. 2019, 45, 18037–18043. [Google Scholar] [CrossRef]

- Arab, A.; Ahmad, Z.A.; Ahmad, R. Effects of Yttria Stabilized Zirconia (3Y-TZP) Percentages on the ZTA Dynamic Mechanical Properties. Int. J. Refract. Met. Hard Mater. 2015, 50, 157–162. [Google Scholar] [CrossRef]

- Meunier, C.; Zuo, F.; Peillon, N.; Saunier, S.; Marinel, S.; Goeuriot, D. In Situ Study on Microwave Sintering of ZTA Ceramic: Effect of ZrO2 Content on Densification, Hardness, and Toughness. J. Am. Ceram. Soc. 2017, 100, 929–936. [Google Scholar] [CrossRef]

- Ipek, M.; Zeytin, S.; Bindal, C. An Evaluation of Al2O3–ZrO2 Composites Produced by Coprecipitation Method. J. Alloys Compd. 2011, 509, 486–489. [Google Scholar] [CrossRef]

- Prajapati, P.K.; Biswas, P.; Singh, B.K.; Bapanapalle, C.O.; Ghosh, R.; Mandal, N. Reinforcing Potential of MWCNTs on Mechanical and Machining Performance of Hot-Pressed ZTA-MgO Ceramic Cutting Inserts. Diam. Relat. Mater. 2023, 138, 110202. [Google Scholar] [CrossRef]

- Norfauzi, T.; Hadzley, A.; Azlan, U.; Afuza, A.; Faiz, M.; Naim, M. Fabrication and Machining Performance of Ceramic Cutting Tool Based on the Al2O3-ZrO2-Cr2O3 Compositions. J. Mater. Res. Technol. 2019, 8, 5114–5123. [Google Scholar] [CrossRef]

- Sktani, Z.D.I.; Rejab, N.A.; Ahmad, Z.A. Tougher and Harder Zirconia Toughened Alumina (ZTA) Composites through in Situ Microstructural Formation of LaMgAl11O19. Int. J. Refract. Met. Hard Mater. 2019, 79, 60–68. [Google Scholar] [CrossRef]

- Terrizzi, A.R.; Fersini, M.; Contaldi, V.; Kunjalukkal Padmanabhan, S.; Einarsrud, M.-A.; Licciulli, A. Mechanical and Tribological Properties of Injection Molded Zirconia-Alumina for Orthopedic Implants. Ceram. Int. 2022, 48, 31211–31222. [Google Scholar] [CrossRef]

- Tõldsepp, E.; Schoenstein, F.; Amamra, M.; Saar, R.; Feldbach, E.; Kanaev, A.; Kirm, M. Spark Plasma Sintering of Ultra-Porous γ-Al2O3. Ceram. Int. 2016, 42, 11709–11715. [Google Scholar] [CrossRef]

- Xu, X.; Yang, Y.; Wang, X.; Su, X.; Liu, J. Low-Temperature Preparation of Al2O3-ZrO2 Nanoceramics via Pressureless Sintering Assisted by Amorphous Powders. J. Alloys Compd. 2019, 783, 806–812. [Google Scholar] [CrossRef]

- Azar, M.; Palmero, P.; Lombardi, M.; Garnier, V.; Montanaro, L.; Fantozzi, G.; Chevalier, J. Effect of Initial Particle Packing on the Sintering of Nanostructured Transition Alumina. J. Eur. Ceram. Soc. 2008, 28, 1121–1128. [Google Scholar] [CrossRef]

- Niihara, K. New design concepts of structural ceramics–ceramic nanocomposites. J. Ceram. Soc. Jpn. 1991, 99, 974–982. [Google Scholar] [CrossRef]

- Yi, M.; Wang, J.; Bai, X.; Xu, Y.; Xiao, G.; Chen, Z.; Zhang, J.; Chen, H.; Xu, C. Synthesis and Properties Characterization of an Al2O3-Based Ceramic Materials with Intragranular Self-Lubricating Nanostructure. Int. J. Refract. Met. Hard Mater. 2022, 104, 105800. [Google Scholar] [CrossRef]

- Du, W.; Ai, Y.; He, W.; Chen, W.; Liang, B.; Lv, C. Formation and Control of “Intragranular” ZrO2 Strengthened and Toughened Al2O3 Ceramics. Ceram. Int. 2020, 46, 8452–8461. [Google Scholar] [CrossRef]

- Moraes, M.C.C.D.S.E.B.D.; Elias, C.N.; Duailibi Filho, J.; Oliveira, L.G.D. Mechanical Properties of Alumina-Zirconia Composites for Ceramic Abutments. Mater. Res. 2004, 7, 643–649. [Google Scholar] [CrossRef]

- Sagar, K.G.; Suresh, P.M. A Critical Evaluation of Indentation Techniques for Measuring the Hardness vs Toughness: A Review. In Proceedings of the International Conference on Sustainable Engineering and Technology (ICONSET 2018), Karnataka, India, 19–20 April 2018; p. 020073. [Google Scholar]

- Xu, X.; Wang, Y.; Guo, A.; Geng, H.; Ren, S.; Tao, X.; Liu, J. Enhanced Plasticity by Nanocrystallite in Bulk Amorphous Al2O3–ZrO2–Y2O3. Int. J. Plast. 2016, 79, 314–327. [Google Scholar] [CrossRef]

- Lamouri, S.; Hamidouche, M.; Bouaouadja, N.; Belhouchet, H.; Garnier, V.; Fantozzi, G.; Trelkat, J.F. Control of the γ-Alumina to α-Alumina Phase Transformation for an Optimized Alumina Densification. Bol. Soc. Esp. Cerámica Vidr. 2017, 56, 47–54. [Google Scholar] [CrossRef]

- Smuk, B.; Szutkowska, M.; Walter, J. Alumina Ceramics with Partially Stabilized Zirconia for Cutting Tools. J. Mater. Process. Technol. 2003, 133, 195–198. [Google Scholar] [CrossRef]

- Lee, K.T.; Cha, S.I.; Kim, K.T.; Lee, K.H.; Hong, S.H. Sintering Behavior, Microstructural Evolution, and Mechanical Properties of Ultra-Fine Grained Alumina Synthesized via in-Situ Spark Plasma Sintering. Ceram. Int. 2016, 42, 4290–4297. [Google Scholar] [CrossRef]

- Liu, X.; Yuan, Y.; Wang, R.; Zhu, S.; Bai, Y.; Fang, C.; Li, J.; Chen, C.; Zheng, Y. Pressureless Sintering Behaviour of Al2O3/ZrO2 Amorphous/Solid Solution Powder with Ultra-Fine ZrO2 Nanoparticle Precipitation. Ceram. Int. 2023, 49, 39886–39897. [Google Scholar] [CrossRef]

- Patil, S.; Patil, D.R.; Jung, I.C.; Ryu, J. Effect of Cooling Rates on Mechanical Properties of Alumina-Toughened Zirconia Composites. Ceram. Int. 2022, 48, 21048–22105. [Google Scholar] [CrossRef]

- Li, J.; Zhong, X.; Luo, G.; Cai, Q.; Shen, Q.; Tu, R.; Guo, X.; Ding, R. Microstructure and Mechanical Properties of Dense ZTA Ceramics with High Cr2O3 Solution. J. Mater. Sci. 2023, 58, 7868–7879. [Google Scholar] [CrossRef]

- He, W.; Ai, Y.L.; Liu, C.H.; Zhang, J.P.; Ding, J.Y. Microstructure and Properties of Al2O3-ZrO2(n) Composite Ceramics Prepared by Microwave Sintering. Adv. Mater. Res. 2010, 177, 364–368. [Google Scholar] [CrossRef]

- Yu, W.; Zheng, Y.; Yu, Y.; Su, X. Combustion Synthesis Assisted Water Atomization-Solid Solution Precipitation: A New Guidance for Nano-ZTA Ceramics. J. Eur. Ceram. Soc. 2019, 39, 4313–4321. [Google Scholar] [CrossRef]

- Sommer, F.; Landfried, R.; Kern, F.; Gadow, R. Mechanical Properties of Zirconia Toughened Alumina with 10–24vol.% 1.5mol% Y-TZP Reinforcement. J. Eur. Ceram. Soc. 2012, 32, 3905–3910. [Google Scholar] [CrossRef]

- Xia, J.-F.; Nian, H.-Q.; Liu, W.; Wang, X.-G.; Jiang, D.-Y. Effect of Cr2O3 Derived from Cr(NO3)3·9H2O Precursor on the Densification and Mechanical Properties of Zirconia-Toughened Alumina (ZTA) Composites. Ceram. Int. 2016, 42, 9116–9124. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, W.; Wu, H.; Huang, R.; He, R.; Jiang, Q.; Chen, Y.; Ji, X.; Tian, Z.; Wu, S. Research into the Mechanical Properties, Sintering Mechanism and Microstructure Evolution of Al2O3-ZrO2 Composites Fabricated by a Stereolithography-Based 3D Printing Method. Mater. Chem. Phys. 2018, 207, 1–10. [Google Scholar] [CrossRef]

- Liu, G.; Xie, Z.; Wu, Y. Fabrication and Mechanical Properties of Homogeneous Zirconia Toughened Alumina Ceramics via Cyclic Solution Infiltration and in Situ Precipitation. Mater. Des. 2011, 32, 3440–3447. [Google Scholar] [CrossRef]

- Niihara, K.; Morena, R.; Hasselman, D.P.H. Evaluation of KIc of Brittle Solids by the Indentation Method with Low Crack-to-Indent Ratios. J. Mater. Sci. Lett. 1982, 1, 13–16. [Google Scholar] [CrossRef]

| Sample Identity | Calcination Temperature (°C) | Phase Composition |

|---|---|---|

| C700 | 700 | amorphous |

| C900 | 900 | t-ZrO2 and γ-Al2O3 |

| C1100 | 1100 | t-ZrO2 and θ-Al2O3 |

| C1300 | 1300 | t-ZrO2 and α-Al2O3 |

| Material | ZrO2 Content | KIC (MPa·m1/2) | Equation Type of IM | Hv (GPa) | ZrO2 Distribution | Sintering |

|---|---|---|---|---|---|---|

| This work | 25.0 wt.% | 6.18 ± 0.06 (IM) | Anstis, Equation (2) | 19.30 ± 0.43 | Intragranular/intergranular | SPS |

| Al2O3/ZrO2 [30] | 15.0 wt.% | 6.41 (IM) | Anstis, Equation (2) | N/A | Intragranular/intergranular | SPS |

| Al2O3/ZrO2 [31] | 34.9 wt.% | 6.72 ± 0.30 (SENB) | N/A | 17.21 ± 0.25 | Intragranular/intergranular | HP |

| Al2O3/ZrO2 [32] | 17.0 wt.% | 5.7 (IM) | Niihara, Equation (3) | 18.26 | Intragranular/intergranular | HP |

| Al2O3/ZrO2/Cr2O3 [33] | 15.0 wt.% | 4.67 ± 0.03 (IM) | Anstis, Equation (2) | 18.10 ± 0.15 | Intergranular | PS |

| Al2O3/ZrO2 [10] | 10.0 wt.% | 4.90 ± 0.10 (IM) | Anstis, Equation (2) | 16.80 ± 0.40 | Intergranular | PS |

| Al2O3/ZrO2 [34] | 20.0 wt.% | 5.20 (IM) | Evans and Charles, Equation (4) | 17.60 | Intergranular | 3D printing |

| Al2O3/ZrO2 [35] | 12.5 wt.% | 5.40 ± 0.40 (IM) | Anstis, Equation (2) | 18.30 ± 0.40 | Intergranular | PS |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Cai, Q.; Luo, G.; Zhong, X.; Shen, Q.; Tu, R.; Guo, X.; Ding, R. Zirconia Toughened Alumina Ceramics via Forming Intragranular Structure. Materials 2024, 17, 1309. https://doi.org/10.3390/ma17061309

Li J, Cai Q, Luo G, Zhong X, Shen Q, Tu R, Guo X, Ding R. Zirconia Toughened Alumina Ceramics via Forming Intragranular Structure. Materials. 2024; 17(6):1309. https://doi.org/10.3390/ma17061309

Chicago/Turabian StyleLi, Junguo, Qiwang Cai, Guoqiang Luo, Xinyu Zhong, Qiang Shen, Rong Tu, Xiaoping Guo, and Renchi Ding. 2024. "Zirconia Toughened Alumina Ceramics via Forming Intragranular Structure" Materials 17, no. 6: 1309. https://doi.org/10.3390/ma17061309