A Study of the Superplastic Deformation Behavior of Low-Cost Ti-2Fe-0.1B Alloys

Abstract

:1. Introduction

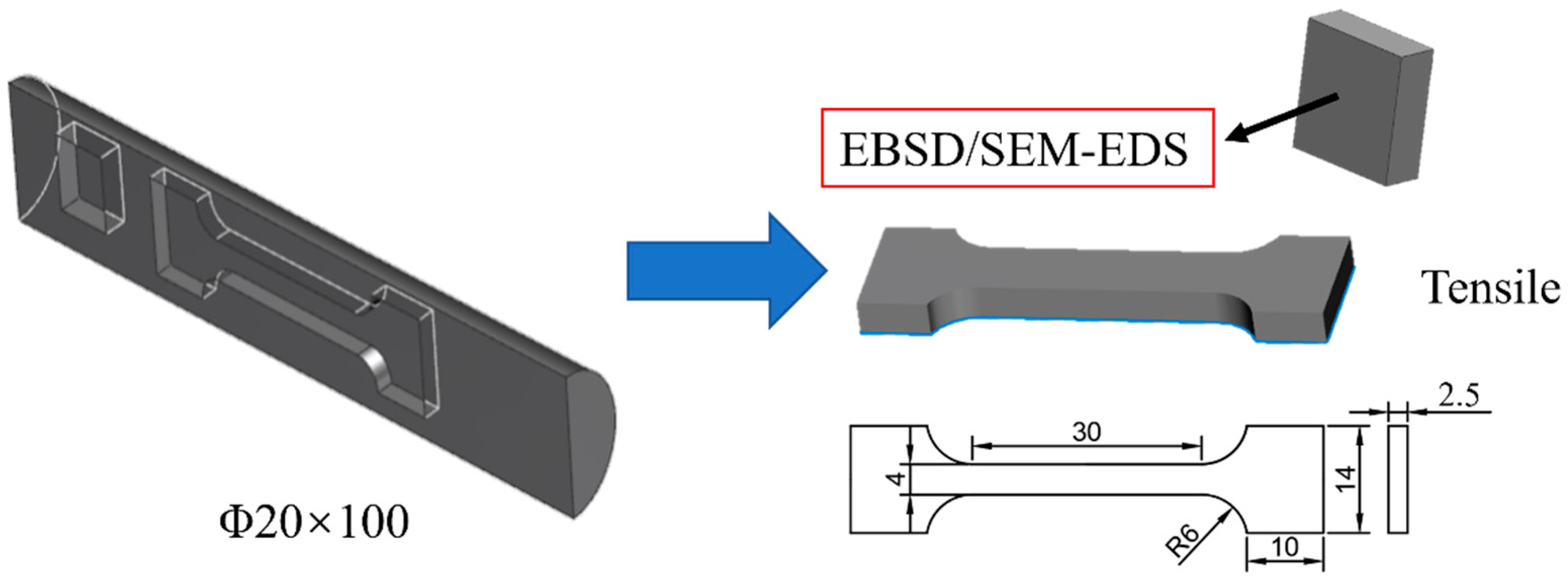

2. Experimental Methods

2.1. Material

2.2. High-Temperature Tensile Test

2.3. Microstructural Characterization

3. Results and Discussion

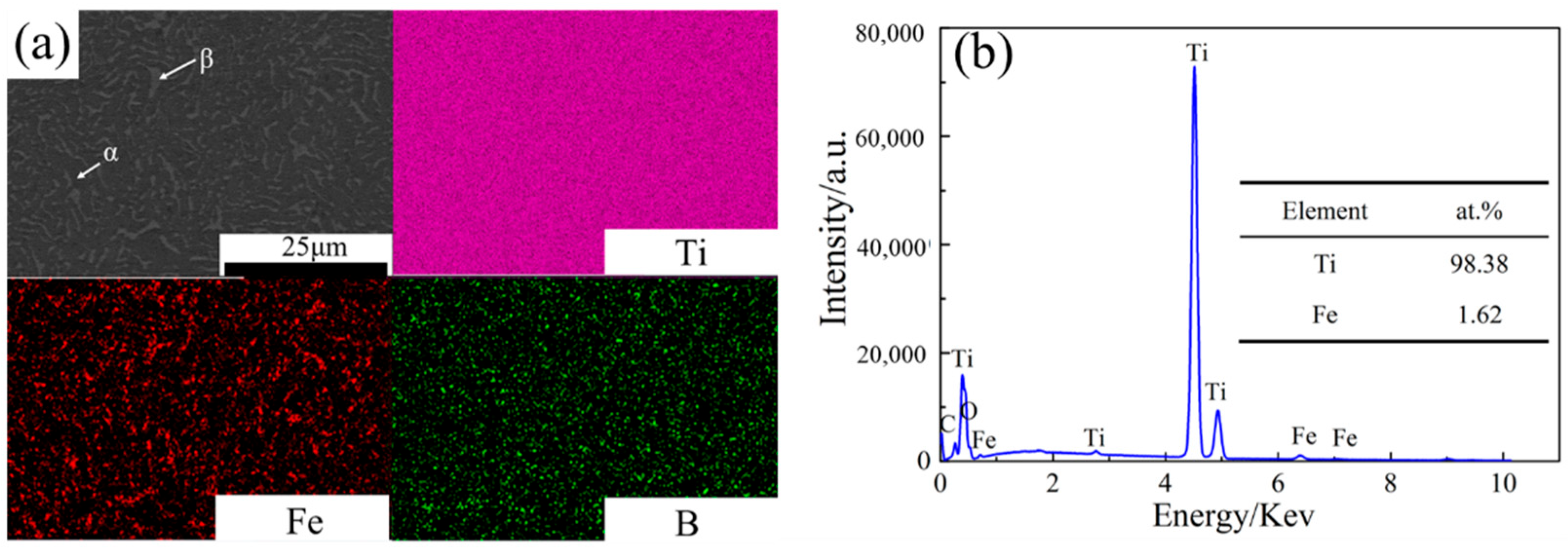

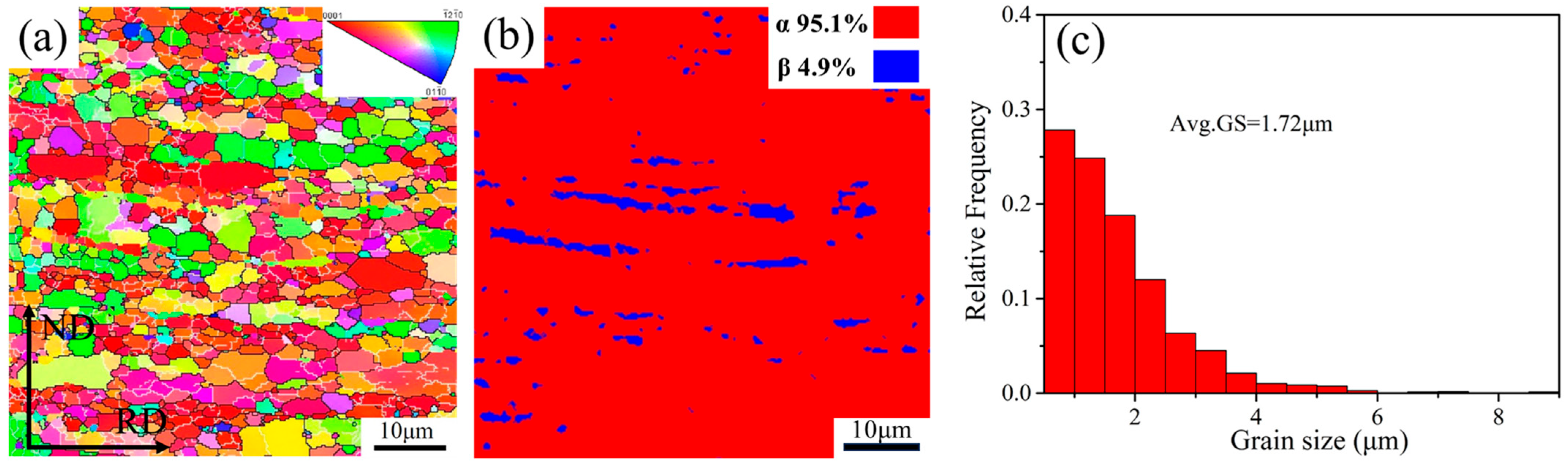

3.1. Initial Microstructure

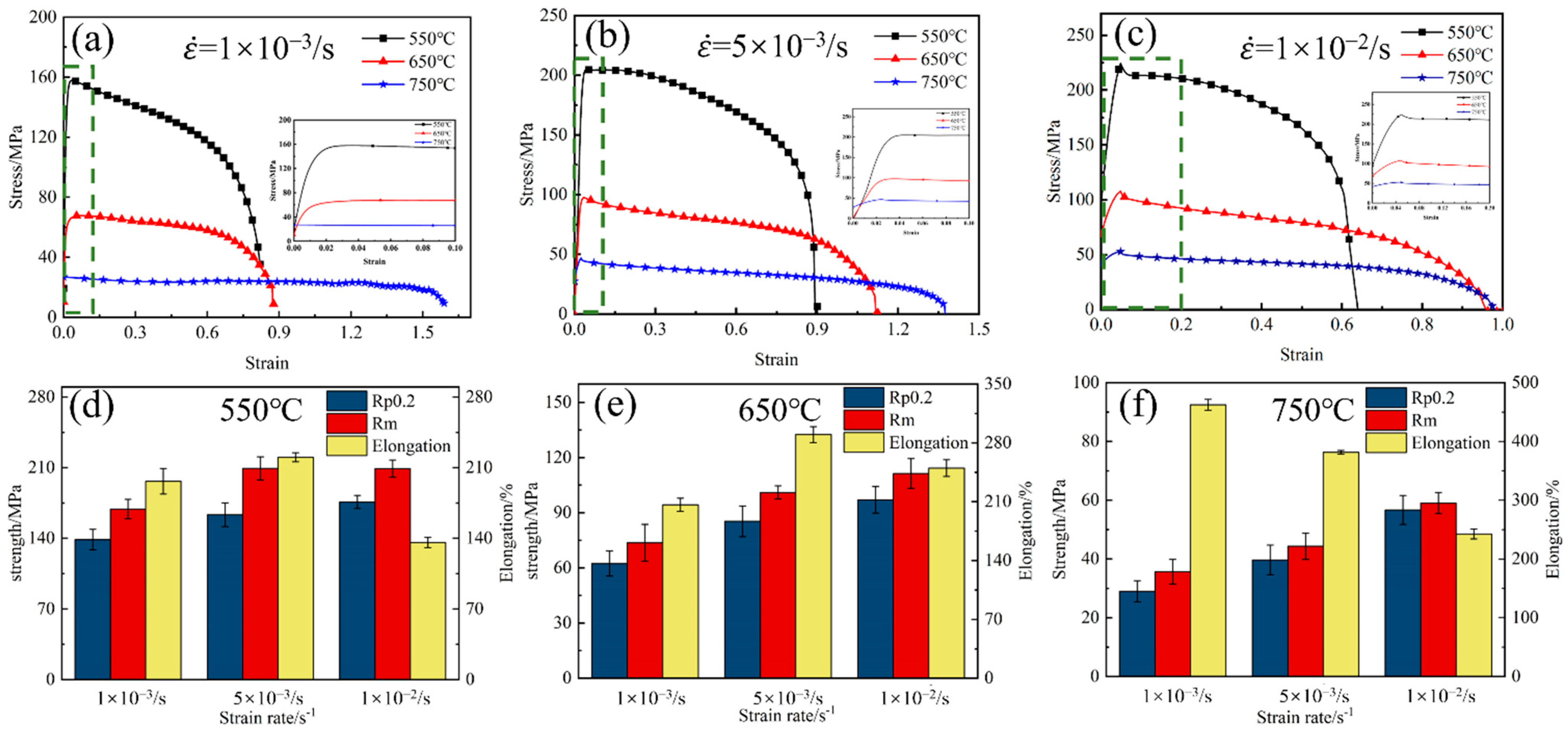

3.2. Superplastic Deformation

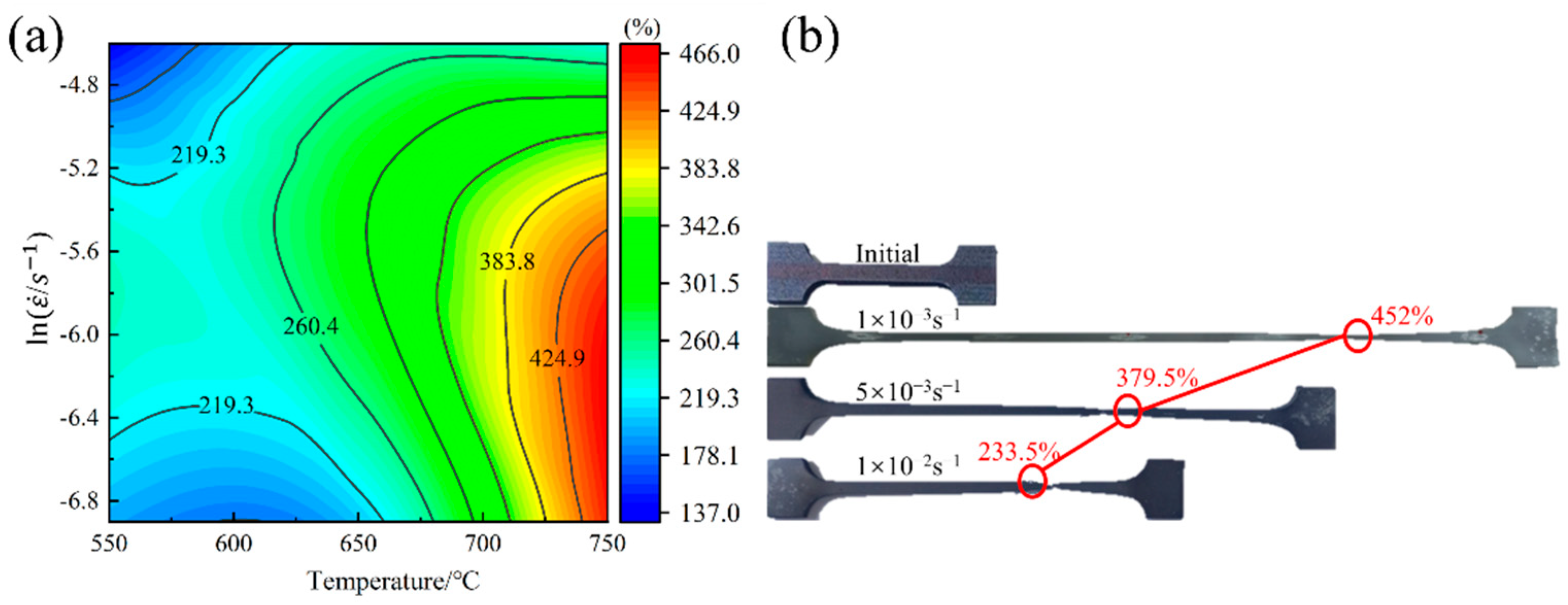

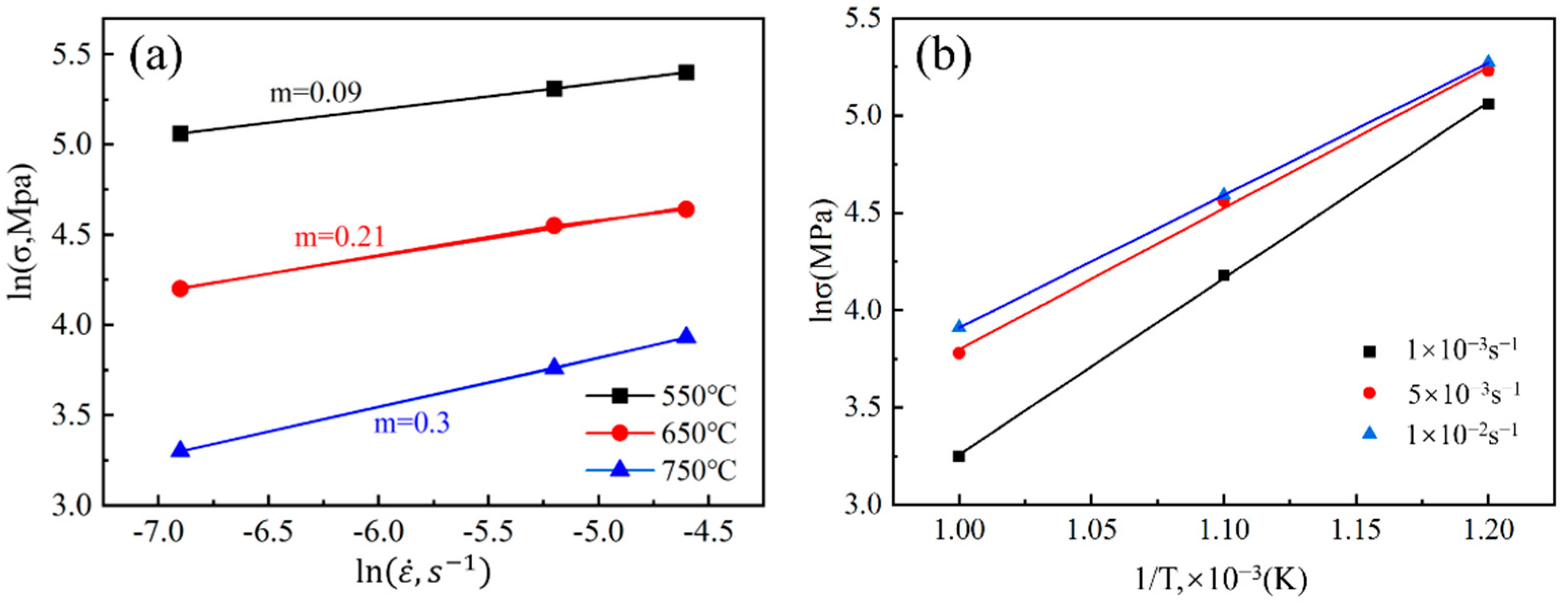

3.3. Microstructure Evolution

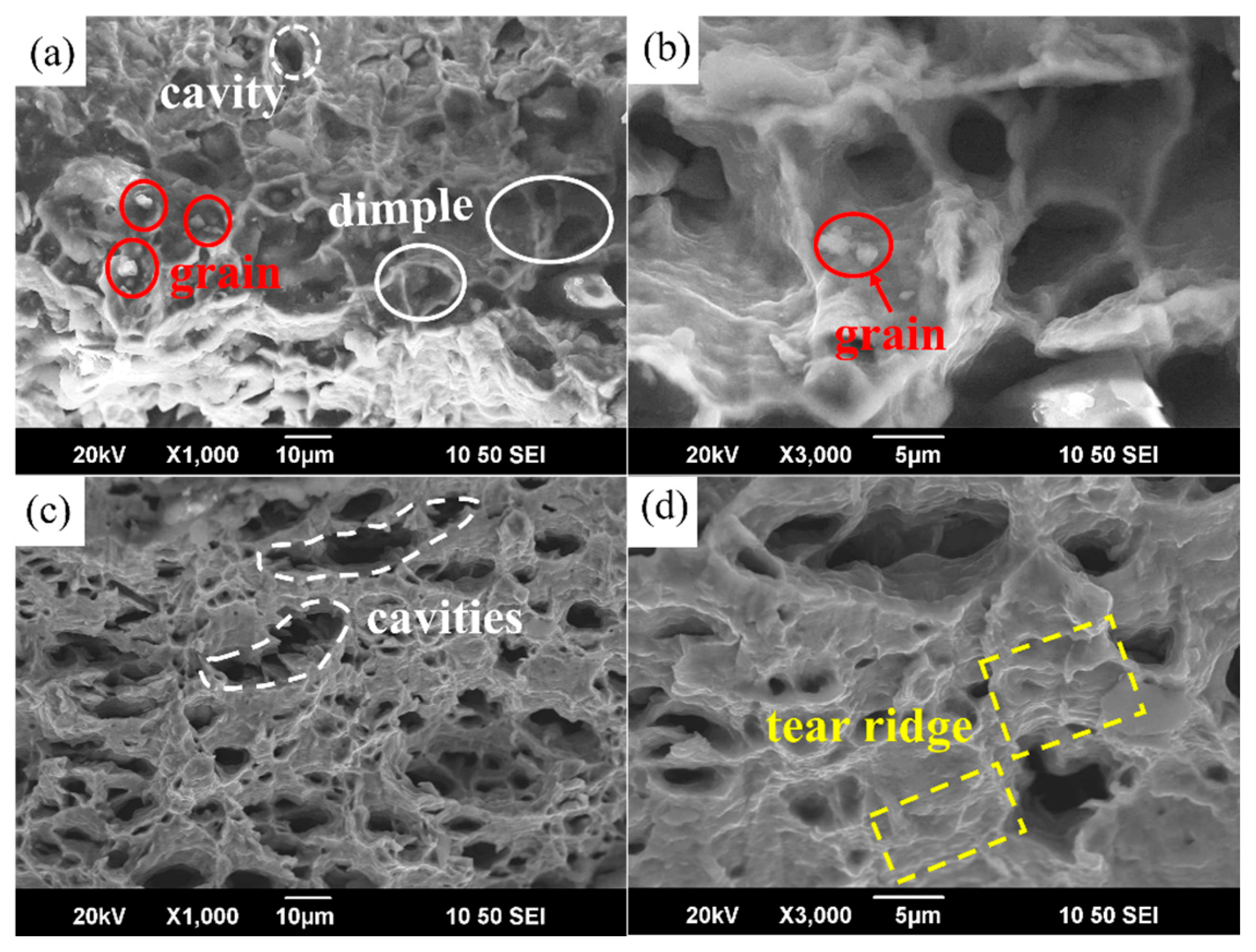

3.4. Fracture Morphology

- (1)

- The average grain size of the Ti-2Fe-0.1B alloy reached 1.72 μm due to the effect of Fe and B elements, which gave the alloy good superplasticity even at a high strain rate (1 × 10−2 s−1) and a low deformation temperature of 550 °C. The elongation of the alloy reached 137.5% under this deformation condition. The high strain rate sensitivity coefficient m (0.3) and the maximum elongation (452%) were obtained at a strain rate of 1 × 10−3 s−1 and a temperature of 750 °C.

- (2)

- The TiB phase provides nucleation sites for DRX and induces significant DRX and dynamic globularization during superplastic deformation. The main mechanism of superplastic deformation of the Ti-2Fe-0.1B alloy is grain boundary sliding under the coordination of dislocation motion, accompanied by DRX.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiao, M.J.; Tian, Y.X.; Mao, G.W.; Li, S.J.; Hao, Y.L.; Yang, R. Superplasticity of Ti2448 Alloy with Nanostructured Grains. J. Mater. Sci. Technol. 2011, 27, 1099–1104. [Google Scholar] [CrossRef]

- Zhao, Z.L.; Li, H.; Fu, M.W.; Guo, H.Z.; Yao, Z.K. Effect of the Initial Microstructure on the Deformation Behavior of Ti60 Titanium Alloy at High Temperature Processing. J. Alloys Compd. 2014, 617, 525–533. [Google Scholar] [CrossRef]

- Roy, S.; Suwas, S. Deformation Mechanisms during Superplastic Testing of Ti–6Al–4V–0.1B Alloy. Mater. Sci. Eng. A 2013, 574, 205–217. [Google Scholar] [CrossRef]

- Cai, C.; Gao, X.; Teng, Q.; Kiran, R.; Liu, J.; Wei, Q.; Shi, Y. Hot Isostatic Pressing of a Near α-Ti Alloy: Temperature Optimization, Microstructural Evolution and Mechanical Performance Evaluation. Mater. Sci. Eng. A 2021, 802, 140426. [Google Scholar] [CrossRef]

- Barnes, A.J. Superplastic Forming 40 Years and Still Growing. J. Mater. Eng. Perform. 2013, 22, 2935–2949. [Google Scholar] [CrossRef]

- Beliakova, T.A.; Goncharov, I.A. The Effect of Metal Alloy Microstructureon the Thickness Distribution in the Circular Plate Under the Superplastic Blow-Forming. Vestn. Samara Univ. Nat. Sci. Ser. 2020, 26, 50–62. [Google Scholar]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Mosleh, A.O.; Kotov, A.D.; Vidal, V.; Mochugovskiy, A.G.; Velay, V.; Mikhaylovskaya, A.V. Initial Microstructure Influence on Ti–Al–Mo–V Alloy’s Superplastic Deformation Behavior and Deformation Mechanisms. Mater. Sci. Eng. A 2021, 802, 140626. [Google Scholar] [CrossRef]

- Grabovetskaya, G.P.; Mishin, I.P.; Stepanova, E.N.; Zabudchenko, O.V.; Ratochka, I.V. Effect of the Structural and Phase State on the Deformation Behavior and Mechanical Properties of the Ultrafine-Grained Titanium Alloy (Ti–Al–V–Mo) at Temperatures in the Range of 293–973 K. Mater. Sci. Eng. A 2021, 800, 140334. [Google Scholar] [CrossRef]

- Nguyen, M.T.; Le, V.T.; Le, M.H.; Nguyen, T.A. Superplastic Properties in a Ti5Al3Mo1.5 V Titan Alloy Processed by Multidirectional Forging Process. Mater. Lett. 2022, 307, 131004. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Yakovtseva, O.A.; Golovin, I.S.; Pozdniakov, A.V.; Portnoy, V.K. Superplastic Deformation Mechanisms in Fine-Grained Al–Mg Based Alloys. Mater. Sci. Eng. A 2015, 627, 31–41. [Google Scholar] [CrossRef]

- Sergueeva, A.V.; Stolyarov, V.V.; Valiev, R.Z.; Mukherjee, A.K. Enhanced superplasticity in a Ti-6Al-4V alloy processed by severe plastic deformation. Scr. Mater. 2000, 819–824, 1359–6462. [Google Scholar]

- Dyakonov, G.S.; Mironov, S.; Enikeev, N.; Semenova, I.P.; Valiev, R.Z.; Semiatin, S.L. Annealing behavior of severely-deformed titanium Grade 4. Mater. Sci. Eng. A 2019, 742, 89–101. [Google Scholar] [CrossRef]

- Kim, B.; Hong, C.H.; Kim, J.C.; Lee, S.; Baek, S.; Jeong, H.Y.; Park, S.S. Factors Affecting the Grain Refinement of Extruded Mg–6Zn–0.5Zr Alloy by Ca Addition. Scripta Mater. 2020, 187, 24–29. [Google Scholar] [CrossRef]

- Kotov, A.D.; Postnikova, M.N.; Mosleh, A.O.; Mikhaylovskaya, A.V. Effect of Mo Content on the Microstructure, Superplastic Behavior, and Mechanical Properties of Ni and Fe-modified Titanium Alloys. Mater. Sci. Eng. A 2023, 877, 145166. [Google Scholar] [CrossRef]

- Alabort, E.; Barba, D.; Shagiev, M.R.; Murzinova, M.A.; Galeyev, R.M.; Valiakhmetov, O.R.; Aletdinov, A.F.; Reed, R.C. Alloys-By-Design: Application to Titanium Alloys for Optimal Superplasticity. Acta Mater. 2019, 178, 275–287. [Google Scholar] [CrossRef]

- Wert, J.A.; Paton, N.E. Enhanced Superplasticity and Strength in Modified Ti-6AI-4V Alloys. Metall. Trans. A Phys. Metall. Mater. Sci. 1983, 14, 2535–2544. [Google Scholar] [CrossRef]

- Ma, L.; Han, X.; Zhang, J.; Li, W. Elucidating the Influence of Temperature and Strain Rate on Superplasticity and Microstructure Evolution of Near-α TNW700 Titanium Alloy. Mater. Sci. Eng. A 2023, 871, 144924. [Google Scholar] [CrossRef]

- Kotov, A.D.; Postnikova, M.N.; Mosleh, A.O.; Mikhaylovskaya, A.V. Influence of Fe on the Microstructure, Superplasticity and Room-Temperature Mechanical Properties of Ti–4Al–3Mo–1V-0.1B Alloy. Mater. Sci. Eng. A 2022, 845, 143245. [Google Scholar] [CrossRef]

- Zhu, J.; Kamiya, A.; Yamada, T.; Shi, W.; Naganuma, K. Influence of Boron Addition on Microstructure and Mechanical Properties of Dental Cast Titanium Alloys. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2003, 339, 53–62. [Google Scholar] [CrossRef]

- Tamirisakandala, S.; Bhat, R.B.; Tiley, J.S.; Miracle, D.B. Grain Refinement of Cast Titanium Alloys Via Trace Boron Addition. Scr. Mater. 2005, 53, 1421–1426. [Google Scholar] [CrossRef]

- Lee, S.-M.; Perng, T.-P. Effects of boron and carbon on the hydrogenation properties of TiFe and Ti1.1Fe. Int. J. Hydrogen Energy 2000, 25, 831–836. [Google Scholar] [CrossRef]

- Qiu, P.; Han, Y.; Le, J.; Huang, G.; Lei, L.; Xiao, L.; Lu, W. Particulate Induced Dynamic Globularization/Recrystallization and Unique Superplasticity in TiB/near-α Ti Matrix Composites. Mater. Charact. 2020, 167, 110458. [Google Scholar] [CrossRef]

- Anil Kumar, V.; Murty, S.V.S.N.; Gupta, R.K.; Rao, A.G.; Prasad, M.J.N.V. Effect of Boron On Microstructure Evolution and Hot Tensile Deformation Behavior of Ti-5Al-5V-5Mo-1Cr-1Fe Alloy. J. Alloys Compd. 2020, 831, 154672. [Google Scholar] [CrossRef]

- Niu, J.; Guo, Y.; Li, K.; Liu, W.; Dan, Z.; Sun, Z.; Chang, H.; Zhou, L. Improved Mechanical, Bio-Corrosion Properties and in Vitro Cell Responses of Ti-Fe Alloys as Candidate Dental Implants. Mater. Sci. Eng. C 2021, 122, 111917. [Google Scholar] [CrossRef]

- Mi, Y.; Wang, Y.; Wang, Y.; Dong, Y.; Chang, H.; Alexandrov, I.V. Effect of Heat Treatment on Microstructure and Mechanical Behavior of Ultrafine-Grained Ti-2Fe-0.1B. Materials 2023, 16, 2955. [Google Scholar] [CrossRef]

- Sun, Y.; Chang, H.; Fang, Z.; Dong, Y.; Dan, Z.; Guo, Y.; Zhou, L. Study on Microstructure and Mechanical Properties of Low Cost Ti-Fe-B Alloy. MATEC Web Conf. 2020, 321, 11029. [Google Scholar] [CrossRef]

- Hémery, S.; Nait-Ali, A.; Guéguen, M.; Villechaise, P. Mechanical Study of Crystalline Orientation Distribution in Ti-6Al-4V: An Assessment of Micro-Texture Induced Load Partitioning. Mater. Des. 2018, 137, 22–32. [Google Scholar] [CrossRef]

- Zhou, M.; Clode, M.P. Constitutive Equations for Modelling Flow Softening Due to Dynamic Recovery and Heat Generation During Plastic Deformation. Mech. Mater. 1998, 27, 63–76. [Google Scholar] [CrossRef]

- Ghosh, A.K. Tensile instability and necking in materials with strain hardening and strain-rate hardening. Acta Metall. 1977, 25, 1413–1424. [Google Scholar] [CrossRef]

- McHargue, C.J.; Hammond, J.P. Deformation mechanisms in titanium at elevated temperatures. Acta Metall. 1953, 1, 700–705. [Google Scholar] [CrossRef]

- Paton, N.E.; Backofen, W.A. Plastic deformation of titanium at elevated temperatures. Metall. Trans. 1970, 1, 2839–2847. [Google Scholar] [CrossRef]

- Song, H.; Zhang, S.; Cheng, M. Subtransus Deformation Mechanisms of TC11 Titanium Alloy with Lamellar Structure. T. Nonferr. Metal. Soc. 2010, 20, 2168–2173. [Google Scholar] [CrossRef]

- Ma, L.; Wan, M.; Li, W.; Shao, J.; Han, X.; Zhang, J. On the Superplastic Deformation Mechanisms of Near-α TNW700 Titanium Alloy. J. Mater. Sci. Technol. 2022, 108, 173–185. [Google Scholar] [CrossRef]

- Ma, L.; Wan, M.; Li, W.; Shao, J.; Bai, X. Constitutive Modeling and Processing Map for Hot Deformation of Ti–15Mo–3Al-2.7Nb-0.2Si. J. Alloys Compd. 2019, 808, 151759. [Google Scholar] [CrossRef]

- Cheng, C.; Chen, Z.; Li, H.E.; Wang, X.; Zhu, S.; Wang, Q. Vacuum Superplastic Deformation Behavior of a Near-α Titanium Alloy TA32 Sheet. Mater. Sci. Eng. A 2021, 800, 140362. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Kudryavtsev, E.A.; Salishchev, G.A.; Straumal, B.B.; Semiatin, S.L. Microstructure Evolution and Mechanical Behavior of Ultrafine Ti 6Al 4V During Low-Temperature Superplastic Deformation. Acta Mater. 2016, 121, 152–163. [Google Scholar] [CrossRef]

- Dieringa, H.; Hort, N.; Kainer, K.U. Investigation of Minimum Creep Rates and Stress Exponents Calculated From Tensile and Compressive Creep Data of Magnesium Alloy AE42. Mater. Sci. Eng. A 2009, 510–511, 382–386. [Google Scholar] [CrossRef]

- Ji, G.; Li, F.; Li, Q.; Li, H.; Li, Z. A Comparative Study on Arrhenius-type Constitutive Model and Artificial Neural Network Model to Predict High-Temperature Deformation Behaviour in Aermet100 Steel. Mater. Sci. Eng. A 2011, 528, 4774–4782. [Google Scholar] [CrossRef]

- Han, Y.; Qiao, G.; Sun, J.; Zou, D. A Comparative Study on Constitutive Relationship of As-Cast 904L Austenitic Stainless Steel During Hot Deformation Based on Arrhenius-type and Artificial Neural Network Models. Comp. Mater. Sci. 2013, 67, 93–103. [Google Scholar] [CrossRef]

- Quan, G.; Wen, H.; Pan, J.; Zou, Y. Construction of processing maps based on expanded data by BP-ANN and identification of optimal deforming parameters for Ti-6Al-4V alloy. Int. J. Precis. Eng. Manuf. 2016, 17, 171–180. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, Y.; Zeng, W. Effect of Hydrogen on the Superplasticity of Ti600 Alloy. Int. J. Hydrogen Energy 2010, 35, 4354–4360. [Google Scholar] [CrossRef]

- Kaibyshev, O.A.; Pshenichniuk, A.I.; Astanin, V.V. Superplasticity resulting from cooperative grain boundary sliding. Acta Mater. 1998, 46, 4911–4916. [Google Scholar] [CrossRef]

- Zhang, X.; Cao, L.; Zhao, Y.; Chen, Y.; Tian, X.; Deng, J. Superplastic Behavior and Deformation Mechanism of Ti600 Alloy. Mater. Sci. Eng. A 2013, 560, 700–704. [Google Scholar] [CrossRef]

- Ma, X.Z.; Xiang, Z.L.; Ma, M.Z.; Tan, C.; Yang, Z.A.; Shen, G.L.; Chen, Z.Y.; Shu, Q. Effect of Trace Boron Addition on Microstructures, Textures, Mechanical Properties and Fracture Behaviors of Near-α Titanium Alloy. Mater. Sci. Eng. A 2020, 772, 138749. [Google Scholar] [CrossRef]

- Liu, G.; Li, K. Micro/Nano Optical Fibers for Label-Free Detection of Abrin with High Sensitivity. Sens. Actuators B Chem. 2015, 215, 146–151. [Google Scholar] [CrossRef]

- Li, X.; Jiang, J.; Wang, S.; Chen, J.; Wang, Y. Effect of Hydrogen On the Microstructure and Superplasticity of Ti-55 Alloy. Int. J. Hydrogen Energy 2017, 42, 6338–6349. [Google Scholar] [CrossRef]

- Huang, K.; Logé, R.E. A Review of Dynamic Recrystallization Phenomena in Metallic Materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Eleti, R.R.; Chokshi, A.H.; Shibata, A.; Tsuji, N. Unique High-Temperature Deformation Dominated by Grain Boundary Sliding in Heterogeneous Necklace Structure Formed by Dynamic Recrystallization in HfNbTaTiZr BCC Refractory High Entropy Alloy. Acta Mater. 2020, 183, 64–77. [Google Scholar] [CrossRef]

- Postnikova, M.N.; Kotov, A.D.; Bazlov, A.I.; Mosleh, A.O.; Medvedeva, S.V.; Mikhaylovskaya, A.V. Effect of Boron on the Microstructure, Superplastic Behavior, and Mechanical Properties of Ti-4Al-3Mo-1V Alloy. Materials 2023, 16, 3714. [Google Scholar] [CrossRef]

- Koike, J.; Shimoyama, Y.; Ohnuma, I.; Okamura, T.; Kainuma, R.; Ishida, K.; Maruyama, K. Stress-Induced Phase Transformation During Superplastic Deformation in Two-Phase Ti–Al–Fe Alloy. Acta Mater. 2000, 48, 2059–2069. [Google Scholar] [CrossRef]

| Fe | B | C | O | N | H | Ti |

|---|---|---|---|---|---|---|

| 1.89 | 0.08 | 0.014 | 0.062 | 0.004 | 0.0012 | Balance |

| Strain Rate/s−1 | Rp0.2/MPa | Rm/MPa | Elongation/% | |

|---|---|---|---|---|

| 550 °C | 1 × 10−3/s | 138.7 ± 10.3 | 169.0 ± 9.6 | 196.5 ± 12.6 |

| 5 × 10−3/s | 163.3 ± 11.7 | 209.3 ± 11.4 | 220.3 ± 4.5 | |

| 1 × 10−2/s | 176.0 ± 6.6 | 209.0 ± 8.5 | 135.8 ± 5.2 | |

| 650 °C | 1 × 10−3/s | 62.3 ± 6.8 | 73.7 ± 10.0 | 206.3 ± 7.7 |

| 5 × 10−3/s | 85.3 ± 8.4 | 101.0 ± 3.6 | 289.8 ± 9.5 | |

| 1 × 10−2/s | 97.0 ± 7.2 | 111.3 ± 8.1 | 250.0 ± 10.0 | |

| 750 °C | 1 × 10−3/s | 29.0 ± 3.6 | 35.7 ± 4.2 | 462.3 ± 9.3 |

| 5 × 10−3/s | 39.7 ± 5.0 | 44.3 ± 4.5 | 381.5 ± 3.0 | |

| 1 × 10−2/s | 56.7 ± 4.9 | 59.0 ± 3.6 | 242.5 ± 8.3 |

| Deformation Conditions | m | Q (kJ/mol) | |

|---|---|---|---|

| Strain Rate (s−1) | Temperature (°C) | ||

| 1 × 10−3–1 × 10−2 | 550 | 0.09 | 835.94 |

| 650 | 0.21 | 286.91 | |

| 750 | 0.3 | 188.26 | |

| Average value | 0.2 | 437.04 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mi, Y.; Lu, Y.; Wang, D.; Zhao, Y.; Dong, Y.; Chang, H.; Alexandrov, I.V. A Study of the Superplastic Deformation Behavior of Low-Cost Ti-2Fe-0.1B Alloys. Materials 2024, 17, 1282. https://doi.org/10.3390/ma17061282

Mi Y, Lu Y, Wang D, Zhao Y, Dong Y, Chang H, Alexandrov IV. A Study of the Superplastic Deformation Behavior of Low-Cost Ti-2Fe-0.1B Alloys. Materials. 2024; 17(6):1282. https://doi.org/10.3390/ma17061282

Chicago/Turabian StyleMi, Yaoyao, Yu Lu, Delong Wang, Yihui Zhao, Yuecheng Dong, Hui Chang, and I. V. Alexandrov. 2024. "A Study of the Superplastic Deformation Behavior of Low-Cost Ti-2Fe-0.1B Alloys" Materials 17, no. 6: 1282. https://doi.org/10.3390/ma17061282