On Crossover Temperatures of Viscous Flow Related to Structural Rearrangements in Liquids

Abstract

:1. Introduction

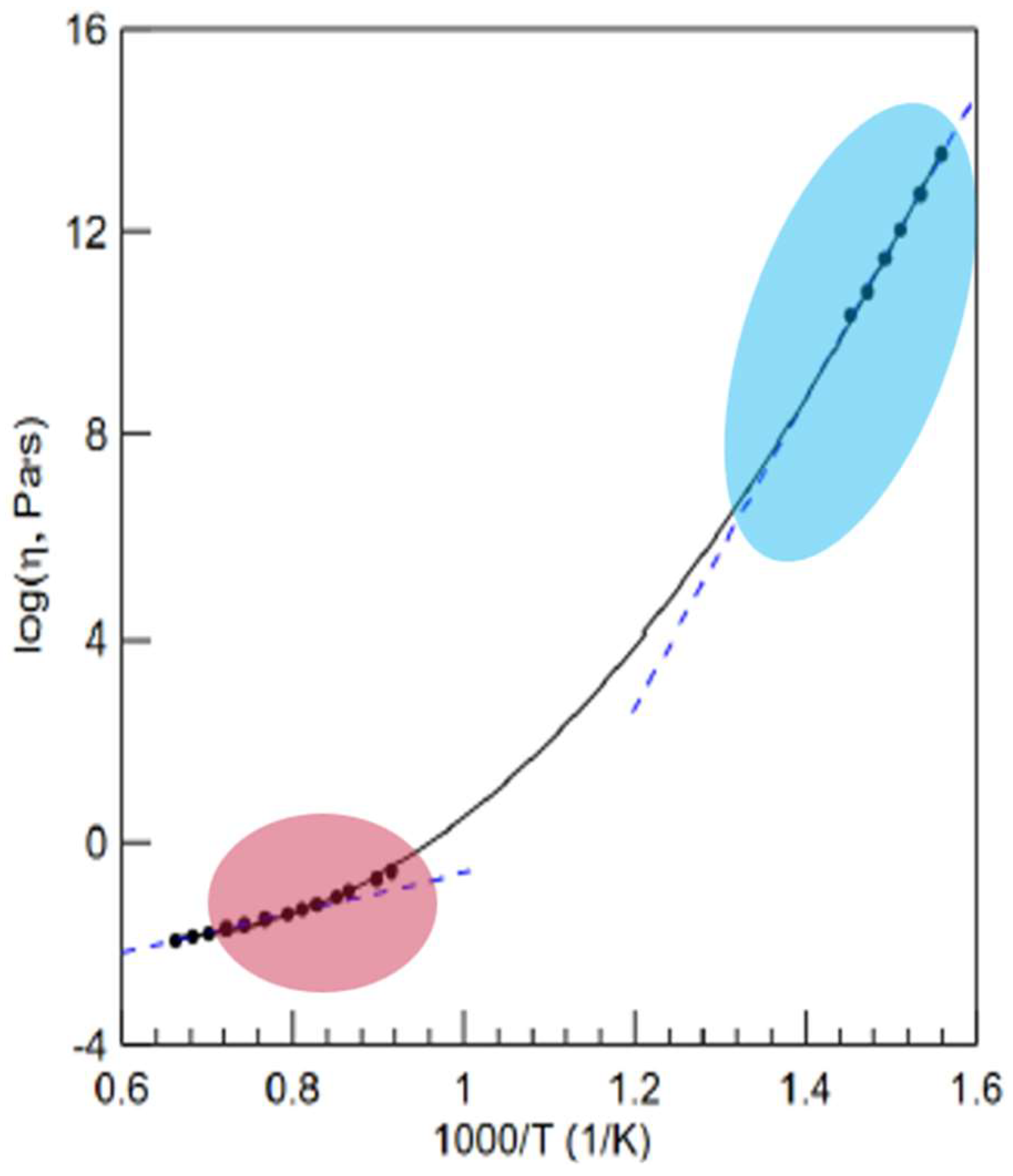

2. Temperature Crossovers

- Low-temperature (high viscosity) end when T < Tg: Arrhenius-type viscosity of glass characterized by the high activation energy of flow E = EH;

- Intermediate temperatures Tg < T < TA: non-Arrhenius-type law formally expressed with an exponent with the variable activation energy of viscosity E = E(T);

- High-temperature (low viscosity) end T > TA: Arrhenius-type viscosity of liquids characterized by a relatively lower (compared to glass) activation energy of flow E = EL.

3. Viscosity at the Low-Temperature (High Viscosity and High E) End

4. Viscosity at the High-Temperature (Low Viscosity and Low E) End

5. Results

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IAEA. Liquid Metal Coolants for Fast Reactors Cooled by Sodium, Lead, and Lead-Bismuth Eutectic, IAEA Nuclear Energy Series NG-T-1.6; IAEA: Vienna, Austria, 2012; 81p. [Google Scholar]

- Perez-Valseca, A.-D.; Quezada-García, S.; Gomez-Torres, A.-M.; Vazquez-Rodríguez, A.; Espinosa-Paredes, G. Reactor behavior comparisons for two liquid metal-cooled fast reactors during an event of loss of coolant. Case Stud. Therm. Eng. 2019, 16, 100556. [Google Scholar] [CrossRef]

- Richet, P.; Conradt, R.; Takada, A.; Dyon, J. (Eds.) Encyclopedia of Glass Science, Technology, History, and Culture; Wiley: Hoboken, NJ, USA, 2021; 1568p. [Google Scholar]

- Kivelson, D.; Tarjus, G.; Zhao, X.; Kivelson, S.A. Fitting of viscosity: Distinguishing the temperature dependences predicted by various models of supercooled liquids. Phys. Rev. E 1996, 53, 751–758. [Google Scholar] [CrossRef] [PubMed]

- Varshneya, A.K. Fundamentals of Inorganic Glasses; Society of Glass Technology: Sheffield, UK, 2006. [Google Scholar]

- Mauro, J.C.; Yue, Y.; Ellison, A.J.; Gupta, P.K.; Allan, D.C. Viscosity of glass-forming liquids. Proc. Natl. Acad. Sci. USA 2009, 106, 19780–19784. [Google Scholar] [CrossRef] [PubMed]

- Ojovan, M. Viscous flow and the viscosity of melts and glasses. Phys. Chem. Glas. 2012, 53, 143–150. [Google Scholar]

- Mauro, J.C.; Smedskjaer, M.M. Statistical mechanics of glass. J. Non-Cryst. Solids 2014, 396–397, 41–53. [Google Scholar] [CrossRef]

- Isayev, A.I. Encyclopedia of Polymer Blends: Volume 3: Structure, 1st ed.; Wiley-VCH: Weinheim, Germany, 2016; pp. 1–134. [Google Scholar]

- Zheng, Q.; Mauro, J.C. Viscosity of glass-forming systems. J. Am. Ceram. Soc. 2017, 100, 1551–2916. [Google Scholar] [CrossRef]

- Kelton, K.F. Kinetic and structural fragility—A correlation between structures and dynamics in metallic liquids and glasses. J. Phys. Condens. Matter 2017, 29, 23002. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Q.; Zheng, J.; Solvang, M.; Yue, Y.; Mauro, J.C. Determining the liquidus viscosity of glass-forming liquids through differential scanning calorimetry. Proc. Natl. Acad. Sci. USA 2020, 103, 6070–6074. [Google Scholar] [CrossRef]

- Kovtun, P.K.; Son, D.T.; Starinets, A.O. Viscosity in Strongly Interacting Quantum Field Theories from Black Hole Physics. Phys. Rev. Lett. 2005, 94, 111601. [Google Scholar] [CrossRef]

- Busza, W.; Rajagopal, K.; Van Der Schee, W. Heavy ion collisions: The big picture and the big questions. Annu. Rev. Nucl. Part. Sci. 2018, 68, 339. [Google Scholar] [CrossRef]

- Zannen, J. Planckian dissipation, minimum viscosity and transport in cuprate strange metals. SciPost Phys. 2019, 6, 61. [Google Scholar] [CrossRef]

- Andreev, A.V.; Kivelson, S.A.; Spivak, B. Hydrodynamic Description of Transport in Strongly Correlated Electron Systems, Phys. Rev. Lett. 2011, 106, 256804. [Google Scholar] [CrossRef] [PubMed]

- Nussinov, Z.; Chakrabarty, S. Exact universal chaos, speed limit, acceleration, Planckian transport coefficient “collapse” to equilibrium, and other bounds in thermal quantum systems. Ann. Phys. 2022, 443, 168970. [Google Scholar] [CrossRef]

- Turdukozhaeva, A.M. Temperature Dependence of the Dynamic Viscosity of Liquid Mercury. Russ. J. Phys. Chem. A 2013, 87, 1595–1597. [Google Scholar] [CrossRef]

- Trachenko, K.; Brazhkin, V.V. Minimal quantum viscosity from fundamental physical constants. Sci. Adv. 2020, 6, eaba3747. [Google Scholar] [CrossRef] [PubMed]

- Ojovan, M.I. Configurons: Thermodynamic parameters and symmetry changes at glass transition. Entropy 2008, 10, 334–364. [Google Scholar] [CrossRef]

- Trachenko, K.; Brazhkin, V.V. The quantum mechanics of viscosity. Phys. Today 2021, 74, 66–67. [Google Scholar] [CrossRef]

- Gangopadhyay, A.K.; Nussinov, Z.; Kelton, K.F. Quantum mechanical interpretation of the minimum viscosity of metallic liquids. Phys. Rev. E 2022, 106, 54150. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Bell, I.H.; Huber, M.L.; McLinden, M.O. Thermophysical Properties of Fluid Systems. In NIST Chemistry WebBook; NIST Standard Reference Database Number 69; Linstrom, P.J., Mallard, W.G., Eds.; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2010. [Google Scholar] [CrossRef]

- Patouillet, K.; Delacroix, J. Development of an oscillating cup viscometer for viscosity measurement of liquid metals at very high temperatures. Measurement 2023, 220, 113370. [Google Scholar] [CrossRef]

- Ojovan, M.I. On Viscous Flow in Glass-Forming Organic Liquids. Molecules 2020, 25, 4029. [Google Scholar] [CrossRef]

- Louzguine-Luzgin, D.V.; Georgarakis, K.; Andrieux, J.; Hennet, L.; Morishita, T.; Nishio, K.; Belosludov, R.V. An atomistic study of the structural changes in a Zr–Cu–Ni–Al glass-forming liquid on vitrification monitored in-situ by X-ray diffraction and molecular dynamics simulation. Intermetallics 2020, 122, 106795. [Google Scholar] [CrossRef]

- Bolmatov, D.; Brazhkin, V.; Trachenko, K. The phonon theory of liquid thermodynamics. Sci. Rep. 2012, 2, 421. [Google Scholar] [CrossRef] [PubMed]

- Bolmatov, D.; Musaev, E.T.; Trachenko, K. Symmetry Breaking Gives Rise to Energy Spectra of Three States of Matter. Sci. Rep. 2013, 3, 2794. [Google Scholar] [CrossRef]

- Bolmatov, D.; Zav’yalov, D.; Zhernenkov, M.; Musaev, E.T.; Cai, Y.Q. Unified Phonon-Based Approach to The Thermodynamics of Solid, Liquid and Gas States. Ann. Phys. 2015, 363, 221–242. [Google Scholar] [CrossRef]

- Trachenko, K.; Brazhkin, V.V. Collective modes and thermodynamics of the liquid state. Rep. Prog. Phys. 2016, 79, 16502. [Google Scholar] [CrossRef] [PubMed]

- Bolmatov, D. The Phonon Theory of Liquids and Biological Fluids: Developments and Applications. J. Phys. Chem. Lett. 2022, 13, 7121–7129. [Google Scholar] [CrossRef] [PubMed]

- Trachenko, K. Theory of Liquids: From Excitations to Thermodynamics; Cambridge University Press: Cambridge, UK, 2023. [Google Scholar]

- Xue, J.; Nogueira, F.S.; Kelton, K.F.; Nussinov, Z. Deviations from Arrhenius dynamics in high temperature liquids, a possible collapse, and a viscosity bound. Phys. Rev. Res. 2022, 4, 43047. [Google Scholar] [CrossRef]

- Eyring, H. Viscosity, Plasticity, and Diffusion as Examples of Absolute Reaction Rates. J. Chem. Phys. 1936, 4, 283–291. [Google Scholar] [CrossRef]

- Kaptay, G. A unified equation for the viscosity of pure liquid metals. Z. Met. 2005, 96, 24–31. [Google Scholar] [CrossRef]

- Hrma, P.; Ferkl, P.; Kruger, A.A. Arrhenian to non-Arrhenian crossover in glass melt viscosity. J. Non-Cryst. Solids 2023, 619, 122556. [Google Scholar] [CrossRef]

- Louzguine-Luzgin, D.V. Structural Changes in Metallic Glass-Forming Liquids on Cooling and Subsequent Vitrification in Relationship with Their Properties. Materials 2022, 15, 7285. [Google Scholar] [CrossRef] [PubMed]

- Deubener, J. Viscosity of glass-forming melts. In Encyclopedia of Glass Science, Technology, History, and Culture; Wiley: New York, NY, USA, 2021; pp. 431–451, Chapter 4.1; Available online: https://onlinelibrary.wiley.com/share/XXDSCVXE5TGXXGX2VT3R?target=10.1002/9781118801017.ch4.1 (accessed on 16 February 2024).

- Ojovan, M.I.; Lee, W.E. Topologically disordered systems at the glass transition. J. Phys. Condens. Matter 2006, 18, 11507–11520. [Google Scholar] [CrossRef]

- Galimzyanov, B.; Doronina, M.; Mokshin, A. Arrhenius Crossover Temperature of Glass-Forming Liquids Predicted by an Artificial Neural Network. Materials 2023, 16, 1127. [Google Scholar] [CrossRef] [PubMed]

- Hrma, P.; Kruger, A.A. High-temperature viscosity of many-component glass melts. J. Non-Cryst. Solids 2016, 437, 17–25. [Google Scholar] [CrossRef]

- Shi, Q.L.; Wang, X.D.; Cao, Q.P.; Ding, S.Q.; Zhang, D.X.; Beyer, K.A.; Jiang, J.Z. Temperature-induced gradual polymorphic structural crossover in liquid indium, tin, and antimony. Phys. Rev. B 2024, 109, 24112. [Google Scholar] [CrossRef]

- Zheng, Q.; Zhang, Y.; Montazerian, M.; Gulbiten, O.; Mauro, J.C.; Zanotto, E.D.; Yue, Y. Understanding glass through differential scanning calorimetry. Chem. Rev. 2019, 119, 7848–7939. [Google Scholar] [CrossRef] [PubMed]

- IUPAC. Compendium of Chemical Terminology; Royal Society of Chemistry: Cambridge, UK, 1997. [Google Scholar]

- Louzguine-Luzgin, D.V. Metallic Glasses and Their Composites, 2nd ed.; Materials Research Forum LLC: Millersville, PA, USA, 2020; 344p. [Google Scholar]

- Kantor, Y.; Webman, I. Elastic properties of random percolating systems. Phys. Rev. Lett. 1984, 52, 1891–1894. [Google Scholar] [CrossRef]

- Angell, C.A.; Rao, K.J. Configurational Excitations in Condensed Matter, and the “Bond Lattice” Model for the Liquid-glass Transition. J. Chem. Phys. 1972, 57, 470–481. [Google Scholar] [CrossRef]

- Iwashita, T.; Nicholson, D.M.; Egami, T. Elementary Excitations and Crossover Phenomenon in Liquids. Phys. Rev. Lett. 2013, 110, 205504. [Google Scholar] [CrossRef]

- Ojovan, M.I.; Tournier, R.F. On structural rearrangements near the glass transition temperature in amorphous silica. Materials 2021, 14, 5235. [Google Scholar] [CrossRef]

- Sanditov, D.S.; Ojovan, M.I.; Darmaev, M.V. Glass transition criterion and plastic deformation of glass. Phys. B Condens. Matter 2020, 582, 411914. [Google Scholar] [CrossRef]

- Ojovan, M.I.; Louzguine-Luzgin, D.V. Revealing Structural Changes at Glass Transition via Radial Distribution Functions. J. Phys. Chem. B 2020, 124, 3186–3194. [Google Scholar] [CrossRef] [PubMed]

- Ojovan, M.I.; Louzguine-Luzgin, D.V. On Structural Rearrangements during the Vitrification of Molten Copper. Materials 2022, 15, 1313. [Google Scholar] [CrossRef] [PubMed]

- Benigni, P. CALPHAD modeling of the glass transition for a pure substance, coupling thermodynamics and relaxation kinetics. Calphad 2021, 72, 102238. [Google Scholar] [CrossRef]

- Tournier, R.F.; Ojovan, M.I. Building and Breaking Bonds in Glasses leading to Three Liquid States above the Melting Temperature. Materials 2021, 14, 2287. [Google Scholar] [CrossRef]

- Tournier, R.F.; Ojovan, M.I. Multiple melting temperatures in glass-forming melts. Sustainability 2022, 14, 2351. [Google Scholar] [CrossRef]

- Tournier, R.F.; Ojovan, M.I. NiTi2, a New Liquid Glass. Materials 2023, 16, 6681. [Google Scholar] [CrossRef] [PubMed]

- Fang, T.T.; Chen, M.I.; Hsu, W.D. Insight into understanding the jump frequency of diffusion in solids. AIP Adv. 2020, 10, 65132. [Google Scholar] [CrossRef]

- Frenkel, J. Kinetic Theory of Liquids; Oxford University Press: Oxford, UK, 1955. [Google Scholar]

- Zaccone, A. Viscosity of Supercooled Liquids. In Theory of Disordered Solids; Lecture Notes in Physics; Springer: Cham, Switzerland, 2023; Volume 1015. [Google Scholar] [CrossRef]

- Doremus, R.H. Viscosity of silica. J. Appl. Phys. 2002, 92, 7619. [Google Scholar] [CrossRef]

- Culpin, M.F. The Viscosity of Liquid Indium and Liquid Tin. Proc. Phys. Soc. B 1957, 70, 1069–1078. [Google Scholar] [CrossRef]

- Kanda, F.A.; Colburn, R.P. The Absolute Viscosity of Some Lead-Tin Alloys. Phys. Chem. Liq. 1968, 1, 159–170. [Google Scholar] [CrossRef]

- Gancarz, T.; Moser, Z.; Gasior, W.; Pstrus, J.; Henein, H. A comparison of surface tension, viscosity, and density of Sn and Sn–Ag alloys using different measurement techniques. Int. J. Thermophys. 2011, 32, 1210–1233. [Google Scholar] [CrossRef]

- Brandes, E.A.; Brook, G.B. Smithells Metals Reference Book, 7th ed.; Butterworth-Heinemann: Oxford, UK, 1992; pp. 10–14. [Google Scholar]

- Battezzati, L.; Greer, A.L. The viscosity of liquid metals and alloys. Acta Metall. 1989, 37, 1791–1802. [Google Scholar] [CrossRef]

- Balyakin, I.A.; Yuryev, A.A.; Filippov, V.V.; Gelchinski, B.R. Viscosity of liquid gallium: Neural network potential molecular dynamics and experimental study. Comput. Mater. Sci. 2022, 215, 111802. [Google Scholar] [CrossRef]

- Gangopadhyay, A.K.; Kelton, K.F. Prediction of elemental glass-transition temperatures of metals from thermophysical properties of liquids. J. Non-Cryst. Solids X 2019, 2, 100016. [Google Scholar] [CrossRef]

- Lai, S.K.; Chen, H.C. The structural and dynamical liquid-glass transition for metallic sodium. J. Phys. Condens. Matter 1993, 5, 4325. [Google Scholar] [CrossRef]

- Chen, H.C.; Lai, S.K. Dynamical and structural liquid-glass transition for metallic potassium. Mater. Sci. Eng. A 1994, 179, 261–264. [Google Scholar] [CrossRef]

- Tournier, R.F.; Ojovan, M.I. Prediction of Second Melting Temperatures Already Observed in Pure Elements by Molecular Dynamics Simulations. Materials 2021, 14, 6509. [Google Scholar] [CrossRef]

- Tournier, R.F. Multiple Glass Transitions in Bismuth and Tin beyond Melting Temperatures. Metals 2022, 12, 2085. [Google Scholar] [CrossRef]

- Galimzyanov, B.N.; Doronina, M.A.; Mokshin, A.V. Neural Network as a Tool for Design of Amorphous Metal Alloys with Desired Elastoplastic Properties. Metals 2023, 13, 812. [Google Scholar] [CrossRef]

- Cassar, D.R.; Santos, G.G.; Zanotto, E.D. Designing optical glasses by machine learning coupled with a genetic algorithm. Ceram. Int. 2021, 47, 10555–10564. [Google Scholar] [CrossRef]

- Möbus, G.; Ojovan, M.; Cook, S.; Tsai, J.; Yang, G. Nano-scale quasi-melting of alkali-borosilicate glasses under electron irradiation. J. Nucl. Mater. 2010, 396, 264–271. [Google Scholar] [CrossRef]

- Zheng, K.; Wang, C.; Cheng, Y.Q.; Yue, Y.; Han, X.; Zhang, Z.; Ma, E. Electron-beam-assisted superplastic shaping of nanoscale amorphous silica. Nat. Commun. 2010, 1, 24. [Google Scholar] [CrossRef] [PubMed]

- Ojovan, M.I. The Flow of Glasses and Glass–Liquid Transition under Electron Irradiation. Int. J. Mol. Sci. 2023, 24, 12120. [Google Scholar] [CrossRef] [PubMed]

- Onodera, Y.; Kohara, S.; Tahara, S.; Masuno, A.; Inoue, H.; Shiga, M.; Hirata, M.; Tsuchiya, K.; Hiraoka, Y.; Obayashi, I.; et al. Understanding diffraction patterns of glassy, liquid and amorphous materials via persistent homology analyses. J. Ceram. Soc. Jpn. 2019, 127, 853–863. [Google Scholar] [CrossRef]

- Sørensen, S.S.; Du, T.; Biscio, C.A.N.; Fajstrup, L.; Smedskjaer, M.M. Persistent homology: A tool to understand medium-range order glass structure. J. Non-Cryst. Solids X 2022, 16, 100123. [Google Scholar] [CrossRef]

- Obayashi, I.; Nakamura, T.; Hiraoka, Y. Persistent Homology Analysis for Materials Research and Persistent Homology Software: HomCloud. J. Phys. Soc. Jpn. 2022, 91, 91013. [Google Scholar] [CrossRef]

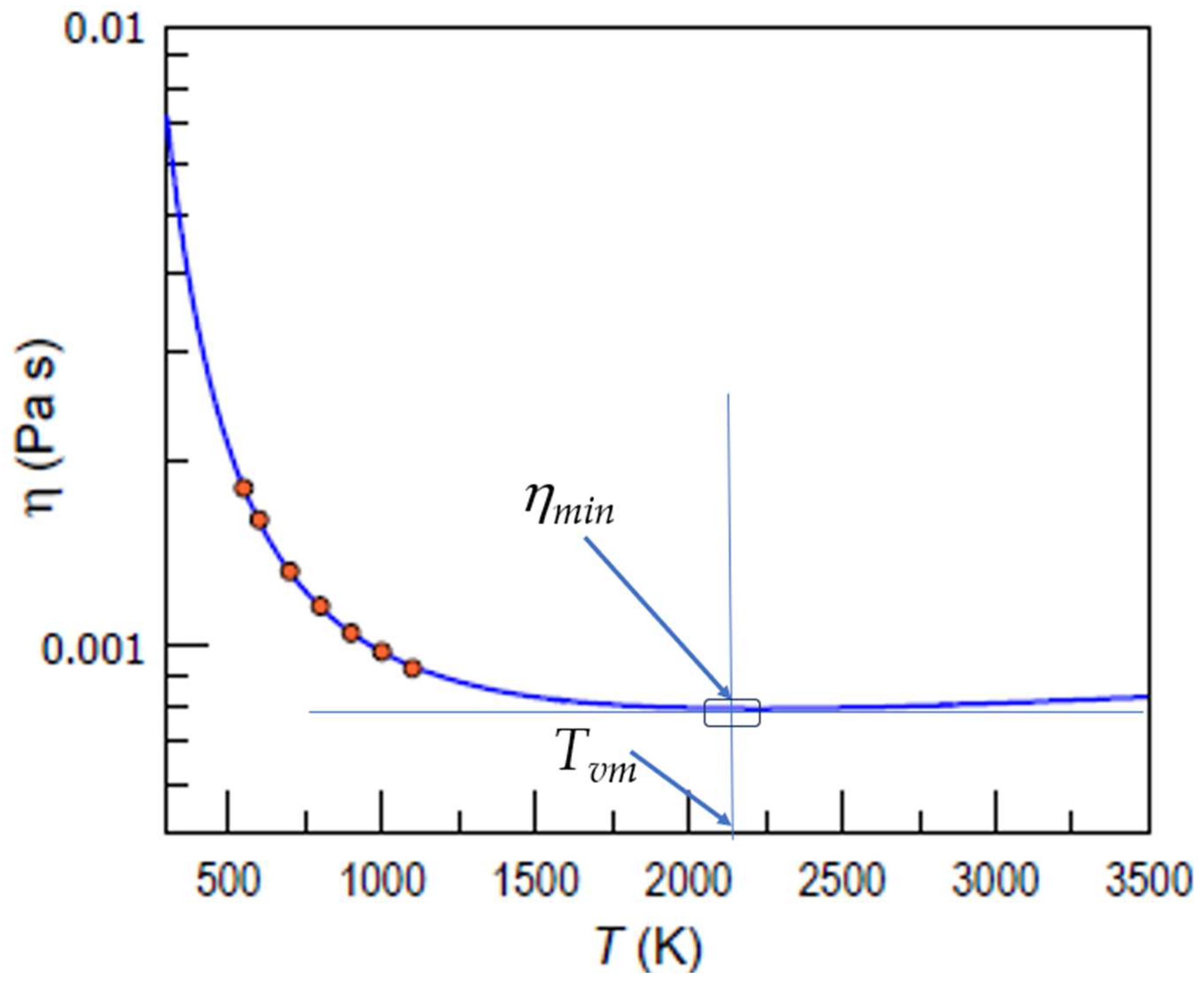

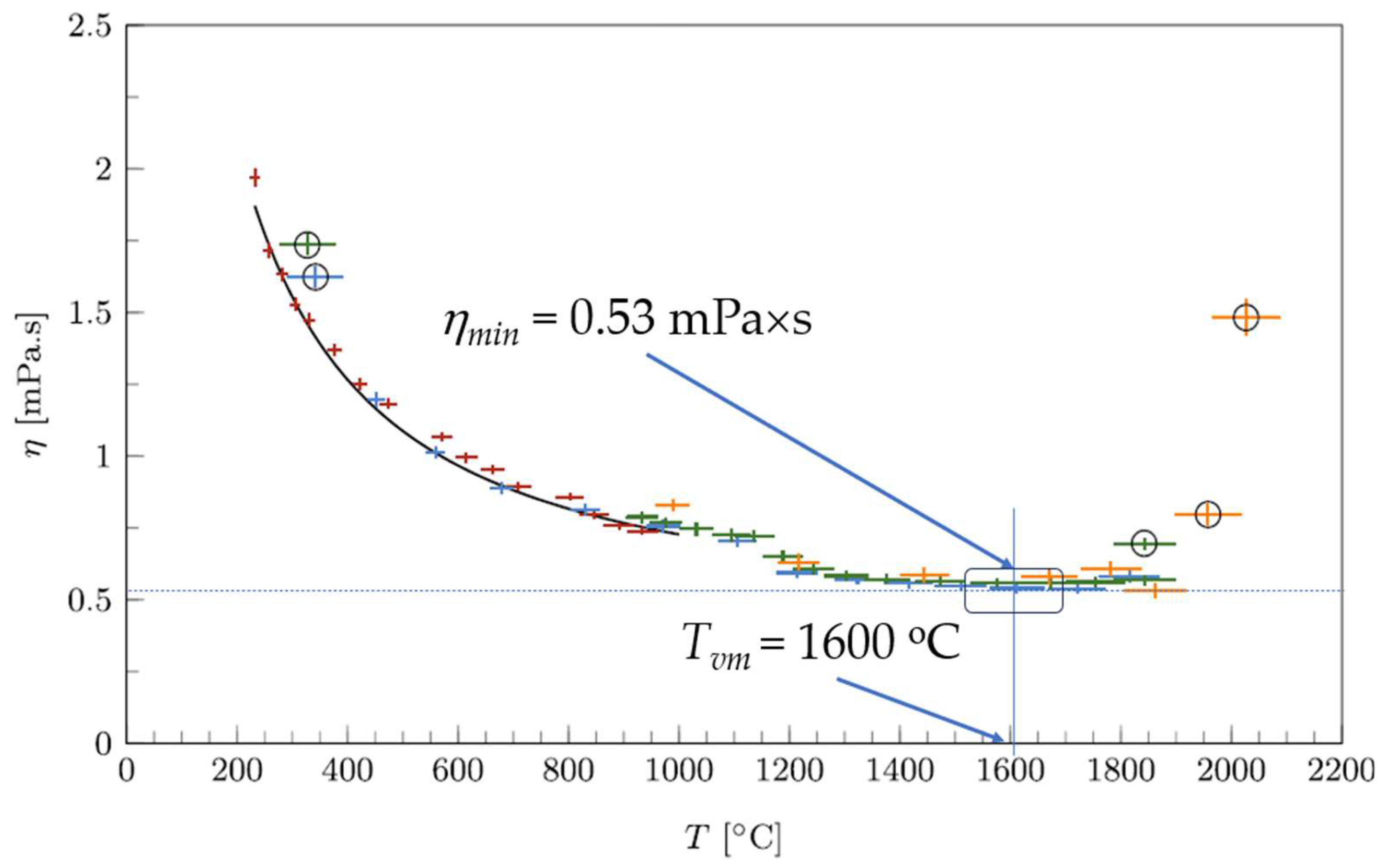

| Metal | T 2, K | η(T), mPa·s | Ea, kJ/mol | Tvm, K | ηmin, mPa·s |

|---|---|---|---|---|---|

| Hg | 273 | 1.55 | 2.51 | 604 | 1.26 |

| Na | 723 | 0.25 | 5.24 | 1260 | 0.23 |

| K | 337 | 0.51 | 5.02 | 1210 | 0.26 |

| Pb | 600 | 2.04 | 10.43 | 2510 | 0.85 |

| Bi | 723 | 1.28 | 6.45 | 1550 | 1.06 |

| Ga | 1000 | 0.62 | 3.8 | 920 | 0.62 |

| Sn | 505 | 1.97 | 7.15 | 1720 | 1.1 |

| Zr57Nb5Cu15.4Ni12.6Al10 | 1538 | 11 | 65.8 | 15,840 | 0.37 |

| Metal | Tm, K | Tg, K | TA, K | Tvm, K | Tvm/Tm |

|---|---|---|---|---|---|

| Hg | 234 | 169 | 257 | 604 | 2.6 |

| Na | 370 | 189 | 407 | 1260 | 3.4 |

| K | 337 | 166 | 371 | 1210 | 3.6 |

| Pb | 600 | ..?.. | 660 | 2510 | 4.2 |

| Bi | 544 | 202 | 598 | 1550 | 2.8 |

| Ga | 303 | 97 | 333 | 920 | 3 |

| Sn | 505 | 159 | 556 | 1720 | 3.4 |

| Zr57Nb5Cu15.4Ni12.6Al10 | 1123 | 671 | 1349 | 15,840 | 14.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ojovan, M.I.; Louzguine-Luzgin, D.V. On Crossover Temperatures of Viscous Flow Related to Structural Rearrangements in Liquids. Materials 2024, 17, 1261. https://doi.org/10.3390/ma17061261

Ojovan MI, Louzguine-Luzgin DV. On Crossover Temperatures of Viscous Flow Related to Structural Rearrangements in Liquids. Materials. 2024; 17(6):1261. https://doi.org/10.3390/ma17061261

Chicago/Turabian StyleOjovan, Michael I., and Dmitri V. Louzguine-Luzgin. 2024. "On Crossover Temperatures of Viscous Flow Related to Structural Rearrangements in Liquids" Materials 17, no. 6: 1261. https://doi.org/10.3390/ma17061261