Comparison of Linear and Nonlinear Twist Extrusion Processes with Crystal Plasticity Finite Element Analysis

Abstract

1. Introduction

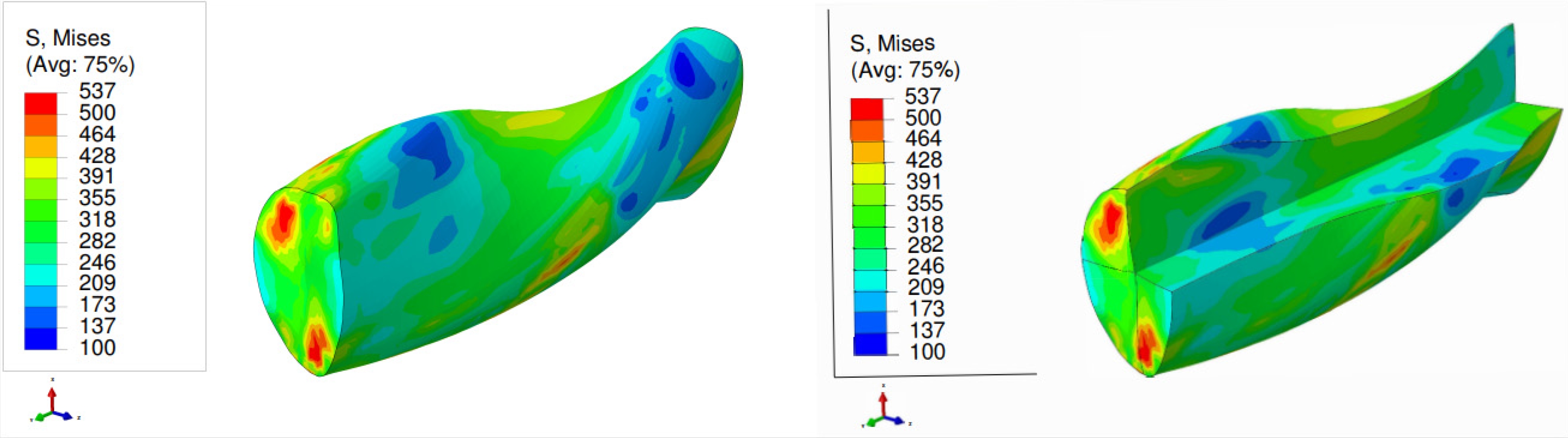

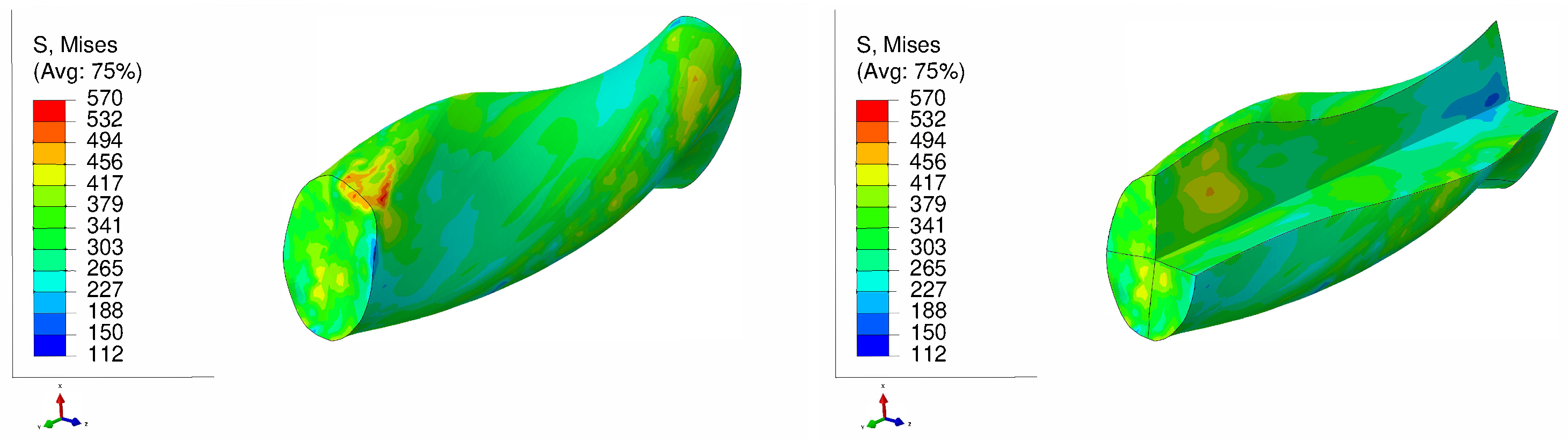

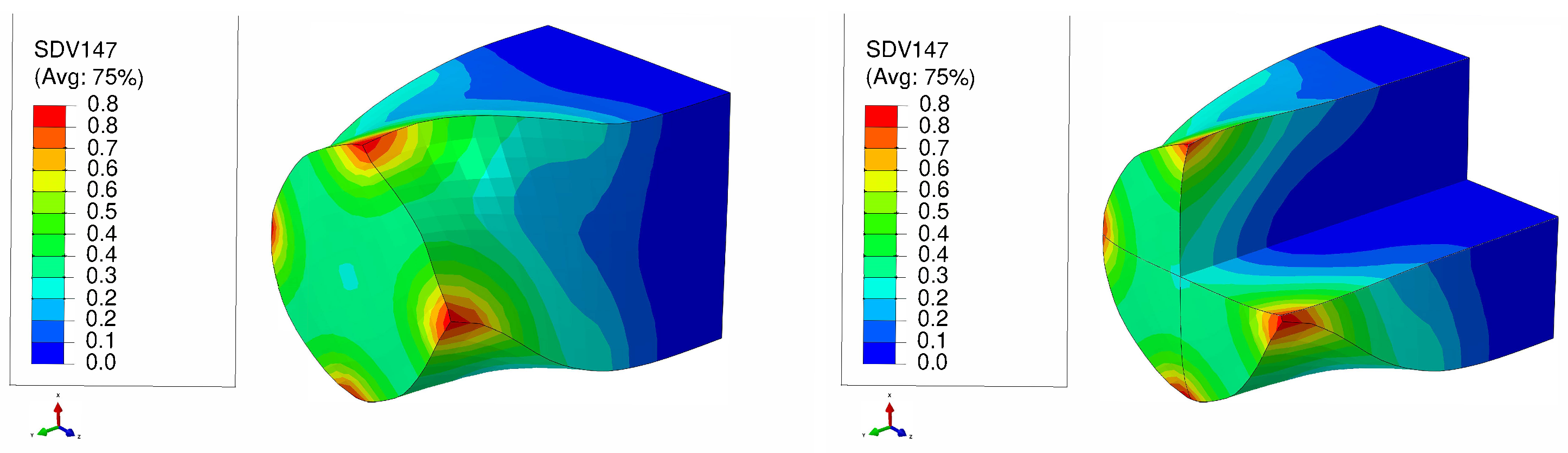

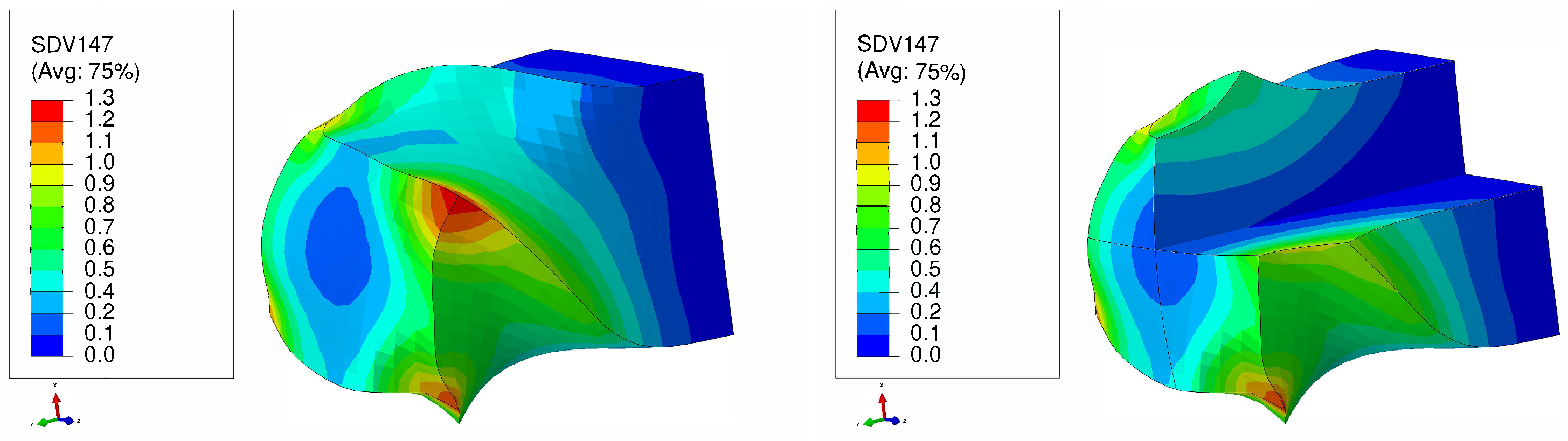

2. Extrusion Process Modeling and Constitutive Behavior

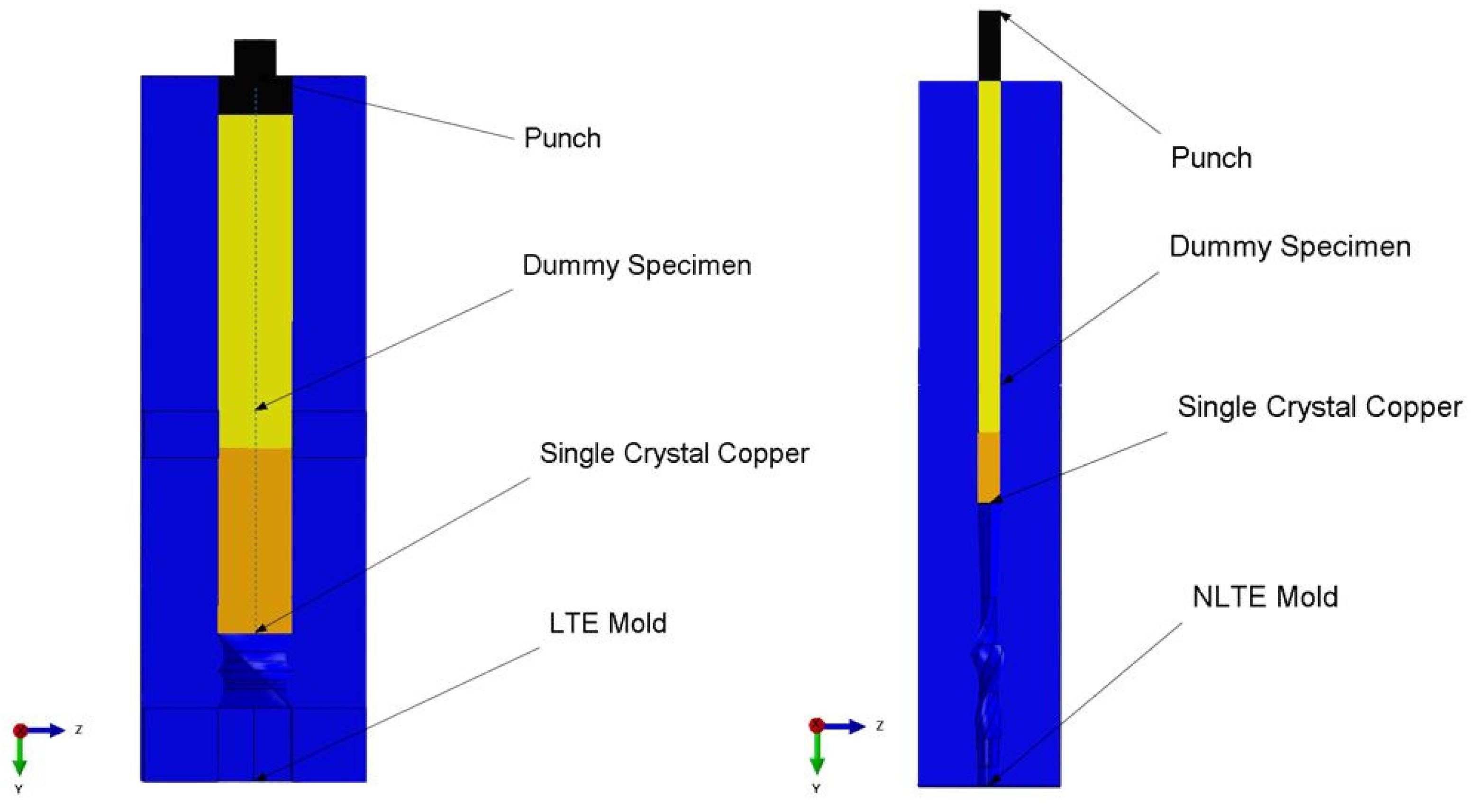

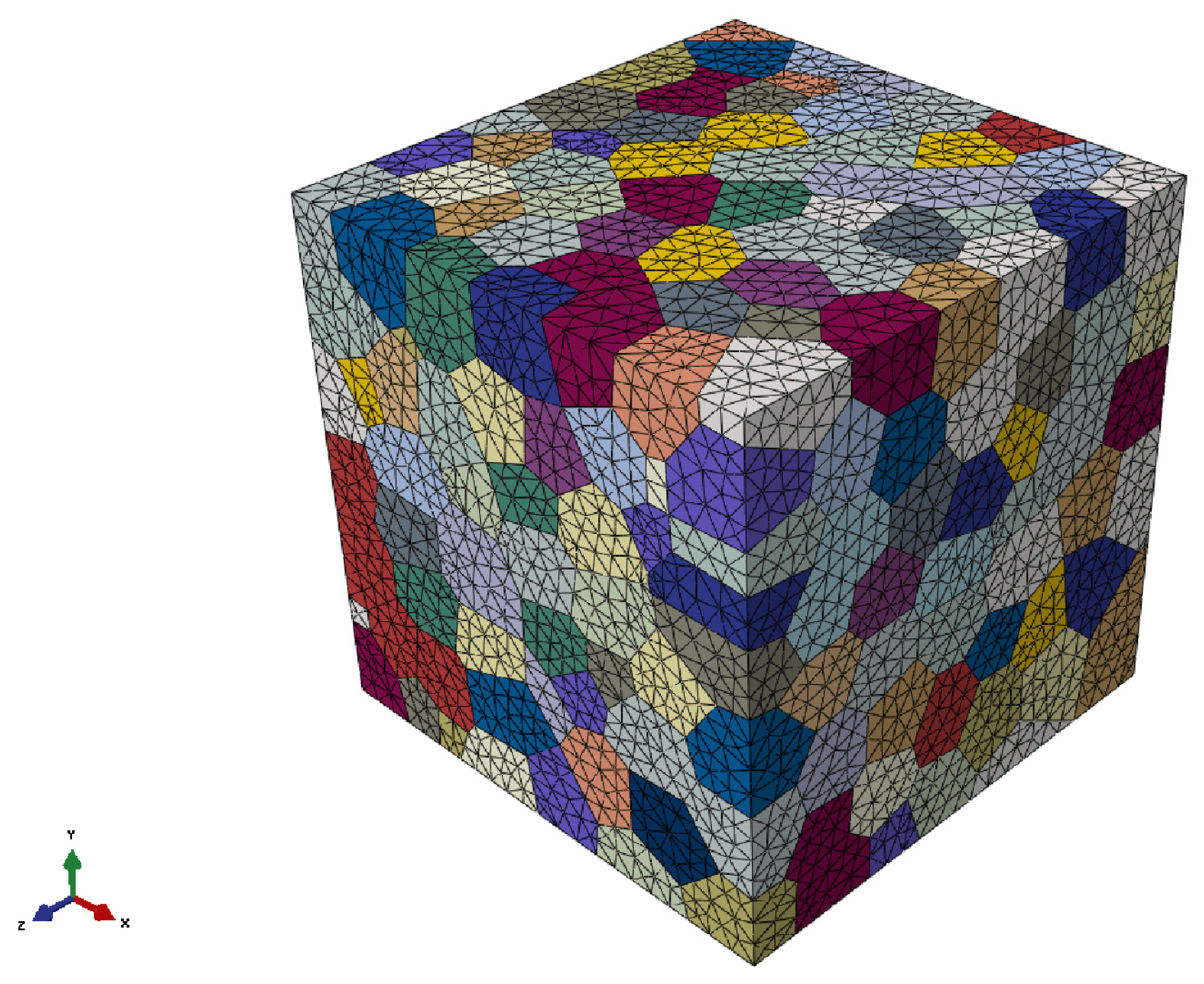

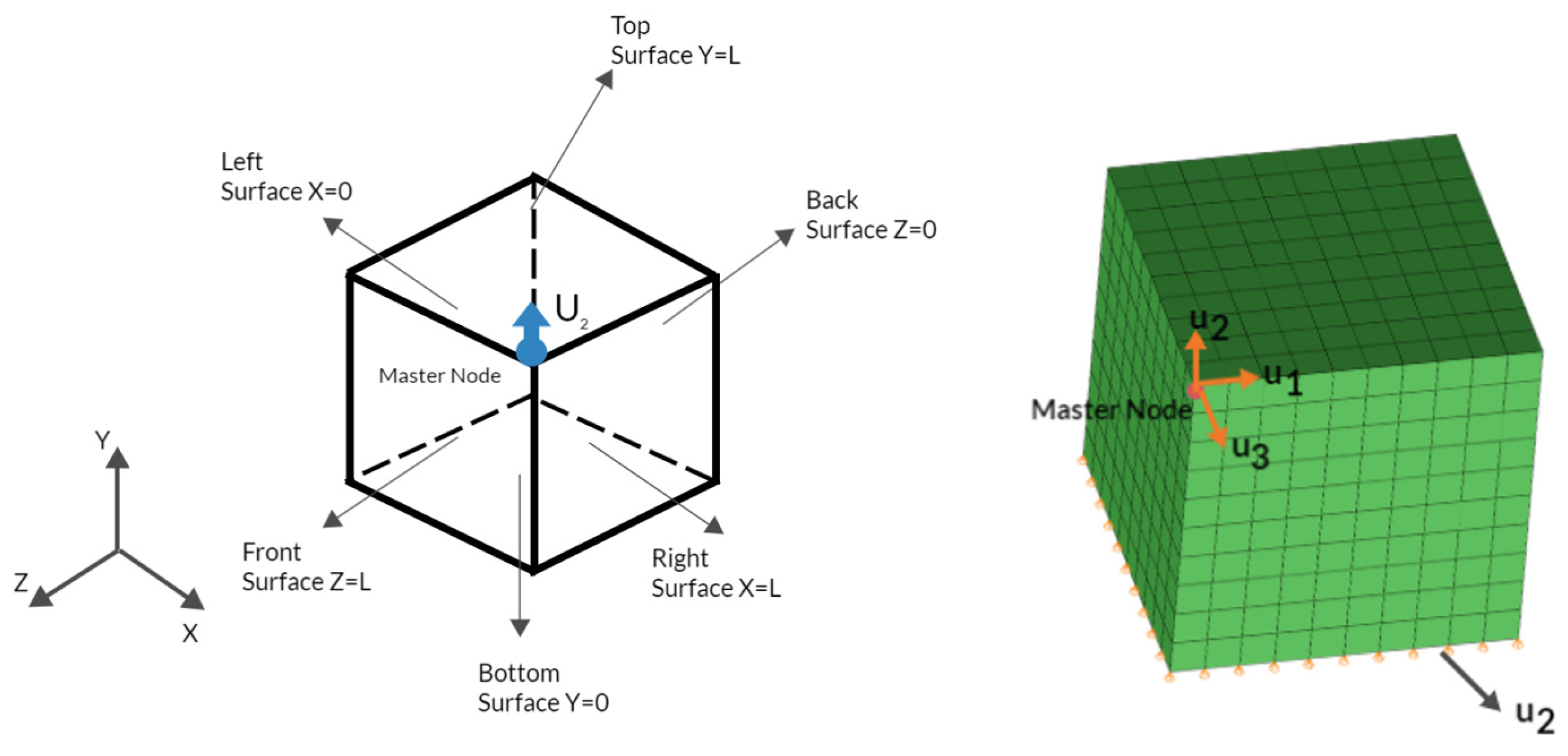

2.1. Finite Element Models of NLTE and LTE Processes

2.2. Constitutive Models for NLTE and LTE Processes

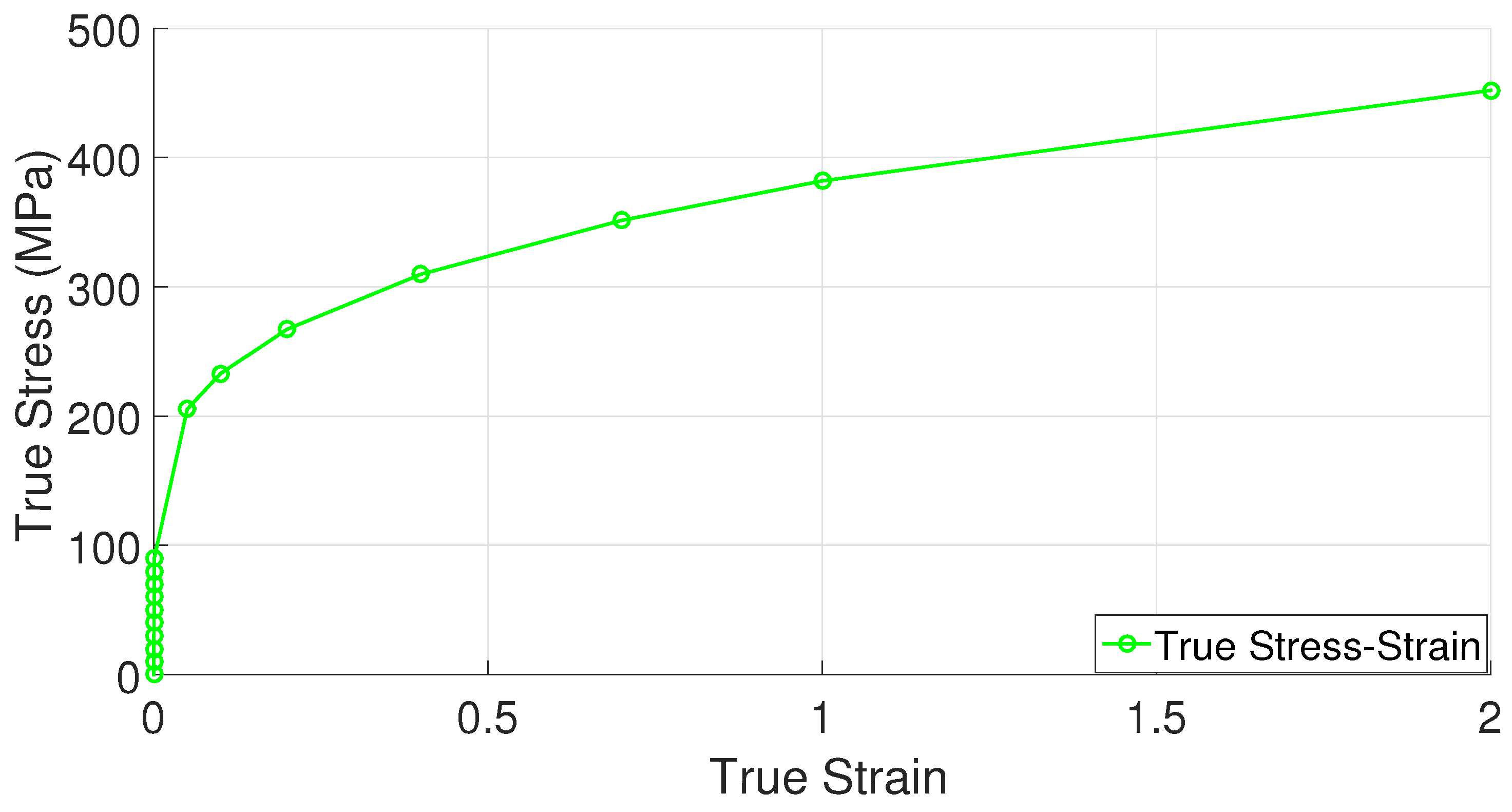

2.3. Calibration of Crystal Plasticity Model

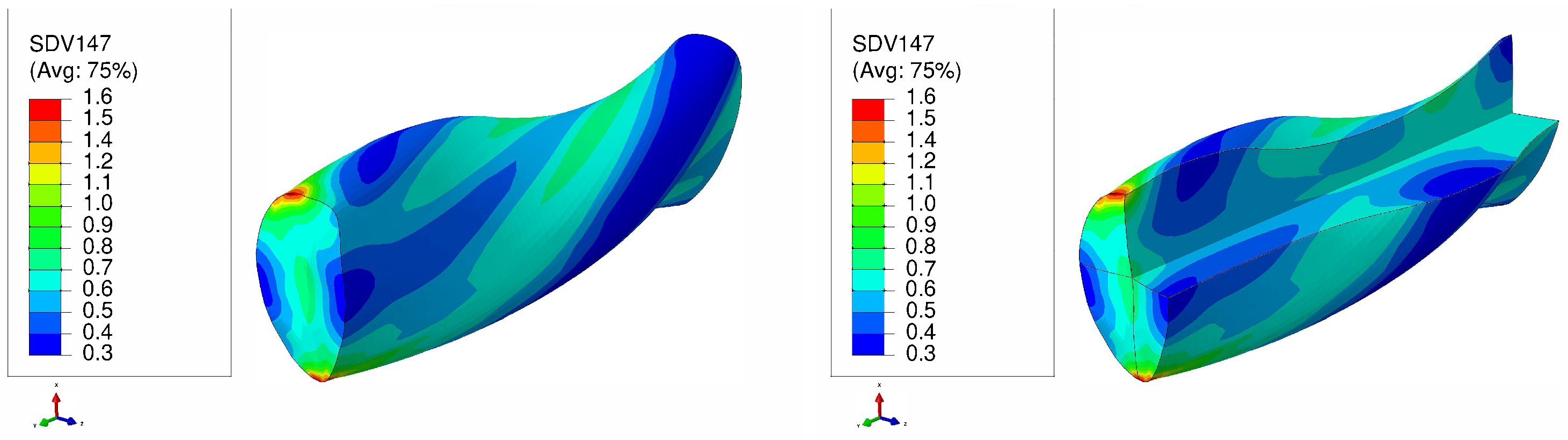

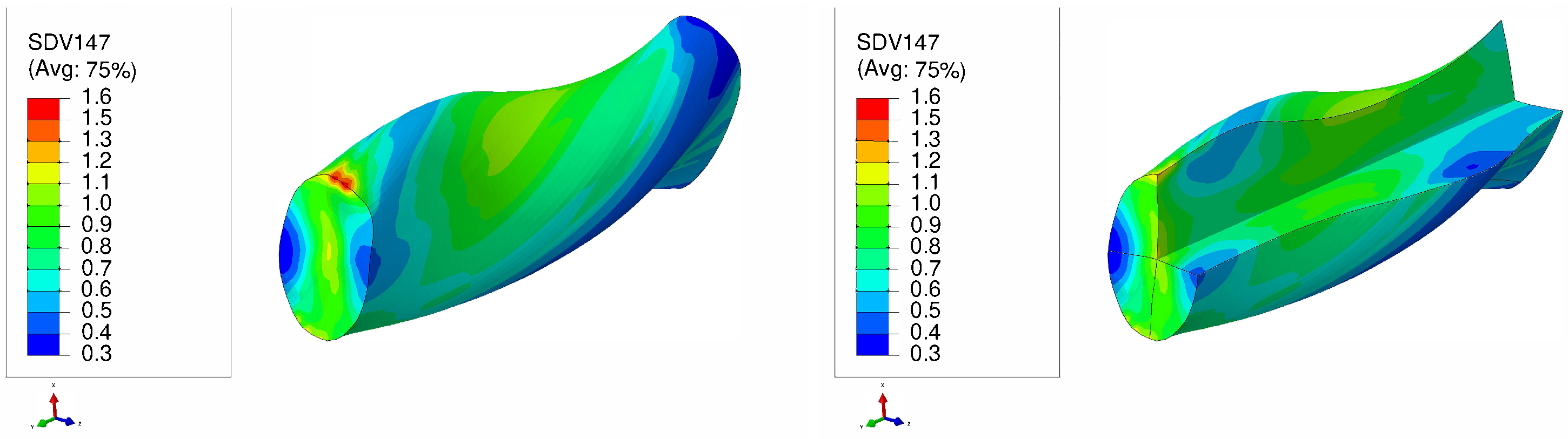

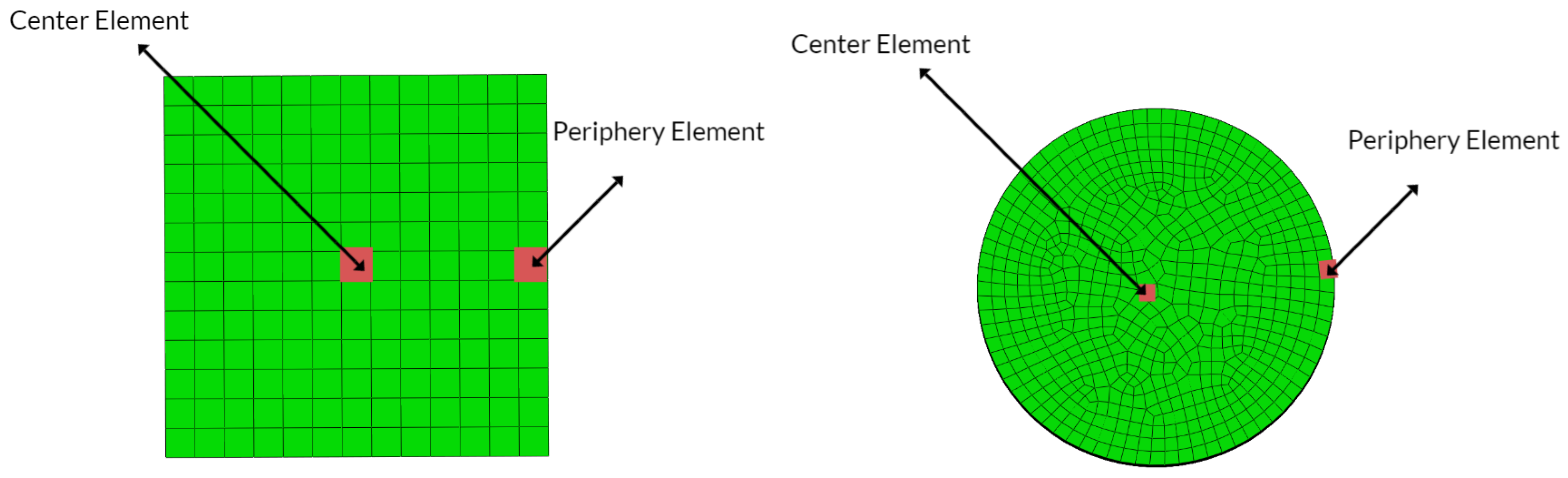

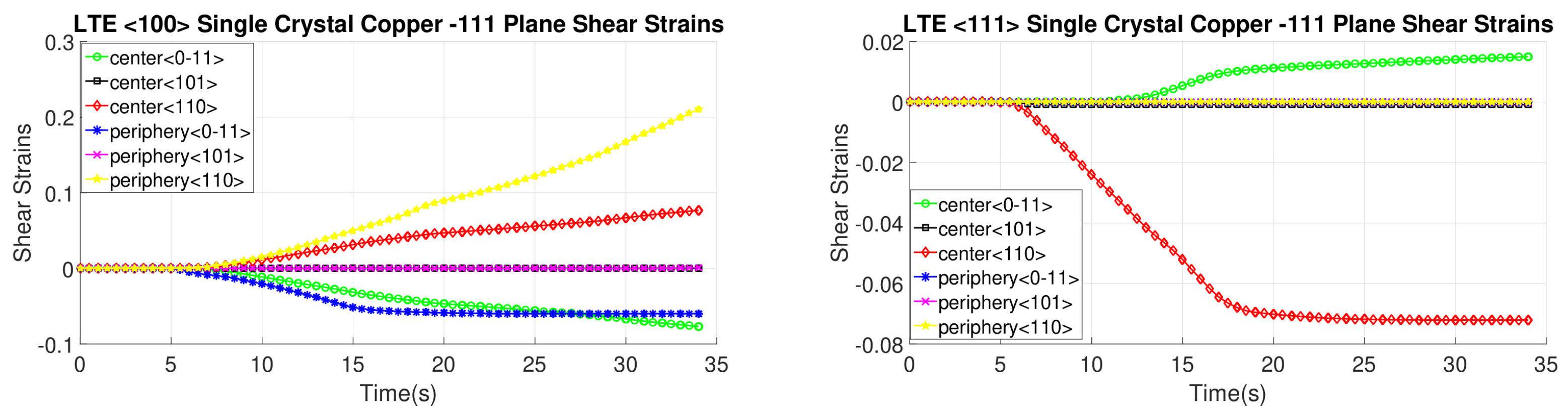

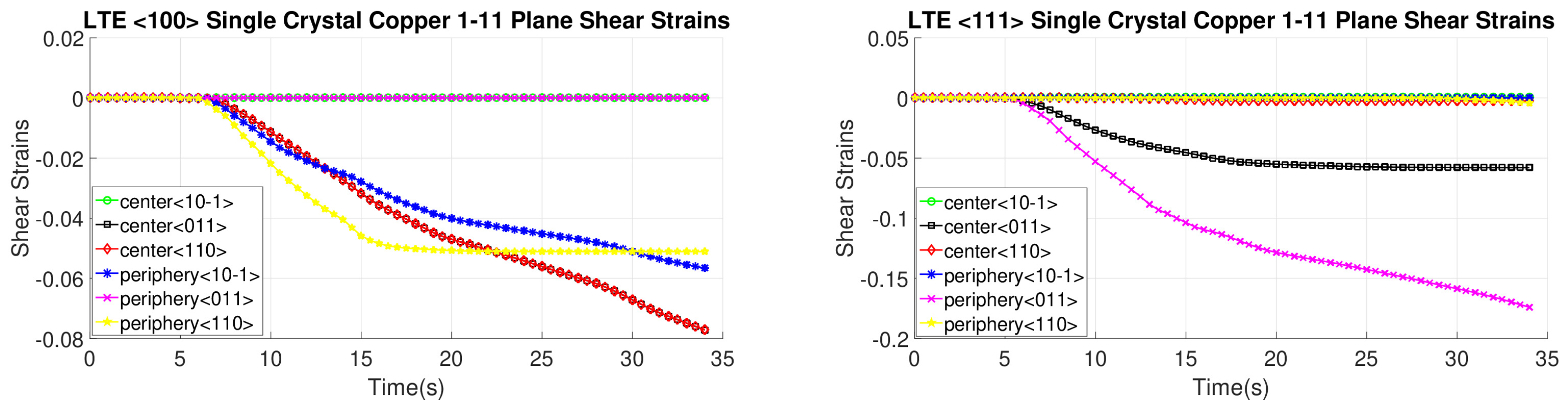

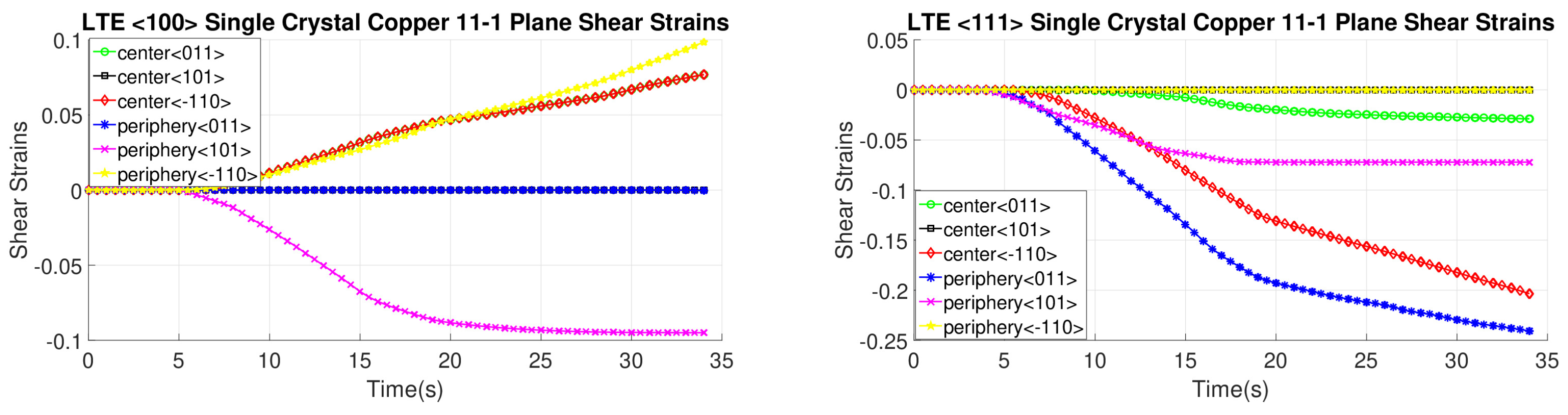

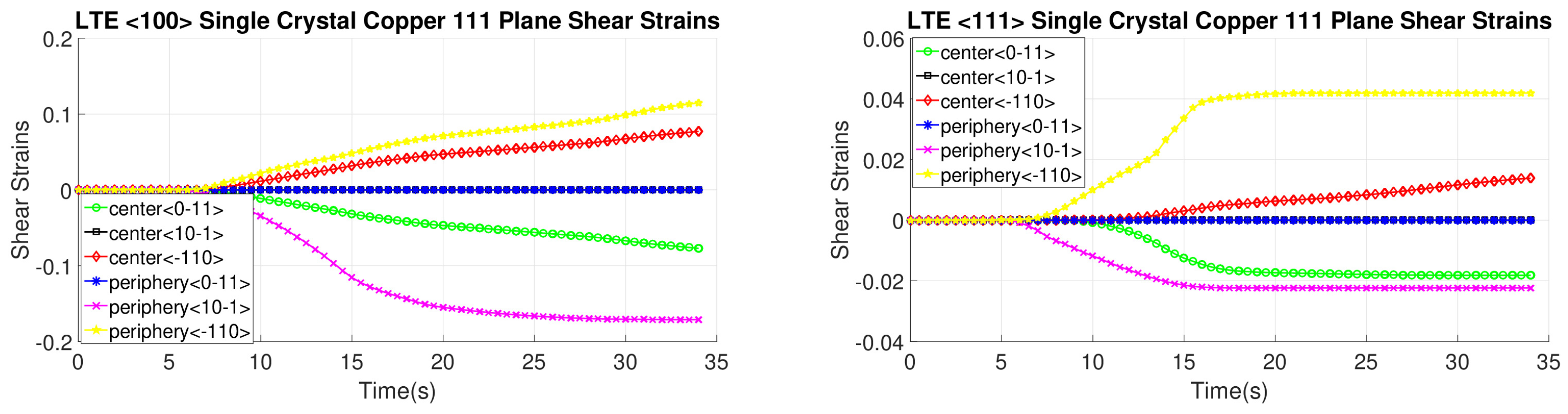

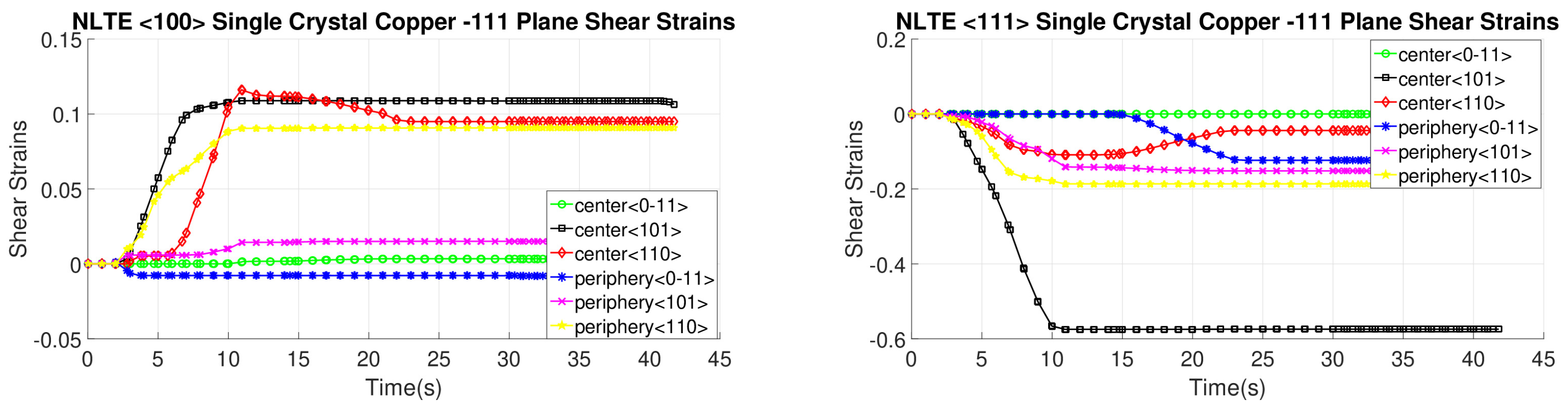

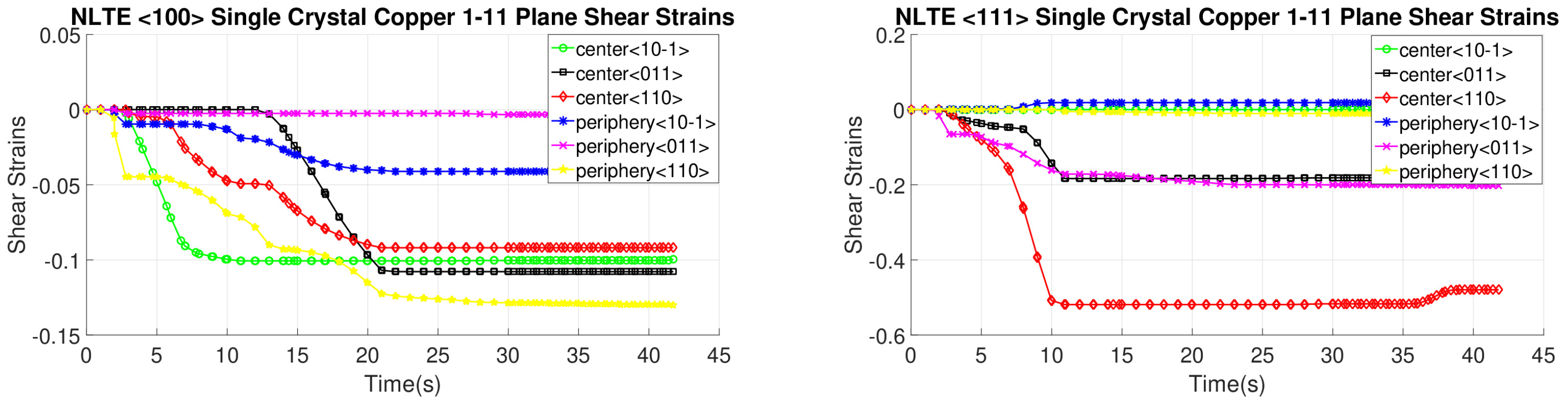

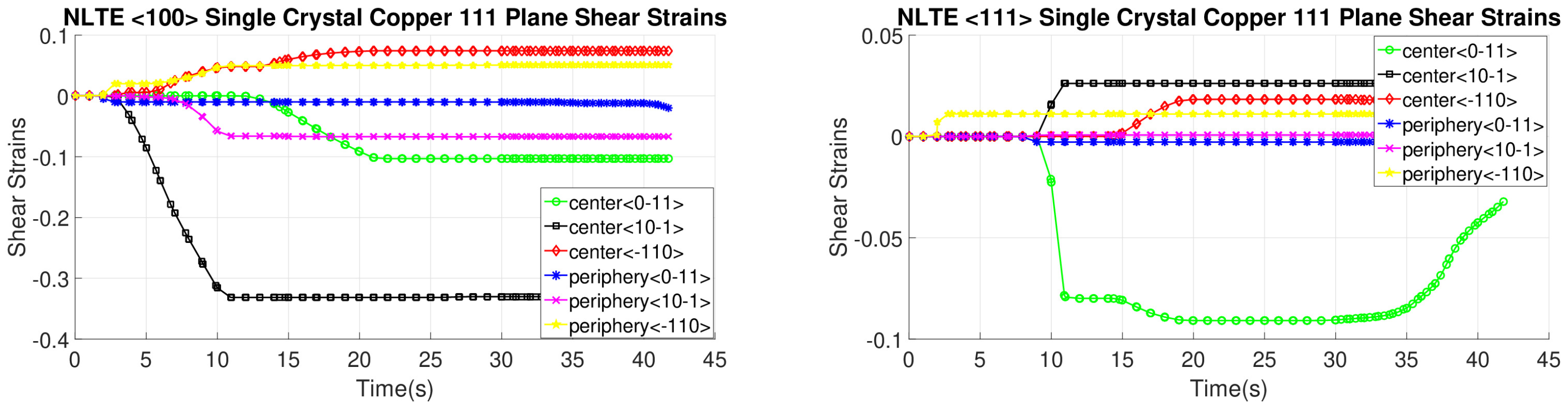

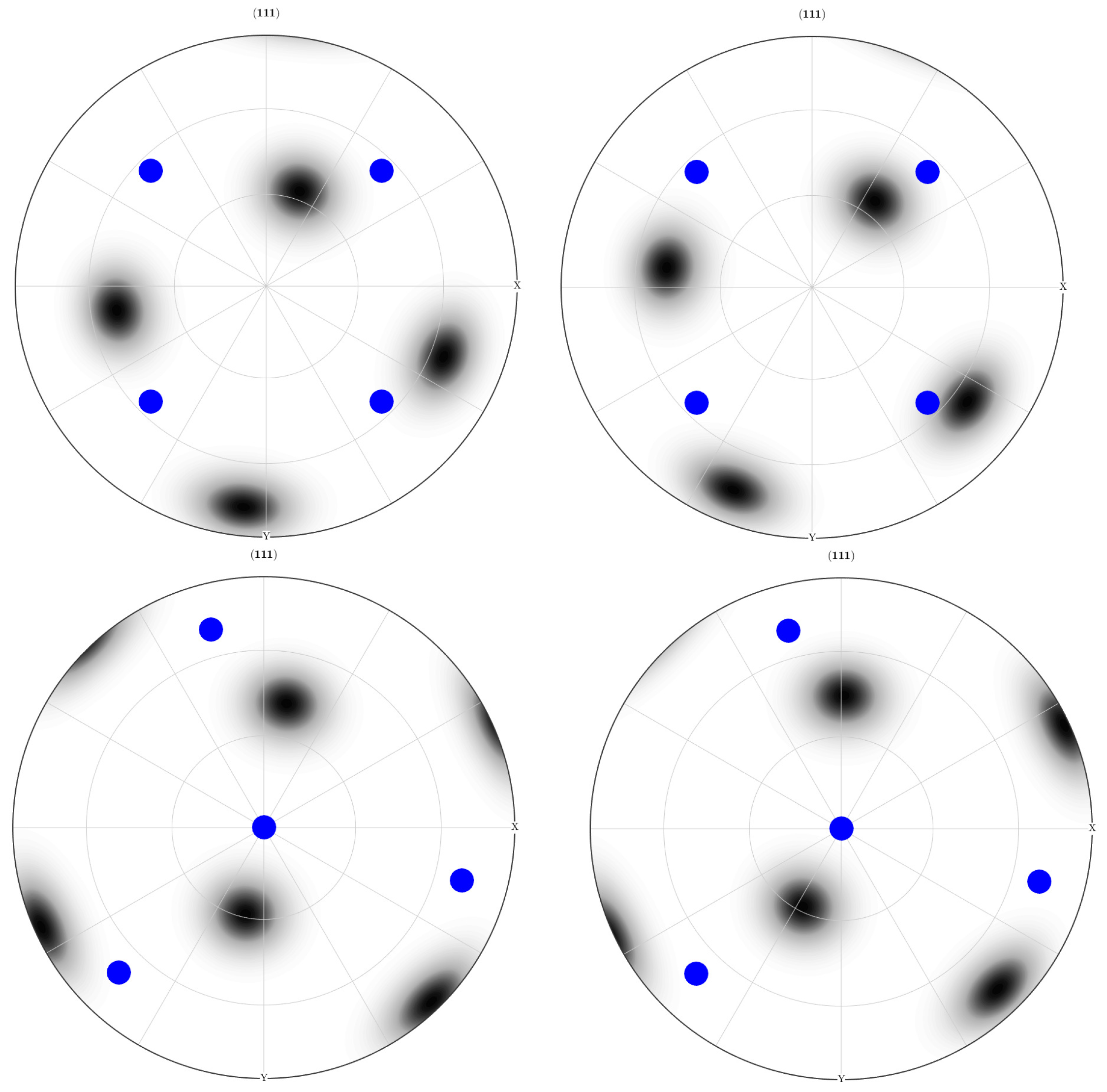

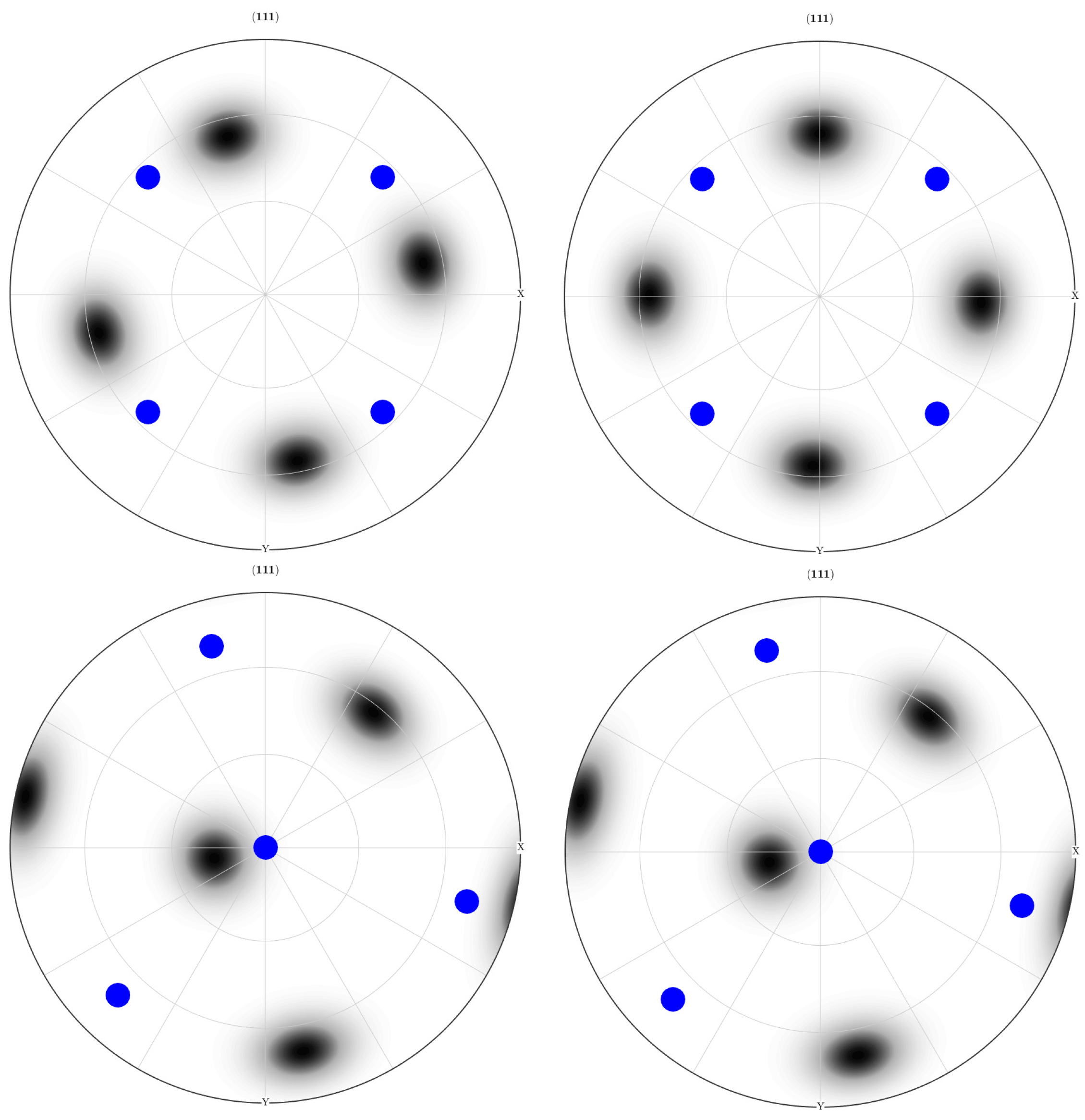

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhilyaev, A.P.; Langdon, L.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Agnew, S.; Weertman, J. Cyclic softening of ultrafine grain copper. Mater. Sci. Eng. A 1998, 244, 145–153. [Google Scholar] [CrossRef]

- Jia, D.; Wang, Y.M.; Ramesh, K.T.; Ma, E.; Zhu, Y.T.; Valiev, R.Z. Deformation behavior and plastic instabilities of ultrafine-grained titanium. Appl. Phys. Lett. 2001, 79, 611–613. [Google Scholar] [CrossRef]

- Murashkin, M.; Sabirov, I.; Prosvirnin, D.; Ovid’ko, I.; Terentiev, V.; Valiev, R.; Dobatkin, S. Fatigue behavior of an ultrafine-grained Al-Mg-Si alloy processed by high-pressure torsion. Metals 2015, 5, 578–590. [Google Scholar] [CrossRef]

- Valiev, R. Nanostructuring of metals by severe plastic deformation for advanced properties. Nat. Mater. 2004, 3, 511–516. [Google Scholar] [CrossRef]

- Valiev, R.; Langdon, L. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- A. Babaei, M.M.; Sofiani, F.M. Crystal plasticity modeling of grain refinement in aluminum tubes during tube cyclic expansion-extrusion. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2016, 232, 481–494. [Google Scholar]

- Liu, B.; Lei, Q.; Xie, L.; Wang, M.; Li, Z. Microstructure and mechanical properties of high product of strength and elongation Al-Zn-Mg-Cu-Zr alloys fabricated by spray deposition. Mater. Des. 2016, 96, 217–223. [Google Scholar] [CrossRef]

- Segal, V. Equal channel angular extrusion: From macromechanics to structure formation. Mater. Sci. Eng. A 1999, 271, 322–333. [Google Scholar] [CrossRef]

- Bridgman, P.W. On torsion combined with compression. J. Appl. Phys. 1943, 14, 274–283. [Google Scholar] [CrossRef]

- Tsuji, N.; Saito, Y.; Utsunomiya, H.; Tanigawa, S. Ultra-fine grained bulk steal produced by accumulative roll-bonding (ARB) process. Acta Metall. 1999, 40, 795–800. [Google Scholar]

- Imaev, R.; Imaev, V.; Salischev, G. Formation of submicrocrystalline microstructure in TiAl intermetallic compound. J. Mater. Sci. 1999, 27, 4465–4469. [Google Scholar] [CrossRef]

- Beygelzimer, Y.; Varyukhin, V.; Synkov, S.; Orlov, D. Useful properties of twist extrusion. Mater. Sci. Eng. A 2009, 503, 14–17. [Google Scholar] [CrossRef]

- Halfa, H. Overview of processing, microstructure and mechanical properties of ultrafine grained bcc steels. J. Miner. Mater. Charact. Eng. 2014, 2, 1–42. [Google Scholar]

- Langdon, T.G. Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement. Acta Mater. 2013, 61, 7035–7059. [Google Scholar] [CrossRef]

- Kalashnikov, K.N.; Kalashnikova, T.A.; Chumaevski, A.V.; Ivanov, A.N. Production of materials with ultrafine-grained structure of aluminum alloy by friction stir processing. J. Phys. 2018, 1115, 42–48. [Google Scholar] [CrossRef]

- Beygelzimer, Y.; Varyukhin, V.; Orlov, D.; Synkov, S. Twist extrusion—Process for strain accumulation. Donetsk TEAN 2003, 1, 87. [Google Scholar]

- Nassef, A.; Samy, S.; Garaihy, W.H.E. Enhancement of mechanical properties for Al-Mg-Si alloy using equal channel angular pressing. World Acad. Sci. Eng. Technol. 2015, 9, 131–136. [Google Scholar]

- Bagherpour, E.; Reihanian, M.; Pardis, N.; Ebrahimi, R.; Langdon, T.G. Ten years of severe plastic deformation (SPD) in Iran, part I: Equal-channel angular pressing (ECAP). Iran. J. Mater. Form. 2018, 5, 71–113. [Google Scholar]

- Cetlin, P.; Aguilar, M.; Figueiredo, R.; Langdon, T. Avoiding cracks and inhomogeneities in billets processed by ECAP. J. Mater. Sci. 2010, 45, 4561–4570. [Google Scholar] [CrossRef]

- Jiang, J.M.; Wang, Y.; Liu, Y.; Xiao, G.; Li, H. Microstructure and mechanical properties of 7005 aluminum alloy processed by one-pass equal channel reciprocating extrusion. Trans. Nonferrous Met. Soc. China 2021, 31, 609–625. [Google Scholar] [CrossRef]

- Duan, Y.; Tang, L.; Xu, G.; Deng, Y.; Yin, Z. Microstructure and mechanical properties of 7005 aluminum alloy processed by room temperature ECAP and subsequent annealing. J. Alloys Compd. 2016, 664, 518–529. [Google Scholar] [CrossRef]

- Shen, J.; Gartnerova, V.; Kecskes, L.J.; Kondoh, K.; Jager, A.; Wei, Q. Residual stress and its effect on the mechanical properties of Y-doped Mg alloy fabricated via back-pressure assisted equal channel angular pressing (ECAP-BP). Mater. Sci. Eng. 2016, A669, 111–117. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Lowe, T.C. Observations and issues on mechanisms of grain refinement during ECAP process. Mater. Sci. Eng. A 2000, 291, 46–53. [Google Scholar] [CrossRef]

- Lee, H.; Han, J.; Janakiraman, S.; Ahn, B.; Kawasaki, M.; Langdon, T.G. Significance of grain refinement on microstructure and mechanical properties of an Al-3 Mg alloy processed by high-pressure torsion. J. Alloys Compd. 2016, 686, 998–1007. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Langdon, T.G. Fabricating Ultra fine-Grained Materials through the application of severe plastic deformation: A Review of Developments in Brazil. J. Mater. Res. Technol. 2012, 54, 1587–1591. [Google Scholar]

- Lee, D.J.; Kim, H. Finite element analysis for the geometry effect on strain inhomogeneity during high-pressure torsion. J. Mater. Sci. 2014, 29, 1316–1329. [Google Scholar] [CrossRef]

- Ghalehbandi, S.M.; Malaki, M.; Gupta, M. Accumulative Roll Bonding—A Review. Mater. Sci. Eng. 2019, 9, 3627. [Google Scholar] [CrossRef]

- Djavanroodi, F.; Ebrahimi3, M.; Nayfeh, J.F. Tribological and mechanical investigation of multi-directional forged nickel. Sci. Rep. 2019, 9, 241. [Google Scholar] [CrossRef]

- Obara, C.; Mwema, F.M.; Keraita, J.N.; Shagwira, H.; Obiko, J.O. A multi-response optimization of the multi-directional forging process for aluminium 7075 alloy using grey-based taguchi method. SN Appl. Sci. 2021, 3, 596–616. [Google Scholar] [CrossRef]

- Heczel, A.; Akbaripanah, F.; Salevati, M.; Mahmudi, R.; Vida, A.; Gubicza, J. A comparative study on the microstructural evolution in AM60 alloy processed by ECAP and MDF. J. Alloys Compd. 2018, 763, 629–637. [Google Scholar] [CrossRef]

- Sharath, P.C.; Udupa, K.R.; Kumar, G.V.P. Effect of multi directional forging on the microstructure and mechanical properties of Zn-24 wt Al-2 wt Cu alloy. Trans. Indian Inst. Met. 2016, 2, 863–901. [Google Scholar] [CrossRef]

- Beygelzimer, Y.; Orlov, D.; Korshunov, A.; Synkov, S.; Varyukhin, V.; Vedernikova, I.; Reshetov, A.; Synkov, A.; Polyakov, L.; Korotchenkova, I. Features of twist extrusion: Method, structures and material properties. Solid State Phenom. 2006, 114, 69–78. [Google Scholar] [CrossRef]

- Beygelzimer, Y.; Orlov, D. Metal plasticity during the twist extrusion. Defect Diffus. Forum 2002, 208–209, 311–314. [Google Scholar] [CrossRef]

- Latypov, M.I.; Beygelzimer, Y.; Kim, H.S. Comparative analysis of two twist-based SPD processes: Elliptical cross-section spiral equal-channel extrusion vs. twist extrusion. Metall. Mater. Trans. A 2013, 54, 1587–1591. [Google Scholar] [CrossRef]

- Mousavi, S.A.; Bahadori, S.R.; Shahab, A. Numerical and experimental studies of the plastic strains distribution using subsequent direct extrusion after three twist extrusion passes. Mater. Sci. Eng. A 2010, 527, 3967–3974. [Google Scholar] [CrossRef]

- Varyukhina, V.; Beygelzimer, Y.; Kulaginc, R.; Prokofeva, O.; Reshetov, A. Twist Extrusion: Fundamentals and Applications. Mater. Sci. Forum 2011, 667–669, 31–37. [Google Scholar] [CrossRef]

- Berta, M.; Orlov, D.; Prangnella, P.B. Grain refinement response during twist extrusion of an Al-0.13 Mg alloy. Int. J. Mater. Res. 2007, 98, 200–204. [Google Scholar] [CrossRef]

- Joudaki, J.; Safari, M.; Alhosseini, S.M. Hollow twist extrusion: Introduction, strain distribution, and process parameters investigation. Met. Mater. Int. 2019, 7, 1593–1602. [Google Scholar] [CrossRef]

- Iqbal, U.M.; Kumar, V.S. An analysis on effect of multipass twist extrusion process of AA6061 alloy. Mater. Des. 2013, 50, 946–953. [Google Scholar] [CrossRef]

- Noor, S.V.; Eivani, A.; Jafarian, H.; Mirzaei, M. Inhomogeneity in microstructure and mechanical properties during twist extrusion. Mater. Sci. Eng. A 2016, 652, 186–191. [Google Scholar] [CrossRef]

- Iqbal, U.M.; Senthilkumar, V. Experimental investigation and analysis of microstructure and mechanical properties on twist extrusion forming process of AA7075-T6 aluminum alloy. Int. J. Mech. Mater. Eng. 2012, 7, 24–30. [Google Scholar]

- Beygelzimer, Y.; Prilepoa, D.; Kulagina, R.; Grishaeva, V.; Abramovaa, O.; Varyukhina, V.; Kulakov, M. Planar twist extrusion versus twist extrusion. J. Mater. Process. Technol. 2011, 211, 522–529. [Google Scholar] [CrossRef]

- Nouri, M.; Semnani, H.M.; Emadoddin, E. Computational and experimental studies on the efect back pressure on twist extrusion process. Met. Mater. Int. 2021, 27, 2910–2918. [Google Scholar] [CrossRef]

- Bahadori, S.R.; Mousavi, S.A.A.A.; Synkov, S.; Shahab, A.R. Microstructure and mechanical properties of the twist extruded pure copper after rolling. Int. J. Mod. Phys. 2012, 5, 359–366. [Google Scholar] [CrossRef]

- Maulidi, M.; Miyamoto, H.; Yuasa, M. Grain Refinement of Pure Magnesium Using Nonlinear TwistExtrusion. Mater. Sci. Forum 2018, 939, 54–62. [Google Scholar] [CrossRef]

- Yalçinkaya, T.; Şimşek, U.; Miyamoto, H.; M. Yuasa. Numerical analysis of a new nonlinear twist extrusion process. Metals 2019, 9, 513. [Google Scholar] [CrossRef]

- Kalidindi, S.R.; Donohue, B.R.; Li, S. Modeling texture evolution in equal channel angular extrusion using crystal plasticity finite element models. Int. J. Plast. 2009, 25, 768–779. [Google Scholar] [CrossRef]

- Deng, G.; Lu, C.; Su, L.; Liu, X.; Tieu, A. Modeling texture evolution during ECAP of copper single crystal by crystal plasticity FEM. Mater. Sci. Eng. A 2012, 534, 68–74. [Google Scholar] [CrossRef]

- Latypov, M.I.; Lee, M.; Beygelzimer, Y.; Prilepo, D.; Gusar, Y.; Kim, H.S. Modeling and characterization of texture evolution in twist extrusion. Miner. Met. Mater. Soc. ASM Int. 2016, 47, 1248–1260. [Google Scholar] [CrossRef]

- Sheikh, H.; Ebrahimi, R. Modeling the effect of backpressure on dislocation cell structure during simple shear extrusion. In Proceedings of the 6th Biennial International Conference on Ultrafine Grained and Nanostructured Materials, Kish Island, Iran, 12–13 November 2017; Volume 17, pp. 175–186. [Google Scholar]

- Xu, Z.; Zhang, C.; Wang, K.; Zhang, K.; Zhao, G.; Chen, L. Crystal plasticity prediction of texture evolution during helical extrusion process of aluminium alloys under three-dimensional deformation path. J. Alloys Compd. 2020, 830, 154598. [Google Scholar] [CrossRef]

- Kim, S.H.; Yeon, S.M.; Lee, J.H.; Kim, Y.W.; Lee, H.; Park, J.; Lee, N.K.; Choi, J.P.; Aranas, J.C.; Lee, Y.L.; et al. Additive manufacturing of a shift block via laser powder bed fusion: The simultaneous utilisation of optimised topology and a lattice structure. Virtual Phys. Prototyp. 2020, 15, 460–480. [Google Scholar] [CrossRef]

- Vural, H.; Erdoğan, C.; Fenercioğlu, T.O.; Yalçinkaya, T. Ductile failure prediction during the flow forming process. Procedia Struct. Integr. 2022, 35, 25–33. [Google Scholar] [CrossRef]

- Günay, E.; Fenercioğlu, T.O.; Yalçinkaya, T. Numerical analysis of thermo-mechanical behavior in flow forming. Procedia Struct. Integr. 2022, 35, 42–50. [Google Scholar] [CrossRef]

- Erdogan, C.; Vural, H.; Karakaş, A.; Fenercioğlu, T.O.; Yalçinkaya, T. Ductile failure of Inconel 718 during flow forming process and its numerical investigation. Eng. Fail. Anal. 2023, 152, 107424. [Google Scholar] [CrossRef]

- Latypov, M.; Yoon, E.Y.; Lee, D.J.; Kulagin, R.; Beygelzimer, Y.; Salehi, M.S.; Kim, H.S. Microstructure and Mechanical Properties of Copper Processed by Twist Extrusion with a Reduced Twist-Line Slope. Metal. Mater. 2014, 45, 2232–2241. [Google Scholar] [CrossRef]

- Bakhtiari, H.; Karimi, M.; Rezazadeh, S. Modeling, analysis and multi-objective optimization of twist extrusion process using predictive models and meta-heuristic approaches, based on finite element results. J. Intell. Manuf. 2016, 27, 463–473. [Google Scholar] [CrossRef]

- Heydari, F.; Saljoghi, H.; Nourbakhsh, S. Numerical Investigation of the Cross-section and Twist Extrusion Die Angle on the Distribution of Plastic Strain and Microstructure of Al7050 Alloy. J. Stress Anal. 2019, 1, 1–8. [Google Scholar]

- Parshikov, R.A.; Rudskoy, A.I.; Zolotov, A.M.; Tolochko, O.V. Technological problems of equal channel angular pressing. Rev. Adv. Mater. Sci. 2013, 34, 26–36. [Google Scholar]

- Moshkovich, A.; Perfilyev, V.; Gorni, D.; Lapsker, I.; Rapoport, L. The effect of Cu grain size on transition from EHL to BL regime (Stribeck curve). Wear 2011, 271, 1726–1732. [Google Scholar] [CrossRef]

- Deng, G.; Lu, C.; Tieu, A.; Su, L.; Huynh, N.; Liu, X. Crystal plasticity investigation of friction effect on texture evolution of Al single crystal during ECAP. J. Mater. Sci. 2010, 45, 4711–4717. [Google Scholar] [CrossRef]

- Sheikh, H.; Ebrahimi, R.; Bagherpour, E. Crystal plasticity finite element modeling of crystallographic textures in simple shear extrusion (SSE) process. Mater. Des. 2016, 109, 289–299. [Google Scholar] [CrossRef]

- Alkorta, J.; Sevillano, J.G. A comparison of FEM and upper-bound type analysis of equal-channel angular pressing (ECAP). J. Mater. Process. Technol. 2003, 141, 313–318. [Google Scholar] [CrossRef]

- Huang, Y. A user-material subroutine incorporating single crystal plasticity in the abaqus finite element program. Div. Appl. Sci. Harv. Univ. 1991, 20, 1–47. [Google Scholar]

- Yalçinkaya, T.; Brekelmans, W.A.M.; Geers, M.G.D. BCC single crystal plasticity modelling and its experimental identification. Model. Simul. Mat. Sci. Eng. 2008, 16, 085007. [Google Scholar] [CrossRef]

- Acar, S.S.; Bulut, O.; Yalçinkaya, T. Crystal plasticity modeling of additively manufactured metallic microstructures. Procedia Struct. Integr. 2022, 35, 219–227. [Google Scholar] [CrossRef]

- Bulut, O.; Acar, S.S.; Yalçinkaya, T. The influence of thickness/grain size ratio in microforming through crystal plasticity. Procedia Struct. Integr. 2022, 35, 228–236. [Google Scholar] [CrossRef]

- Shih, C.F.; Hutchinson, J.W. Fully plastic solutions and large scale yielding estimates for plane stress crack problems. J. Eng. Mater. Technol. 1976, 98, 289–295. [Google Scholar] [CrossRef]

- Pierce, D.; Asora, R.J.; Needleman, A. An analysis of nonuniform and localized deformation in ductile single crystals. Acta Metall. 1982, 30, 1087–1119. [Google Scholar] [CrossRef]

- Tekoğlu, C. Representative volume element calculations under constant stress triaxiality, Lode parameter, and shear ratio. Int. J. Solids Struct. 2014, 51, 4544–4553. [Google Scholar] [CrossRef]

- Yalçinkaya, T.; Çakmak, S.; Tekoğlu, C. A crystal plasticity based finite element framework for RVE calculations of two-phase materials: Void nucleation in dual-phase steels. Finite Elem. Anal. Des. 2021, 187, 103510. [Google Scholar] [CrossRef]

- Yalçinkaya, T.; Güngör, G.; Çakmak, S.O.; Tekoğlu, C. A Micromechanics Based Numerical Investigation of Dual Phase Steels. Procedia Struct. Integr. 2019, 21, 61–72. [Google Scholar] [CrossRef]

- Aydiner, I.U.; Tatli, B.; Yalçinkaya, T. Investigation of failure mechanisms in dual-phase steels through cohesive zone modeling and crystal plasticity frameworks. Int. J. Plast. 2024, 174, 103898. [Google Scholar] [CrossRef]

- Wang, Z.; Beyerlein, I.; LeSar, R. Plastic anisotropy in fcc single crystals in high rate deformation. Int. J. Plast. 2009, 25, 26–48. [Google Scholar] [CrossRef]

- Mahesh, S.; Tome, C.; McCabe, C.; Kaschner, G.; Beyerlin, I.; Misra, A. Application of a substructure-based hardening model to copper under loading path changes. Metall. Mater. Eng. 2004, A35, 3763–3774. [Google Scholar] [CrossRef]

- Xue, Q.; Beyerlein, I.; Alexander, D.; Gray, G. Mechanisms for initial grain refinement of OFHC copper during equal channel angular presssing. Acta Mater. 2007, 55, 665–668. [Google Scholar] [CrossRef]

- Hansen, N.; Huang, X. Microstructure and flow stress of polycrystals and single crystals. Acta Metall. 1998, 46, 1827–1836. [Google Scholar] [CrossRef]

- Kawasaki, Y.; Takeuchi, T. Cell structures in copper single crystals deformed in [001] and [111] axes. Scr. Metall. 1980, 14, 183–188. [Google Scholar] [CrossRef]

- Raabe, D.; Roters, F. Using texture components in crystal plasticity finite element simulations. Int. J. Plast. 2004, 20, 339–361. [Google Scholar] [CrossRef]

- Yan, H.; Zhao, X.; Jia, N.; Zheng, Y. Influence of Shear banding on the formation of brass-type textures in polycrystalline fcc Metals with Low Stacking Fault Energy. J. Mech. Sci. Technol. 2014, 30, 408–416. [Google Scholar] [CrossRef]

- Kestens, L.; Pirgazi, H. Texture formation in metal alloys with cubic crystal structures. Mater. Sci. Technol. 2016, 32, 1303–1315. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhiyi, L.; Huang, T.; Xia, P.; Li, F. Enhanced fracture toughness in an annealed Al-Cu-Mg alloy by increasing Goss/Brass texture ratio. Mater. Charact. 2016, 119, 47–54. [Google Scholar] [CrossRef]

- Cantergiani, E.; Falkinger, G.; Mitsche, S.; Theissing, M.; Klitschke, S.; Roters, F. Influence of strain rate sensitivity on cube texture evolution in aluminium alloys. Metall. Mater. Trans. A 2022, 53, 18–36. [Google Scholar] [CrossRef]

- Ridha, A.; Hutchinson, W. Recrystallisation mechanisms and the origin of cube texture in copper. Acta Metall. 1982, 30, 1929–1939. [Google Scholar] [CrossRef]

- Doherty, R.; Chen, L.; Samajdar, I. Cube recrystallization texture experimental results and modeling. Mater. Sci. Eng. 1998, 257, 18–36. [Google Scholar] [CrossRef]

| Design Element | Analysis Type | Element Type | Element Number |

|---|---|---|---|

| NLTE Mold | Implicit | Tetrahedral-C3D4 | 419316 |

| NLTE Punch | Implicit | Hexahedral-C3D8R | 1679 |

| NLTE Specimen | Implicit | Hexahedral-C3D8R | 48750 |

| NLTE Dummy Specimen | Implicit | Hexahedral-C3D8R | 15794 |

| LTE Mold | Implicit | Tetrahedral-C3D4 | 33777765 |

| LTE Punch | Implicit | Hexahedral-C3D8R | 925 |

| LTE Specimen | Implicit | Hexahedral-C3D8R | 159989 |

| LTE Dummy Specimen | Implicit | Hexahedral-C3D8R | 36000 |

| Model | Punch Speed | CPU Time | Approximate Analysis Completion Time |

|---|---|---|---|

| UMAT CP LTE | 2 mm/s | 720 h:47 min:50 s | 30 days |

| UMAT CP NLTE | 2 mm/s | 1078 h:17 min:21 s | 45 days |

| Model | n | q | |||||||

|---|---|---|---|---|---|---|---|---|---|

| UMAT CP | 168,000 MPa | 121,400 MPa | 75,400 MPa | 25 MPa | 115 MPa | 120 MPa | 0.001 | 17 | 1.4 |

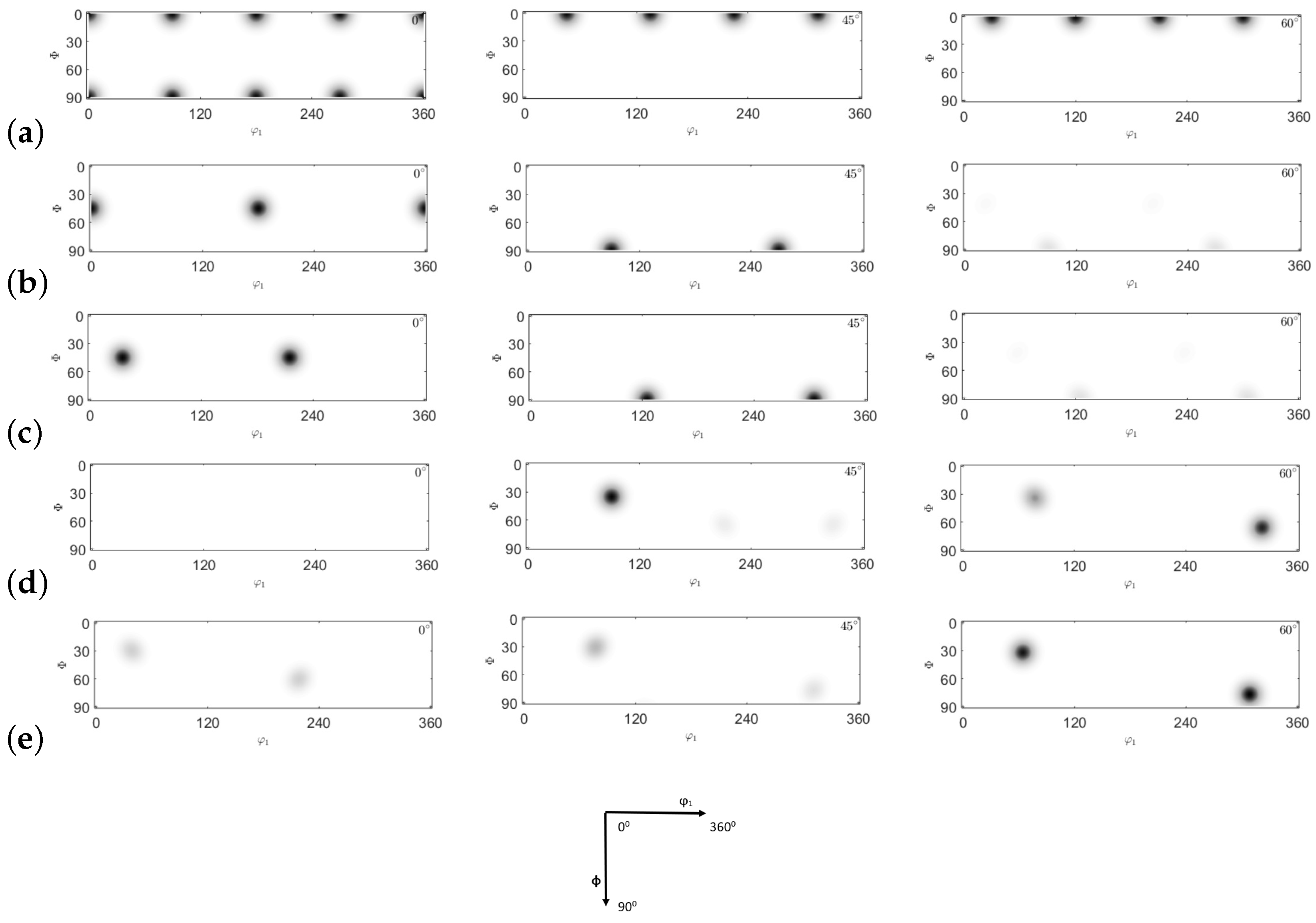

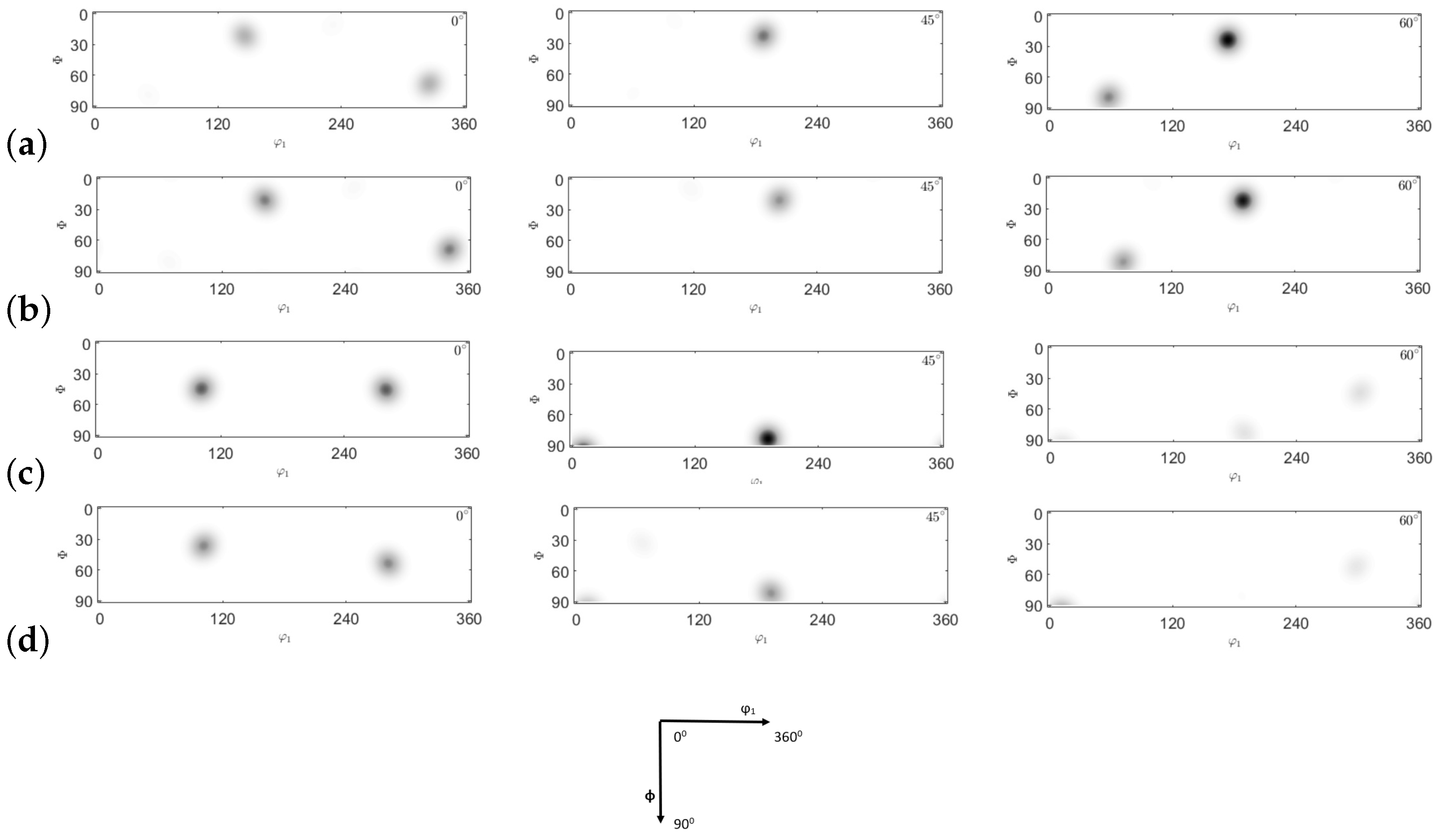

| Elemental Texture Name | Orientations | Bunge Euler Angles ( ) | Pole Figures of Elemental Textures [111] [110] [100] |

|---|---|---|---|

| Cube | [001]<100> | (0 0 0) |  |

| Goss | [011]<100> | (0 45 0) |  |

| Brass | [01]<211> | (35 45 0) |  |

| Copper | [11]<111> | (90 35 45) |  |

| S | [12]<634> | (60 32 65) |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Şimşek, Ü.; Davut, K.; Miyamoto, H.; Yalçinkaya, T. Comparison of Linear and Nonlinear Twist Extrusion Processes with Crystal Plasticity Finite Element Analysis. Materials 2024, 17, 1139. https://doi.org/10.3390/ma17051139

Şimşek Ü, Davut K, Miyamoto H, Yalçinkaya T. Comparison of Linear and Nonlinear Twist Extrusion Processes with Crystal Plasticity Finite Element Analysis. Materials. 2024; 17(5):1139. https://doi.org/10.3390/ma17051139

Chicago/Turabian StyleŞimşek, Ülke, Kemal Davut, Hiroyuki Miyamoto, and Tuncay Yalçinkaya. 2024. "Comparison of Linear and Nonlinear Twist Extrusion Processes with Crystal Plasticity Finite Element Analysis" Materials 17, no. 5: 1139. https://doi.org/10.3390/ma17051139

APA StyleŞimşek, Ü., Davut, K., Miyamoto, H., & Yalçinkaya, T. (2024). Comparison of Linear and Nonlinear Twist Extrusion Processes with Crystal Plasticity Finite Element Analysis. Materials, 17(5), 1139. https://doi.org/10.3390/ma17051139