A 30-Year Review on Nanocomposites: Comprehensive Bibliometric Insights into Microstructural, Electrical, and Mechanical Properties Assisted by Artificial Intelligence

Abstract

1. Introduction

2. Methodology

2.1. Scopus Database Search Strategy

2.2. Textual Analytics Approach

2.3. Scholarly Literature Analysis on Nanocomposite Themes

2.4. Analysis of MAP and NET Files

2.5. Bibliometric Data Analysis and Visualization Report

3. Results and Discussions

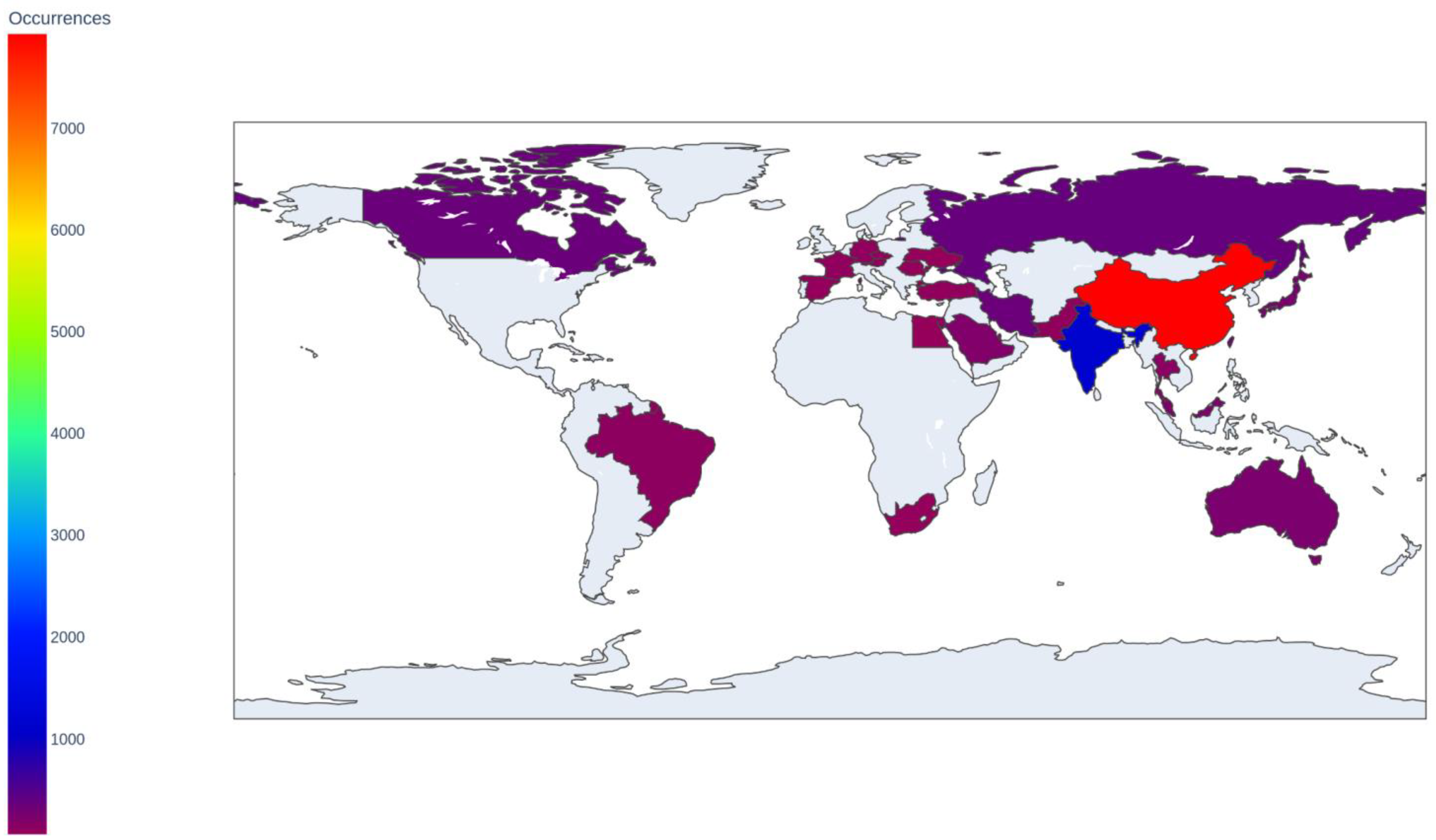

3.1. Scopus Database Search Strategy

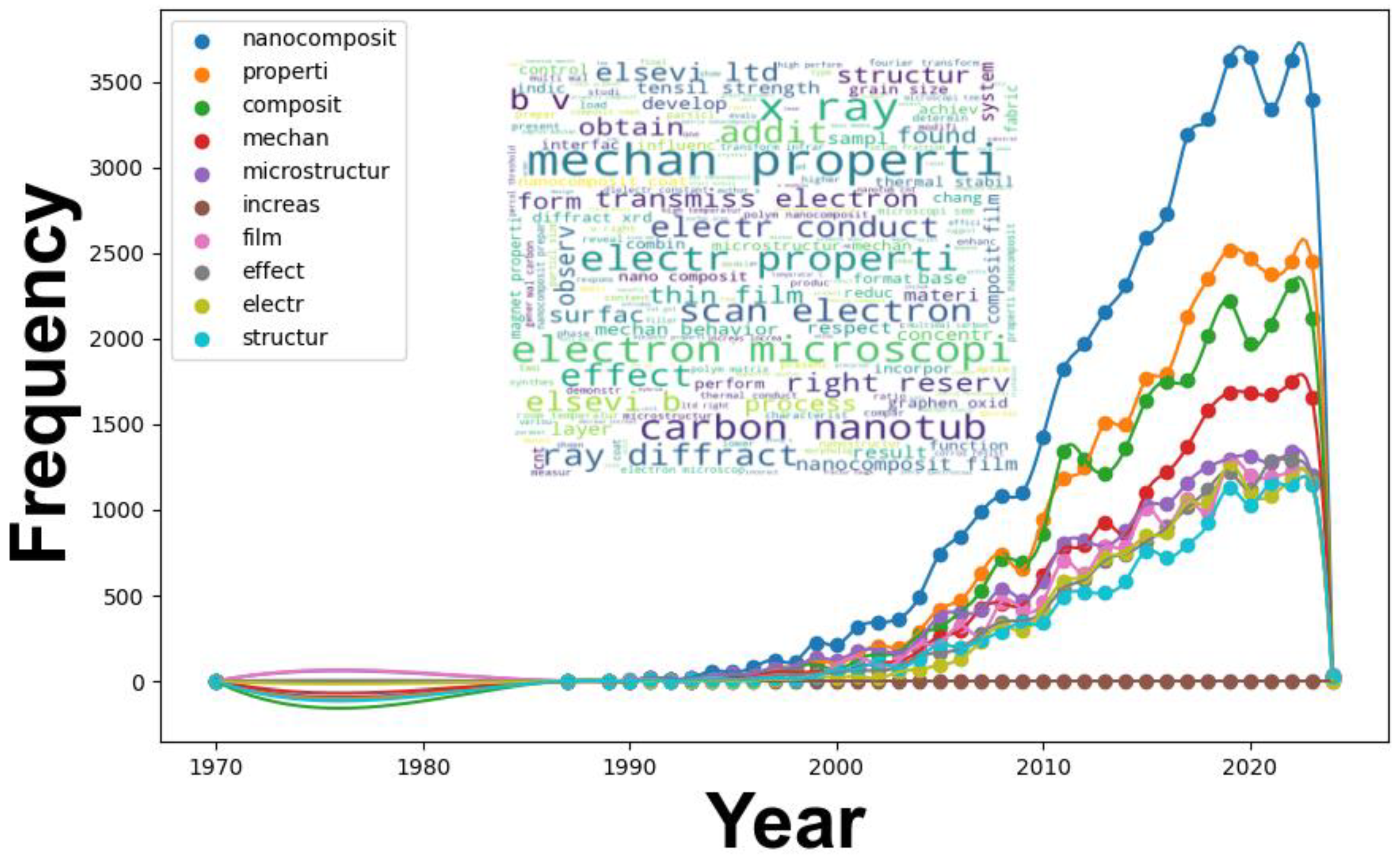

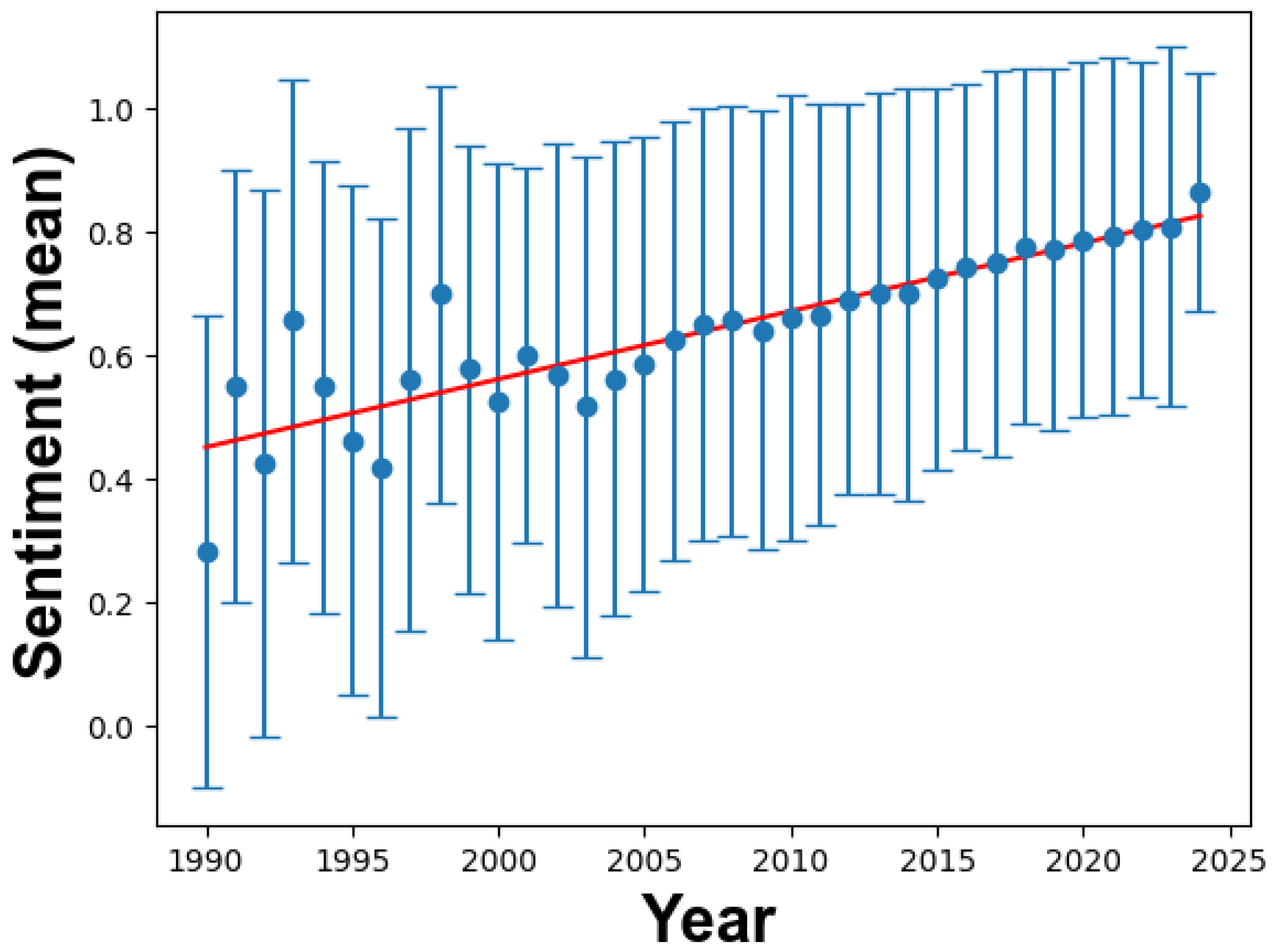

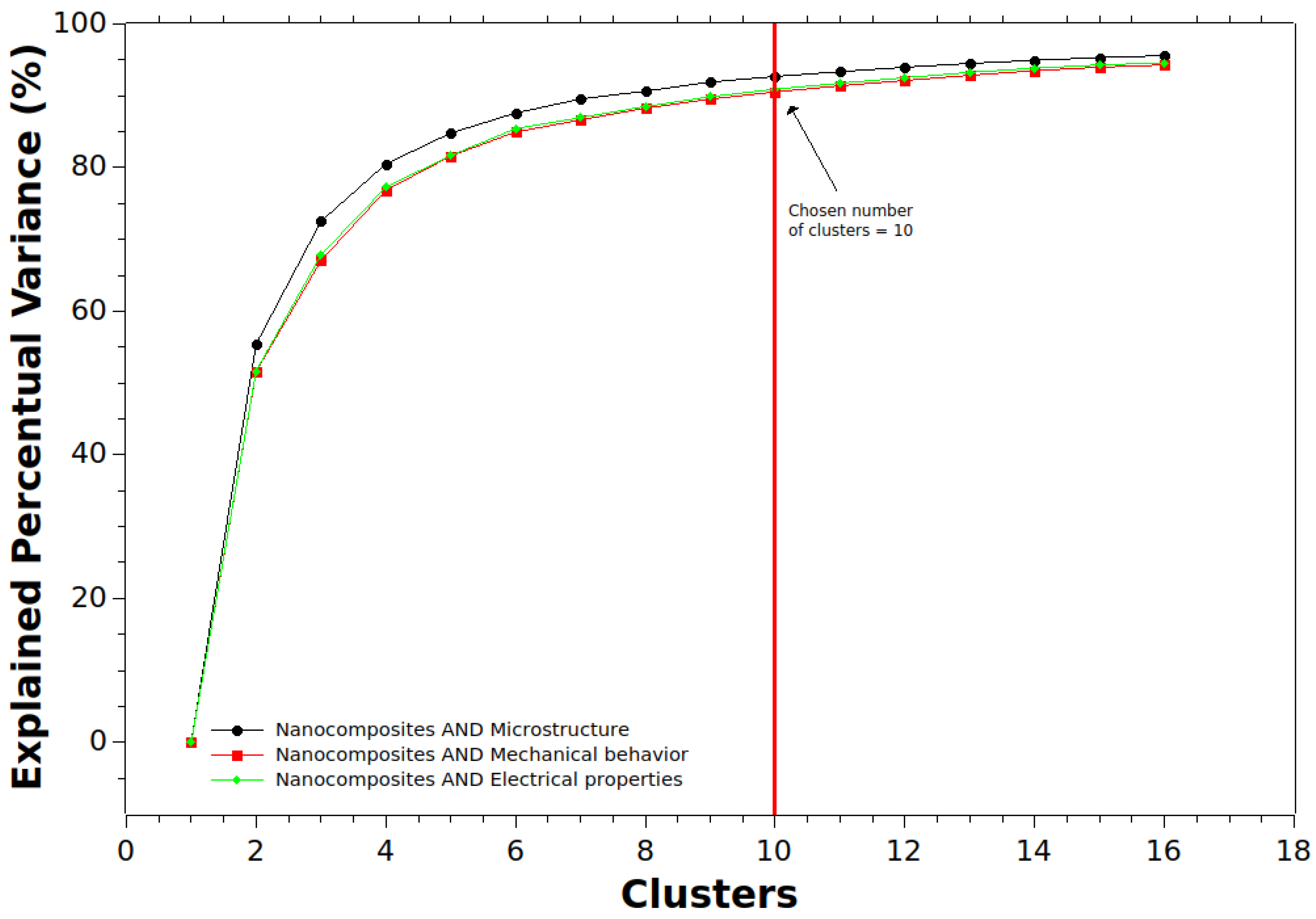

3.2. Textual Analytics Approach

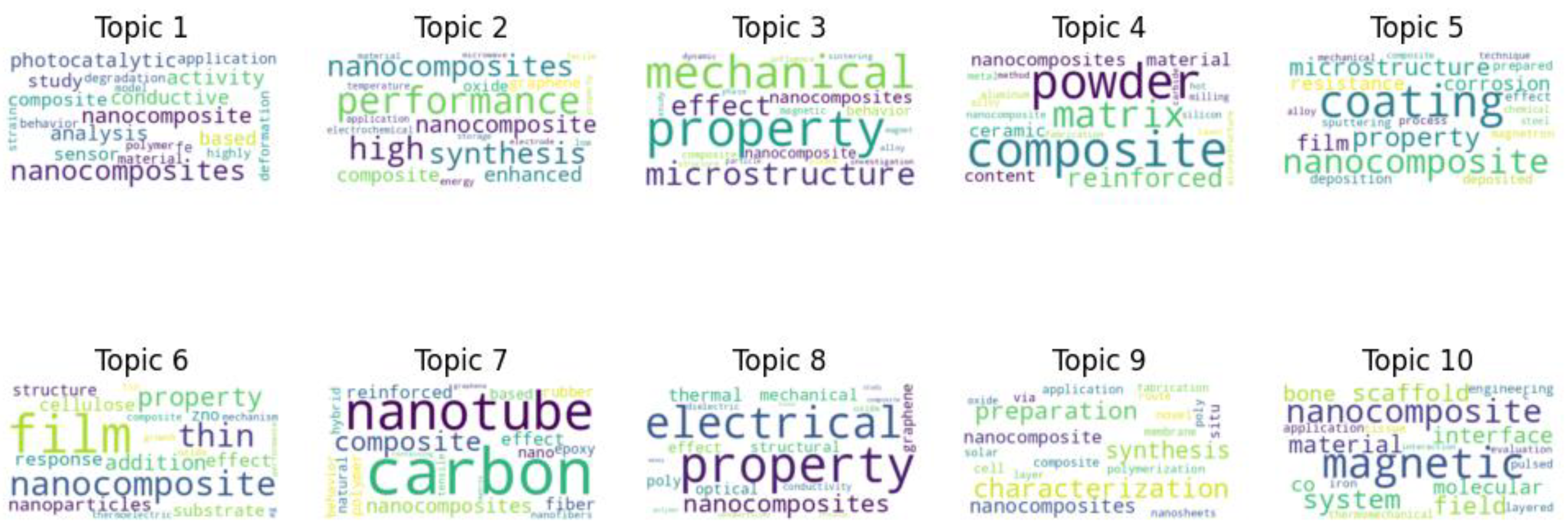

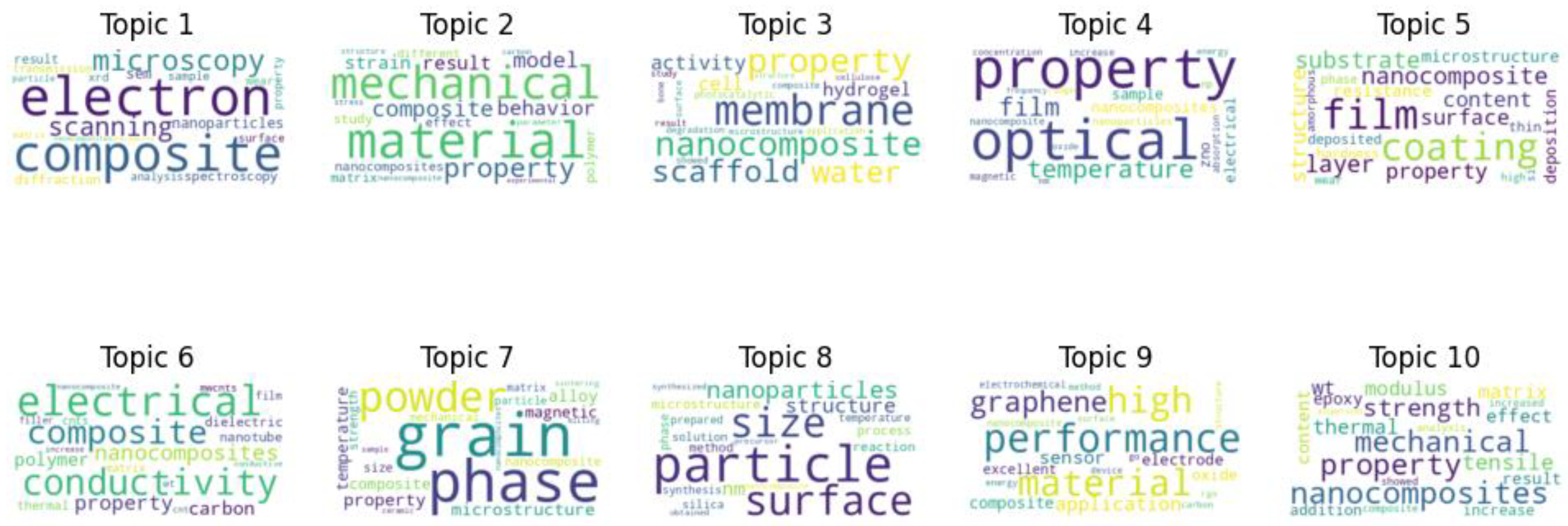

3.3. Scholarly Literature Analysis on Nanocomposite Themes

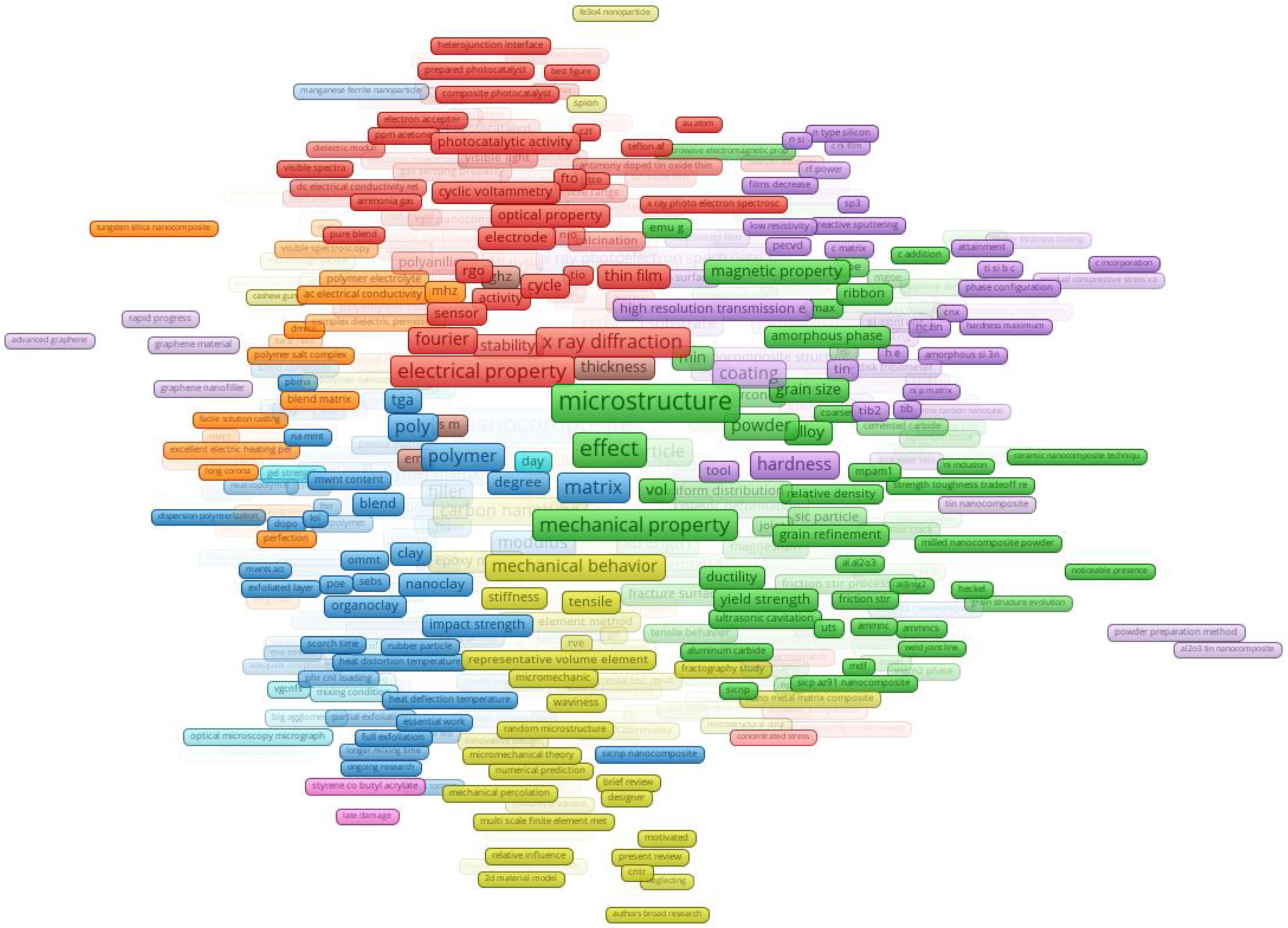

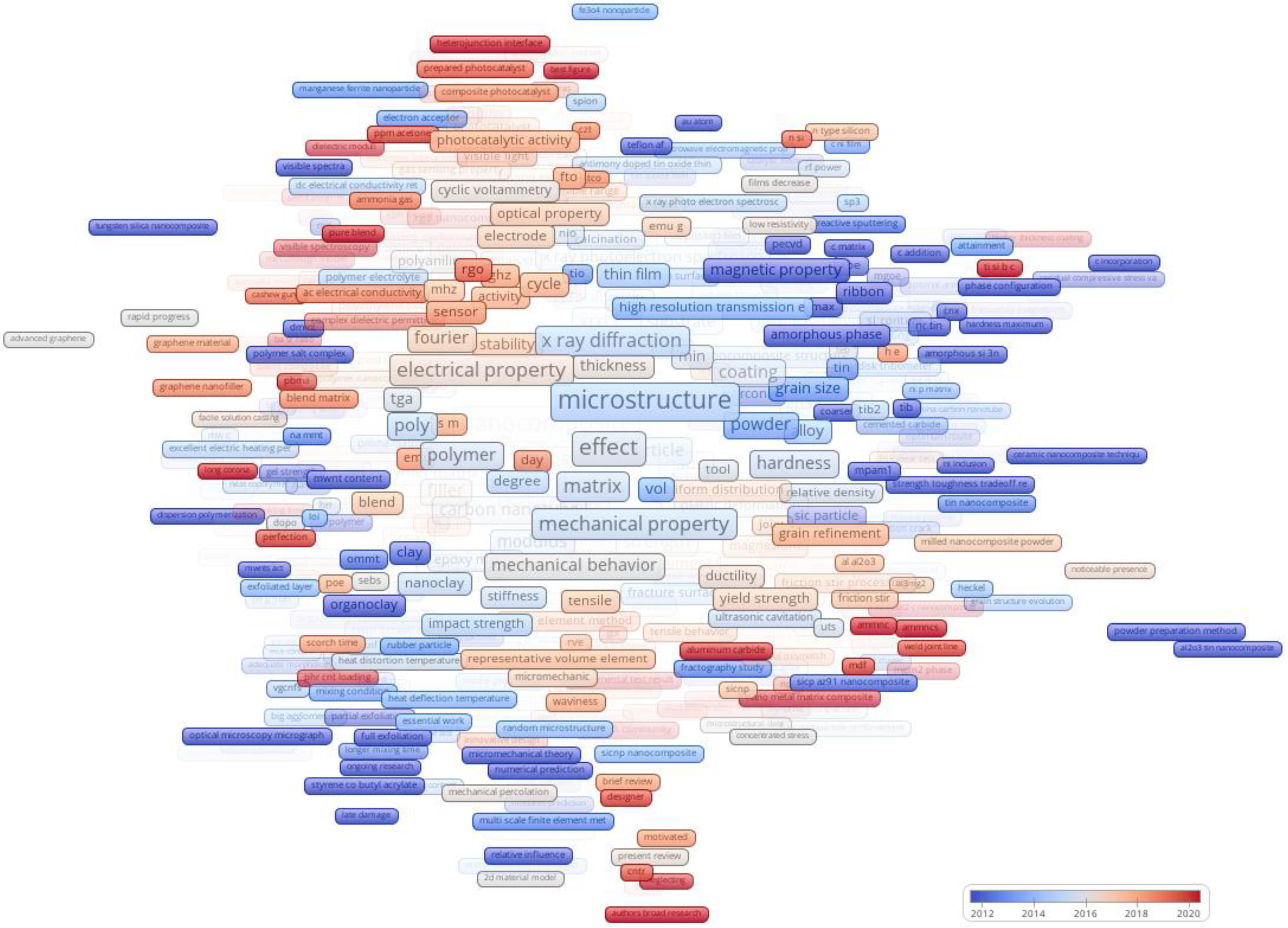

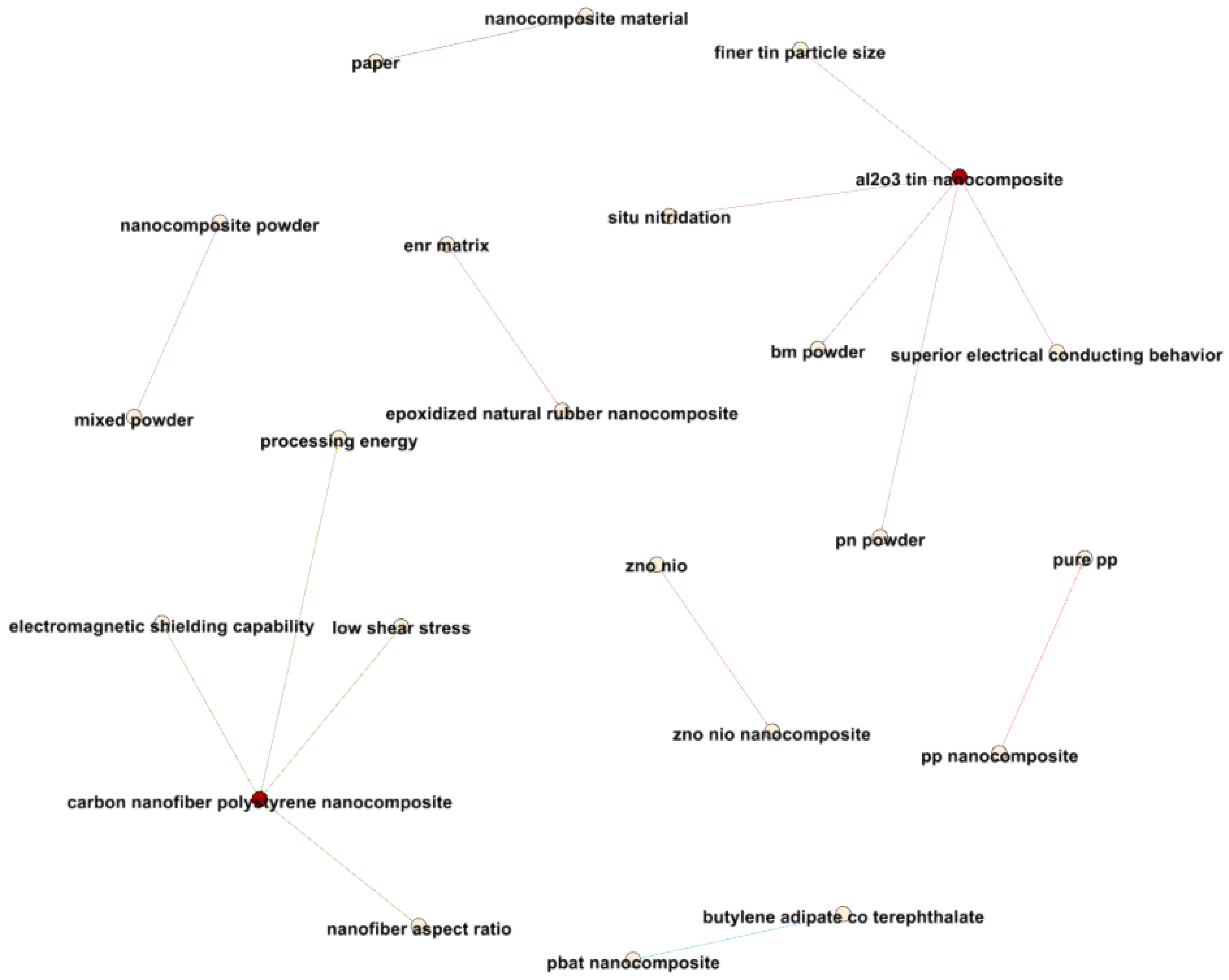

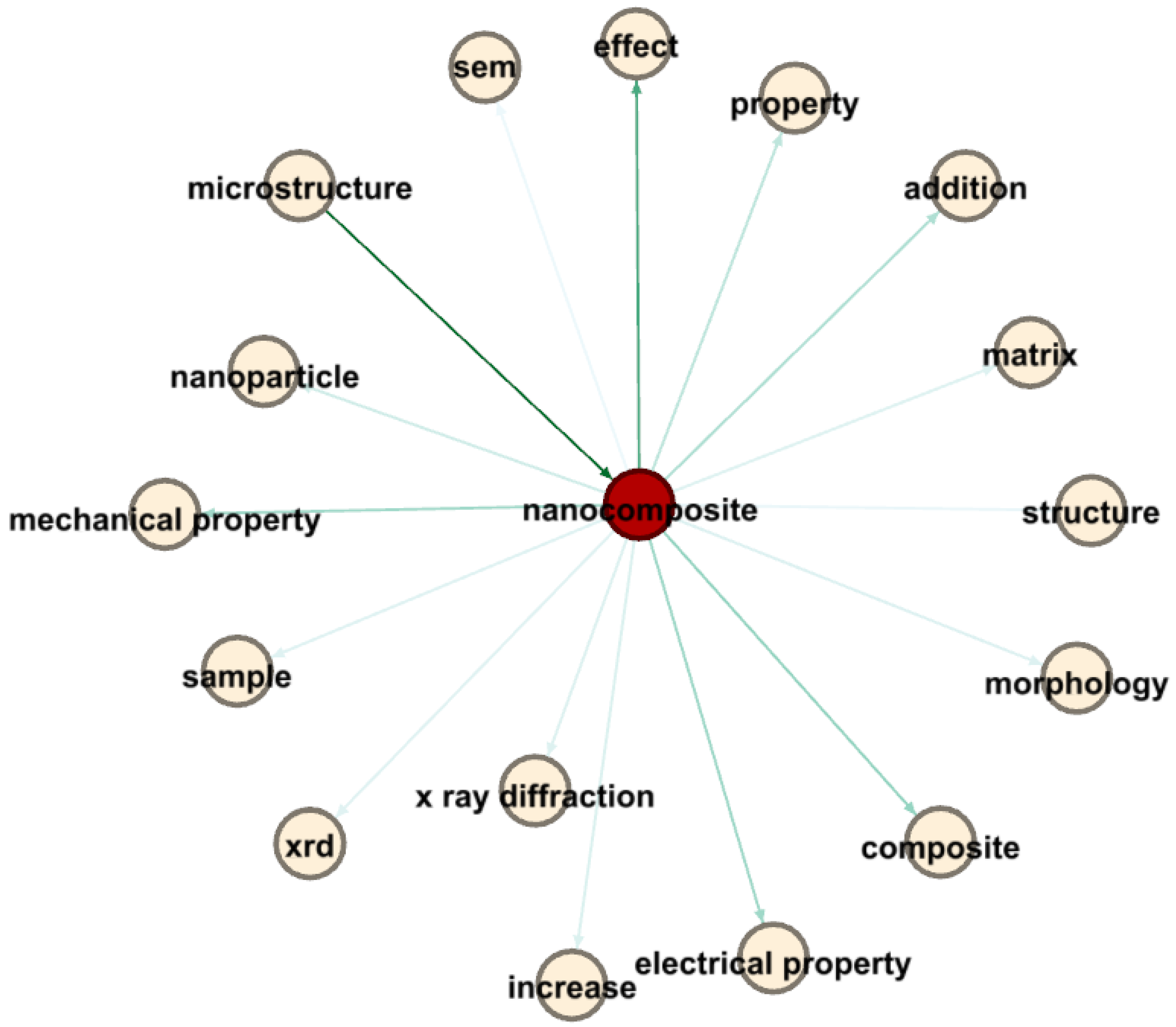

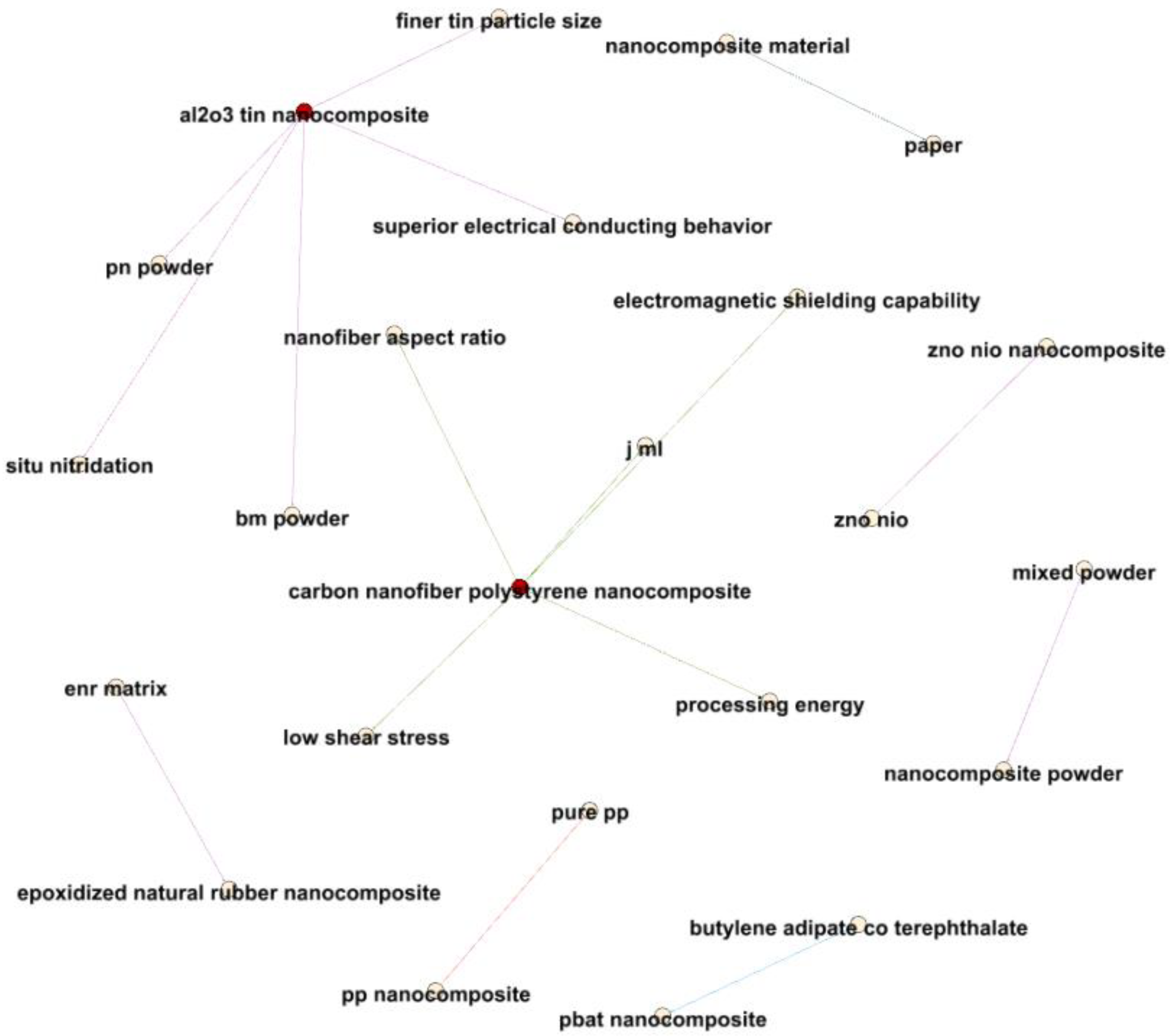

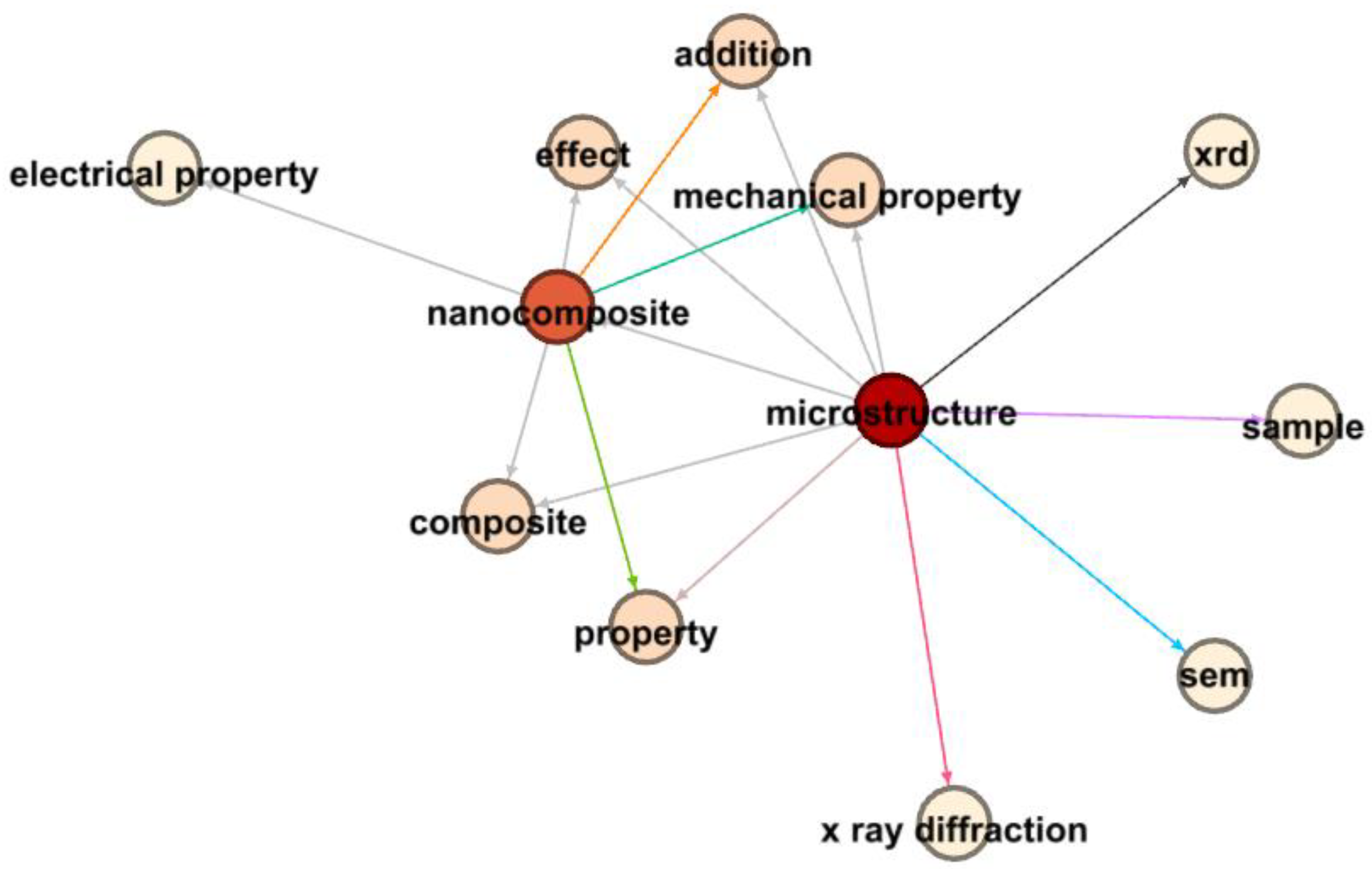

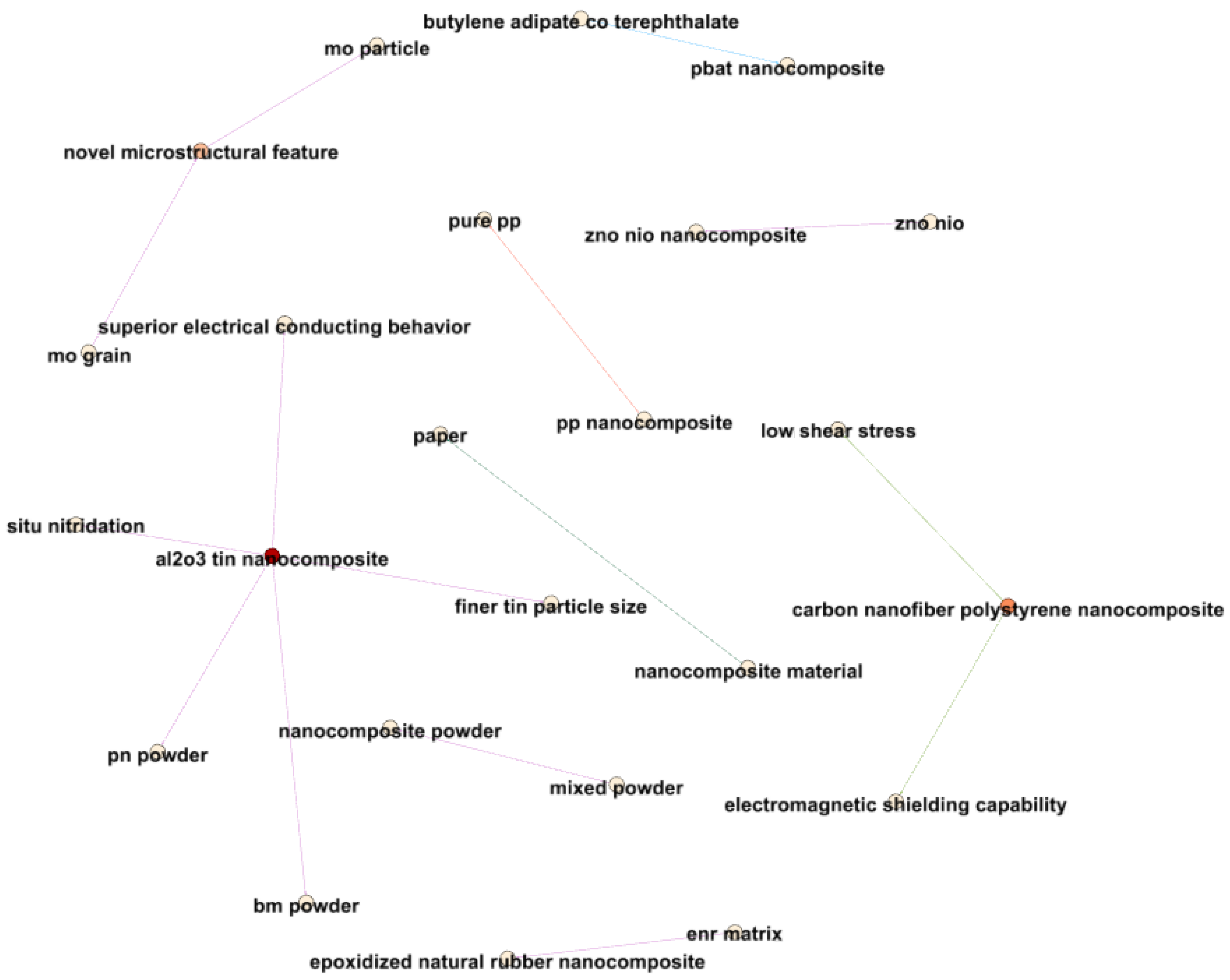

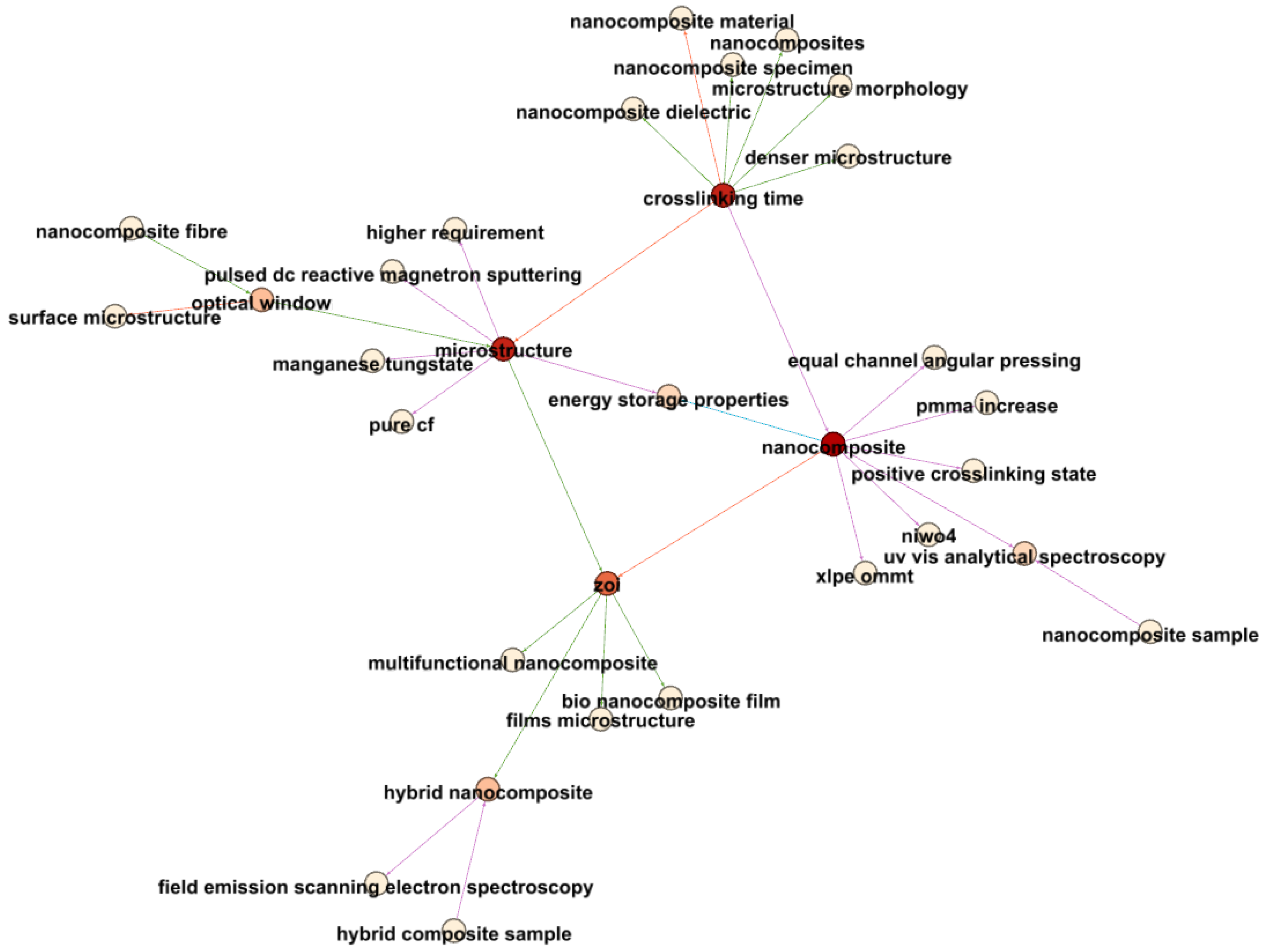

3.4. Analysis of MAP and NET Files

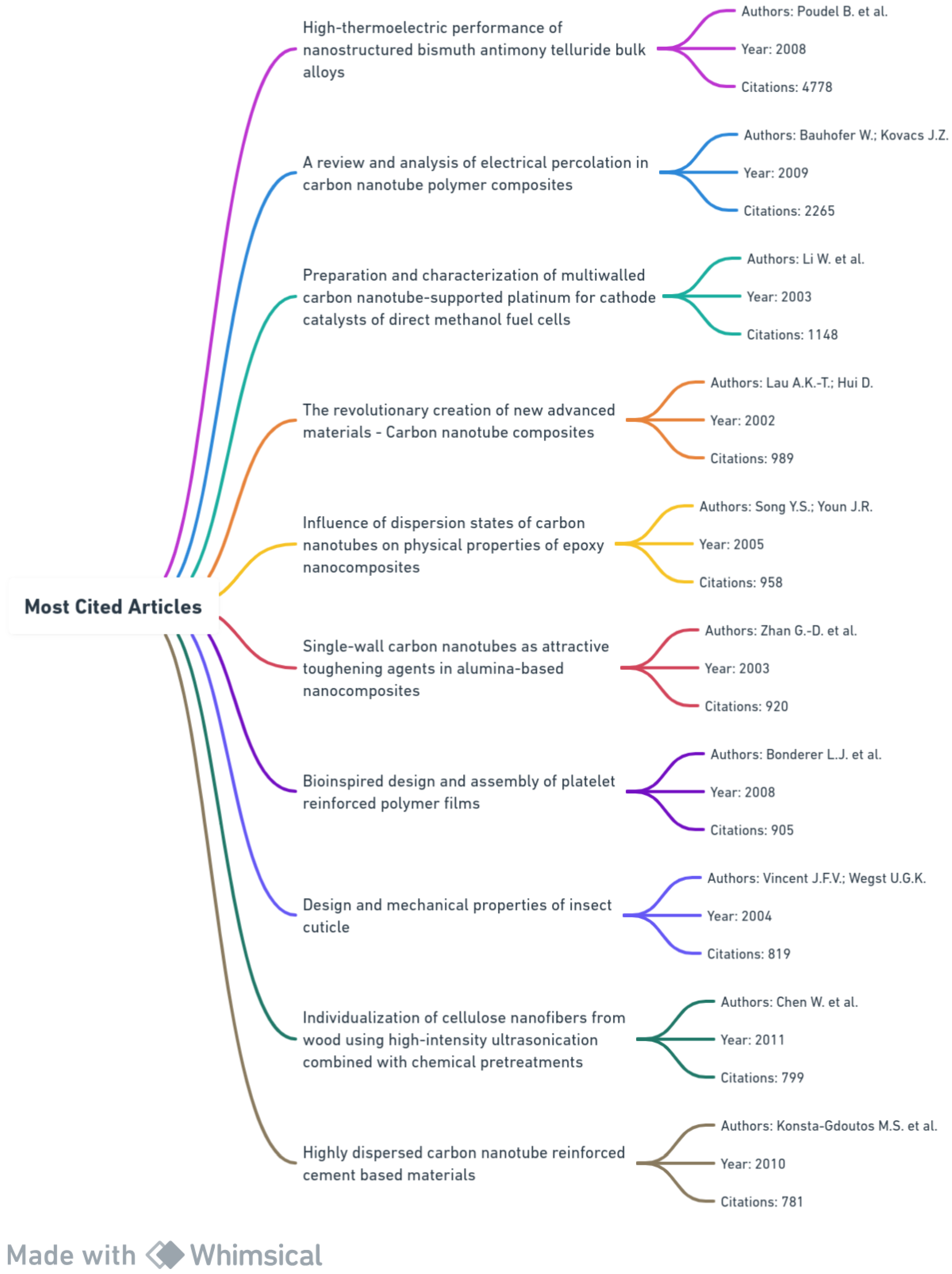

3.5. Bibliometric Data Analysis and Visualization Report

3.5.1. Nanocomposites and Electrical Properties

3.5.2. Nanocomposites and Mechanical Behavior

3.5.3. Nanocomposites and Microstructure

4. State of the Art and Gaps Extracted from Results and Discussions

4.1. Insights from Section 3.1: Scopus Database Search Strategy

4.2. Insights from Section 3.2: Textual Analytics Approach

4.3. Insights from Section 3.3: Scholarly Literature Analysis on Nanocomposite Themes

4.4. Findings from Section 3.4: Analysis of MAP and NET Files

4.5. Findings from Section 3.5: Bibliometric Data Analysis and Visualization Report

4.5.1. Nanocomposites and Electrical Properties

4.5.2. Nanocomposites and Mechanical Behavior

4.5.3. Nanocomposites and Microstructure

5. Literature Revision Guided by Artificial Intelligence

5.1. Nanocomposites and Electrical Properties

5.1.1. Crosslinking Degree and Its Influence on XLPE/OMMT Nanocomposites

5.1.2. BaTiO3 Nanofillers in Polymer Blend Nanocomposites: A Study on PVDF/PMMA/BaTiO3

5.1.3. Enhancing Fatigue Life in Aluminum–Graphene Nanocomposites for Power Transmission

5.1.4. Water-Tree Aging in XLPE/OMMT Nanocomposites: The Role of Crosslinking Degree

5.1.5. Sn Doping Effects in CdO Nanocomposites: A Laser Ablation Study

5.1.6. ZnO/TiO2 Nanoparticles in PEO/CMC Nanocomposites: Implications for Flexible Optoelectronics

5.1.7. Partial Conclusions

5.2. Nanocomposites and Mechanical Behavior

5.2.1. Enhancement of WE43 Magnesium-Based Nanocomposites through Friction Stir Processing

5.2.2. Role of Crosslinking in XLPE/OMMT Nanocomposites

5.2.3. Al2O3 Reinforcement in Brass Matrix Nanocomposites

5.2.4. Zinc Oxide Nanoparticles in PLA/PCL Bionanocomposites

5.2.5. Aluminum Oxyhydroxide in Dental Nanocomposites

5.2.6. Partial Conclusions

5.3. Nanocomposites and Microstructure

5.3.1. Modulation of Electro-Optical Properties in PDLC Films Using MWCNT-Loaded Reticular Nanofiber Films

5.3.2. Enhancing Nanocomposites with Well-Crystallized Zinc Oxide Nanorods and Chitosan/PVP Polymers

5.3.3. High-Entropy Nanofibers Transforming the Energy Storage Performance of Polymer Composites

5.3.4. Surface Decoration of MnNiWO4 Nanostructures on Carbon Nanofiber for Photocatalytic Dye Removal

5.3.5. Synthesis and Characterization of ZnO:GO/rGO Composite Thin Films for Energy Harvesting

5.3.6. Promoting Cell Growth with Laser-Synthesized Magnesium Nanoparticles for Tissue Engineering

5.3.7. Enhancing Bio-Based PLA Composites with Graphene-Based Materials and Wheat Straw

5.3.8. Improving Carbon Foam with Multiwalled Carbon Nanotubes and Functionalized Nanodiamonds

5.3.9. Partial Conclusions

5.4. Results Overview

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AFM | Atomic Force Microscopy |

| AI | Artificial Intelligence |

| Al2O3 | Aluminum Oxide |

| BET | Brunauer–Emmett–Teller theory |

| BM | Ball Milling |

| BM | Ball Milling |

| CF | Carbon Fiber or Carbon Foam |

| CP | Catalytic Performance |

| CSV | Comma-Separated Values |

| DE | Euclidean Distance |

| DNA | Deoxyribonucleic Acid |

| DOCTYPE | Document Type |

| DOCX | Microsoft Word Document File Format |

| DOI | Digital Object Identifier |

| Dye | Organic compound used for coloring |

| EC | Electrocatalyst |

| EDS | Energy-Dispersive X-ray Spectroscopy |

| EDX | Energy-Dispersive X-ray |

| EM | Electron Microscopy |

| EMI | Electromagnetic Interference |

| ENR | Epoxidized Natural Rubber |

| ENR | Epoxidized Natural Rubber |

| FESS | Field Emission Scanning Electron Spectroscopy |

| FT-IR or FTIR | Fourier Transform Infrared Spectroscopy |

| H2O2 | Hydrogen Peroxide |

| HN | Hybrid Nanocatalyst |

| LDA | Latent Dirichlet Allocation |

| LSBI | Link Strength Between Items |

| LST | Low Shear Stress |

| MAP file | Visualization file format used by VOSviewer |

| MWCNT | Multiwalled Carbon Nanotube |

| NaN | Not a Number |

| NET file | Network file format used by VOSviewer |

| NiO | Nickel Oxide |

| NiWO4 | Nickel Tungstate |

| NLP | Natural Language Processing |

| NLTK | Natural Language Toolkit |

| NMR | Nuclear Magnetic Resonance |

| ORCID | Open Researcher and Contributor ID |

| PA | Photocatalytic Activity |

| PBAT | Polybutylene Adipate Co-terephthalate |

| PBVS | Python Boosted Visualization of Similarities |

| PMMA | Polymethyl Methacrylate |

| PN | Polymer Nanocomposite |

| PP | Polypropylene |

| Pt | Platinum |

| PU | Polyurethane |

| R2 | Coefficient of Determination |

| RIS | Research Information Systems File |

| RMSE | Root Mean Squared Error |

| ROS | Reactive Oxygen Species |

| Scopus | A bibliographic database for academic research |

| SEM | Scanning Electron Microscopy |

| TEM | Transmission Electron Microscopy |

| TITLE-ABS-KEY | Search for terms only in Titles, Abstracts, and Keywords in the Scopus database |

| TLS | Total Link Strength |

| TXT | Text File |

| UV | Ultraviolet |

| UV–Vis | Ultraviolet–Visible Spectroscopy |

| UV–Vis Analytical Spectroscopy | Ultraviolet–Visible Analytical Spectroscopy |

| VL | Visible Light |

| VOSviewer | Visualization of Similarities Viewer |

| XLPE | Crosslinked Polyethylene |

| XPS | X-ray Photoelectron Spectroscopy |

| XRD | X-ray Diffraction |

| XRF | X-ray Fluorescence |

| ZnO | Zinc Oxide |

| ZOId | Diameters of Zone of Inhibition |

| ZOI | Zone of Inhibition |

References

- Omanović-Mikličanin, E.; Badnjević, A.; Kazlagić, A.; Hajlovac, M. Nanocomposites: A Brief Review. Health Technol. 2020, 10, 51–59. [Google Scholar] [CrossRef]

- Rajani, A.; Chauhan, P.; Dave, P.Y. Nanocomposites: A New Tendency of Structure in Nanotechnology and Material Science. J. Nanosci. Technol. 2021, 7, 937–941. [Google Scholar] [CrossRef]

- Dhinakaran, V.; Sai, M.S.; Shree, M.V. Nanocomposites: Introduction, Structure, Properties and Preparation Methods. In Current and Future Developments in Nanomaterials and Carbon Nanotubes; Singh, M., Rai, V.K., Rai, A., Eds.; Bentham Science Publishers: Sharjah, United Arab Emirates, 2022; Volume 2, pp. 1–14. ISBN 978-981-5050-98-1. [Google Scholar]

- Fu, S.-Y.; Mai, Y.-W.; Du, S.-Y.; Hui, D. Preparation, Properties and Applications of Nanocomposites. Compos. Part B Eng. 2011, 42, 2091–2092. [Google Scholar] [CrossRef]

- Martínez, E.D.; Prado, A.; Gonzalez, M.; Anguiano, S.; Tosi, L.; Salazar Alarcón, L.; Pastoriza, H. Recent Advances on Nanocomposite Resists With Design Functionality for Lithographic Microfabrication. Front. Mater. 2021, 8, 629792. [Google Scholar] [CrossRef]

- Andritsch, T.; Fabiani, D.; Cherney, E.; Ramirez, I. Processing of Nanocomposites. In Dielectric Polymer Nanocomposites; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Faulkner, J.M. Processing of Nanocomposites and Their Thermal and Rheological Characterization. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 2019; p. 1763697. [Google Scholar] [CrossRef]

- Calebrese, C.; Hui, L.; Schadler, L.S.; Nelson, J.K. A Review on the Importance of Nanocomposite Processing to Enhance Electrical Insulation. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 938–945. [Google Scholar] [CrossRef]

- Peponi, L.; Puglia, D.; Torre, L.; Valentini, L.; Kenny, J.M. Processing of Nanostructured Polymers and Advanced Polymeric Based Nanocomposites. Mater. Sci. Eng. R Rep. 2014, 85, 1–46. [Google Scholar] [CrossRef]

- Di Maio, L.; Scarfato, P.; Garofalo, E.; Galdi, M.R.; D’Arienzo, L.; Incarnato, L. Processing-Structure-Properties Relationships in PLA Nanocomposite Films. In Proceedings of the 29th International Conference of the Polymer-Processing-Society (PPS), Nuremberg, Germany, 15–19 July 2013; American Institute of Physics: College Park, MD, USA, 2014; pp. 308–311. [Google Scholar]

- Scaffaro, R.; Maio, A.; Gammino, M. Electrospun Polymeric Nanohybrids with Outstanding Pollutants Adsorption and Electroactivity for Water Treatment and Sensing Devices. Adv. Compos. Hybrid Mater. 2024, 7, 13. [Google Scholar] [CrossRef]

- Huang, S.; Liu, H.; Liao, K.; Hu, Q.; Guo, R.; Deng, K. Functionalized GO Nanovehicles with Nitric Oxide Release and Photothermal Activity-Based Hydrogels for Bacteria-Infected Wound Healing. ACS Appl. Mater. Interfaces 2020, 12, 28952–28964. [Google Scholar] [CrossRef]

- Scaffaro, R.; Gammino, M.; Maio, A. Wet Electrospinning-Aided Self-Assembly of Multifunctional GO-CNT@PCL Core-Shell Nanocomposites with Spider Leg Bioinspired Hierarchical Architectures. Compos. Sci. Technol. 2022, 221, 109363. [Google Scholar] [CrossRef]

- Yu, L.; Hao, G.; Liang, Q.; Jiang, W. Fabrication of Magnetic Porous Silica Submicroparticles for Oil Removal from Water. Ind. Eng. Chem. Res. 2015, 54, 9440–9449. [Google Scholar] [CrossRef]

- Mohammadi, A.; Shojaei, A.; Khasraghi, S.S. Improvement of Nanosilica Effects on the Performance of Mechanically Processed Styrene-Butadiene Rubber by Rational Hybridization with Nanodiamond. Diam. Relat. Mater. 2022, 130, 109487. [Google Scholar] [CrossRef]

- Elbasuney, S.; El-Sayyad, G.S.; Tantawy, H.; Hashem, A.H. Promising Antimicrobial and Antibiofilm Activities of Reduced Graphene Oxide-Metal Oxide (RGO-NiO, RGO-AgO, and RGO-ZnO) Nanocomposites. RSC Adv. 2021, 11, 25961–25975. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.A.M.; Saleh, A.A.; Ali, H.A.M.; Nabeel, A.I.; Fouad, R. Dual Function of New Nd(III) and Gd(III) Complexes for Cytotoxic and Optoelectronic Fields: Synthesis, Characterization, DFT Calculations, and PVA Composite Films. Appl. Organomet. Chem. 2023, 37, e7192. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Oliveira, G.E.; Anzai, T.; Richa, P.; Cosme, T.; Nele, M.; Rodrigues, C.H.M.; Soares, B.G.; Pinto, J.C. A Sensor for Acid Concentration Based on Cellulose Paper Sheets Modified with Polyaniline Nanoparticles. Macromol. Mater. Eng. 2009, 294, 739–748. [Google Scholar] [CrossRef]

- Araujo, R.T.; Ferreira, G.R.; Segura, T.; Souza, F.G., Jr.; Machado, F. An Experimental Study on the Synthesis of Poly(Vinyl Pivalate)-Based Magnetic Nanocomposites through Suspension Polymerization Process. Eur. Polym. J. 2015, 68, 441–459. [Google Scholar] [CrossRef]

- Péres, E.U.X.; Souza, F.G., Jr.; Silva, F.M.; Chaker, J.A.; Suarez, P.A.Z. Biopolyester from Ricinoleic Acid: Synthesis, Characterization and Its Use as Biopolymeric Matrix for Magnetic Nanocomposites. Ind. Crops Prod. 2014, 59, 260–267. [Google Scholar] [CrossRef]

- Gomes de Souza, F., Jr.; Nogueira Barradas, T.; de Freitas Caetano, V.; Becerra Lovera, A. Can Nanoparticles Improve Polyaniline Electrical Conductivity? 2021. Available online: https://www.qeios.com/read/17WBLJ.2 (accessed on 23 October 2023).

- Souza, F.G., Jr.; Soares, B.G.; Dahmouche, K. Effect of Preparation Method on Nanoscopic Structure of Conductive SBS/PANI Blends: Study Using Small-angle X-ray Scattering. J. Polym. Sci. Part B Polym. Phys. 2007, 45, 3069–3077. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Oliveira, G.E.; Lopes, M.C. Environmental Recovery by Magnetic Nanocomposites Based on Castor Oil—Chapter 22. In Natural Polymers, Biopolymers, Biomaterials, and Their Composites, Blends, and IPNs—CRC Press Book; Recent Advances in Materials Sciences; Apple Academic Press, Inc.: Point Pleasant, NJ, USA, 2012; Volume 2, p. 370. ISBN 978-1-926895-16-1. [Google Scholar]

- Pal, K.; Aljabali, A.A.; Kralj, S.; Thomas, S.; Gomes de Souza, F. Graphene-Assembly Liquid Crystalline and Nanopolymer Hybridization: A Review on Switchable Device Implementations. Chemosphere 2021, 263, 128104. [Google Scholar] [CrossRef]

- Neves, J.S.; Souza, F.G., Jr.; Suarez, P.A.Z.; Umpierre, A.P.; Machado, F. In Situ Production of Polystyrene Magnetic Nanocomposites through a Batch Suspension Polymerization Process. Macromol. Mater. Eng. 2011, 296, 1107–1118. [Google Scholar] [CrossRef]

- Pereira, E.D.; Souza, F.G.; Santana, C.I.; Soares, D.Q.; Lemos, A.S.; Menezes, L.R. Influence of Magnetic Field on the Dissolution Profile of Cotrimoxazole Inserted into Poly(Lactic Acid-Co-Glycolic Acid) and Maghemite Nanocomposites. Polym. Eng. Sci. 2013, 53, 2308–2317. [Google Scholar] [CrossRef]

- Middea, A.; Spinelli, L.; Souza, F.G., Jr.; Neumann, R.; Fernandes, T.; Faulstich, F.R.L.; Gomes, O. Magnetic Polystyrene–Palygorskite Nanocomposite Obtained by Heterogeneous Phase Polymerization to Apply in the Treatment of Oily Waters. J. Appl. Polym. Sci. 2018, 135, 46162. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Ferreira, A.C.; Varela, A.; Oliveira, G.E.; Machado, F.; Pereira, E.D.; Fernandes, E.; Pinto, J.C.; Nele, M. Methodology for Determination of Magnetic Force of Polymeric Nanocomposites. Polym. Test. 2013, 32, 1466–1471. [Google Scholar] [CrossRef]

- Vargas, A.; Souza, F.G., Jr. Nanocomposites of Poly(L-Lactic Acid) and Maghemite for Drug Delivery of Caffeine. In Biomaterials Science—Processing, Properties, and Applications; Narayan, R., Bandyopadhyay, A., Bose, S., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; pp. 95–105. ISBN 978-1-118-14456-5. [Google Scholar]

- Neto, W.S.; Simões Dutra, G.V.; de Sousa Brito Neta, M.; Chaves, S.B.; Valadares, L.F.; Souza, F.G., Jr.; Machado, F. Nanodispersions of Magnetic Poly(Vinyl Pivalate) for Biomedical Applications: Synthesis and in Vitro Evaluation of Its Cytotoxicity in Cancer Cells. Mater. Today Commun. 2021, 27, 102333. [Google Scholar] [CrossRef]

- de Souza Junior, F.G.; Barradas, T.N.; Caetano, V.F.; Becerra, A. Nanoparticles Improving Polyaniline Electrical Conductivity: A Meta-Analysis Study. Braz. J. Exp. Des. Data Anal. Inferent. Stat. 2022, 2, 25–58. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Oliveira, G.E.; Rodrigues, C.H.M.; Soares, B.G.; Nele, M.; Pinto, J.C. Natural Brazilian Amazonic (Curauá) Fibers Modified with Polyaniline Nanoparticles. Macromol. Mater. Eng. 2009, 294, 484–491. [Google Scholar] [CrossRef]

- Varela, A.; Oliveira, G.; Souza, F.G., Jr.; Rodrigues, C.H.M.; Costa, M.A.S. New Petroleum Absorbers Based on Cardanol-Furfuraldehyde Magnetic Nanocomposites. Polym. Eng. Sci. 2013, 53, 44–51. [Google Scholar] [CrossRef]

- Grance, E.G.O.; Souza, F.G., Jr.; Varela, A.; Pereira, E.D.; Oliveira, G.E.; Rodrigues, C.H.M. New Petroleum Absorbers Based on lignin-CNSL-formol Magnetic Nanocomposites. J. Appl. Polym. Sci. 2012, 126, E305–E312. [Google Scholar] [CrossRef]

- Elias, E.; Sarathchandran, C.; Joseph, S.; Zachariah, A.K.; Thomas, J.; Devadasan, D.; Souza, F.G., Jr.; Thomas, S. Photoassisted Degradation of Rhodamine B Using Poly(Ε-caprolactone) Based Nanocomposites: Mechanistic and Kinetic Features. J. Appl. Polym. Sci. 2021, 138, 50612. [Google Scholar] [CrossRef]

- Asthana, N.; Pal, K.; Aljabali, A.A.A.; Tambuwala, M.M.; Souza, F.G., Jr.; Pandey, K. Polyvinyl Alcohol (PVA) Mixed Green–Clay and Aloe Vera Based Polymeric Membrane Optimization: Peel-off Mask Formulation for Skin Care Cosmeceuticals in Green Nanotechnology. J. Mol. Struct. 2020, 1229, 129592. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Soares, D.; Freitas, R.; Soares, V.; Ferreira, L.; Ramon, J.; Oliveira, G.E. Praziquantel Release Systems Based on Poly(Butylene Succinate)/Polyethylene Glycol Nanocomposites. Curr. Appl. Polym. Sci. 2017, 1, 45–51. [Google Scholar] [CrossRef]

- de Souza Junior, F.G. Preface: Recent Trends in Natural Polymers, Bio-Composites and Bio-Nanocomposites. Abstr. Int. Conf. Meet. 2021, 1, 2. [Google Scholar]

- Ferreira, L.P.; Moreira, A.N.; Souza, F.G., Jr.; Pinto, J.C.C.d.S. Preparation of Nanocomposites Based on Poly(Butylene Succinate) and Montmorillonite Organoclay via in Situ Polymerization. Polímeros 2014, 24, 604–611. [Google Scholar] [CrossRef]

- da Paixão, C.P.S.; Júnior, F.G.S.; Lima, A.S. Production of Biopolymeric Energy Nanocomposite. Abstr. Int. Conf. Meet. 2021, 1, 6. [Google Scholar]

- Elias, E.; Chandran, N.; Souza, F.G.; Thomas, S. Others Segmental Dynamics, Morphology and Thermomechanical Properties of Electrospun Poly (ε-Caprolactone) Nanofibers in the Presence of an Interacting Filler. RSC Adv. 2016, 6, 21376–21386. [Google Scholar] [CrossRef]

- Neto, W.S.; Dutra, G.V.S.; Jensen, A.T.; Araújo, O.A.; Garg, V.; de Oliveira, A.C.; Valadares, L.F.; de Souza, F.G.; Machado, F. Superparamagnetic Nanoparticles Stabilized with Free-Radical Polymerizable Oleic Acid-Based Coating. J. Alloys Compd. 2018, 739, 1025–1036. [Google Scholar] [CrossRef]

- Péres, E.U.X.; Sousa, M.H.; Souza, F.G., Jr.; Machado, F.; Suarez, P.A.Z. Synthesis and Characterization of a New Biobased Poly(Urethane-Ester) from Ricinoleic Acid and Its Use as Biopolymeric Matrix for Magnetic Nanocomposites: Biopolymer as Matrix for Magnetic Nanocomposites. Eur. J. Lipid Sci. Technol. 2017, 119, 1600451. [Google Scholar] [CrossRef]

- Xu, X.; Liu, F.; Jiang, L.; Zhu, J.Y.; Haagenson, D.; Wiesenborn, D.P. Cellulose Nanocrystals vs. Cellulose Nanofibrils: A Comparative Study on Their Microstructures and Effects as Polymer Reinforcing Agents. ACS Appl. Mater. Interfaces 2013, 5, 2999–3009. [Google Scholar] [CrossRef] [PubMed]

- Rojas, O.J.; Montero, G.A.; Habibi, Y. Electrospun Nanocomposites from Polystyrene Loaded with Cellulose Nanowhiskers. J. Appl. Polym. Sci. 2009, 113, 927–935. [Google Scholar] [CrossRef]

- Yan, C.; Wang, J.; Kang, W.; Cui, M.; Wang, X.; Foo, C.Y.; Chee, K.J.; Lee, P.S. Highly Stretchable Piezoresistive Graphene-Nanocellulose Nanopaper for Strain Sensors. Adv. Mater. 2014, 26, 2022–2027. [Google Scholar] [CrossRef] [PubMed]

- Tian, D.; Hu, J.; Bao, J.; Chandra, R.P.; Saddler, J.N.; Lu, C. Lignin Valorization: Lignin Nanoparticles as High-Value Bio-Additive for Multifunctional Nanocomposites. Biotechnol. Biofuels 2017, 10, 192. [Google Scholar] [CrossRef]

- Lively, B.T. Carbon Based Nanofiller-Polymer Composites: Quantitative Dispersion Characterization, Processing, and Properties. Ph.D. Thesis, Washington State University, Pullman, WA, USA, 2013. [Google Scholar]

- Gibbons, L.J. Nanocomposite Dispersion: Quantifying the Structure-Function Relationship. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2011. [Google Scholar]

- Atalie, D.; Gideon, R.; Tesfaye, K.; Ma, P.-C. Nanocomposites: Homogenization and Kinematic Relations. In Mechanics of Nanomaterials and Polymer Nanocomposites; Abdellaoui, H., Sanjay, M.R., Siengchin, S., Eds.; Smart Nanomaterials Technology; Springer Nature: Singapore, 2023; pp. 213–257. ISBN 978-981-9923-51-9. [Google Scholar]

- Hassinger, I.; Li, X.; Zhao, H.; Xu, H.; Huang, Y.; Prasad, A.; Schadler, L.; Chen, W.; Catherine Brinson, L. Toward the Development of a Quantitative Tool for Predicting Dispersion of Nanocomposites under Non-Equilibrium Processing Conditions. J. Mater. Sci. 2016, 51, 4238–4249. [Google Scholar] [CrossRef]

- Aboelkheir, M.; Gomes, F.; Meiorin, C.; Galdino, T. Tenebrio Molitor Larvae-Based Magnetic Polyurea Employed as Crude Oil Spill Removal Tool. Materials 2022, 15, 5063. [Google Scholar] [CrossRef] [PubMed]

- Bedor, P.B.A.; Rondelli, P.; Filho, S.T.; Souza, F.G., Jr.; Leite, S.G.F. Production and Toxicological Evaluation of PBS-Urea Microspheres Targeting Bioremediation. J. Chem. Technol. Biotechnol. 2021, 96, 1842–1853. [Google Scholar] [CrossRef]

- Borges, G.R.; Aboelkheir, M.G.; de Souza Junior, F.G.; Waldhelm, K.C.; Kuster, R.M. Poly (Butylene Succinate) and Derivative Copolymer Filled with Dendranthema Grandiflora Biolarvicide Extract. Environ. Sci. Pollut. Res. 2020, 27, 23575–23585. [Google Scholar] [CrossRef]

- Ferreira, L.P.; Moreira, A.N.; Delazare, T.; Oliveira, G.E.; Souza, F.G., Jr. Petroleum Absorbers Based on CNSL, Furfural and Lignin—The Effect of the Chemical Similarity on the Interactions among Petroleum and Bioresins. Macromol. Symp. 2012, 319, 210–221. [Google Scholar] [CrossRef]

- Elias, E.; Costa, R.; Marques, F.; Oliveira, G.; Guo, Q.; Thomas, S.; Souza, F.G., Jr. Oil-Spill Cleanup: The Influence of Acetylated Curaua Fibers on the Oil-Removal Capability of Magnetic Composites. J. Appl. Polym. Sci. 2015, 132, 41732–41740. [Google Scholar] [CrossRef]

- da Silveira Maranhão, F.; Souza, F.G., Jr.; Thode, S.; Das, D.B.; Pereira, E.; Lima, N.; Carvalho, F.; Aboelkheir, M.; Costa, V.; Pal, K. Oil Spill Sorber Based on Extrinsically Magnetizable Porous Geopolymer. Materials 2021, 14, 5641. [Google Scholar] [CrossRef] [PubMed]

- Silva, J.C.; Oliveira, G.E.; Toledo Filho, R.D.; Souza, F.G., Jr. Oil Spill Clean-Up Tool Based on Castor Oil and Coffee Grounds Magnetic Resins. Macromol. Symp. 2018, 380, 1800095. [Google Scholar] [CrossRef]

- Caetano, R.M.J.; Bedor, P.B.A.; de Jesus, E.F.O.; Leite, S.G.F.; Souza, F.G., Jr. Oil Biodegradation Systems Based on γ Irradiated Poly (Butylene Succinate). Macromol. Symp. 2018, 380, 1800123. [Google Scholar] [CrossRef]

- de Freitas Caetano, V.; Paula, P.S.T.A.; de Souza, F.G., Jr. Nanomaterials Improving CO2 Removal Efficiency in Membranes: A Systematic Review. Braz. J. Exp. Des. Data Anal. Inferent. Stat. 2022, 2, 3–24. [Google Scholar] [CrossRef]

- Maranhão, F.S.; de Souza Junior, F.G.; Filho, S.T.; de Oliveira Athayde, B.H.; de Carvalho, F.F.; Lino, A.; Malm, O. Magnetic Porous Geopolymer: A Cheaper and Efficient Environmental Tool for Heavy Metal Sorption. Macromol. Symp. 2021, 398, 2000182. [Google Scholar] [CrossRef]

- Varela, A.; Lopes, M.C.; Delazare, T.; Oliveira, G.E.; Souza, F.G., Jr. Magnetic and Green Resins Useful to Oil Spill Cleanup. In Oil: Production, Consumption and Environmental Impact; Xiu, S., Ed.; Nova Science Publishers: New York, NY, USA, 2012; p. 7. ISBN 978-1-61942-899-7. [Google Scholar]

- Maranhão, F.D.S.; Almeida, T.M.; de Souza, F.G.; Batista, D.; de Carvalho, F.F.; Pal, K.; Thomas, S. Geopolymer Microparticles as Up-and-Coming H2S Sorbers. Macromol. Symp. 2021, 398, 2000175. [Google Scholar] [CrossRef]

- Figueiredo, A.S.; Icart, L.P.; Marques, F.D.; Fernandes, E.R.; Ferreira, L.P.; Oliveira, G.E.; Souza, F.G. Extrinsically Magnetic Poly(Butylene Succinate): An up-and-Coming Petroleum Cleanup Tool. Sci. Total Environ. 2019, 647, 88–98. [Google Scholar] [CrossRef]

- Lopes, M.C.; Marques, F.; Souza, F.G., Jr.; Oliveira, G.E. Experimental Design Optimization of Castor Oil, Phthalic Anhydride, and Glycerin Magnetic Nanocomposites Useful as Oil Spill Cleanup Tool. Macromol. Symp. 2018, 380, 1800085. [Google Scholar] [CrossRef]

- Baldanza, V.A.R.; Souza, F.G.; Filho, S.T.; Franco, H.A.; Oliveira, G.E.; Caetano, R.M.J.; Hernandez, J.A.R.; Ferreira Leite, S.G.; Furtado Sousa, A.M.; Nazareth Silva, A.L. Controlled-Release Fertilizer Based on Poly(Butylene Succinate)/Urea/Clay and Its Effect on Lettuce Growth: Controlled-Release Fertilizer Based on Poly(Butylene Succinate)/Urea/Clay and Its Effect on Lettuce Growth. J. Appl. Polym. Sci. 2018, 135, e46858. [Google Scholar] [CrossRef]

- Nath, N.; Kumar, A.; Chakroborty, S.; Soren, S.; Barik, A.; Pal, K.; de Souza, F.G., Jr. Carbon Nanostructure Embedded Novel Sensor Implementation for Detection of Aromatic Volatile Organic Compounds: An Organized Review. ACS Omega 2023, 8, 4436–4452. [Google Scholar] [CrossRef]

- Bedor, P.B.A.; Caetano, R.M.J.; de Souza Júnior, F.G.; Leite, S.G.F. Advances and Perspectives in the Use of Polymers in the Environmental Area: A Specific Case of PBS in Bioremediation. Polímeros 2020, 30, e2020023. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Marins, J.A.; Rodrigues, C.H.M.; Pinto, J.C. A Magnetic Composite for Cleaning of Oil Spills on Water. Macromol. Mater. Eng. 2010, 295, 942–948. [Google Scholar] [CrossRef]

- Pal, K.; Asthana, N.; Aljabali, A.A.; Bhardwaj, S.K.; Kralj, S.; Penkova, A.; Thomas, S.; Zaheer, T.; de Souza, F.G. A Critical Review on Multifunctional Smart Materials ‘Nanographene’ Emerging Avenue: Nano-Imaging and Biosensor Applications. Crit. Rev. Solid State Mater. Sci. 2021, 47, 691–707. [Google Scholar] [CrossRef]

- Mounika, B.; Ajayan, J.; Bhattacharya, S. 2.5 A/Mm/350 GHz Aggressively Scaled Gate Engineered Fe-Doped AlN/GaN Channel HEMT with Graded InGaN Backbarrier on SiC-Wafer for next Generation RF Power Electronics Applications. Mater. Sci. Eng. B 2024, 301, 117194. [Google Scholar] [CrossRef]

- Waheed, W.; Anwer, S.; Khan, M.U.; Sajjad, M.; Alazzam, A. 2D Ti3C2Tx-MXene Nanosheets and Graphene Oxide Based Highly Sensitive Humidity Sensor for Wearable and Flexible Electronics. Chem. Eng. J. 2024, 480, 147981. [Google Scholar] [CrossRef]

- Pradhan, S.; Yadavalli, V.K. A Dual Function Conductive Nano Ink for Printed Electronics Connections. Org. Electron. 2024, 124, 106959. [Google Scholar] [CrossRef]

- Li, R.; Song, P.; Ji, Z.; Zhou, H.; Xue, Y.; Kong, L.; Shen, X. Coaxial Core-Sheath Shaped Supercapacitor Based on Polypyrrole Functionalized Graphene/Carbon Nanotubes Hollow Fibers with Ultrahigh Length Specific Capacitance and Energy Density for Wearable Electronics. Appl. Surf. Sci. 2024, 649, 159188. [Google Scholar] [CrossRef]

- Kim, S.; Nawaz, F.; Lee, H.; Jeong, S.; Choi, C.; Jeon, I.; Lee, K. Development of Highly Sensitive and Solar Blind Surface Acoustic Wave UV-C Photodetector Based on the In2O3/Ta2O5 Nano-Heterojunction and Its Interface Electronics. Sens. Actuators Phys. 2024, 367, 115027. [Google Scholar] [CrossRef]

- Mugheri, A.Q.; Ali, K.; Sangah, A.A.; Daudpoto, M.R.; Laghari, M.Y.; Mugheri, A.A. Effort in Speeding up High-Performance, Stable, High-Rate Thin-Film Electronics Based for Ultra-Long Life with Enhanced Electrochemical Performance for next Generation Technology. J. Energy Storage 2024, 77, 109863. [Google Scholar] [CrossRef]

- Monakhov, K.Y. Implication of Counter-Cations for Polyoxometalate-Based Nano-Electronics. Comments Inorg. Chem. 2024, 44, 1–10. [Google Scholar] [CrossRef]

- Yang, W.; Zhu, W.; Wang, X.; Hu, S.; Cui, P.; Fang, Y.; Li, Z.; Qi, F.; Cao, H.; Xu, H.; et al. Low-Temperature Packaging through Ag-Cu Supersaturated Solid Solution Nanoparticle Paste for High-Temperature Power Electronics. Mater. Lett. 2024, 357, 135675. [Google Scholar] [CrossRef]

- Ma, L.; Wang, Y.; Jia, Q.; Zhang, H.; Wang, Y.; Li, D.; Zou, G.; Guo, F. Low-Temperature-Sintered Nano-Ag Film for Power Electronics Packaging. J. Electron. Mater. 2024, 53, 228–237. [Google Scholar] [CrossRef]

- Luo, R.; Hu, D.; Qian, C.; Liu, X.; Fan, X.; Zhang, G.; Fan, J. Molecular Dynamics Simulations on Mechanical Behaviors of Sintered Nanocopper in Power Electronics Packaging. Microelectron. Reliab. 2024, 152, 115284. [Google Scholar] [CrossRef]

- Zhu, W.; Feng, T.; Zhang, M.; Tan, J.; Wu, M. Surface Electronics Regulation and Enhanced Electrochemical Performance of Nitrogen-Doped Carbon Layer Encapsulated NiCo2S4 Nanosheets for Supercapacitors. Vacuum 2024, 220, 112729. [Google Scholar] [CrossRef]

- Sajjad, M.; Zhang, J.; Mao, Z.; Chen, Z. A Review on Iron-Nitride (Fe2N) Based Nanostructures for Electrochemical Energy Storage Applications: Research Progress, and Future Perspectives. J. Alloys Compd. 2024, 976, 172626. [Google Scholar] [CrossRef]

- Magar, H.S.; Mansour, A.M.; Hammad, A.B.A. Advancing Energy Storage and Supercapacitor Applications through the Development of Li+-Doped MgTiO3 Perovskite Nano-Ceramics. Sci. Rep. 2024, 14, 1849. [Google Scholar] [CrossRef]

- El Sayed, A.M. Boosting the Optical and Electrical Properties of PVA/Na-CMC Blend by Cr2O3 Nanoparticles for Photonic and Energy Storage Applications. J. Energy Storage 2024, 82, 110609. [Google Scholar] [CrossRef]

- Li, Q.; Yang, C.; Wang, S.; Zhou, M.; Xie, H.; Qiao, G.; Du, Y.; Li, C.; Wu, Y. Challenges and Strategies for Imidazolium Ionic Liquids as Novel Phase Change Materials for Low and Medium Temperature Thermal Energy Storage: A Critical Review. J. Mol. Liq. 2024, 395, 123812. [Google Scholar] [CrossRef]

- Sathishkumar, A.; Sundaram, P.; Cheralathan, M.; Kumar, P.G. Effect of Nano-Enhanced Phase Change Materials on Performance of Cool Thermal Energy Storage System: A Review. J. Energy Storage 2024, 78, 110079. [Google Scholar] [CrossRef]

- Rajamony, R.K.; Paw, J.K.S.; Pandey, A.K.; Tak, Y.C.; Pasupuleti, J.; Tiong, S.K.; Yusaf, T.; Samykano, M.; Sofiah, A.G.N.; Kalidasan, B.; et al. Energizing the Thermophysical Properties of Phase Change Material Using Carbon-Based Nano Additives for Sustainable Thermal Energy Storage Application in Photovoltaic Thermal Systems. Mater. Today Sustain. 2024, 25, 100658. [Google Scholar] [CrossRef]

- Mottakin, M.; Selvanathan, V.; Su’ait, M.S.; Razali, S.A.; Islam, M.A.; Ibrahim, M.A.; Muhammad, G.; Akhtaruzzaman, M. Enhancing Pseudocapacitive Energy Storage System Performance with Electrodeposited CuSx and CoSx Biphasic Transitional Metal Sulfide (TMS) Based Nanostructured Electrode on Nickel Foam. J. Phys. Chem. Solids 2024, 186, 111795. [Google Scholar] [CrossRef]

- Bhosale, M.; Baby, N.; Magdum, S.S.; Murugan, N.; Kim, Y.A.; Thangarasu, S.; Oh, T.-H. Hierarchical Nanoassembly of Ni3S2-MoS2 Interconnected with CeO2 as a Highly Remarkable Hybrid Electrocatalyst for Enhancing Water Oxidation and Energy Storage. J. Energy Storage 2024, 80, 110301. [Google Scholar] [CrossRef]

- Wang, K.; Li, W.; Zhao, R.; Tang, X.; Zhang, S.; Zhang, Y.; Hu, J.; Shen, Z.; Jiang, Y.; Guo, X. High Energy Storage Density Obtained by Bi(Ni0.5Hf0.5)O3-Modified NBT-Based Ceramic at a Low Electric Field. Ceram. Int. 2024, 50, 5276–5284. [Google Scholar] [CrossRef]

- Zhou, J.; Dabaghian, M.; Wang, Y.; Sotzing, M.; LaChance, A.M.; Shen, K.; Gao, W.; Konstantinou, A.; Wu, C.; Hao, J.; et al. High-Temperature Dielectric Energy Storage Films with Self-Co-Assembled Hot-Electron Blocking Nanocoatings. Nano Energy 2024, 120, 109184. [Google Scholar] [CrossRef]

- Sun, J.; Yan, G.; Fang, B.; Zhao, X.; Zhang, S.; Lu, X.; Ding, J. Improving Energy Storage Performance of Barium Titanate-Based Ceramics by Doping MnO2. J. Energy Storage 2024, 78, 110007. [Google Scholar] [CrossRef]

- Rajasekaran, B.; Kumaresan, G.; Arulprakasajothi, M.; Vellaiyan, S. Latent Heat Energy Storage Using Nanomaterials as a Heat Sink for the Prevention of Thermal Runaway: A Study in Conjugate Heat Dissipation. Int. Commun. Heat Mass Transf. 2024, 151, 107225. [Google Scholar] [CrossRef]

- Zhang, Y.; Niu, Z.; Zheng, P.; Zheng, X.; Zhou, J.; Liu, J.; Fan, Q.; Zheng, L.; Bai, W.; Zhang, Y. Multiphase Coexistence and High Energy Storage Performance in BKT-Based Lead-Free Relaxor Ferroelectric Ceramics. Appl. Mater. Today 2024, 37, 102097. [Google Scholar] [CrossRef]

- Shah, S.S.A.; Zafar, H.K.; Javed, M.S.; Din, M.A.U.; Alarfaji, S.S.; Balkourani, G.; Sohail, M.; Tsiakaras, P.; Najam, T. Mxenes for Zn-Based Energy Storage Devices: Nano-Engineering and Machine Learning. Coord. Chem. Rev. 2024, 501, 215565. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, S.; Ying, H.; Liu, B.; Jia, W.; Xie, J.; Sun, Y. Preparation and Thermal Properties of Eutectic Phase Change Materials (EPCMs) with Nanographite Addition for Cold Thermal Energy Storage. Energy 2024, 290, 130148. [Google Scholar] [CrossRef]

- Farid, G.; Amade-Rovira, R.; Ma, Y.; Chaitoglou, S.; Ospina, R.; Bertran-Serra, E. Revolutionizing Energy Storage: Silicon Nanowires (SiNWs) Crafted through Metal-Assisted Chemical Etching. Arab. J. Chem. 2024, 17, 105631. [Google Scholar] [CrossRef]

- Shang, B.; Zhang, L.; Li, B.; Huo, Y. Thermal Energy Storage System Based on Nanoparticle Distribution Optimisation for Enhanced Heat Transfer. J. Energy Storage 2024, 80, 110075. [Google Scholar] [CrossRef]

- Kazaz, O.; Karimi, N.; Kumar, S.; Falcone, G.; Paul, M.C. Thermally Enhanced Nanocomposite Phase Change Material Slurry for Solar-Thermal Energy Storage. J. Energy Storage 2024, 78, 110110. [Google Scholar] [CrossRef]

- Kolavada, H.; Gajjar, P.N.; Gupta, S.K. Unraveling Quantum Capacitance in Supercapacitors: Energy Storage Applications. J. Energy Storage 2024, 81, 110354. [Google Scholar] [CrossRef]

- Grira, S.; Alkhedher, M.; Abu Khalifeh, H.; Ramadan, M.; Ghazal, M. Using Algae in Li-Ion Batteries: A Sustainable Pathway toward Greener Energy Storage. Bioresour. Technol. 2024, 394, 130225. [Google Scholar] [CrossRef] [PubMed]

- Mansour, R.M.; EL-Sayad, N.; El-Gizawi, L.S.E.-D. Applying Nano Coatings on Buildings to Improve Thermal Performance & Energy Efficiency: A Simulation of a Health Care Building in Egypt. ISVS E-J. 2023, 10, 384–396. [Google Scholar]

- Saqib, A.; Pattar, S.; Karigar, C.S.; Sekhar, S. Caspase Activators: Phytochemicals with Apoptotic Properties Targeting Cancer, a Health Care Strategy to Combat This Disease. Indian J. Pharm. Educ. Res. 2020, 54, S43–S55. [Google Scholar] [CrossRef]

- Han, X.; Qin, Y.; Mei, C.; Jiao, F.; Khademolqorani, S.; Nooshin Banitaba, S. Current Trends and Future Perspectives of Stroke Management through Integrating Health Care Team and Nanodrug Delivery Strategy. Front. Cell. Neurosci. 2023, 17, 1266660. [Google Scholar] [CrossRef] [PubMed]

- Han, H.; Chen, B.-T.; Liu, Y.; Wang, Y.; Xing, L.; Wang, H.; Zhou, T.-J.; Jiang, H.-L. Engineered Stem Cell-Based Strategy: A New Paradigm of next-Generation Stem Cell Product in Regenerative Medicine. J. Control. Release 2024, 365, 981–1003. [Google Scholar] [CrossRef] [PubMed]

- Chandrasekar, S.; Vijayakumar, S.; Rajendran, R. Functional Finishing of Health Care Cotton for Enhanced Efficiency of Antibacterial Activity by Chitosan and Herbal Nanocomposites. Acta Ecol. Sin. 2020, 40, 473–477. [Google Scholar] [CrossRef]

- Hoveidaei, A.H.; Sadat-Shojai, M.; Mosalamiaghili, S.; Salarikia, S.R.; Roghani-shahraki, H.; Ghaderpanah, R.; Ersi, M.H.; Conway, J.D. Nano-Hydroxyapatite Structures for Bone Regenerative Medicine: Cell-Material Interaction. Bone 2024, 179, 116956. [Google Scholar] [CrossRef] [PubMed]

- Moreddu, R. Nanotechnology and Cancer Bioelectricity: Bridging the Gap Between Biology and Translational Medicine. Adv. Sci. 2024, 11, 2304110. [Google Scholar] [CrossRef]

- Mariyam, S.; Upadhyay, S.K.; Chakraborty, K.; Verma, K.K.; Duhan, J.S.; Muneer, S.; Meena, M.; Sharma, R.K.; Ghodake, G.; Seth, C.S. Nanotechnology, a Frontier in Agricultural Science, a Novel Approach in Abiotic Stress Management and Convergence with New Age Medicine—A Review. Sci. Total Environ. 2024, 912, 169097. [Google Scholar] [CrossRef]

- Zeng, C.; Evans, J.P.; Pearson, R.; Qu, P.; Zheng, Y.-M.; Robinson, R.T.; Hall-Stoodley, L.; Yount, J.; Pannu, S.; Mallampalli, R.K.; et al. Neutralizing Antibody against SARS-CoV-2 Spike in COVID-19 Patients, Health Care Workers, and Convalescent Plasma Donors. JCI Insight 2020, 5, e143213. [Google Scholar] [CrossRef]

- Prajwal, A.T.; Muddukrishna, B.S.; Vasantharaju, S.G. Pharma 4.0–Impact of the Internet of Things on Health Care. Int. J. Appl. Pharm. 2020, 12, 64–69. [Google Scholar] [CrossRef]

- Viola, M.; Migliorini, C.; Ziarelli, F.; Viel, S.; Cencetti, C.; Di Risola, D.; Mosca, L.; Masuelli, L.; Matricardi, P.; Di Meo, C. Polyacrylate–Cholesterol Amphiphilic Derivative: Formulation Development and Scale-up for Health Care Applications. J. Funct. Biomater. 2023, 14, 482. [Google Scholar] [CrossRef] [PubMed]

- Rajabathar, J.R.; Arunachalam, P.; AL-Lohedan, H.A.; Thankappan, R.; Appaturi, J.N.; Pulingam, T.; Mohammed Dahan, W. Polymer Surfactant (Triton-100) Assisted Low Cost Method for Preparing Silver and Graphene Oxide Modified Bi-MnOx Nanocomposite for Enhanced Sensor and Anti-Microbial Health Care Applications. J. Sol. Gel. Sci. Technol. 2021, 97, 638–650. [Google Scholar] [CrossRef]

- Peng, Y.; Yang, Z.; Li, J.; Liu, S. Research Progress on Nanotechnology of Traditional Chinese Medicine to Enhance the Therapeutic Effect of Osteoarthritis. Drug Deliv. Transl. Res. 2024. [Google Scholar] [CrossRef] [PubMed]

- Cruz-Pacheco, A.F.; Echeverri, D.; Orozco, J. Role of Electrochemical Nanobiosensors in Colorectal Cancer Precision Medicine. TrAC Trends Anal. Chem. 2024, 170, 117467. [Google Scholar] [CrossRef]

- Ejidike, I.P.; Ogunleye, O.; Bamigboye, M.O.; Ejidike, O.M.; Ata, A.; Eze, M.O.; Clayton, H.S.; Nwankwo, V.U.; Fatokun, J.O. Role of Nanotechnology in Medicine: Opportunities and Challenges. In Biogenic Nanomaterials for Environmental Sustainability: Principles, Practices, and Opportunities; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2024; Volume Part F2070, pp. 353–375. ISBN 18635520. [Google Scholar]

- Zheng, M.; Liu, K.; Li, L.; Feng, C.; Wu, G. Traditional Chinese Medicine Inspired Dual-Drugs Loaded Inhalable Nano-Therapeutics Alleviated Idiopathic Pulmonary Fibrosis by Targeting Early Inflammation and Late Fibrosis. J. Nanobiotechnol. 2024, 22, 14. [Google Scholar] [CrossRef]

- Si, A.; Pal, K.; Kralj, S.; El-Sayyad, G.S.; de Souza, F.G.; Narayanan, T. Sustainable Preparation of Gold Nanoparticles via Green Chemistry Approach for Biogenic Applications. Mater. Today Chem. 2020, 17, 100327. [Google Scholar] [CrossRef]

- Brum, N.F.D.; Mussi, T.d.C.; de Azevedo, A.D.; Monteiro, S.G.; Souza, F.G., Jr. Physical-chemical characterization of reference drugs for the treatment of tuberculosis using fourier transform infrared spectroscopy (FTIR) and thermal analysis (TG/DTG & DSC). J. Biol. Pharm. Agric. Manag. 2021, 17, 963–975. [Google Scholar]

- Santos, J.F.; del Rocío Silva-Calpa, L.; de Souza, F.G.; Pal, K. Central Countries’ and Brazil’s Contributions to Nanotechnology. Curr. Nanomater. 2024, 9, 109–147. [Google Scholar] [CrossRef]

- Wan, S.; Peng, J.; Jiang, L.; Cheng, Q. Bioinspired Graphene-Based Nanocomposites and Their Application in Flexible Energy Devices. Adv. Mater. 2016, 28, 7862–7898. [Google Scholar] [CrossRef]

- Kovalenko, M.V.; Manna, L.; Cabot, A.; Hens, Z.; Talapin, D.V.; Kagan, C.R.; Klimov, V.I.; Rogach, A.L.; Reiss, P.; Milliron, D.J.; et al. Prospects of Nanoscience with Nanocrystals. ACS Nano 2015, 9, 1012–1057. [Google Scholar] [CrossRef]

- Bukvić, M.; Gajević, S.; Skulić, A.; Savić, S.; Ašonja, A.; Stojanović, B. Tribological Application of Nanocomposite Additives in Industrial Oils. Lubricants 2024, 12, 6. [Google Scholar] [CrossRef]

- Veličković, S.; Stojanović, B.; Babić, M.; Vencl, A.; Bobić, I.; Vadászné Bognár, G.; Vučetić, F. Parametric Optimization of the Aluminium Nanocomposites Wear Rate. J. Braz. Soc. Mech. Sci. Eng. 2018, 41, 19. [Google Scholar] [CrossRef]

- Santos, R.D.; Ferreira, S.R.; Santos, E.R.F.; Oliveira, G.E.; Silva, F.A.; Souza, F.G., Jr.; Toledo Filho, R.D. Effect of Alkaline Hornification in Sisal Fibers on the Mechanical Behaviour; Materials Research Forum LLC.: Millersville, PA, USA, 2018; pp. 449–456. [Google Scholar]

- Santos, R.D.; Ferreira, S.R.; Oliveira, G.E.; Silva, F.A.; Souza, F.G., Jr.; Filho, R.D.T. Influence of Alkaline Hornification Treatment Cycles on the Mechanical Behavior in Curaua Fibers. Macromol. Symp. 2018, 381, 1800096. [Google Scholar] [CrossRef]

- Souza, F.G.; Soares, B.G.; Siddaramaiah; Barra, G.M.O.; Herbst, M.H. Influence of Plasticizers (DOP and CNSL) on Mechanical and Electrical Properties of SBS/Polyaniline Blends. Polymer 2006, 47, 7548–7553. [Google Scholar] [CrossRef]

- da Silveira Maranhão, F.; de Souza Junior, F.G.; Soares, P.; Alcan, H.G.; Çelebi, O.; Bayrak, B.; Kaplan, G.; Aydın, A.C. Physico-Mechanical and Microstructural Properties of Waste Geopolymer Powder and Lime-Added Semi-Lightweight Geopolymer Concrete: Efficient Machine Learning Models. J. Build. Eng. 2023, 72, 106629. [Google Scholar] [CrossRef]

- Rocha Ferreira, S.; Rodrigues Sena Neto, A.; de Andrade Silva, F.; Gomes de Souza, F.; Dias Toledo Filho, R. The Influence of Carboxylated Styrene Butadiene Rubber Coating on the Mechanical Performance of Vegetable Fibers and on Their Interface with a Cement Matrix. Constr. Build. Mater. 2020, 262, 120770. [Google Scholar] [CrossRef]

- Loh, J.Y.; Yap, F.M.; Ong, W.-J. 2D/2D Heterojunction Interface: Engineering of 1T/2H MoS2 Coupled with Ti3C2T Heterostructured Electrocatalysts for pH-Universal Hydrogen Evolution. J. Mater. Sci. Technol. 2024, 179, 86–97. [Google Scholar] [CrossRef]

- Habes, A.; Derradji, M.; Mehelli, O.; Benaliouche, F.; Abdous, S.; Medjaouri, Y.; Abderrahim, N.C.; Fodil, H.; Kadi, M.E.A. Effective Attenuation of Electromagnetic Waves via Silane Surface Modified Zinc Oxide/Polybenzoxazine Nanocomposites for EMI Shielding Application. Mater. Today Commun. 2024, 38, 107608. [Google Scholar] [CrossRef]

- Tang, L.; Ruan, K.; Liu, X.; Tang, Y.; Zhang, Y.; Gu, J. Flexible and Robust Functionalized Boron Nitride/Poly(p-Phenylene Benzobisoxazole) Nanocomposite Paper with High Thermal Conductivity and Outstanding Electrical Insulation. Nano-Micro Lett. 2024, 16, 38. [Google Scholar] [CrossRef]

- Li, Y.T.; Chen, X.M.; Zeng, X.K.; Liu, M.; Jiang, X.; Leng, Y.X. Hard yet Tough and Self-Lubricating (CuNiTiNbCr)Cx High-Entropy Nanocomposite Films: Effects of Carbon Content on Structure and Properties. J. Mater. Sci. Technol. 2024, 173, 20–30. [Google Scholar] [CrossRef]

- Naseem, K.; Rehman, A.; Haider, S.; Akhtar, M.S. Inorganic Nanoparticles Fabricated Alginate Based Nanocomposites for the Treatment of Brilliant Blue Dye. J. Mol. Struct. 2024, 1298, 137055. [Google Scholar] [CrossRef]

- Li, W.; Bai, L.; Ming, K.; Zheng, S. Plasticity Dependence on Amorphous Continuity in Fe-SiOC Dual-phase Nanocomposites. J. Mater. Sci. Technol. 2024, 173, 80–85. [Google Scholar] [CrossRef]

- Xue, J.; Zhou, Y.; Qu, S.; Xiao, Y.; Bian, H.; Li, L.; Wang, C. Preparation and Characterization of Electrospun Cellulose Nanocrystals-Reinforced Trans-1,4-Polyisoprene Nanocomposite Elastomeric Fiber Membranes. Mater. Today Commun. 2024, 38, 107705. [Google Scholar] [CrossRef]

- Jafari Eskandari, M.; Araghchi, M.; Daneshmand, H.; Hadipour, A. Repeatable and Controllable Notch and Pre-Crack Sharpening via Continuous-Wave Laser for Fracture Toughness of Epoxy Resin/MWCNTs Nanocomposites: Fabrication, Preparation, and Characterization. Opt. Laser Technol. 2024, 170, 110272. [Google Scholar] [CrossRef]

- Yang, Z.; Li, M.; Li, Y.; Huang, X.; Li, Z.; Zhai, X.; Shi, J.; Zou, X.; Xiao, J.; Sun, Y.; et al. Sodium Alginate/Guar Gum Based Nanocomposite Film Incorporating β-Cyclodextrin/Persimmon Pectin-Stabilized Baobab Seed Oil Pickering Emulsion for Mushroom Preservation. Food Chem. 2024, 437, 137891. [Google Scholar] [CrossRef] [PubMed]

- Souza, F.G., Jr.; Michel, R.C.; Soares, B.G. A Methodology for Studying the Dependence of Electrical Resistivity with Pressure in Conducting Composites. Polym. Test. 2005, 24, 998–1004. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Bhansali, S.; Pal, K.; da Silveira Maranhão, F.; Oliveira, M.S.; Valladão, V.S.; Brandão, D.; Bezerra, G.S. Advancements in Nanocomposites: An In-Depth Exploration of Microstructural, Electrical, and Mechanical Dynamics. Preprints 2024, 2024010091. [Google Scholar] [CrossRef]

- Hamada, H.M.; Shi, J.; Al Jawahery, M.S.; Majdi, A.; Yousif, S.T.; Kaplan, G. Application of Natural Fibres in Cement Concrete: A Critical Review. Mater. Today Commun. 2023, 17, 105833. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Soares, B.G.; Mantovani, G.L.; Manjunath, A.; Somashekarappa, H.; Somashekar, R. Siddaramaiah Blends of Styrene Butadiene Styrene TRI Block Copolymer/Polyaniline-Characterization by WAXS. Polymer 2006, 47, 2163–2171. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Soares, B.G.; Siddaramaiah; Manjunath, A.; Somashekar, R. Blends of Styrene–Butadiene–Styrene Tri-Block Copolymer/Polyaniline—Characterization by SAXS. Mater. Sci. Eng. A 2008, 476, 240–247. [Google Scholar] [CrossRef]

- Ferreira, S.R.; da Silva, A.M.; Souza, F.G., Jr.; Filho, R.D.T.; de Andrade Silva, F. Effect of Polyaniline and H2O2 Surface Modification on the Tensile Behavior and Chemical Properties of Coir Fibers. J. Biobased Mater. Bioenergy 2014, 8, 578–586. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Orlando, M.T.D.; Michel, R.C.; Pinto, J.C.; Cosme, T.; Oliveira, G.E. Effect of Pressure on the Structure and Electrical Conductivity of Cardanol–Furfural–Polyaniline Blends. J. Appl. Polym. Sci. 2011, 119, 2666–2673. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Pinto, J.C.; de Oliveira, G.E.; Soares, B.G. Evaluation of Electrical Properties of SBS/Pani Blends Plasticized with DOP and CNSL Using an Empirical Statistical Model. Polym. Test. 2007, 26, 720–728. [Google Scholar] [CrossRef]

- Si, A.; Kyzas, G.Z.; Pal, K.; Souza, F.G., Jr. Graphene Functionalized Hybrid Nanomaterials for Industrial-Scale Applications: A Systematic Review. J. Mol. Struct. 2021, 1239, 130518. [Google Scholar] [CrossRef]

- Siddaramaiah; Souza, F.G., Jr.; Soares, B.G.; Somashekar, R. Investigation on Microstructural Behavior of Styroflex/Polyaniline Blends by WAXS. J. Appl. Polym. Sci. 2012, 124, 5097–5105. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Marins, J.; Pinto, J.; de Oliveira, G.; Rodrigues, C.; Lima, L. Magnetic Field Sensor Based on a Maghemite/Polyaniline Hybrid Material. J. Mater. Sci. 2010, 45, 5012–5021. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Carlos Pinto, J.; Alves Garcia, F.; de Oliveira, G.E.; Bruno Tavares, M.I.; da Silva, A.M.; Daher Pereira, E. Modification of Coconut Fibers with Polyaniline for Manufacture of Pressure-Sensitive Devices. Polym. Eng. Sci. 2014, 54, 2887–2895. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Pinto, J.C.; Rodrigues, M.V.; Anzai, T.K.; Richa, P.; Melo, P.A.; Nele, M.; Oliveira, G.E.; Soares, B.G. New Polyaniline/Polycardanol Conductive Blends Characterized by FTIR, NIR, and XPS. Polym. Eng. Sci. 2008, 48, 1947–1952. [Google Scholar] [CrossRef]

- Veloso de Carvalho, F.; Pal, K.; Souza, F.G., Jr.; Dias Toledo Filho, R.; Moraes de Almeida, T.; Daher Pereira, E.; Thode Filho, S.; Galal Aboelkheir, M.; Corrêa Costa, V.; Barbosa de Lima, N.R.; et al. Polyaniline and Magnetite on Curaua Fibers for Molecular Interface Improvement with a Cement Matrix. J. Mol. Struct. 2021, 1233, 130101. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Almeida, M.; Soares, B.G.; Pinto, J.C. Preparation of a Semi-Conductive Thermoplastic Elastomer Vulcanizate Based on EVA and NBR Blends with Polyaniline. Polym. Test. 2007, 26, 692–697. [Google Scholar] [CrossRef]

- França, D.; Rebessi, A.C.; Camilo, F.F.; Souza, F.G., Jr.; Faez, R. Pressure Sensibility of Conductive Rubber Based on NBR- and Polypyrrole-Designed Materials. Front. Mater. 2019, 6, 189. [Google Scholar] [CrossRef]

- da Silveira Maranhão, F.; de Athayde, B.H.O.; da Motta, A.G.B.; de Souza, F.G., Jr. Production of Geopolymeric Microspheres by Reaction in Suspension Gelatin Medium. Abstr. Int. Conf. Meet. 2021, 1, 12. [Google Scholar]

- Yusoff, N.H.; Pal, K.; Narayanan, T.; de Souza, F.G. Recent Trends on Bioplastics Synthesis and Characterizations: Polylactic Acid (PLA) Incorporated with Tapioca Starch for Packaging Applications. J. Mol. Struct. 2021, 1232, 129954. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Soares, B.G.; Pinto, J.C. SBS/Polyaniline or Carbon Black System: Finding the Optimal Process and Molding Temperatures Through Experimental Design. Macromol. Mater. Eng. 2006, 291, 463–469. [Google Scholar] [CrossRef]

- Ferreira, L.P.; da Cunha, B.P.; Kuster, R.M.; Pinto, J.C.; Souza, M.N.; Souza, F.G., Jr. Synthesis and Chemical Modification of Poly(Butylene Succinate) with Rutin Useful to the Release of Silybin. Ind. Crops Prod. 2017, 97, 599–611. [Google Scholar] [CrossRef]

- Yeissel Becerra Lovera, A.; de Souza Junior, F.G. The Bio Components in the Vitrimers Reprocessability: A Meta- Analysis Study. Braz. J. Exp. Des. Data Anal. Inferent. Stat. 2022, 2, 101–117. [Google Scholar] [CrossRef]

- Soares, B.G.; Amorim, G.S.; Souza, F.G., Jr.; Oliveira, M.G.; da Silva, J.E.P. The in Situ Polymerization of Aniline in Nitrile Rubber. Synth. Met. 2006, 156, 91–98. [Google Scholar] [CrossRef]

- Lopes, E.S.; Domingos, E.; Neves, R.S.; Romão, W.; de Souza, K.R.; Valaski, R.; Archanjo, B.S.; Souza, F.G.; Silva, A.M.; Kuznetsov, A.; et al. The Role of Intermolecular Interactions in Polyaniline/Polyamide-6,6 Pressure-Sensitive Blends Studied by DFT and 1H NMR. Eur. Polym. J. 2016, 85, 588–604. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Soares, B.G.; Silveira, F.; Renukappa, N.M.; Siddaramaiah, S. Dielectric Behavior of SBS/Polyaniline Thermally Processable Blends. Chem. Chem. Technol. 2018, 12, 441–446. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Soares, B.G.; Pinto, J.C. Electrical Surface Resistivity of Conductive Polymers—A Non-Gaussian Approach for Determination of Confidence Intervals. Eur. Polym. J. 2008, 44, 3908–3914. [Google Scholar] [CrossRef]

- Maranhão, F.d.S.; Galdino, T.; da Paixão, C.P.S.; Souza, F.G., Jr.; Das, D.B.; Thode, S.; Narayanan, T. Evaluation of the Electrical Conductivity of Geopolymers Loaded with Carbon Black. Braz. J. Exp. Des. Data Anal. Inferent. Stat. 2021, 1, 61–69. [Google Scholar] [CrossRef]

- da Silveira Maranhão, F.; da Paixão, C.P.S.; Thode Filho, S.; Das, D.B.; de Souza Junior, F.G. Reaction of Geopolymers in Acid Medium and Application of Polyaniline as a Conductor of Electricity. Braz. J. Exp. Des. Data Anal. Inferent. Stat. 2021, 1, 47–53. [Google Scholar] [CrossRef]

- Zhang, Z.; Ou, X.; Ma, L.; Li, C.; Yang, Z.; Duan, J. A Double Methylene Blue Labeled Single-Stranded DNA and Hairpin DNA Coupling Biosensor for the Detection of Fusarium oxysporum f. Sp. Cubense Race 4. Bioelectrochemistry 2024, 156, 108612. [Google Scholar] [CrossRef]

- Ke, C.; Wu, Y.; Song, Z.; Zheng, M.; Zhu, H.; Guo, H.; Sun, H.; Liu, M. A Novel Competitive Fluorescence Colorimetric Dual-Mode Immunosensor for Detecting Ochratoxin A Based on the Synergistically Enhanced Peroxidase-like Activity of AuAg NCs-SPCN Nanocomposite. Food Chem. 2024, 437, 137930. [Google Scholar] [CrossRef]

- Yu, Z.; Li, F.; Xiang, Q. Carbon Dots-Based Nanocomposites for Heterogeneous Photocatalysis. J. Mater. Sci. Technol. 2024, 175, 244–257. [Google Scholar] [CrossRef]

- Liao, Y.-Y.; Sun, Q.; Jiang, X.-P.; Wu, H.; Tian, B.-Z.; Wang, Z.-G.; Zheng, K.; Yang, L. Constructing Cell-Membrane-Mimic Grain Boundaries for High-Performance n-Type Ag2Se Using High-Dielectric-Constant TiO2. J. Mater. Sci. Technol. 2024, 179, 138–144. [Google Scholar] [CrossRef]

- Jia, T.; Hao, Y.; Qi, X.; Rao, Y.; Wang, L.; Ding, J.; Qu, Y.; Zhong, W. Interface Engineering and Impedance Matching Strategy to Develop Core@shell Urchin-like NiO/Ni@carbon Nanotubes Nanocomposites for Microwave Absorption. J. Mater. Sci. Technol. 2024, 176, 1–12. [Google Scholar] [CrossRef]

- Nason, C.A.F.; Vijaya Kumar Saroja, A.P.; Lu, Y.; Wei, R.; Han, Y.; Xu, Y. Layered Potassium Titanium Niobate/Reduced Graphene Oxide Nanocomposite as a Potassium-Ion Battery Anode. Nano-Micro Lett. 2024, 16, 1. [Google Scholar] [CrossRef] [PubMed]

- Song, X.T.; Fan, G.H.; Liu, Y.; Fan, R.H. MOF-Derived ZrO2/C- Polyvinylidene Fluoride Composite towards Negative Permittivity Regulation Mechanism. J. Mater. Sci. Technol. 2024, 179, 50–56. [Google Scholar] [CrossRef]

- Han, E.; Li, L.; Gao, T.; Pan, Y.; Cai, J. Nitrite Determination in Food Using Electrochemical Sensor Based on Self-Assembled MWCNTs/AuNPs/Poly-Melamine Nanocomposite. Food Chem. 2024, 437, 137773. [Google Scholar] [CrossRef]

- Jiang, H.; Zhou, H.; Ke, Q.; Chen, P.; Wang, S.; Rao, B.; Wu, G. Rational Construction of CoFe-S/rGO Composites with Enriched Sulfur Vacancies for High-Performance Supercapacitor. Appl. Surf. Sci. 2024, 648, 159063. [Google Scholar] [CrossRef]

- Rodrigues, C.H.M.; Toniato, M.; Souza, F.G., Jr.; Paes, H.R., Jr. A Influência Dos Parâmetros de Deposição Na Morfologia Dos Eletrólitos Para Células a Combustível de Óxido Sólido, à Base de Filmes de Zircônia: 8 Mol% Ítria Depositados Por Spray Pirólise. Cerâmica 2013, 59, 451–459. [Google Scholar] [CrossRef][Green Version]

- Souza, F.G., Jr.; Varela, A. Construção de Ferramenta de Aquisição e Inspeção de Dados Eletromecânicos Usando Python. Programar. Rev. Port. Programação 2012, 34, 32–38. [Google Scholar]

- Marinho, V.S.; Neves, M.A.F.S.; Pedrosa, M.S.; Souza, F.G., Jr. Efeito Do Meio Contínuo Na Incorporação de Material Magnético Em Resinas de Estirenodivinilbenzeno. Rev. Eletrônica Perspect. Ciênc. E Tecnol. 2018, 10, 110. [Google Scholar] [CrossRef]

- Picciani, P.H.S.; Souza, F.G., Jr.; Comerlato, N.M.; Soares, B.G. A Novel Material Based on Polyaniline Doped with [Cs][In(Dmit)2], (Cesium) [Bis(1,3-Dithiole-2-Thione-4,5-Dithiolato)Indium (III)]. Synth. Met. 2007, 157, 1074–1079. [Google Scholar] [CrossRef]

- Barbosa de Lima, N.R.; Souza, F.G., Jr.; Gaëlle Roullin, V.; Pal, K. Amphipathic Au-Sulfur-Poly (Ethylene Glycol)-b-Poly (Butylene Succinate) System Prepared by Interfacial Reaction as in-Silico Photosensitizer and Antineoplastic Carrier. J. Drug Deliv. Sci. Technol. 2021, 64, 102584. [Google Scholar] [CrossRef]

- Almeida Moraes, T.; Farrôco, M.J.; Pontes, K.; Fontes Bittencourt, M.; Guenter Soares, B.; Gomes Souza, F. An Optical-Magnetic Material as a Toxic Gas Filter and Sensing Device. RSC Adv. 2020, 10, 23233–23244. [Google Scholar] [CrossRef]

- Mussi, T.d.C.; Brum, N.F.D.; de Azevedo, A.D.; Monteiro, S.G.; Souza, F.G., Jr. Application of experimental design for poly(butylene succinate) synthesis and obtaining rifampicin-loaded microparticles. J. Biol. Pharm. Agric. Manag. 2021, 17, 1066–1076. [Google Scholar]

- Souza, F.G., Jr.; da Silva, A.M.; de Oliveira, G.E.; Costa, R.M.; Fernandes, E.R.; Pereira, E.D. Conducting and Magnetic Mango Fibers. Ind. Crops Prod. 2015, 68, 97–104. [Google Scholar] [CrossRef]

- Morgan, V.G.; Sum, A.K.; Wu, N.; Dante, A.; Gomes, A.M.S.; Ferreira, L.S.; Fernando, G.S.J.; Werneck, M.M.; Allil, R.C.S.B. Development of Experimental Device for Inductive Heating of Magnetic Nanoparticles. Meas. Sci. Technol. 2024, 35, 045602. [Google Scholar] [CrossRef]

- Pérez, A.I.; Materón, E.M.; Zanoni, M.V.B.; Moreira, J.C.; Farias, P.A.M.; Souza, F.G., Jr. Electrochemical Detection of Sotalol on a Magnetographite-Epoxy Electrode Using Magnetite Nanoparticles. Pramana 2020, 94, 114. [Google Scholar] [CrossRef]

- Picciani, P.H.S.; Soares, B.G.; Medeiros, E.S.; Souza, F.G., Jr.; Wood, D.F.; Orts, W.J.; Mattoso, L.H.C. Electrospinning of Polyaniline/Poly(Lactic Acid) Ultrathin Fibers: Process and Statistical Modeling Using a Non Gaussian Approach. Macromol. Theory Simul. 2009, 18, 528–536. [Google Scholar] [CrossRef]

- Neto, W.S.; Dutra, G.V.S.; Valadares, L.F.; Souza, F.G.; Sousa, M.H.; Machado, F. Experimental Evaluation of the Miniemulsion Polymerization of Vinyl Pivalate: The Role of the Main Process Variables. Macromol. React. Eng. 2020, 15, 2000049. [Google Scholar] [CrossRef]

- Santiago, J.P.; de Campos Silva, P.; Marques, F.D.; Souza, F.G., Jr. Glycerin-Based Polyurethane Obtained by Inverse Emulsion: Comparison Between Magnetic Induction and Conventional Heating. Macromol. Symp. 2018, 380, 1800091. [Google Scholar] [CrossRef]

- Raji, V.; Pal, K.; Zaheer, T.; Kalarikkal, N.; Sabu, T.; de Souza, F.G.; Asiya, S.I. Gold Nanoparticles against Respiratory Diseases: Oncogenic and Viral Pathogens Review. Ther. Deliv. 2020, 11, 521. [Google Scholar] [CrossRef]

- Costa, R.M.D.D.; Hungerbühler, G.; Saraiva, T.; De Jong, G.; Moraes, R.S.; Furtado, E.G.; Silva, F.M.; Oliveira, G.E.D.; Ferreira, L.S.; Souza, F.G.D. Green Polyurethane Synthesis by Emulsion Technique: A Magnetic Composite for Oil Spill Removal. Polímeros 2017, 27, 273–279. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Sirelli, L.; Michel, R.C.; Soares, B.G.; Herbst, M.H. In Situ Polymerization of Aniline in the Presence of Carbon Black. J. Appl. Polym. Sci. 2006, 102, 535–541. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Anzai, T.K.; Melo, P.A., Jr.; Soares, B.G.; Nele, M.; Pinto, J.C. Influence of Reaction Media on Pressure Sensitivity of Polyanilines Doped with DBSA. J. Appl. Polym. Sci. 2008, 107, 2404–2413. [Google Scholar] [CrossRef]

- Elkodous, M.A.; El-Sayyad, G.S.; Mohamed, A.E.; Pal, K.; Asthana, N.; de Souza Junior, F.G.; Mosallam, F.M.; Gobara, M.; El-Batal, A.I. Layer-by-Layer Preparation and Characterization of Recyclable Nanocomposite (CoxNi1−xFe2O4; X = 0.9/SiO2/TiO2). J. Mater. Sci. Mater. Electron. 2019, 30, 8312–8328. [Google Scholar] [CrossRef]

- Siddaramaiah; Souza, F.G., Jr.; Soares, B.G.; Parameswara, P.; Somashekar, R. Microstructural Behaviors of Polyaniline/CB Composites by SAXS. J. Appl. Polym. Sci. 2010, 116, 673–679. [Google Scholar] [CrossRef]

- Bouider, B.; Haffad, S.; Bouakaz, B.S.; Berd, M.; Ouhnia, S.; Habi, A. MOF-5/Graphene Oxide Composite Photocatalyst for Enhanced Photocatalytic Activity of Methylene Blue Degradation Under Solar Light. J. Inorg. Organomet. Polym. Mater. 2023, 33, 4001–4011. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Richa, P.; de Siervo, A.; Oliveira, G.E.; Rodrigues, C.H.M.; Nele, M.; Pinto, J.C. New in Situ Blends of Polyaniline and Cardanol Bio-Resins. Macromol. Mater. Eng. 2008, 293, 675–683. [Google Scholar] [CrossRef]

- Elias, E.; Zachariah, A.K.; Sunil, M.A.; Bose, S.; Souza, F.G.; Thomas, S. Percolated Network Formation in Biocidal 3D Porous PCL/Clay Nanocomposite Scaffolds: Effect of Organic Modifier on Interfacial and Water Sorption Properties. RSC Adv. 2016, 6, 85107–85116. [Google Scholar] [CrossRef]

- Adedoja, O.S.; Sadiku, E.R.; Hamam, Y. Prospects of Hybrid Conjugated Polymers Loaded Graphene in Electrochemical Energy Storage Applications. J. Inorg. Organomet. Polym. Mater. 2023, 33, 3915–3934. [Google Scholar] [CrossRef]

- Souza, F.G., Jr.; Pinto, J.C.; Soares, B.G. SBS/Pani…DBSA Mixture Plasticized with DOP and NCLS—Effect of the Plasticizers on the Probability Density of Volume Resistivity Measurements. Eur. Polym. J. 2007, 43, 2007–2016. [Google Scholar] [CrossRef]

- Marques, F.D.; Nele de Souza, M.; Souza, F.G., Jr. Sealing System Activated by Magnetic Induction Polymerization. J. Appl. Polym. Sci. 2017, 134, 45549. [Google Scholar] [CrossRef]

- Pal, K.; Sajjadifar, S.; Abd Elkodous, M.; Alli, Y.A.; Gomes, F.; Jeevanandam, J.; Thomas, S.; Sigov, A. Soft, Self-Assembly Liquid Crystalline Nanocomposite for Superior Switching. Electron. Mater. Lett. 2018, 15, 84–101. [Google Scholar] [CrossRef]

- Moraes, R.; Gomes Souza, F., Jr.; Saez, V.; Silva, L.; Middea, A. Surface Modification of Magnetite with PBS Using a Ricinoleic-Toluene Diisocyanate Fragment as the Binder Structure. Macromol. Symp. 2021, 398, 2000193. [Google Scholar] [CrossRef]

- Aboelkheir, M.G.; Visconte, L.Y.; Oliveira, G.E.; Toledo Filho, R.D.; Souza, F.G. The Biodegradative Effect of Tenebrio Molitor Linnaeus Larvae on Vulcanized SBR and Tire Crumb. Sci. Total Environ. 2019, 649, 1075–1082. [Google Scholar] [CrossRef] [PubMed]

- Souza, F.G., Jr.; Sena, M.E.; Soares, B.G. Thermally Stable Conducting Composites Based on a Carbon Black-filled Polyoxadiazole Matrix. J. Appl. Polym. Sci. 2004, 93, 1631–1637. [Google Scholar] [CrossRef]

- Mello e Alvim, T.M.; Maranhão, F.D.S.; Batista, J.H.G.; Reales, O.A.M.; De Souza Júnior, F.G.; Toledo Filho, R.D. Effect of Magnetic Nanoparticles on Strength Development and Microstructural Properties of Cement Slurry. In Proceedings of the Offshore Technology Conference, Kuala Lumpur, Malaysia, 25 April 2022; OnePetro: Richardson, TX, USA, 2022. [Google Scholar]

- Deka, S.; Mozafari, F.; Mallick, A. A Comprehensive Experimental and Modeling Study of the Strain Rate- and Temperature-Dependent Deformation Behavior of Bio-Degradable Mg-CeO2 Nanocomposites. Compos. Part Appl. Sci. Manuf. 2024, 177, 107936. [Google Scholar] [CrossRef]

- Zhang, Y.; Ling, S.; Chen, Y.; Qin, X.; Wang, K.; Zhu, Q.; Liu, Y. Application of Ag/Tannic Acid-FeIII Nanocomposite as Multifunctional Bacteriostatic to Enhance the Performance of Chitosan/Gelatin/Polyvinyl Alcohol Complex Films. Food Hydrocoll. 2024, 147, 109302. [Google Scholar] [CrossRef]

- Wang, X.; Meng, X.; Zhu, Y.; Gao, W. Design of Ultrahigh-Response Gas Sensor Based on Pd-WO3/WS2 Ternary Nanocomposites for Ultrafast Hydrogen Detection. Sens. Actuators B Chem. 2024, 401, 134991. [Google Scholar] [CrossRef]

- Chen, P.; Zhou, A.; Lou, L.; Bi, Z.; Kou, J.; Sun, W.; Li, W.; Guo, D.; Li, X. Effect of Hyperfine Structure on Crystallization, Microstructure and Magnetic Properties of Amorphous Nd9Fe85B6 Alloy. J. Alloys Compd. 2024, 976, 172991. [Google Scholar] [CrossRef]

- Wang, L.; Wang, H.; Zhou, X.; Fu, H.; Surjadi, J.U.; Qu, S.; Song, X.; Fan, R.; Lu, Y. Hierarchical Crystalline–Amorphous Nanocomposites with High Strength and Large Deformability Enabled by Elemental Diffusion. J. Mater. Sci. Technol. 2024, 171, 150–161. [Google Scholar] [CrossRef]

- Staab, F.; Yang, Y.; Foya, E.; Bruder, E.; Zingsem, B.; Adabifiroozjaei, E.; Nasiou, D.; Skokov, K.; Koch, D.; Farle, M.; et al. Influence of Amorphous Phase on Coercivity in SmCo5-Cu Nanocomposites. Scr. Mater. 2024, 240, 115808. [Google Scholar] [CrossRef]

- Wang, H.; Hao, Y.; Xiang, L.; Qi, X.; Wang, L.; Ding, J.; Qu, Y.; Xu, J.; Zhong, W. Interface and Magnetic-Dielectric Synergy Strategy to Develop Fe3O4-Fe2CO3/Multi-Walled Carbon Nanotubes/Reduced Graphene Oxide Mixed-Dimensional Multicomponent Nanocomposites for Microwave Absorption. Mater. Res. Bull. 2024, 171, 112631. [Google Scholar] [CrossRef]

- Lu, L.; Wen, T.; Li, W.; Wen, Q.; Yu, Z.; Tao, S.; Yang, J.; Wang, Y.; Luan, X.; Xiong, X.; et al. Single-Source-Precursor Synthesis of Dense Monolithic SiC/(Ti0.25Zr0.25Hf0.25Ta0.25)C Ceramic Nanocomposite with Excellent High-Temperature Oxidation Resistance. J. Eur. Ceram. Soc. 2024, 44, 595–609. [Google Scholar] [CrossRef]

- Liu, H.; Xie, J.; Zhao, J.; Wang, R.; Qi, Y.; Sun, S. Temperature and Photo Sensitive PVDF-g-PNIPAAm/BN@PDA-Ag Nanocomposite Membranes with Superior Wasterwater Separation and Light-Cleaning Capabilities. Sep. Purif. Technol. 2024, 331, 125692. [Google Scholar] [CrossRef]

- Cunha, S.R.d.S.; Souza, F.G., Jr. Adsorbent Biopolymers Based on Couroupita Guianensis. Abstr. Int. Conf. Meet. AICM 2021, 1, 4. [Google Scholar] [CrossRef]

- Silva, G.B.; da Silveira Maranhão, F.; de Souza, F.G.; Pal, K.; Middea, A.; Lima, R.C.; Machado, S.L.; Feitosa, S.B.H.; de Araújo, K.V.; do Nascimento Peçanha, T. Artificial Chrysocolla with Catalyst Nanomodified with Copper and Zinc. Top. Catal. 2023, 67, 86–102. [Google Scholar] [CrossRef]

- Almeida, T.; Pal, K.; Souza, F.G., Jr. Bibliometric Analysis of the Hot Theme “Phytosynthesized Nanoparticles”. Arch. Biomed. Eng. Biotechnol. 2020, 4, 5. [Google Scholar] [CrossRef]

- Gomes Souza, F.; Pal, K.; Ampah, J.D.; Dantas, M.C.; Araújo, A.; Maranhão, F.; Domingues, P. Biofuels and Nanocatalysts: Python Boosting Visualization of Similarities. Materials 2023, 16, 1175. [Google Scholar] [CrossRef] [PubMed]

- Barradas, T.N.; de Souza Junior, F.G. Chitosan-Based Films for Wound Healing Applications: A Meta- Analysis to Access the Impact on Wound Closure Rate. Braz. J. Exp. Des. Data Anal. Inferent. Stat. 2022, 2, 83–99. [Google Scholar] [CrossRef]

- da Costa, V.C.; de Souza Junior, F.G.; Sousa, L.d.C.; Pal, K.; Filho, R.D.T. Core-Shell System Based on Gelatin and Poly(Vinyl Alcohol) (PVA) for Concrete Self-Healing Applications: Synthesis, Characterization, and Optimization. Macromol. Symp. 2021, 398, 2000194. [Google Scholar] [CrossRef]

- Costa, R.C.D.; Pereira, E.D.; Silva, F.M.; Jesus, E.O.D.; Souza, F.G. Drug Micro-Carriers Based on Polymers and Their Sterilization. Chem. Chem. Technol. 2018, 12, 473–487. [Google Scholar] [CrossRef]

- Pereira, E.D.; de Souza Junior, F.G.; Pinto, J.C.; Filho, S.T.; Pal, K.; dos Santos Pyrrho, A.; da Costa, R.C.; da Cunha, B.P.; da Silveira Maranhão, F.; de Almeida, T.M. Evaluation of Hyperthermic Potential and Acute Toxicity of PLGA-PEG/Magnetite Microspheres Loaded with Oxaliplatin Using Mice as a Test System. Macromol. React. Eng. 2023, 17, 2300005. [Google Scholar] [CrossRef]

- Santos, R.D.; Thomas, S.; Ferreira, S.R.; Silva, F.A.; Combariza, M.Y.; Tirado, C.B.; Serrano, S.A.O.; Souza, F.G.; Oliveira, G.E.; Toledo Filho, R.D. Molecular Grafting of Nanoparticles onto Sisal Fibers—Adhesion to Cementitious Matrices and Novel Functionalities. J. Mol. Struct. 2021, 1234, 130171. [Google Scholar] [CrossRef]

- Peña Icart, L.; Fernandes dos Santos, E.; Agüero Luztonó, L.; Zaldívar Silva, D.; Andrade, L.; Lopes Dias, M.; Trambaioli da Rocha e Lima, L.M.; Souza, F.G., Jr. Paclitaxel-Loaded PLA/PEG/Magnetite Anticancer and Hyperthermic Agent Prepared From Materials Obtained by the Ugi’s Multicomponent Reaction. Macromol. Symp. 2018, 380, 1800094. [Google Scholar] [CrossRef]

- Icart, L.P.; Souza, F.G., Jr.; Lima, L.M.T.R. Polymeric Microparticle Systems for Modified Release of Glucagon-like-Peptide-1 Receptor Agonists. J. Microencapsul. 2021, 38, 249–261. [Google Scholar] [CrossRef]

- Saez, V.; Cerruti, R.; Ramón, J.A.; Santos, E.R.F.; Silva, D.Z.; Pinto, J.C.; Souza, F.G., Jr. Quantification of Oxaliplatin Encapsulated into PLGA Microspheres by TGA. Macromol. Symp. 2016, 368, 116–121. [Google Scholar] [CrossRef]

- Pal, K.; Kyzas, G.Z.; Kralj, S.; Souza, F.G., Jr. Sunlight Sterilized, Recyclable and Super Hydrophobic Anti-COVID Laser-Induced Graphene Mask Formulation for Indelible Usability. J. Mol. Struct. 2021, 1233, 130100. [Google Scholar] [CrossRef] [PubMed]

- Icart, L.P.; Souza, F.G.; Lima, L.M. Sustained Release and Pharmacologic Effects of Human Glucagon-like Peptide-1 and Liraglutide from Polymeric Microparticles. J. Microencapsul. 2019, 36, 747–758. [Google Scholar] [CrossRef] [PubMed]

- Ramon, J.; Saez, V.; Souza, F.G., Jr.; Pinto, J.; Nele, M. Synthesis and Characterization of PEG-PBS Copolymers to Obtain Microspheres With Different Naproxen Release Profiles. Macromol. Symp. 2018, 380, 1800065. [Google Scholar] [CrossRef]

- Ferreira, G.; Segura, T.; Souza, F.G., Jr.; Umpierre, A.P.; Machado, F. Synthesis of Poly(Vinyl Acetate)-Based Magnetic Polymer Microparticles. Eur. Polym. J. 2012, 48, 2050–2069. [Google Scholar] [CrossRef]

- Aboelkheir, M.G.; Lima Junior, J.G.; Toledo Filho, R.D.; Souza, F.G., Jr.; dos Santos Siqueira, C.Y. Thermo-Oxidative Degradation of Vulcanized SBR: A Comparison between Ultraviolet (UV) and Microwave as Recovery Techniques. J. Polym. Res. 2021, 28, 141. [Google Scholar] [CrossRef]

- Rahman, M.; Islam, K.S.; Dip, T.M.; Chowdhury, M.F.M.; Debnath, S.R.; Hasan, S.M.d.M.; Sakib, M.d.S.; Saha, T.; Padhye, R.; Houshyar, S. A Review on Nanomaterial-Based Additive Manufacturing: Dynamics in Properties, Prospects, and Challenges. Prog. Addit. Manuf. 2023, 1–28. [Google Scholar] [CrossRef]

- Huang, X.; Li, X.; Tay, A. Advances in Techniques to Characterize Cell-Nanomaterial Interactions (CNI). Nano Today 2024, 55, 102149. [Google Scholar] [CrossRef]

- Wang, J.; Feng, J.; Lian, Y.; Sun, X.; Wang, M.; Sun, M. Advances of the Functionalized Covalent Organic Frameworks for Sample Preparation in Food Field. Food Chem. 2023, 405, 134818. [Google Scholar] [CrossRef]

- Zhang, X.; Hou, X.; Ma, L.; Shi, Y.; Zhang, D.; Qu, K. Analytical Methods for Assessing Antimicrobial Activity of Nanomaterials in Complex Media: Advances, Challenges, and Perspectives. J. Nanobiotechnol. 2023, 21, 97. [Google Scholar] [CrossRef]

- Farhoudi, L.; Fobian, S.-F.; Oei, A.L.; Amin, M.; Jaafari, M.R.; ten Hagen, T.L. Applications of Biomimetic Nanoparticles in Breast Cancer as a Blueprint for Improved Next-Generation Cervical Cancer Therapy. Nano Today 2023, 53, 102032. [Google Scholar] [CrossRef]

- Malode, S.J.; Shanbhag, M.M.; Kumari, R.; Dkhar, D.S.; Chandra, P.; Shetti, N.P. Biomass-Derived Carbon Nanomaterials for Sensor Applications. J. Pharm. Biomed. Anal. 2023, 222, 115102. [Google Scholar] [CrossRef] [PubMed]

- Herdiana, Y. Chitosan Nanoparticles for Gastroesophageal Reflux Disease Treatment. Polymers 2023, 15, 3485. [Google Scholar] [CrossRef] [PubMed]

- Harish, V.; Ansari, M.M.; Tewari, D.; Yadav, A.B.; Sharma, N.; Bawarig, S.; García-Betancourt, M.-L.; Karatutlu, A.; Bechelany, M.; Barhoum, A. Cutting-Edge Advances in Tailoring Size, Shape, and Functionality of Nanoparticles and Nanostructures: A Review. J. Taiwan Inst. Chem. Eng. 2023, 149, 105010. [Google Scholar] [CrossRef]

- Lin, D.-Y.; Yu, C.-Y.; Ku, C.-A.; Chung, C.-K. Design, Fabrication, and Applications of SERS Substrates for Food Safety Detection. Micromachines 2023, 14, 1343. [Google Scholar] [CrossRef] [PubMed]

- Achi, F.; Attar, A.M.; Lahcen, A.A. Electrochemical Nanobiosensors for the Detection of Cancer Biomarkers in Real Samples: Trends and Challenges. TrAC Trends Anal. Chem. 2023, 170, 117423. [Google Scholar] [CrossRef]

- Fondaj, D.; Arduino, I.; Lopedota, A.A.; Denora, N.; Iacobazzi, R.M. Exploring the Microfluidic Production of Biomimetic Hybrid Nanoparticles and Their Pharmaceutical Applications. Pharmaceutics 2023, 15, 1953. [Google Scholar] [CrossRef]

- Ghobashy, M.M.; Alkhursani, S.A.; Alqahtani, H.A.; El-damhougy, T.K.; Madani, M. Gold Nanoparticles in Microelectronics Advancements and Biomedical Applications. Mater. Sci. Eng. B 2024, 301, 117191. [Google Scholar] [CrossRef]

- Fabio, S.; Pankaj, K.S.; Kazem, S.; Michela, M.; Demetrio, L.; Michael, A.M. High Throughput Microscopy and Single Cell Phenotypic Image-Based Analysis in Toxicology and Drug Discovery. Biochem. Pharmacol. 2023, 216, 115770. [Google Scholar]

- Chao, Y.-W.; Lee, Y.-L.; Tseng, C.-S.; Wang, L.U.-H.; Hsia, K.-C.; Chen, H.; Fustin, J.-M.; Azeem, S.; Chang, T.-T.; Chen, C.-Y.; et al. Improved CaP Nanoparticles for Nucleic Acid and Protein Delivery to Neural Primary Cultures and Stem Cells. ACS Nano 2024, 18, 4822–4839. [Google Scholar] [CrossRef]

- Gimondi, S.; Ferreira, H.; Reis, R.L.; Neves, N.M. Microfluidic Devices: A Tool for Nanoparticle Synthesis and Performance Evaluation. ACS Nano 2023, 17, 14205–14228. [Google Scholar] [CrossRef] [PubMed]

- Yu, Q.; Wu, T.; Tian, B.; Li, J.; Liu, Y.; Wu, Z.; Jin, X.; Wang, C.; Wang, C.; Gu, B. Recent Advances in SERS-Based Immunochromatographic Assay for Pathogenic Microorganism Diagnosis: A Review. Anal. Chim. Acta 2023, 1286, 341931. [Google Scholar] [CrossRef]

- Silva-Neto, H.A.; Arantes, I.V.; Ferreira, A.L.; do Nascimento, G.H.; Meloni, G.N.; de Araujo, W.R.; Paixão, T.R.; Coltro, W.K. Recent Advances on Paper-Based Microfluidic Devices for Bioanalysis. TrAC Trends Anal. Chem. 2023, 158, 116893. [Google Scholar] [CrossRef]

- Devi, L.; Kushwaha, P.; Ansari, T.M.; Kumar, A.; Rao, A. Recent Trends in Biologically Synthesized Metal Nanoparticles and Their Biomedical Applications: A Review. Biol. Trace Elem. Res. 2023; ahead of print. [Google Scholar] [CrossRef] [PubMed]

- Ni, X.; Tang, X.; Wang, D.; Zhang, J.; Zhao, L.; Gao, J.; He, H.; Dramou, P. Research Progress of Sensors Based on Molecularly Imprinted Polymers in Analytical and Biomedical Analysis. J. Pharm. Biomed. Anal. 2023, 235, 115659. [Google Scholar] [CrossRef] [PubMed]

- Barrias, S.; Ibáñez, J.; Fernandes, J.R.; Martins-Lopes, P. The Role of DNA-Based Biosensors in Species Identification for Food Authenticity Assessment. Trends Food Sci. Technol. 2024, 145, 104350. [Google Scholar] [CrossRef]

- Kianipour, S.; Ansari, M.; Farhadian, N.; Moradi, S.; Shahlaei, M. A Molecular Dynamics Study on Using of Naturally Occurring Polymers for Structural Stabilization of Erythropoietin at High Temperature. J. Biomol. Struct. Dyn. 2022, 40, 9042–9052. [Google Scholar] [CrossRef]

- Noman, A.B.M.A.; Chowdhury, E.U.K. American and European Policies in Nanotechnology Patents and Human Rights Related Issues. Online J. Model. New Eur. 2015, 17, 68–92. [Google Scholar]

- Chang, S.-J.; Liou, N.-H.; Cherng, J.-H.; Liu, C.-C.; Chiu, Y.-C.; Fang, T.-J.; Hsu, M.-L. Application of Refractable Nanocomposite on Cell Based Therapy in Central Nervous System. Int. J. Nanotechnol. 2013, 10, 891–904. [Google Scholar] [CrossRef]

- Rezabakhsh, A.; Sokullu, E.; Rahbarghazi, R. Applications, Challenges and Prospects of Mesenchymal Stem Cell Exosomes in Regenerative Medicine. Stem Cell Res. Ther. 2021, 12, 521. [Google Scholar] [CrossRef]

- Fu, Q.; Song, L.; Li, J.; Yi, B.; Huang, Y.; Zhang, Z.; Xin, Z.; Zhu, J. Biodegradable Nano Black Phosphorus Based SDF1-α Delivery System Ameliorates Erectile Dysfunction in a Cavernous Nerve Injury Rat Model by Recruiting Endogenous Stem/Progenitor Cells. J. Nanobiotechnol. 2023, 21, 487. [Google Scholar] [CrossRef]

- Iavicoli, I.; Leso, V.; Schulte, P.A. Biomarkers of Susceptibility: State of the Art and Implications for Occupational Exposure to Engineered Nanomaterials. Toxicol. Appl. Pharmacol. 2016, 299, 112–124. [Google Scholar] [CrossRef] [PubMed]

- Vance, S.; Zeidan, E.; Henrich, V.C.; Sandros, M.G. Comparative Analysis of Human Growth Hormone in Serum Using SPRi, Nano-SPRi and ELISA Assays. J. Vis. Exp. 2016, 2016, 53508. [Google Scholar] [CrossRef]

- Chen, G.; Peijnenburg, W.J.G.M.; Kovalishyn, V.; Vijver, M.G. Development of Nanostructure-Activity Relationships Assisting the Nanomaterial Hazard Categorization for Risk Assessment and Regulatory Decision-Making. RSC Adv. 2016, 6, 52227–52235. [Google Scholar] [CrossRef]

- Ferrari, A. Developments in the Debate on Nanoethics: Traditional Approaches and the Need for New Kinds of Analysis. NanoEthics 2010, 4, 27–52. [Google Scholar] [CrossRef]

- Kermisch, C. Do New Ethical Issues Arise at Each Stage of Nanotechnological Development? NanoEthics 2012, 6, 29–37. [Google Scholar] [CrossRef][Green Version]

- Ahmadi, M.; Ahmadi, L. Ethical Considerations of Nanobiotechnology. J. Biomater. Tissue Eng. 2013, 3, 335–352. [Google Scholar] [CrossRef]

- Tarţǎu, L.; Lupuşoru, R.V.; Melnig, V. Experimental Researches on the Effects of Nano-Vesicles Encapsulating Dexketoprofen in a Visceral Pain Model in Mice. Ann. Rom. Soc. Cell Biol. 2010, 15, 202–206. [Google Scholar]

- Tarţǎu, L.; Chiriac, A.; Niţǎ, L.; Melnig, V. Experimental Researches on the Effects of Acetaminophen Vesicles Carrier in a Cutaneous Pain Model in Mice. Ann. Rom. Soc. Cell Biol. 2009, 14, 87–92. [Google Scholar]

- Tartau, L.; Lupusoru, R.V.; Andritoiu, C.; Melnig, V. Experimental Researches on the Effects of Tramadol Soft Matter Vesicles in Nociceptive Processes in Mice. Ann. Rom. Soc. Cell Biol. 2011, 16, 194–198. [Google Scholar]

- Bontems, V.K. How to Accommodate to the Invisible? The “halo” of “Nano”. NanoEthics 2011, 5, 175–183. [Google Scholar] [CrossRef]

- Gilbert, F.; Dodds, S. Is There a Moral Obligation to Develop Brain Implants Involving NanoBionic Technologies? Ethical Issues for Clinical Trials. NanoEthics 2014, 8, 49–56. [Google Scholar] [CrossRef]

- Bragazzi, N.L. Nanomedicine: Insights from a Bibliometrics-Based Analysis of Emerging Publishing and Research Trends. Med. Lith. 2019, 55, 785. [Google Scholar] [CrossRef]

- Shubhika, K. Nanotechnology and Medicine—The Upside and the Downside. Int. J. Drug Dev. Res. 2013, 5, 1–10. [Google Scholar]

- Mishra, N.K.; Jahan, N.; Baba, M.H. Nanotechnology Powered COVID-19 Pandemic Management: Medical Ethics Review. JK Pract. 2022, 27, S223–S229. [Google Scholar]

- Baran, A. Nanotechnology: Legal and Ethical Issues. Eng. Manag. Prod. Serv. 2016, 8, 47–54. [Google Scholar] [CrossRef]

- Patra, D.; Haribabu, E.; McComas, K.A. Perceptions of Nano Ethics among Practitioners in a Developing Country: A Case of India. NanoEthics 2010, 4, 67–75. [Google Scholar] [CrossRef]

- Patra, D. Responsible Development of Nanoscience and Nanotechnology: Contextualizing Socio-Technical Integration into the Nanofabrication Laboratories in the USA. NanoEthics 2011, 5, 143–157. [Google Scholar] [CrossRef]

- Kraftl, P.; Lynch, I.; Jarman, P.; Menzel, A.; Walker, A.; Till, R.; Hadfield-Hill, S. So You’re Literally Taking the Piss?! Critically Analysing and Accounting for Ethics (and Risk) in Interdisciplinary Research on Children and Plastics. Child. Geogr. 2021; ahead of print. [Google Scholar] [CrossRef]

- Fages, V.; Albe, V. Social Issues in Nanoscience and Nanotechnology Master’s Degrees: The Socio-Political Stakes of Curricular Choices. Cult. Stud. Sci. Educ. 2015, 10, 419–435. [Google Scholar] [CrossRef]

- Boancă, M.; Popa, E.G.; Lupuşoru, R.V.; Poroch, V.; Mititelu-Tarţău, L.; Lupuşoru, C.E. The Effects of Magnesium Nanovesicle Formulations on Spatial Memory Performance in Mice. Rev. Med. Chir. Soc. Med. Nat. Iasi 2014, 118, 847–853. [Google Scholar]

- Tarţǎu, L.; Lupuşoru, C.E.; Melnig, V. The Effects of Variation in Ketoprofen Soft Matter Vesicles Dosage on Mice Cutaneous Nociceptive Reactivity. Ann. Rom. Soc. Cell Biol. 2010, 15, 207–211. [Google Scholar]

- Çapar, N.; Polat, İ.; Yola, B.B.; Atar, N.; Yola, M.L. A novel molecular imprinted QCM sensor based on MoS2NPs-MWCNT nanocomposite for Zearalenone Determination. Microchim. Acta 2023, 190, 262. [Google Scholar] [CrossRef]

- Lochab, A.; Jindal, K.; Chowdhuri, A.; Tomar, M.; Saxena, R. Conductive Polymer Based MWCNTs Nanocomposite as Electrochemical Sensing Platform to Detect Chloramphenicol. Synth. Met. 2023, 297, 117397. [Google Scholar] [CrossRef]

- Slekiene, N.; Snitka, V. Nanocomposite Au/Si Cantilevers for Tip-Enhanced Raman Scattering (TERS) Sensors. Chemosensors 2023, 11, 218. [Google Scholar] [CrossRef]

- Salikhov, R.B.; Zilberg, R.A.; Bulysheva, E.O.; Ostaltsova, A.D.; Salikhov, T.R.; Teres, Y.B. Nanocomposite Thin-Film Structures Based on a Polyelectrolyte Complex of Chitosan and Chitosan Succinamide with SWCNT. Lett. Mater. 2023, 13, 132–137. [Google Scholar] [CrossRef]