Characterization and Environmental Evaluation of Recycled Aggregates from Construction and Demolition Waste in Belgrade City Area (Serbia)

Abstract

1. Introduction

2. Materials and Methods

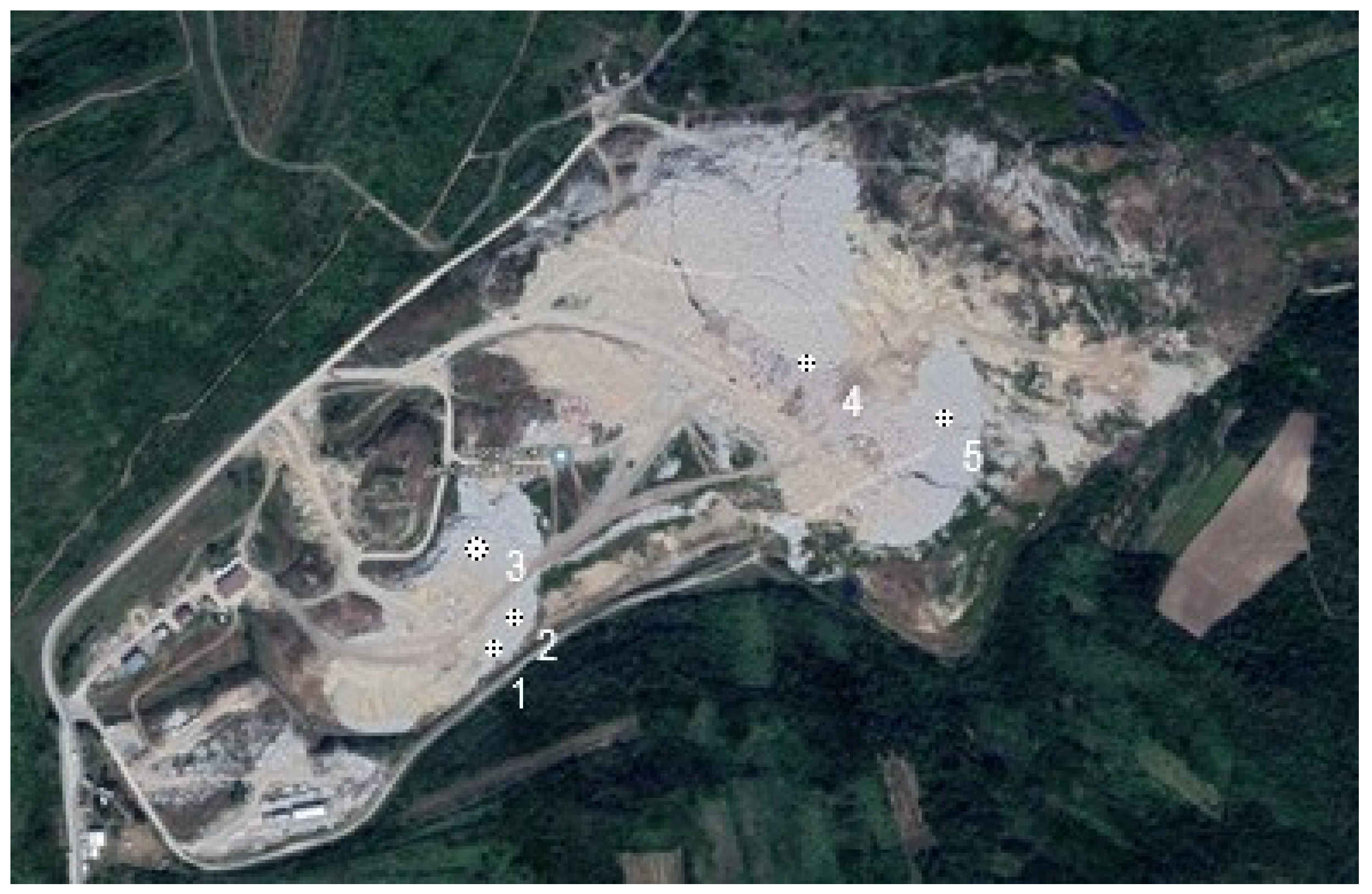

2.1. Methods of Sampling and of Sample Preparation from Landfill Site

2.2. Methods of Analyzing Samples from Landfill Site

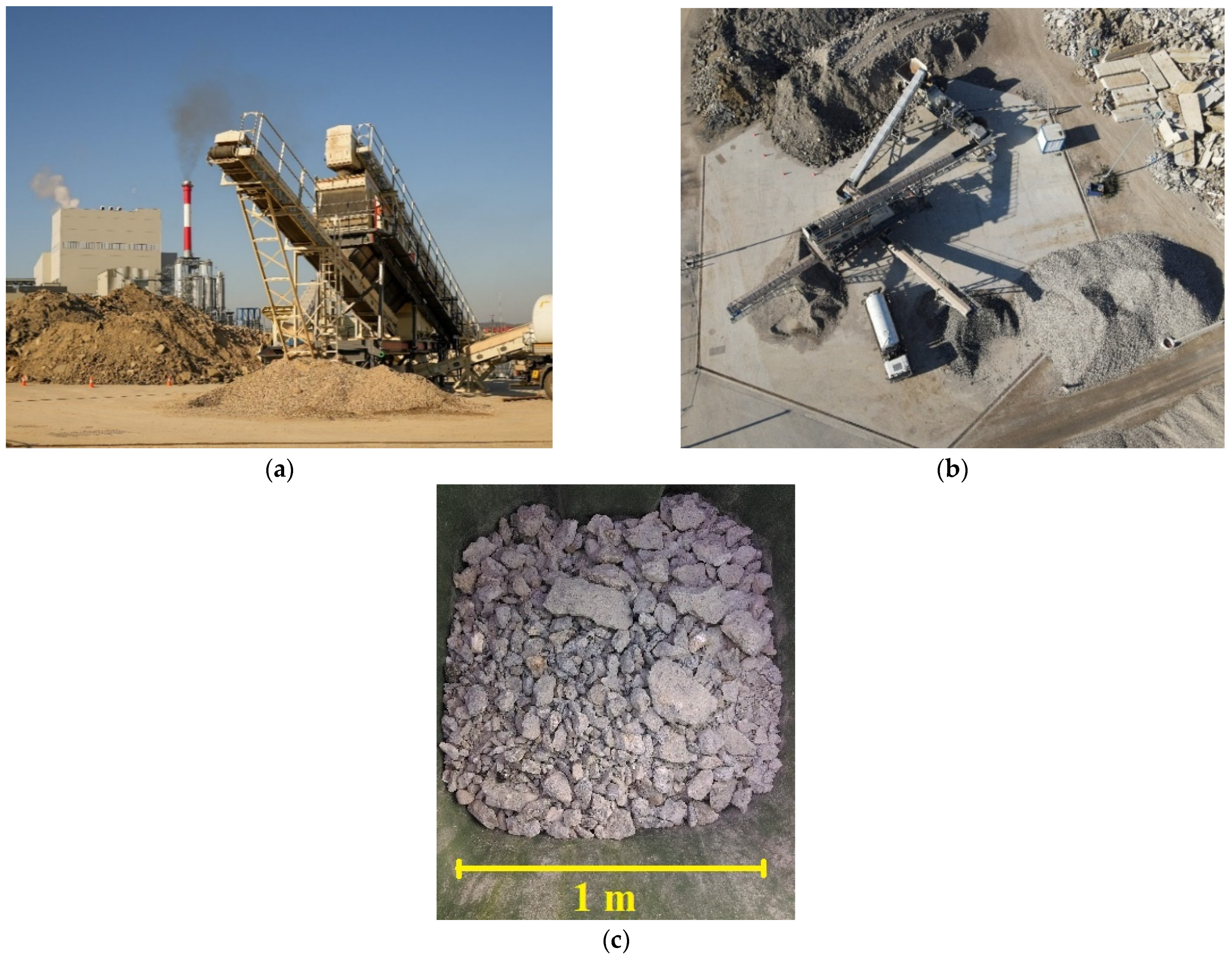

2.3. Methods of Preparation and Analyzing Samples from the New Recycling Facility

3. Results

4. Discussion

4.1. Characterization and Possible Utilization

4.2. Selling and Landscaping Benefits

4.3. Assessed Environmental and Economic Benefits from Energy Savings

5. Conclusions

- (1)

- Materials obtained by recycling the construction waste generated in the Belgrade area are in accordance with the aforementioned imposed propositions.

- (2)

- These materials can be used as a substitute of natural aggregates: as unbound bearing layers, as unbound wearing-out layers, and as sealing/strengthening aggregates, as well as cement-containing concrete mixtures.

- (3)

- There are significant selling and landscaping potential benefits from using the recycled CDW.

- (4)

- A notable environmental and economic benefit can be achieved by nearly EUR 0.5/t savings (and 23% less energy consumption) from recycled aggregate use instead of aggregate production from natural resources.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- SRCS Technical Conditions for Roads Construction (Official Documents of the Roads of Serbia Public Enterprise). Available online: https://www.putevi-srbije.rs/index.php/en/srcs-technical-conditions-for-roads-construction (accessed on 25 December 2023).

- Planning and Building Act, Official Herald of the Republic of Serbia: Nos. 72/2009, 81/2009-Correction, 64/2010-Decision of the CC, 24/2011, 121/2012, 42/2013-Decision of the CC, 50/2013-Decision of the CC, 98/2013-Decision of the CC, 132/2014, 145/2014, 83/2018, 31/2019, 37/2019-Other Act, 9/2020 and 52/2021. Available online: https://www.paragraf.rs/propisi/planning-and-building-act-serbia.html (accessed on 25 December 2023).

- Menegaki, M.E.; Kaliampakos, D.C. European aggregates production: Drivers, correlations and trends. Resour. Policy 2010, 35, 235–244. [Google Scholar] [CrossRef]

- Simić, V.; Životić, D.; Andrić, N.; Miladinović, Z. Sustainable aggregates planning in southeast europe—Why and how. In Proceedings of the 16th Geological Congress of Serbia, Donji Milanovac, Serbia, 22–25 May 2014; pp. 741–742. [Google Scholar]

- Simić, V.; Abramović, F.; Andrić, N.; Delić, I.; Miladinović, Z.; Životić, D. Need to Improve the Natural Aggregate Resources Supply in the City of Belgrade (Serbia). Acta Montan. Slovaca 2016, 21, 191–199. Available online: https://actamont.tuke.sk/pdf/2016/n3/3simic.pdf (accessed on 4 January 2024).

- Exploitation of Non-Energy Mineral Resources and Natura 2000, Internal Market, Industry, Entrepreneurship and SMEs. Available online: https://single-market-economy.ec.europa.eu/sectors/raw-materials/eip/raw-materials-commitment/sustainable-non-energy-mineral-extraction-activities-natura-2000-protected-sites_en (accessed on 25 December 2023).

- Elmqvist, T.; Setala, H.; Handel, S.N.; van der Ploeg, S.; Aronson, J.; Blignaut, J.N.; Gomez-Baggethun, E.; Nowak, D.J.; Kronenberg, J.; de Groot, R. Benefits of restoring ecosystem services in urban areas. Curr. Opin. Environ. Sustain. 2015, 14, 101–108. [Google Scholar] [CrossRef]

- Resource Efficient Use of Mixed Wastes Improving Management of Construction and Demolition Waste; Final Report, Deloitte. October 2017, p. 128. Available online: https://op.europa.eu/en/publication-detail/-/publication/78e42e6c-d8a6-11e7-a506-01aa75ed71a1/language-en (accessed on 25 December 2023).

- Colangelo, F.; Petrillo, A.; Farina, I. Comparative environmental evaluation of recycled aggregates from construction and demolition wastes in Italy. Sci. Total Environ. 2021, 798, 149250. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0048969721043230 (accessed on 4 January 2024). [CrossRef] [PubMed]

- Cardoso, R.; Silva, R.V.; de Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2016, 149, 131–145. [Google Scholar] [CrossRef] [PubMed]

- Pereira, P.M.; Vieira, C.S. A Literature Review on the Use of Recycled Construction and Demolition Materials in Unbound Pavement Applications. Sustainability 2022, 14, 13918. [Google Scholar] [CrossRef]

- Chalangaran, N.; Farzampour, A.; Paslar, N.; Fatemi, H. Experimental investigation of sound transmission loss in concrete containing recycled rubber crumbs. Adv. Concr. Constr. 2021, 11, 447–454. [Google Scholar] [CrossRef]

- Contreras, M.; Gázquez, M.J.; García-Díaz, I.; Alguacil, F.; López, F.A.; Bolívar, J.P. Valorisation of waste ilmenite mud in the manufacture of Sulphur Polymer Cement. J. Environ. Manag. 2013, 128, 625–630. [Google Scholar] [CrossRef]

- Contreras-Llanes, M.; Gázquez, M.J.; Romero, M. Eco-Friendly Pavements Manufactured from Mixed Recycled Aggregates Obtained from Construction and Demolition Waste: An Industrial-Scale Validation. Materials 2023, 16, 7544. [Google Scholar] [CrossRef] [PubMed]

- Braga, A.M.; Silvestre, J.D.; de Brito, J. Compared environmental and economic impact from cradle to gate of concrete with natural and recycled coarse aggregates. J. Clean. Prod. 2017, 162, 529–543. [Google Scholar] [CrossRef]

- Faleschini, F.; Zanini, M.A.; Pellegrino, C.; Pasinato, S. Sustainable management and supply of natural and recycled aggregates in a medium-size integrated plant. Waste Manag. 2016, 49, 146–155. [Google Scholar] [CrossRef]

- Kim, J.; Grabiec, A.M.; Ubysz, A. An Experimental Study on Structural Concrete Containing Recycled Aggregates and Powder from Construction and Demolition Waste. Materials 2022, 15, 2458. [Google Scholar] [CrossRef]

- Braga, M.; de Brito, J.; Veiga, R. Incorporation of fine concrete aggregates in mortars. Constr. Build. Mater. 2012, 36, 960–968. [Google Scholar] [CrossRef]

- Klang, A.; Vikman, P.-A.; Bratteba, H. Sustainable management of demolition waste-an integrated model for the evaluation of environmental, economic and social aspects. Resour. Conserv. Recycl. 2003, 38, 317–334. [Google Scholar] [CrossRef]

- Kashkash, S.; Czoboly, O.; Orban, Z. Effect of Moisture Condition and the Composition of Aggregate from Demolition Waste on Strength and Workability Properties of Recycled Concrete. Buildings 2023, 13, 1870. [Google Scholar] [CrossRef]

- Mulder, E.; De Jong, T.P.R.; Feenstra, L. Closed Cycle Construction: An integrated process for the separation and reuse of C&D waste. Waste Manag. 2007, 27, 1408–1415. [Google Scholar] [CrossRef] [PubMed]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef]

- Blengini, G.A.; Garbarino, E. Resources and waste management in Turin (Italy): The role of recycled aggregates in the sustainable supply mix. J. Clean. Prod. 2010, 18, 1021–1030. [Google Scholar] [CrossRef]

- Saiz Martínez, P.; Ferrández, D.; Melane-Lavado, A.; Zaragoza-Benzal, A. Characterization of Three Types of Recycled Aggregates from Different Construction and Demolition Waste: An Experimental Study for Waste Management. Int. J. Environ. Res. Public Health 2023, 20, 3709. [Google Scholar] [CrossRef]

- EU Construction and Demolition Waste Protocol and Guidelines, Internal Market, Industry, Entrepreneurship and SMEs. Available online: https://single-market-economy.ec.europa.eu/news/eu-construction-and-demolition-waste-protocol-2018-09-18_en (accessed on 25 December 2023).

- European Commission. Directive 2018/851 on Waste (Waste Framework Directive), Brussels, Belgium. 2018. Available online: https://eur-lex.europa.eu/legal-content/ES/TXT/?uri=celex%3A32008L0098 (accessed on 5 January 2024).

- Eurostat—Statistics Explained, Waste Statistics (Data Extracted in January 2023). Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics#Total_waste_generation (accessed on 29 January 2024).

- “Recovery Rate of Construction and Demolition Waste (CDW) in the European Union (EU-27) in 2018, by Country”, in: Statista. Available online: https://www.statista.com/statistics/1316268/recovery-rate-of-construction-and-demolition-waste-eu-by-country/#:~:text=The%20recovery%20rate%20of%20construction,recovery%20operations%20such%20as%20backfilling (accessed on 29 January 2024).

- UEPG—Annual Review 2020–2021, European Aggregates Association. Available online: https://www.aggregates-europe.eu/wp-content/uploads/2023/03/Final_-_UEPG-AR2020_2021-V05_spreads72dpiLowQReduced.pdf (accessed on 29 January 2024).

- Waste Management Act, Official Herald of the Republic of Serbia: Nos. 36/2009, 88/2010, 14/2016, 95/2018—Other Law, and 35/2023. Available online: https://aktivasistem.com/regulations/Waste-Management-Act.pdf (accessed on 5 January 2024).

- Local Waste Management Plan of the City of Belgrade 2022–2030, Službeni List Grada Beograda, 66/5, 31 January 2022. ISSN 0350-4727. Available online: https://www.sllistbeograd.rs/pdf/2022/05-2022.pdf#view=Fit&page=1 (accessed on 25 December 2023).

- Statistical Yearbook. Statistical Office of the Republic of Serbia. 2021. Available online: https://www.stat.gov.rs/en-us/publikacije/publication/?p=13253 (accessed on 29 January 2024).

- “Waste Management Program of the Republic of Serbia for the Period 2022–2031”. Official Gazette of the Republic of Serbia, 05/2022. Available online: https://www.ekologija.gov.rs/sites/default/files/2022-03/program_upravljanja_otpadom_eng_-_adopted_version.pdf (accessed on 27 January 2024).

- Wooden Market Forecast Q4/2023 with Q1/2024 outlook, KRONUS—Carrying Your Business (27 November 2023). Available online: https://www.kronus.eu/wooden-market-forecast-q4-2023-with-q1-2024-outlook/ (accessed on 25 December 2023).

- EN 12620:2002+A1:2008; Aggregates for Concrete. European Committee for Standardization, Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2008.

- EN 13242:2002+A1:2007; Aggregates for Unbound and Hydraulically Bound Materials for Use in Civil Engineering Work and Road Construction. European Committee for Standardization, Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2007.

- Available online: https://www.bcenergy.rs/ (accessed on 7 February 2024).

- EN 1097-2:2010; Tests for Mechanical and Physical Properties of Aggregates—Part 2: Methods for the Determination of Resistance to Fragmentation. European Committee for Standardization, Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2010.

- EN 1097-3:1998; Tests for Mechanical and Physical Properties of Aggregates—Part 3: Determination of Loose Bulk Density and Voids. European Committee for Standardization, Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 1998.

- EN 933-1:2012; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. European Committee for Standardization, Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2012.

- EN 1744-1:2009+A1:2012; Tests for Chemical Properties of Aggregates—Part 1: Chemical Analysis. European Committee for Standardization. Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2013.

- EN 1097-1:2011; Tests for Mechanical and Physical Properties of Aggregates—Part 1: Determination of the Resistance to Wear (Micro-Deval). European Committee for Standardization, Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2011.

- EN 1097-6:2013; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. European Committee for Standardization, Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2014.

- EN 933-3:2012; Tests for Geometrical Properties of Aggregates—Part 3: Determination of Particle Shape—Flakiness Index. European Committee for Standardization, Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2012.

- SRPS B.B8.019:1961; Crushing-Test of Concrete-Aggregates by Means of Treton-Apparatus. Institute for standardization of Serbia: Belgrade, Serbia, 1961.

- SRPS B.B8.044:1982; Natural and Crushed Stone Aggregate—Test for Freezing Resistance. Institute for standardization of Serbia: Belgrade, Serbia, 1982.

- SRPS B.B8.033:1994; Mineral Aggregate -Determination of Crushability by Compression in Cylinder. Institute for standardization of Serbia: Belgrade, Serbia, 1994.

- EN ISO 17892-1:2014; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 1: Determination of Water Content. European Committee for Standardization, Technical Committee CEN/TC 341 “Geotechnical Investigation and Testing”: Brussels, Belgium, 2015.

- EN ISO 17892-1:2016; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 4: Determination of Particle Size Distribution. European Committee for Standardization, Technical Committee CEN/TC 341 “Geotechnical Investigation and Testing”: Brussels, Belgium, 2017.

- SRPS U.B1.024:1968; Testing of Soils: Determination of the Combustible and Organic Matter Content of a Soil. Institute for standardization of Serbia: Belgrade, Serbia, 1968.

- EN 13286-2:2010; Unbound and Hydraulically Bound Mixtures—Part 2: Test Methods for Laboratory Reference Density and Water Content—Proctor Compaction. European Committee for Standardization, Technical Committee CEN/TC 227 “Road materials”: Brussels, Belgium, 2011.

- EN 13286-47:2012; Unbound and Hydraulically Bound Mixtures—Part 47: Test Method for the Determination of California Bearing Ratio, Immediate Bearing Index and Linear Swelling. European Committee for Standardization, Technical Committee CEN/TC 227 “Road materials”: Brussels, Belgium, 2012.

- EN ISO 14688-2:2018; Geotechnical Investigation and Testing—Identification and Classification of Soil—Part 2: Principles for a Classification. European Committee for Standardization, Technical Committee CEN/TC 341 “Geotechnical Investigation and Testing”: Brussels, Belgium, 2018.

- SRPS U.B1.001:1990; General Classification of Soils for Engineering Purposes. Institute for standardization of Serbia: Belgrade, Serbia, 1990.

- Chen, X.; Capiau, L.; Reynaert, I.; Zheng, K.; Gruyaert, E.; Li, J. Comparative study on modelling concrete properties using physical and mechanical properties of recycled coarse aggregate. Constr. Build. Mater. 2022, 345, 128249. [Google Scholar] [CrossRef]

- Dhir, R.K.; De Brito, J.; Silva, R.V.; Lye, C.Q. Sustainable Construction Materials: Recycled Aggregates; Woodhead Publishing: Sawston, UK, 2019. [Google Scholar] [CrossRef]

- EN 206-1:2000; Concrete—Part 1: Specification, Performance, Production and Conformity. European Committee for Standardization, Technical Committee CEN/TC 104 “Concrete and Related Products”: Brussels, Belgium, 2001.

- Djokic, O.; Milicevic, V. Main technical characteristics of rocks used in road construction in Serbia. Bull. Eng. Geol. Environ. 2013, 72, 137–141. [Google Scholar] [CrossRef]

- Venkrbec, V.; Nováková, I.; Henková, S. Characteristics of Recycled Concrete Aggregates from Precast Slab Block Buildings. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 032076. [Google Scholar] [CrossRef]

- Ulsen, C.; Tseng, E.; Cirelli Angulo, S.; Landmann, M.; Contessotto, R.; Tadeu Balbo, J.; Kahn, H. Concrete aggregates properties crushed by jaw and impact secondary crushing. J. Mater. Res. Technol. 2018, 8, 494–502. [Google Scholar] [CrossRef]

- Basilico, V.; Quattrone, M. Recycled Aggregate Production: Remark and Assessment of the Economical Advantage of a Case Study. In Portugal SB07: Sustainable Construction-Materials and Practices (Challenge of the Industry for the New Millenium); Braganca, L., Pinheiro, M., Jalali, S., Mateus, R., Amoeda, R., Correia Guedes, M., Eds.; IOS Press: Amsterdam, The Nederland, 2007; (incorporated); pp. 795–802. ISBN 9781607502746/9781586037857. Available online: https://www.irbnet.de/daten/iconda/CIB11758.pdf (accessed on 25 December 2023).

- Sterk, E. Willingness to Pay for Recycled Aggregates in Concrete among German Construction Clients, MAGKS Joint Discussion Paper Series in Economics, No. 11-2023. Available online: https://www.econstor.eu/bitstream/10419/278495/1/184611022X.pdf (accessed on 25 December 2023).

- Bressi, G.; Volpe, G.; Pavesi, E. La produzione di aggregati riciclati da rifiuti inerti. I manuali di SARMa. In The Production of Recycled Aggregates from Inert Waste. The Manuals of SARMa; Centro Stampa Regione Emilia-Romagna: Bologna, Italy, 2011; Available online: http://www.sarmaproject.eu/index.php?id=1964 (accessed on 29 January 2024).

- Statistical Yearbook. Statistical Office of the Republic of Serbia. 2023. Available online: https://www.stat.gov.rs/en-us/publikacije/publication/?p=15431 (accessed on 31 January 2024).

- Hammond, G.P.; Jones, C.I. Embodied energy and carbon in construction materials. Proc. Inst. Civil Eng. 2008, 161, 87–98. [Google Scholar] [CrossRef]

- Pratt, K.; Lenaghan, M. The Carbon Impacts of the Circular Economy, Summary Report, June 2015. Available online: https://consult.gov.scot/zero-waste-delivery/making-things-last/supporting_documents/CIoCE%20Summary%20Report%20%20FINAL%20%2015.06.15.pdf (accessed on 1 January 2024).

| Sieve (mm) | Sample No. | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Cumulative Passing (%) | |||||

| 120 | 100 | 100 | 100 | 100 | 100 |

| 90 | 100 | 100 | 100 | 100 | 100 |

| 63 | 80 | 95 | 90 | 93 | 93 |

| 31.5 | 58 | 78 | 69 | 66 | 64 |

| 16 | 43 | 51 | 57 | 49 | 42 |

| 8 | 27 | 29 | 41 | 32 | 19 |

| 4 | 16 | 16 | 26 | 18 | 9 |

| 2 | 10 | 10 | 19 | 11 | 6 |

| 1 | 7 | 6 | 12 | 6 | 4 |

| 0.5 | 5 | 5 | 9 | 4 | 3 |

| 0.25 | 3 | 3 | 6 | 2 | 2 |

| 0.125 | 3 | 3 | 4 | 2 | 1 |

| 0.063 | 2.2 | 2.3 | 3.7 | 1.2 | 0.8 |

| Property | Sample No. | Mean Value | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||||

| ρb (Mg/m3) | 1.50 | 1.50 | 1.56 | 1.45 | 1.38 | 1.48 | ||

| ρa | (Mg/m3) | 4/8 | 2.63 | / | / | / | 2.64 | 2.64 |

| ρrd | 2.33 | / | / | / | 2.33 | 2.33 | ||

| ρssd | 2.45 | / | / | / | 2.44 | 2.45 | ||

| ρa | 8/16 | 2.59 | / | / | / | 2.62 | 2.61 | |

| ρrd | 2.33 | / | / | / | 2.34 | 2.34 | ||

| ρssd | 2.43 | / | / | / | 2.45 | 2.44 | ||

| ρa | 16/32 | 2.53 | / | / | / | 2.64 | 2.59 | |

| ρrd | 2.32 | / | / | / | 2.33 | 2.33 | ||

| ρssd | 2.40 | / | / | / | 2.44 | 2.42 | ||

| WA24 (%) | 4/8 | 4.81 | 4.80 | 4.81 | 4.81 | 5.12 | 4.87 | |

| 8/16 | 4.18 | 4.17 | 4.18 | 4.18 | 4.69 | 4.28 | ||

| 16/32 | 3.51 | 3.50 | 3.51 | 3.51 | 5.05 | 3.81 | ||

| FI (%) | 16 | 13 | 11 | 14 | 9 | 13 | ||

| OM (%) | / | / | / | / | / | / | ||

| FR (% loss of mass) | 9.5 | 9.0 | 14.8 | 10.1 | 11.1 | 10.9 | ||

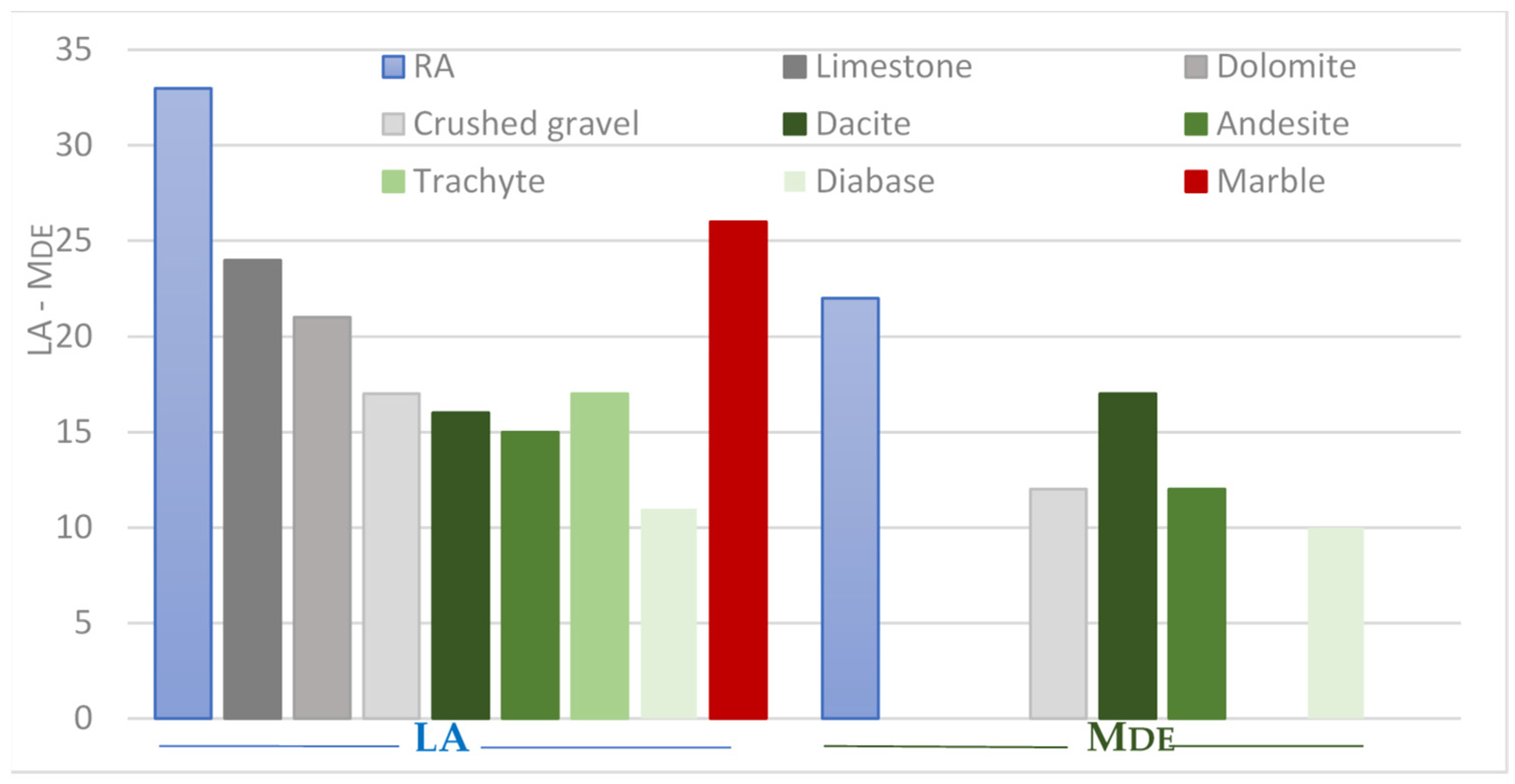

| LA | 34 | 31 | 31 | 34 | 34 | 33 | ||

| MDE | 23 | 23 | 25 | 21 | 19 | 22 | ||

| T (%) | 22.65 | 21.03 | 22.04 | 26.38 | 23.58 | 23.14 | ||

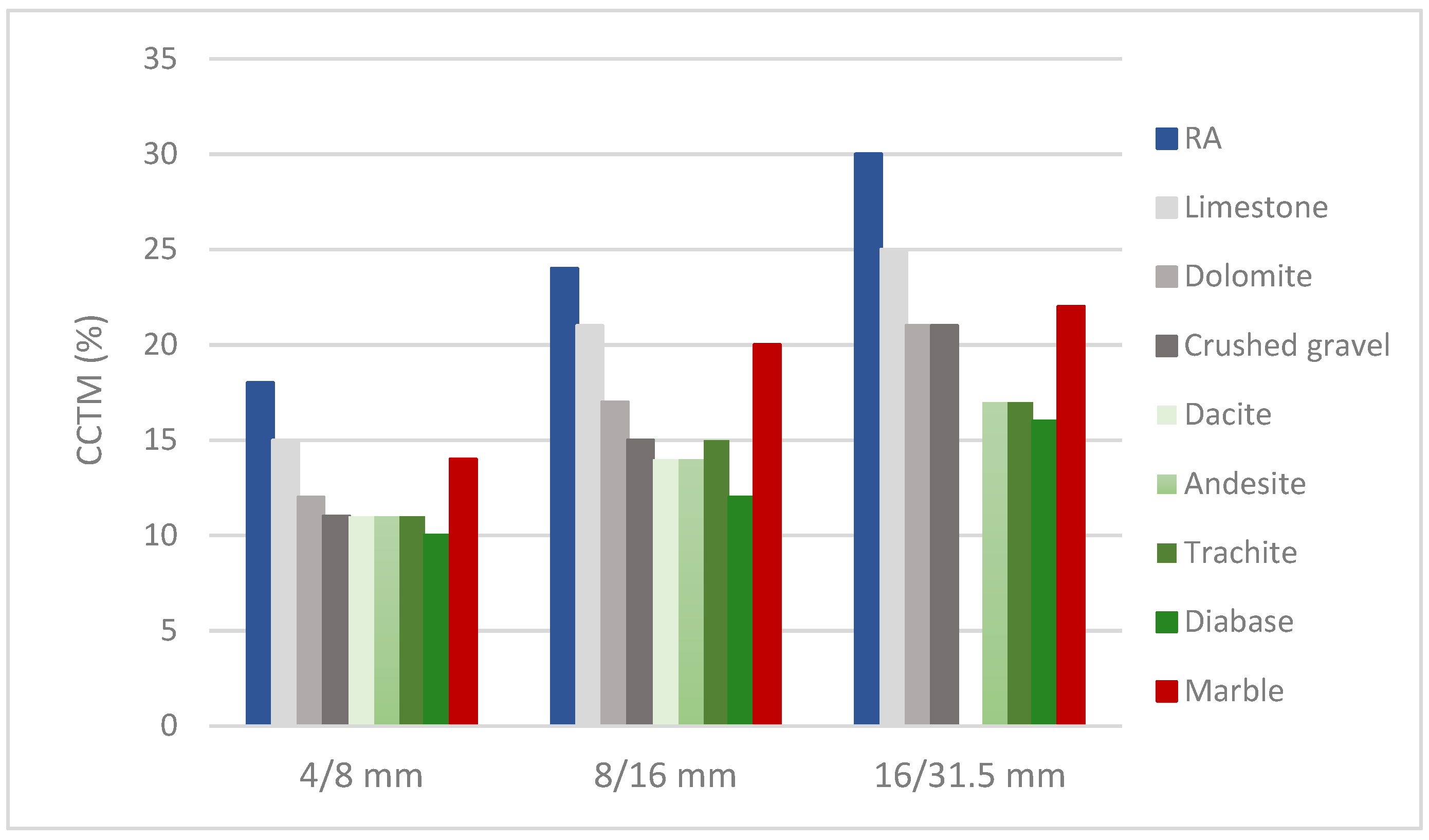

| CCTM (%) | 4/8 | 18.25 | 19.24 | 20.81 | 17.41 | 16.64 | 18.47 | |

| 8/16 | 26.32 | 24.54 | 25.65 | 23.12 | 21.86 | 24.29 | ||

| 16/32 | 30.17 | 29.12 | 30.91 | 28.75 | 30.54 | 29.89 | ||

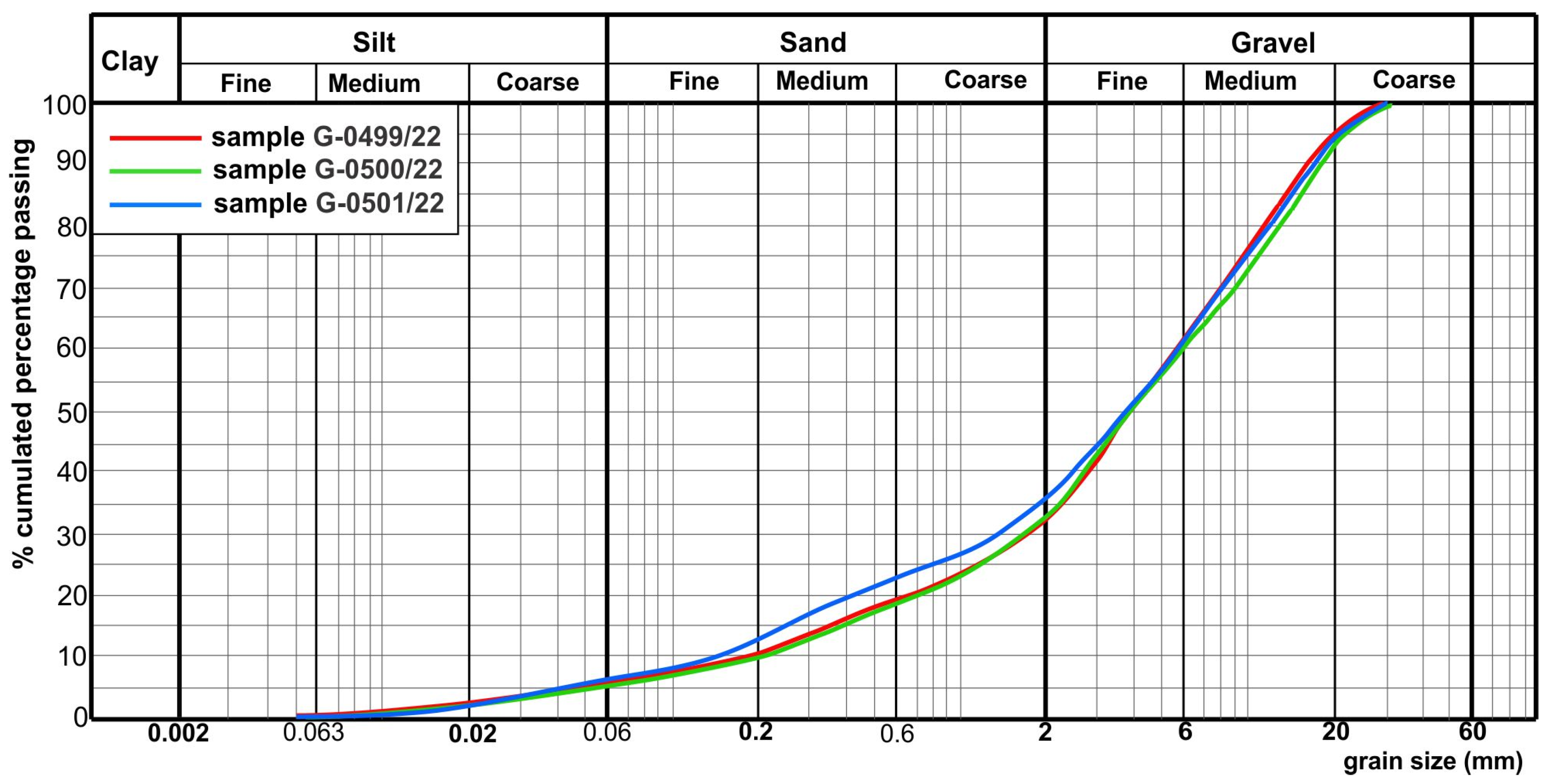

| Soil Samples Data | Fraction (%) | Examinations | Classification EN ISO 14688-2:2018 [53] | General Classification SRPS U.B1.001 [54] | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CDW Sample No. | Sample Code | Sample Class (1–6) | Granulation/mm | Moisture, w (%) | % of Grains <0.063 mm | d10 | d30 | d60 | |||||||

| Clay <0.002 | Silt 0.002–0.06 | Sand 0.06–2.00 | Gravel 2.00–64.0 | ||||||||||||

| 1 | G-0499/22 | 3 | 1 | 5 | 26 | 68 | 5.8 | 6.0 | 0.19 | 1.75 | 5.60 | 29.47 | 2.88 | GW-GM | sacIGrW |

| 2 | G-0500/22 | 3 | 1 | 4 | 28 | 67 | 5.2 | 5.1 | 0.21 | 1.71 | 5.99 | 28.52 | 2.32 | ||

| 3 | G-0501/22 | 3 | 1 | 6 | 29 | 64 | 5.8 | 6.8 | 0.13 | 1.31 | 5.51 | 42.38 | 2.40 | ||

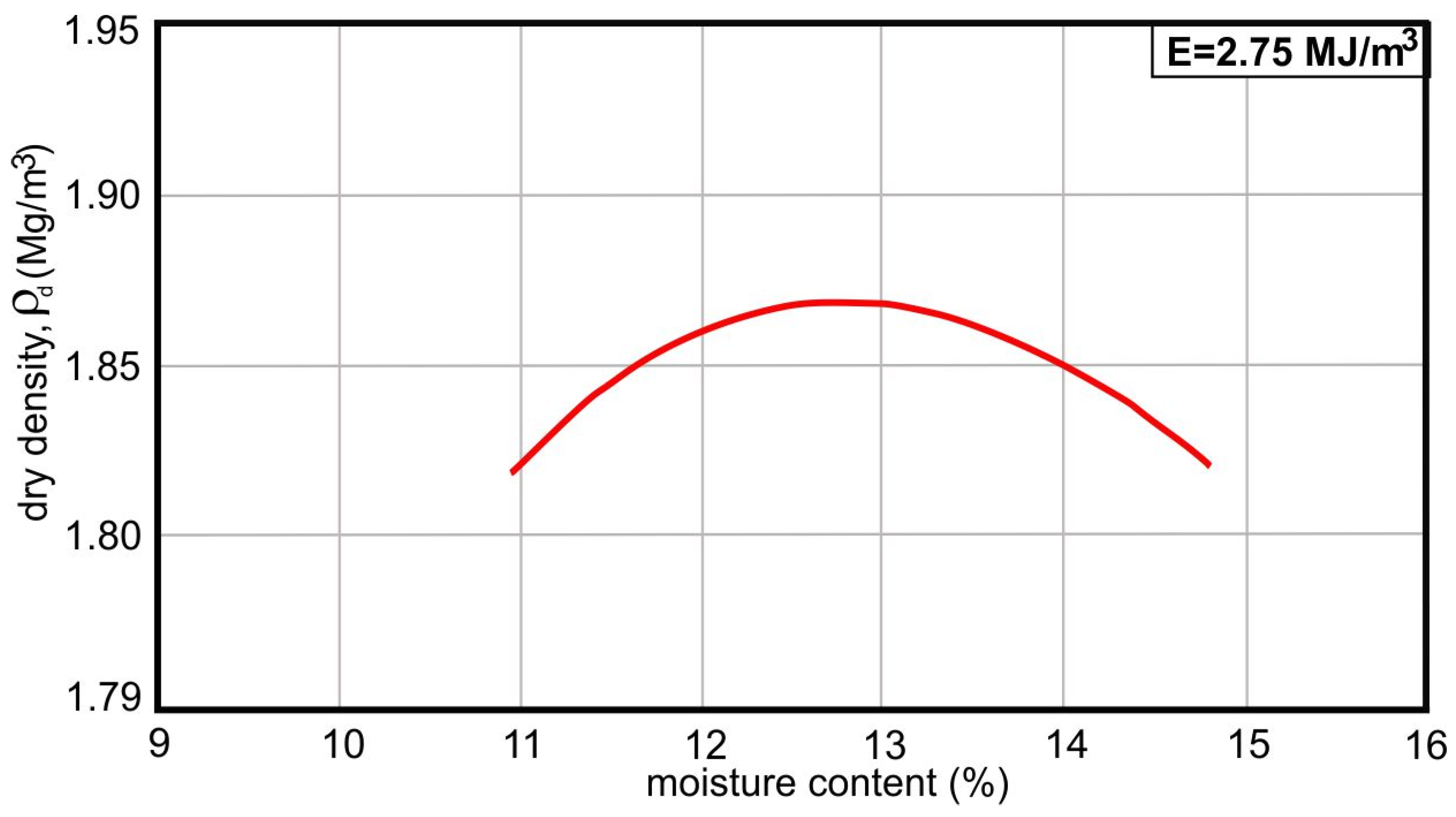

| CDW Sample No. | Dry Volumetric Mass (t/m3) | Moisture Content during Preparation (%) | Burnable Matter (%) | Organic Matter (%) | Proctor Test | CBR (%) | ||

|---|---|---|---|---|---|---|---|---|

| Dry Density, ρd (Mg/m3) | Dry Unit Weight, γd (kN/m3) | Optimal Moisture Content, w (%) | ||||||

| 3 | 1.861 | 12.3 | 7.6 | 1.7 | 1.87 | 18.33 | 12.8 | 111 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abramović, F.; Popović, M.P.; Simić, V.; Matović, V.; Šerović, R. Characterization and Environmental Evaluation of Recycled Aggregates from Construction and Demolition Waste in Belgrade City Area (Serbia). Materials 2024, 17, 820. https://doi.org/10.3390/ma17040820

Abramović F, Popović MP, Simić V, Matović V, Šerović R. Characterization and Environmental Evaluation of Recycled Aggregates from Construction and Demolition Waste in Belgrade City Area (Serbia). Materials. 2024; 17(4):820. https://doi.org/10.3390/ma17040820

Chicago/Turabian StyleAbramović, Filip, Miroslav P. Popović, Vladimir Simić, Vesna Matović, and Radmila Šerović. 2024. "Characterization and Environmental Evaluation of Recycled Aggregates from Construction and Demolition Waste in Belgrade City Area (Serbia)" Materials 17, no. 4: 820. https://doi.org/10.3390/ma17040820

APA StyleAbramović, F., Popović, M. P., Simić, V., Matović, V., & Šerović, R. (2024). Characterization and Environmental Evaluation of Recycled Aggregates from Construction and Demolition Waste in Belgrade City Area (Serbia). Materials, 17(4), 820. https://doi.org/10.3390/ma17040820