Polishing Mechanism of CMP 4H-SiC Crystal Substrate (0001) Si Surface Based on an Alumina (Al2O3) Abrasive

Abstract

1. Introduction

2. Materials and Methods

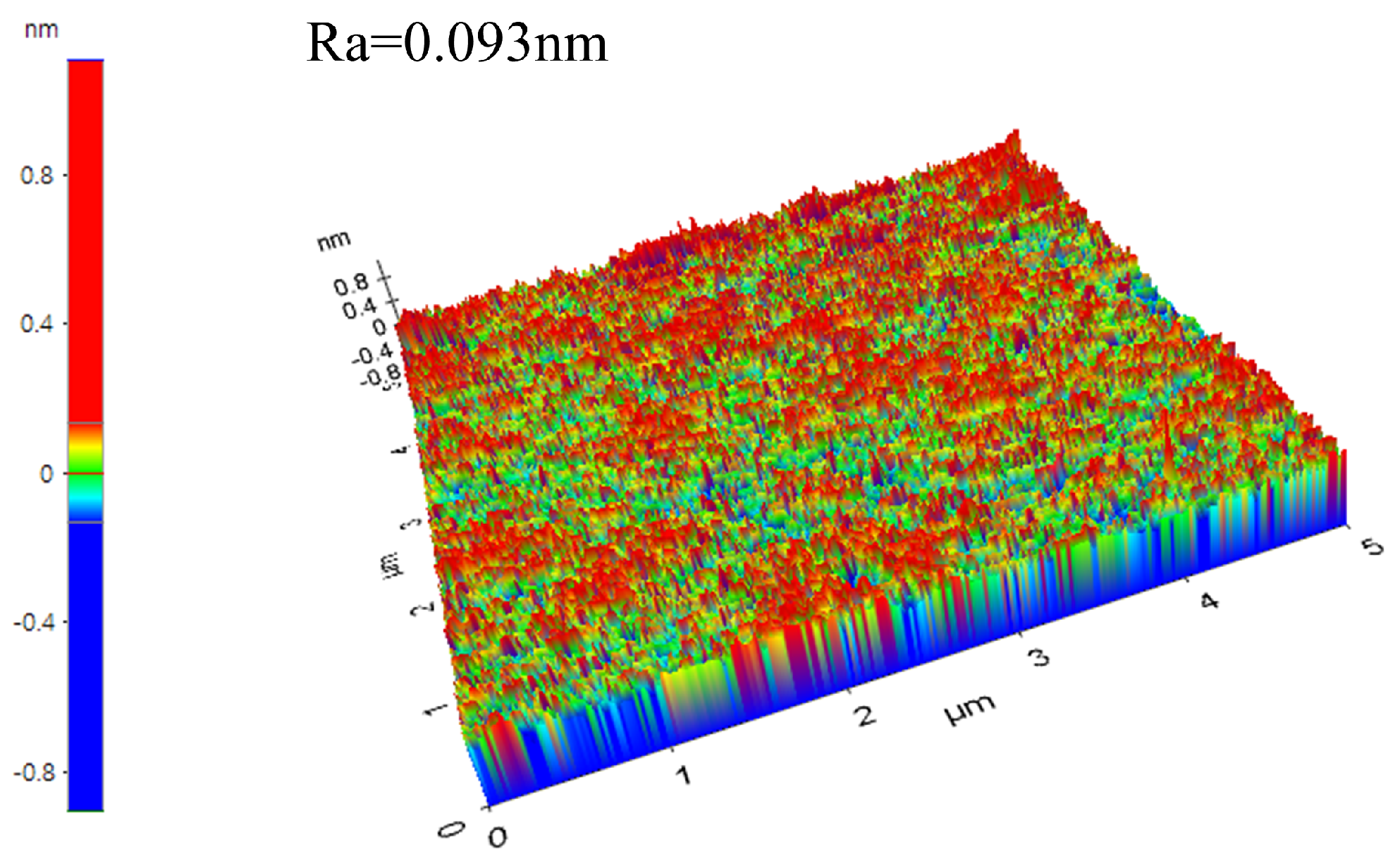

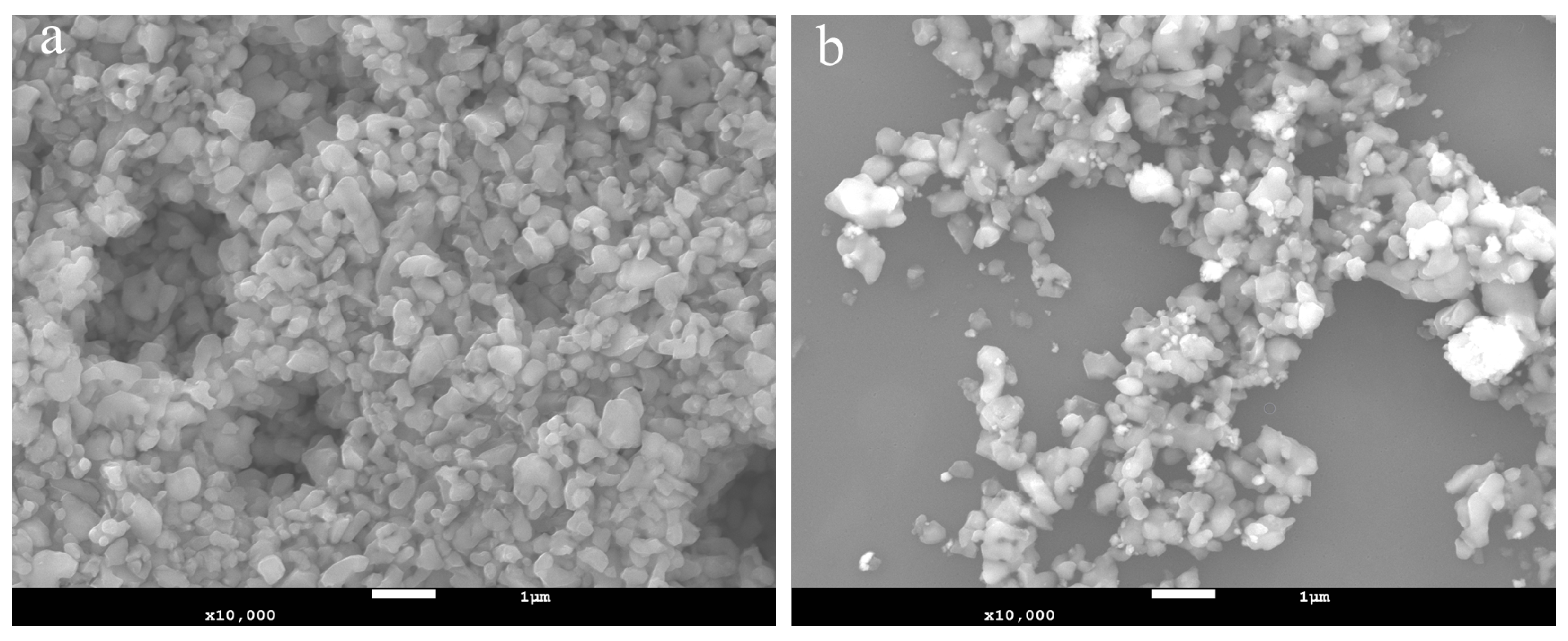

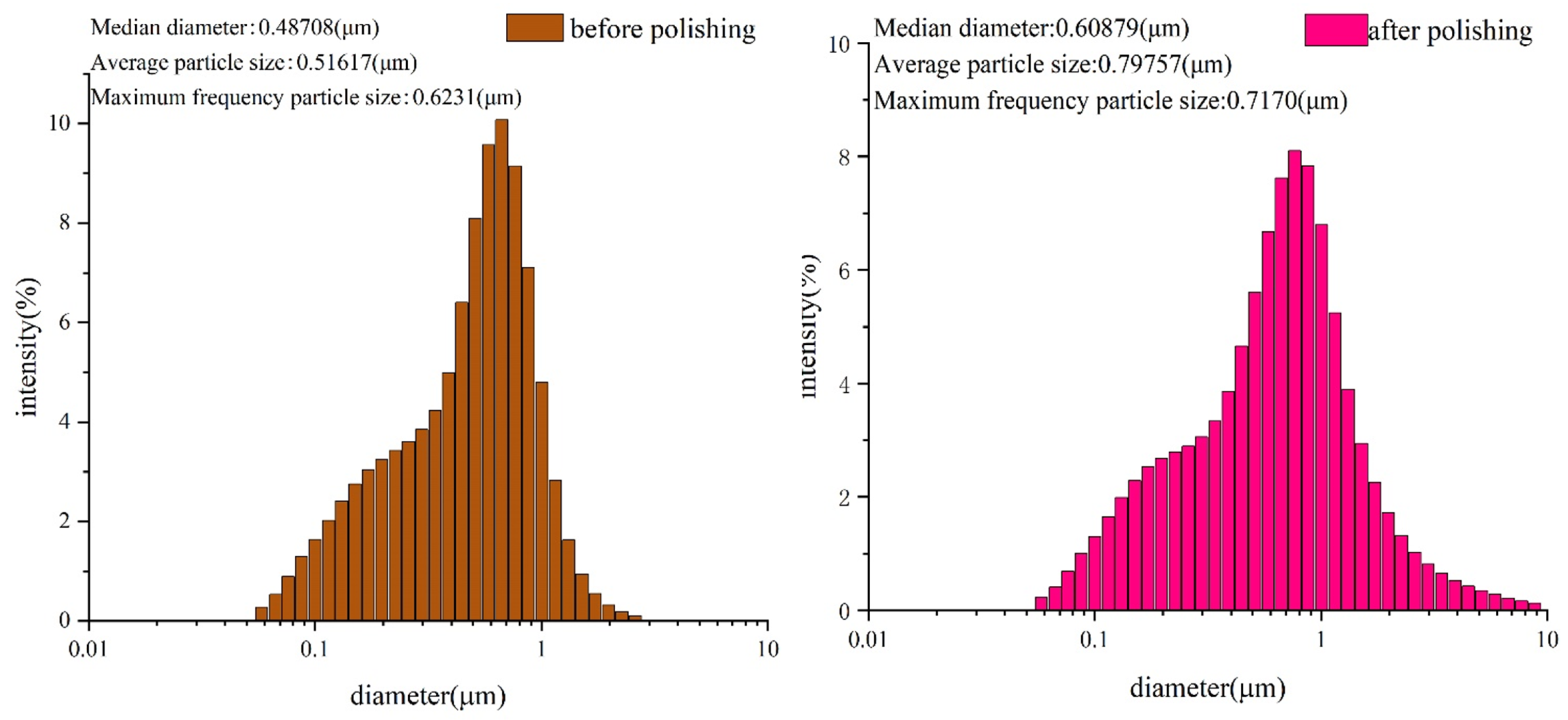

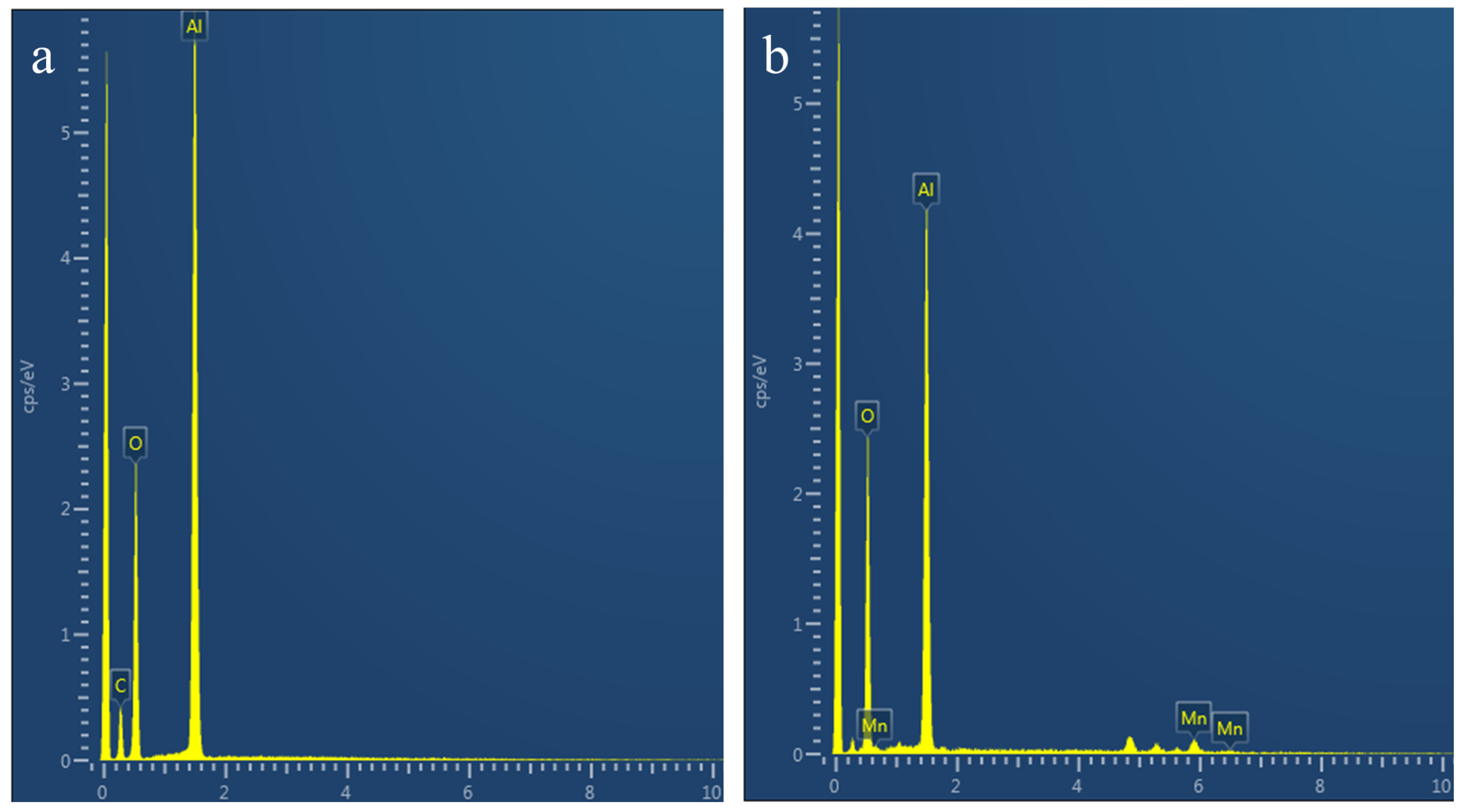

3. Results and Discussion

3.1. Orthogonal Design Experiment

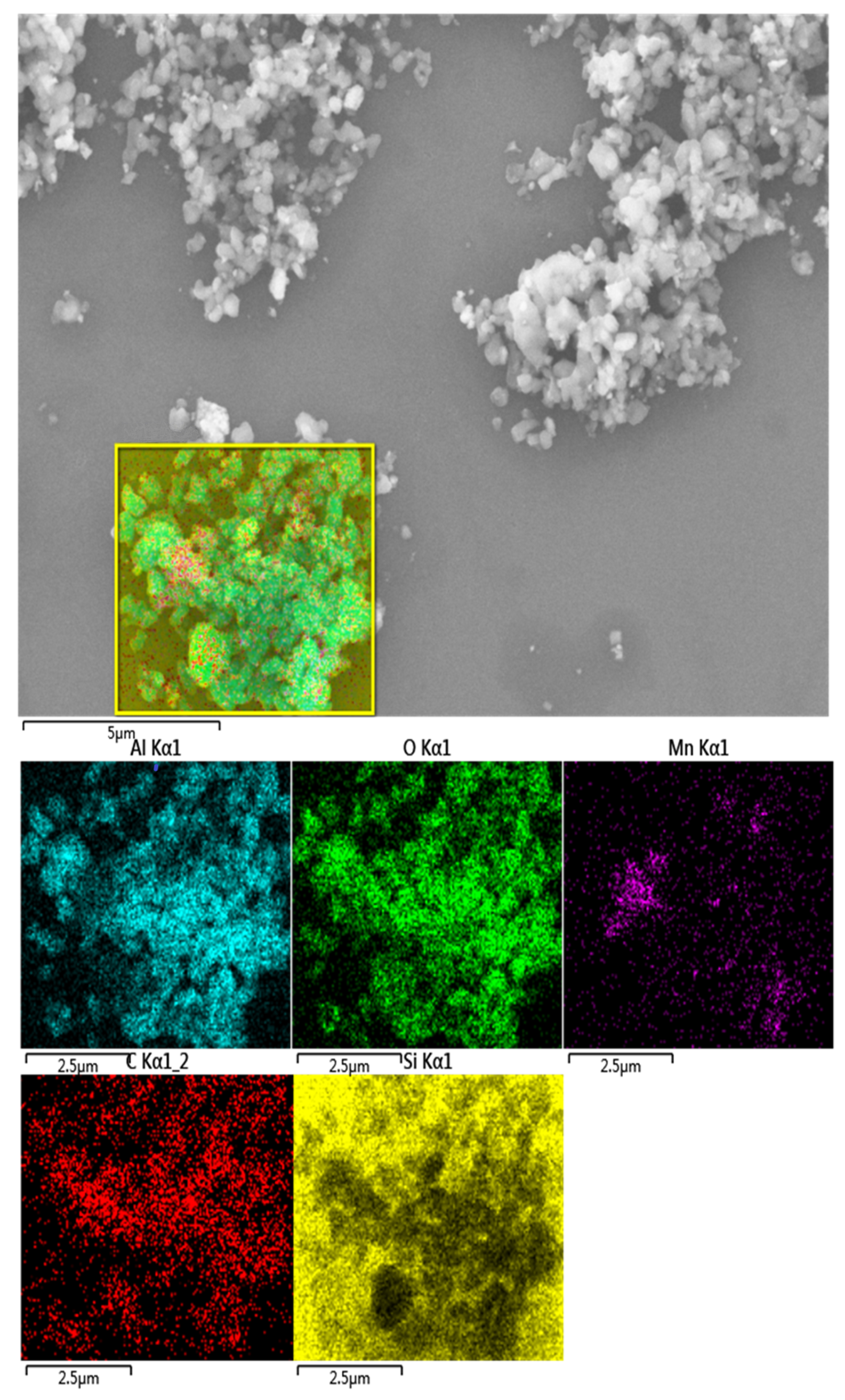

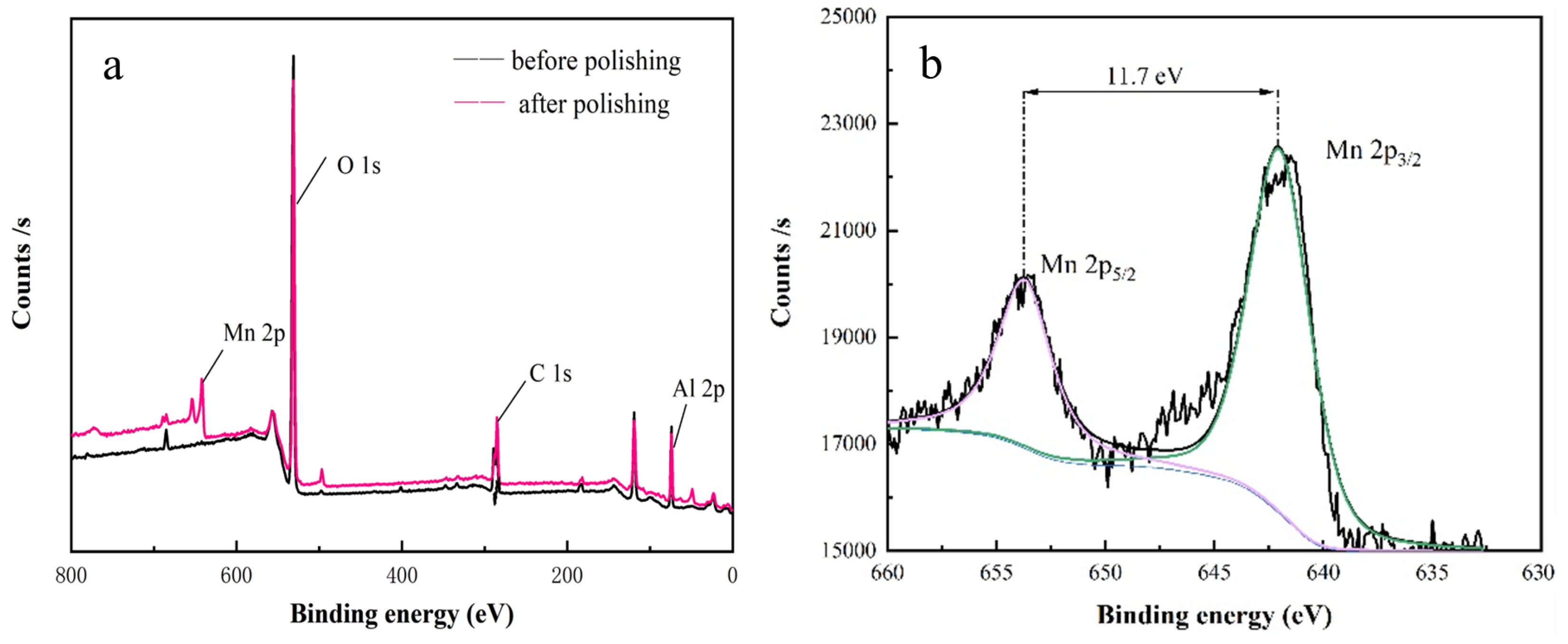

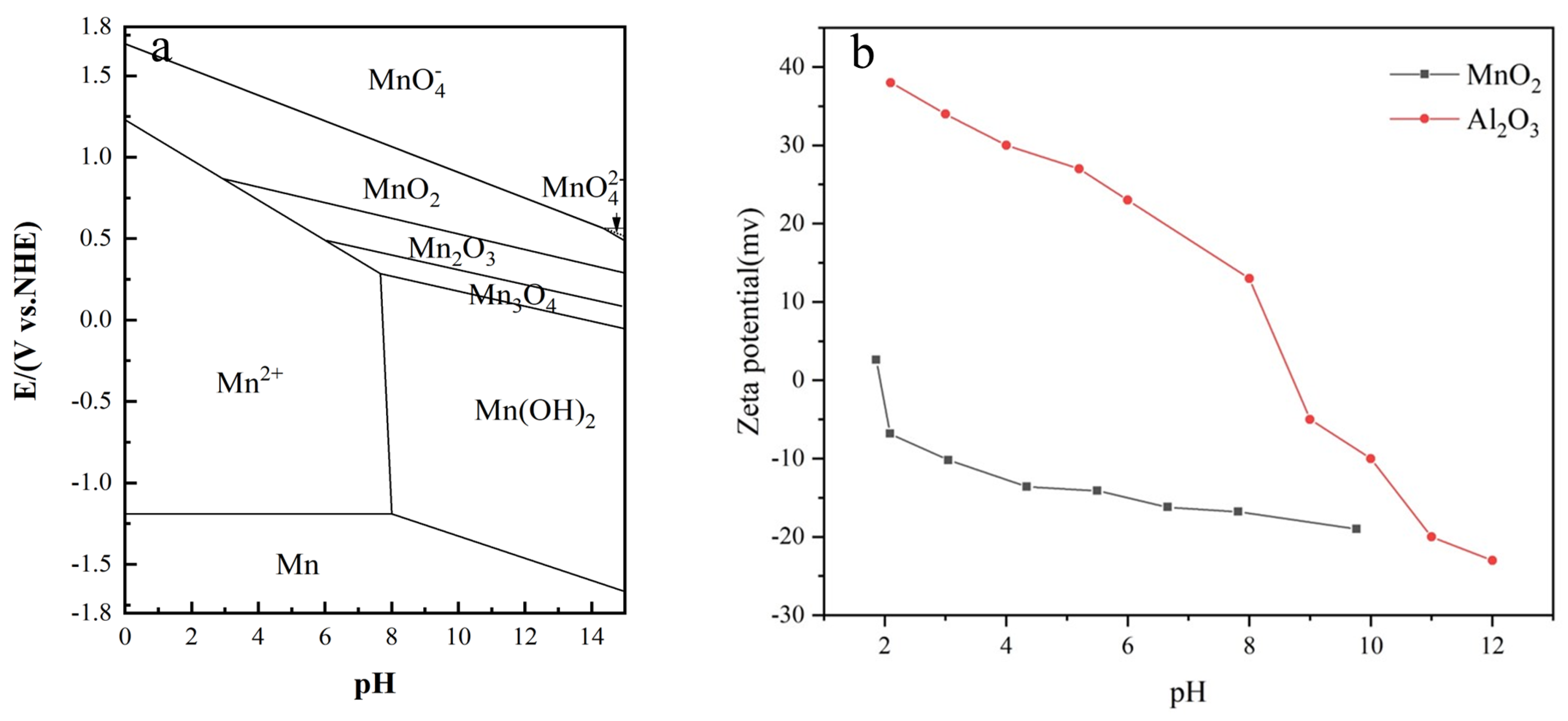

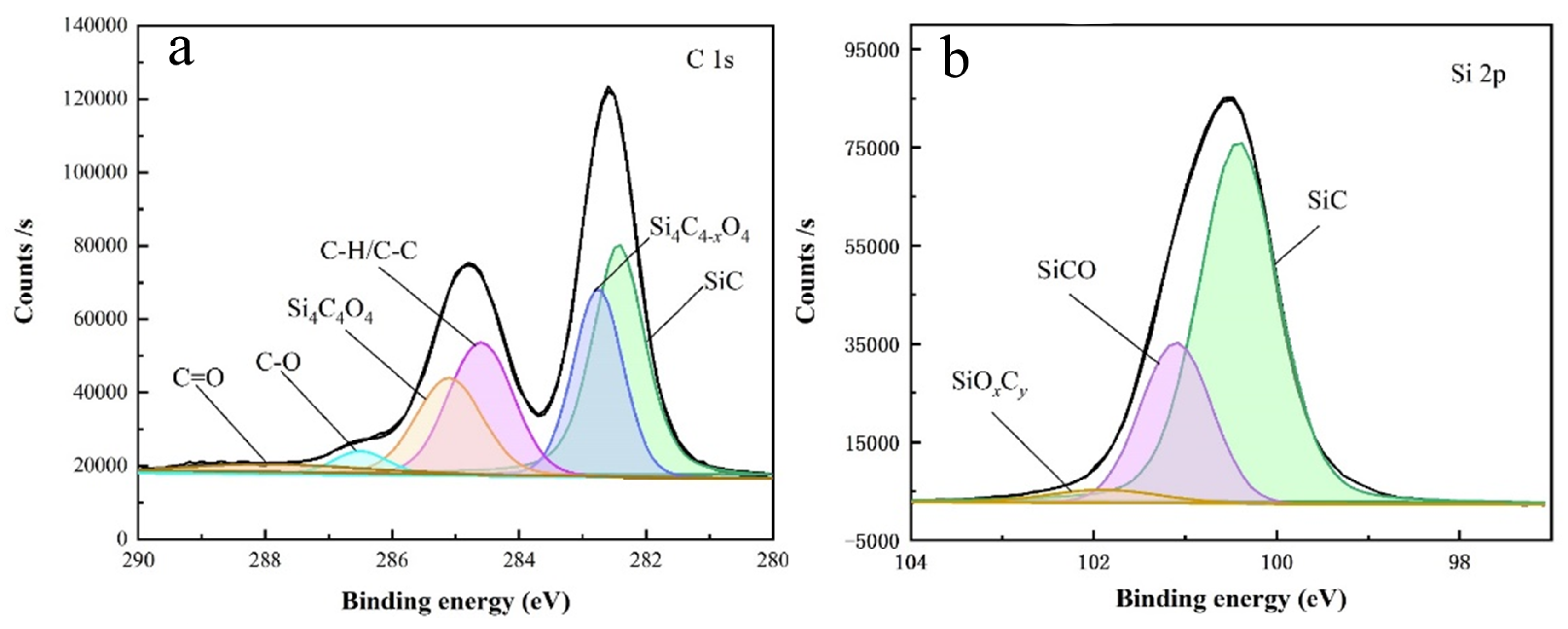

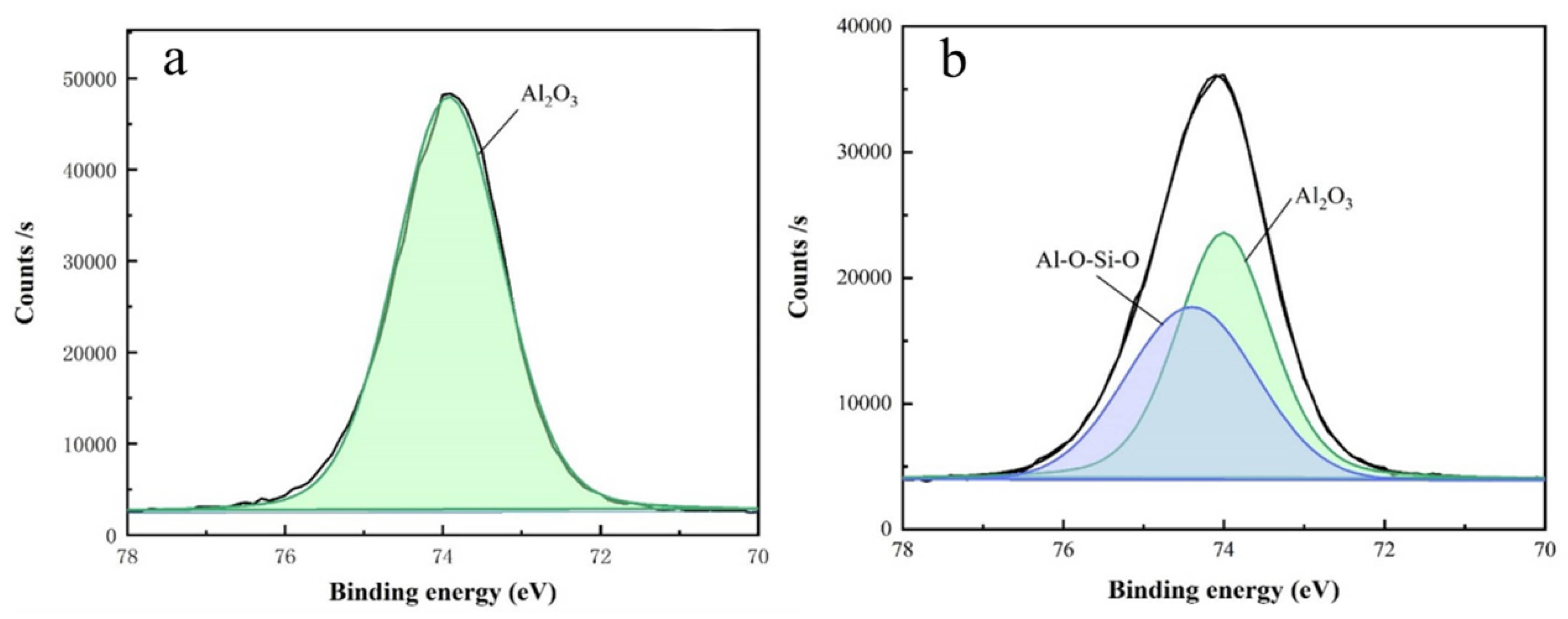

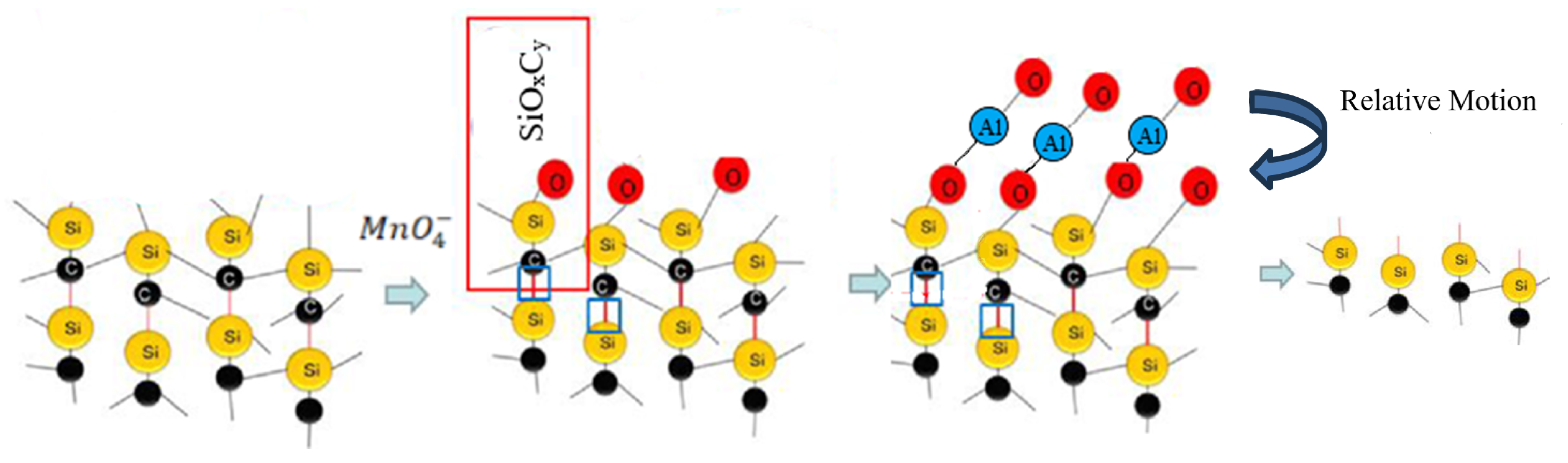

3.2. Analysis of Polishing Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rafin, S.M.S.H.; Ahmed, R.; Haque, M.A.; Hossain, M.K.; Haque, M.A.; Mohammed, O.A. Power Electronics Revolutionized: A Comprehensive Analysis of Emerging Wide and Ultrawide Bandgap Devices. Micromachines 2023, 14, 2045. [Google Scholar] [CrossRef]

- Motohiro, I. Silicon carbide: Fundamentals. Nucl. Instrum. Methods Phys. Res. Sect. A 2001, 466, 406–411. [Google Scholar] [CrossRef]

- Chaudhary, O.S.; Denaï, M.; Refaat, S.S.; Pissanidis, G. Technology and Applications of Wide Bandgap Semiconductor Materials: Current State and Future Trends. Energies 2023, 16, 6689. [Google Scholar] [CrossRef]

- Ranjbar, A. Applications of Wide Bandgap (WBG) Devices in the Transportation Sector. Recent Advances in (WBG) Semiconductor Material (e.g., SiC and GaN) and Circuit Topologies. In Transportation Electrification: Breakthroughs in Electrified Vehicles, Aircraft, Rolling Stock, and Watercraft; Mohamed, A.A., Khan, A.A., Elsayed, A.T., Elshaer, M.A., Eds.; IEEE: Piscataway, NJ, USA, 2022; pp. 47–72. [Google Scholar]

- Lee, H.; Kim, H.; Jeong, H. Approaches to Sustainability in Chemical Mechanical Polishing (CMP): A Review. Int. J. Precis. Eng. Manuf.-Green Technol. 2022, 9, 349–367. [Google Scholar] [CrossRef]

- Akbar, W.; Ertunç, Ö. A Coupled Material Removal Model for Chemical Mechanical Polishing Processes. ECS J. Solid State Sci. 2021, 10, 104003. [Google Scholar] [CrossRef]

- Aida, H.; Doi, T.; Takeda, H.; Katakura, H.; Kim, S.W.; Koyama, K.; Yamazaki, T.; Uneda, M. Ultraprecision CMP for sap phire, GaN, and SiC for advanced optoelectronics materials. Curr. Appl. Phys. 2012, 12, 41–46. [Google Scholar] [CrossRef]

- Lagudu, U.R.K.; Isono, S.; Krishnan, S.; Babu, S.V. Role of ionic strength in chemical mechanical polishing of silicon carbide using silica slurries. Colloids Surf. A Physicochem. Eng. Asp. 2014, 445, 119–127. [Google Scholar] [CrossRef]

- Pan, G.; Zhou, Y.; Luo, G.; Shi, X.; Zou, C.; Gong, H. Chemical mechanical polishing (CMP) of on-axis Si-face 6H-SiC wafer for obtaining atomically flat defect-free surface. J. Mater. Sci. Mater. Electron. 2013, 24, 5040–5047. [Google Scholar] [CrossRef]

- Heydemann, V.; Everson, W.J.; Gamble, R.D.; Snyder, D.W.; Skowronski, M. Chemi-Mechanical Polishing of On-Axis Semi-Insulating SiC Substrates. Mater. Sci. Forum 2004, 457, 805–808. [Google Scholar] [CrossRef]

- Su, J.X.; Du, J.X.; Liu, H.N.; Liu, X.L. Research on Material Removal Rate of CMP 6H-SiC Crystal Substrate (0001) Si Surface Based on Abrasive Alumina (Al2O3). Procedia Eng. 2011, 24, 441–446. [Google Scholar] [CrossRef]

- Chen, G.P.; Li, J.G.; Long, J.Y.; Luo, H.M.; Zhou, Y.; Xie, X.Z.; Pan, G.S. Surface modulation to enhance chemical mechanical polishing performance of sliced silicon carbide Si-face. Appl. Surf. Sci. 2021, 536, 147963. [Google Scholar] [CrossRef]

- Wang, W.T.; Zhang, B.G.; Shi, Y.H.; Zhou, J.K.; Wang, R.; Zeng, N.Y. Improved chemical mechanical polishing performance in 4H-SiC substrate by combining novel mixed abrasive slurry and photocatalytic effect. Appl. Surf. Sci. 2022, 575, 151676. [Google Scholar] [CrossRef]

- Poltavets, V.; Krawczyk, M.; Maslak, G.; Abraimova, O.; Jönsson-Niedziółka, M. Formation of MnO2-coated ITO electrodes with high catalytic activity for enzymatic glucose detection. Dalton Trans. 2023, 52, 13769–13780. [Google Scholar] [CrossRef] [PubMed]

- Keal, M.E.; Courtney, J.M.; Rees, N.V. Redox Electrochemistry of Mn(II) via Carbon Black Nanoparticle Impacts. J. Phys. Chem. C 2023, 127, 13380–13388. [Google Scholar] [CrossRef]

- Kurokawa, S.; Doi, T.; Ohnishi, O.; Yamazaki, T.; Tan, Z.; Yin, T. Characteristics in SiC-CMP using MnO2 slurry with Strong Oxidant under Different Atmospheric Conditions. MRS Online Proc. Libr. 2013, 1560, 301. [Google Scholar] [CrossRef]

- Wang, W.T.; Zhang, B.G.; Shi, Y.H.; Ma, T.D.; Zhou, J.K.; Wang, R.; Wang, H.X.; Zeng, N.Y. Improvement in chemical mechanical polishing of 4H-SiC wafer by activating persulfate through the synergistic effect of UV and TiO2. J. Mater. Process. Technol. 2021, 295, 117150. [Google Scholar] [CrossRef]

- Lagudu, U.R.K. Advances in Chemical Mechanical Planarization (CMP), 2nd ed.; Woodhead Publishing: Cambridge, UK, 2022; pp. 175–194. [Google Scholar]

- Hometz, B.; Michel, H.-J.; Halbritter, J. ARXPS studies of SiO2-SiC interfaces and oxidation of 6H SiC single crystal Si-(001) and C-(00) surfaces. J. Mater. Process. Technol. 1994, 9, 3088–3094. [Google Scholar] [CrossRef]

- Rowson, D.M.; Quinn, T.F.J. Frictional heating and the oxidational theory of wear. J. Phys. D Appl. Phys 1980, 13, 209. [Google Scholar] [CrossRef]

- Quinn, T.F.J.; Winer, W.O. The Thermal Aspects of Oxidational Wear. Wear 1985, 102, 67–68. [Google Scholar] [CrossRef]

- Bowden, F.P.; Ridler, K.E.W. Physical properties of surfaces-III—The surface temperature of sliding metals-The temperature of lubricated surfaces. Proc. R. Soc. Lond. A 1936, 154, 640–656. [Google Scholar] [CrossRef]

| Items | Value |

|---|---|

| Wafer | 2-inch 4H-SiC |

| Polishing machine | Bruker CP-4 |

| Polishing pad | Suba 800 |

| Load (psi) | 4 |

| Polishing head rotation speed (r/min) | 100 |

| Polishing platen speed (r/min) | 90 |

| Polishing fluid flow rate (mL/min) | 90 |

| Polishing time (min) | 60 |

| Test Number | pH Value | Oxidant Content (wt%) | Abrasive Content (wt%) | MRR (μm/h) | Ra (nm) |

|---|---|---|---|---|---|

| 1 | 2 | 1 | 1 | 0.5212 | 0.348 |

| 2 | 2 | 2 | 3 | 0.7665 | 1.277 |

| 3 | 2 | 3 | 5 | 0.7972 | 0.365 |

| 4 | 2 | 4 | 2 | 0.4906 | 0.122 |

| 5 | 2 | 5 | 4 | 0.6439 | 0.113 |

| 6 | 3 | 1 | 5 | 0.5519 | 0.248 |

| 7 | 3 | 2 | 2 | 0.4599 | 0.311 |

| 8 | 3 | 3 | 4 | 0.7052 | 0.355 |

| 9 | 3 | 4 | 1 | 0.6439 | 0.123 |

| 10 | 3 | 5 | 3 | 0.6439 | 1.358 |

| 11 | 4 | 1 | 4 | 0.4906 | 0.176 |

| 12 | 4 | 2 | 1 | 0.7052 | 0.809 |

| 13 | 4 | 3 | 3 | 0.5212 | 1.828 |

| 14 | 4 | 4 | 5 | 0.7052 | 0.129 |

| 15 | 4 | 5 | 2 | 0.7358 | 2.468 |

| 16 | 5 | 1 | 3 | 0.5212 | 0.225 |

| 17 | 5 | 2 | 5 | 0.7052 | 0.766 |

| 18 | 5 | 3 | 2 | 0.7052 | 0.408 |

| 19 | 5 | 4 | 4 | 0.8278 | 0.149 |

| 20 | 5 | 5 | 1 | 0.7972 | 1.970 |

| 21 | 6 | 1 | 2 | 0.5825 | 0.268 |

| 22 | 6 | 2 | 4 | 0.7358 | 0.264 |

| 23 | 6 | 3 | 1 | 0.6745 | 0.210 |

| 24 | 6 | 4 | 3 | 0.7665 | 0.110 |

| 25 | 6 | 5 | 5 | 0.7052 | 0.116 |

| Parameter | pH Value | Oxidant Content (wt%) | Abrasive Content (wt%) |

|---|---|---|---|

| 3.2193 | 2.66742 | 3.34194 | |

| 3.00468 | 3.3726 | 2.97402 | |

| 3.15798 | 3.40326 | 3.2193 | |

| 3.55656 | 3.43392 | 3.40326 | |

| 3.46458 | 3.5259 | 3.46458 | |

| 0.64386 | 0.533484 | 0.668388 | |

| 0.60094 | 0.67452 | 0.594804 | |

| 0.631596 | 0.680652 | 0.64386 | |

| 0.711312 | 0.686784 | 0.680652 | |

| 0.692916 | 0.70518 | 0.692916 | |

| 0.110376 | 0.171696 | 0.097812 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, J.; Wang, W.; Liu, W.; Song, Z. Polishing Mechanism of CMP 4H-SiC Crystal Substrate (0001) Si Surface Based on an Alumina (Al2O3) Abrasive. Materials 2024, 17, 679. https://doi.org/10.3390/ma17030679

Gong J, Wang W, Liu W, Song Z. Polishing Mechanism of CMP 4H-SiC Crystal Substrate (0001) Si Surface Based on an Alumina (Al2O3) Abrasive. Materials. 2024; 17(3):679. https://doi.org/10.3390/ma17030679

Chicago/Turabian StyleGong, Juntao, Weilei Wang, Weili Liu, and Zhitang Song. 2024. "Polishing Mechanism of CMP 4H-SiC Crystal Substrate (0001) Si Surface Based on an Alumina (Al2O3) Abrasive" Materials 17, no. 3: 679. https://doi.org/10.3390/ma17030679

APA StyleGong, J., Wang, W., Liu, W., & Song, Z. (2024). Polishing Mechanism of CMP 4H-SiC Crystal Substrate (0001) Si Surface Based on an Alumina (Al2O3) Abrasive. Materials, 17(3), 679. https://doi.org/10.3390/ma17030679