Study on the Constitutive Modeling of (2.5 vol%TiB + 2.5 vol%TiC)/TC4 Composites under Hot Compression Conditions

Abstract

1. Introduction

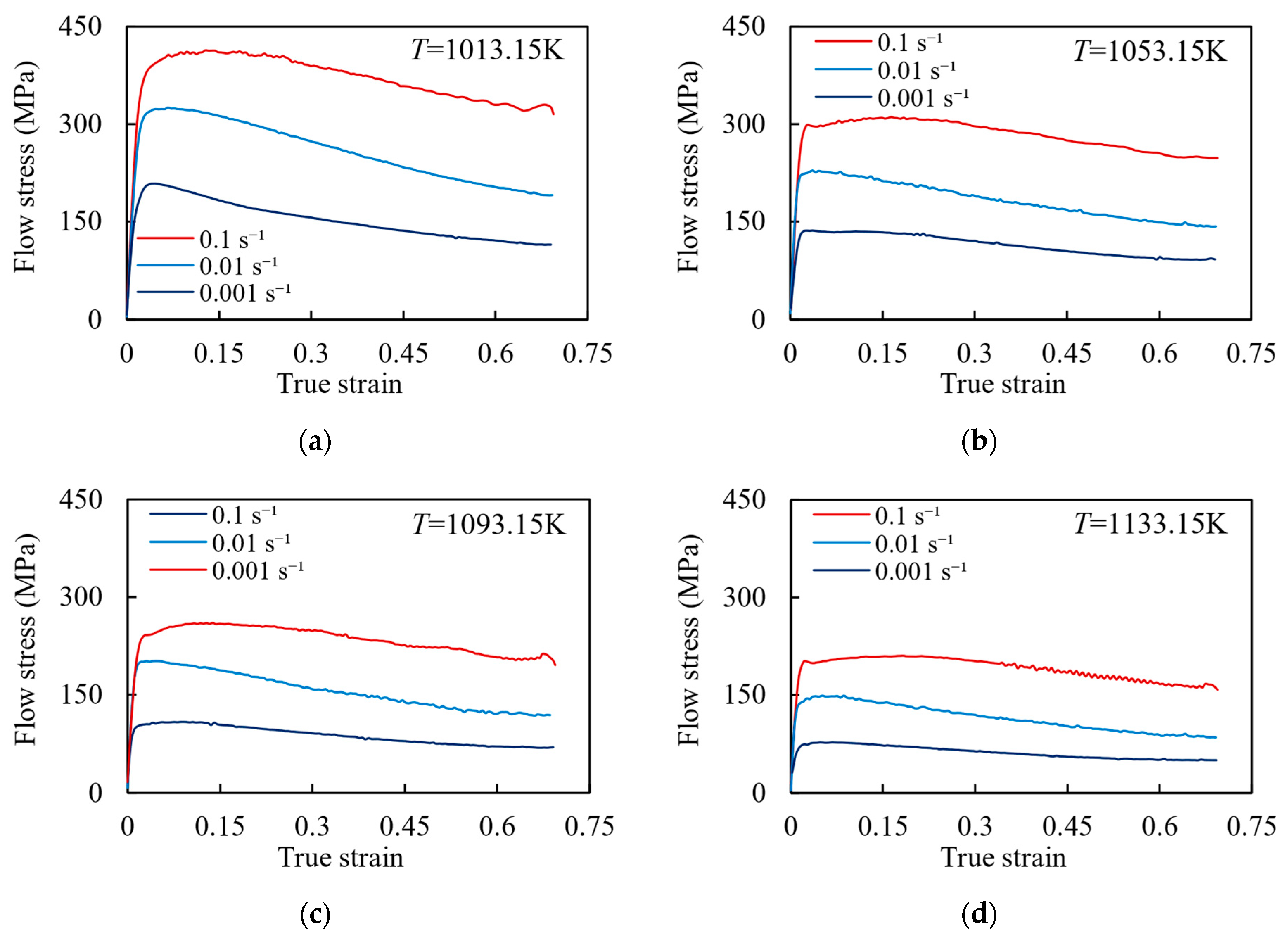

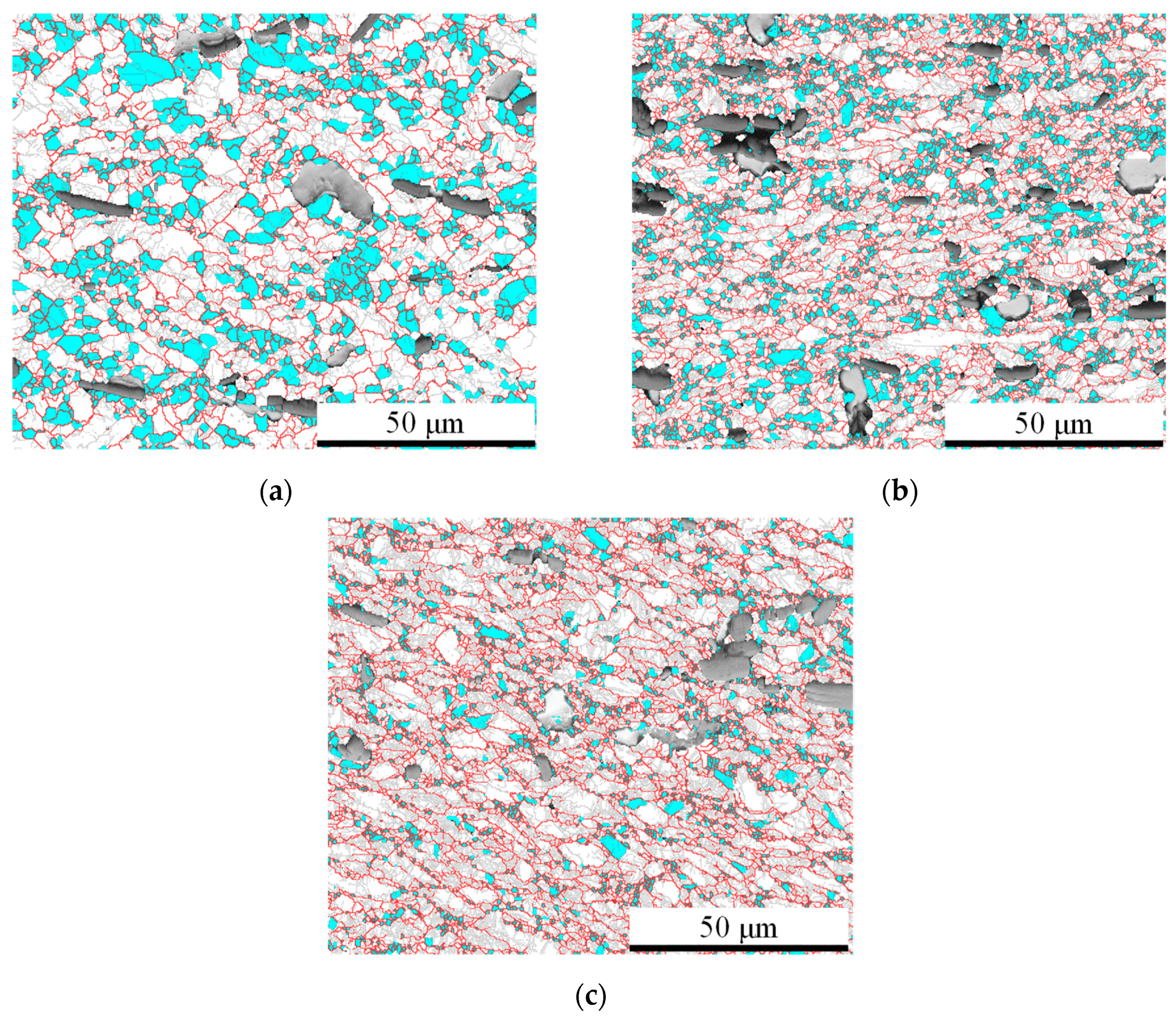

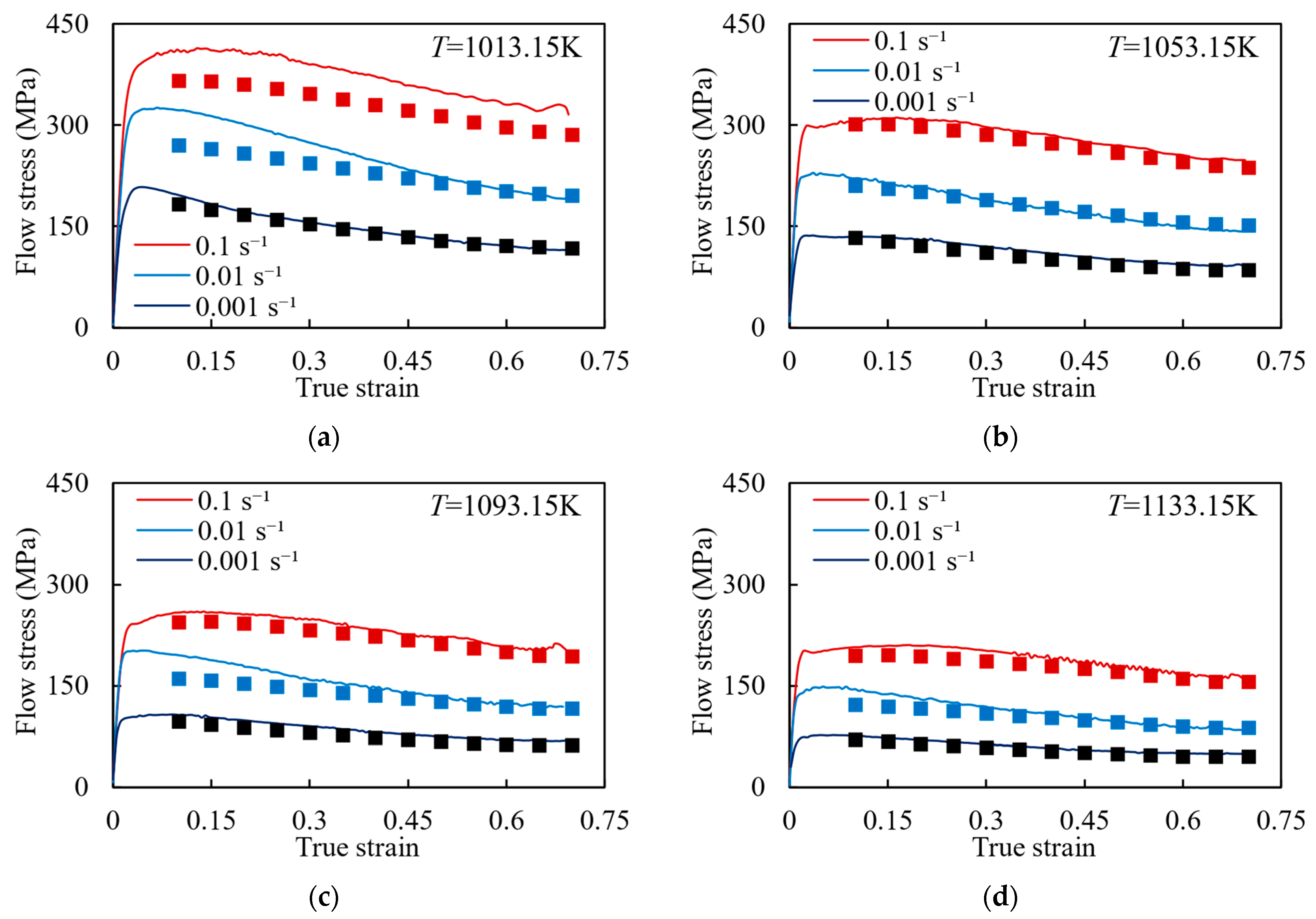

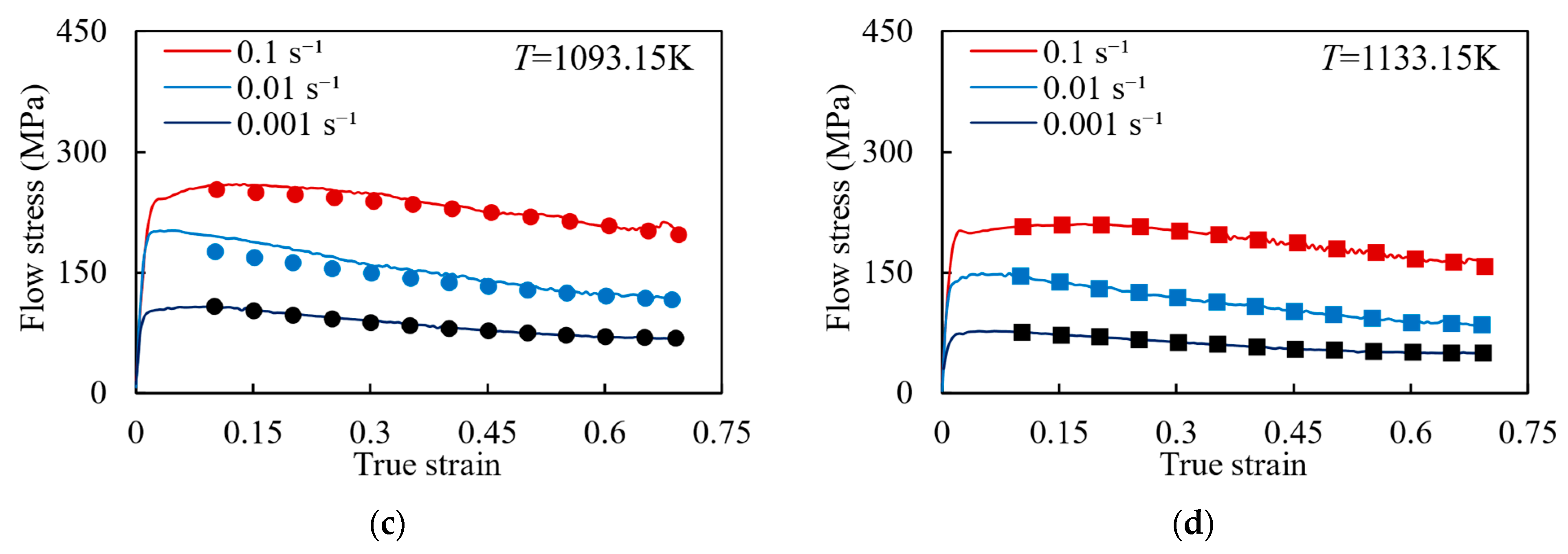

2. Experimental Methods and Results

3. Description of Constitutive Model

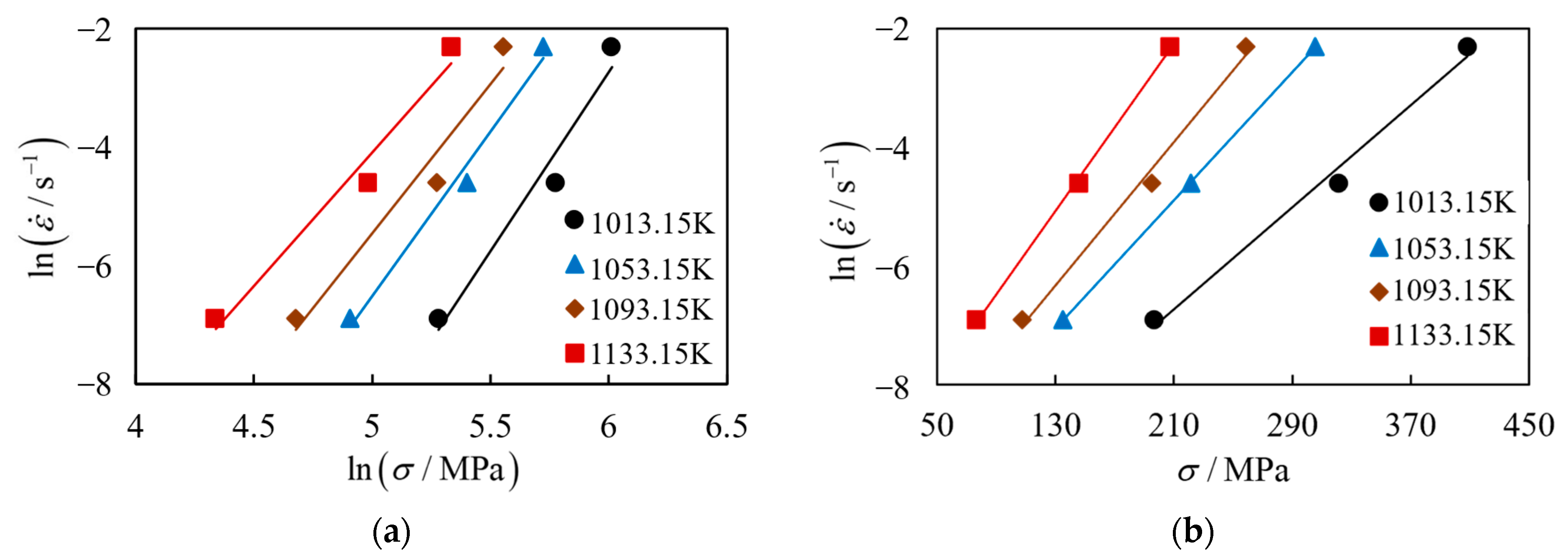

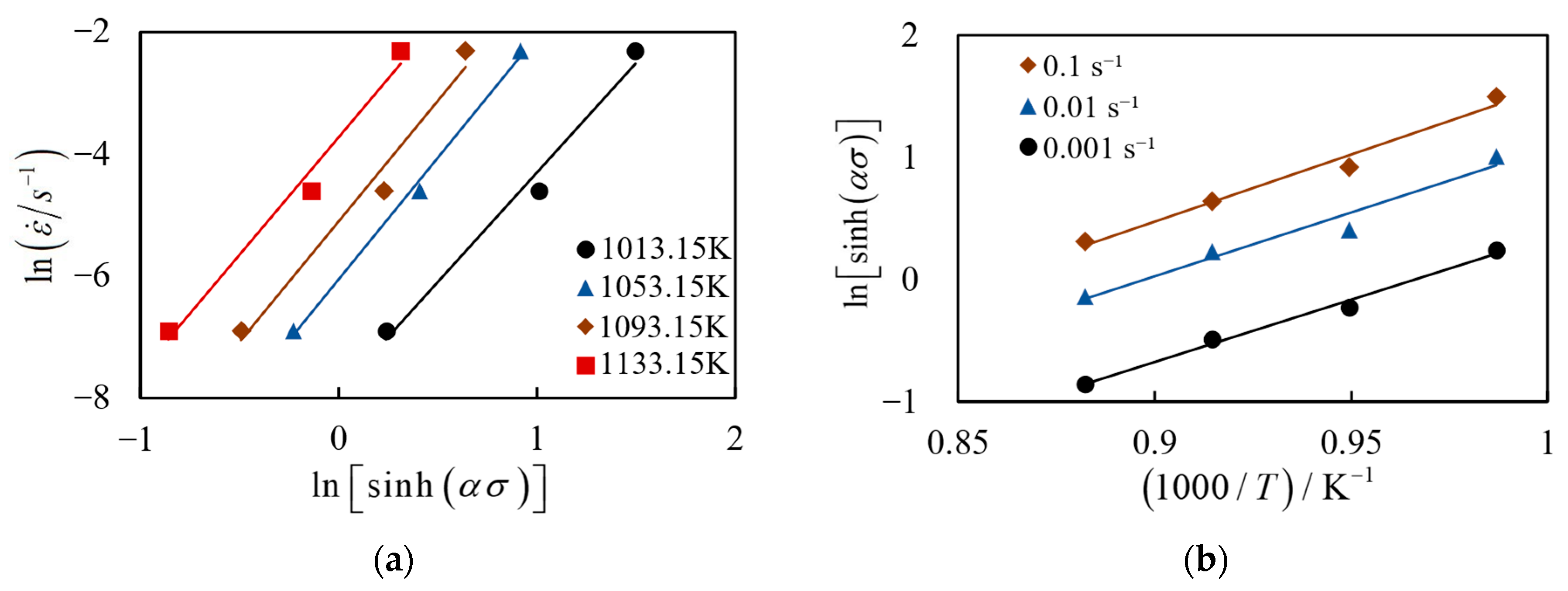

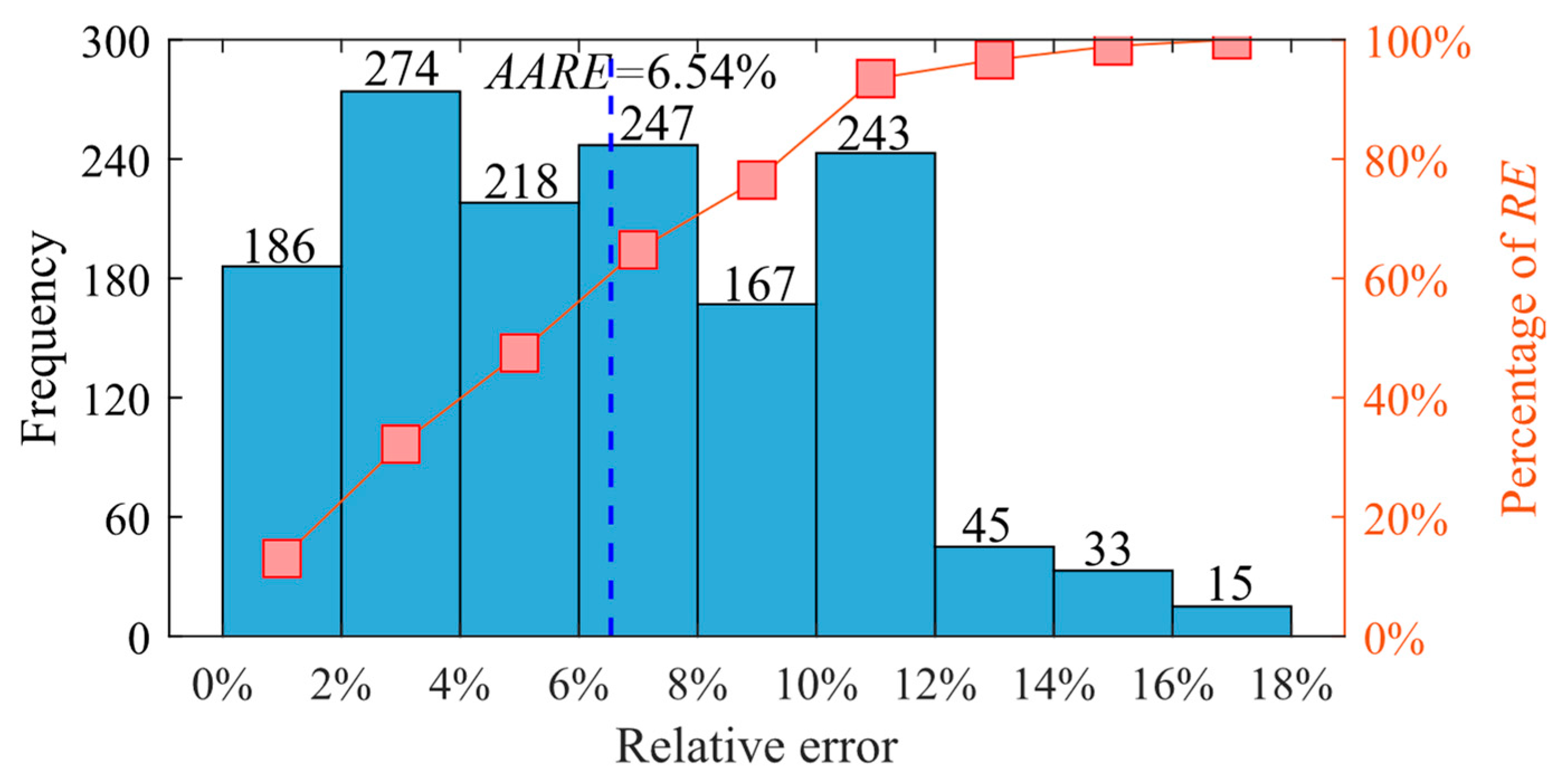

3.1. Arrhenius Model

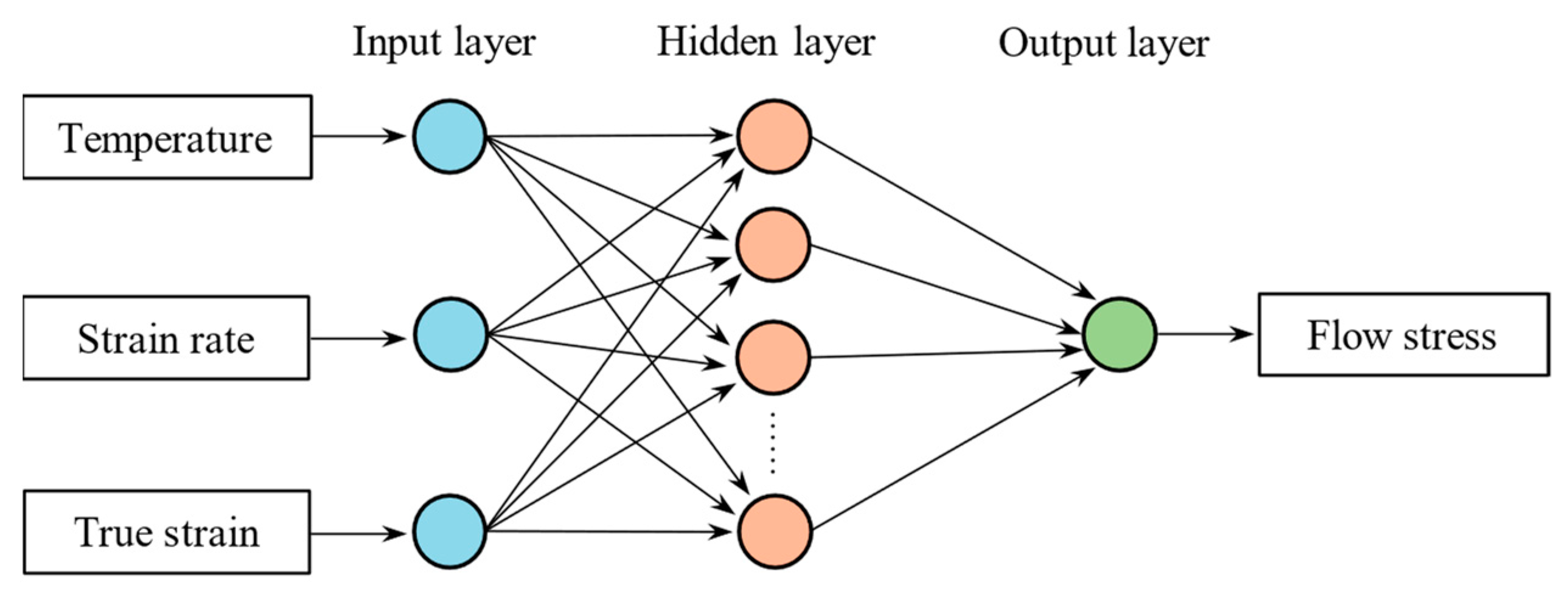

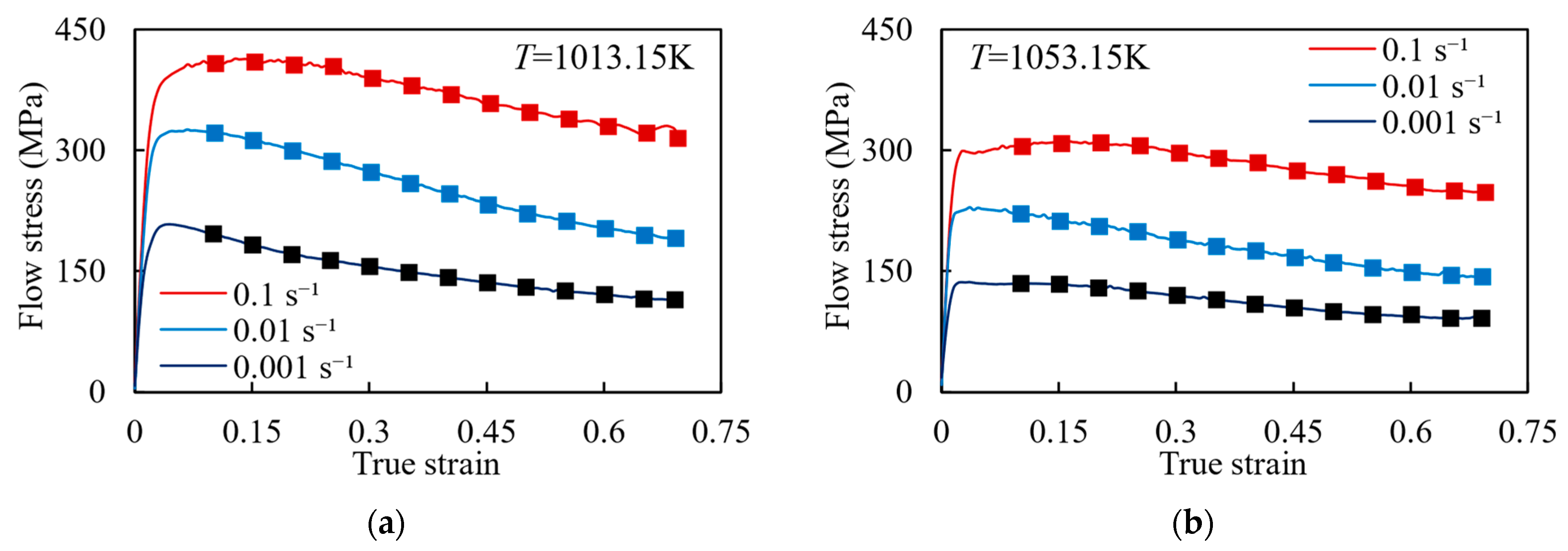

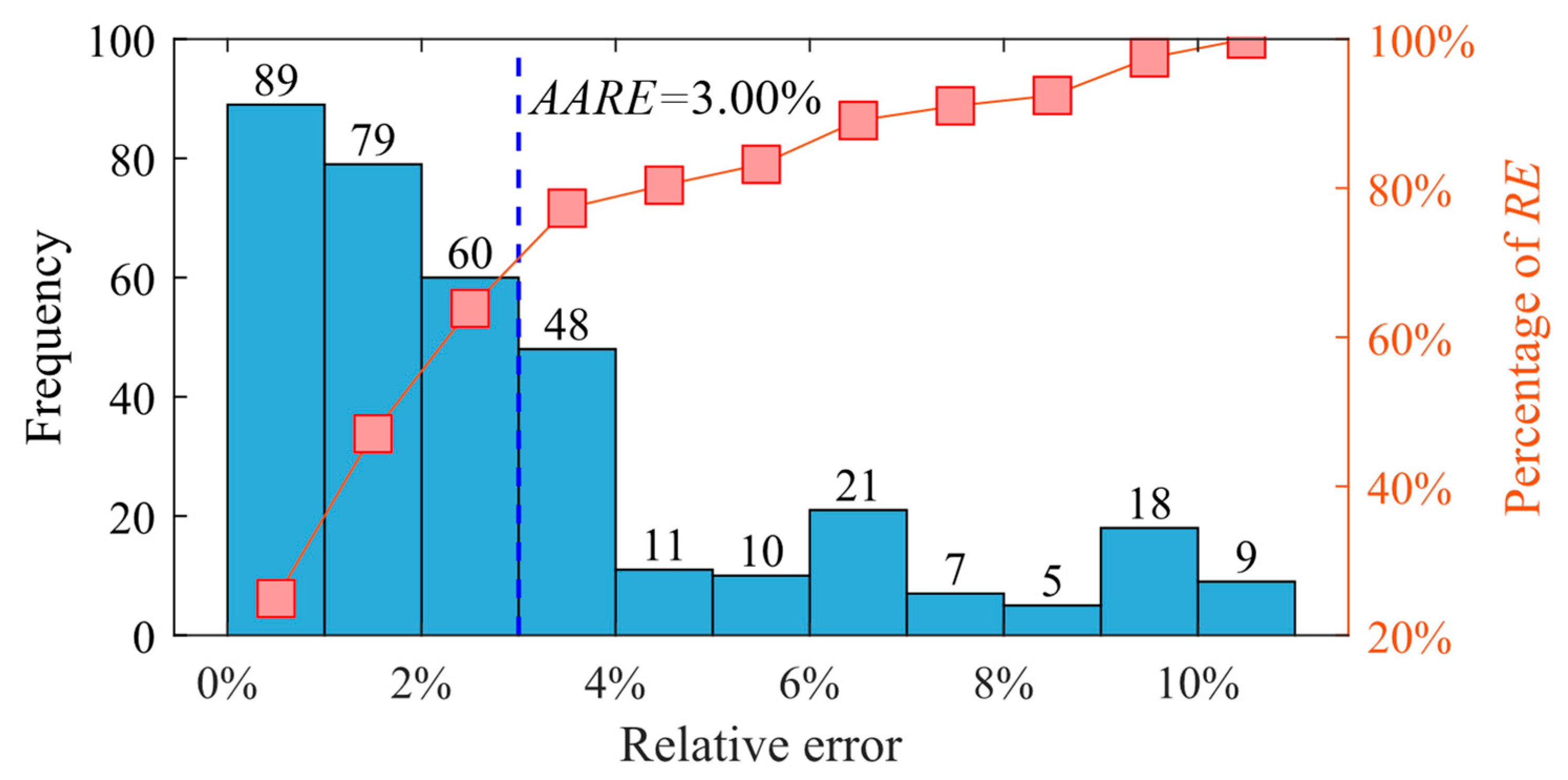

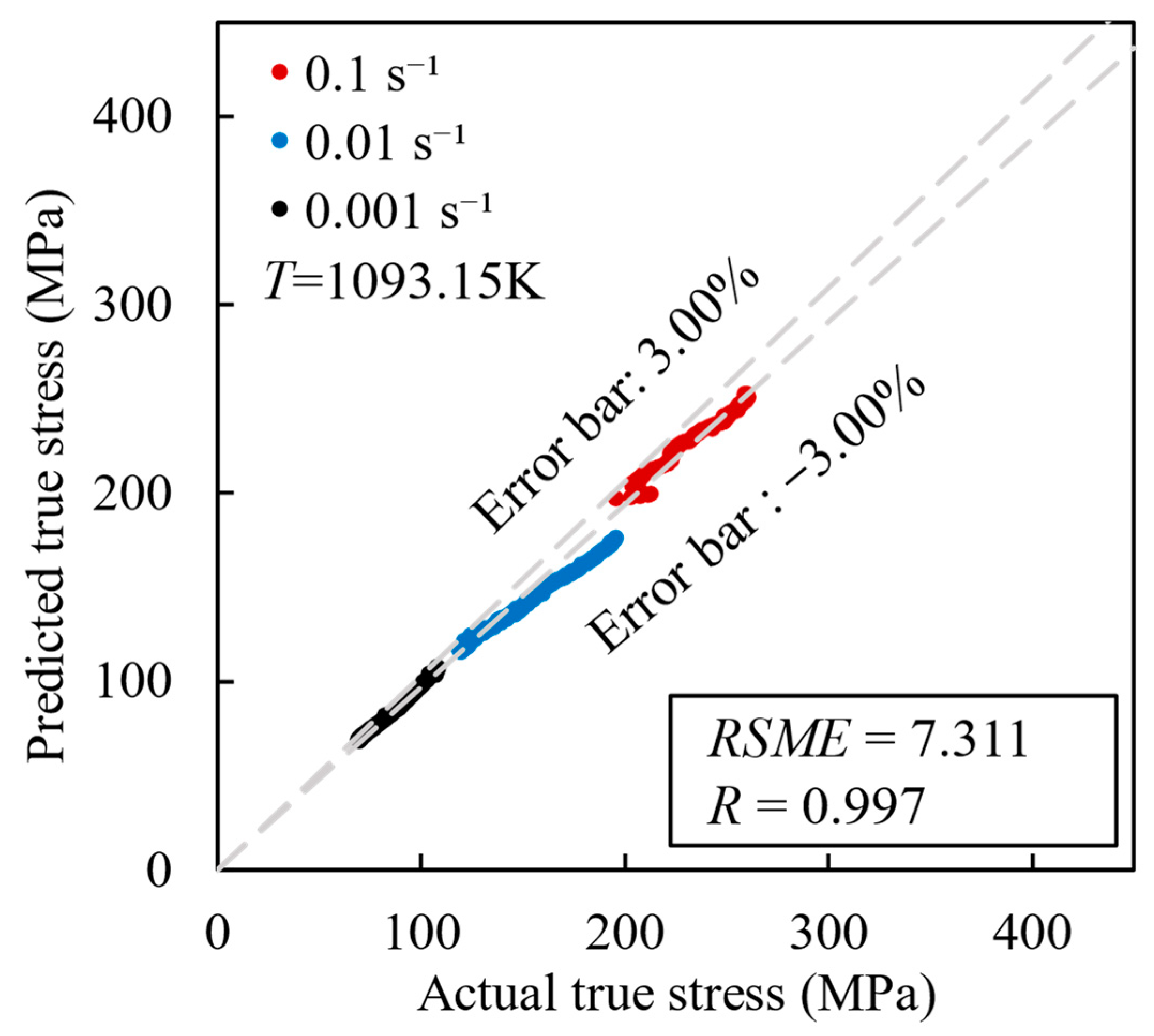

3.2. BP Neural Network Algorithm

4. Model Evaluation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Caha, I.; Alves, A.C.; Kuroda, P.A.B.; Pinto, A.M.P.; Rocha, L.A.; Toptan, F. Degradation behavior of Ti-Nb alloys: Corrosion behavior through 21 days of immersion and tribocorrosion behavior against alumina. Corros. Sci. 2022, 167, 108488. [Google Scholar] [CrossRef]

- Banerjee, B.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Jahani, A.; Aval, H.J.; Rajabi, M.; Jamaati, R. Effects of Ti2SnC max phase reinforcement content on the properties of copper matrix composite produced by friction stir back extrusion process. Mater. Chem. Phys. 2023, 299, 127497. [Google Scholar] [CrossRef]

- Liu, W.-J.; Guo, X.-L.; Meng, J.-L.; Wang, F.-Q.; Wang, L.-Q.; Zhang, D. Analysis of the coupling effects of tib whiskers and tic particles on the fracture toughness of (TiB + TiC)/TC4 composites: Experiment and modeling. Met. Mater. Trans. A 2015, 46, 3490–3501. [Google Scholar] [CrossRef]

- Sajadifar, S.V.; Maier, H.J.; Niendorf, T.; Yapici, G.G. Elevated temperature mechanical characteristics and fracture behavior of a novel beta titanium alloy. Crystals 2023, 13, 269. [Google Scholar] [CrossRef]

- Nochovnaya, N.A.; Shiryaev, A.A.; Davydova, E.A. Influence of manufacturing parameters on pseudo-β-titanium alloy VT47 sheet structural state and mechanical property anisotropy. Metallurgist 2023, 66, 1216–1224. [Google Scholar] [CrossRef]

- Illarionov, A.G.; Vodolazskii, F.V.; Kosmatskii, Y.I.; Gornostaeva, E.A. Effect of the temperature and rate parameters of hot deformation on the mechanical behavior of forged titanium alloy VT14 under compression and tension. Met. Sci. Heat Treat. 2023, 65, 426–431. [Google Scholar] [CrossRef]

- Ebied, S.; Hamada, A.; Gadelhaq, M.H.A.; Yamanaka, K.; Bian, H.-K.; Cui, Y.-J.; Chiba, A.; Gepreel, M.A.H. Study on hot deformation behavior of beta Ti-17Mo alloy for biomedical applications. JOM 2022, 74, 494–505. [Google Scholar] [CrossRef]

- Li, H.-E.; Sha, A.-X. Effects of hot process parameters on flow stress and microstructures of TC18 titanium alloy. J. Mater. Eng. Perform. 2010, 24, 85–88. [Google Scholar]

- Cui, J.-H.; Yang, H.; Sun, Z.-C. Research on hot deformation behavior and constitutive model of titanium alloy TB6. Rare Met. Mat. Eng. 2012, 41, 1166–1170. [Google Scholar]

- Dan, D.-B.; Shi, K.; Xu, W.-C.; Lui, Y. Isothermal precision forging of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si alloy impeller with twisted blades. Trans. Nonferrous Met. Soc. China 2006, 016, 2086–2090. [Google Scholar]

- Mahadule, D.; Kumar, D.; Dandekar, T.R.; Khatirkar, R.K.; Suwas, S. Modelling of flow stresses during hot deformation of Ti-6Al-4Mo-1V-0.1Si alloy. J. Mater. Res. 2022, 38, 3750–3763. [Google Scholar] [CrossRef]

- Roy, A.M.; Arróyave, R.; Sundararaghavan, V. Incorporating dynamic recrystallization into a crystal plasticity model for high-temperature deformation of Ti-6Al-4V. Mater. Sci. Eng. A 2023, 880, 145211. [Google Scholar] [CrossRef]

- Sukumar, G.; Singh, B.B.; Balasundar, I.; Bhattacharjee, A.; Sarma, V.S. Primary hot working characteristics and microstructural evolution of as- cast and homogenized Ti-4Al-2.5V-1.5Fe alloy. J. Alloys Compd. 2023, 947, 169556. [Google Scholar] [CrossRef]

- Jaimin, A.; Kotkunde, N.; Singh, S.K. Hot tensile rate-dependent deformation behaviour of AZ31B alloy using different Johnson-Cook constitutive models. Arab. J. Sci. Eng. 2023, 1–16. [Google Scholar] [CrossRef]

- Aranas, C.; Pasco, J.; McCarthy, T. Material constitutive modelling of Fe-based, Ni-based and high-entropy alloys: Development of Simu-Mat 1.0. MRS Commun. 2022, 12, 585–591. [Google Scholar] [CrossRef]

- Olejarczyk-Wozenska, I.; Mrzyglód, B.; Hojny, M. Modelling the high-temperature deformation characteristics of S355 steel using artificial neural networks. Arch. Civ. Mech. Eng. 2022, 23, 1. [Google Scholar] [CrossRef]

- Jaimin, A.; Kotkunde, N.; Singh, S.K.; Saxena, K.K. Studies on flow stress behaviour prediction of AZ31B alloy: Microstructural evolution and fracture mechanism. J. Mater. Res. Technol. 2023, 27, 5541–5558. [Google Scholar] [CrossRef]

- Murugesan, M.; Yu, J.H.; Chung, W.J.; Lee, C.W. Warm deformation behavior and flow stress modeling of AZ31B magnesium alloy under tensile deformation. Materials 2023, 16, 5088. [Google Scholar] [CrossRef]

- Singh, G.; Chakraborty, P.; Tiwari, V. Constitutive behavior of a homogenized at61 magnesium alloy under different strain rates and temperatures: An experimental and numerical investigation. J. Mater. Civ. Eng. 2023, 35, 04023314. [Google Scholar] [CrossRef]

- Deb, S.; Muraleedharan, A.; Immanuel, R.J.; Panigrahi, S.K.; Racineux, G.; Marya, S. Establishing flow stress behaviour of Ti-6Al-4V alloy and development of constitutive models using Johnson-cook method and artificial neural network for quasi-static and dynamic loading. Theor. Appl. Fract. Mech. 2022, 119, 103338. [Google Scholar] [CrossRef]

- Yang, H.-B.; Bu, H.-Y.; Li, M.-N.; Lu, X. Prediction of flow stress of annealed 7075Al alloy in hot deformation using strain-compensated arrhenius and neural network models. Materials 2021, 14, 5986. [Google Scholar] [CrossRef]

- Yu, R.-H.; Li, X.; Li, W.-J.; Chen, J.-T.; Xin, G.; Li, J.-H. Application of four different models for predicting the high-temperature flow behavior of TG6 titanium alloy. Mater. Today Commun. 2021, 26, 102004. [Google Scholar] [CrossRef]

- Rogoff, E.; Antony, M.; Markle, P. Calculating Ti-6Al-4V β transus through a chemistry based equation derived from combined element binary phase diagrams. J. Mater. Eng. Perform. 2018, 27, 5227–5235. [Google Scholar] [CrossRef]

- Wanjara, P.; Jahazi, M.; Monajati, H.; Yue, S.; Immarigeon, J.P. Hot working behavior of near- alloy IMI834. Mat. Sci. Eng. A 2005, 369, 50–60. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Lahoti, G.D. Deformation and unstable flow in hot torsion of Ti-6AI-2Sn-4Zr-2 Mo-0.1Si. Met. Mater. Trans. A 1981, 12, 1719–1728. [Google Scholar] [CrossRef]

- Wang, S.-S.; Deng, X.-Q.; Gao, P.-F.; Ren, Z.-P.; Wang, X.-X.; Feng, H.-L.; Zeng, L.-Y.; Zheng, Z.-D. Physical constitutive modelling of hot deformation of titanium matrix composites. Int. J. Mech. Sci. 2024, 262, 108712. [Google Scholar] [CrossRef]

- Sellars, C.M.; Tegart, W.J. La relation entre le resistance et la structure dans la deformation a chaud. Mem. Sci. Rev. Metall. 1966, 63, 731–746. [Google Scholar]

- Sun, Y.; Zeng, W.-D.; Zhao, Y.-Q. Development of constitutive relationship model of Ti600 alloy using artificial neural network. Comp. Mater. Sci. 2010, 48, 686–691. [Google Scholar] [CrossRef]

- Long, J.-C.; Xia, Q.-X.; Xiao, G.; Qin, Y.; Yuan, S. Flow characterization of magnesium alloy ZK61 during hot deformation with improved constitutive equations and using activation energy maps. Int. J. Mech. Sci. 2021, 191, 106069. [Google Scholar] [CrossRef]

- Shen, C.-W.; Yang, H.; Sun, Z.-C.; Cui, J.-H. Based on BP artificial neural network to building the constitutive relationship of TA15 alloy. J. Plast. Eng. 2007, 14, 101–104+132. [Google Scholar]

- Stöcker, J.; Fuchs, A.; Leichsenring, F.; Kaliske, M. A novel self-adversarial training scheme for enhanced robustness of inelastic constitutive descriptions by neural networks. Comput. Struct. 2022, 265, 106774. [Google Scholar] [CrossRef]

- Shaheen, M.A.; Presswood, R.; Afshan, S. Application of machine learning to predict the mechanical properties of high strength steel at elevated temperatures based on the chemical composition. Structure 2023, 52, 17–29. [Google Scholar] [CrossRef]

- Mcclelland, J.; Rumelhart, D. Parallel Distributed Processing; Explorations in the Microstructure of Cognition: Psychological and Biological Models; MIT Press: Cambridge, MA, USA, 1987. [Google Scholar]

- Murugesan, M.; Yu, J.H.; Chung, W.J.; Lee, C.W. Hybrid artificial neural network-based models to investigate deformation behavior of AZ31B magnesium alloy at warm tensile deformation. Materials 2023, 16, 5308. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi, H.; Ashtiani, H.R.R.; Heidari, M. A comparative study of phenomenological, physically-based and artificial neural network models to predict the hot flow behavior of API 5CT-L80 steel. Mater. Today Commun. 2020, 25, 101528. [Google Scholar] [CrossRef]

| Serial Number | Strain Rate (s−1) | Temperature (K) |

|---|---|---|

| 1 | 0.001 | 1013.15 |

| 2 | 0.01 | |

| 3 | 0.1 | |

| 4 | 0.001 | 1053.15 |

| 5 | 0.01 | |

| 6 | 0.1 | |

| 7 | 0.001 | 1093.15 |

| 8 | 0.01 | |

| 9 | 0.1 | |

| 10 | 0.001 | 1133.15 |

| 11 | 0.01 | |

| 12 | 0.1 |

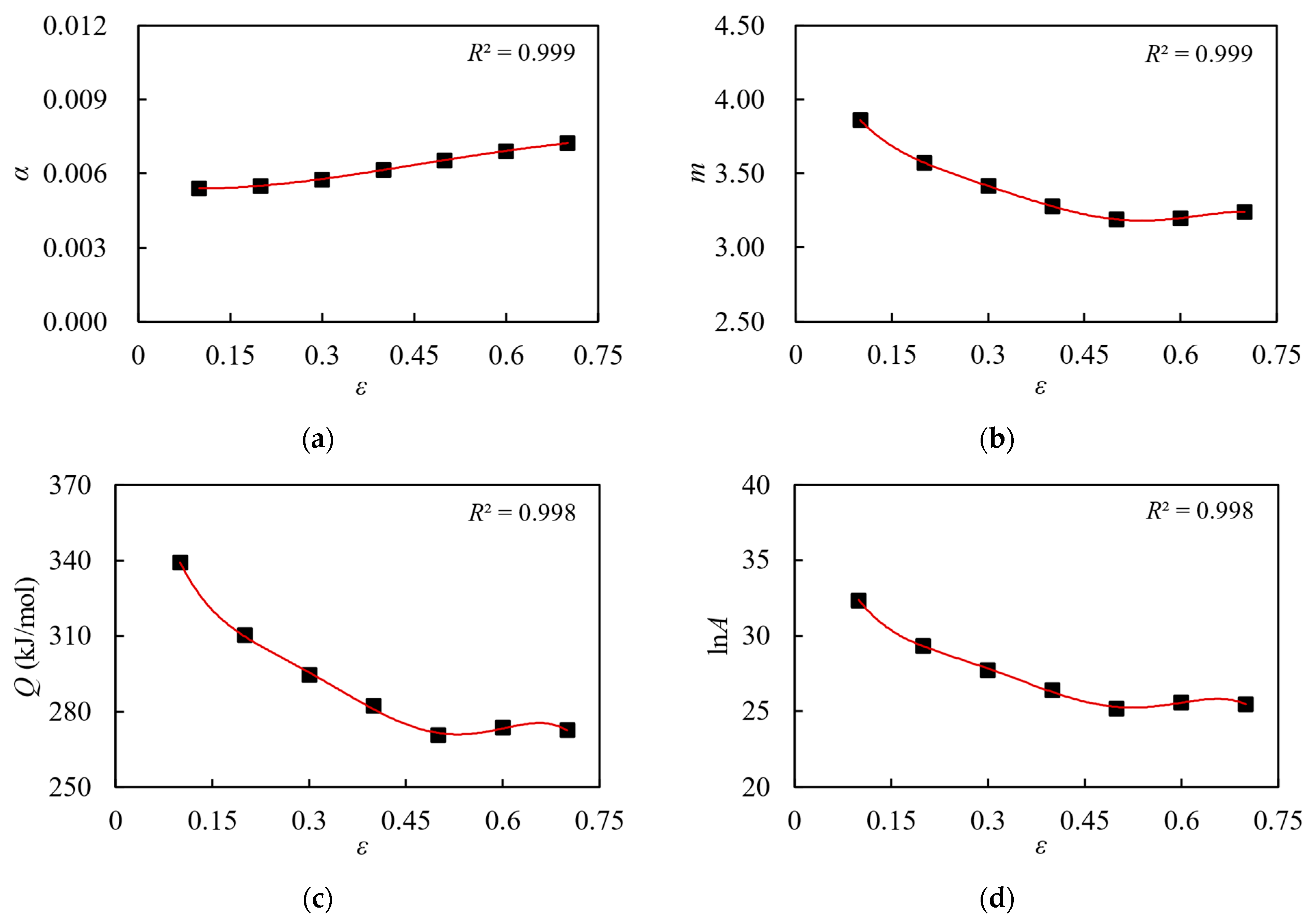

| α | m | Q (kJ/mol) | ||

|---|---|---|---|---|

| 0.1 | 0.005396 | 3.8622 | 339.236 | 32.356 |

| 0.2 | 0.005514 | 3.5735 | 310.272 | 29.334 |

| 0.3 | 0.005773 | 3.4156 | 294.554 | 27.724 |

| 0.4 | 0.006166 | 3.2785 | 282.275 | 26.409 |

| 0.5 | 0.006542 | 3.1902 | 270.509 | 25.185 |

| 0.6 | 0.006927 | 3.1987 | 273.668 | 25.604 |

| 0.7 | 0.007235 | 3.2396 | 272.444 | 25.448 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiang, K.; Wang, S.; Wang, H.; Zeng, Z.; Qi, L. Study on the Constitutive Modeling of (2.5 vol%TiB + 2.5 vol%TiC)/TC4 Composites under Hot Compression Conditions. Materials 2024, 17, 619. https://doi.org/10.3390/ma17030619

Qiang K, Wang S, Wang H, Zeng Z, Qi L. Study on the Constitutive Modeling of (2.5 vol%TiB + 2.5 vol%TiC)/TC4 Composites under Hot Compression Conditions. Materials. 2024; 17(3):619. https://doi.org/10.3390/ma17030619

Chicago/Turabian StyleQiang, Kehao, Shisong Wang, Haowen Wang, Zhulin Zeng, and Liangzhao Qi. 2024. "Study on the Constitutive Modeling of (2.5 vol%TiB + 2.5 vol%TiC)/TC4 Composites under Hot Compression Conditions" Materials 17, no. 3: 619. https://doi.org/10.3390/ma17030619

APA StyleQiang, K., Wang, S., Wang, H., Zeng, Z., & Qi, L. (2024). Study on the Constitutive Modeling of (2.5 vol%TiB + 2.5 vol%TiC)/TC4 Composites under Hot Compression Conditions. Materials, 17(3), 619. https://doi.org/10.3390/ma17030619