Low Concentrations of Gold Nanoparticles as Electric Charge Carriers in Piezoelectric Cement-Based Materials

Abstract

1. Introduction

2. Materials and Methods

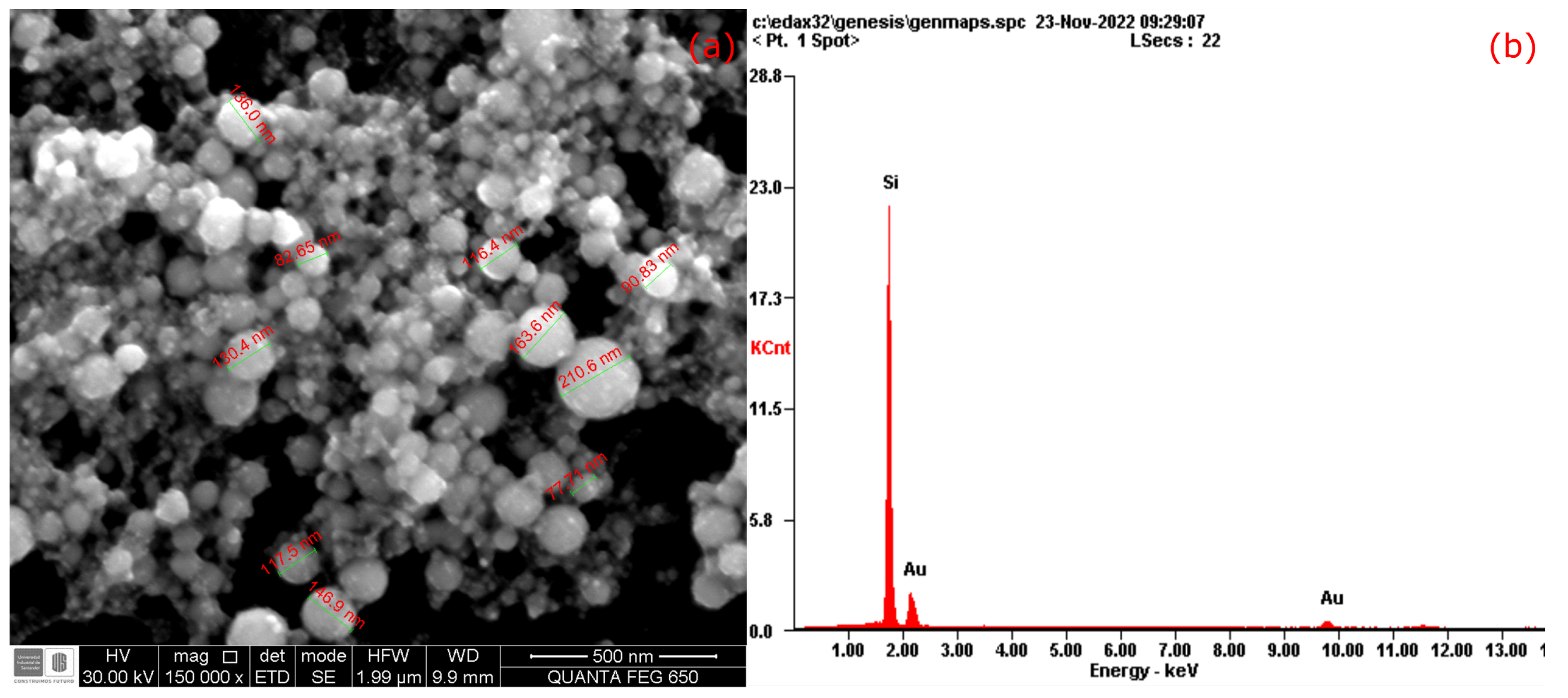

2.1. Gold Nanoparticles Synthesis and Characterization

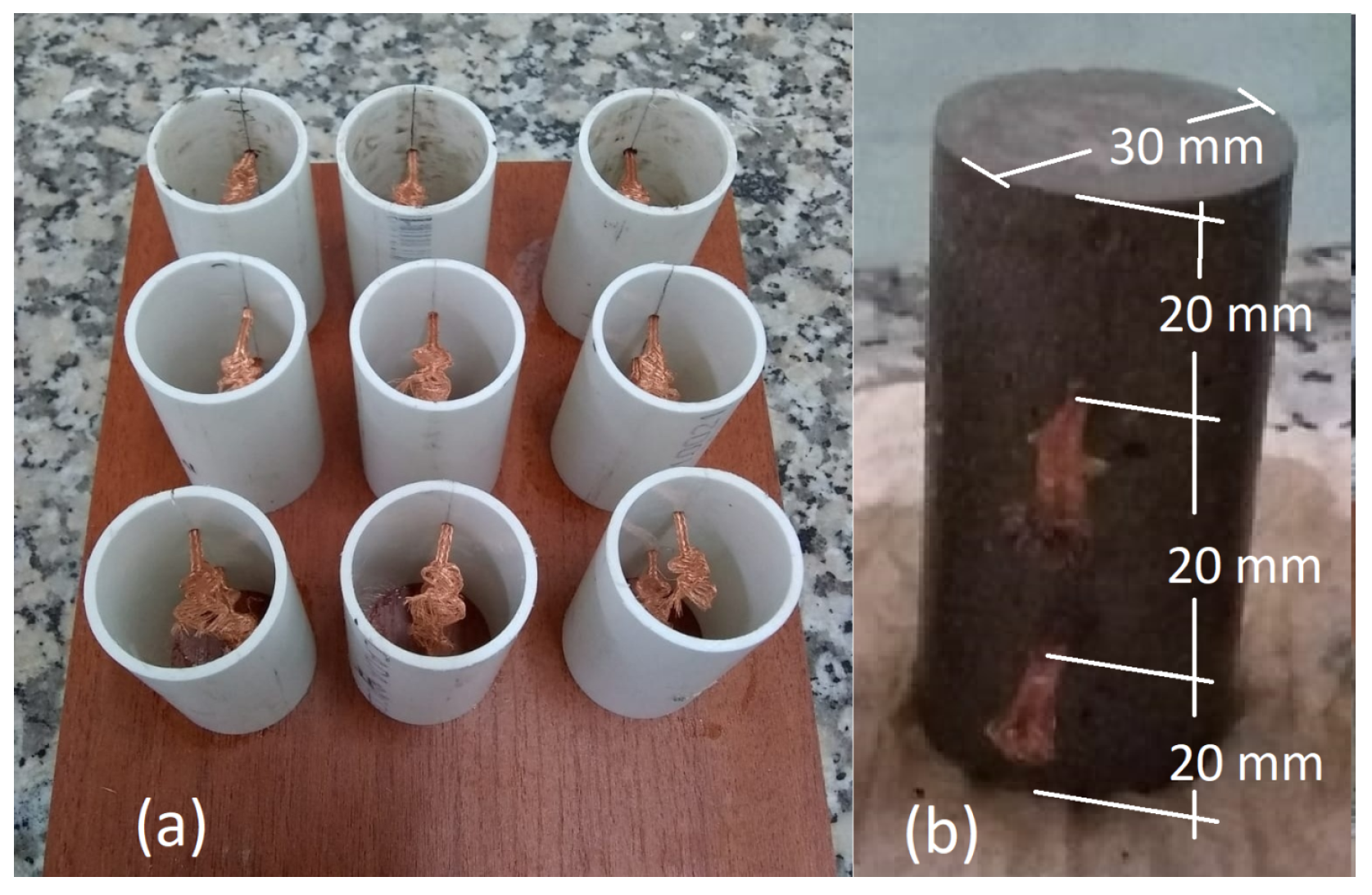

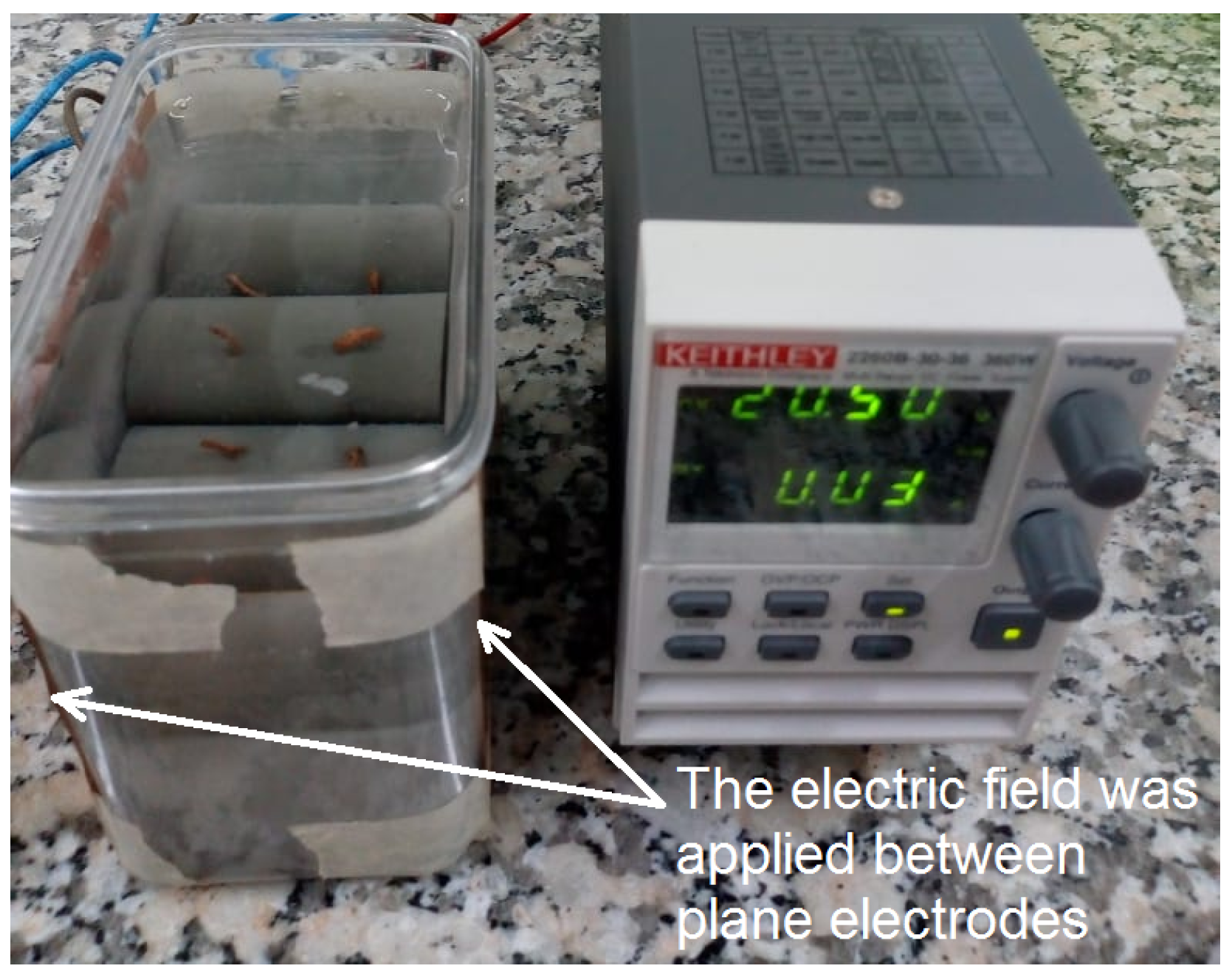

2.2. Au NPs–Cement Composites Fabrication

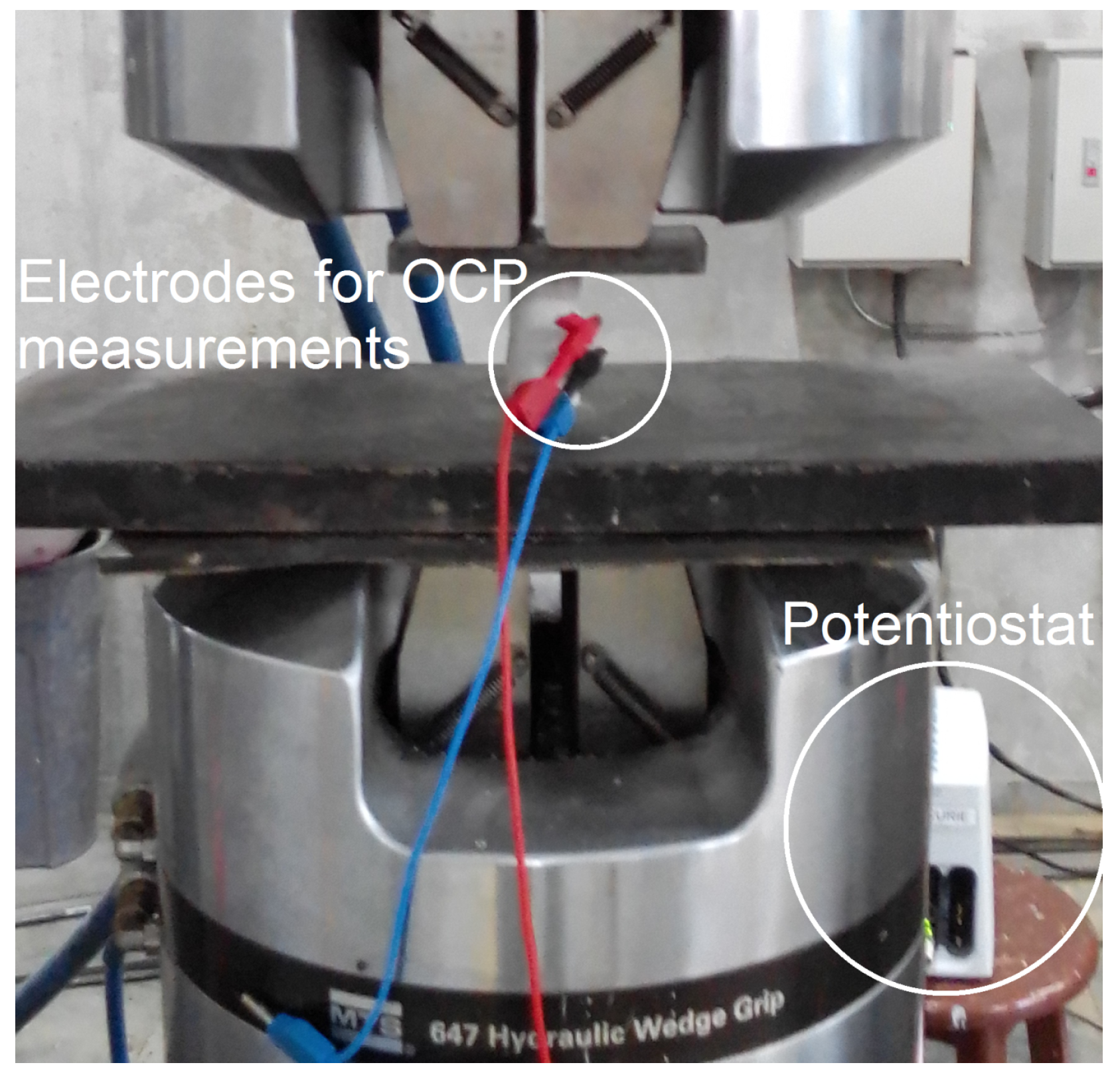

2.3. Electric and Piezoelectric Characterization

3. Results

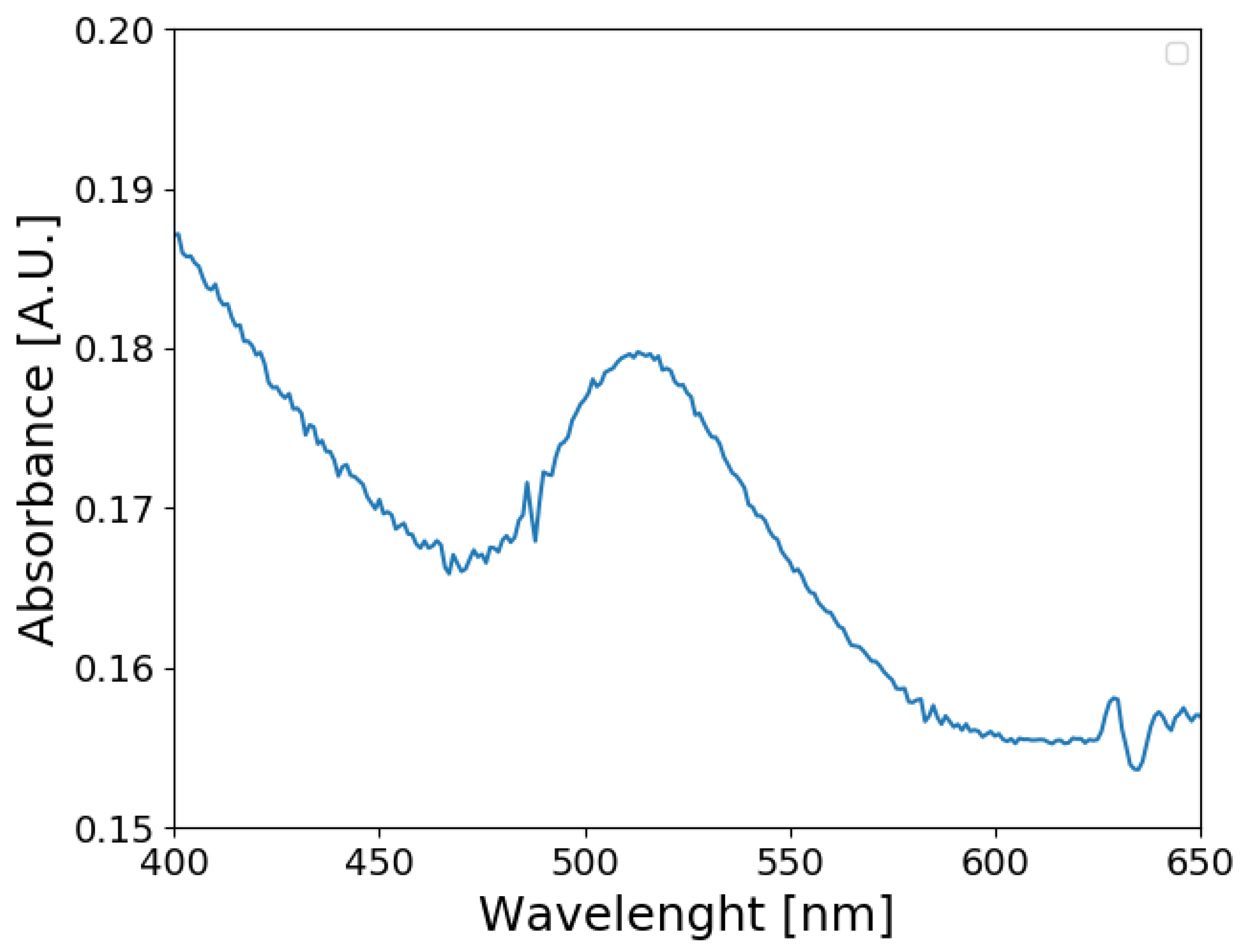

3.1. Au NPs Characterization

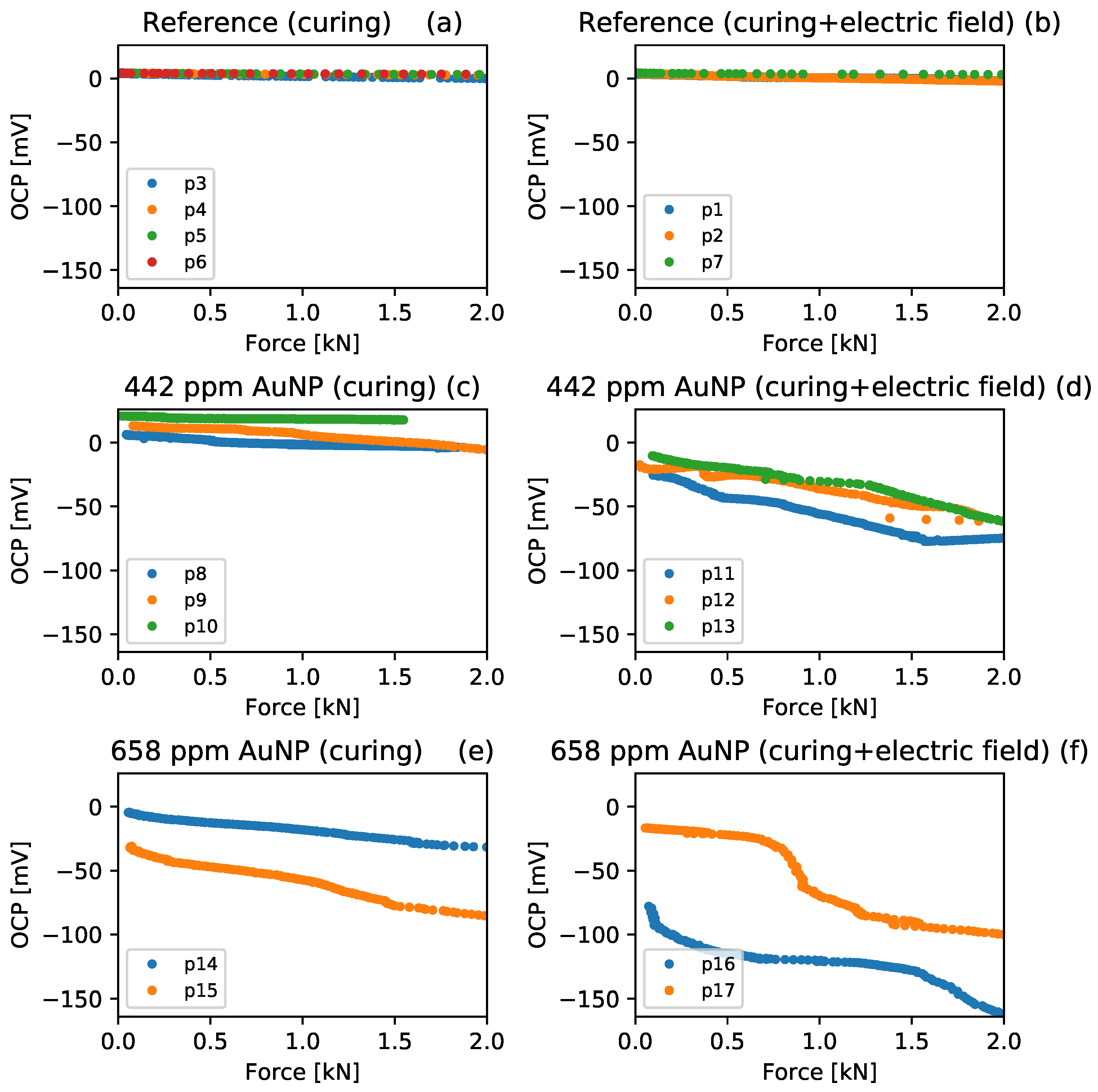

3.2. Piezoelectric Response

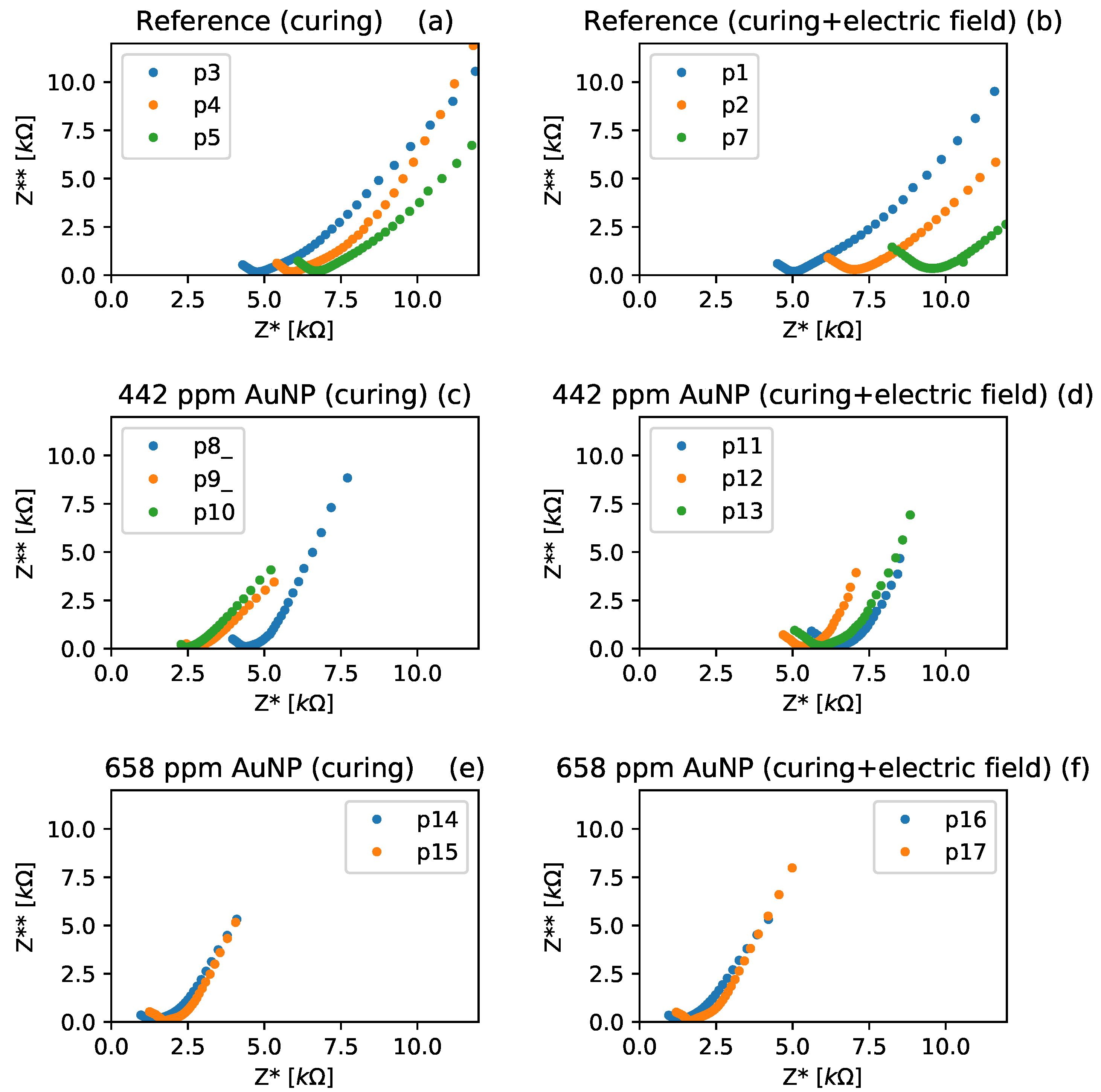

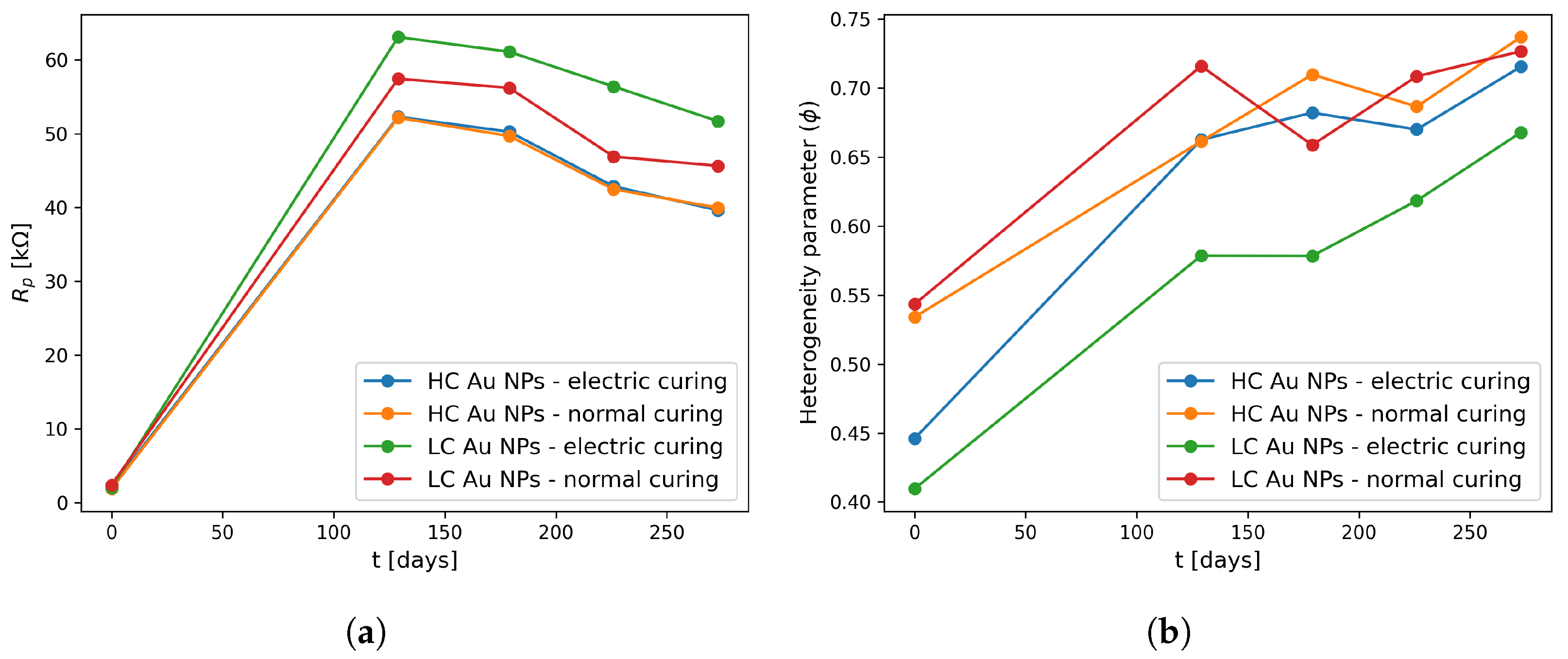

3.3. Electrical Impedance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SHM | Structural health monitoring |

| OCP | Open-circuit potential |

| Au NPs | Gold nanoparticles |

| FCR | Fractional change in resistance |

| CPE | Constant phase element |

References

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Highly dispersed carbon nanotube reinforced cement based materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Paul, S.C.; van Rooyen, A.S.; van Zijl, G.P.; Petrik, L.F. Properties of cement-based composites using nanoparticles: A comprehensive review. Constr. Build. Mater. 2018, 189, 1019–1034. [Google Scholar] [CrossRef]

- Onaizi, A.M.; Huseien, G.F.; Lim, N.H.A.S.; Amran, M.; Samadi, M. Effect of nanomaterials inclusion on sustainability of cement-based concretes: A comprehensive review. Constr. Build. Mater. 2021, 306, 124850. [Google Scholar] [CrossRef]

- Hanus, M.J.; Harris, A.T. Nanotechnology innovations for the construction industry. Prog. Mater. Sci. 2013, 58, 1056–1102. [Google Scholar] [CrossRef]

- Han, B.; Wang, Y.; Dong, S.; Zhang, L.; Ding, S.; Yu, X.; Ou, J. Smart concretes and structures: A review. J. Intell. Mater. Syst. Struct. 2015, 26, 1303–1345. [Google Scholar] [CrossRef]

- Ramachandran, K.; Vijayan, P.; Murali, G.; Vatin, N.I. A review on principles, theories and materials for self sensing concrete for structural applications. Materials 2022, 15, 3831. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Qiu, Q.; Han, Y.; Lau, D. Piezoelectric materials for sustainable building structures: Fundamentals and applications. Renew. Sustain. Energry Rev. 2019, 101, 14–25. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Vessalas, K.; He, X.; Sun, Z.; Sheng, D. Piezoresistivity deterioration of smart graphene nanoplate/cement-based sensors subjected to sulphuric acid attack. Compos. Commun. 2021, 23, 100563. [Google Scholar] [CrossRef]

- Qi, G.; Wang, Q.; Zhang, R.; Guo, Z.; Zhan, D.; Liu, S. Effect of rGO/GNP on the electrical conductivity and piezoresistance of cement-based composite subjected to dynamic loading. Constr. Build. Mater. 2023, 368, 130340. [Google Scholar] [CrossRef]

- Triana-Camacho, D.A.; Quintero-Orozco, J.H.; Mejía-Ospino, E.; Castillo-López, G.; García-Macías, E. Piezoelectric composite cements: Towards the development of self-powered and self-diagnostic materials. Cem. Concr. Compos. 2023, 139, 105063. [Google Scholar] [CrossRef]

- Zhang, N.; She, W.; Du, F.; Xu, K. Experimental Study on Mechanical and Functional Properties of Reduced Graphene Oxide/Cement Composites. Materials 2020, 13, 3015. [Google Scholar] [CrossRef]

- Saidin, S.S.; Kudus, S.A.; Jamadin, A.; Anuar, M.A.; Amin, N.M.; Ya, A.B.Z.; Sugiura, K. Vibration-based approach for structural health monitoring of ultra-high-performance concrete bridge. Case Stud. Constr. Mater. 2023, 18, e01752. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Karayannis, C.G.; Angeli, G.M.; Papadopoulos, N.A.; Favvata, M.J.; Providakis, C.P. Applications of smart piezoelectric materials in a wireless admittance monitoring system (WiAMS) to Structures—Tests in RC elements. Case Stud. Constr. Mater. 2016, 5, 1–18. [Google Scholar] [CrossRef]

- Sun, M.; Liu, Q.; Li, Z.; Hu, Y. A study of piezoelectric properties of carbon fiber reinforced concrete and plain cement paste during dynamic loading. Cem. Concr. Res. 2000, 30, 1593–1595. [Google Scholar] [CrossRef]

- Al-Qaralleh, M. Piezoelectric behavior of polarized fresh cement pastes under the effect of different direct current voltages. Results Eng. 2022, 14, 100430. [Google Scholar] [CrossRef]

- Ma, C.; Peng, J.; Zhou, H.; Zhou, R.; Ren, W.; Du, Y. An effective method for preparing high early-strength cement-based materials: The effects of direct electric curing on Portland cement. J. Build. Eng. 2021, 43, 102485. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, Y.; Lu, Z.; Liu, C.; Sun, G.; Li, Z. A new smart traffic monitoring method using embedded cement-based piezoelectric sensors. Smart Mater. Struct. 2015, 24, 025023. [Google Scholar] [CrossRef]

- Chaipanich, A. Dielectric and piezoelectric properties of PZT–silica fume cement composites. Curr. Appl. Phys. 2007, 7, 532–536. [Google Scholar] [CrossRef]

- Banerjee, S.; Torres, J.; Cook-Chennault, K. Piezoelectric and dielectric properties of PZT–cement–aluminum nano-composites. Ceram. Int. 2015, 41, 819–833. [Google Scholar] [CrossRef]

- Gong, H.; Li, Z.; Zhang, Y.; Fan, R. Piezoelectric and dielectric behavior of 0-3 cement-based composites mixed with carbon black. J. Eur. Ceram. Soc. 2009, 29, 2013–2019. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Lu, N.; Qu, F.; Vessalas, K.; Sheng, D. Piezoresistive behaviours of cement-based sensor with carbon black subjected to various temperature and water content. Compos. Part B Eng. 2019, 178, 107488. [Google Scholar] [CrossRef]

- Borzov, P.; Topolov, V.Y.; Bowen, C. Relations between the piezoelectric performance and quality factors in a corundum-containing composite. Mater. Chem. Phys. 2019, 233, 194–202. [Google Scholar] [CrossRef]

- Pasinszki, T.; Krebsz, M.; Tung, T.T.; Losic, D. Carbon Nanomaterial Based Biosensors for Non-Invasive Detection of Cancer and Disease Biomarkers for Clinical Diagnosis. Sensors 2017, 17, 1919. [Google Scholar] [CrossRef] [PubMed]

- Tung, T.T.; Nine, M.J.; Krebsz, M.; Pasinszki, T.; Coghlan, C.J.; Tran, D.N.H.; Losic, D. Recent Advances in Sensing Applications of Graphene Assemblies and Their Composites. Adv. Funct. Mater. 2017, 27, 1702891. [Google Scholar] [CrossRef]

- Ahmed, M.; Hassanean, Y.; Assaf, K.; EL-Dek, S.; Shawkey, M. Piezoelectric response of MWCNTs/cement nanocomposites. Microelectron. Eng. 2015, 146, 53–56. [Google Scholar] [CrossRef]

- Triana-Camacho, D.A.; Ospina-Ospina, R.; Quintero-Orozco, J.H. Method for fabricating self-powered cement sensors based on gold nanoparticles. MethodsX 2023, 11, 102280. [Google Scholar] [CrossRef] [PubMed]

- Bertok, T.; Sediva, A.; Katrlik, J.; Gemeiner, P.; Mikula, M.; Nosko, M.; Tkac, J. Label-free detection of glycoproteins by the lectin biosensor down to attomolar level using gold nanoparticles. Talanta 2013, 108, 11–18. [Google Scholar] [CrossRef]

- Wang, W.; Fan, X.; Xu, S.; Davis, J.J.; Luo, X. Low fouling label-free DNA sensor based on polyethylene glycols decorated with gold nanoparticles for the detection of breast cancer biomarkers. Biosens. Bioelectron. 2015, 71, 51–56. [Google Scholar] [CrossRef]

- Pusty, M.; Shirage, P.M. Gold nanoparticle–cellulose/PDMS nanocomposite: A flexible dielectric material for harvesting mechanical energy. RSC Adv. 2020, 10, 10097–10112. [Google Scholar] [CrossRef]

- Hernández-Maya, M.; Rivera-Quintero, P.; Ospina, R.; Quintero-Orozco, J.H.; García-Castro, A.C. Ablation energy, water volume and ablation time: Gold nanoparticles obtained through by pulsed laser ablation in liquid. J. Phys. Conf. Ser. 2019, 1386, 012062. [Google Scholar] [CrossRef]

- Maagi, M.T.; Jun, G. Effect of the particle size of nanosilica on early age compressive strength in oil-well cement paste. Constr. Build. Mater. 2020, 262, 120393. [Google Scholar] [CrossRef]

- Li, S.; Chen, G.; Xu, Z.; Luo, X.; Gao, J. Particle-size effect of recycled clay brick powder on the pore structure of blended cement paste. Constr. Build. Mater. 2022, 344, 128288. [Google Scholar] [CrossRef]

- Arévalo, A.C.; Quintero, J.H.; Rincón, S.A.; Rodriguez, J.; Ospina, R. Gold nanoparticles size distribution by pulsed laser varying the wavelength. J. Phys. Conf. Ser. 2019, 1418, 012019. [Google Scholar] [CrossRef]

- Echeverry-Cardona, L.M.; Álzate, N.; Restrepo-Parra, E.; Ospina, R.; Quintero-Orozco, J.H. Time-Stability Dispersion of MWCNTs for the Improvement of Mechanical Properties of Portland Cement Specimens. Materials 2020, 13, 4149. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Poon, C.S. Chloride-related steel corrosion initiation in cement paste prepared with the incorporation of blast-furnace slag. Cem. Concr. Compos. 2022, 126, 104349. [Google Scholar] [CrossRef]

- Saleh, H.E.D.M. Cement Industry; IntechOpen: Rijeka, Croatia, 2021. [Google Scholar] [CrossRef]

- Dong, B.; Xing, F.; Li, Z. Electrical response of cement-based piezoelectric ceramic composites under mechanical loadings. Smart Mater. Res. 2011, 2011, 236719. [Google Scholar] [CrossRef]

- Shirzadi-Ahodashti, M.; Mizwari, Z.M.; Mohammadi-Aghdam, S.; Ahmadi, S.; Ali Ebrahimzadeh, M.; Mortazavi-Derazkola, S. Optimization and evaluation of anticancer, antifungal, catalytic, and antibacterial activities: Biosynthesis of spherical-shaped gold nanoparticles using Pistacia vera hull extract (AuNPs@PV). Arab. J. Chem. 2023, 16, 104423. [Google Scholar] [CrossRef]

- Khaniabadi, P.M.; Ahmed, N.M.; Dheyab, M.A.; Aziz, A.A.; Almessiere, M. Structure, morphology and absorption characteristics of gold nanoparticles produced via PLAL method: Role of low energy X-ray dosage. Surf. Interfaces 2021, 24, 101139. [Google Scholar] [CrossRef]

- Li, X.; Jiang, L.; Zhan, Q.; Qian, J.; He, S. Localized surface plasmon resonance (LSPR) of polyelectrolyte-functionalized gold-nanoparticles for bio-sensing. Colloids Surf. A Physicochem. Eng. Asp. 2009, 332, 172–179. [Google Scholar] [CrossRef]

- Sun, M.; Li, Z.; Song, X. Piezoelectric effect of hardened cement paste. Cem. Concr. Compos. 2004, 26, 717–720. [Google Scholar] [CrossRef]

- Yaphary, Y.L.; Hu, S.; Lau, D.; Lam, R.H.W. Piezoelectricity of Portland cement hydrates cured under the influence of electric field. In Proceedings of the 2016 IEEE 16th International Conference on Nanotechnology (IEEE-NANO), Sendai, Japan, 22–25 August 2016; pp. 911–914. [Google Scholar] [CrossRef]

- Song, G. Equivalent circuit model for AC electrochemical impedance spectroscopy of concrete. Cem. Concr. Res. 2000, 30, 1723–1730. [Google Scholar] [CrossRef]

- Li, W.-W.; Ji, W.-M.; Fang, G.-H.; Liu, Y.-Q.; Xing, F.; Liu, Y.-K.; Dong, B.-Q. Electrochemical impedance interpretation for the fracture toughness of carbon nanotube/cement composites. Constr. Build. Mater. 2016, 114, 499–505. [Google Scholar] [CrossRef]

- Jain, J.; Neithalath, N. Electrical impedance analysis based quantification of microstructural changes in concretes due to non-steady state chloride migration. Mater. Chem. Phys. 2011, 129, 569–579. [Google Scholar] [CrossRef]

- Zhang, J.; Zheng, F.; Liu, Z.; Hong, S.; Dong, B.; Xing, F. Nondestructive monitoring on hydration behavior of cement pastes via the electrochemical impedance spectroscopy method. Measurement 2021, 185, 109884. [Google Scholar] [CrossRef]

- Danoglidis, P.A.; Konsta-Gdoutos, M.S.; Shah, S.P. Relationship between the carbon nanotube dispersion state, electrochemical impedance and capacitance and mechanical properties of percolative nanoreinforced OPC mortars. Carbon 2019, 145, 218–228. [Google Scholar] [CrossRef]

- Triana-Camacho, D.A.; Miranda, D.A.; García-Macías, E.; Reales, O.A.M.; Quintero-Orozco, J.H. Effective medium electrical response model of carbon nanotubes cement-based composites. Constr. Build. Mater. 2022, 344, 128293. [Google Scholar] [CrossRef]

- García-Macías, E.; D’Alessandro, A.; Castro-Triguero, R.; Pérez-Mira, D.; Ubertini, F. Micromechanics modeling of the electrical conductivity of carbon nanotube cement-matrix composites. Compos. Part B Eng. 2017, 108, 451–469. [Google Scholar] [CrossRef]

- Lasia, A. The Origin of the Constant Phase Element. J. Phys. Chem. Lett. 2022, 13, 580–589. [Google Scholar] [CrossRef]

- Vajdle, O.; Šekuljica, S.; Guzsvány, V.; Nagy, L.; Kónya, Z.; Avramov Ivić, M.; Mijin, D.; Petrović, S.; Anojčić, J. Use of carbon paste electrode and modified by gold nanoparticles for selected macrolide antibiotics determination as standard and in pharmaceutical preparations. J. Electroanal. Chem. 2020, 873, 114324. [Google Scholar] [CrossRef]

- Rengaraju, S.; Neelakantan, L.; Pillai, R.G. Investigation on the polarization resistance of steel embedded in highly resistive cementitious systems—An attempt and challenges. Electrochim. Acta 2019, 308, 131–141. [Google Scholar] [CrossRef]

| Material | Reference | 442 ppm Au NPs | 658 ppm Au NPs |

|---|---|---|---|

| Cement (g) | 60.0 | 60.0 | 60.0 |

| Water (g) | 28.2 | 28.2 | 28.2 |

| Au NPs (mg) | - | 39 | 58 |

| w/c | 0.47 |

| Specimens | Normal Curing | Electrical Curing |

|---|---|---|

| Reference | p3, p4, p5, p6 | p1, p2, p7 |

| 442 ppm Au NPs | p8, p9, p10 | p11, p12, p13 |

| 658 ppm Au NPs | p14, p15 | p16, p17 |

| Sample | Normal Curing | Electrical Curing | ||||

|---|---|---|---|---|---|---|

| [] | [mV] | [] | [mV] | |||

| Reference | 2.5 ± 1.9 | 3.8 ± 0.2 | 0.99 | 6.6 ± 3.6 | 3.6 ± 0.3 | 0.98 |

| 442 ppm | 18.3 ± 12.2 | −12.9 ± 6.9 | 0.88 | 92.1 ± 12.3 | −15.4 ± 7.0 | 0.97 |

| 658 ppm | 72.4 ± 24.3 | −18.9 ± 13.6 | 0.98 | 146.0 ± 45.0 | −49.5 ± 44.6 | 0.88 |

| Sample | Total Resistance (k) | |

|---|---|---|

| Normal Curing | Electrical Curing | |

| Reference | 5.8 ± 0.8 | 7.2 ± 1.9 |

| 442 ppm Au NPs | 3.2 ± 0.9 | 5.9 ± 0.5 |

| 658 ppm Au NPs | 1.5 ± 0.2 | 1.4 ± 0.2 |

| Sample | Initial () | Final () | () | FCR% |

|---|---|---|---|---|

| Reference (electrical curing) | 11,336.0 | 11,630.0 | +294.0 | 2.6 |

| 442 ppm Au NPs (electrical curing) | 10,968.6 | 11,269.1 | +300.5 | 2.7 |

| 658 ppm Au NPs (electrical curing) | 1563.5 | 1629.2 | +65.7 | 4.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Triana-Camacho, D.A.; Mendoza Reales, O.A.; Quintero-Orozco, J.H. Low Concentrations of Gold Nanoparticles as Electric Charge Carriers in Piezoelectric Cement-Based Materials. Materials 2024, 17, 615. https://doi.org/10.3390/ma17030615

Triana-Camacho DA, Mendoza Reales OA, Quintero-Orozco JH. Low Concentrations of Gold Nanoparticles as Electric Charge Carriers in Piezoelectric Cement-Based Materials. Materials. 2024; 17(3):615. https://doi.org/10.3390/ma17030615

Chicago/Turabian StyleTriana-Camacho, Daniel A., Oscar A. Mendoza Reales, and Jorge H. Quintero-Orozco. 2024. "Low Concentrations of Gold Nanoparticles as Electric Charge Carriers in Piezoelectric Cement-Based Materials" Materials 17, no. 3: 615. https://doi.org/10.3390/ma17030615

APA StyleTriana-Camacho, D. A., Mendoza Reales, O. A., & Quintero-Orozco, J. H. (2024). Low Concentrations of Gold Nanoparticles as Electric Charge Carriers in Piezoelectric Cement-Based Materials. Materials, 17(3), 615. https://doi.org/10.3390/ma17030615