Abstract

Pyroelectric materials are naturally electrically polarized and exhibits a built-in spontaneous polarization in their unit cell structure even in the absence of any externally applied electric field. These materials are regarded as one of the ideal detector elements for infrared applications because they have a fast response time and uniform sensitivity at room temperature across all wavelengths. Crystals of the perovskite lead titanate (PbTi) family show pyroelectric characteristics and undergo structural phase transitions. They have a high Curie temperature (the temperature at which the material changes from the ferroelectric (polar) to the paraelectric (nonpolar) phase), high pyroelectric coefficient, high spontaneous polarization, low dielectric constant, and constitute important component materials not only useful for infrared detection, but also with vast applications in electronic, optic, and MEMS devices. However, the preparation of large perfect and pure single crystals PbTi is challenging. Additionally, difficulties arise in the application of such bulk crystals in terms of connection to processing circuits, large size, and high voltages required for their operation. In this part of the review paper, we explain the electrical behavior and characterization techniques commonly utilized to unravel the pyroelectric properties of lead titanate and its derivatives. Further, it explains how the material preparation techniques affect the electrical characteristics of resulting thin films. It also provides an in-depth discussion of the measurement of pyroelectric coefficients using different techniques.

1. Introduction

The electrical characteristics and characterization methods of magnetron-sputtered lead titanate thin films play a crucial role in understanding and optimizing their performance for pyroelectric applications. In this second part of the review article, we focus on providing a comprehensive insight into the advances made in the electrical characterization of these materials. A key aspect of this exploration is the systematic study of the conduction mechanism within lead titanate thin films. It is essential to explore the conduction mechanism as it can provide information about phenomena such as contact effects, the physical nature of the interface, and the bulk space charges that often dominate the transport mechanisms in these materials. By delving into the conduction mechanisms, researchers can gain invaluable information about the intricate interplay of charges and the material’s electrical properties. Understanding the conduction mechanisms becomes particularly crucial when addressing device-reliability issues. Imprint, for instance, refers to the preference of a ferroelectric (FE) capacitor for one polarization state over the other. Investigating the conduction mechanisms aids in deciphering the factors influencing imprint and finding ways to mitigate its effects, thereby enhancing the stability and reliability of devices. Fatigue is another important reliability concern, involving the loss of polarization due to bipolar cycling of the capacitor. By studying the conduction mechanisms, researchers can identify the underlying causes of fatigue and develop strategies to improve the endurance of lead titanate thin films in practical applications. Polarization relaxation, characterized by the momentary lag in the dielectric constant of a material, is also a significant aspect addressed in the electrical characterization. This phenomenon is typically caused by the delay in molecular polarization concerning a changing electric field in a dielectric medium. Understanding the conduction mechanisms aids in elucidating the factors contributing to polarization relaxation, enabling researchers to design materials with improved response times. Resistance degradation and breakdown are additional challenges that demand a thorough exploration of the electrical characteristics. It is essential to identify the mechanisms leading to resistance degradation and breakdown to ensure the longevity and robustness of devices based on magnetron-sputtered lead titanate thin films. In conclusion, the systematic study of the conduction mechanisms in lead titanate thin films offers crucial insights into various electrical phenomena and device-reliability issues. This knowledge is instrumental in advancing the understanding and optimization of these materials for pyroelectric applications, ultimately paving the way for enhanced performance and reliability in practical devices [1].

2. Measurement of the Electrical Characteristics

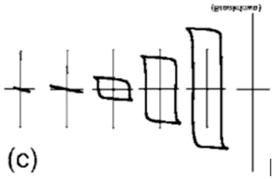

Methods developed for the electrical characterization of FE materials such as current-voltage, I(V), current-time, I(t), capacitance-voltage dielectric constant- electric field , and polarization-electric field are also compatible with the characterization of the pyroelectrics. However, for pyroelectric materials, the measurement of the pyroelectric coefficient, is also extremely important. In this part, we discuss the abovementioned development and measurement methods and identify the strongest stress on thin-film pyroelectric materials. In this section, we delve further into the specific electrical characterization methods and processes relevant to thin film pyroelectric materials, as outlined in the following. The first point is the measurement of hysteresis. Hysteresis curves are essential for understanding the ferroelectric and pyroelectric behavior of materials. By applying an electric field and measuring the polarization response, researchers can characterize the hysteresis loop, providing insights into the switching dynamics and polarization properties of thin-film pyroelectric materials. Second, dielectric permittivity measurements involve determining the ability of a material to store electrical energy in an electric field. This is crucial for understanding the energy storage capabilities of thin-film pyroelectric materials, influencing their performance in various applications. Third, the measurement of capacitance-voltage characteristics provides information about the capacitive properties and response to varying voltages since capacitance-voltage characteristics are pivotal for understanding the charge storage and transport mechanisms in thin-film pyroelectric materials. The fourth point is that the measurement of leakage current characteristics in lead titanate (PT)-based thin films helps identify potential issues such as defects or breakdowns that could affect device performance, where it is critical to understand leakage currents to assess the integrity and reliability of pyroelectric devices. Fifth, fatigue measurements involve studying the degradation of polarization over repeated cycles. Assessing fatigue in PT-based materials is essential for predicting the lifespan and durability of pyroelectric devices. Techniques such as pulse testing or continuous cycling are employed for fatigue evaluation. Sixth, poling is a process where an electric field is applied to align the polar domains in a ferroelectric or pyroelectric material. For thin-film pyroelectric materials, optimizing the poling process is crucial for enhancing their pyroelectric performance and ensuring a stable polarization state. Then, pyroelectric measurements involve assessing the ability of a material to generate polarization in response to temperature changes. These measurements, often involving the pyroelectric coefficient (p), are fundamental for characterizing the pyroelectric properties of thin-film materials. Lastly, understanding the interplay between the processing methods and resulting electrical properties is crucial for optimizing thin-film pyroelectric materials. Factors such as deposition techniques, annealing processes, and film thickness can significantly influence the electrical characteristics of the material.

2.1. Measurement of the Hysteresis Curves

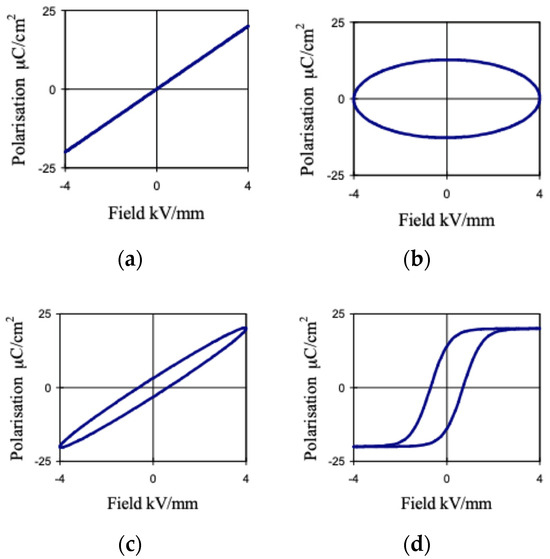

A P(E) loop is a plot of the charge per unit area or polarization (P) developed because of a field applied to that device (E) at a given frequency. Most testing methods of FE capacitors utilize either charge or current integration techniques for measuring hysteresis loops (see Appendix A.1). Hysteresis loops in the context of lead titanate films play a crucial role in understanding and characterizing the electrical behavior of these materials. Hysteresis, in general, refers to the phenomenon where the response of a system lags behind and depends on its history. In the case of lead titanate films, hysteresis loops are often observed in the polarization-electric field curve. These loops are indicative of the ferroelectric nature of lead titanate films. Ferroelectric materials, such as lead titanate, exhibit spontaneous polarization that can be switched by an external electric field. The hysteresis loop represents the relationship between the polarization and the applied electric field during both the polarization and depolarization processes. The significance of hysteresis loops lies in their ability to provide insights into the ferroelectric properties of lead titanate films. The loop’s shape and size can reveal information about the coercive field (the electric field required to switch the polarization) and the remanent polarization (the polarization retained when the external field is removed). These parameters are crucial in understanding the switching behavior and stability of lead titanate films. In practical applications, lead titanate films are used in various devices, including ferroelectric random access memory (FeRAM), sensors, actuators, and transducers. The ability to control and manipulate polarization in lead titanate films, as indicated by hysteresis loops, is exploited in these applications. For example, in FeRAM, the hysteresis loop characteristics help store and retrieve information based on the polarization states, providing a non-volatile memory solution. Hysteresis loops in pyroelectric materials are typically measured using a ferroelectric tester or a precision analyzer. The material is subjected to an oscillating electric field, and the resulting polarization is recorded as a function of the applied field. The hysteresis loop provides information about the ferroelectric and pyroelectric properties of the material. Understanding the coercive field, remanent polarization, and switching behavior is crucial for optimizing the material’s performance in pyroelectric applications. The hysteresis loop provides insight into the switching behavior, essential for the design of reliable infrared sensors.

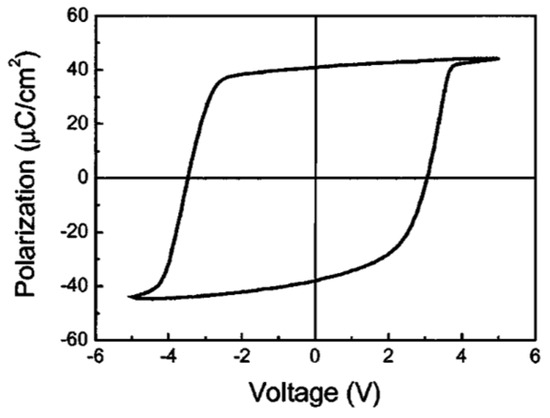

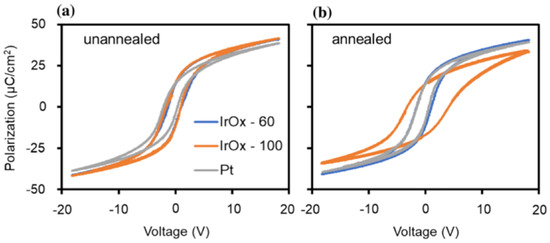

Pintilie et al. [2] measured the hysteresis loop at 1 kHz using a TF 2000 analyzer in dynamic mode (aixACCT Systems GmbH, Aachen, Germany) for the epitaxial Pb()(PZT) layers with both top and bottom electrodes made of SrRu(SRO).

As shown in Figure 1, typically, a remnant polarization of about 40 μC/ and a coercive field of about 150 kV/cm was achieved [2]. The shape of the hysteresis loop is nearly rectangular and very close to an ideal loop. Yet, the reversal is not symmetric with voltage polarity, which suggests that the two FE interfaces with the electrodes are not equivalent, as discussed later.

Figure 1.

A typical hysteresis loop acquired on an epitaxial SRO/PZT (20/80)/SRO layer structure at 1 kHz [2]. Reproduced from [2], Figure 1, Figure 2, Figure 3 and Figure 4, with the permission of AIP Publishing. https://doi.org/10.1063/1.1926403.

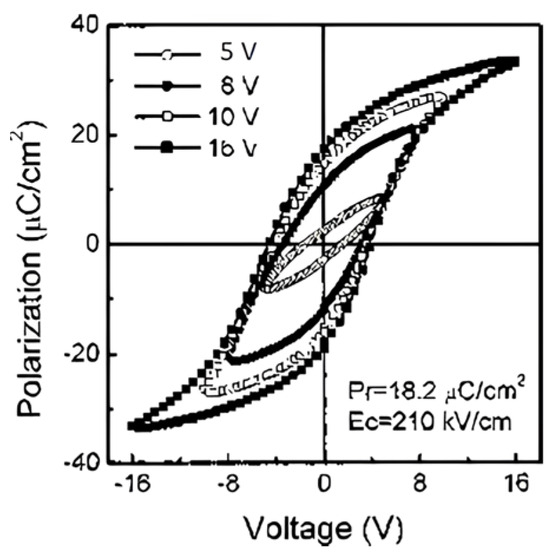

Tang, et al. [3] prepared 200 nm thick, highly (111)-oriented () Ti (PCT) thin films on Pt/Ti/Si/Si substrates using a sol–gel process. Their capacitor structure consisted of top (0.2-mm diameter, Ohmic) Au/PCT/bottom (Schottky) Pt on Ti/Si/Si (100) substrate. Figure 2 shows the typical P(E) hysteresis loops at an applied field of 800 kV/cm with remnant polarization () and coercive electric field () values of 18.2 m C/ and 210 kV/cm, respectively [3].

Figure 2 shows that the P(E) hysteresis loop is asymmetric, with an imprint voltage . The voltage shift indicates the presence of a trap distribution near film-substrate interface [4], and its magnitude is affected by parameters such as the top and bottom electrodes’ work function difference, the magnitude of polarization, and/or the contribution of defect-dipole complexes. The polarization establishes a potential well that attracts the charge carriers to the interfacial defect sites where they are trapped. Remnant polarization and coercive electric field for several processes are compared in Table 1.

Table 1.

Remnant polarization and coercive electric field for several processes.

Asymmetrical contacts to FE films lead to the built-in electric fields and imprint the FE hysteresis loop toward one bias [7]. Simulation has shown that unequal Schottky barriers at the film/electrode interface are the main source of imprint [8]. Symmetrical electrodes can also give rise to the imprint due to the presence of a fabrication defect-induced passive layer within the metal/FE/metal capacitor [9]. Imprint can be beneficial since it allows the observation of high field properties even at low or zero applied fields. In pyroelectric applications, beneficial pyroelectric coefficients increase, and detrimental dielectric loss decreases at higher fields [10]. It is valuable to observe these properties at lower fields.

2.2. Measurement of the Dielectric Permittivity

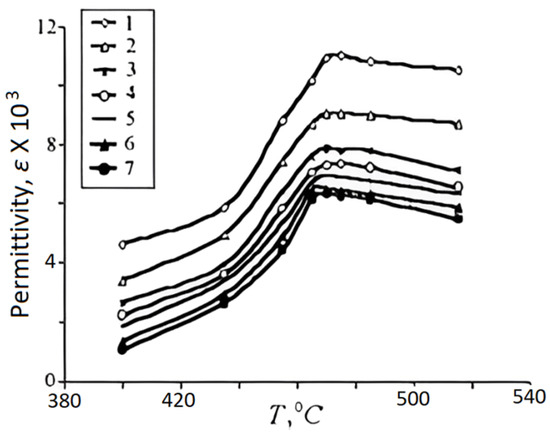

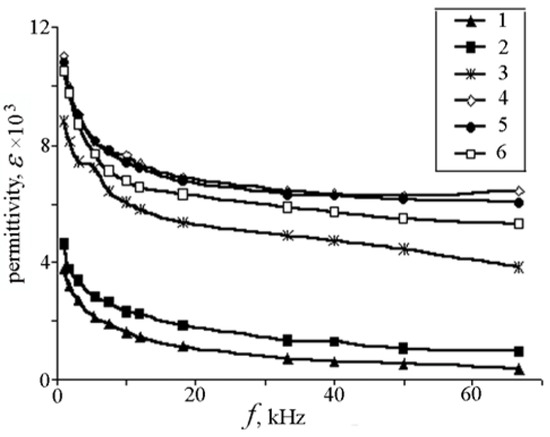

The relative permittivity () of a dielectric (dielectric constant) indicates to what extent a finite volume of a dielectric is polarized when it is biased under an electric field. Dielectric permittivity is often measured using impedance analyzers or LCR meters. The sample is subjected to an alternating electric field, and the response in terms of capacitance and phase shift is analyzed. Dielectric permittivity is indicative of the material’s ability to store electrical energy. In pyroelectric materials, the permittivity may change with temperature, affecting the material’s overall pyroelectric response. Understanding dielectric permittivity aids in designing efficient pyroelectric energy harvesting devices that can convert temperature variations into electrical energy. Sidorkin et al. [11] prepared lead titanate films on using layer by layer magnetron sputter deposition of Ti and Pb in an argon environment, without interruption to atmosphere, in a chamber evacuated to a pressure of Pa, followed by annealing in at 700 °C for one hour. Under these conditions, a in the deposited films provided optimal PT stoichiometry and crystallinity. The frequency dependence of , for (around of the phase transition temperature) and the temperature dependence of for are shown in Figure 3 and Figure 4, respectively [11]. Measurements were carried out under an applied voltage of .

Curie temperature (Tc) is the temperature at which any in Figure 3 reaches its maximum and marks the borderline between (orthorhombic) ferro- and (cubic) para-electric phases. In other words, the Curie temperature is defined as the temperature when the phase of a material changes because of the application of an electric field. Like the bulk samples, Figure 4 shows a relaxation character of dispersion: At any temperature, is reduced as is increased, and at high frequencies, it assumes a relatively constant value. This behavior stems from dipole inertia: Various dipoles lag behind the electric field. At low frequencies, all the dipoles contribute to the value of the dielectric constant. As the frequency is increased, those dipoles with larger relaxation time constants cease to respond and hence, the dielectric constant decreases. The delay in response leads to a loss and decline in the dielectric constant.

The dielectric constant of thin film ferroelectric materials is smaller than that of their bulk counterparts and generally decreases as the film thickness is reduced [12]. It is measured via the capacitance of parallel plate-type capacitors at the low-frequency end and is interpreted in terms of an interfacial layer with the low dielectric constant in series with the bulk dielectric. Such a rationale conforms with theoretical polarization models since the loss of dipole-dipole interactions at the film interface results in the reduction of the dielectric constant. A second source contributing to the reduction of the measured capacitance from the value expected for an ideal parallel plate capacitor is associated with electric field penetration into the metal electrodes [13,14]. However, the dielectric properties of the thin films depend on their microstructure, and it is challenging to separate the influence of thickness-dependent variations in the microstructure on the dielectric constant from intrinsic thickness variations of the dielectric constant. Studies on the dielectric properties of thin polycrystalline (PZT) films conform with the general thickness dependence trend [15,16]. For epitaxial films, Fujisawa et al. [17] report that the variation of the dielectric constant with thickness is smaller compared to that of polycrystalline PZT films. Pintilie et al. [18] found that the intrinsic dielectric constant is close to the measured value in the fully depleted thin films and attributed the decrease in the dielectric constant with decreasing film thickness to the leaky bulk region of the film.

2.3. Measurement of Capacitance-Voltage Characteristics

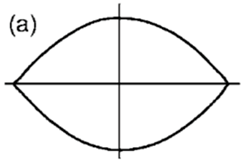

The small signal capacitance is measured using a composite signal obtained by superimposing a small signal (with an amplitude mV) AC voltage at some specific frequency, typically 1 kHz, over a DC voltage (typically a slowly varying triangular or sinusoidal waveform) that traces the hysteresis loop. Then, the component of the current will be 90° out of phase with respect to the driving AC voltage that defines the capacitance. C-V measurements involve applying a voltage across the material and measuring the resulting capacitance. This is particularly useful for understanding the electronic properties of interfaces in pyroelectric devices. C-V characteristics help determine the density of charge carriers, interface states, and the effectiveness of the material in responding to varying electric fields, which is crucial for optimizing device performance. C-V characteristics help optimize the interface properties of pyroelectric materials in thermal imaging devices, enhancing their sensitivity and resolution [2,12,19,20,21].

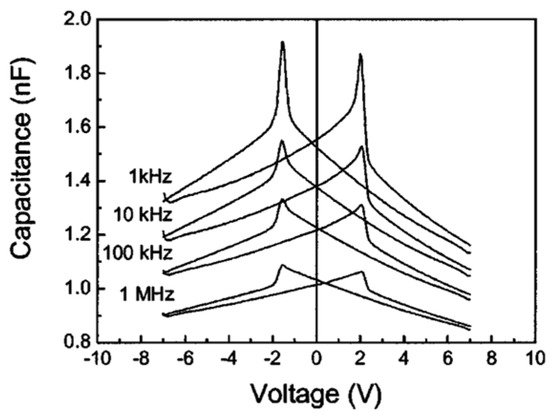

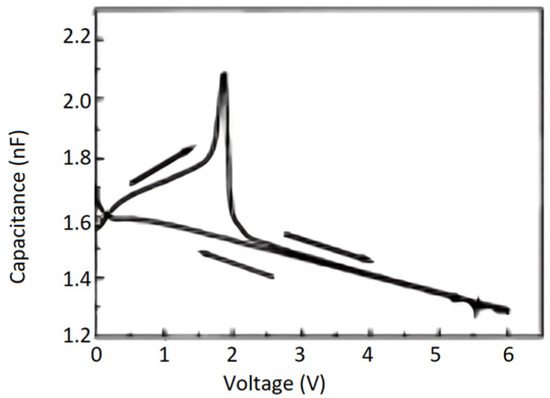

The C-V characteristics of an FE capacitor have a butterfly-loop shape with sharp capacitance peaks at both positive and negative voltages. The peak values depend on frequency as shown in Figure 5 and transform into capacitance discontinuities at higher frequencies [2].

Figure 5.

C-V characteristics at different frequencies. The AC signal was 50 and the step size was 35 mV. The corresponding frequency was about 0.028 Hz. The shape is the same when the voltage is swept up-down and vice versa [2]. Reproduced from [2], Figure 1, Figure 2, Figure 3 and Figure 4, with the permission of AIP Publishing.

Poling affects the C-V curve as shown in Figure 6. Pintilie et al. [2] established that the sharp capacitance peaks/discontinuities observed in the C-V characteristics at different frequencies are associated with the polarization reversal and took the difference between slopes toward the switching peaks for the two branches as qualitative evidence supporting their proposition. Furthermore, if the FE film acts as a large band-gap semiconductor and the SRO-PZT interface behaves as a Schottky contact, according to Pintilie et al. [2], this structure can be modeled as two Schottky diodes connected back–to–back. The PZT film was considered p-type. The built-in potential, which is a measure of the band bending near the electrode interfaces [19], is controlled by the value and sign of the polarization charge. Polarization charges have opposite effects on the built-in potentials () at the two SRO-PZT interfaces [12]. At one interface, the polarization charge decreases compared to the case where the polarization is absent, while at the other interface, the polarization charge increases with . Therefore, when the polarization switches, charges change suddenly, and this is accompanied by changing the sign of the polarization charges at the two interfaces. The sudden and irreversible change in charge due to polarization reversal leads to the discontinuity in C-V. Once the polarization is reversed and saturated, the built-in potential remains the same up to the coercive voltage (of opposite sign).

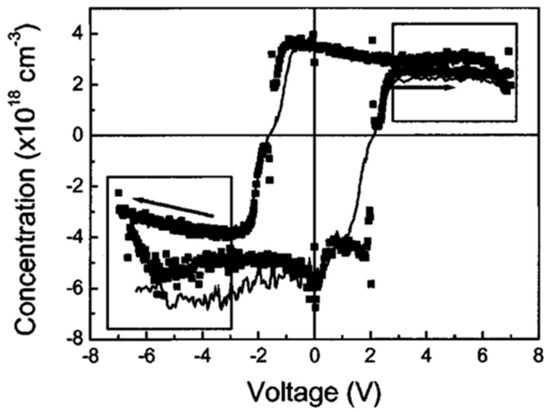

The behavior of the C-V curve for values is governed by the voltage dependence of the dielectric constant. For or , the polarization becomes fully saturated, and the dielectric constant becomes relatively independent of voltage. For these regions, shown in the boxes in Figure 7, the system behaves like a normal Schottky contact with dielectric material acting as a semiconductor. Thus, the C-V can be used to extract the (donor or acceptor) impurity concentration in the dielectric material using the relation:

Caution must be exercised to avoid artifacts such as contributions from spurious elements in the system including electrodes, grain boundaries, leads, etc.

The DC bias sets the polarization value, while the small-signal AC voltage produces reversible movements of the domain walls. Bolten et al. [19] used this phenomenon to measure the reversible component of P and separate it from its irreversible component. Furthermore, they investigated the influence of the dielectric composition on the reversible and irreversible contribution of polarization in FE thin films. Monitoring the reversible polarization component is also helpful in determining fatigue. The electric field can be measured from the C-V curve using the Equation (2):

C-V characteristics of metal-insulator-metal (MIM) systems () bear contributions from two sources: changes in and the changes in the depletion layer width, , which acts as an artifact when measuring the dielectric constant of a FE material. When the field dependence of the dielectric constant explains the C-V characteristics, the dielectric acts like an ideal insulator. On the other hand, when the voltage dependence of the dielectric’s depletion layers describes C-V behavior, it acts like a semiconductor [14].

Considering the nonlinearity of the PZT’s dielectric response, Basceri et al. [20] expressed their C-V results based on a Landau-Ginzburg expansion of the polarization. Outzourhit et al. [21] calculated the change in the field due to a nonlinear dielectric response. Interestingly, both the Landau-Ginzburg expansion and the semiconductor model expansion of the polarization provided similar results. The relative size of the contributions may vary depending on the sample and experimental conditions. It can be concluded that C-V measurement may convey an ambiguous value for [2].

Domain walls contribute to the permittivity in an FE material. FE domains in a dielectric nucleate at specific sites in the vicinity of structural defects. Upon application of an external field, the domain walls propagate [17]. However, their motion is influenced by the existing local defects [18]. This phenomenon is referred to as the “pinning” of the domain wall movement by a local defect. Motion and/or pinning of domain walls can contribute to the permittivity when , where the density and structure of the domain walls and phase boundaries remain unchanged with field cycling.

Domain wall pinning of PZT contributes to dielectric permittivity according to Raleigh law. It has two components: a reversible component—, the relative dielectric constant and an irreversible component—, both of which contribute to the dielectric permittivity [19,20,21]:

2.4. Measurement of Leakage Current Characteristics in PT-Based Materials

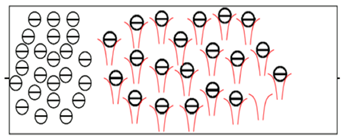

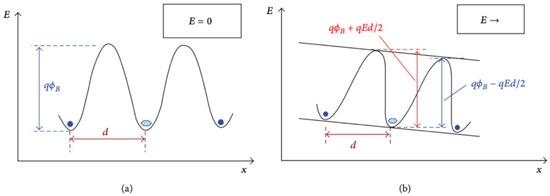

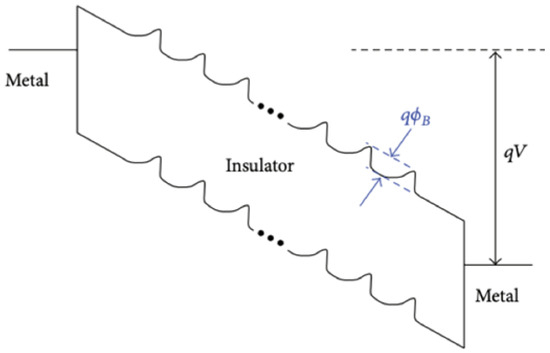

The leakage current reduces the overall efficiency of the pyroelectric detectors. In thin insulating films, the current depends on the applied voltage (), time (), and temperature (). A compilation of possible transport mechanisms in thin films is provided in Appendix A.1. PT-based materials exhibit different conduction behavior depending on physical parameters such as film microstructure, thickness, doping level, and electrode materials. Among different PT-based materials, PZT has been the focus of much attention due to its applicability in ferroelectric random access memory (FERAM) technology and has been prepared by the sol-gel technique almost exclusively.

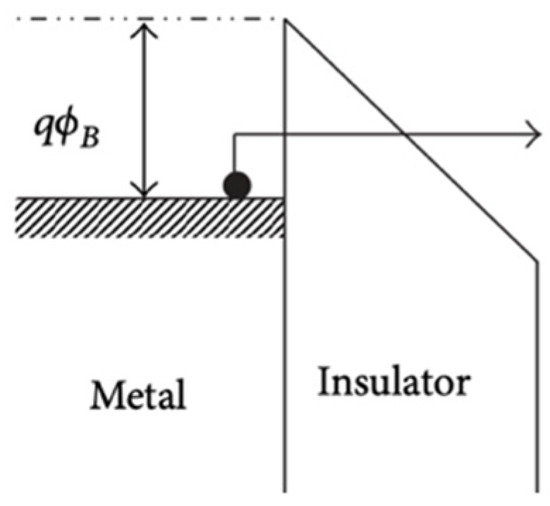

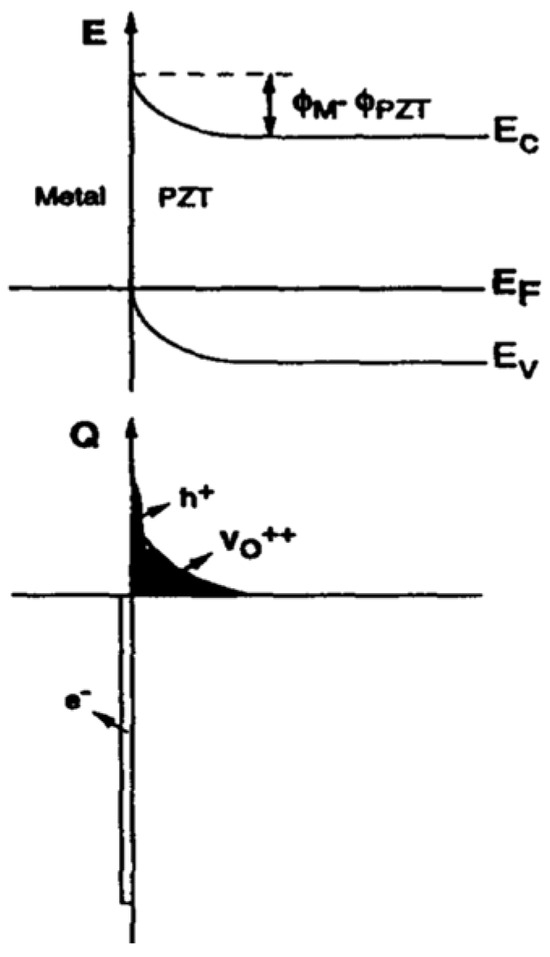

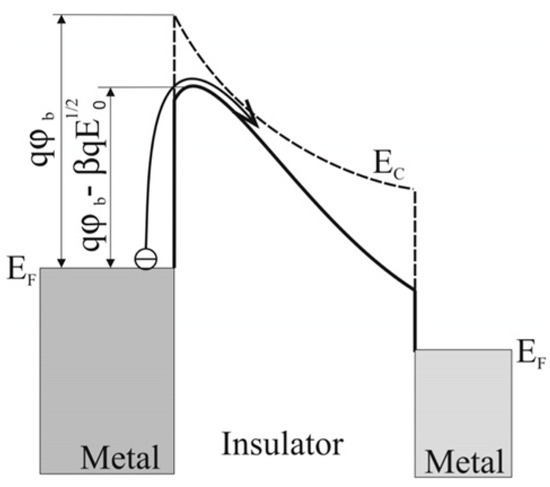

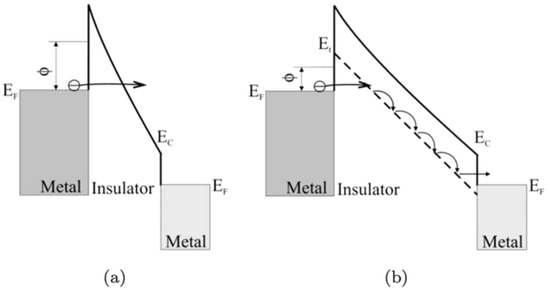

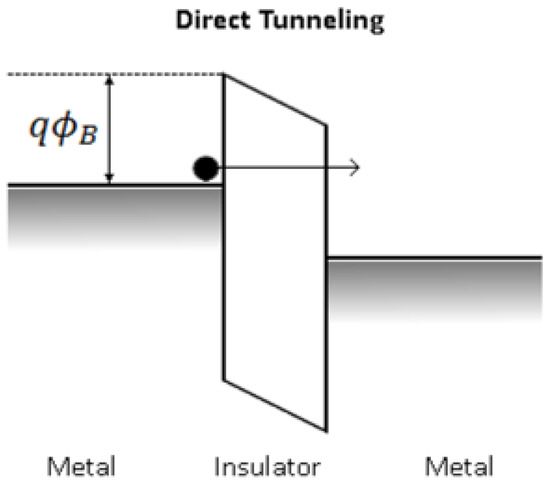

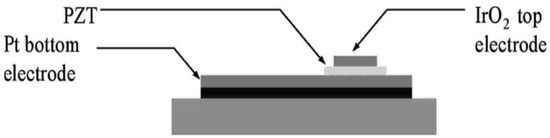

2.4.1. Metal/PZT Band Diagram

To identify leakage mechanisms in PT-based dielectric insulators, it is crucial to consider the band diagram of the metal-semiconductor (M-S) contacts. In this section, we discuss the electronic properties of PZT material. We begin with the theoretical analysis of the Pt/PZT interface.

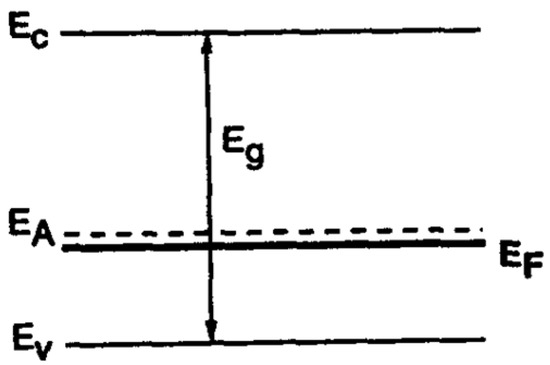

PZT is a relatively wide bandgap semiconductor with and generally has p-type conductivity. Raymond and Smyth [22] studied polycrystalline bulk samples at high temperatures (). At such high temperatures, both grain boundary and bulk conduction may contribute to the transport mechanism. Unintentionally doped PZT possesses a large concentration of acceptor impurities but is generally compensated by the formation of oxygen vacancies (), which leads to a relatively small concentration of the active acceptors. Hence, the Fermi level () resides at energy relatively far from the valence band edge ().

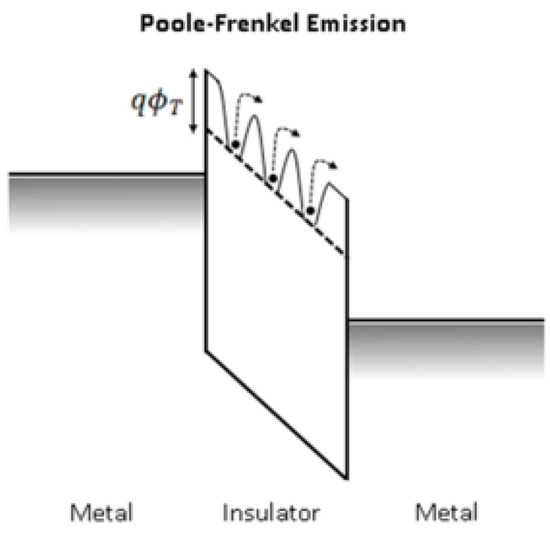

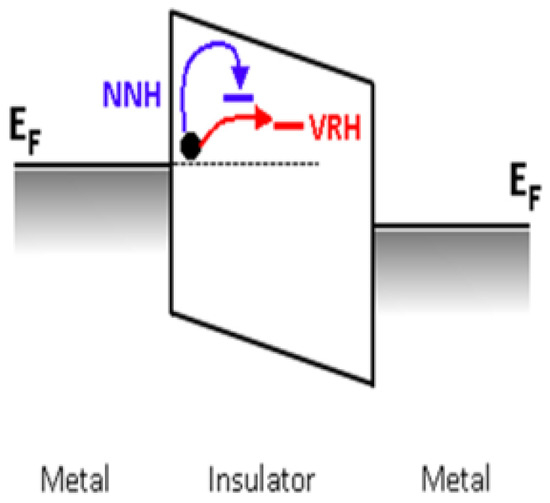

Due to the large ionization energy (0.71 eV) of the acceptor impurity level (), the impurities freeze out at lower temperatures (). In this case, resides below , as shown in Figure 8. Except for the deep hole trap formed by the acceptor impurities, can act as a shallow hole trap and as a deeper (~1 eV) electron trap. These traps can influence the free-carrier conduction in PZT via Poole-Frenkel or hopping conduction [12,23,24]. Two kinds of crystalline structures are important in thin-film PZTs:

- fine-grained films, with grain boundaries (GB) parallel and perpendicular to the current flow, and

- columnar grain structures, with GBs parallel to the current flow.

Grain boundaries can act as barriers when they stand perpendicular to the current flow. These structural differences may result in a variety of I(V) behaviors. In the following analysis, to simplify the discussion, PZT film is assumed to be a single crystal material.

Below , PZT accommodates only a minute concentration of holes and thus, behaves very much like an insulator. Consequently, in a PZT ferroelectric capacitor (FECAP) with blocking contacts, a supply of carriers at the metal-PZT contacts is required if the charge is to be transported across the insulator.

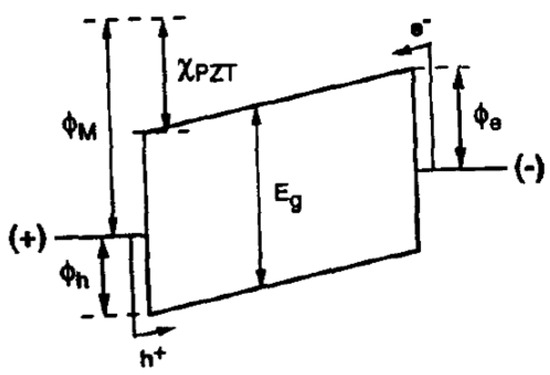

Figure 9 depicts the energy band diagram proposed by Wouter et al. [22] for the structure, which predicts a hole barrier of and an electron barrier of for injection from the metal into the fully depleted PZT. Assuming PZT behaves like a fully depleted “insulator”, Pt contacts are employed and Schottky theory applies () [23]. Wouter et al. [22] argued that hole injection prevails. The electron affinity for PZT () is derived by assuming and using the experimental value of for the PZT work function [24].

At higher temperatures, oxygen vacancies (), which act as compensating negatively charged acceptors, are mobilized and drifted under the influence of the electrical field, induced by contact potential, for example [25]. These charges will then accumulate near the Pt electrode and provide the required positive space charge needed to neutralize the negative electrode charges caused by contact potential.

This process is important during the annealing of the Pt-PZT interface [26].

If the metal is negatively (or positively) biased relative to the semiconductor (PZT), the required balancing charge in the semiconductor (PZT) interfacial region is positive (or negative), which must be supplied through hole accumulation (hole depletion, i.e., ionized acceptors or inversion) and is accompanied by an upward (or downward) bending of the energy bands. For the lightly p-doped compensated PZT films, the concentration of the holes in the thin film is inadequate to support balancing charges on the electrodes. Hence, negligible band bending may occur even when a large negative (or positive) voltage is applied. As a result, in both cases, PZT will become fully depleted and behave as an ideal insulator. Since > , accumulates near the Pt contact during the annealing. Throughout the cooling down period, however, the space charge created remains frozen-in near the Pt/PZT interface. This causes the bands to bend up, as shown in Figure 10.

While the oxygen vacancies freeze-in at lower temperatures, the accumulated holes remain mobile. If this carrier reservoir can be easily refilled, either by carriers supplied by the metal (when ), or by fast carrier generation, an Ohmic contact is achieved, which enables a hole current to flow from the positively biased contact through the PZT film. At least in a low current regime, this hole current is not controlled by the interface but by the conduction process in the bulk of the PZT film.

The hole accumulation region eventually disappears if the bias is increased, and the contact returns to a blocking state, where the current will become interface-limited, and holes can only be injected into the PZT film by crossing over the barrier.

The non-annealed Pt-PZT interfaces present a poor interface, which further impedes the injection of carriers. Then, ionic conduction becomes dominant.

In contrast to bulk models, the current increase in the current-degradation regime is not caused by bulk conductivity changes but by (increased) carrier injection at the Pt-PZT interface, while either the carrier injection mechanism or bulk conduction processes may limit the current in the saturation current region.

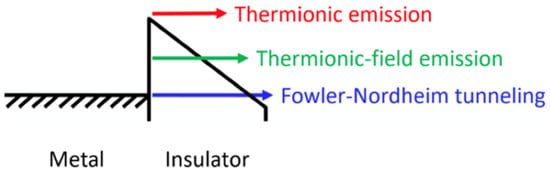

2.4.2. Leakage Mechanisms in PT-Based Materials

Various processing steps are utilized for the preparation of PT-based thin films, which lead to different electrical properties. Consequently, numerous physical models have been proposed to describe the leakage current behavior in PZT films. A summary of the proposed conduction mechanisms in PT-based films is provided in Table 2 and has been analyzed by Wouters [22] (see Appendix A.1).

Table 2.

Summary of the proposed conduction mechanisms in PT-based films.

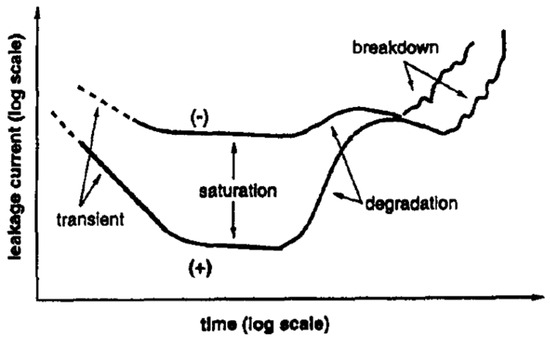

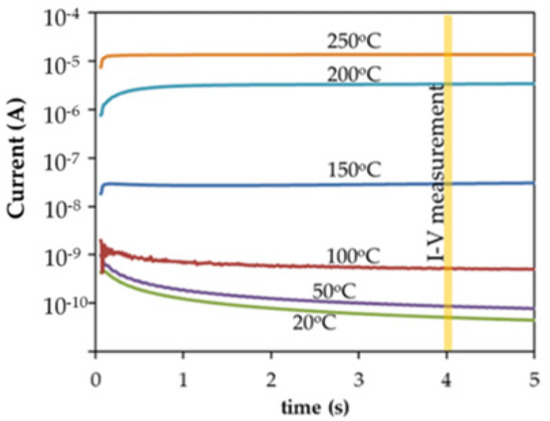

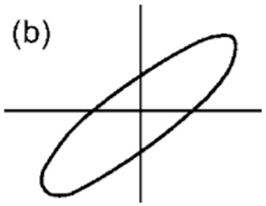

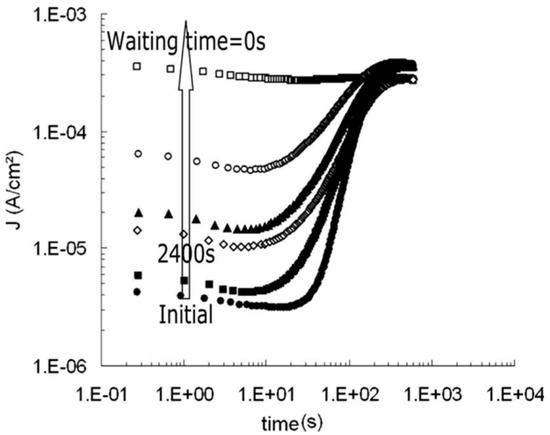

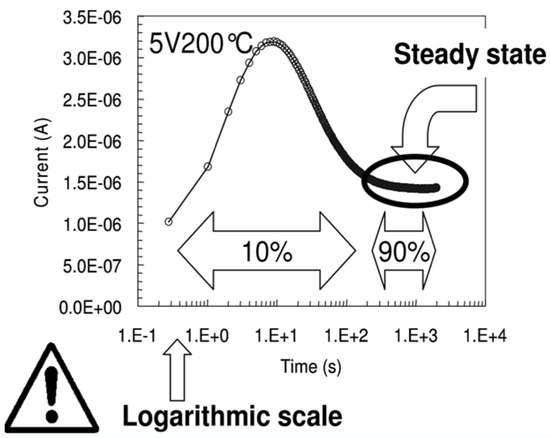

Figure 11 shows the typical transient, saturation (true leakage), and degradation regime, as well as the breakdown region commonly observed in I(t) characteristics of Pt-PZT-Pt capacitors. Four distinct regimes in I(t) characteristics of the Pt-PZT-Pt FECAP can be identified [27]:

- The transient current: This is the initial decrease in current with time.

- The saturation (“true” leakage), which becomes pronounced after current transients are died out and predominates leakage for a certain period.

- The resistance degradation regime, where I(t) increases until a maximum value is reached.

- The dielectric breakdown region.

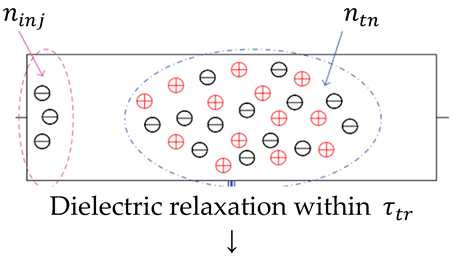

Thin polycrystalline alkaline-earth titanates normally contain substantial concentrations of positively charged oxygen vacancies. Thus, in a DC electrical field, they migrate toward the cathode. This makes it easier for carriers (electrons) to overcome the barrier because it modifies the shape of the barrier. These vacancies are positively charged with respect to the regular lattice and are commonly held responsible for resistance degradation [29,39] that provides a quantitative analytical model for the resistance degradation regime.

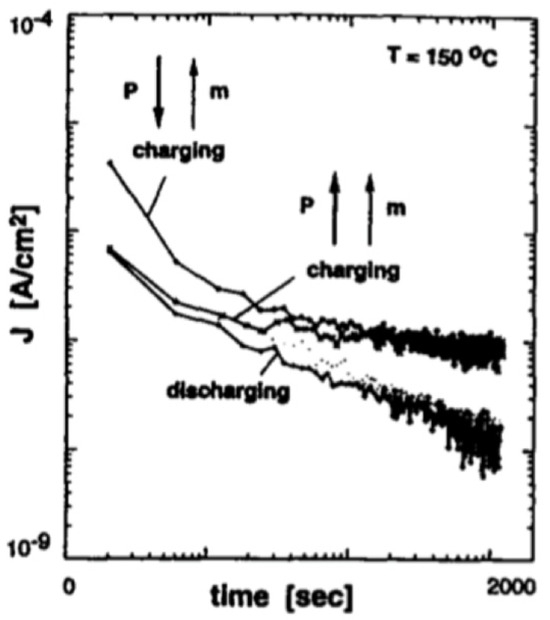

Figure 12 shows the charging and discharging currents measured at . This sample was pre-poled with a poling field parallel or antiparallel to the applied electric field. The magnitude of I(t) depends on the sample history [22]. These observations show that the identification of the conduction mechanism (s) in PT-based films is complex. This is because:

- The data on I(V) and I(t) measurements depend on the separation technique used for the “true” leakage current from the dielectric relaxation current. In perovskites, the current comprises a time-dependent component dielectric relaxation, which is strongly dependent on the measurement technique, prior history of the sample, and other factors, as seen in Figure 12.

- Often, different conduction mechanisms result in similar I(V) curves, especially when the analysis is carried out on a limited voltage interval.

- Different processing factors and physical parameters including microstructure, thickness, doping level, and electrode materials affect conduction behavior in polycrystalline films.

Thus, a comprehensive experimental study on transport mechanisms in PT-based perovskite dielectrics requires the utilization of diverse measuring techniques for samples prepared with various processing parameters such as thickness, grain structure, interface structure, and doping levels.

In the case of perovskite materials, the leakage current can be described as a superposition of two components: the relaxation current, [] which tends to vanish as the stress time is increased, and the “true” leakage current, which reflects the real evolution of leakage current inside the dielectric [22,40]. Although the true leakage current is usually considered static, it does evolve with time. To consider this time evolution, two complementary factors is introduced: the resistance degradation factor [41] and the resistance restoration factor [42].

where is the slope of in the log-log plot. becomes predominant after a certain time has elapsed [43]. There are three well-known mechanisms that can give rise to the exponential dependence of current density on the elapsed time; these are space-charge trapping, relaxation time distribution, and electrical charge hopping [44].

The precise determination of conduction mechanisms requires accurate measurements of the “true” leakage current. Measurements of and characteristics must be carried out in the saturated current regime at . The time dependency of the current density makes it challenging to obtain curves representative of the true leakage current.

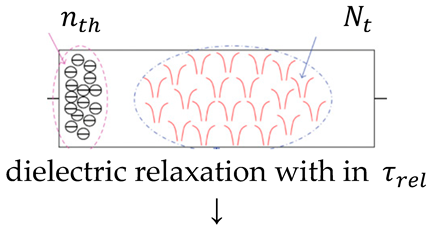

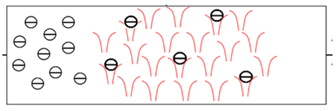

- Dielectric relaxation regime.

The first term on the right-hand side of Equation (4) follows a Curie Von-Schweidler law and is due to dielectric relaxation [42]. As shown in Figure 11, it is attributed to the transient regime and characterized by the initial decrease in current due to the displacement of charges [45]. For PT-based insulators, the relaxation mechanism is pronounced at , while the term is thermally activated with an activation energy , and the slope in relaxation regime () appears to be temperature-independent, with . Several authors proposed possible mechanisms responsible for the dielectric relaxation process for PT-based materials. Chen et al. [45] attributed dielectric relaxation to either the electrical charge hopping or to a Maxwell-Wagner polarization with a wide distribution of relaxation times. Nagaraj et al. [46] assumed oxygen vacancies as well as ions as possible trapping sites and considering the energy levels of these defects in the band gap of PZT, they attributed dielectric relaxation to charge entrapment in respective trapping sites. On the other hand, Simons [47] suggested that electrons associated with oxygen vacancies account for the relaxation current.

- 2.

- The saturation region.

This is the relatively constant low-level current density component in Figure 11 and represents the true leakage current. It can be described as a thermionic Schottky injection of holes through the anode/PZT interface, which follows the relationship:

where is the Richardson constant, is the initial potential barrier height at the anode interface, and is the Boltzmann constant. This region is characterized by the fact that the charging and discharging currents are not identical [45]. Saturation is not usually a prominent component of the leakage current at room temperature even after a few . Except for small biases, it is best revealed in the temperature range of .

- 3.

- Resistance degradation and restoration region.

This is the term attributed to the increasing current region in Figure 11, next to the saturation region. The amount of increase in the current depends on the sample, which is noticeable for positively biased samples with unannealed top electrode [41] (not to be confused with dielectric breakdown). Oxygen vacancies are present in significant concentrations in alkaline-earth titanates. They are positively charged with respect to the regular lattice. In a DC electric field, they migrate toward the cathode. The redistribution of the oxygen vacancies near the interfaces alters the shape of the barrier for carrier injection, making it easier for electrons to overcome [41]. This increase in current density may be modeled by a decrease in the effective barrier height at the cathode. Zafar et al. [39] modeled this resistance degradation region by a factor as:

where represents the metal/PZT barrier height lowering [41]. The onset of this current degradation regime is shifted to shorter times with increasing temperature and voltage [41], making it difficult to distinguish the transition from the saturated current regime to the resistance degradation regime.

As the time elapsed, oxygen vacancies accumulated near the neutralized cathode. Consequently, space charge density is decreased at the cathode interface, for which electron injection may be modeled by an effective increase in the barrier height leakage, which reaches a maximum and then starts to decrease. This behavior is modeled by the resistance restoration factor [42]:

where describes the barrier height restoration potential. Then, after a certain period of stress time, the metal/PZT barrier height tends to recover its initial value due to space charge reorganization induced by lead vacancies.

To investigate the conduction processes, measurements of the I(V) and I(t) characteristics should be carried out in the saturated current regime () [41].

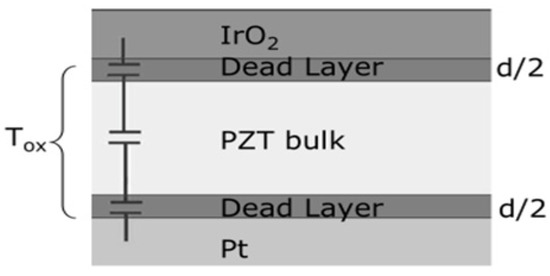

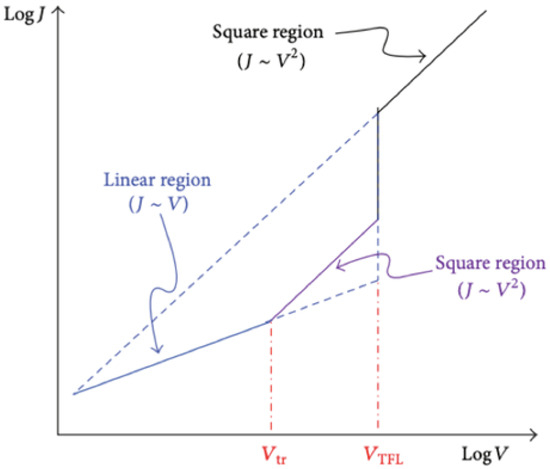

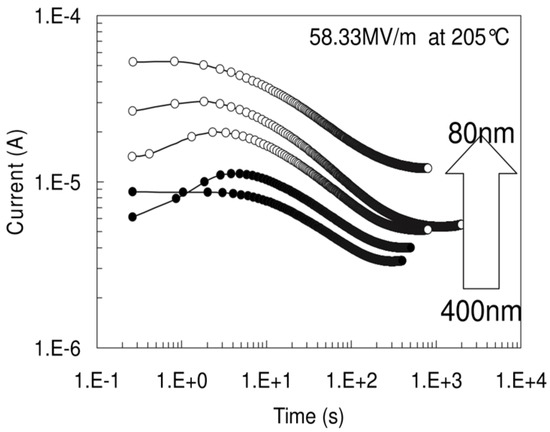

2.4.3. The Effect of Dielectric Thickness on Leakage Current Mechanisms

Chentir et al. [27] investigated the evolution of leakage current in PZT capacitors as a function of dielectric thickness. A protocol was introduced, which avoids artifacts commonly encountered in the measurement of current in perovskite dielectrics (Appendix A.4). A change in leakage current mechanism from Schottky to Poole–Frenkel (PF) mechanisms (Appendix A.3) was observed as PZT thickness decreased and was accompanied by a drift in the value of the device capacitance. Modeling the capacitor as in Figure 13 provides an estimate of nm thickness for the “dead layer”, although the nature of such layer has long been a matter of much controversy [29,48]. The switch from an interface-limited conduction mode to a bulk-limited mode is attributed to the presence of a higher defect concentration due to oxygen vacancies (in comparison with PZT bulk) in the dead layer present at PZT-electrode interfaces.

Figure 13.

Schematic representation of three series capacitors modeling for dead layer thickness extraction [27]. Reprinted from [27], Figure 5, Figure 7, Figure 8 and Figure 14, with the permission of AIP Publishing. https://doi.org/10.1063/1.3055416.

2.4.4. Case Study: Leakage Current Mechanisms in Au/PCT/Pt Structure

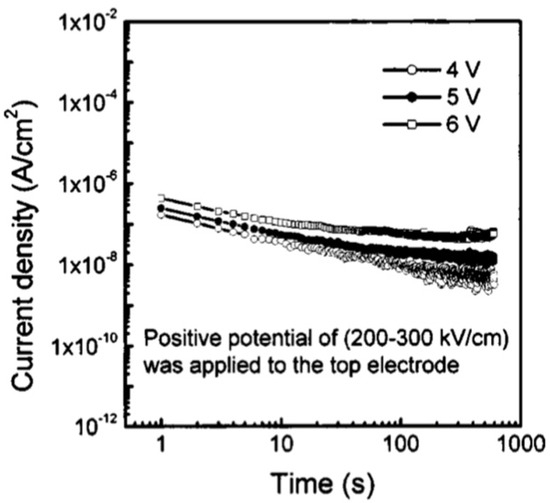

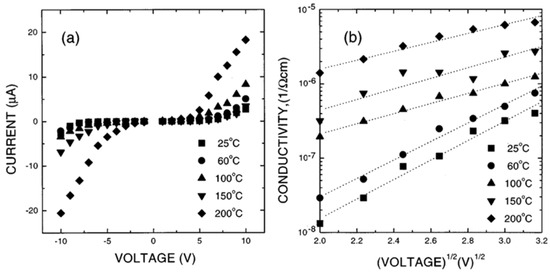

Tang et al. [3] measured the room temperature characteristics of the structure under different applied DC voltages (with the positive or negative potential connected to the Pt and maintained for ). The dielectric relaxation current versus time characteristics of the capacitor was measured after removal of the field.

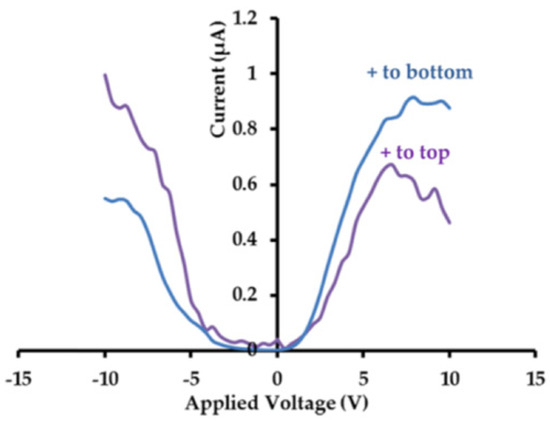

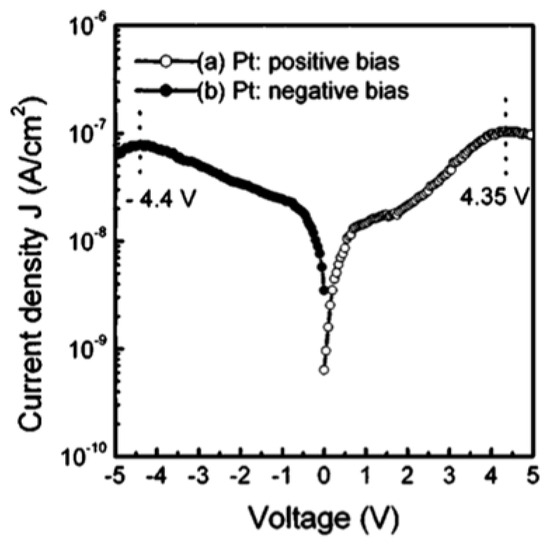

Figure 14 shows the current density as a function of voltage with Pt electrode biased at . At low electric fields with negatively biased electrodes, the interface exhibits a Schottky barrier characteristics, while the Au/PCT interface forms an Ohmic contact. This explains the dependence of leakage current density on the bias polarity.

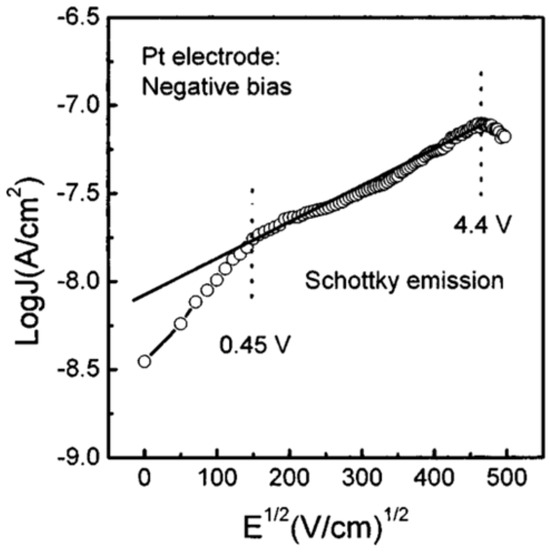

As shown in Figure 15, when the Pt electrode is biased negatively, the interface forms an Ohmic contact for . Schottky emissions over the barrier dominate when .

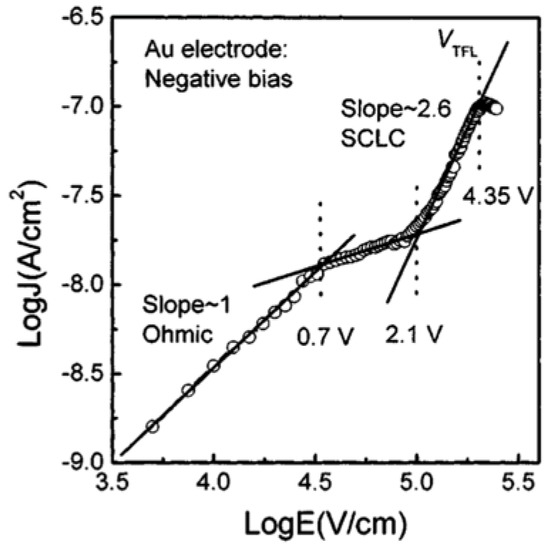

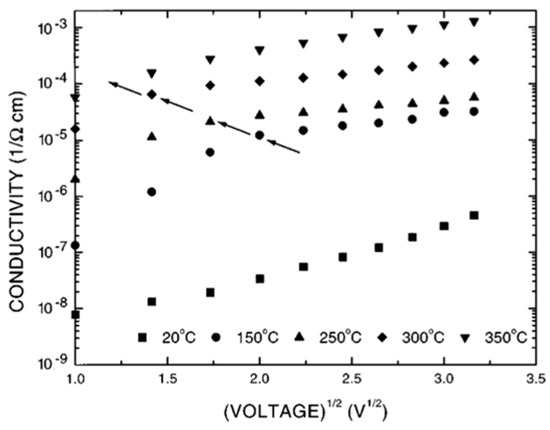

Figure 16 indicates that an Ohmic contact is formed when , while the current obeys SCLC behavior (when ) and the voltage range of marks the region where conduction mechanism is transformed from Ohmic to SCLC. The trap-filled limit voltage is . The dielectric relaxation current behavior of capacitor conforms to the universal (Curie–von Schweidler) law at a low electric field. At higher fields, the current has contributions from both a dielectric relaxation current and a leakage current.

Figure 16.

vs. plot when the Au electrode of the thin-film capacitor is negatively biased. The conduction current shows space-charge-limited behavior for when the Au electrode is negatively biased [3]. Reprinted from [3], Figure 2, Figure 3, Figure 4, Figure 5, Figure 6 and Figure 7, with the permission of AIP Publishing.

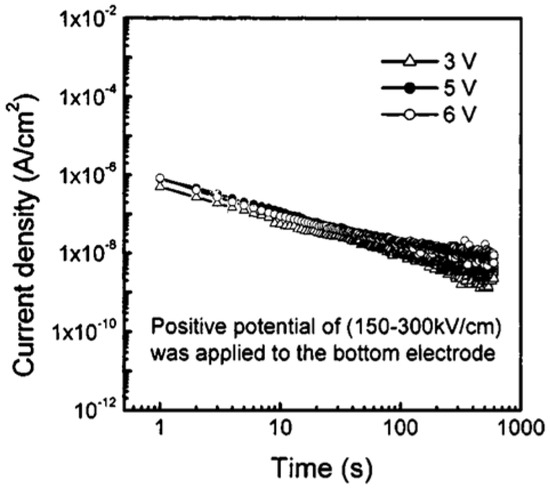

Figure 17 depicts the for several bias voltages applied to the bottom Pt electrodes. The currents measured at low fields (150 and 250 kV/cm) indicate the contribution of pure dielectric relaxation currents.

The dielectric relaxation current behavior of Au/PCT (24)/Pt capacitor obeys the Curie–von Schweidler law at low electric fields, with and at and , respectively. Similarly, when positive potential is applied to the bottom electrode at low fields, indicates the contribution of pure relaxation current (Figure 18). While at higher fields (250 and ), the current has contributions from both a dielectric relaxation current and a leakage current, which itself comprises effects of oxygen vacancy concentration, the magnitude of polarization, space charge trapping, electrical charge hopping, and/or the contribution of defect-dipole complexes.

2.5. Measurement of Fatigue in PT Based Materials

Considerable disagreement exists in the literature regarding fatigue mechanisms in Pt/Pb (Zr, Ti)/Pt (Pt/PZT/Pt). Dimos [49] attributed fatigue to domain pinning, while Desu et al. [50] corelated fatigue to the space charge. Conductive oxide electrodes are known to improve fatigue properties of FE memory devices. When Pt electrodes are replaced by oxide electrodes such as Ru, SrRu, and (La, Sr) Co(LSCO), the capacitors show excellent fatigue and imprint properties [51,52]. It has been proposed that oxide electrodes act as sinks for oxygen vacancies, thereby eliminating fatigue. To understand fatigue and degradation mechanisms in Pt/Pb (Zr, Ti)/Pt (Pt/PZT/Pt) heterostructures, Nagaraj et al. [26] investigated leakage current mechanisms in lead-based thin-film FE capacitors. Distinct differences exist between the electrical behavior of Pt/PZT and LSCO/PZT capacitors, which may stem from their interface disparities. Leakage in Pb based perovskite-type titanates Pb (Zr, Ti) thin films has been previously investigated [37]. Studies on Pt/PZT/Pt structures reported Schottky emission with a barrier potential of 1.41 eV [45,53,54].

Nagaraj et al. [26] prepared epitaxial (La, Sr) Co/Pb (Zr, Sr) /(La, Sr) Co capacitor structures to investigate the dominant leakage current-voltage, I(V) and the behaviors of such capacitors. Epitaxial growth of (La, Sr) Co was purposely utilized to eliminate the effects associated with grain boundaries. It has been established that PZT and PLZT capacitors show Ohmic conduction at low fields (10 kV/cm), with a slope of nearly 1 (Figure 19). The I(V) curves are (i) nearly symmetric, (ii) dependent on temperature, and (iii) possess a positive temperature coefficient (TC).

Figure 19.

(a) I-V-T plots for a typical LSCO/PZT/LSCO capacitor showing nonlinear I-V characteristics and positive TC current. (b) plot for a typical LSCO/PZT/LSCO capacitor showing linear trend at fields higher than V/cm [26]. Reprinted from [26], Figure 2, Figure 3 and Figure 5, with permission from the American Physical Society.

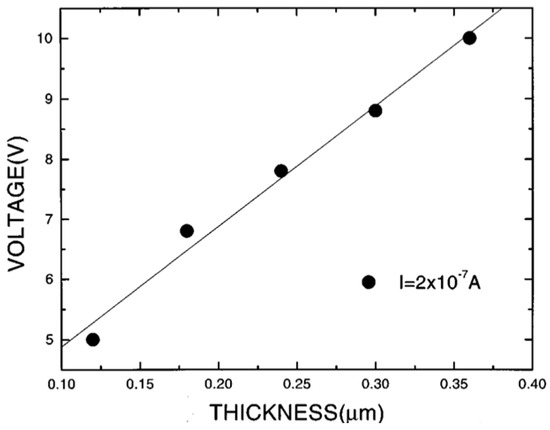

I(V) is nearly symmetrical but nonlinear at higher fields and temperatures. Figure 20 shows the plots at different temperatures. A linear relationship is detected at high temperatures and fields. From the slope of these curve, is obtained for the PZT and PLZT films. This behavior also suggests that at high fields and temperatures, conduction is dominated by field-enhanced thermal ionization of trapped carriers (i.e., Poole-Frenkel emission). Figure 21 shows the plot of voltage versus thickness (V-d) at a constant current in the LSCO/PZT/ LSCO capacitor. The linear trend indicates a uniform field in the bulk of PZT.

The fact that the electric field is uniform in the FE film and that both temperature and field activate the current further confirms that PF emission is responsible for the transport mechanism. The trap ionization energies calculated from the slope of lnσ_0 versus 1/T plots are in the range for PZT and PLZT capacitors. This suggests that the same trap center acts as the P-F center in both PZT and PLZT films. The fact that the ionization energy of to is 0.5 eV suggests that could be the possible PF center. No space-charge region is created at the (PZT or PLZT)/LSCO interface. This could be the reason for good fatigue and imprint characteristics in these capacitors.

Bouyssou et al. [55] investigated the reliability properties and the degradation mechanisms in the Ir/Pb (PZT)/Pt capacitors by characterizing leakage current conduction and provided a model for the evolution of current in the Ir/PZT/Pt capacitor as a function of time, voltage, and temperature.

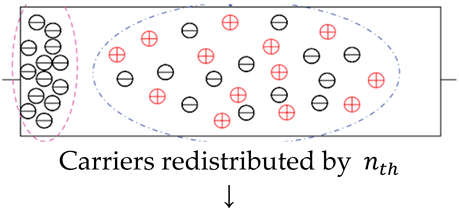

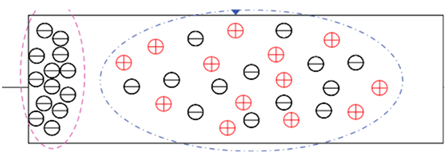

The leakage current conduction in Ir/PZT/Pt structures was found to be controlled by the energetics of the barrier height at the cathode interface. Hence, the voltage and temperature evolution of leakage current were interpreted as an interface-controlled thermionic injection of carriers over a potential barrier at the cathode/PZT contact. The time evolution of the leakage current is mainly characterized by the resistance degradation phenomenon. The model is based on the redistribution of oxygen vacancies near the cathode interface, but also includes the role of oxygen vacancies on dielectric relaxation and trapping phenomena.

2.6. Poling of Pyroelectric Thin Films

Poling is the process carried out to achieve maximum possible FE polarization parallel to an external electric field. During this process, domains with a favorable polarization direction are encouraged to grow at the expense of domains with unfavorable directions. In an unpoled polycrystalline thin film, most grains have an unfavorable crystallographic orientation which prevents the polarization direction to attain a direction perpendicular to the substrate plane and hence leads to a reduction of the maximum.

Once poled, an FE sample will remain poled unless it is de-poled, via repetitive heating and cooling through its transition temperature.

Kohli et al. [56] studied poling conditions for <111> oriented Pb1−xCaxTi(PCT), with as well as <111> and <l00> oriented PbZrTi1−xTi, with (PZT 15/85) thin films. Ca addition to PbTi decreased the tetragonality of the unit cell and thus reduced the Tc, which in turn resulted in higher pyroelectric coefficients. Kohli et al. [56] also used the controlled heating-rate technique [57] to achieve reduced values for dielectric permittivity for the PCT15 by controlling porosity by adjusting nucleation and growth of their sol-gel grown films.

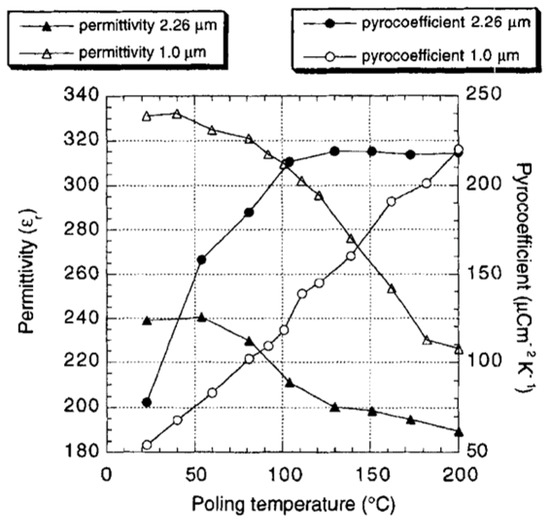

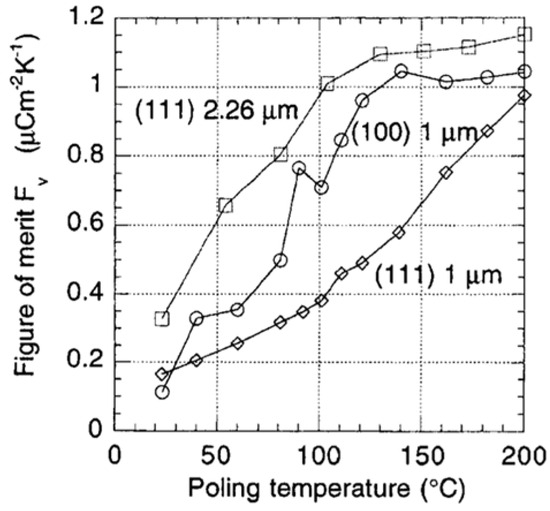

The effect of poling temperature on p and at a constant field of 250 kV/cm is shown in Figure 22. In both films, the pyroelectric coefficient increases with the poling temperature, whereas the permittivity as well as the dielectric loss tangent decreases.

Figure 22.

Permittivity and pyroelectric coefficient as a function of the poling temperature for (111) oriented PZT 15/85 thin films. The films were poled at 250 kV/cm for 10 min [56]. Reprinted from [56], Figure 1, Figure 3, Figure 4 and Figure 5, with permission from the Copyright Clearance Center Inc. (CCC) on Taylor and Francis’s behalf.

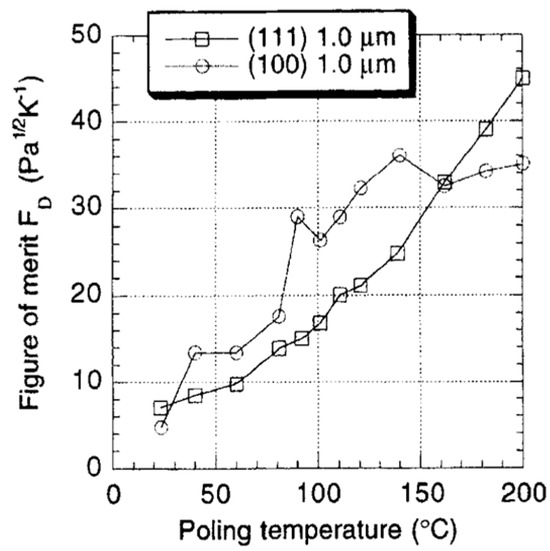

Two figures of merits are of interest: one for voltage response , favoring a high pyroelectric coefficient p and a low permittivity and the other for detectivity , which, in addition, requires a low . Figure 23 depicts the voltage figure of merit versus poling temperature (poled at 250 kV/cm) of (111) and (100) oriented PZT 15/85 thin films.

Optimization of the poling temperature and the electrical field leads to improvement, as shown in the figure of merit for voltage and detectivity. Due to a significant reduction in the dielectric constant of porous films, values of Fv are 3X higher in PCT than in PZT thin films, which suggests that PCT is an excellent candidate for pyroelectric applications. Figure 24 shows that detectivity () versus poling temperature (poled at 250 kV/cm) of (111) and (100) oriented PZT 15/85 thin films 180 domains contribute to phase instability. Thermal activation helps to avoid obtaining such domain configuration.

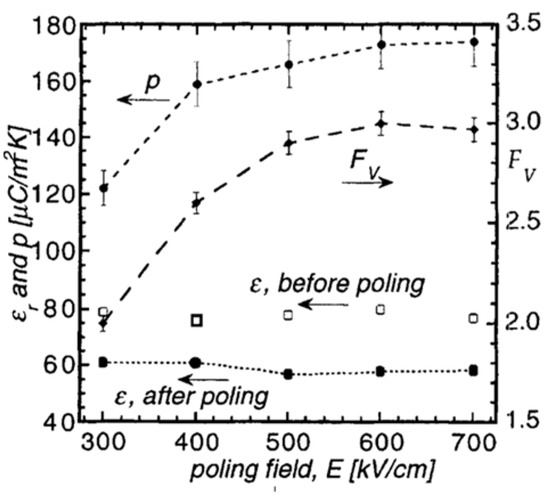

Figure 25 depicts the changes of the pyroelectric coefficient, the permittivity and the figure corresponding to voltage for the PCT15 as a function of poling electric field. Poling was performed at 170 °C for 10 min. Pyroelectric coefficient is seen to steadily increase, reaching a plateau at about 600 kV/cm, which can be attributed to the continued switching of 90°- and/or 180°-domains. The permittivity measured after poling remains approximately constant for all electric fields; thus, remains constant when changes. The necessary poling fields are high compared to PZT, which may be due to the small grain size of about 55 nm for porous PCT15. Domain wall motion and thus polarizability is known to be significantly reduced in small-grained material [55,58]. The dielectric breakdown strength for films of all compositions was equally high and occurred after about 5 min at 160 °C between 1 and 1.5 MV/cm.

Hot poling reduces a-domain population in <100> oriented PZT thin films. At high temperatures, the mobility of oxygen vacancies increases such that it can migrate even under small electric fields. The oxygen vacancies combine with lead vacancies as well as other impurities like , and to form defect dipoles that interact with the domain walls [59]. The defect-dipole complexes reorient themselves under an applied field [60].

The FE domain configuration is frozen during cool-down to room temperature and the polarization is stabilized. The domain pinning by defects leads to a large internal field of 140 to 180 kV/cm (imprint) [56,61]. After poling, some of the poled domains may switch back due to phase instability. Back switching reduces the polarization, and as a result, the pyroelectric signal decreases with time. High coercive field materials with good retention are thus better candidates for pyroelectric applications. Interestingly, these materials also offer comparatively lower dielectric constants.

The decrease in the and after the poling process is attributed to the elimination of domain walls by the internal field (Figure 25). As the DC-poling field increases, the dependence of and on the AC-field drops compared to the unpoled state. This is because domain walls are removed. Hence, the wall contribution diminishes. The combination of these phenomena with porosity and an increased pyroelectric coefficient from Ca-addition result in an improved figure of merit.

2.7. Pyroelectric Measurement

It has already been shown that temperature changes in some crystals (e.g., perovskites) modify the magnitude of their permanent dipole moments or their polarization. This phenomenon is referred to as “pyroelectricity”, which may arise from one or more of the following sources [62]:

- Changes in the permanent polarization along the x direction ,

- Changes in dielectric permittivity of medium leading to the electric field induced polarization ,

- Changes in the piezoelectricity , and

- Changes in the flexoelectric polarization .

Therefore, the changes in the polarization along x axis is described by:

where is the permanent polarization along x axis, represents components of the dielectric tensor, represents the electric fields in the k directions, represents components of the piezoelectric tensor, represents components of the stress tensor, represents the components of the flexoelectric tensor, and represents the components of the strain tensor. This 1D analysis can be generalized to 2D or 3D without any loss of generality. By dividing both sides by incremental changes in temperature (ΔT) and considering the limiting case, where ΔT⟶0, the following equation is obtained:

Thus, the pyroelectric coefficient is calculated as follows:

where . When a field is applied externally, the second term in (10), may become enormously large in the vicinity of phase transitions, where becomes very large [63].

This criterion is implemented for the device operation in the “dielectric bolometer mode”. It must be noted that as the electric field increases, decreases, and thus, the second term in (10) remains finite. Nevertheless, it is undesirable for pyroelectric detection because it obscures the pyroelectric effect. The effect of the flexoelectric term, although considerable at the nanoscale [64], where large strain gradients are present, is neglected in the present treatment.

2.7.1. Measurement of the Pyroelectric Effect

There are three main approaches to the measurement of the pyroelectric effects on bulk samples: (1) direct measurement of the polarization and/or dielectric constant at two or more fixed temperatures, (2) measurement of the pyroelectric current induced by a ramping temperature up (or down), and (3) measurement of the pyroelectric current induced by periodic temperature change. These are briefly discussed below:

Direct Measurement of the Polarization and/or Dielectric Constant at Two or More Fixed Temperatures

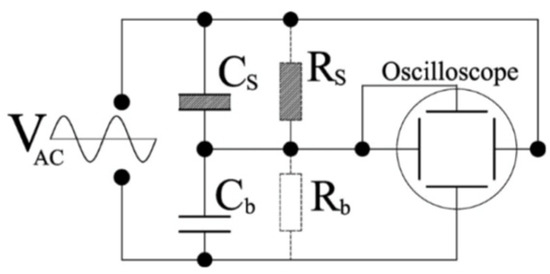

- A.1. Sawyer-Tower (ST) Bridge Technique

Ferroelectrics can reverse the direction of their spontaneous polarization under the influence of an external electric field and hence allow the direct measurement of the magnitude of the permanent dipole moment. In the ST technique [65,66], the polarization and/or dielectric constant of the material is directly measured at two or more fixed temperatures, and the pyroelectric coefficient is obtained from . The method is restricted to ferroelectrics, where coercive fields are much smaller than their breakdown fields. The currents are evaluated by running the ST bridge as shown in Figure 26.

Figure 26.

The Sawyer-Tower bridge. In its original form, it did not consider the presence of the leakage current represented here by . This current must be partially balanced by a shunt resistor and polarization hysteresis curve must be checked. A properly balanced would show a square-shape polarization hysteresis loop. The capacitance of the material is denoted by . The bridge is constructed using a linear capacitor [62]. Reprinted from [62], Figure 1, Figure 2, Figure 3, Figure 4, Figure 5, Figure 6, Figure 7, Figure 8 and Figure 9, with the permission of AIP Publishing.

There are three main approaches to the measurement of the pyroelectric effects on bulk samples.

The analysis above assumes that polarization (P) is perpendicular to the plane of the contacts. If P makes an angle Ω with respect to the to the plane of the contacts, this technique provides the projection of the polarization on the plane of the contacts, . The bridge is generally constructed using a linear capacitor (), where and is the capacitance of the FE material, which includes polarization switching . Here, the sample area is denoted by . The voltage measured across is proportional to the total surface charge on , which represents the polarization charge stored on the surface of the FE material in the absence of a real electric current in the FE medium. Most FE media exhibit ohmic conductivity and/or charge trapping effects. The Ohmic conductivity can be partially compensated for by shunting by resistor, whose value is varied until an ideal square polarization is achieved.

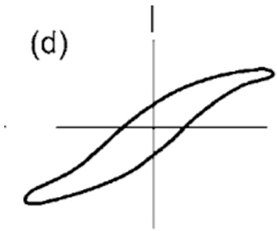

P(E) exhibits an ‘S’ shape rather than a rectangular contour if the coercive field is not uniform over the volume of the medium under investigation. It is then impossible to distinguish between Ohmic conductivity and true polarization effects. Because no value of the shunting resistor exists for which the hysteresis loop becomes rectangular. Then the ST bridge, using a shunting resistor, becomes unreliable for accurate determination of the polarization. This reservation also applies to a variation of the ST bridge, in which is replaced by a current-to-voltage converter, whose output is either electrically or “computationally” integrated and allows for extraction of the polarization and coercive field; this has become a popular ST bridge technique in industry [67].

A second issue associated with ST bridge measurement is due to charge trapping at the contact-sample interface or, sometimes, in the bulk of the medium and leads to real current components. In this case, no technique based on measuring the reversible charge storage using an alternating electric field will produce meaningful data (an example of such FE-like behavior is electret [68]. The ST technique is prone to inaccuracies stemming from the Ohmic conductivity as well as noise currents caused by interface/bulk trapped charges and is appropriate only for ideal pyroelectric materials with square hysteresis loop.

- A.2. Modified ST bridge (Liu) method

This method assumes that the loss (trap) current () is a function of the applied voltage and only the displacement current is proportional to . Liu [69] proposed a similar method that allows the extraction of the polarization and coercive field. The total polarization P* is the sum of the permanent polarization , and the polarization induced by the electric field , where is the sample thickness.

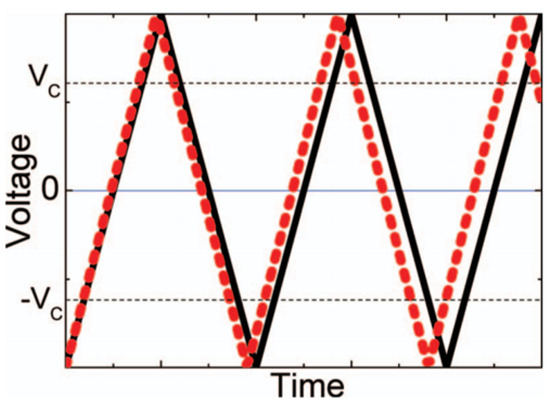

In this method, the currents are evaluated by running the ST bridge with a triangular-shaped voltage input at two closely spaced frequencies. To ensure that complete switching of the polarization takes place between applied voltages, amplitudes of the two input voltages chosen are larger than Vc. (Figure 27).

By integrating the current difference at the same voltage of the two voltage wave forms, it can be shown that:

Equation (11) is useful when polarization switching, rather than the externally applied voltage, dominates the current. This condition is fulfilled when the coercive field is small. By calculating at two different temperatures, one can evaluate the sum .

Furthermore, is determined by evaluating at .

Another technique is based on the use of an AC bridge to measure ; then, is written as:

The measurement of provides a simple means to verify the presence of ferroelectricity in bulk materials since its value is independent of frequency up to the GHz range, at least in the case of “ideal” FE material. The drawback to capacitance measurement by an AC bridge is that it always comprises artifact components due to displacement, ohmic, and charge-injection currents. The latter not only contributes to the inaccuracy of the capacitance measurements but also affects the electric field in the sample.

Measurement of the Pyroelectric Current Induced by Ramping Temperature Up (or Down)

The continuous temperature ramp technique measures the current flowing between two contacts on a pyroelectric sample induced by continuous heating or cooling. Although the thermal diffusion coefficient () for most pyroelectric materials is quite low (0.01–0.1 cm2/s), even very rapid heating rates (~1°K/s) does not lead to inhomogeneous heating of the unclamped samples. Thus, the sample is uniformly heated and hence, only the first two terms in (10) will contribute to the change of polarization. The effective pyroelectric coefficient is obtained by using two measurement techniques: (1) measuring voltage as suggested by Lang and Steckel [70], and (2) measuring the current flowing under short circuit conditions according to Glass [71] and Byer and Roundy [72].

- B.1. Measurement of the pyroelectric voltage developed across the film by ramping temperature up (or down):

Lang and Steckel [70] described the following method for measuring the pyroelectric coefficient, DC dielectric constant, and volume resistivity of lead-zirconate-titanate ceramic over a wide temperature range. The technique is based on the observation of the capacitive charging of a pyroelectric sample by the pyroelectric current generated during a continuous temperature change.

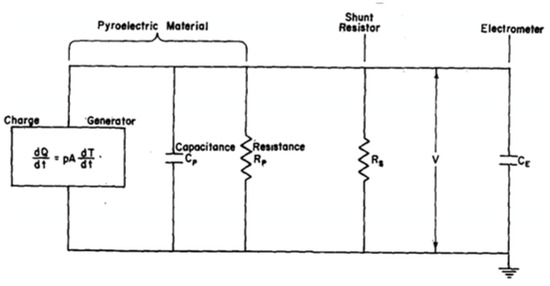

Figure 28 depicts the equivalent circuit for the pyroelectric device, along with its measurement circuit. Assuming that the polar axis is normal to the sample electrodes, the method then leads to , and being parallel to the polar axis. The circuit of Figure 28 is shown below:

where is the equivalent (total) capacitance of the pyroelectric element and the electrometer , and is the equivalent (total) resistance of pyroelectric element , and the shunt resistance (external to sample).

Figure 28.

Lang and Steckel measurement circuit [70]. Reprinted from [70], Figure 1, with the permission of AIP Publishing.

Assuming that the time constant characterizing the rate of temperature change of the samples is much greater than , the integration of (13) with the initial condition gives:

Here, represents the time derivative of the temperature at . The method is easily realizable using a temperature-controlled table. Since the sample temperature is directly measured, can be determined for uniformly heated samples by measuring with at least two different shunt resistors . This technique does not require measurement of heat flux that does not attain isothermal conditions and does not alter the domain structure of a FE material. However, it does require prior knowledge of conductivity as a function of temperature and is a suitable alternative when does not hold.

Measurement of the Short Circuit Current Produced by a Continuous Temperature Ramping (Up or Down)

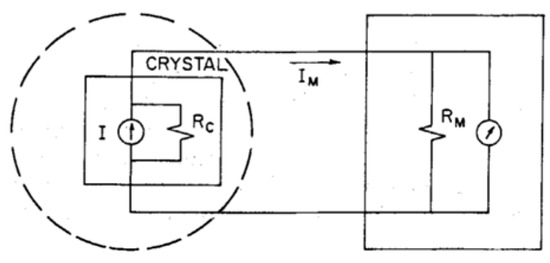

Figure 29 shows the equivalent circuit for DUT that is connected to an ammeter, which was used in [70,71,72] to directly measure pyroelectric current from

where is the pyroelectric coefficient, is the polarization, is the crystal leakage resistance, and is the ammeter input resistance. The measured current is given by:

Figure 29.

Measurement apparatus equivalent circuit [72]. Reprinted from [72], Figure 1, with permission from the Copyright Clearance Center Inc (CCC) on Taylor and Francis’s behalf.

As long as , gives an accurate estimate of the pyroelectric current (denoted by in Figure 29).

Temperature Oscillation (Dynamic) Method

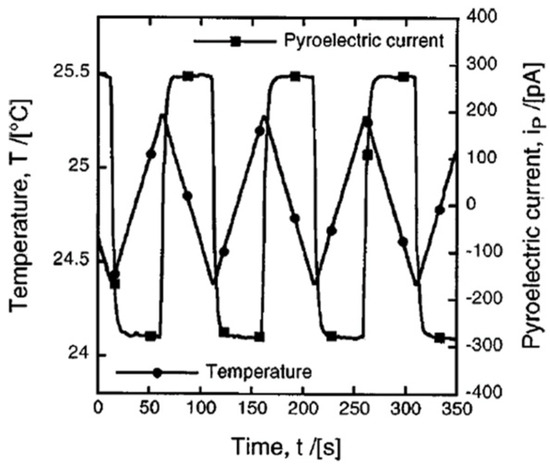

This method was utilized by Davis et al. [73] to measure the pyroelectric coefficient of a thin- plate specimen using the apparatus described by Daglish [74]. The sample temperature is cycled at a frequency of 10 mHz over 1 °C. Using a Peltier element, a triangular temperature wave is formed. The current between the two electrodes is then recorded and the value of p is calculated via (27). A typical temperature waveform as well as resultant pyroelectric current is shown in Figure 30. This technique is simple and direct and does not require prior knowledge of conductivity as a function of temperature. The sample is poled once and then, a series of limited temperature runs is performed at T < Tc. Repeated oscillations over a finite temperature range will eventually deplete the traps [73].

Figure 30.

An example of the dynamic time ramping technique used to measure the pyroelectric coefficient of a single crystal (a Peltier element run at 1 mHz during a 16 min 40 s period was used to create the saw-tooth temperature profile with an amplitude of 1 degree) [62]. Reprinted from [62], Figure 1, Figure 2, Figure 3, Figure 4, Figure 8 and Figure 9, with the permission of AIP Publishing.

Since , the primary unclamped pyroelectric coefficient is obtained from (10) (see Appendix A.3). However, following issues remain:

- Creation and measurement of a large (dT/dt) with low noise.

- Thermoelectric effect is due to contacts which contribute to measured current.

- Thermally activated current due to non-uniformly distributed charged traps [75] is indistinguishable from and may dominate, especially in the poled ferroelectrics. Depletion of the traps requires a large number of repetitions (e.g., in electrets).

- Very long trap time response.

- Measurements of the current through a short circuit require (for all Ts).

In case of thin films, the following obstacles further complicate the measurement of pyroelectric coefficient:

- Depending on their preparation details, thin films generally contain pinholes which decrease the “apparent” resistivity of the sample.

- When the trap concentration , where is the trap concentration in the bulk, it is possible that , where is the pyroelectric current.

- It is possible that the current due to the thermoelectric effect .

Periodic temperature change techniques can be divided into two categories:

- Periodic pulse techniques, and

- The continuous oscillation method.

- C.1. Temperature Changes Using Periodic Pulse Techniques

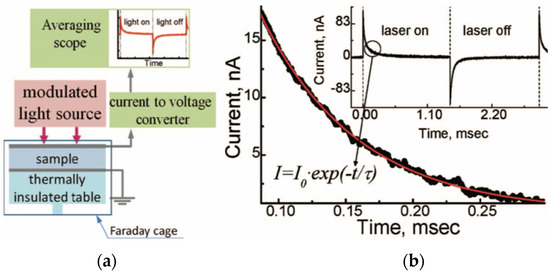

Chynoweth [76] used a periodic step-like heating from a modulated IR laser, which was focused on the thermally insulated sample. A schematic of the instrumentation is given in Figure 31a.

Figure 31.

(a) Scheme of the set-up for the basic Chynoweth method, and (b) an example of the pyroelectric current measured with the Chynoweth technique. The sample is 0.2 × 0.2 μm wide, 0.4 μm thick self-supported film of BaTi tethered to a Si substrate [62]. The top and the bottom contacts are of Ag and account for more than 90% of the heat loss. The inset shows a full period (laser on and off, 666 Hz); the main panel shows an exponential fit. The film was irradiated by an IR laser (λ = 1310 nm) with a flux of 3 mW/mm2. Note: for a self-supported film, a lump model is applicable, and the heating and the cooling processes are fully symmetric [62]. Reprinted from [62], Figure 1, Figure 2, Figure 3, Figure 4, Figure 8 and Figure 9, with the permission of AIP Publishing.

Large pyroelectric currents in response to very small temperature variations is possible if a modulated IR laser is employed as the heating source since, in this case, warm-up and cool-down rates can be much larger than the those in temperature ramping techniques. This technique relies on the following two assumptions:

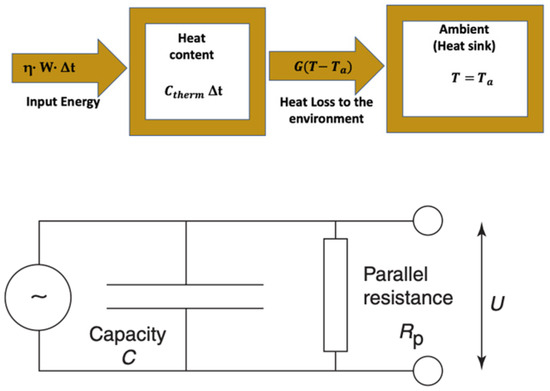

- A lump model can be devised for the DUT (Figure 32). Accurate prediction of the pyroelectric device behavior under broad range of frequencies requires distributed parameter modeling of the thermal gradients. However, if temperature differences within the DUT are much smaller than the temperature changes induced by the input energy (where, is the fraction of absorbed IR power, is the input power, and is the duration period), a reasonably accurate lumped parameter modelling approach is also possible to create. This requires identification of the thermal capacitance and heat conductance to the environment for the DUT if temperature differences within the DUT are much smaller than the temperature changes induced by the input energy. Otherwise, one can introduce “pseudo-lumped” parameters if the temperature rise and fall obey the following:

Figure 32. Lump model for a pyroelectric IR detector: schematic diagram of the thermal model and electrical equivalent circuit of a pyroelectric detector. Upon absorption of fraction of IR radiation (power ), the sensor temperature increases by , which may be obtained from the heat flow balance. The temperature change for a given amount of heat input depends on the heat conductivity to the surrounding environment assumed at temperature , the heat capacity of the element. For a thin film structure uniformly illuminated by the IR radiation, it is generally safe to neglect thermal wavelength effects and assume that the element retains a uniform temperature. Reprinted from [77], Figure 5, with permission from Elsevier.

Figure 32. Lump model for a pyroelectric IR detector: schematic diagram of the thermal model and electrical equivalent circuit of a pyroelectric detector. Upon absorption of fraction of IR radiation (power ), the sensor temperature increases by , which may be obtained from the heat flow balance. The temperature change for a given amount of heat input depends on the heat conductivity to the surrounding environment assumed at temperature , the heat capacity of the element. For a thin film structure uniformly illuminated by the IR radiation, it is generally safe to neglect thermal wavelength effects and assume that the element retains a uniform temperature. Reprinted from [77], Figure 5, with permission from Elsevier.

Here, is the characteristic thermal time constant, and the maximum temperature is , where , with detector area in the input flux [62].

- 2.

- The recording of the pyroelectric current transients and averaging of the output signal is possible over many cycles to improve the signal to noise ratio (SNR).

As schematically shown in Figure 31, the modulated IR laser capable of providing a few mW of power is directed onto the sample. The pyroelectric current generated from the sample is then fed to a current-to-voltage converter and the voltage is recorded using an averaging oscilloscope. Chynoweth [76] modeled DUT as a homogenously heated body with a heat capacitance, connected to its surroundings via . As seen in Figure 31b, the pyroelectric current decays exponentially with time and the response to “radiation on” and “radiation off” is symmetric. is determined from the decay wave form. If voltage is measured, both the and the electrical time constant are obtained and if is known, the only unknown parameter is the amount of radiation being absorbed by the sample.

For bulk samples both the measurement of the and the derivation of the pyroelectric current () generated in response to the periodic heating is relatively simple. For the case of thin films, is found from an analytical solution. With this method, electromechanical isolation of the sample from noise is feasible. Thus, the sensitivity is improved. Also, the effect of trapped charges is detectable [62].

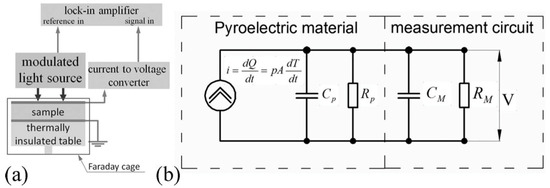

Temperature Change Using Continuous Oscillation Method

In this technique, the sample is subjected to a continuous, sinusoidally modulated heat source (typically a modulated laser), and the generated current or voltage is recorded with a phase sensitive device (typically a lock-in amplifier). The lock-in technique provides a good signal to noise () ratio for a single frequency component (Figure 33).

Figure 33.

(a) The instrumentation diagram for the continuous temperature oscillation technique, and (b) the equivalent electrical circuit with the pyroelectric material and a high-impedance voltmeter connected in parallel [62]. Reprinted from [62], Figure 1, Figure 2, Figure 3, Figure 4, Figure 8 and Figure 9, with the permission of AIP Publishing.

If the sample can be modeled by the lumped parameter approach, the derivation of the current generated in response to the periodic heat input is relatively simple. However, for the case of thin films or multiple layer structures, the lumped parameter model is not always adequate. Holeman [78] proposed models applicable to thin films for a number of practical cases.

- D.1. Extended version of continuous oscillation technique

For the cases in which the material’s conductivity is known, Sharp and Garn [79] and Whatmore [80] proposed to excite the sample by a sinusoidal thermal wave with a frequency low enough to insure homogeneous heating of the DUT (typically 0.2–0.02 Hz). Then, the pyroelectric component of the current will have a 90° phase difference with respect to the sinusoidal thermal wave input. This allows the accurate measurement of the pyroelectric effect in the presence of finite Ohmic losses and thermally stimulated current (TSC) due to the release of trapped charges. This technique requires (for all Ts). However, for thin films or multiple layer structures [81], the lumped parameter model is not always adequate.

- D.2. Temperature change using continuous oscillation method as applied to substrate supported thin films

There are two fundamentally different approaches to measuring the pyroelectric coefficient of thin films on substrates.

- D.2.1. Applying Bulk Techniques to Measure Pyroelectric Coefficient Using the Continuous Oscillation Method

When using periodic temperature change techniques, one has to ensure that the film is uniformly heated and cooled. The first approach of measuring p is to heat and cool the substrate, ignoring the presence of the film. The fact that the thermal capacitance of the substrate is much larger than that of the film ensures that the film is heated homogenously throughout its volume. This criterion is satisfied when the modulation frequency is chosen such that , where is the thermal diffusion time of the film. In this case, the film and the substrate may be treated as a single body during heat-up and cool-down process and any of the temperature change techniques using continuous oscillation method already discussed above is applicable.

- D.2.2. Holeman Periodic Temperature Change Method

The second approach is to use the Holeman methods [62,78]. Holeman has shown that as the modulation frequency increases, the pyroelectric response eventually depends only on the properties of the film and not of the substrate. This occurs if the modulation frequency is at least one order of magnitude higher than the reciprocal of the thermal diffusion time through the film. However, it is necessary to know the thermal properties of the film. is found by plotting the pyroelectric response vs. frequency. The measured under short circuit conditions increases with until . This corresponds to the transition from homogeneous heating of the film (low frequency) to heating of only the top layer of the film (high frequency). Above this transition frequency, the current becomes independent of frequency. However, is needed in order to calculate the p. For very thin films, may easily be so short as to require mHz, thereby making the periodic temperature change technique impractical. This subject is further discussed below:

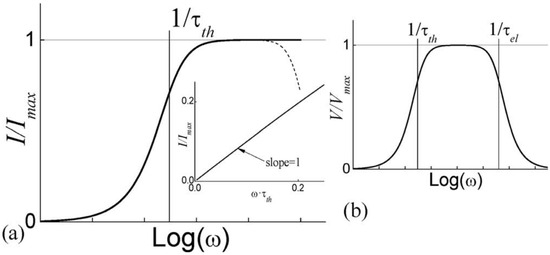

Researchers in [62,78] noted that using complex notation to represent can greatly simplify the mathematical modeling of the relevant heat transfer problem. A “complex” temperature term implies that the absolute value of temperature oscillates with frequency . Researchers in [62,78] developed models for several cases of practical interest and showed that if a thermal detector could be modeled via a lump modeling approach and heated by a sinusoidally modulated heat wave with a modulation frequency at a flux (), the time-dependent portion of temperature varies with frequency as:

where is the thermal time constant. The pyroelectric current is found from (27):

Thus, at low modulation frequencies , the pyroelectric current increases linearly with as:

This corresponds to a homogeneous heating regime, where both the substrate and the film may be treated as a single entity. As is further increased to at least one order of magnitude higher than the reciprocal of the thermal diffusion time through the film, begins to saturate as follows:

This corresponds to the non-homogenous heating regime, where the response is affected only by the film (and is independent of substrate) properties. Therefore, if either or is known for the film, its pyroelectric coefficient can be extracted. In practice, as frequency further increases, the input impedance of the sample reduces while the impedance of the current-to-voltage converter remains relatively constant. Thus, at a sufficiently high frequency, the current flowing through the sample will dominate the total current, causing an apparent decrease in the pyroelectric current flowing through the current-to-voltage converter in Figure 34.

Figure 34.

(a) Typical frequency dependence of pyroelectric current generated in response to sinusoidally modulated heating when the lumped model is applicable; the bold line shows the idealized case when a current-to-voltage converter has a very small impedance over all frequency ranges. At sufficiently high frequencies , the pyroelectric current remains constant . In practical measurements, above some frequency, the input impedance of the sample decreases sufficiently to cause a decrease in the measured current (shown as a dashed line). The actual pyroelectric currents are known to remain constant into the nanosecond time scale. The inset shows that at very low frequencies, the current is directly proportional to frequency. (b) Typical frequency dependence of the pyroelectric voltage. [62]. Reprinted from [62], Figure 1, Figure 2, Figure 3, Figure 4, Figure 8 and Figure 9, with the permission of AIP Publishing.

For very thin films, the thermal diffusion time can easily become so short as to require modulation frequencies in the MHz range, thereby making the periodic temperature change technique impractical. If the measurement is performed with the finite impedance of an equivalent resistor (R) and equivalent capacitor (C) as shown in Figure 33, then the voltage is given by:

where is the electrical time constant. The equivalent resistance is given by and the equivalent capacitance . If , the voltage increases linearly with frequency and then saturates at a value shown in Figure 34b:

for . Since is not known, a comparison of the values of measured with different values of is needed to deduce .

This method has been extended by Sharp-Garn to separate various thermally stimulated relaxation processes from the pyroelectric current [79,82]. By differentiating Equation (21), it is realized that for , the pyroelectric current is out of phase with respect to the input sinusoidal heat wave. On the other hand, as long as the temperature range is limited to less than , thermally stimulated current arising from various relaxation processes can be approximated as:

Here, is the temperature independent term, and is a constant that depends on the nature of the thermal traps. If the sample is heated at a constant rate , superimposed on a sinusoidally modulated component:

Then the non-periodic component of the induced current is given by

and the periodic part of the current is given by

Thus, by measuring , the component that is out of phase with respect to the temperature, p is extracted. Practical applications of this method are described in [79,80].

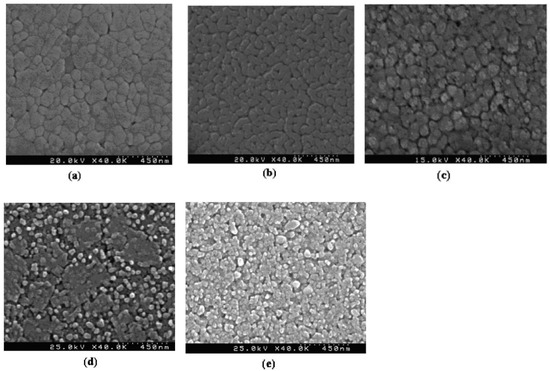

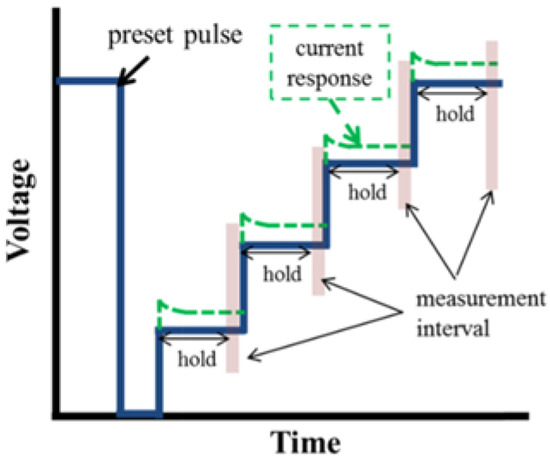

Pyroelectric Current Generated in a Film Supported by a Substrate (Heat Sink) in Response to Sinusoidally Modulated, Uniform, and Lateral Heating