Welding of S960QL High-Strength Steel by the Manual–Automated MAG Technique—A Study of Mechanical Properties, Residual Stresses and Fracture Mechanisms in the Heat-Affected Zone

Abstract

:1. Introduction

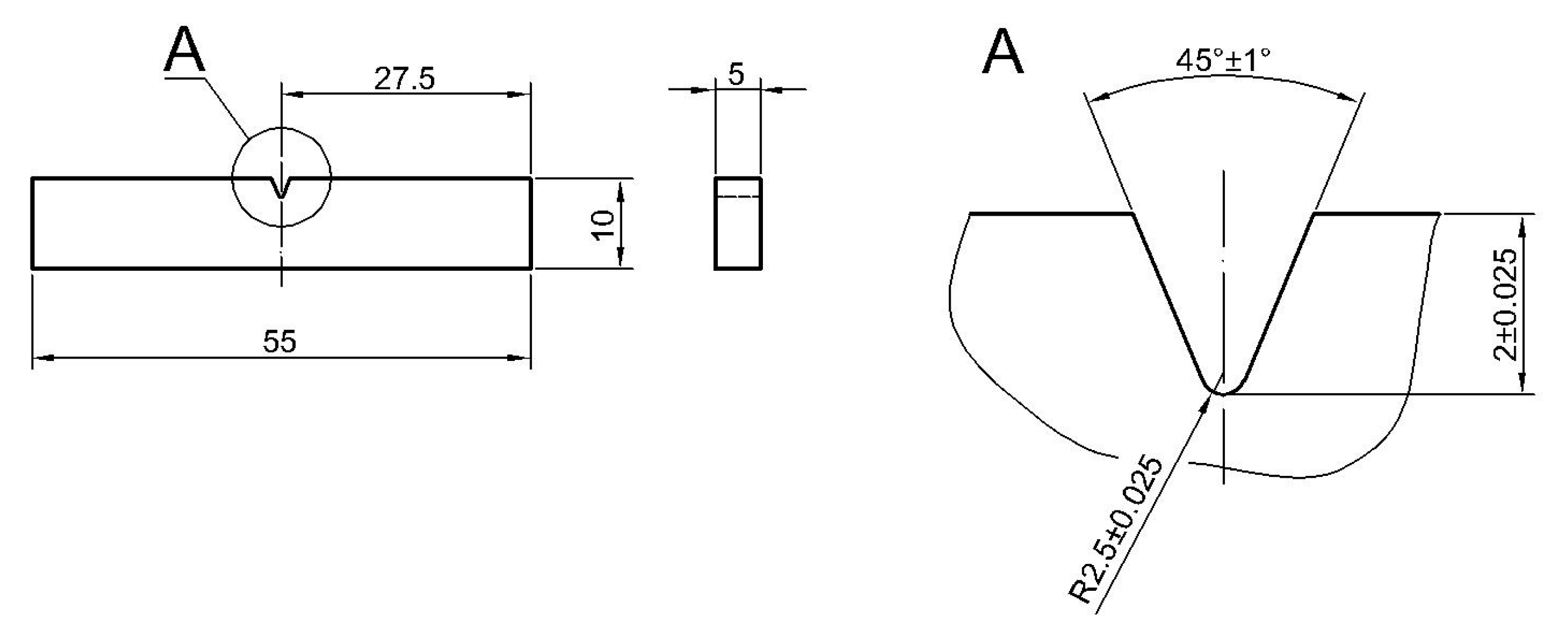

2. Material and Methodology

2.1. Tested Material

2.2. Mechanical Properties

2.3. Residual Stresses

- UOUT—output voltage [V];

- U0—input voltage [V];

- N—coefficient depending on the bridge type, N = 1;

- K—strain gauge constant;

- A—amplification coefficient.

- σmax, σmin—principal stresses;

- ε1, ε2, ε3—strains determined in individual strain gauges of the rosette;

- A, B—coefficients depending on the material properties and geometry of the rosette and hole;

- α—angle between no. 1 strain gauge and the nearest principal stress.

3. Results and Discussion

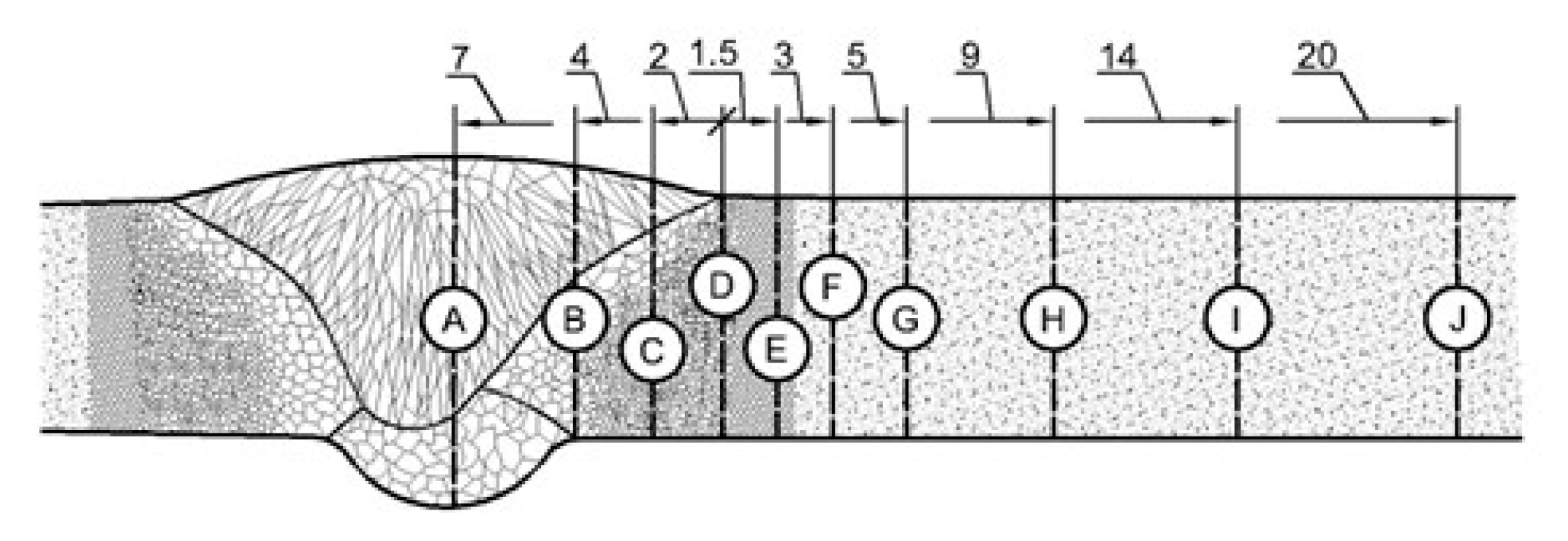

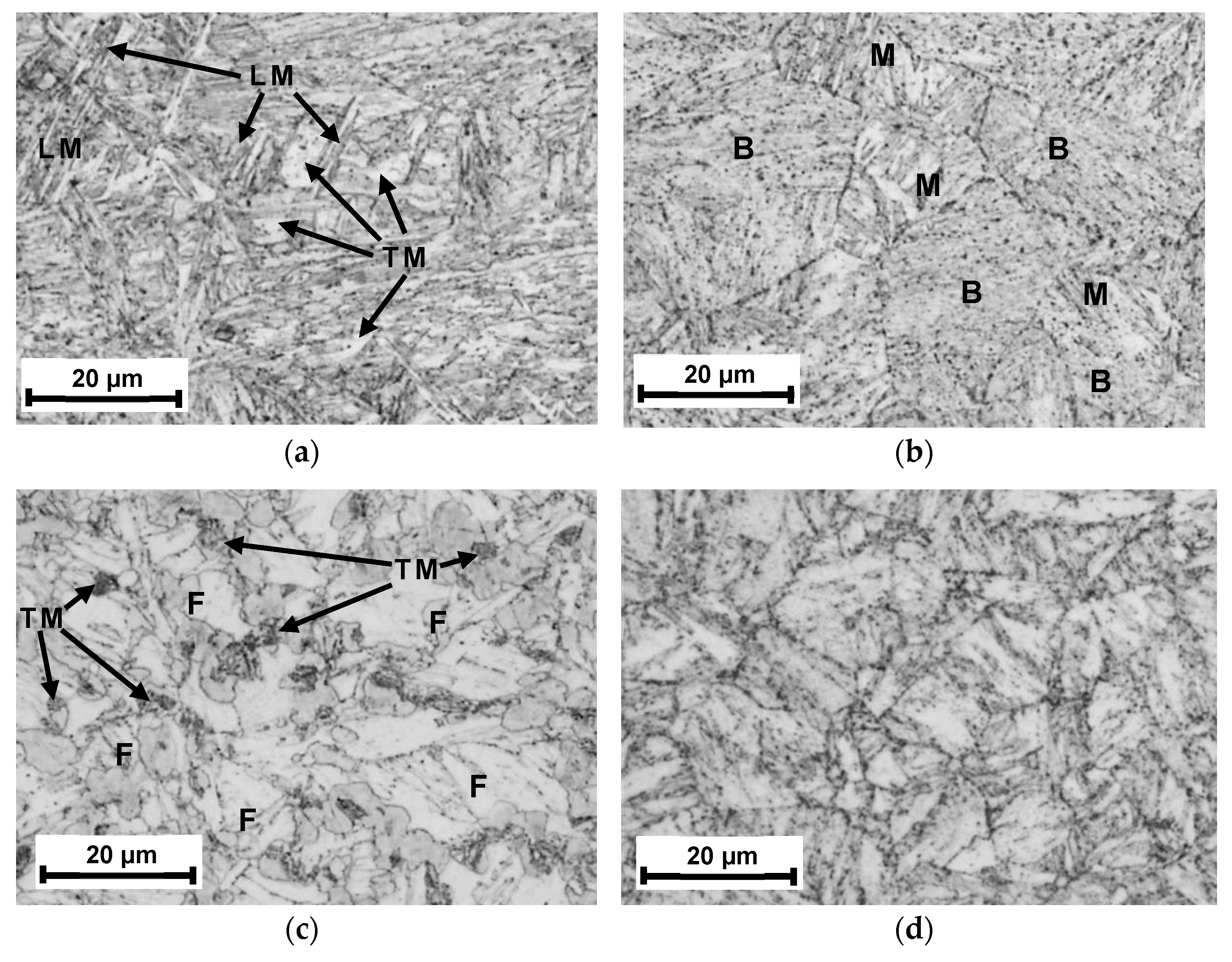

3.1. Microstructure

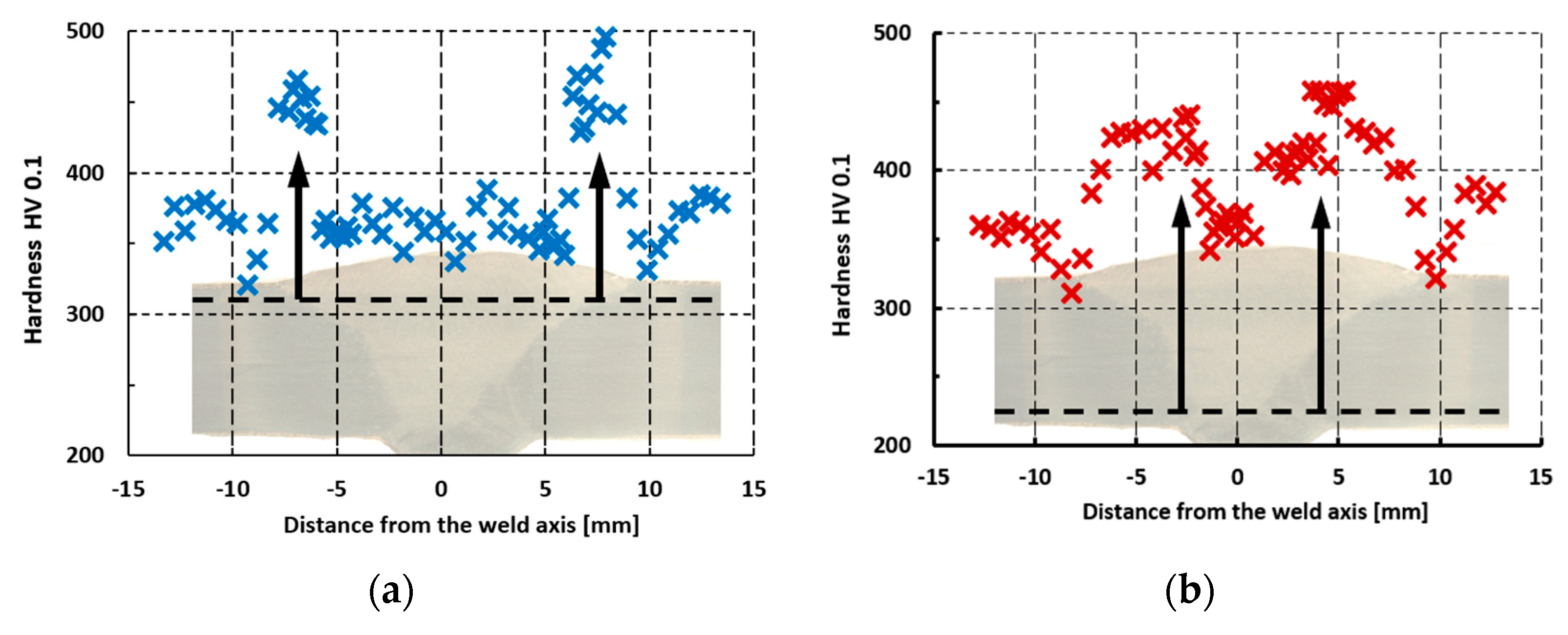

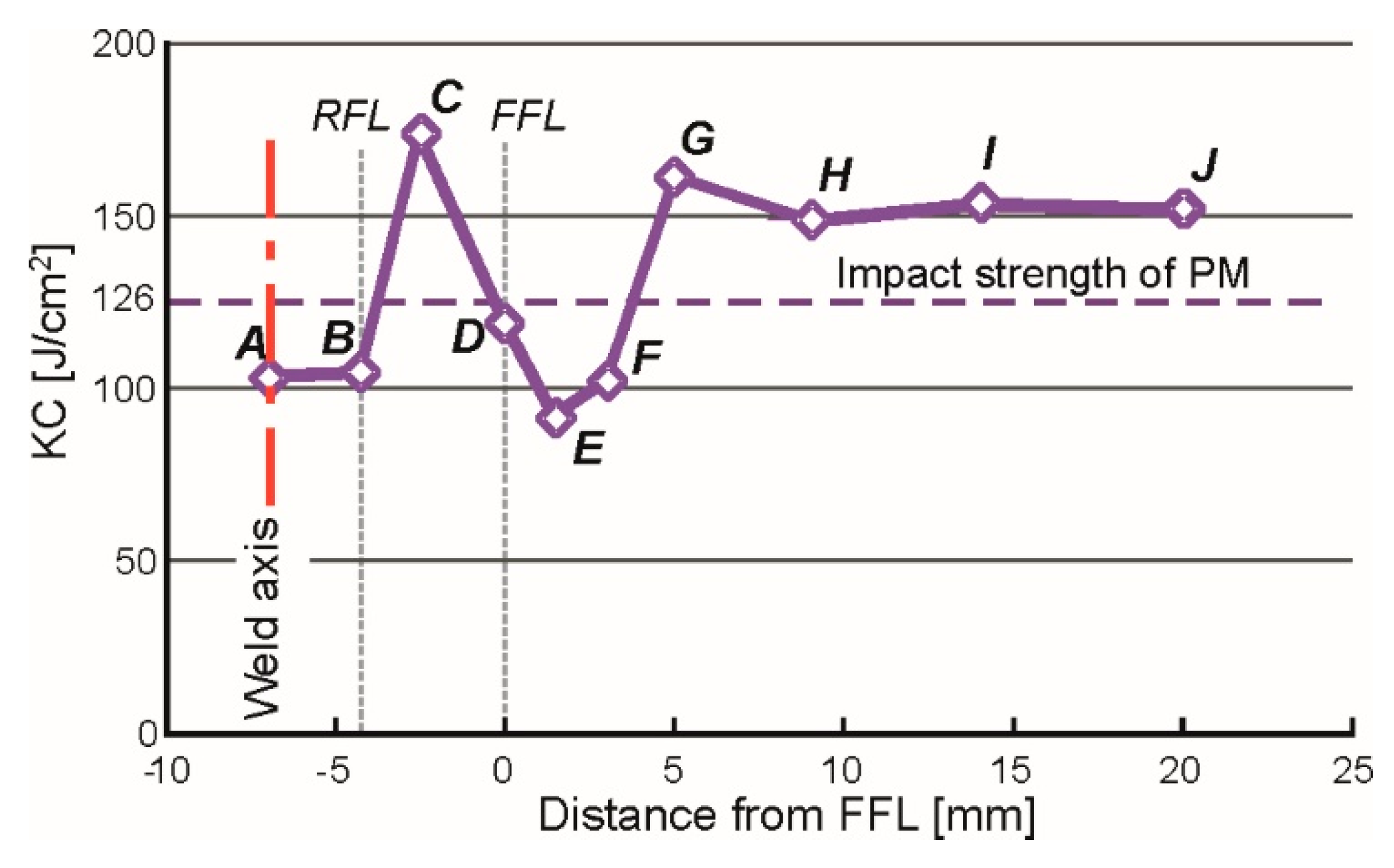

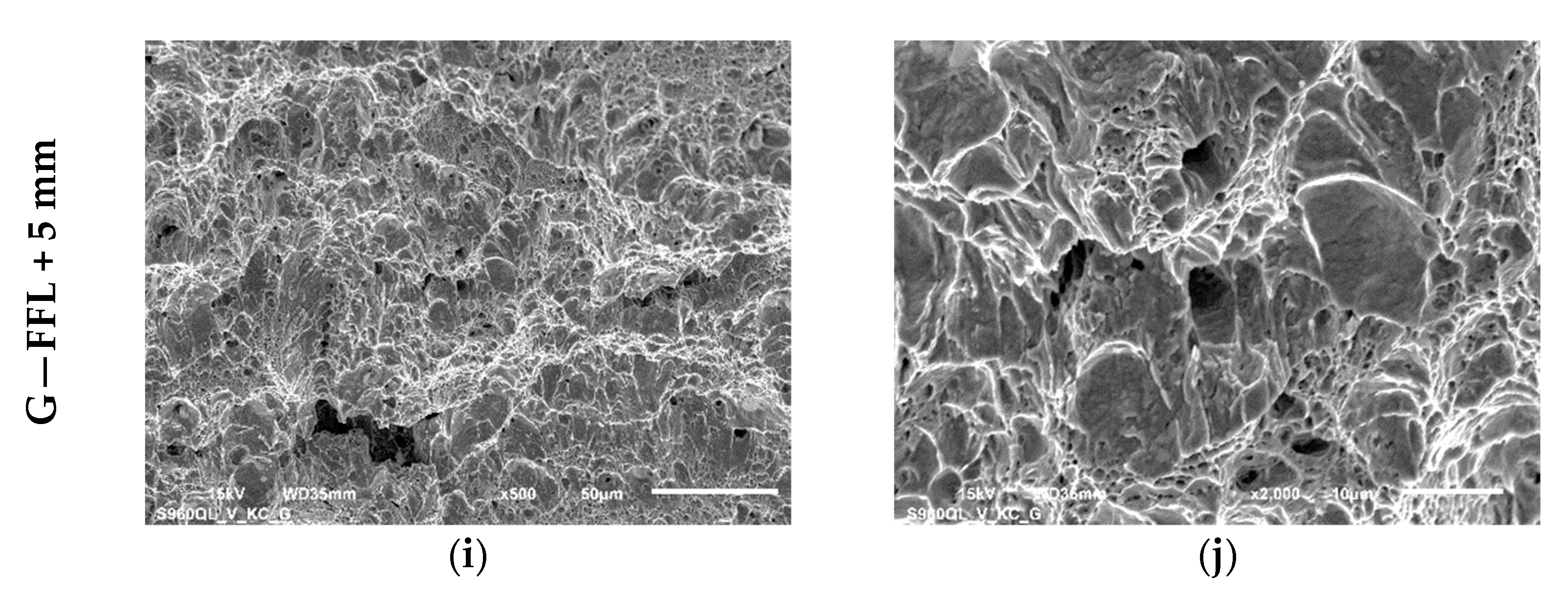

3.2. Mechanical Properties

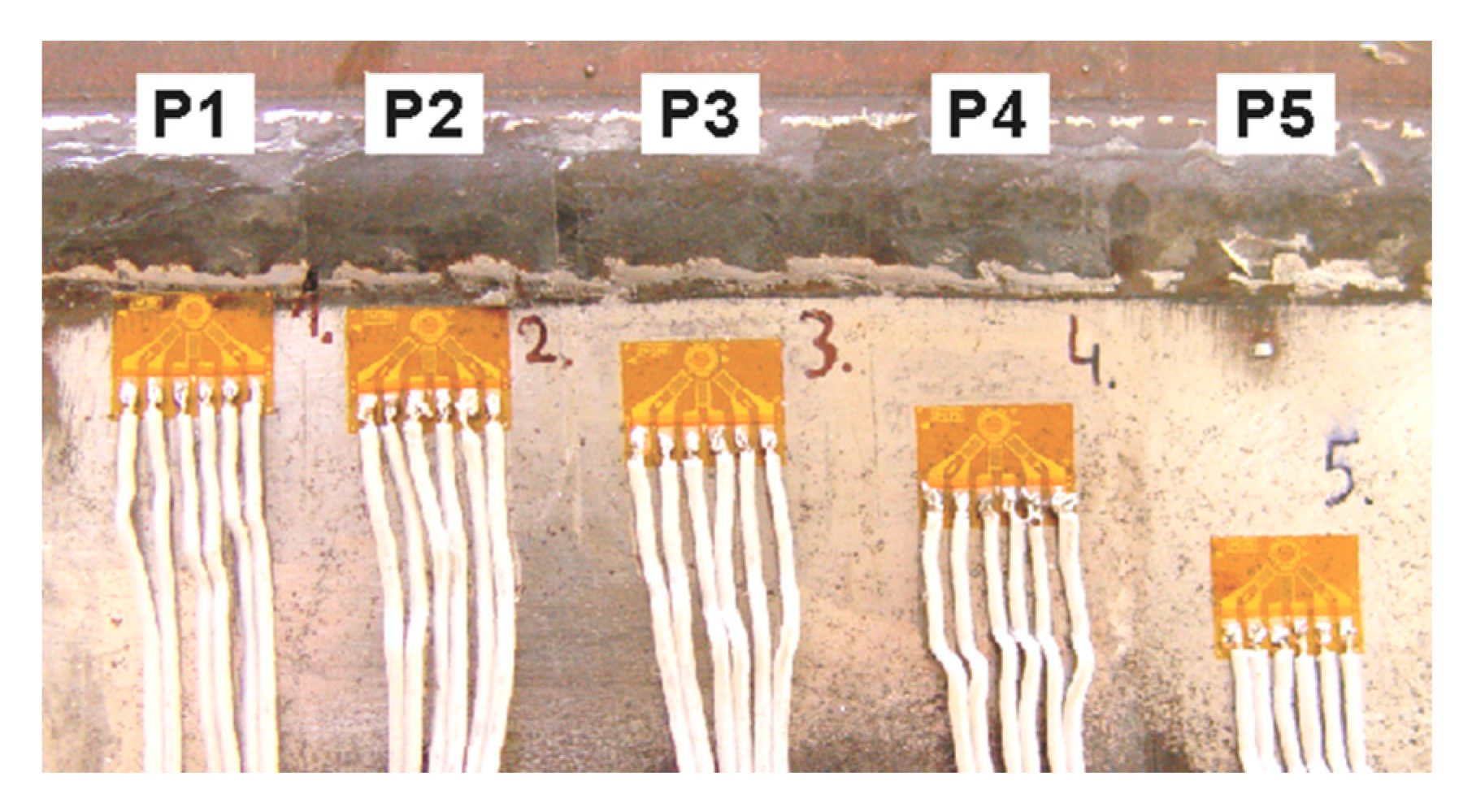

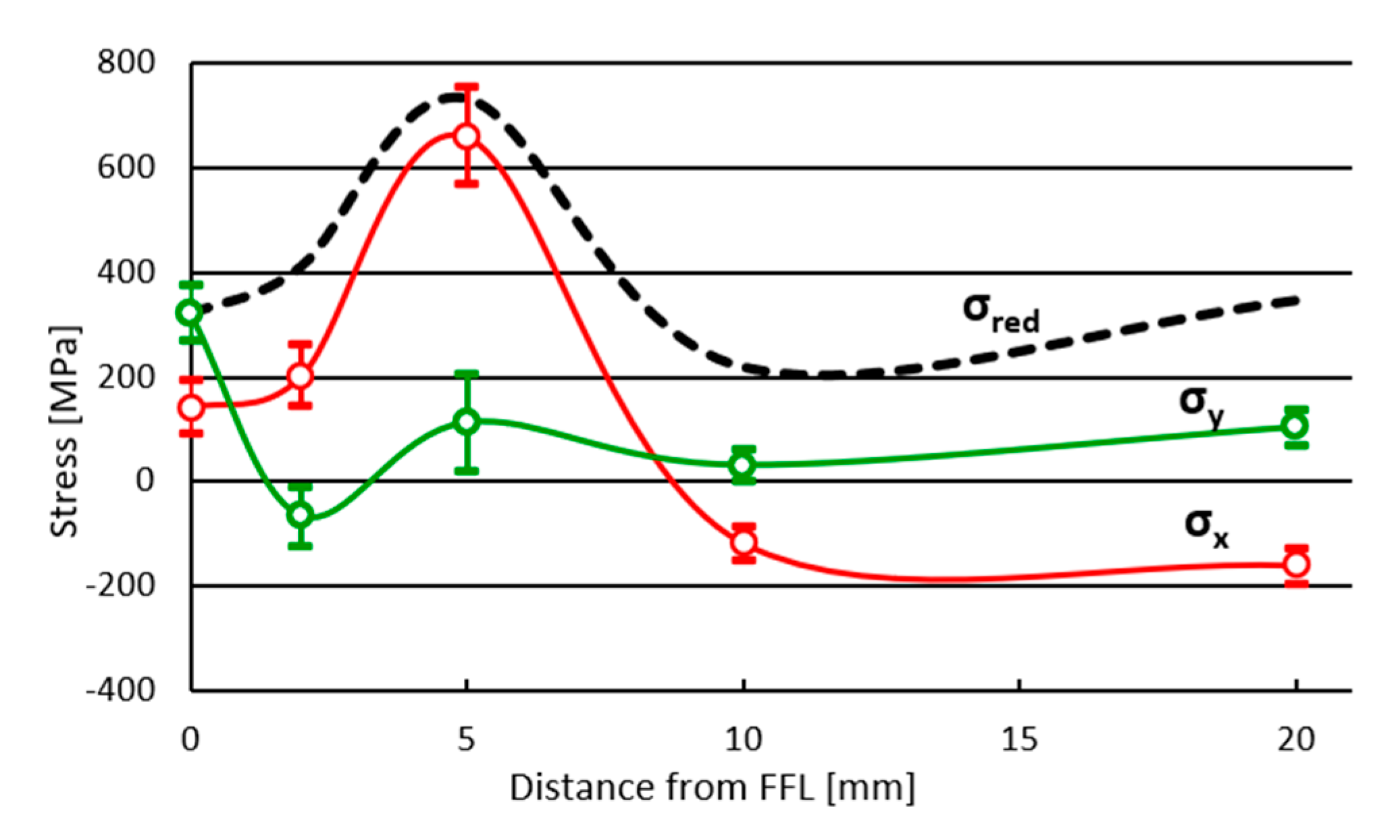

3.3. Residual Stresses

4. Summary and Conclusions

- (i)

- Four sub-zones were determined in the HAZ, namely, coarse-grained (CGHAZ), fine-grained (FGHAZ), intercritical (ICHAZ) and sub-critical (SCHAZ), among which the ICHAZ showed the worst strength properties because of incomplete normalization.

- (ii)

- The highest ductility parameter KC was recorded in the FGHAZ with a value of 174 J/cm2, followed by the SCHAZ with a value of 161 J/cm2. The zone with the lowest impact strength of 92 J/cm2 (ICHAZ) also had the lowest microhardness value of 310–330 HV0.1.

- (iii)

- The residual stresses were obtained using the hole-drilling method and had a characteristic distribution in the heat-affected zone. The highest value of residual stress was recorded in the SCHAZ (approx. 5 mm from the FFL), both for the longitudinal and reduced stresses, exceeding, respectively, 600 MPa and 700 MPa.

- (iv)

- The high quality of the welded joint obtained was confirmed in the tensile test. Rupture occurred in the transition zone between the ICHAZ and the SCHAZ, which is characterized by increased strength and lower ductility, but in this zone, rapidly growing residual stresses occurred, causing the highest initial local strain of the material.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Advanced High-Strength Steel Market—Forecast (2020–2025); Report Code: CMR 82149; IndustryARC: Hyderabad, India, 2020.

- High Strength Steel Market; Report ID: ER_002799; Emergen Research: Surrey, BC, Canada, 2024.

- High Strength Steel Market; Report ID FBI101854; Fortune Business Insights: Pune, India, 2024.

- Liu, X.; Sun, Y.; Li, Y.; Li, W.; Lin, B.; Pei, M. The effect of welding speed on the microstructure, mechanical properties, and fatigue failure of Q690D high-strength steel. Eng. Fail. Anal. 2024, 166, 108885. [Google Scholar] [CrossRef]

- Shi, Y.; Sun, K.; Cui, S.; Zeng, M.; Yi, J.; Shen, X.; Yi, Y. Microstructure Evolution and Mechanical Properties of Underwater Dry and Local Dry Cavity Welded Joints of 690 MPa Grade High Strength Steel. Materials 2018, 11, 167. [Google Scholar] [CrossRef]

- Izumi, T.; Kobayashi, T.; Shohji, I.; Miyanaga, H. Microstructures and Mechanical Properties of Welded Joints of Several High Tensile Strength Steel. Mater. Sci. Forum 2018, 941, 224–229. [Google Scholar] [CrossRef]

- Guo, W.; Crowther, D.; Francis, J.A.; Thompson, A.; Liu, Z.; Li, L. Microstructure and mechanical properties of laser welded S960 high strength steel. Mater. Des. 2015, 85, 534–548. [Google Scholar] [CrossRef]

- Li, W.; Feng, A.; Wang, Y.; Wang, J. Effect of laser welding parameters on the microstructure and tensile properties of low-alloy high-strength steel. Mater. Res. Express 2024, 11, 096526. [Google Scholar] [CrossRef]

- Kumar, A.M.; Kumar, P.S.; Kumar, P.A.; Kiran, D.V.; Arora, K.S.; Venkaiah, N. Influence of single and tandem submerged arc welding on ASTM A572 Gr.50 steels. Int. J. Adv. Manuf. Technol. 2024, 135, 543–559. [Google Scholar] [CrossRef]

- Liu, X.; Sun, Y.; Li, W.; He, J.; Pei, M.; Zhang, K. Effect of welding current on the organization and properties of welded joints of Q690D high-strength steel. Mater. Today Commun. 2024, 40, 110219. [Google Scholar] [CrossRef]

- Pała, T.; Wciślik, W. Strength and Fracture Toughness of TIG- and Laser-Welded Joints of Low Carbon Ferritic Steels. Materials 2024, 17, 3956. [Google Scholar] [CrossRef]

- Szymczak, T.; Makowska, K.; Kowalewski, Z.L. Influence of the Welding Process on the Mechanical Characteristics and Fracture of the S700MC High Strength Steel under Various Types of Loading. Materials 2020, 13, 5249. [Google Scholar] [CrossRef]

- Prochenka, P.; Janiszewski, J.; Kucewicz, M. Crash Response of Laser-Welded Energy Absorbers Made of Docol 1000DP and Docol 1200M Steels. Materials 2021, 14, 2808. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, J.; Liu, W.; Zhao, A. Effect of Welding Peak Temperature on Microstructure and Impact Toughness of Heat-Affected Zone of Q690 High Strength Bridge Steel. Materials 2021, 14, 2981. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Bai, L.; Qian, G.; Sun, X.; Liu, G.; Xie, Z.; Shang, C. Crystallographic Study of Transformation Products of Heat-Affected Zone and Correlation with Properties of FH690 Heavy-Gauge Marine Steel by Multi-Pass Submerged Arc Welding. Metals 2024, 14, 1122. [Google Scholar] [CrossRef]

- Ilić, A.; Miletić, I.; Nikolić, R.R.; Marjanović, V.; Ulewicz, R.; Stojanović, B.; Ivanović, L. Analysis of Influence of the Welding Procedure on Impact Toughness of Welded Joints of the High-Strength Low-Alloyed Steels. Appl. Sci. 2020, 10, 2205. [Google Scholar] [CrossRef]

- Schroeder, N.; Rhode, M.; Kannengiesser, T. Influence of microalloying on precipitation behavior and notch impact toughness of welded high-strength structural steels. Weld World 2024, 68, 2647–2659. [Google Scholar] [CrossRef]

- Saadati, M.; Nobarzad, A.K.E.; Jahazi, M. On the hot cracking of HSLA steel welds: Role of epitaxial growth and HAZ grain size. J. Manuf. Process. 2019, 41, 242–251. [Google Scholar] [CrossRef]

- Pańcikiewicz, K.; Zielińska-Lipiec, A.; Tasak, E. Cracking of high-strength steel welded joints. Adv. Mater. Sci. 2013, 13, 76–85. [Google Scholar] [CrossRef]

- Alipooramirabad, H.; Cornish, N.; Kurji, R.; Roccisano, A.; Ghomashchi, R. Quenched and Tempered Steels Welded Structures: Modified Gas Metal Arc Welding-Pulse vs. Shielded Metal Arc Welding. Metals 2023, 13, 887. [Google Scholar] [CrossRef]

- Hopf, A.; Klug, M.; Durmaz, K.; Goth, K.; Jüttner, S. Introduction of a New Test Methodology for Determining the Delayed Cracking Susceptibility. J. Manuf. Mater. Process. 2023, 7, 26. [Google Scholar] [CrossRef]

- Sága, M.; Blatnická, M.; Blatnický, M.; Dižo, J.; Gerlici, J. Research of the Fatigue Life of Welded Joints of High Strength Steel S960 QL Created Using Laser and Electron Beams. Materials 2020, 13, 2539. [Google Scholar] [CrossRef]

- Jiménez-Peña, C.; Goulas, C.; Preußner, J.; Debruyne, D. Failure Mechanisms of Mechanically and Thermally Produced Holes in High-Strength Low-Alloy Steel Plates Subjected to Fatigue Loading. Metals 2020, 10, 318. [Google Scholar] [CrossRef]

- Keränen, L.; Pylvänäinen, M.; Kaijalainen, A.; Jokiaho, T.; Tulonen, J.; Hyvärinen, A.; Vippola, M.; Kurvinen, E. Residual stresses of MAG-welded ultrahigh-strength steel rectangular hollow sections. Eng. Struct. 2024, 305, 117719. [Google Scholar] [CrossRef]

- Schröpfer, D.; Witte, J.; Kromm, A.; Kannengießer, T. Stresses in repair welding of high-strength steels—Part 1: Restraint and cold cracking risk. Weld World 2024, 68, 685–697. [Google Scholar] [CrossRef]

- Ślęzak, T. Fatigue Examination of HSLA Steel with Yield Strength of 960 MPa and Its Welded Joints under Strain Mode. Metals 2020, 10, 228. [Google Scholar] [CrossRef]

- ISO 6892-1:2016; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2016.

- Datasheet Union X 96. Solid Wire, Low-Alloyed, High Strength. Böhler Welding by Voestalpine. Available online: https://weldingshop.voestalpine.com/ (accessed on 18 October 2024).

- ISO 5817:2014; Welding—Fusion-Welded Joints in Steel, Nickel, Titanium and Their Alloys (Beam Welding Excluded)—Quality Levels for Imperfections. ISO: Geneva, Switzerland, 2014.

- ASTM E8/E8M-13a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2024.

- ISO 6507-1:2005; Metallic Materials—Vickers Hardness Test—Part 1: Test Method. ISO: Geneva, Switzerland, 2005.

- ISO 9015-1:2001; Destructive Tests on Welds in Metallic Materials—Hardness Testing—Part 1: Hardness Test on Arc Welded Joints. ISO: Geneva, Switzerland, 2001.

- ISO 9015-2:2016; Destructive Tests on Welds in Metallic Materials—Hardness Testing—Part 2: Microhardness Testing of Welded Joints. ISO: Geneva, Switzerland, 2016.

- ISO 148-1:2016; Metallic Materials—Charpy Pendulum Impact Test—Part 1: Test Method. ISO: Geneva, Switzerland, 2016.

- ISO 9016:2012; Destructive Tests on Welds in Metallic Materials—Impact Tests—Test Specimen Location, Notch Orientation and Examination. ISO: Geneva, Switzerland, 2012.

- ASTM E 837; Determining Residual Stresses by the Hole-Drilling Strain-Gage Method. ASTM: West Conshohocken, PA, USA, 2021.

- Tech Note TN-503-6. Measurement of Residual Stresses by the Hole-Drilling Strain Gage Method. Micro-Measurements. Available online: https://intertechnology.com/Vishay/pdfs/TechNotes_TechTips/TN-503.pdf (accessed on 18 October 2024).

- Xiang, T.; Zhang, M.; Ma, Q.; Fang, Z.; Li, H.; Wang, H. Research on the Welding Process and Weld Formation in Multiple Solid-Flux Cored Wires Arc Hybrid Welding Process for Q960E Ultrahigh-Strength Steel. Materials 2024, 17, 3178. [Google Scholar] [CrossRef] [PubMed]

- Qi, X.N.; Di, H.S.; Wang, X.N.; Liu, Z.G.; Misra, R.D.K.; Huan, P.C.; Gao, Y. Effect of Secondary Peak Temperature on Microstructure and Toughness in ICCGHAZ of Laser-Arc Hybrid Welded X100 Pipeline Steel Joints. J. Mater. Res. Technol. 2020, 9, 7838–7849. [Google Scholar] [CrossRef]

- Chen, G.; Luo, H.; Yang, H.; Han, Z.; Lin, Z.; Zhang, Z.; Su, Y. Effects of the welding inclusion and notch on the fracture behaviors of low-alloy steel. J. Mater. Res. Technol. 2019, 8, 447–456. [Google Scholar] [CrossRef]

- Qi, X.; Wang, X.; Di, H.; Shen, X.; Liu, Z.; Huan, P.; Chen, L. Effect of Ti content on the inclusions, microstructure and fracture mechanism of X100 pipeline steel laser-MAG hybrid welds. Mater. Sci. Eng. A 2022, 831, 142207. [Google Scholar] [CrossRef]

- Seo, K.; Kim, Y.M.; Kim, H.J.; Lee, C. Characterization of Inclusions Formed in Ti-containing Steel Weld Metals. ISIJ Int. 2015, 55, 1730–1738. [Google Scholar] [CrossRef]

- Wartiainen, J. Residual Stress in Welding. Stresstech Bulletin 15. Available online: www.stresstech.com (accessed on 18 October 2024).

- Nitschke-Pagel, T. Recommendations for the measurement of residual stresses in welded joints by means of X-ray diffraction—Results of the WG6-RR test. Weld World 2021, 65, 589–600. [Google Scholar] [CrossRef]

- Górka, J.; Przybyła, M. Research on the Influence of HMFI and PWHT Treatments on the Properties and Stress States of MAG-Welded S690QL Steel Joints. Materials 2024, 17, 3560. [Google Scholar] [CrossRef]

- Yuan, J.; Ji, H.; Zhong, Y.; Cui, G.; Xu, L.; Wang, X. Effects of Different Pre-Heating Welding Methods on the Temperature Field, Residual Stress and Deformation of a Q345C Steel Butt-Welded Joint. Materials 2023, 16, 4782. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.H.; Chang, K.H.; Van Do, V.N. Finite element modeling of residual stress relaxation in steel butt welds under cyclic loading. Eng. Struct. 2015, 103, 63–71. [Google Scholar] [CrossRef]

- Organek, P.; Gosowski, B.; Redecki, M. Relationship between Brinell hardness and the strength of structural steels. Structures 2024, 59, 105701. [Google Scholar] [CrossRef]

- Tomerlin, D.; Marić, D.; Kozak, D.; Samardžić, I. Post-Weld Heat Treatment of S690QL1 Steel Welded Joints: Influence on Microstructure, Mechanical Properties and Residual Stress. Metals 2023, 13, 999. [Google Scholar] [CrossRef]

| Elements [wt %] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al | Si | V | Cr | Mn | Ni | Cu | Mo | C | Fe | |

| By certificate | 0.08 | 0.28 | 0.03 | 0.22 | 1.13 | 0.08 | 0.18 | 0.67 | 0.18 | balance |

| By measurement | 0.11 | 0.36 | 0.03 | 0.23 | 1.19 | 0.06 | 0.19 | 0.66 | * | balance |

| Strength Properties | |||||||

|---|---|---|---|---|---|---|---|

| E | σPL | σY | σU | σT | L | Z | |

| [MPa] | [MPa] | [MPa] | [MPa] | [MPa] | [%] | [%] | |

| By certificate | --- | --- | 997 | 1069 | --- | 13 | --- |

| By measurement | 2.2 × 105 | 917 | 974 | 1070 | 658 | 14.2 | 45.6 |

| Number of Passes | Current | Arc Voltage | Wending Speed | Wire Feed Rate | Shielding Gas Flow | Heat Input |

|---|---|---|---|---|---|---|

| [A] | [V] | [mm/min] | [m/min] | [l/min] | [kJ/mm] | |

| 1 | 150 | 19.5 | 210 | 5.5 | 14 | 0.67 |

| 2 | 260 | 27.0 | 450 | 7.5 | 14 | 0.75 |

| Position | A | B | C | D | E | F | ||

|---|---|---|---|---|---|---|---|---|

| Cross-section [mm2] | 39.21 | 39.77 | 39.66 | 39.11 | 39.58 | 39.48 | 39.73 | 39.60 |

| Absorbed energy [J] | 40.5 | 40.0 | 43.5 | 68.0 | 50.0 | 44.0 | 36.5 | 40.5 |

| Impact strength KC | 103 | 101 | 110 | 174 | 126 | 111 | 92 | 102 |

| Position | G | H | I | J | PM | |||

| Cross-section [mm2] | 39.06 | 39.66 | 40.02 | 39.42 | 39.70 | 38.67 | 38.94 | |

| Absorbed energy [J] | 63.0 | 59.0 | 61.5 | 60.0 | 49.5 | 49.5 | 49.0 | |

| Impact strength KC | 161 | 149 | 154 | 152 | 125 | 128 | 126 | |

| Measuring Points | Principal Stresses | Shear Stresses | Angle | |||||

|---|---|---|---|---|---|---|---|---|

| σmax [MPa] | P90% | σmin [MPa] | P90% | τmax [MPa] | P90% | α [ ° ] | P90% | |

| P1 | 322 | 377 272 | 142 | 194 91 | 90 | 143 39 | 52 | 55 50 |

| P2 | 201 | 261 146 | −66 | −9 −124 | 134 | 193 78 | −45 | −45 −45 |

| P3 | 660 | 757 571 | 113 | 206 21 | 274 | 368 182 | −48 | −49 −47 |

| P4 | 31 | 63 1 | −117 | −87 −150 | 74 | 106 44 | 48 | 49 48 |

| P5 | 104 | 138 71 | −160 | −128 −195 | 132 | 167 99 | 46 | 46 46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ślęzak, T. Welding of S960QL High-Strength Steel by the Manual–Automated MAG Technique—A Study of Mechanical Properties, Residual Stresses and Fracture Mechanisms in the Heat-Affected Zone. Materials 2024, 17, 5792. https://doi.org/10.3390/ma17235792

Ślęzak T. Welding of S960QL High-Strength Steel by the Manual–Automated MAG Technique—A Study of Mechanical Properties, Residual Stresses and Fracture Mechanisms in the Heat-Affected Zone. Materials. 2024; 17(23):5792. https://doi.org/10.3390/ma17235792

Chicago/Turabian StyleŚlęzak, Tomasz. 2024. "Welding of S960QL High-Strength Steel by the Manual–Automated MAG Technique—A Study of Mechanical Properties, Residual Stresses and Fracture Mechanisms in the Heat-Affected Zone" Materials 17, no. 23: 5792. https://doi.org/10.3390/ma17235792

APA StyleŚlęzak, T. (2024). Welding of S960QL High-Strength Steel by the Manual–Automated MAG Technique—A Study of Mechanical Properties, Residual Stresses and Fracture Mechanisms in the Heat-Affected Zone. Materials, 17(23), 5792. https://doi.org/10.3390/ma17235792