Investigating Structural and Surface Modifications in Ion-Implanted 4H-SiC for Enhanced Dopant Distribution Analysis in Power Semiconductors

Abstract

1. Introduction

2. Materials and Methods

2.1. Ion Implantation of 4H-SiC

2.2. Characterization of Surface and Structural Properties

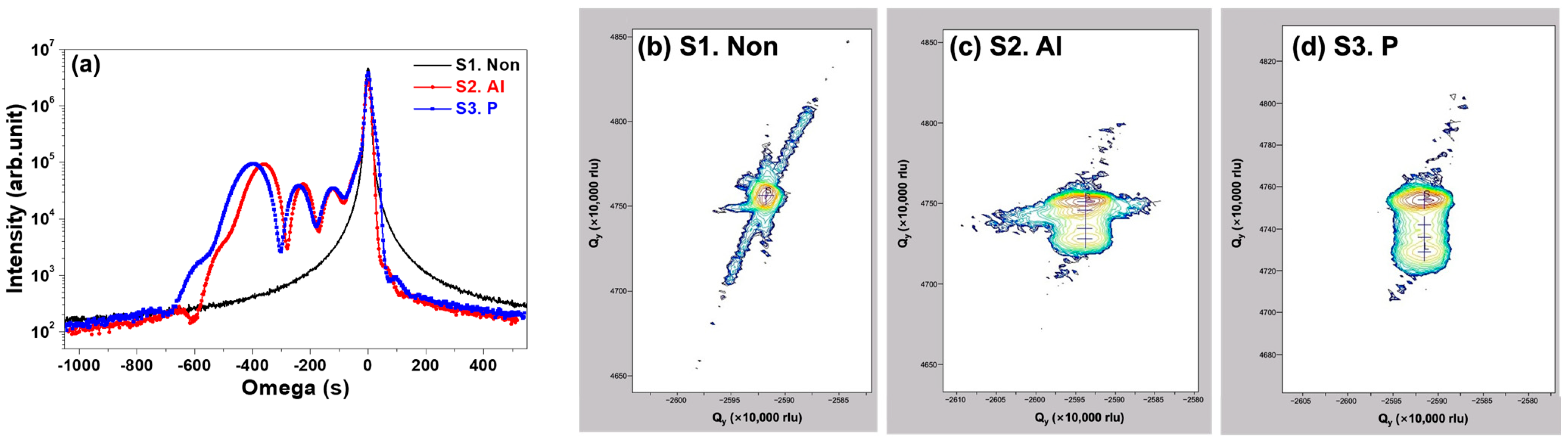

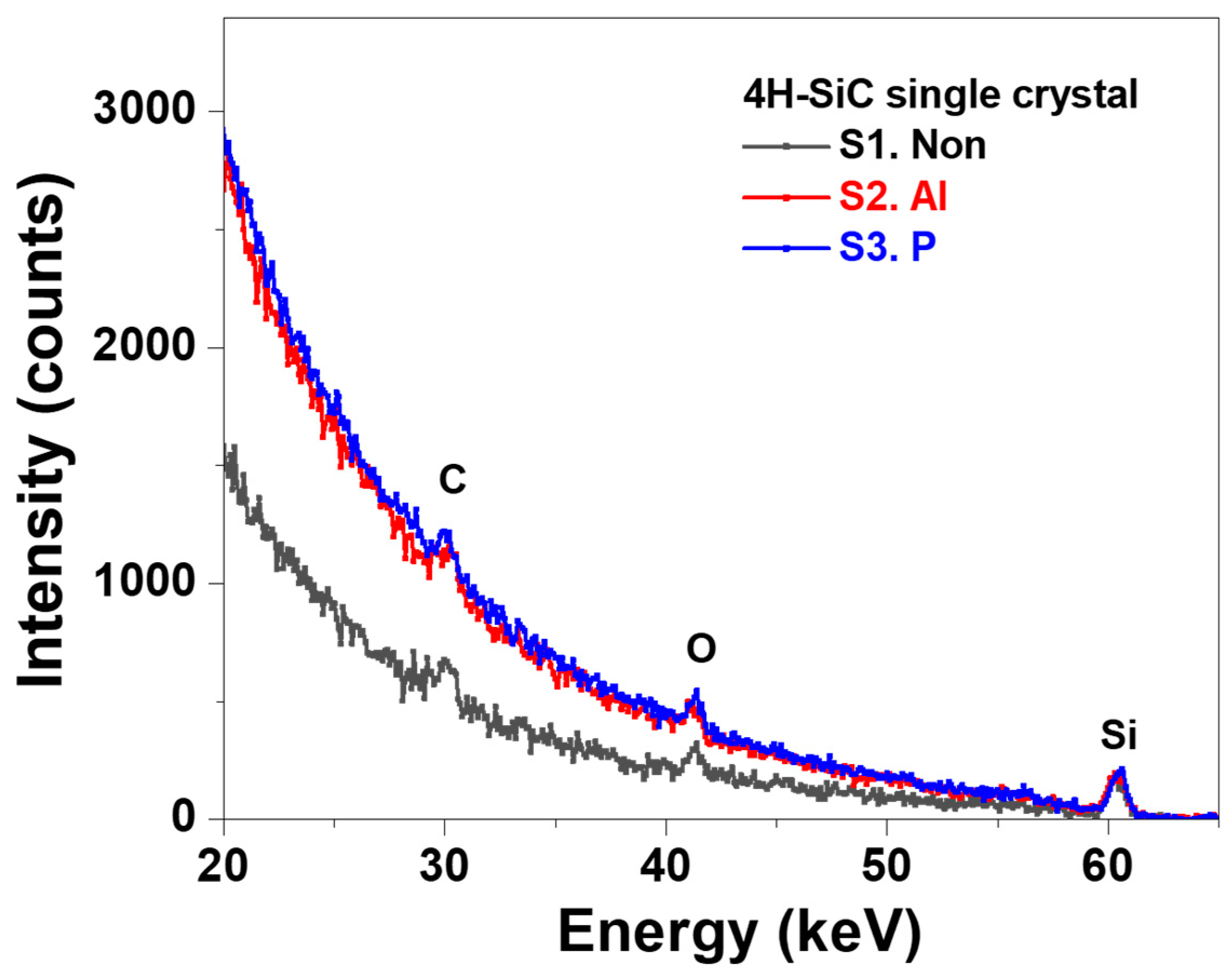

2.2.1. X-Ray Diffraction

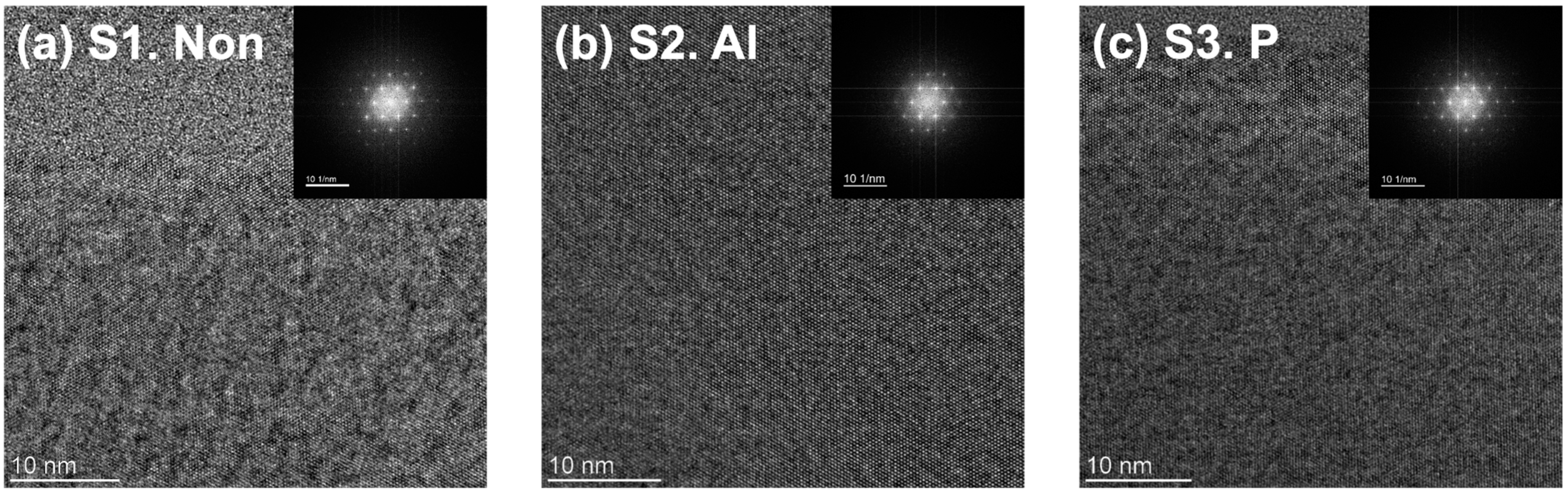

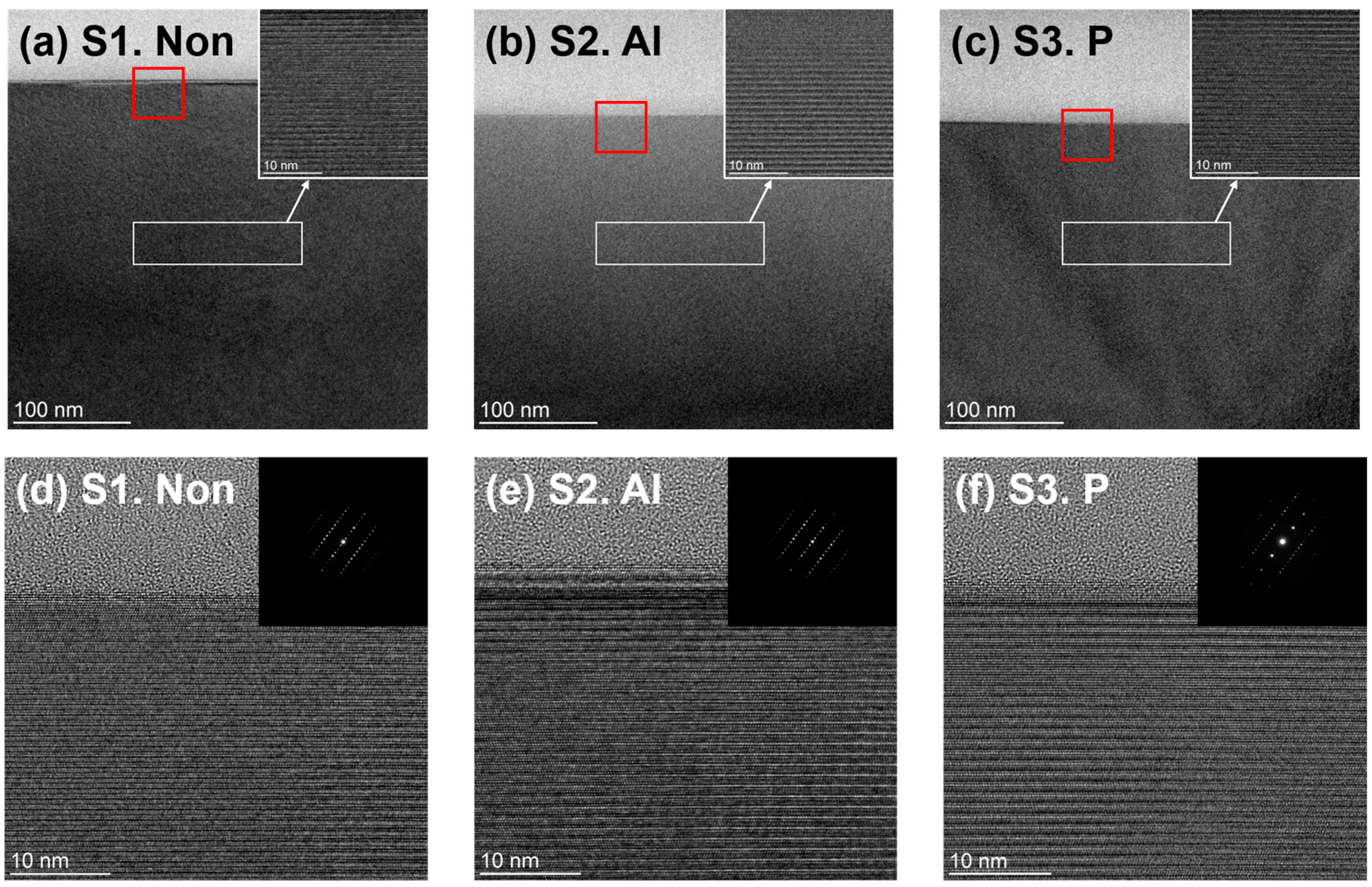

2.2.2. Transmittance Electron Microscope

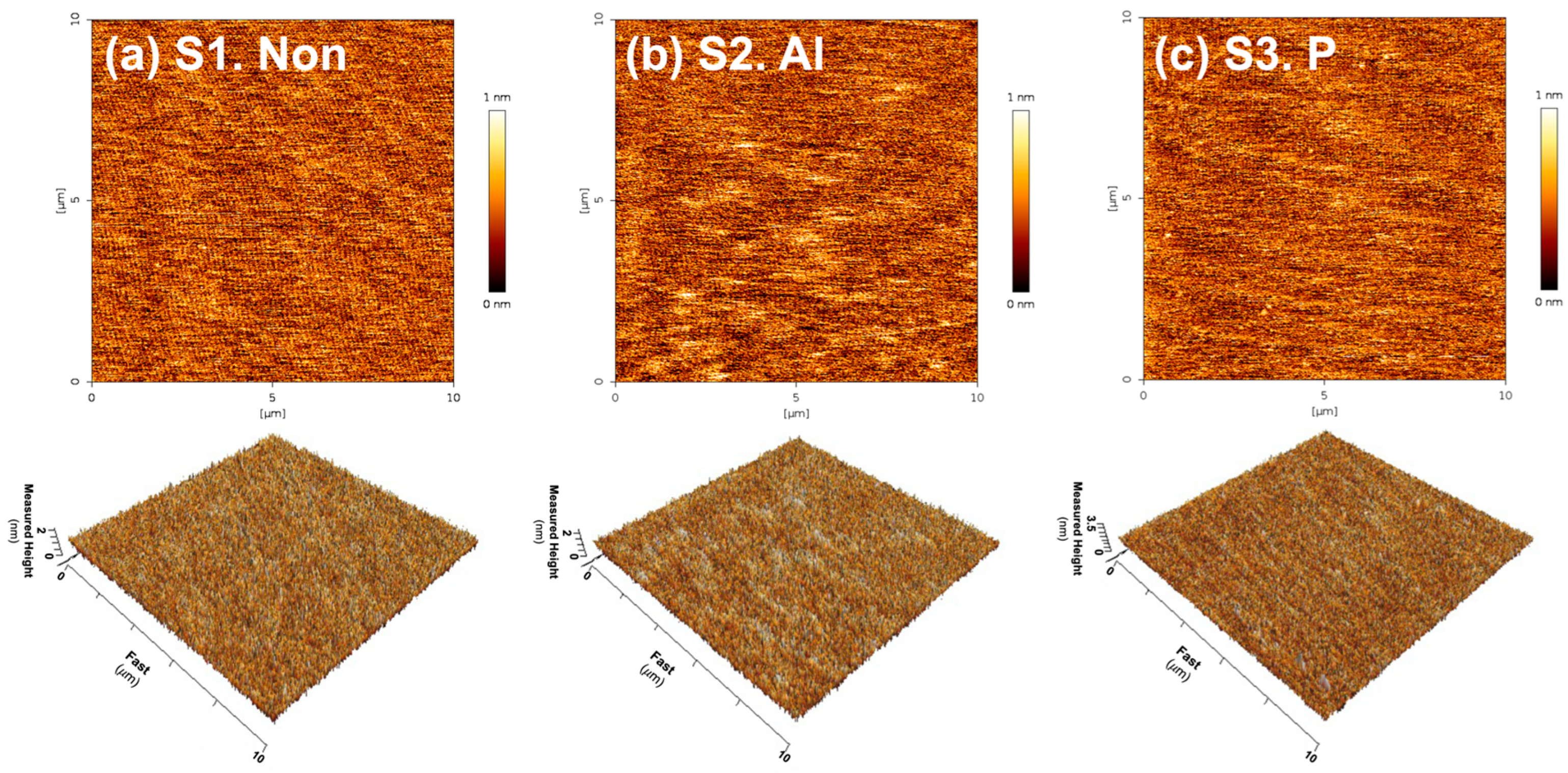

2.2.3. Atomic Force Microscope

2.2.4. Time of Flight Medium Energy Ion Spectroscopy

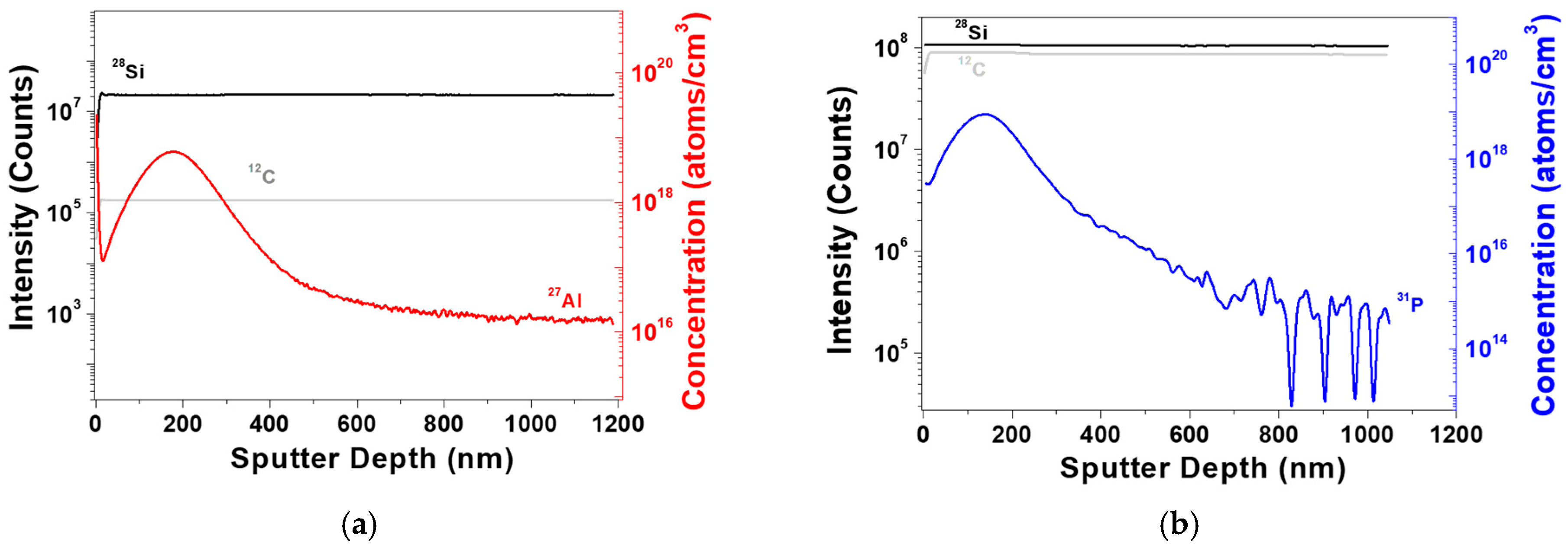

2.2.5. Magnetic Sector Secondary Ion Mass Spectrometry

2.2.6. Stylus Profiler

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Neudeck, P.G. SiC Technology; No. GRC-WO-667840; NASA Lewis Research Center: Cleveland, OH, USA, 1998. [Google Scholar]

- Yoon, D.H.; Reimanis, I.E. A review on the joining of SiC for high-temperature applications. J. Korean Ceram. Soc. 2020, 57, 246–270. [Google Scholar] [CrossRef]

- Kimoto, T. SiC material properties. In Wide Bandgap Semiconductor Power Devices; Woodhead Publishing: Sawston, UK, 2019; pp. 21–42. [Google Scholar]

- Hatakeyama, T.; Watanabe, T.; Kushibe, M.; Kojima, K.; Imai, S.; Suzuki, T.; Shinohe, T.; Tanaka, T.; Arai, K. Measurement of Hall mobility in 4H-SiC for improvement of the accuracy of the mobility model in device simulation. Mater. Sci. Forum 2003, 433, 443–446. [Google Scholar] [CrossRef]

- Kimoto, T.; Kawahara, K.; Niwa, H.; Kaji, N.; Suda, J. Ion implantation technology in SiC for power device applications. In Proceedings of the 2014 International Workshop on Junction Technology (IWJT), Shanghai, China, 18–20 May 2014; pp. 1–6. [Google Scholar]

- Okamoto, K.; Kikuchi, T.; Ikeda, A.; Ikenoue, H.; Asano, T. Formation of low resistance contacts to p-type 4H-SiC using laser doping with an Al thin-film dopant source. Jpn. J. Appl. Phys. 2019, 1, 294–298. [Google Scholar] [CrossRef]

- Ge, H.; Liu, R.; Li, J. Effect of annealing on ion implantation process in 4H-SiC power semiconductor devices. J. Phys. Conf. Ser. 2021, 2033, 012097. [Google Scholar] [CrossRef]

- Roccaforte, F.; Fiorenza, P.; Vivona, M.; Greco, G.; Giannazzo, F. Selective doping in silicon carbide power devices. Materials 2021, 14, 3923. [Google Scholar] [CrossRef]

- Canino, M.; Fedeli, P.; Albonetti, C.; Nipoti, R. 4H-SiC surface morphology after Al ion implantation and annealing with C-cap. J. Microsc. 2020, 280, 229–240. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Huang, Y.; Yang, D.; Pi, X. Impurities and defects in 4H silicon carbide. Appl. Phys. Lett. 2023, 122, 180501. [Google Scholar] [CrossRef]

- Weng, M.H.; Roccaforte, F.; Giannazzo, F.; Di Franco, S.; Bongiorno, C.; Zanetti, E.; Raineri, V. Correlation study of morphology, electrical activation and contact formation of ion implanted 4H-SiC. Solid State Phenom. 2010, 156, 493–498. [Google Scholar] [CrossRef]

- Wu, F.; Zhang, J.; Xi, W.; Chi, Y.Q.; Liu, Q.B.; Yang, L.; Ma, H.-P.; Zhang, Q.C. Insights into the effects of Al-ion implantation temperature on material properties of 4H-SiC. Appl. Surf. Sci. 2023, 613, 156014. [Google Scholar] [CrossRef]

- Erlekampf, J.; Rommel, M.; Rosshirt-Lilla, K.; Kallinger, B.; Berwian, P.; Friedrich, J.; Erlbacher, T. Lifetime limiting defects in 4H-SiC epitaxial layers: The influence of substrate originated defects. J. Cryst. Growth 2021, 560, 126033. [Google Scholar] [CrossRef]

- Lockyer, N.P.; Aoyagi, S.; Fletcher, J.S.; Gilmore, I.S.; van der Heide, P.A.; Moore, K.L.; Tyler, B.J.; Weng, L.T. Secondary ion mass spectrometry. Nat. Rev. Methods Primers 2024, 4, 32. [Google Scholar] [CrossRef]

- Nipoti, R.; Ayedh, H.M.; Svensson, B.G. Defects related to electrical doping of 4H-SiC by ion implantation. Mater. Sci. Semicond. Process. 2018, 78, 13–21. [Google Scholar] [CrossRef]

- Müting, J.; Bobal, V.; Willinger, M.G.; Zadeh, A.B.; Reidt, S.; Vines, L.; Grossner, U. Spatially resolved diffusion of aluminum in 4H-SiC during postimplantation annealing. IEEE Trans. Electron Devices 2020, 67, 4360–4365. [Google Scholar] [CrossRef]

- Hallen, A.; Linnarsson, M. Ion implantation technology for silicon carbide. Surf. Coat. Technol. 2016, 306, 190–193. [Google Scholar] [CrossRef]

- Kumar, V.; Maan, A.S.; Akhtar, J. Defect levels in high energy heavy ion implanted 4H-SiC. Mater. Lett. 2022, 308, 131150. [Google Scholar] [CrossRef]

- Wilson, R.G.; Stevie, F.A.; Magee, C.W. Secondary Ion Mass Spectrometry: A Practical Handbook for Depth Profiling and Bulk Impurity Analysis; Wiley-Interscience: New York, NY, USA, 1989. [Google Scholar]

- Capano, M.A.; Ryu, S.; Cooper, J.A., Jr.; Melloch, M.R.; Rottner, K.; Karlsson, S.; Nordell, N.; Powell, A.; Walker, D.E., Jr. Surface roughening in ion implanted 4H-silicon carbide. J. Electron. Mater. 1999, 28, 214–218. [Google Scholar] [CrossRef]

- Sardela, M. Practical Materials Characterization; Springer: New York, NY, USA, 2014; Chapter 4. [Google Scholar]

- Herner, S.B.; Gila, B.P.; Jones, K.S.; Gossmann, H.J.; Poate, J.M.; Luftman, H.S. Surface roughness-induced artifacts in secondary ion mass spectrometry depth profiling and a simple technique to smooth the surface. J. Vac. Sci. Technol. B 1996, 14, 3593–3595. [Google Scholar] [CrossRef]

- Simons, D.S.; Downing, R.G.; Lamaze, G.P.; Lindstrom, R.M.; Greenberg, R.R.; Paul, R.L.; Schiller, S.B.; Guthrie, W.F. Development of certified reference materials of ion-implanted dopants in silicon for calibration of secondary ion mass spectrometers. J. Vac. Sci. Technol. B 2007, 25, 1365–1375. [Google Scholar] [CrossRef]

- De Hoog, J.C. EIMF Matrix effects during SIMS measurement of the lithium mass fractions of silicate glasses: Correction procedures and updated preferred values of reference materials. Geostand. Geoanalytical Res. 2018, 42, 513–522. [Google Scholar] [CrossRef]

- Gupta, G.; Jozwik, P.; Ojha, S.; Umapathy, G.R.; Pandey, A.; Rath, S. Depth profiling of the Si ion implantation induced disorder and strain in 4H-SiC and the thermal annealing recovery. Appl. Surf. Sci. 2024, 665, 160296. [Google Scholar] [CrossRef]

- Chan, K.S.; Vines, L.; Johansen, K.M.; Monakhov, E.V.; Ye, J.D.; Parkinson, P.; Jagadish, C.; Svensson, B.G.; Wong-Leung, J. Defect formation and thermal stability of H in high dose H implanted ZnO. J. Appl. Phys. 2013, 114, 083111. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, Y.; Peng, H.; Cheng, Q.; Hu, S.; Raghothamachar, B.; Dudley, M.; Ghandi, R.; Kennerly, S.; Thieberger, P. Effect of annealing conditions on recovery of lattice damage in a high-energy-implanted 4H-SiC superjunction PIN diode. ECS J. Solid State Sci. Technol. 2022, 11, 065003. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, Y.; Cheng, Q.; Hu, S.; Raghothamachar, B.; Dudley, M. Analysis of strain in ion implanted 4H-SiC by fringes observed in synchrotron X-ray topography. J. Cryst. Growth 2024, 627, 127535. [Google Scholar] [CrossRef]

- Sasaki, S.; Suda, J.; Kimoto, T. Lattice mismatch and crystallographic tilt induced by high-dose ion-implantation into 4H-SiC. J. Appl. Phys. 2012, 111, 103715. [Google Scholar] [CrossRef]

- Zhao, J.; Ye, L.; Jiao, X.; Yue, Q.; Liu, Y. The damage investigations of 4H–SiC after P-ion irradiation. Appl. Phys. A 2020, 126, 531. [Google Scholar] [CrossRef]

- Slotte, J.; Saarinen, K.; Janson, M.S.; Hallén, A.; Kuznetsov, A.Y.; Svensson, B.G.; Wong-Leung, J.; Jagadish, C. Fluence, flux, and implantation temperature dependence of ion-implantation-induced defect production in 4H–SiC. J. Appl. Phys. 2005, 97, 033513. [Google Scholar] [CrossRef]

- Chu, W.K. Backscattering Spectrometry; Elsevier: Amsterdam, The Netherland, 2012; Chapter 8.4. [Google Scholar]

- Min, W.J.; Kim, J.; Park, K.; Marmitt, G.; England, J.; Moon, D.W. Determination of dimension and conformal arsenic doping profile of a fin field effect transistors by time-of-flight medium energy ion scattering. Anal. Chem. 2019, 91, 9315–9322. [Google Scholar] [CrossRef] [PubMed]

- Pantano, C.G. Secondary Ion Mass Spectroscopy; ASM International: Almere, The Netherland, 1986; pp. 610–627. [Google Scholar]

- Liu, R.; Ng, C.M.; Wee, A.T.S. Surface roughening effect in sub-keV SIMS depth profiling. Appl. Surf. Sci. 2003, 203, 256–259. [Google Scholar] [CrossRef]

- Wilson, R.G.; Zavada, J.M. Secondary ion mass spectrometry of dopant and impurity elements in wide bandgap semiconductors. Mater. Sci. Eng. R Rep. 2012, 73, 101–128. [Google Scholar] [CrossRef]

| Identification | Dopant Elements | Energy (keV) | Dose (Atoms/cm2) | Current (μA) | Temperature (°C) | Time (s) |

|---|---|---|---|---|---|---|

| S1 | - | - | - | - | - | |

| S2 | Al | 150 | 1.00 × 1014 | 3.0 | RT | 93 |

| S3 | P | 150 | 1.00 × 1014 | 3.0 | RT | 93 |

| Sample Identification | Dopants | Ra (nm) | Rrms (nm) |

|---|---|---|---|

| S1 | - | 0.174 | 0.218 |

| S2 | Al | 0.184 | 0.231 |

| S3 | P | 0.177 | 0.223 |

| Identification | Dopant | Rp (nm) | Cp (Atoms/cm3) | Dose (Atoms/cm2) |

|---|---|---|---|---|

| S2 | Al | 179 | 6.04 × 1018 | 8.31 × 1013 |

| S3 | P | 138 | 8.92 × 1018 | 1.05 × 1014 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, T.; Byeon, M.; Kang, M.; Lee, S.-G.; Lee, J.H.; Lee, S.-G.; Min, W.J.; Hong, T.E. Investigating Structural and Surface Modifications in Ion-Implanted 4H-SiC for Enhanced Dopant Distribution Analysis in Power Semiconductors. Materials 2024, 17, 5734. https://doi.org/10.3390/ma17235734

Jang T, Byeon M, Kang M, Lee S-G, Lee JH, Lee S-G, Min WJ, Hong TE. Investigating Structural and Surface Modifications in Ion-Implanted 4H-SiC for Enhanced Dopant Distribution Analysis in Power Semiconductors. Materials. 2024; 17(23):5734. https://doi.org/10.3390/ma17235734

Chicago/Turabian StyleJang, Taehun, Mirang Byeon, Minji Kang, Sang-Gil Lee, Ji Hyun Lee, Sang-Geul Lee, Won Ja Min, and Tae Eun Hong. 2024. "Investigating Structural and Surface Modifications in Ion-Implanted 4H-SiC for Enhanced Dopant Distribution Analysis in Power Semiconductors" Materials 17, no. 23: 5734. https://doi.org/10.3390/ma17235734

APA StyleJang, T., Byeon, M., Kang, M., Lee, S.-G., Lee, J. H., Lee, S.-G., Min, W. J., & Hong, T. E. (2024). Investigating Structural and Surface Modifications in Ion-Implanted 4H-SiC for Enhanced Dopant Distribution Analysis in Power Semiconductors. Materials, 17(23), 5734. https://doi.org/10.3390/ma17235734