Experimental Research on the Performance of Recycled Waste Concrete Powder (RWCP) on Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation of RWCP

2.3. Preparation of Concrete Containing RWCP

2.4. Activity Test of RWCP

2.5. Strength Test

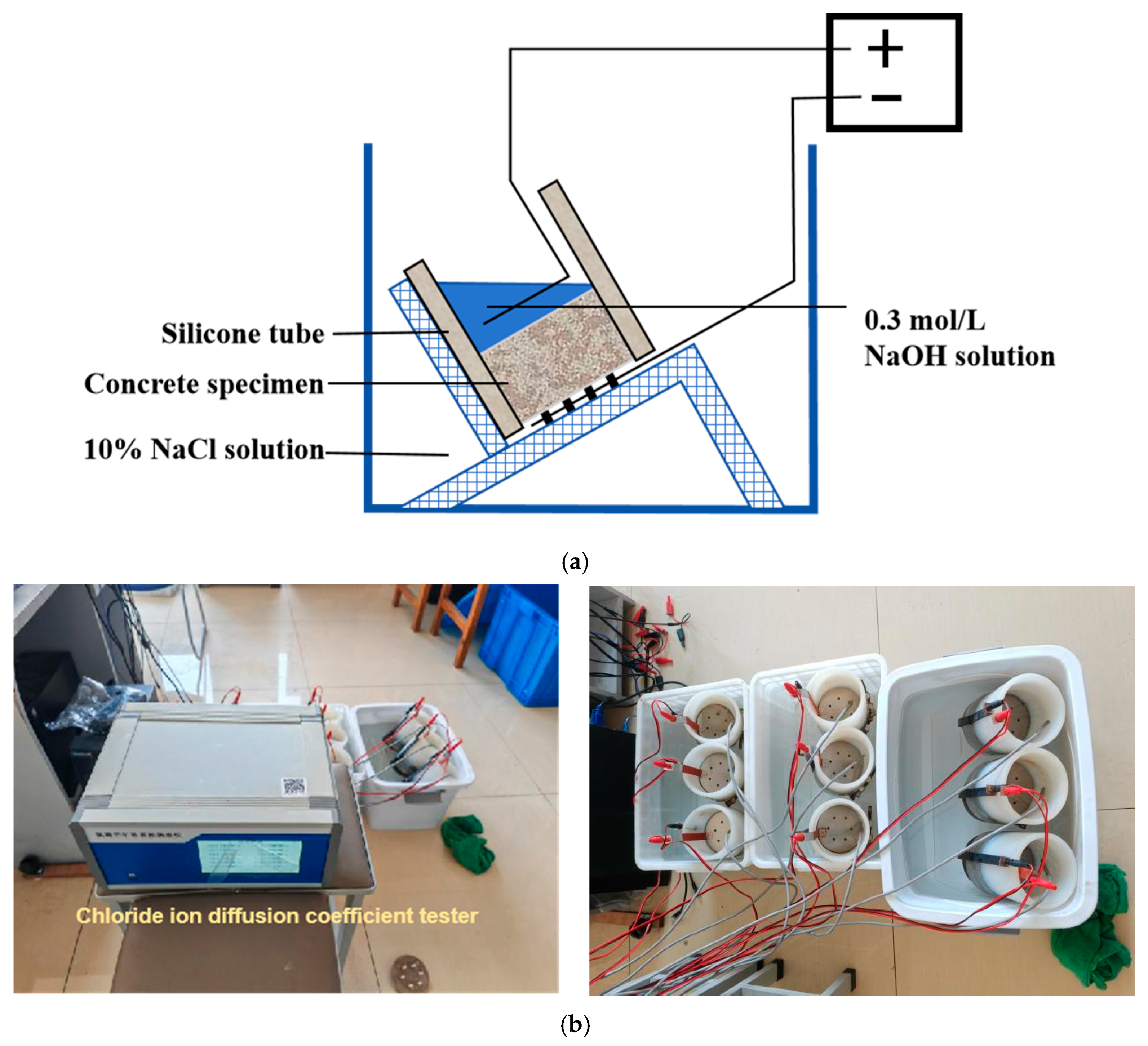

2.6. Electric Flux Test and RCM

2.7. Micro Characterization

3. Results and Discussion

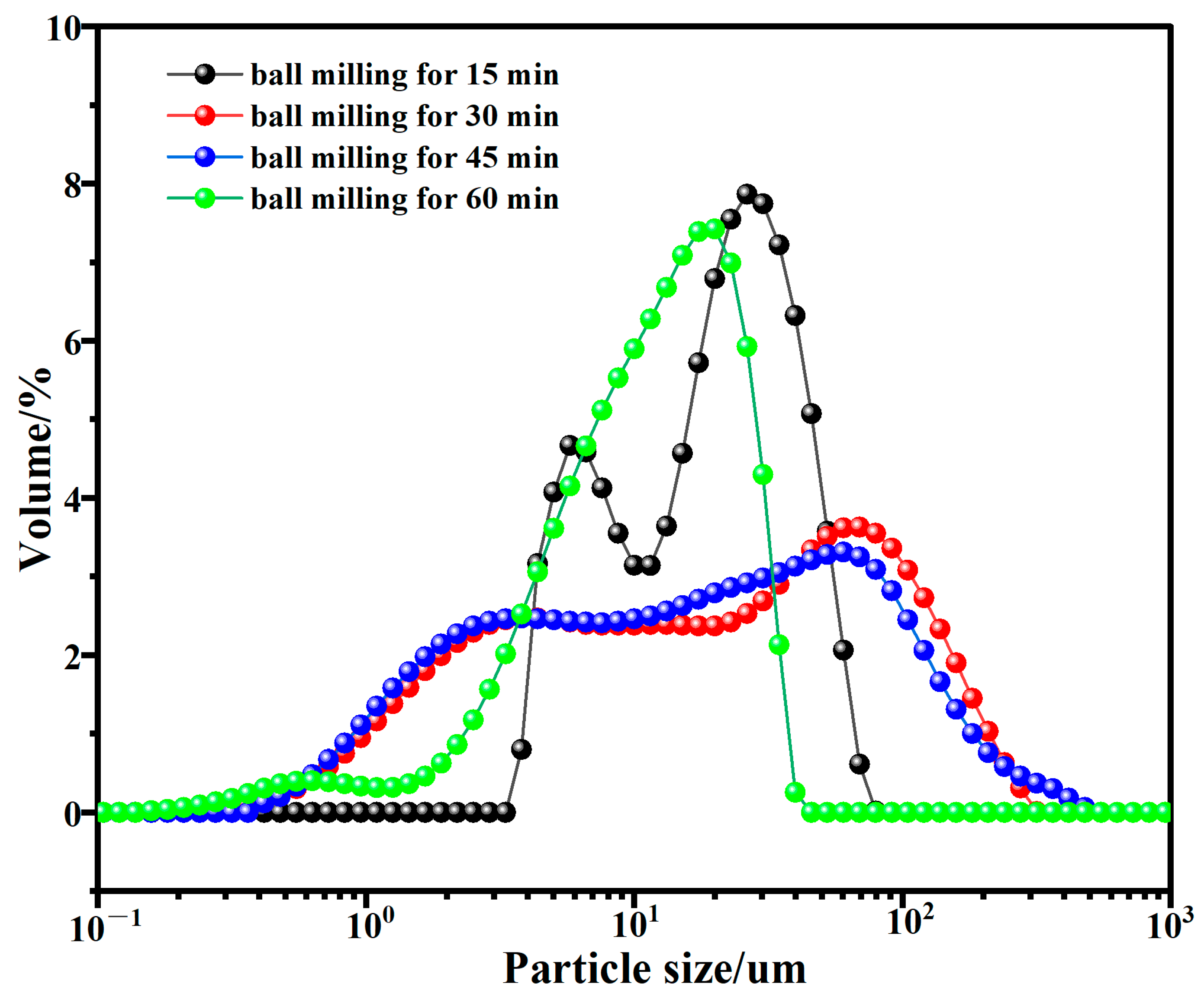

3.1. Characteristics of RWCP

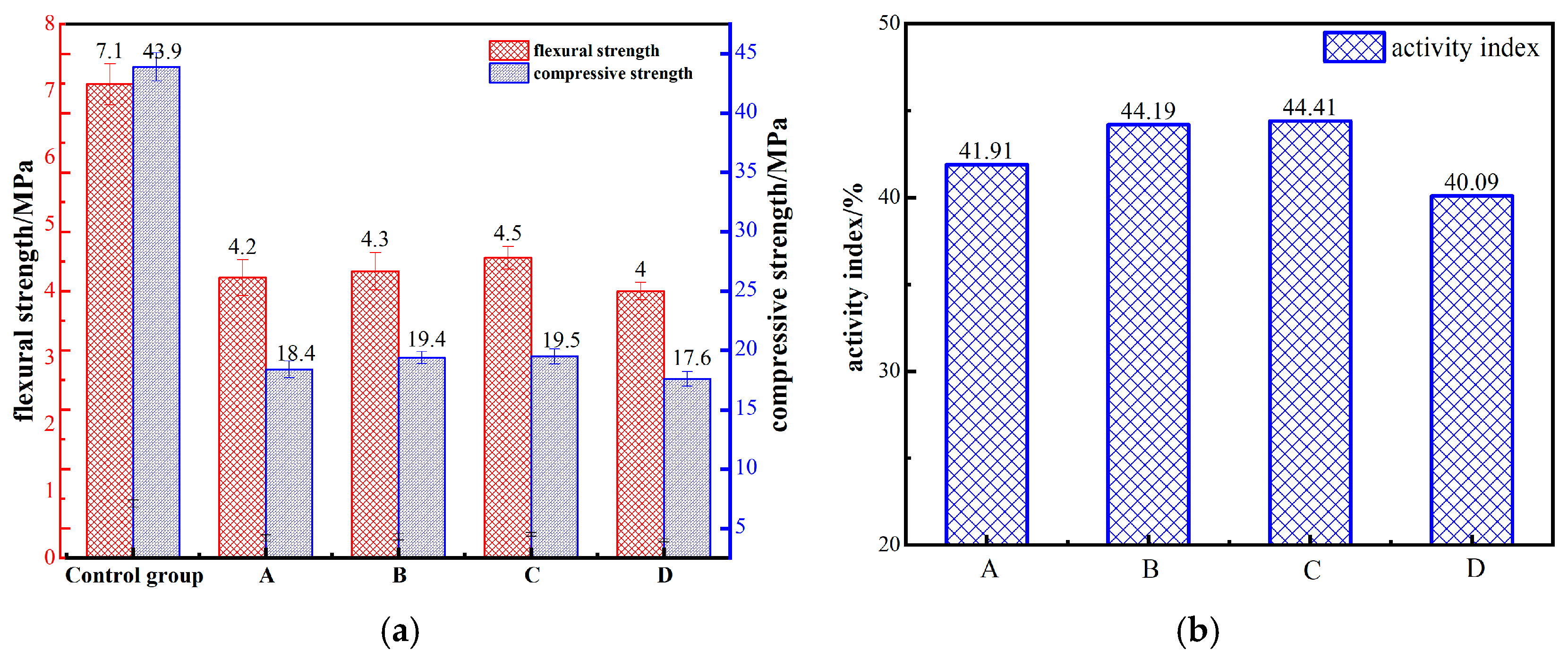

3.2. Activity Index of RWCP

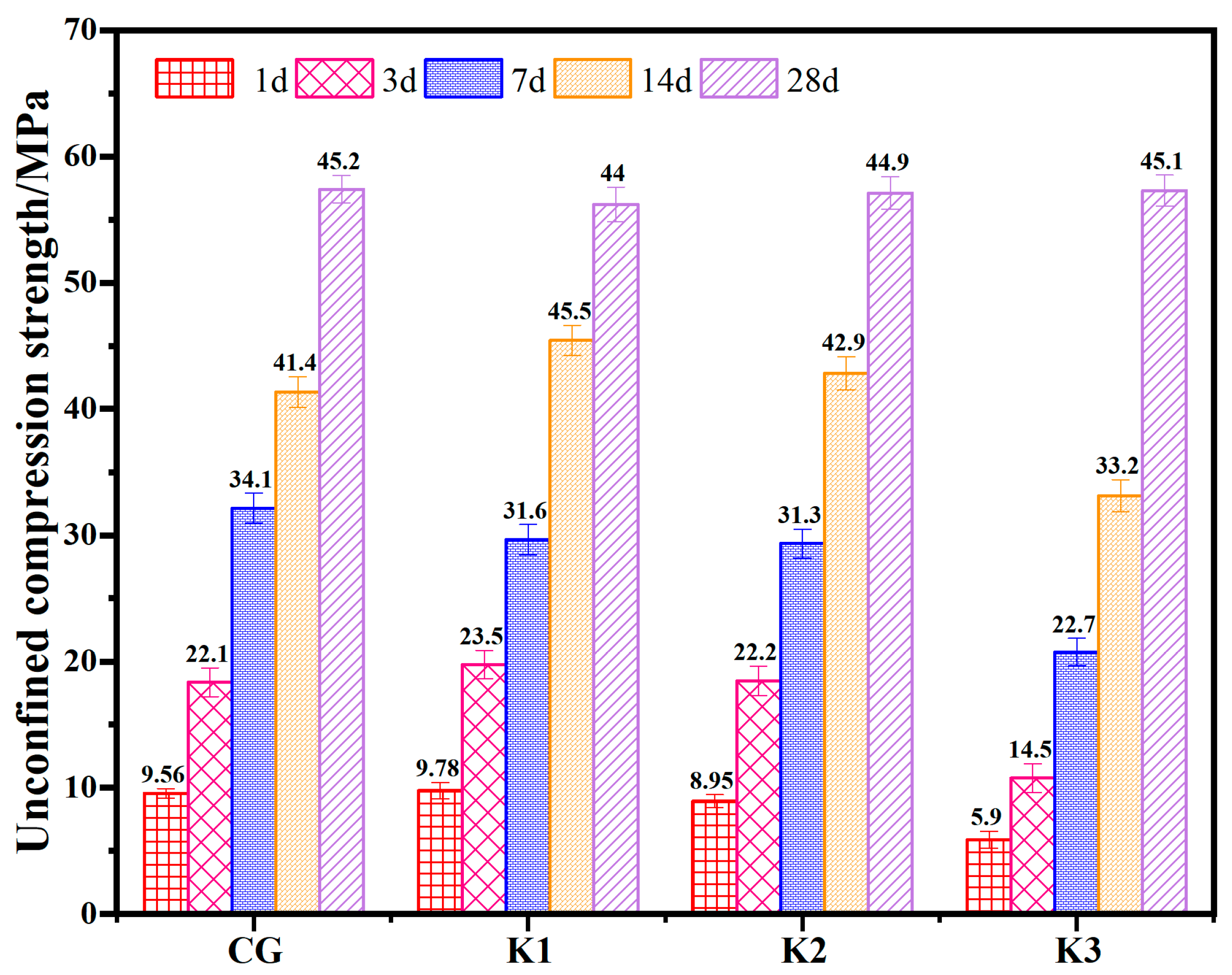

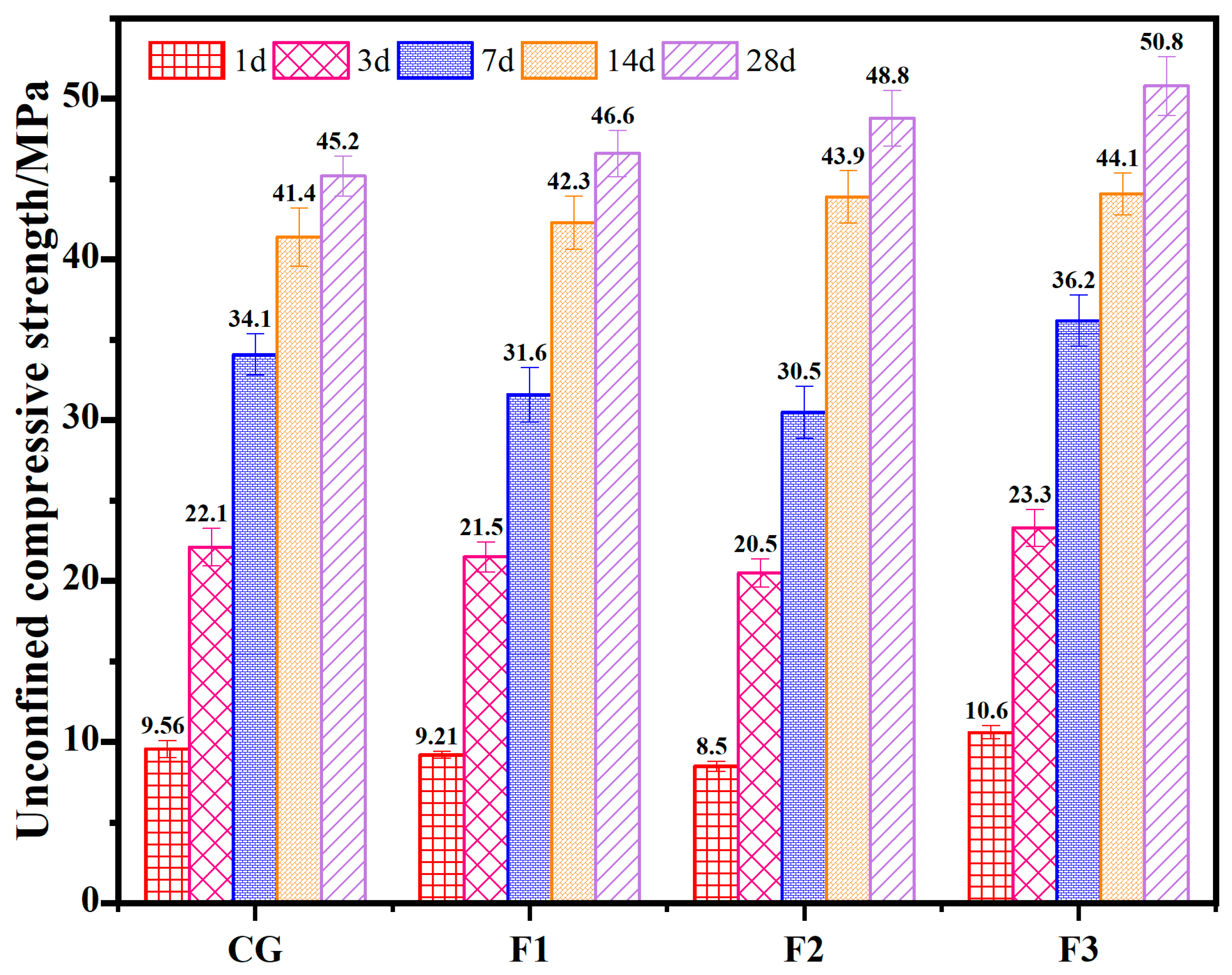

3.3. Strength Analysis of Concrete Containing RWCP

3.4. Slump of Concrete Containing RWCP

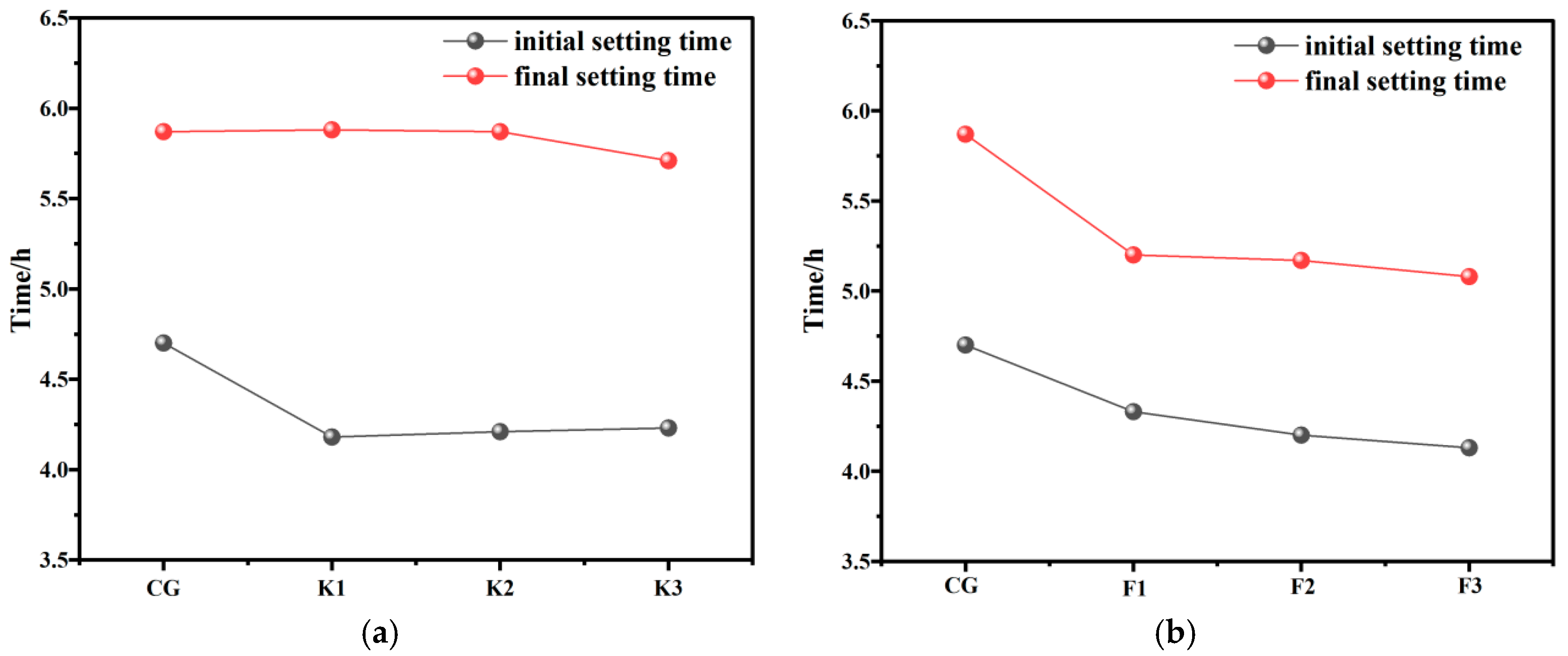

3.5. The Initial and Final Setting Time of Concrete Containing RWCP

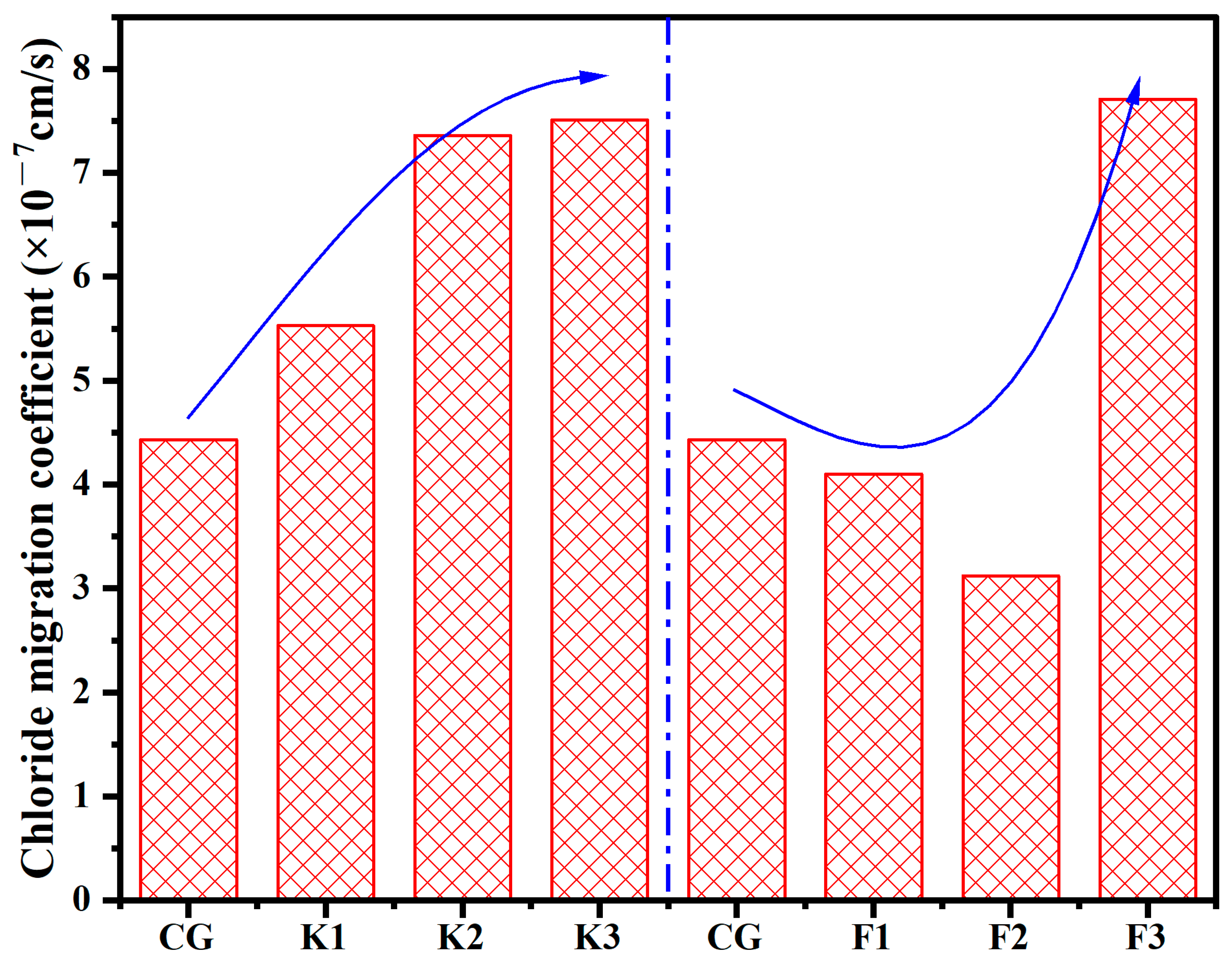

3.6. Impermeability of Concrete

3.6.1. Electric Flux of Concrete

3.6.2. RCM Test

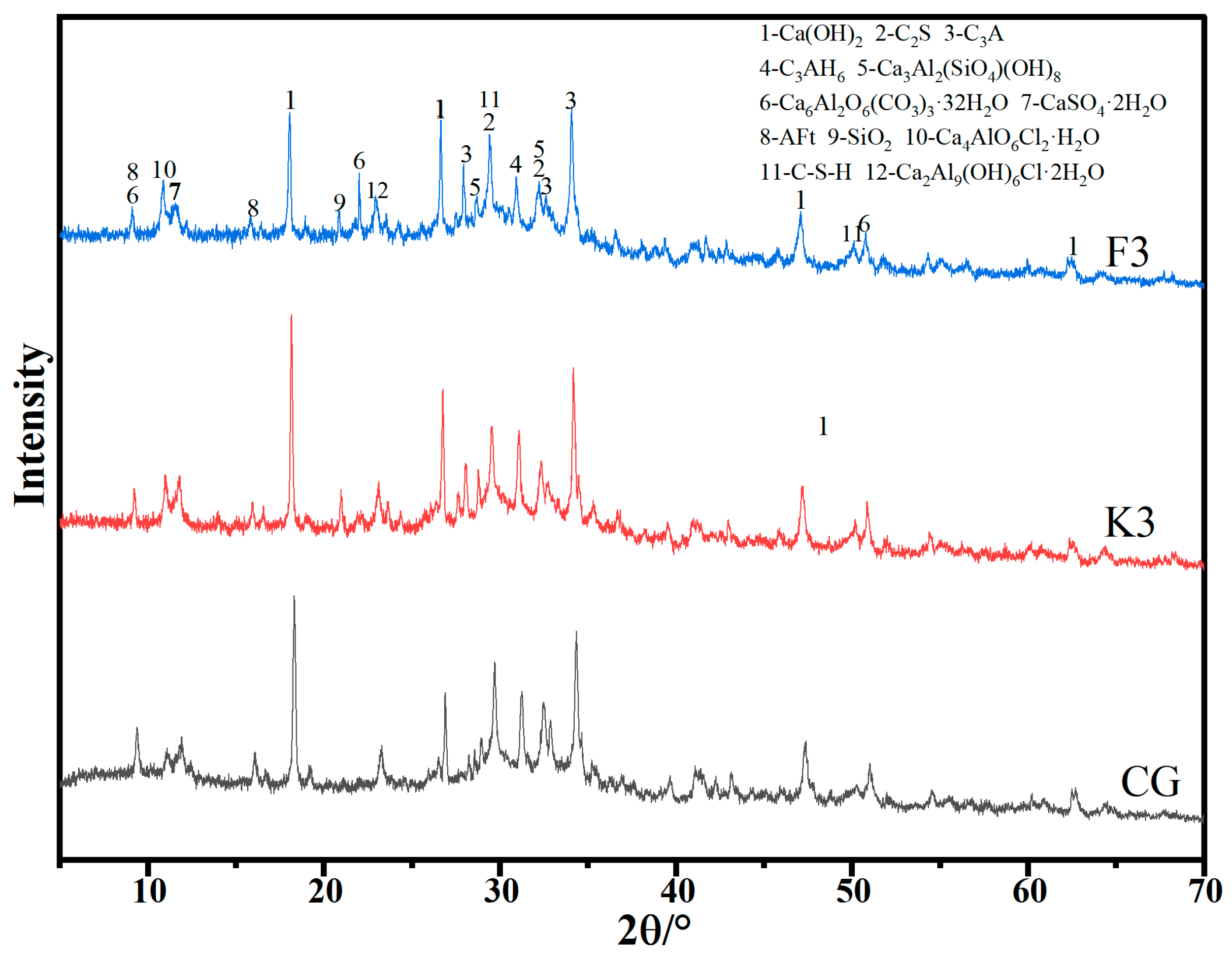

3.7. XRD Analysis

3.8. SEM Analysis

4. Conclusions

- (1)

- The fineness of recycled fine powder particles of WC decreases with the increase in mechanical strengthening time, which is mainly composed of quartz, gismondine, C2S, cancrinite and portlandite. After mechanical activation of WC for 45 min, the best activity index is 44.41%.

- (2)

- The use of RWCP instead of BFS for the preparation of concrete will lead to a decrease in the permeability of concrete. The content of RWCP instead of BFS for the preparation of concrete should be lower than 17.3%. When the substitution amount is less than 17.3%, the early and middle age strength of concrete can be improved. When the substitution rate of RWCP instead of BFS is greater than 17.3%, the early and middle strength of concrete will decrease. When BFS replaces FA for the preparation of concrete, the strength of concrete increases with the increase in replacement rate. When the replacement rate of RWCP replacing FA was 66.6%, the concrete had the best impermeability.

- (3)

- When the RWCP is used to replace the BFS and FA for the preparation of concrete, the slump of concrete can be improved, which is beneficial to the fluidity of concrete. The RWCP has some unhydrated C3A, which promotes the hydration process and reduces the initial setting time of concrete.

- (4)

- The hydration products of RWCP concrete containing RWCP were basically consistent with the CG. The main hydration products were C2S, C3A, C3AH6, Ca3Al2(SiO4)(OH)8, CaAlO(CO3)3·32H2O and AFt,, etc. These hydration products are interlaced and fill the pores to improve the strength and compactness of concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, H.; Xia, J.; Thompson, J.R.; Flower, R.J. Urban construction and demolition waste and landfill failure in Shenzhen, China. Waste Manag. 2017, 63, 393–396. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Zheng, L.; Duan, H.; Yin, F.; Li, J.; Niu, Y. Differences of methods to quantify construction and demolition waste for less-developed but fast-growing countries: China as a case study. Environ. Sci. Pollut. Res. Int. 2019, 26, 25513–25525. [Google Scholar] [CrossRef] [PubMed]

- Su, Y.; Yao, Y.; Wang, Y.; Zhao, X.; Li, L.; Zhang, J. Modification of Recycled Concrete Aggregate and Its Use in Concrete: An Overview of Research Progress. Materials 2023, 16, 7144. [Google Scholar] [CrossRef] [PubMed]

- Yang, W. Expert Suggests to Improve Special Legislation as the Recycling Rate of Construction Waste is Low. Resour. Recycl. 2020, 9, 10–12. (In Chinese) [Google Scholar]

- Wang, Y.; Wang, M.; Wang, H.; Dun, Z.; Ren, L. Experimental Research on Application of Waste Concrete Powder–Waste Brick Powder–Cement Grout for Foundation Reinforcement in Mining Goaf. Materials 2023, 16, 6075. [Google Scholar] [CrossRef] [PubMed]

- Duan, H.; Miller, T.R.; Liu, G.; Tam, V.W. Construction debris becomes growing concern of growing cities. Waste Manag. 2019, 83, 1–5. [Google Scholar] [CrossRef]

- Yao, T.; Tian, Q.; Zhang, M.; Qi, S.; Wang, C.; Ruan, M. Laboratory investigation of foamed concrete prepared by recycled waste concrete powder and ground granulated blast furnace slag. J. Clean. Prod. 2023, 426, 139095. [Google Scholar] [CrossRef]

- Zou, D.; Que, Z.; Su, D.; Liu, T.; Zhou, A.; Li, Y. Sustainable use of recycled autoclaved aerated concrete waste as internal curing materials in ultra-high performance concrete. J. Clean. Prod. 2022, 373, 133910. [Google Scholar] [CrossRef]

- Fang, X.; Xuan, D.; Zhan, B.; Li, W.; Poon, C.S. A novel upcycling technique of recycled cement paste powder by a two-step carbonation process. J. Clean. Prod. 2021, 290, 125192. [Google Scholar] [CrossRef]

- Zhou, M.; Bai, J.; Li, S.; Zhang, K.; Li, C.; Wang, X. Mechanical Properties and Uniaxial Failure Behavior of Concrete with Different Solid Waste Coarse Aggregates. Materials 2022, 15, 6259. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Marvila, M.; de Matos, P.; Rodríguez, E.; Monteiro, S.N.; de Azevedo, A.R.G. Recycled Aggregate: A Viable Solution for Sustainable Concrete Production. Materials 2022, 15, 5276. [Google Scholar] [CrossRef] [PubMed]

- Nie, Z.; Yang, Z.; Fang, Y.; Yang, Y.; Tang, Z.; Wang, X.; Die, Q.; Gao, X.; Zhang, F.; Wang, Q.; et al. Environmental risks of HBCDD from construction and demolition waste: A contemporary and future issue. Environ. Sci. Pollut. Res. Int. 2015, 22, 17249–17252. [Google Scholar] [CrossRef] [PubMed]

- Lee, G.; Poon, C.S.; Wong, Y.L.; Ling, T.C. Effects of recycled fine glass aggregates on the properties of dryemixed concrete blocks. Construct. Build. Mater. 2013, 38, 638–643. [Google Scholar] [CrossRef]

- Li, L.; Xiao, J.Z.; Xuan, D.X.; Poon, C.S. Effect of carbonation of modeled recycled coarse aggregate on the mechanical properties of modeled recycled aggregate concrete. Cem. Concr. Compos. 2018, 89, 169–180. [Google Scholar] [CrossRef]

- Zhan, B.J.; Poon, C.S.; Shi, C.J. CO2 curing for improving the properties of concrete blocks containing recycled aggregates. Cem. Concr. Compos. 2013, 42, 1–8. [Google Scholar] [CrossRef]

- Xiao, J.; Ma, Z.; Sui, T.; Akbarnezhad, A.; Duan, Z. Mechanical properties of concrete mixed with recycled powder produced from construction and demolition waste. J. Clean Prod. 2018, 188, 720–731. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Singh, A.; Miao, X.; Zhou, X.; Deng, Q.; Li, J.; Zou, S.; Duan, Z. Use of recycled fine aggregates and recycled powdersin sustainable recycled concrete. J. Build. Eng. 2023, 77, 107370. [Google Scholar]

- Gao, Q. Study on the Impact of Content of Recycled Concrete Fines on Concrete Performance. Jiangxi Jiancai 2023, 08, 41–43+46. (In Chinese) [Google Scholar]

- Bordy, A.; Younsi, A.; Aggoun, S.; Fiorio, B. Cement substitution by a recycled cement paste fine: Role of the residual anhydrous clinker. Constr. Build. Mater. 2017, 132, 1–8. [Google Scholar] [CrossRef]

- Likes, L.; Markandeya, A.; Haider, M.M.; Bollinger, D.; McCloy, J.S.; Nassiri, S. Recycled concrete and brick powders assupplements to Portland cement for more sustainable concrete. J. Clean Prod. 2022, 364, 132651. [Google Scholar] [CrossRef]

- Lu, B.; Shi, C.J.; Zhang, J.K.; Wang, J.Y. Effects of carbonated hardened cement paste powder on hydration and microstructure of Portland cement. Construct. Build. Mater. 2018, 186, 699–708. [Google Scholar] [CrossRef]

- Zhu, C.; Fang, Y.; Wei, H. Carbonation-cementation of recycled hardened cement paste powder. Constr. Build. Mater. 2018, 192, 224–232. [Google Scholar] [CrossRef]

- Zhang, J.K.; Shi, C.J.; Li, Y.; Pan, X.; Poon, C.S.; Xie, Z. Performance enhancement of recycled concrete aggregates through carbonation. J. Mater. Civ. Eng. 2015, 27, 4015029. [Google Scholar] [CrossRef]

- Lotfi, S.; Rem, P.; Deja, J.; Mróz, R. An experimental study on the relation between input variables and output quality of a new concrete recycling process. Constr. Build. Mater. 2017, 137, 128–140. [Google Scholar] [CrossRef]

- Sui, Y.; Ou, C.; Liu, S.; Zhang, J.; Tian, Q. Study on properties of waste concrete powder by thermal treatment and application in mortar. Appl. Sci. 2020, 10, 998. [Google Scholar] [CrossRef]

- GB/T 18046-2017; Ground Granulated Blast Furnace Slag Used for Cement, Mortar and Concrete. China National Standardization Administration: Beijing, China, 2017.

- GB/T 50081-2019; Standards for Test Methods of Physical and Mechanical Properties of Concrete. China National Standardization Administration: Beijing, China, 2019.

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. China National Standardization Administration: Beijing, China, 2009.

- Yan, Z.; Liu, L.; Sun, J.; Lu, B.; Zu, Q. Study on the Synergy of Tricalcium Aluminate and Calcium Carbonate on the Early Mechanical Strength and Setting Time of Portland Cement. Bull. Chin. Ceram. Soc. 2021, 40, 1470–1476. (In Chinese) [Google Scholar]

- Du, F.; Jin, Z.; Xiong, C.; Yu, Y.; Fan, J. Effects of Transverse Crack on Chloride Ions Diffusion and Steel Bars Corrosion Behavior in Concrete under Electric Acceleration. Materials 2019, 12, 2481. [Google Scholar] [CrossRef]

- Yuan, Y.; Niu, K.; Tian, B.; Li, L.; Ji, J.; Feng, Y. Effect of Metakaolin on the Microstructural and Chloride Ion Transport Properties of Concrete in Ocean Wave Splashing Zones. Materials 2022, 16, 7. [Google Scholar] [CrossRef]

- JGJ/T 193-2009; Standard for Inspection and Assessment of Concrete Durability. China National Standardization Administration: Beijing, China, 2009.

| Group | Sand | Stone | Cement | RWCP | BFS | FA | Water | Water Reducer |

|---|---|---|---|---|---|---|---|---|

| Control group (CG) | 930 | 812 | 314 | / | 52.1 | 36 | 140 | 11.25 |

| K1 | 930 | 812 | 314 | 9 | 43.1 | 36 | 140 | 11.25 |

| K2 | 930 | 812 | 314 | 18 | 34.1 | 36 | 140 | 11.25 |

| K3 | 930 | 812 | 314 | 36 | 16.1 | 36 | 140 | 11.25 |

| F1 | 930 | 812 | 314 | 9 | 52.1 | 27 | 140 | 11.25 |

| F2 | 930 | 812 | 314 | 18 | 52.1 | 18 | 140 | 11.25 |

| F3 | 930 | 812 | 314 | 36 | 52.1 | 0 | 140 | 11.25 |

| Chemical Element Analysis/% | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Constituents | Na2O | MgO | Al2O3 | SiO2 | P2O5 | SO3 | K2O | CaO | TiO2 | Fe2O3 | LOI |

| wt.% | 2.817 | 1.735 | 12.998 | 52.46 | 0.164 | 0.723 | 3.722 | 11.436 | 0.429 | 3.077 | 10.1 |

| Group | Electric Flux/C | Grade |

|---|---|---|

| CG | 3763.44 | Q-II |

| K1 | 3964.68 | Q-II |

| K2 | 4333.68 | Q-I |

| K3 | 4363.12 | Q-I |

| F1 | 3612.24 | Q-II |

| F2 | 3483 | Q-II |

| F3 | 5659.704 | Q-I |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Wang, A.; Fu, X.; Zhang, X.; Li, Z.; Guo, Y.; Li, S.; Wang, M. Experimental Research on the Performance of Recycled Waste Concrete Powder (RWCP) on Concrete. Materials 2024, 17, 5319. https://doi.org/10.3390/ma17215319

Wang S, Wang A, Fu X, Zhang X, Li Z, Guo Y, Li S, Wang M. Experimental Research on the Performance of Recycled Waste Concrete Powder (RWCP) on Concrete. Materials. 2024; 17(21):5319. https://doi.org/10.3390/ma17215319

Chicago/Turabian StyleWang, Shuai, Aixun Wang, Xudong Fu, Xianwei Zhang, Zhe Li, Yongjun Guo, Shenghao Li, and Mingzhao Wang. 2024. "Experimental Research on the Performance of Recycled Waste Concrete Powder (RWCP) on Concrete" Materials 17, no. 21: 5319. https://doi.org/10.3390/ma17215319

APA StyleWang, S., Wang, A., Fu, X., Zhang, X., Li, Z., Guo, Y., Li, S., & Wang, M. (2024). Experimental Research on the Performance of Recycled Waste Concrete Powder (RWCP) on Concrete. Materials, 17(21), 5319. https://doi.org/10.3390/ma17215319