Numerical Simulation of Rubber Concrete Considering Fatigue Damage Accumulation of Cohesive Zone Model

Abstract

1. Introduction

2. Model Establishment

2.1. Constitutive Laws of CZM

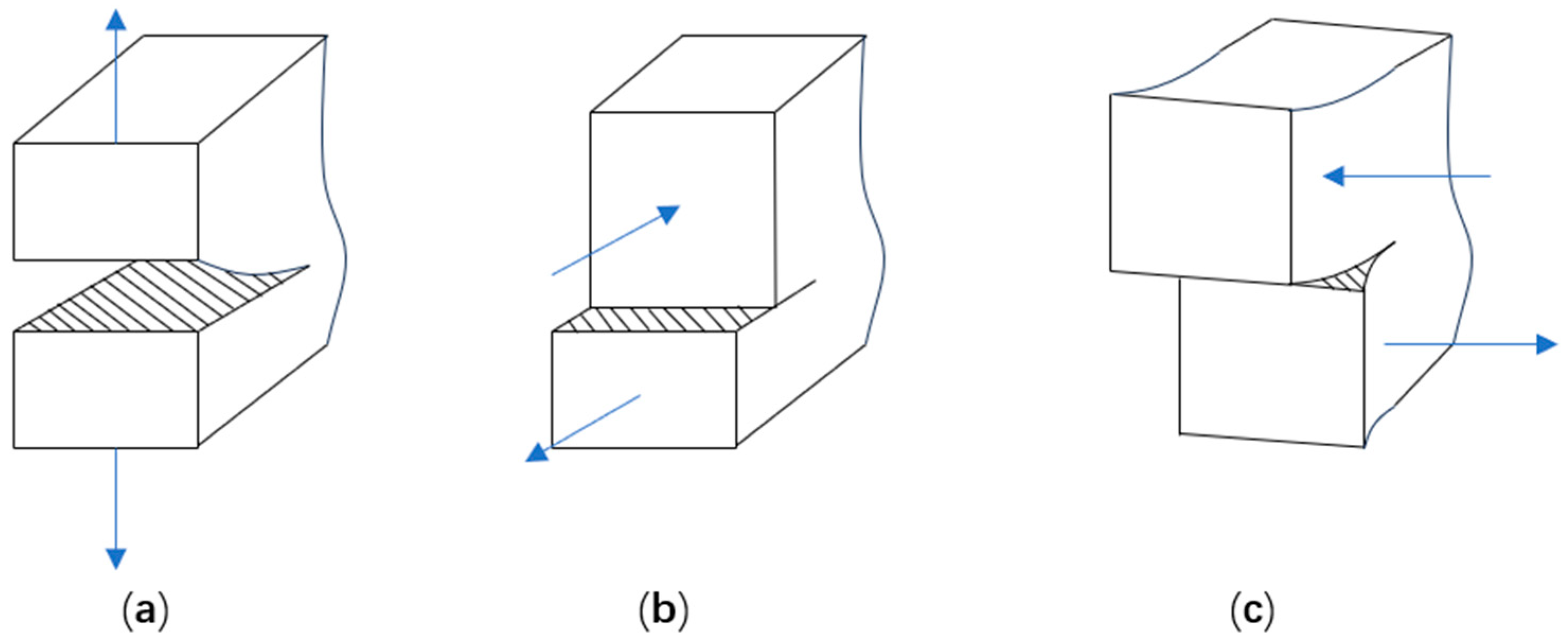

2.1.1. Concrete Crack Expansion Forms

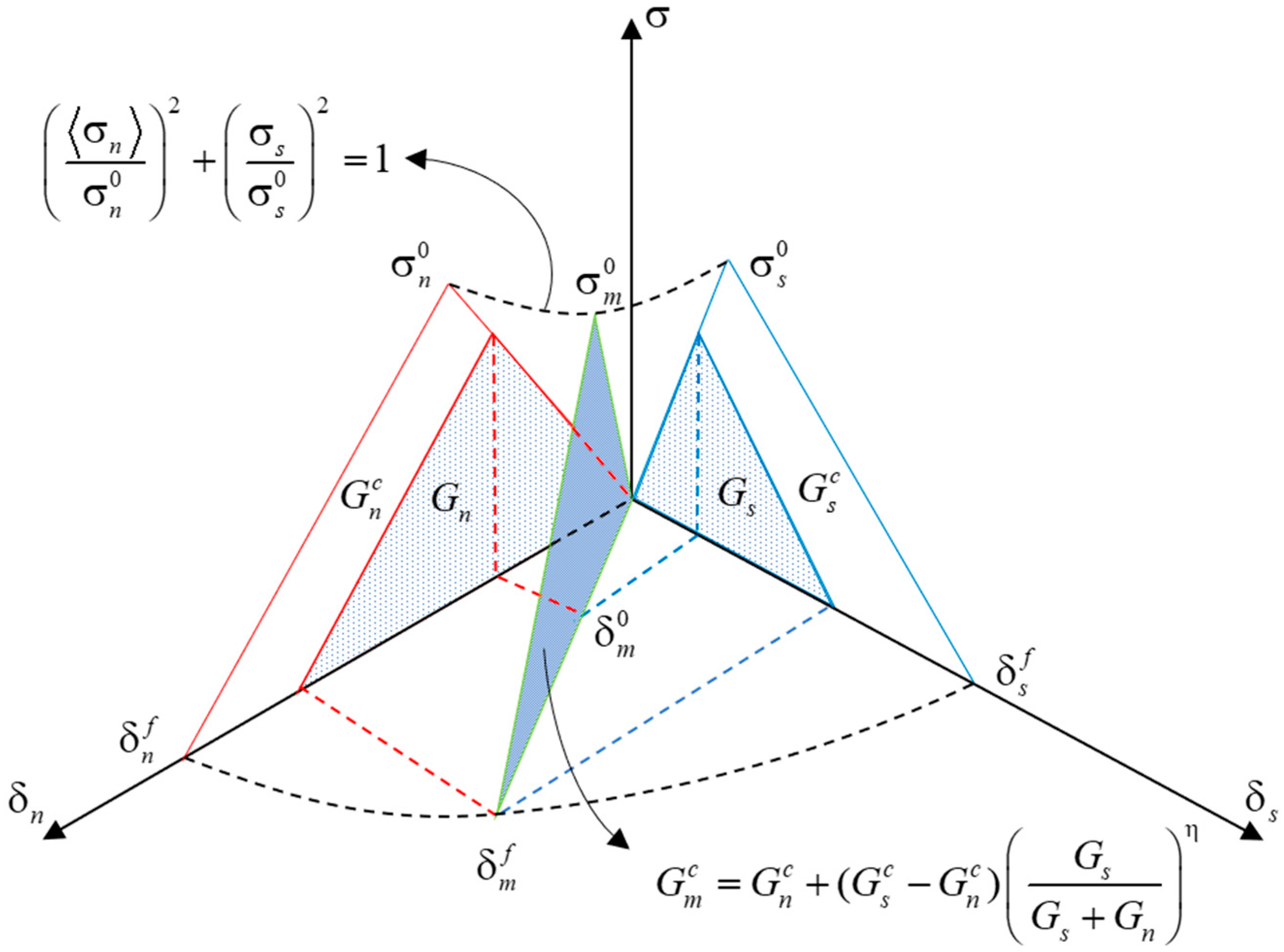

2.1.2. Constitutive Laws for CZM under Monotonic Loading

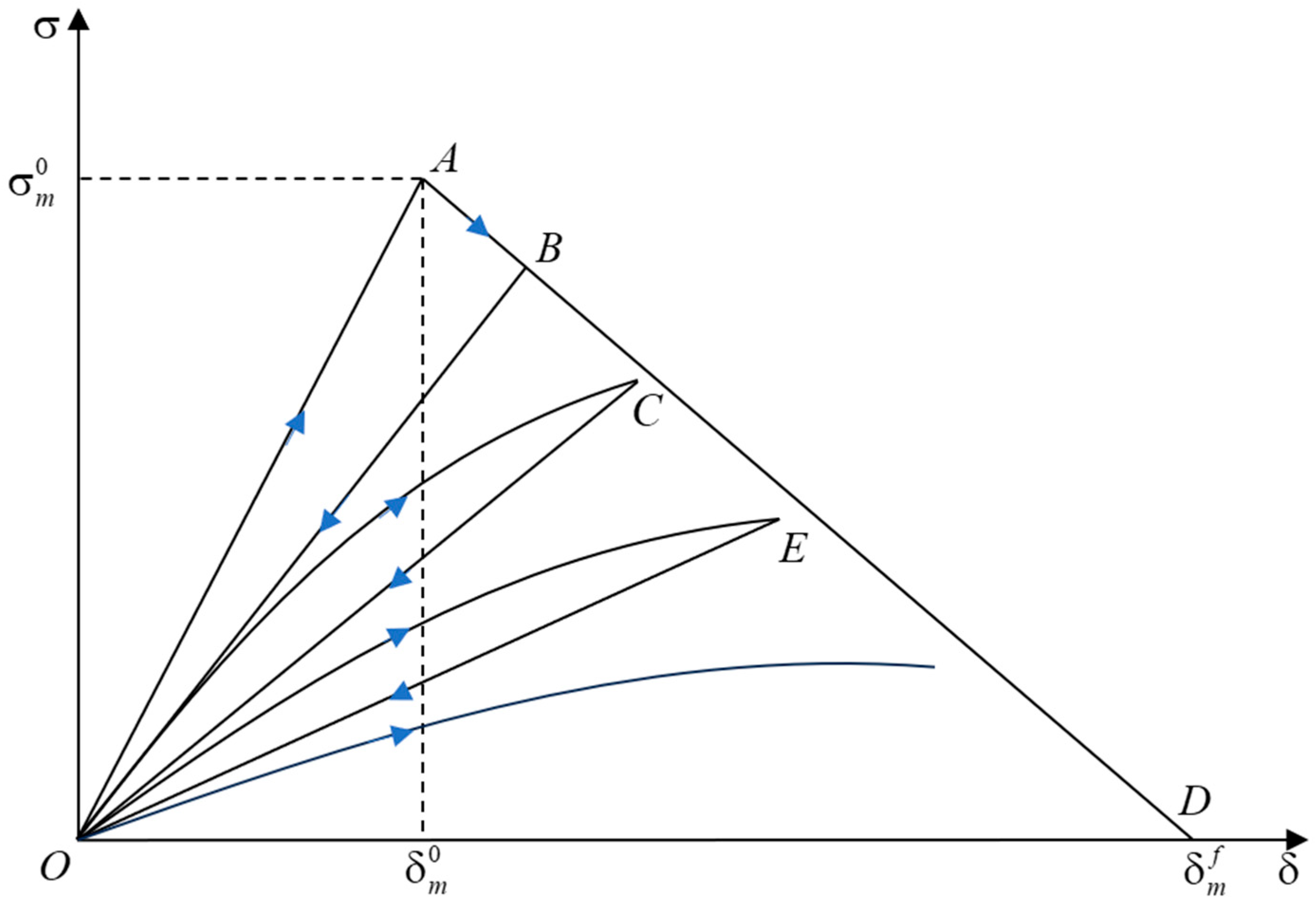

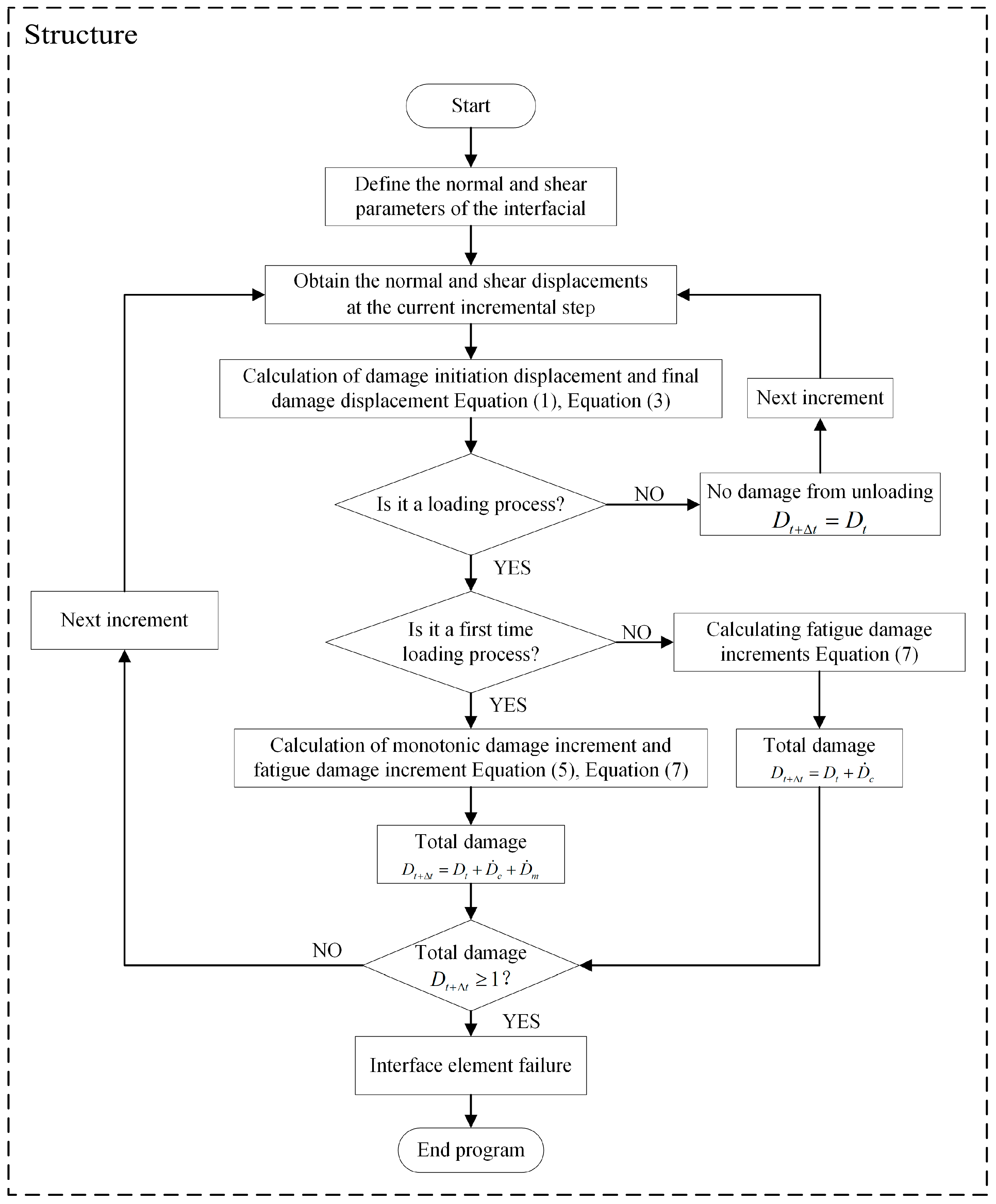

2.1.3. Constitutive Laws for CZM under Fatigue Loading

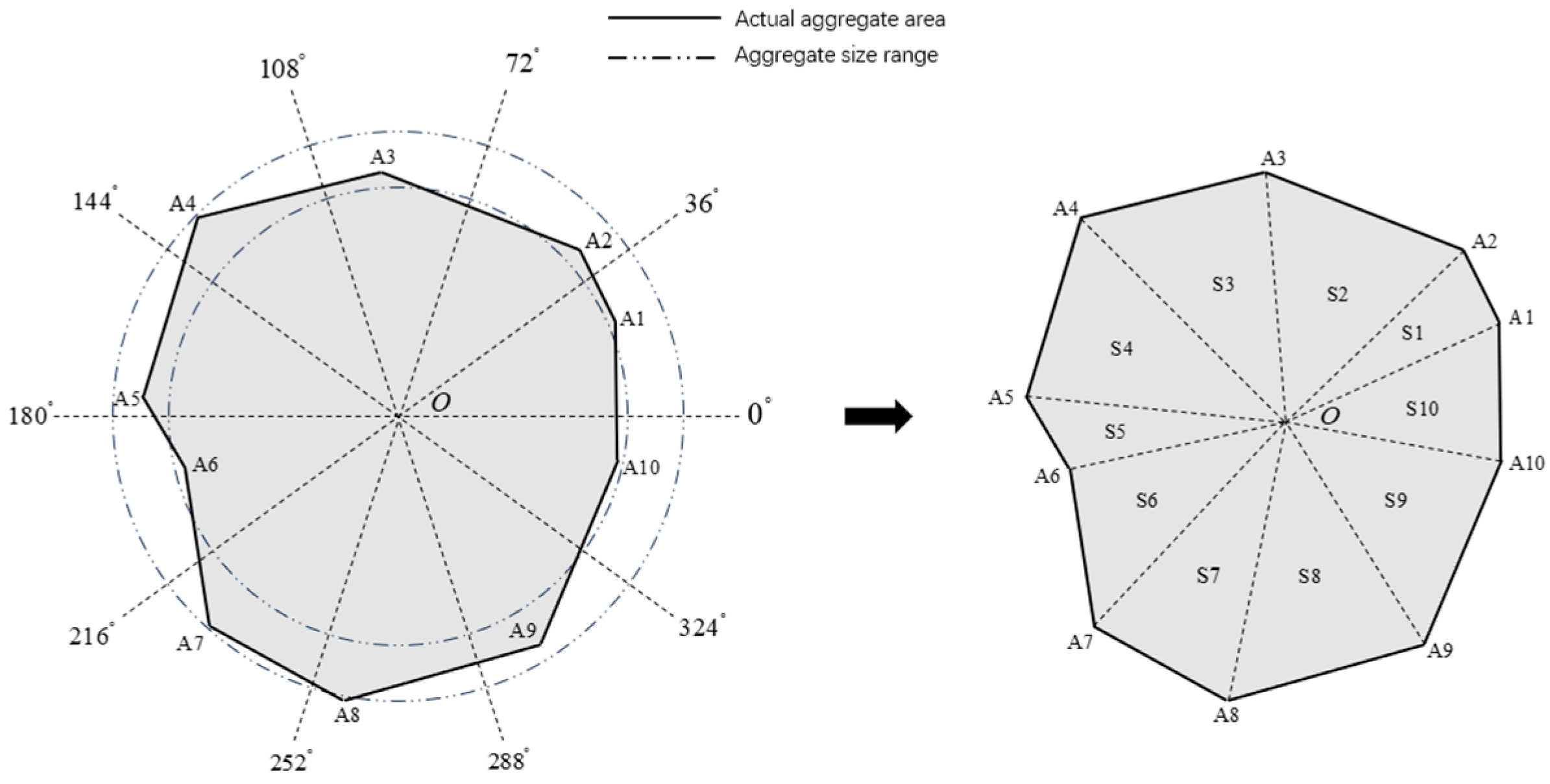

2.2. Methods of Generating Aggregates at the Mesoscale

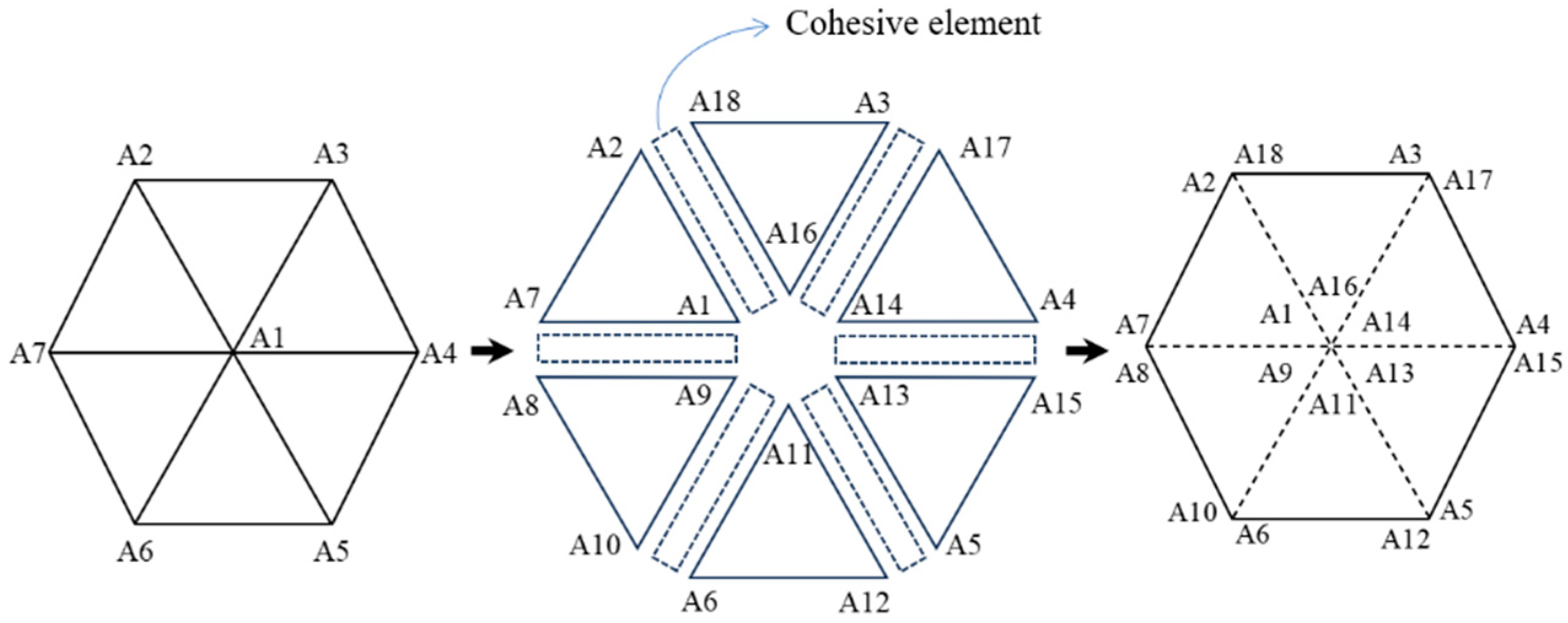

2.3. Methods of Generating Cohesive Elements

2.4. Model Parameters

3. Model Verification

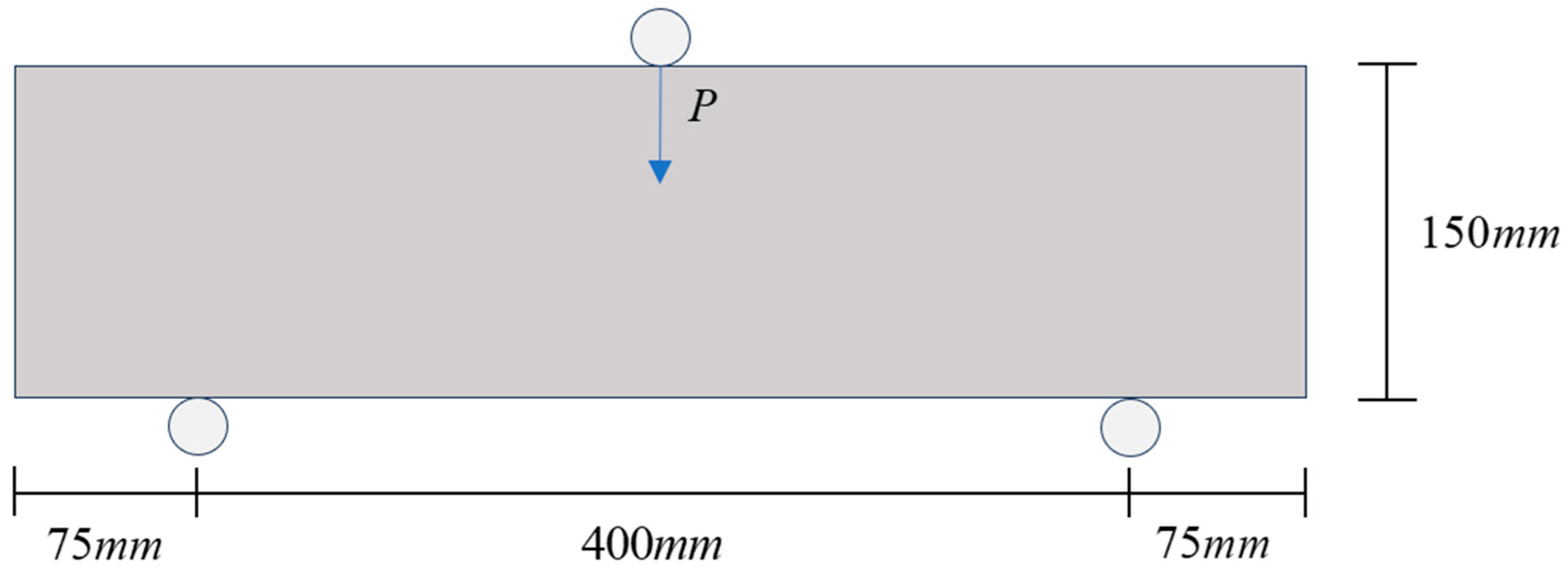

3.1. Experimental Data

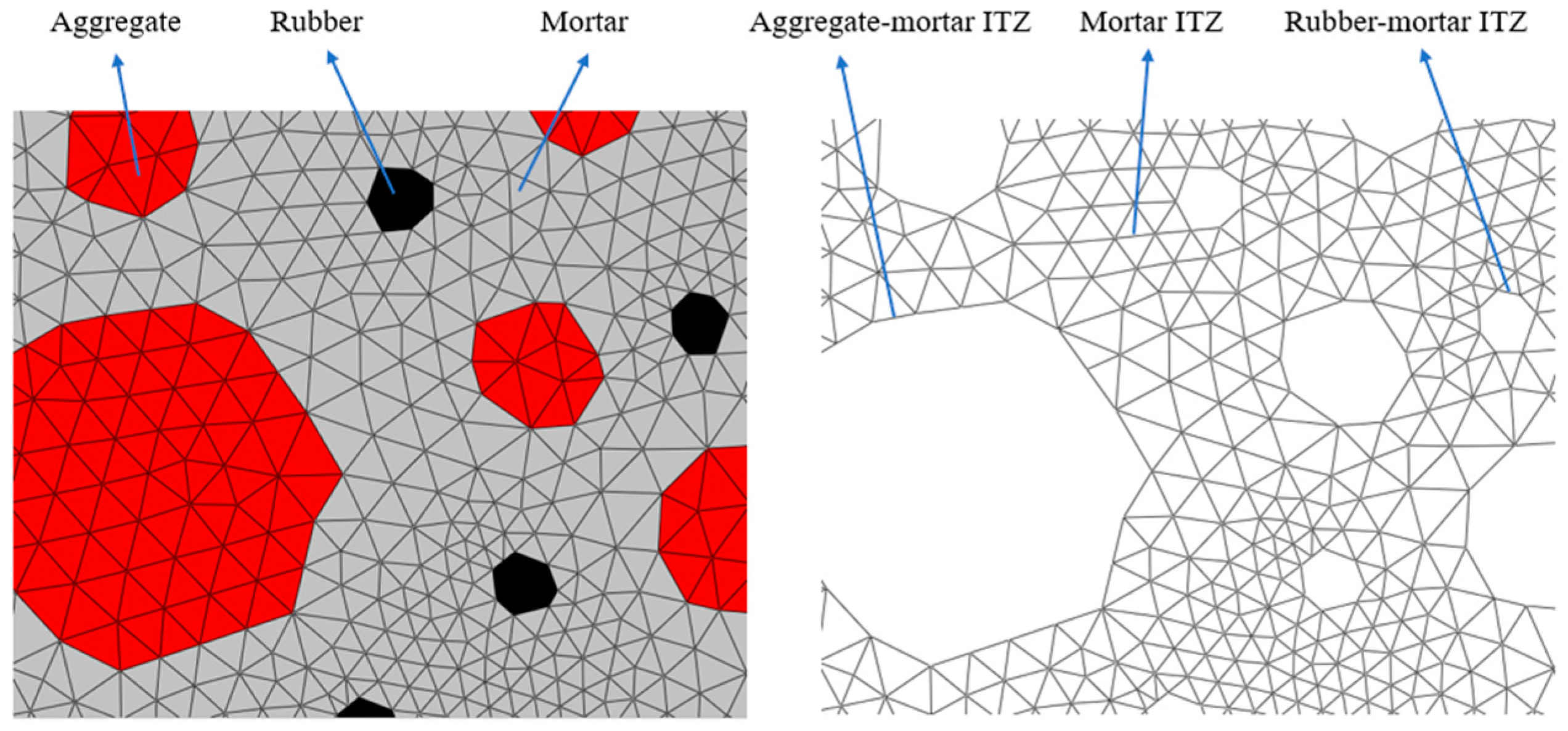

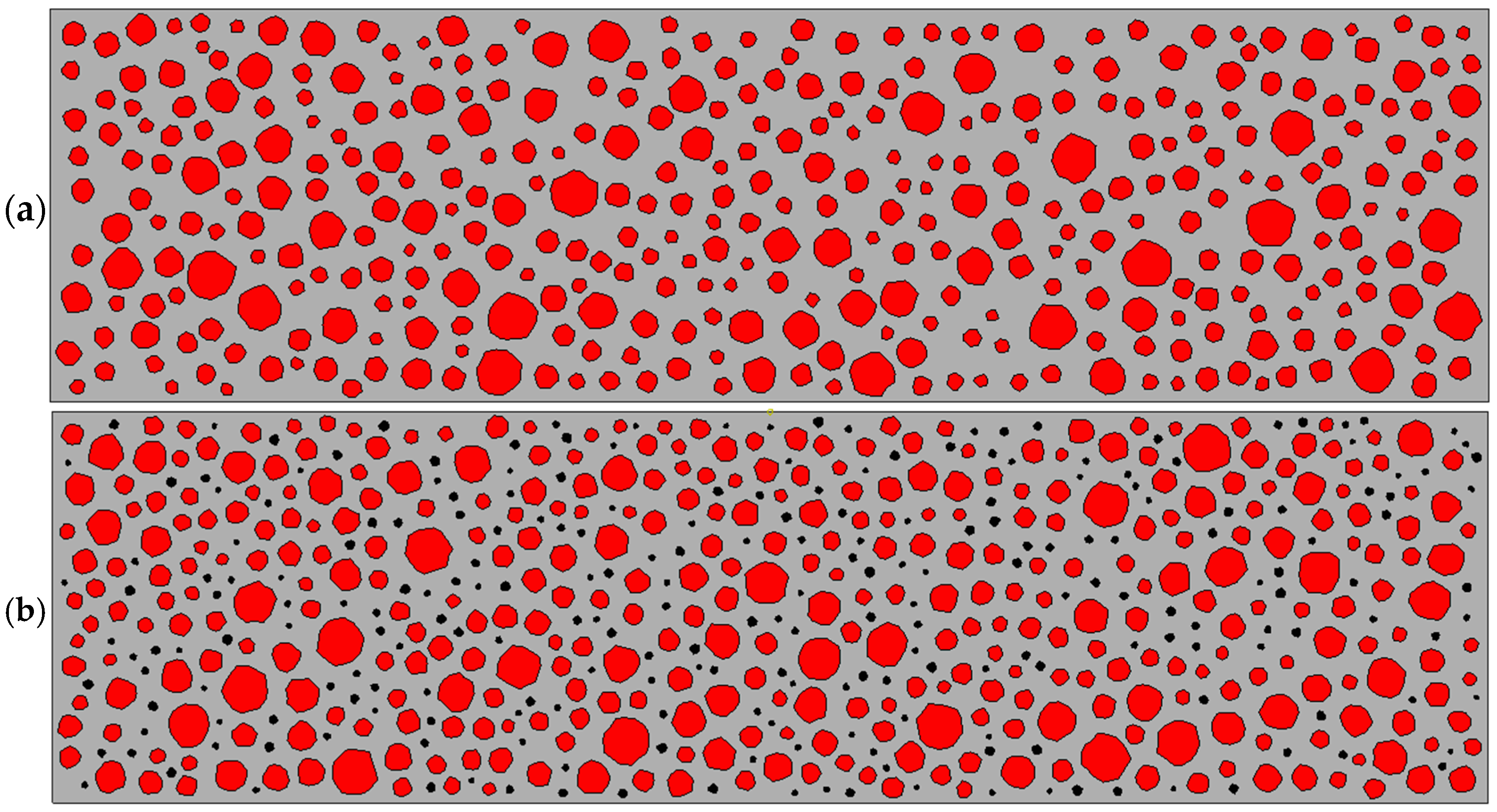

3.2. Mesoscale Modeling of Rubber Concrete

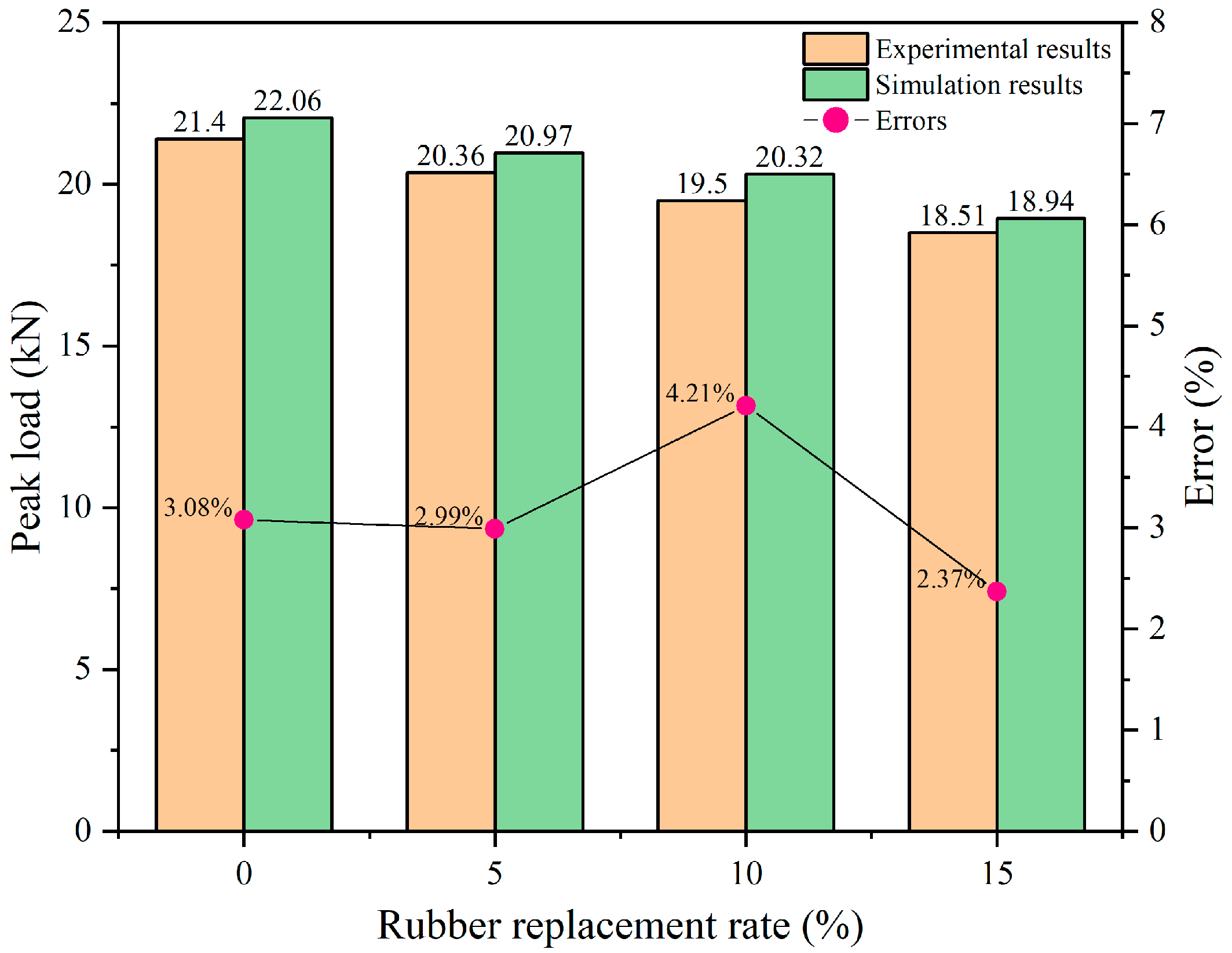

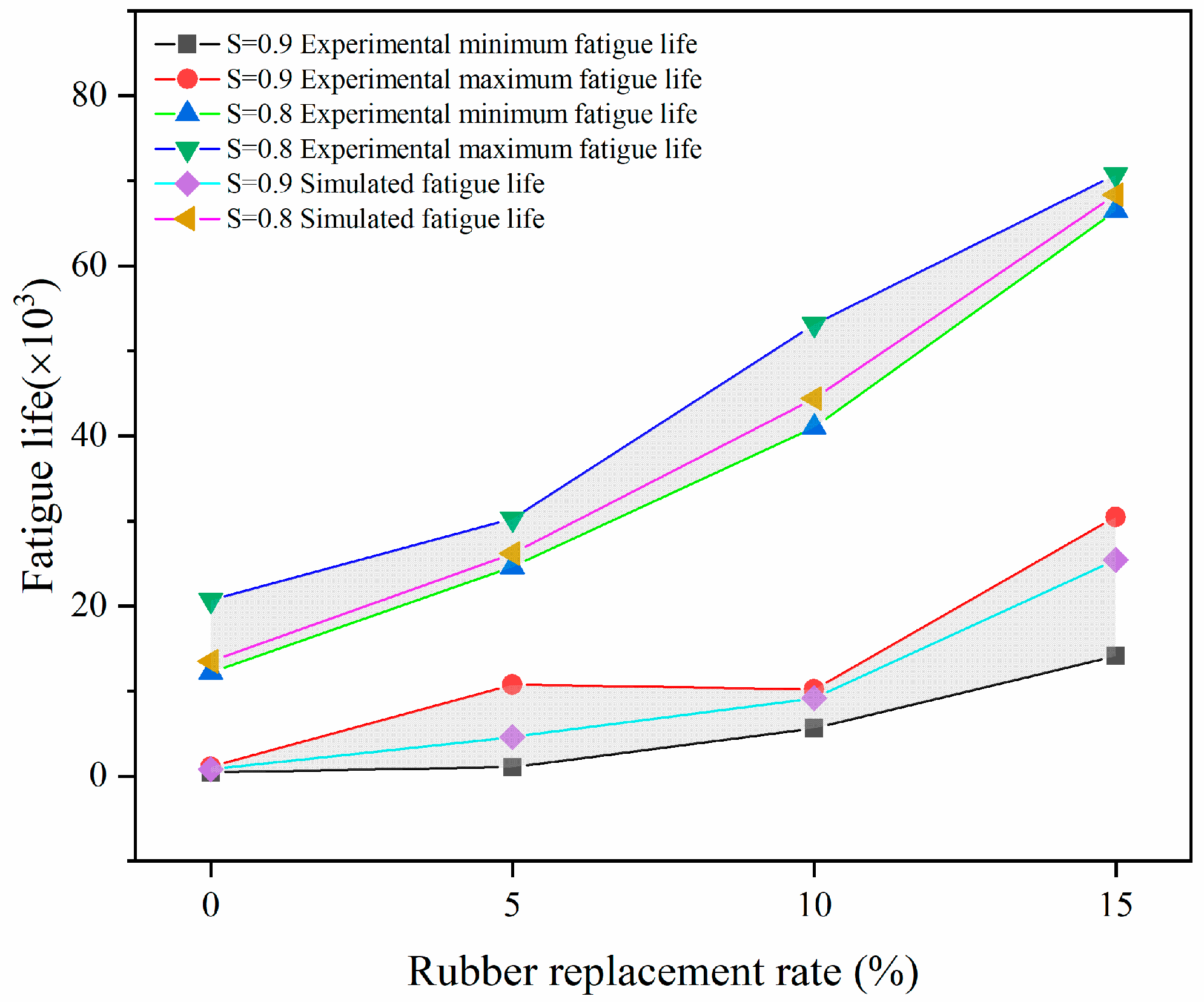

3.3. Comparative Results

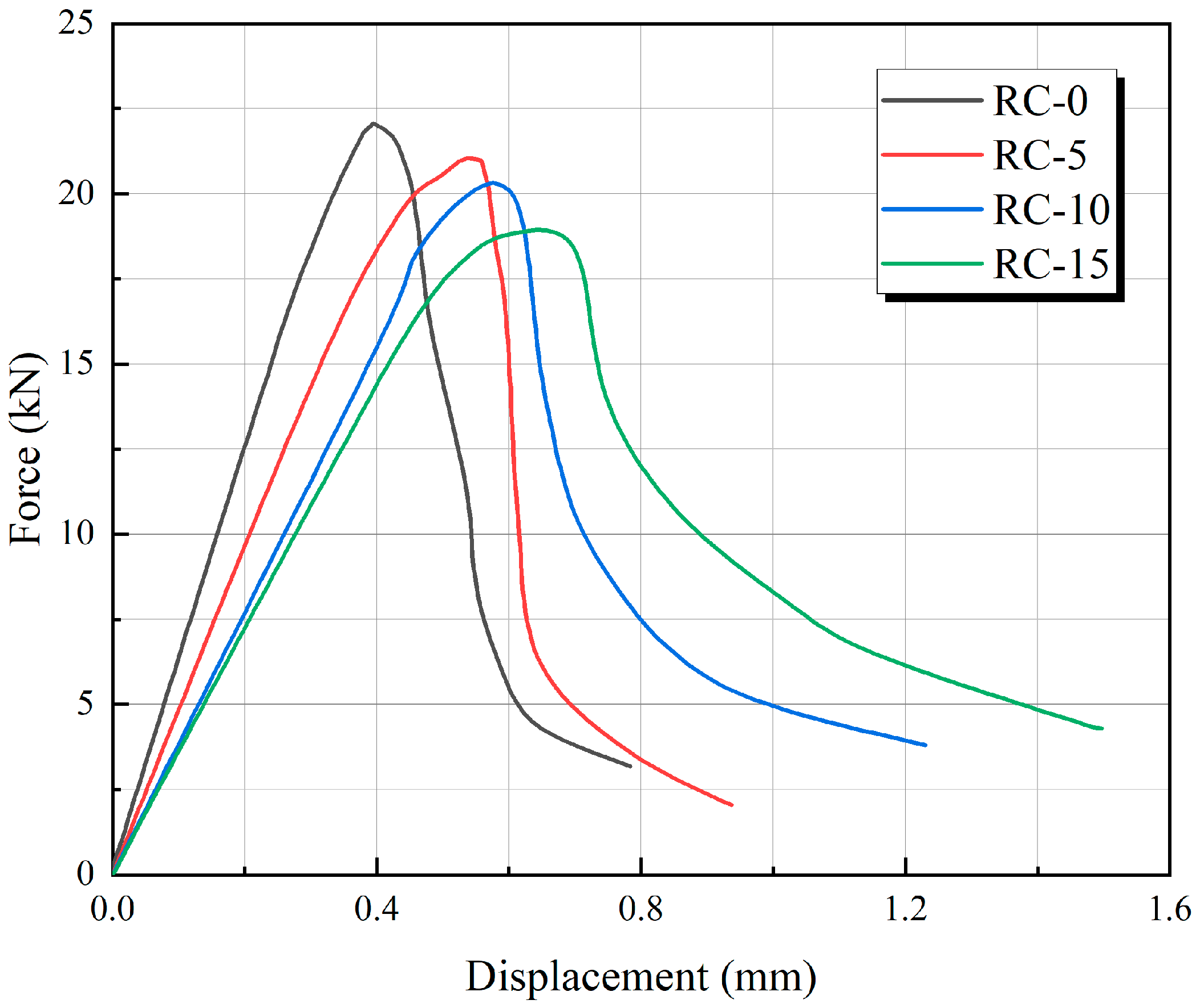

3.3.1. Three-Point Bending Static Load Simulation

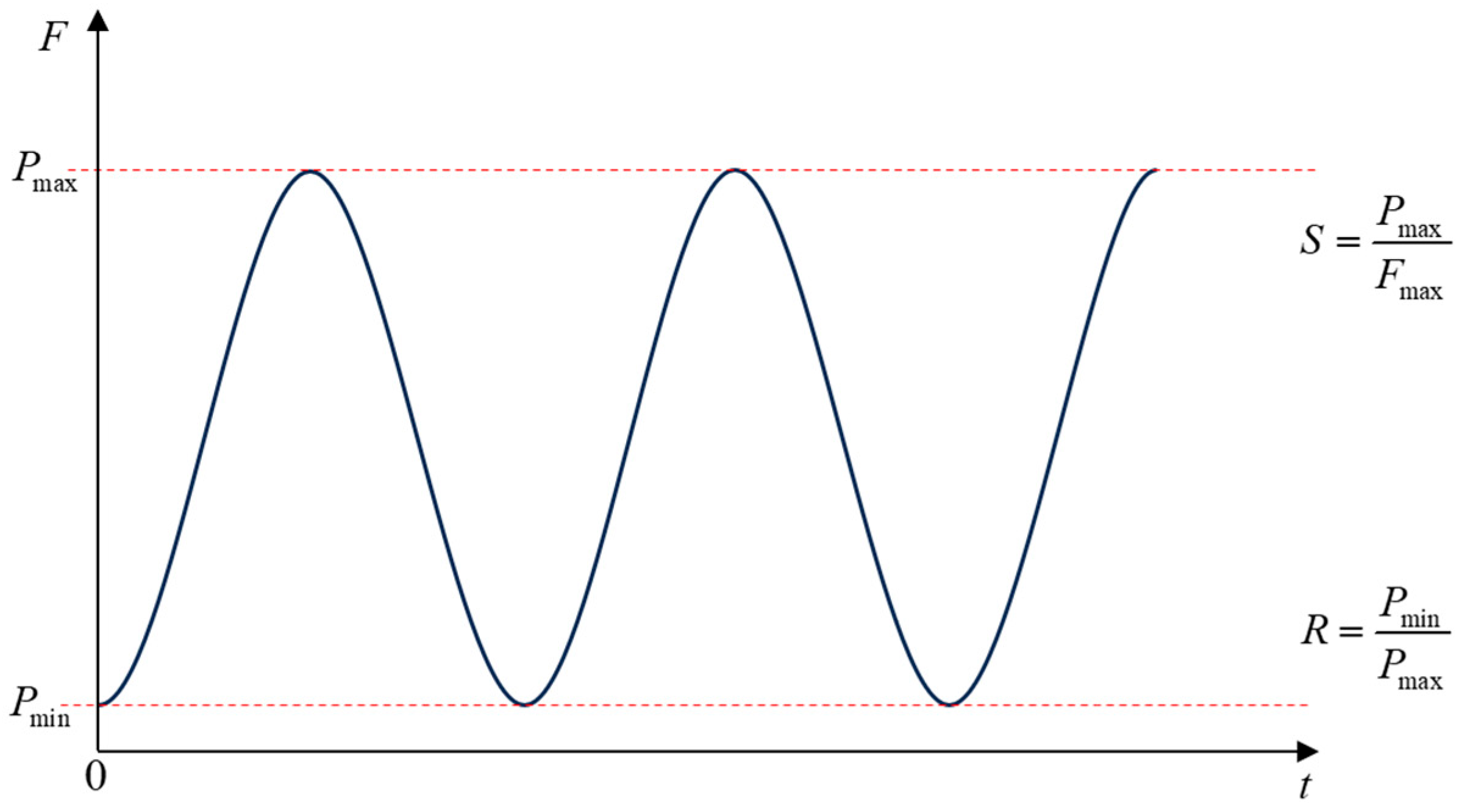

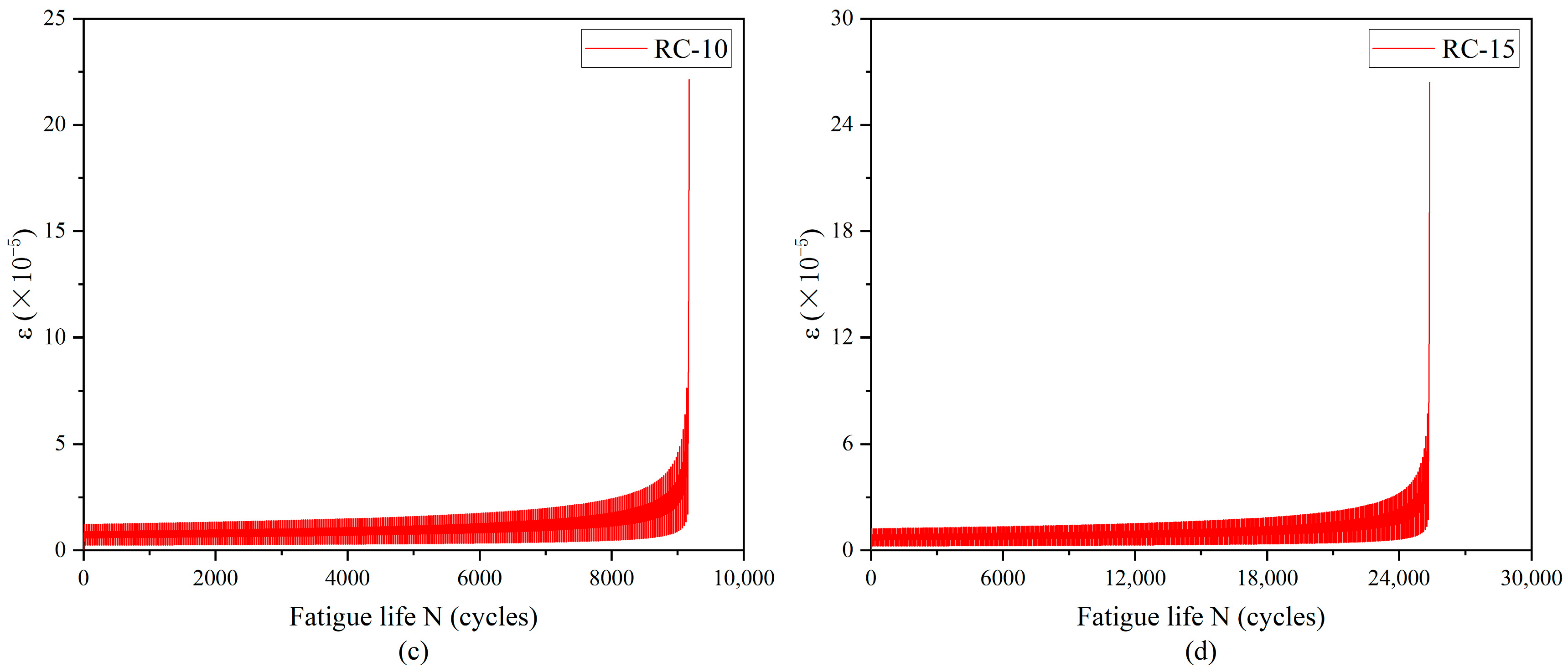

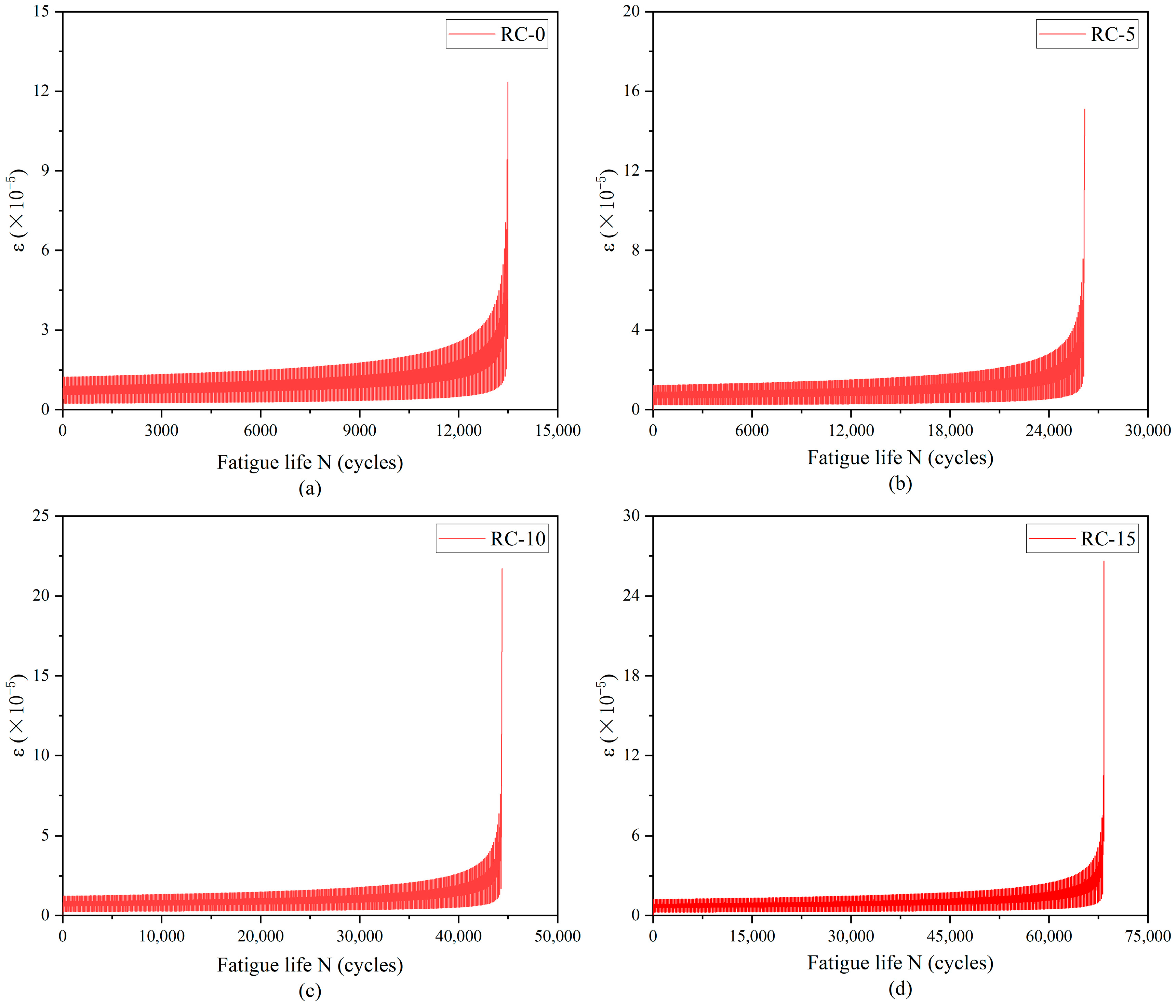

3.3.2. Three-Point Bending Fatigue Loading

4. Results

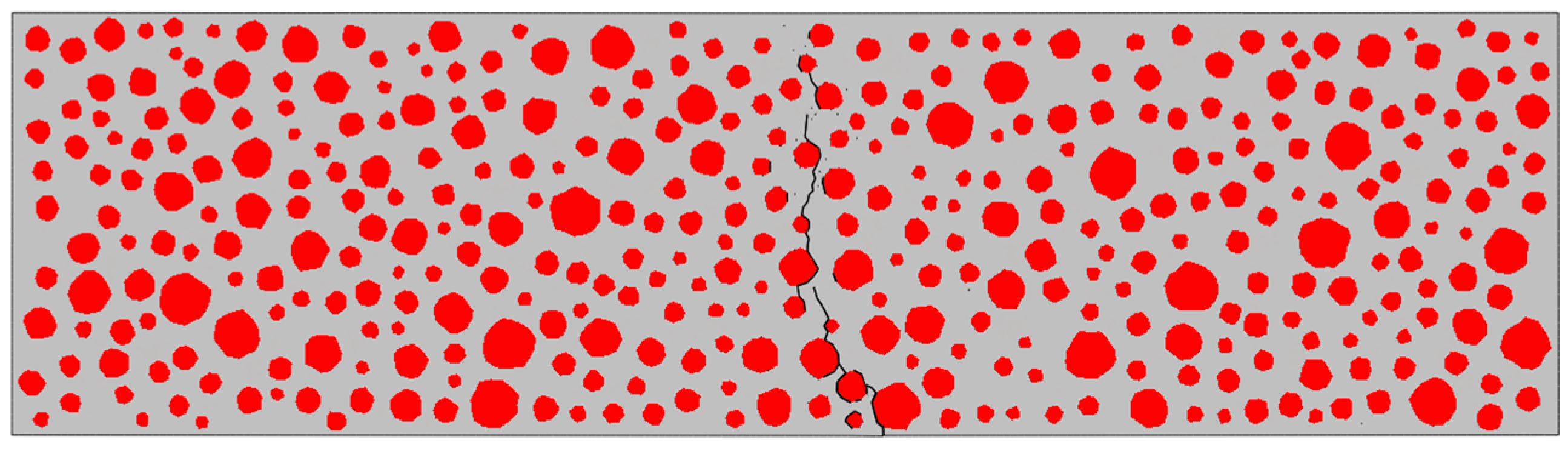

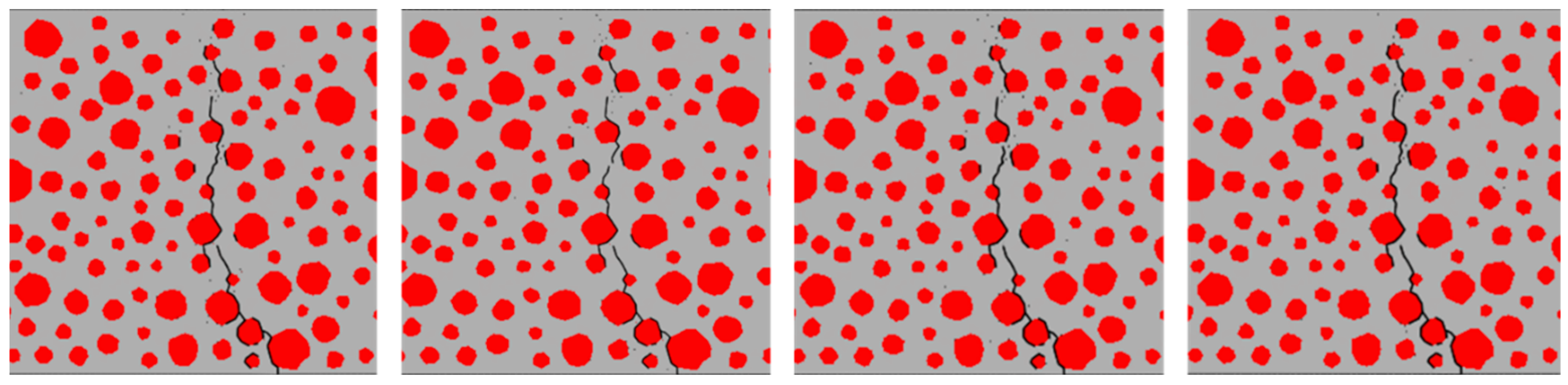

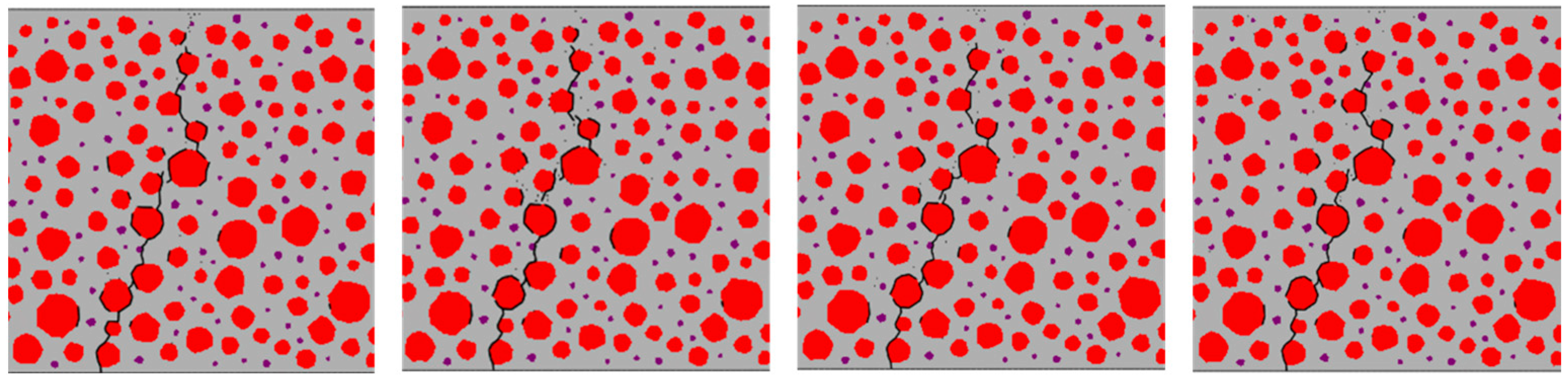

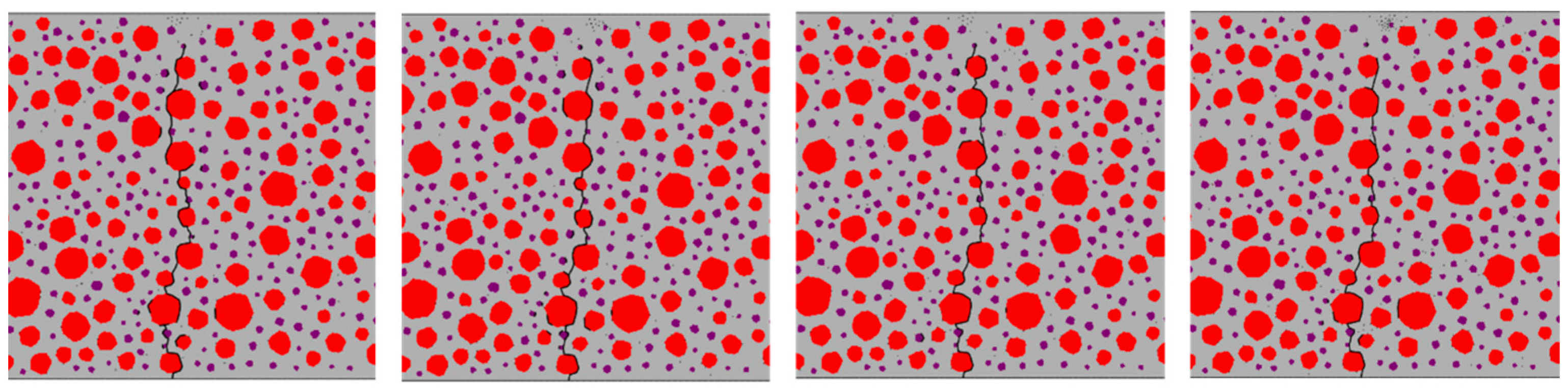

4.1. Damage Forms of Rubber Concrete under Fatigue Loading

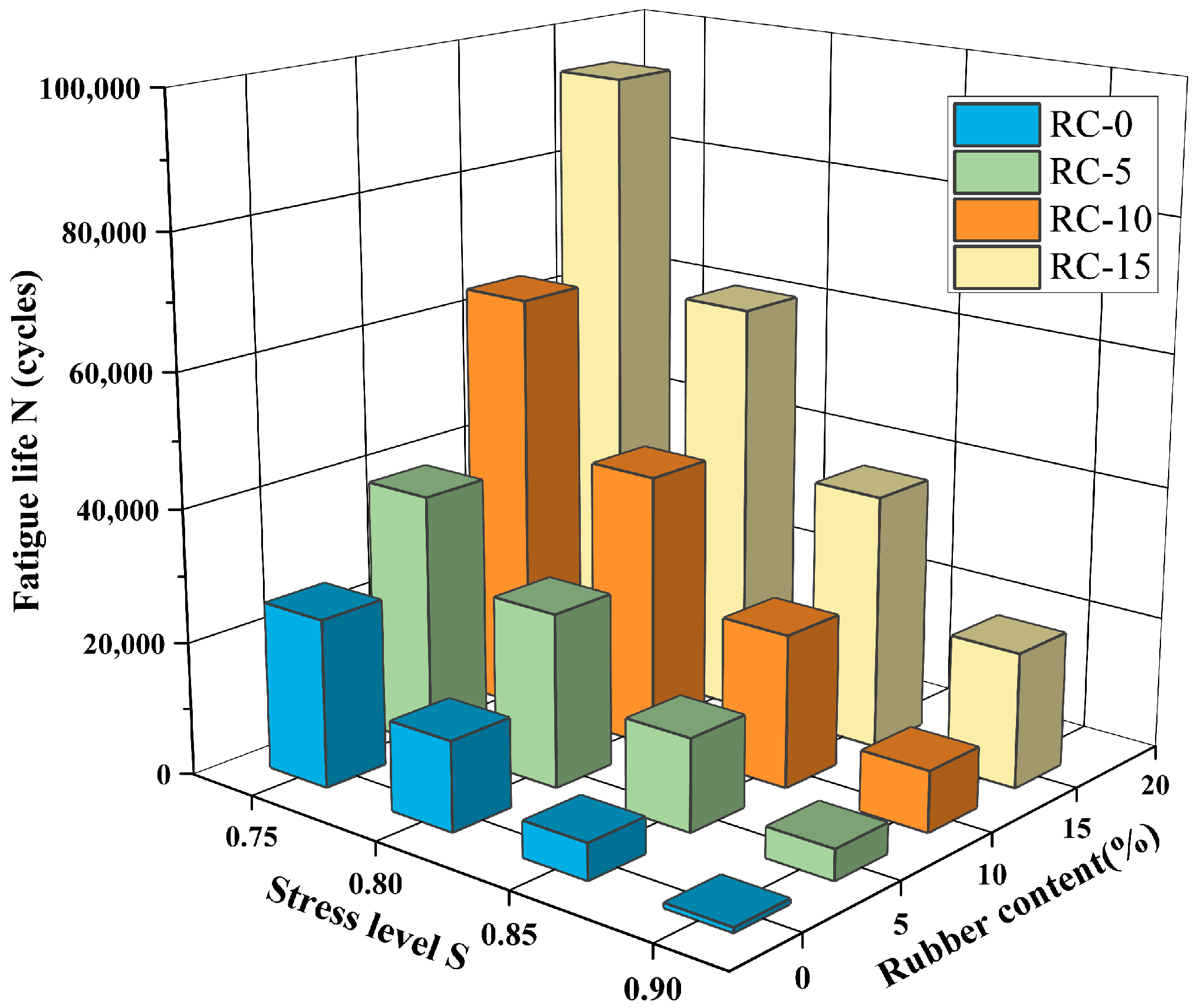

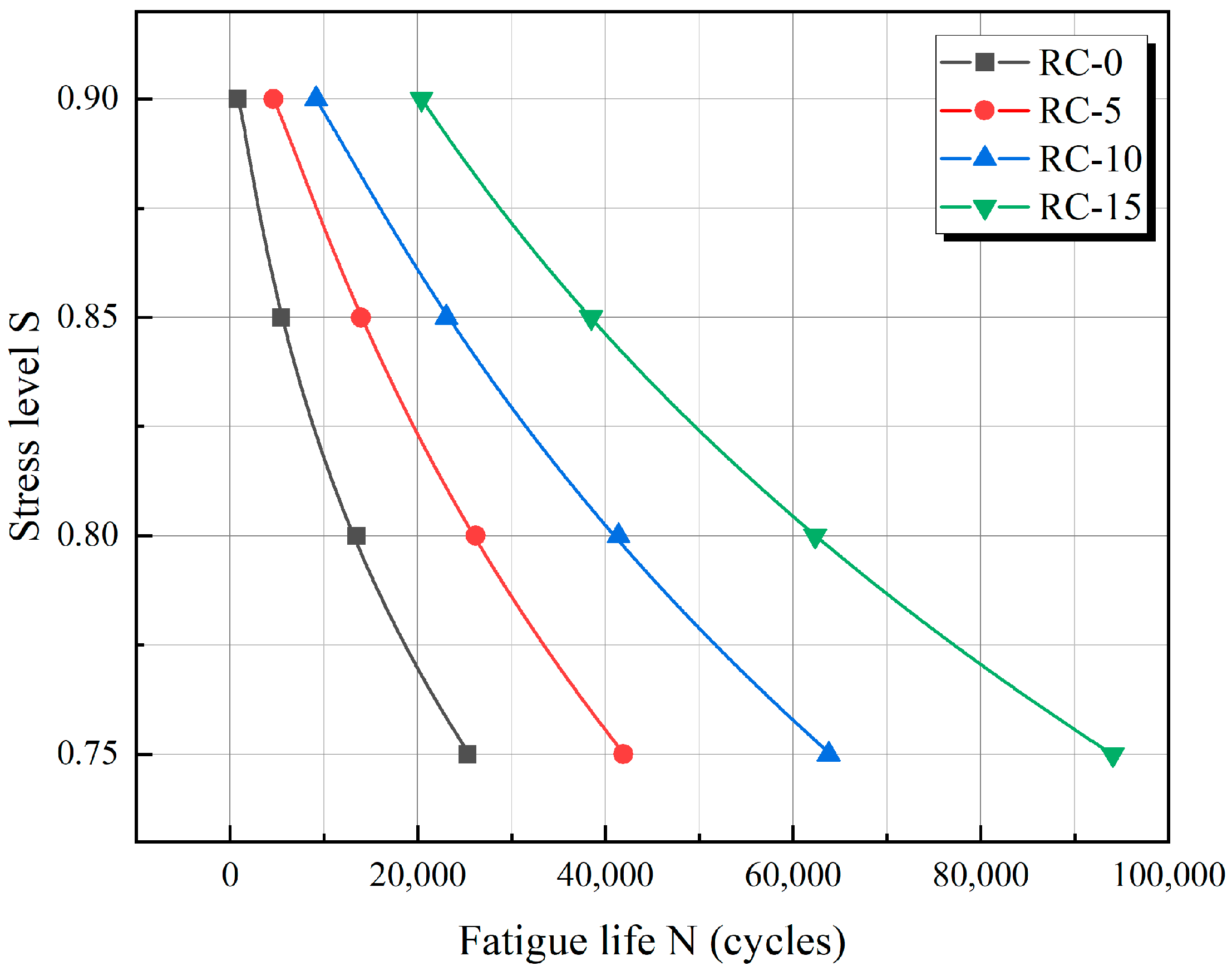

4.2. Fatigue Life of RC

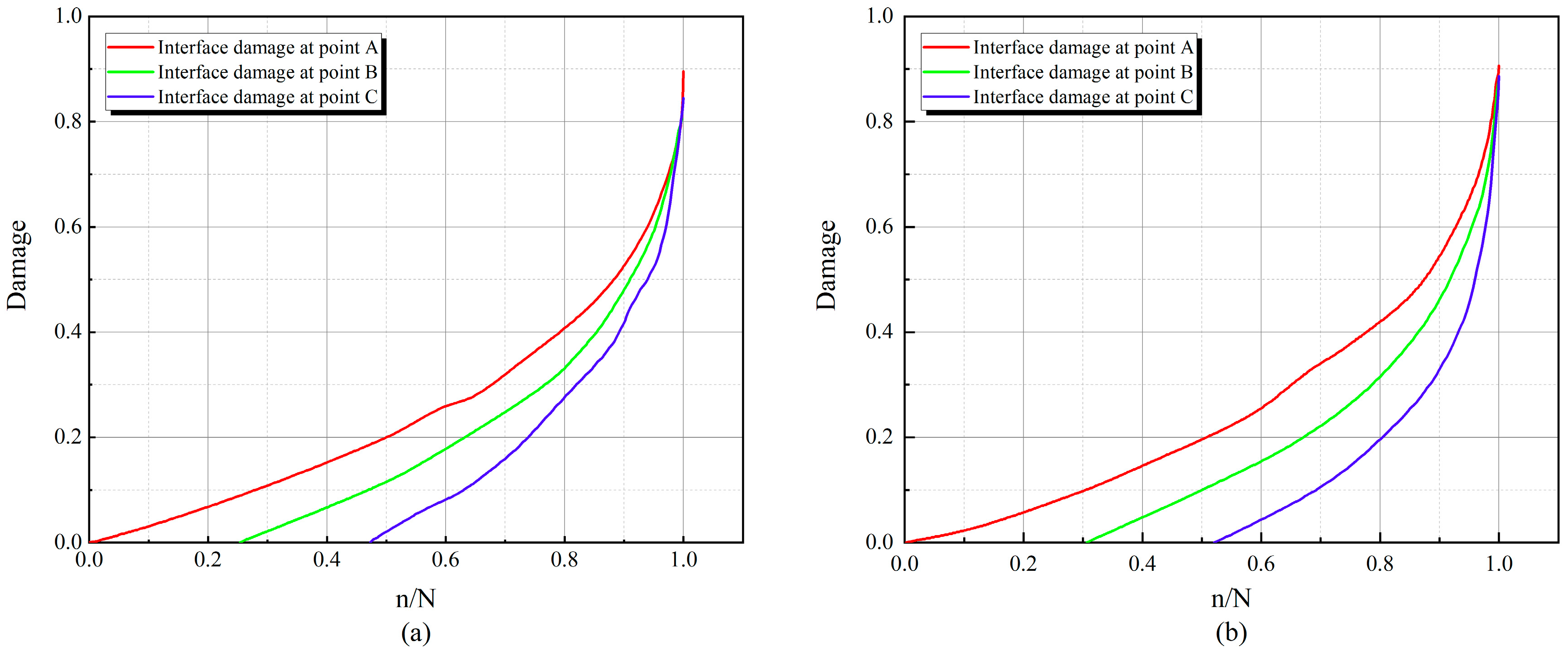

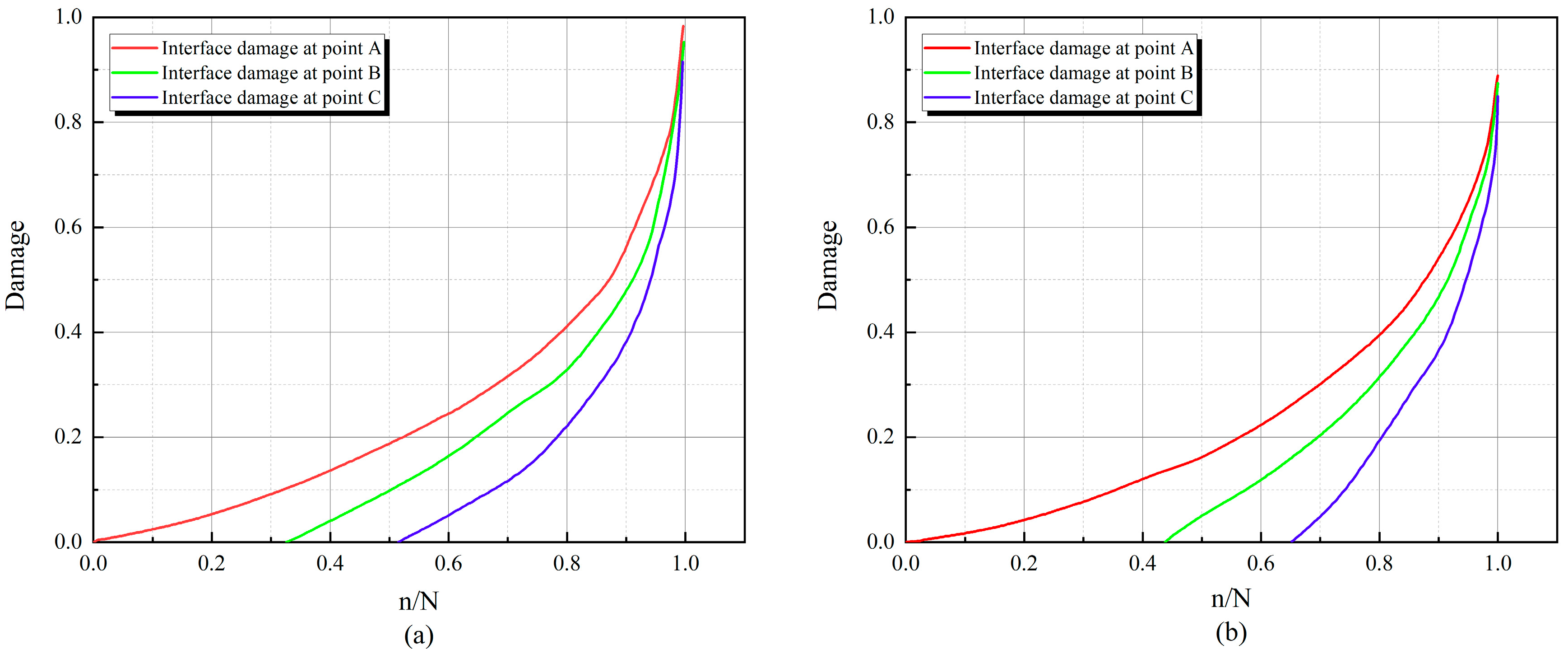

4.3. Interfacial Damage Evolution Laws

5. Discussion

5.1. Analysis of Fatigue Damage Causes of RC

5.2. Fatigue Life Analysis of Rubber Concrete

5.3. Interface Damage Evolution Analysis

5.4. Potential Applications and Perspectives

6. Conclusions

- (1)

- Under fatigue loading, the fatigue crack extension of RC with a 0% rubber substitution rate is simple and extends along the aggregate boundary. The fatigue crack extension of RC with a 5% rubber substitution rate mainly extends along the boundary of aggregate and rubber. The crack branching of RC with a 10% rubber substitution rate in the mortar is reduced. In comparison, the crack of RC with a 15% rubber substitution rate forms a single main crack along the boundary of aggregate and the boundary of rubber. The primary reason for these phenomena is that the incorporation of rubber inhibits the expansion of microcracks.

- (2)

- As the rubber substitution rate increases, the fatigue life of RC exhibits an upward trend at the same stress level. This improvement is attributed to the favorable deformation properties of the rubber particles, which dissipate energy from external loading, allowing the RC to withstand more fatigue loads. Additionally, based on the fatigue life of RC obtained from the simulations, a fatigue equation that is more suitable for medium and high stress levels is proposed.

- (3)

- At the same rubber replacement rate, the damage accumulation rate of the RC interface at high stress levels is faster. At the same stress level, the time of interface damage of RC with a 10% rubber replacement rate lags behind that of RC with a 0% rubber replacement rate. This phenomenon occurs because a higher stress level causes the tensile and compressive state of the interface to change faster. Rubber particles delay the fatigue damage accumulation rate of the interface element at the bottom of the beam, resulting in a lag in transforming the tensile and compressive state of the upper interface element in the beam span.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chittella, H.; Yoon, L.W.; Ramarad, S.; Lai, Z.-W. Rubber Waste Management: A Review on Methods, Mechanism, and Prospects. Polym. Degrad. Stab. 2021, 194, 109761. [Google Scholar] [CrossRef]

- Karimi, H.R.; Aliha, M.R.M.; Khedri, E.; Mousavi, A.; Salehi, S.M.; Haghighatpour, P.J.; Ebneabbasi, P. Strength and Cracking Resistance of Concrete Containing Different Percentages and Sizes of Recycled Tire Rubber Granules. J. Build. Eng. 2023, 67, 106033. [Google Scholar] [CrossRef]

- Huang, Z.; Deng, W.; Du, S.; Gu, Z.; Long, W.; Ye, J. Effect of Rubber Particles and Fibers on the Dynamic Compressive Behavior of Novel Ultra-Lightweight Cement Composites: Numerical Simulations and Metamodeling. Compos. Struct. 2021, 258, 113210. [Google Scholar] [CrossRef]

- Xu, J.; Yao, Z.; Yang, G.; Han, Q. Research on Crumb Rubber Concrete: From a Multi-Scale Review. Constr. Build. Mater. 2020, 232, 117282. [Google Scholar] [CrossRef]

- Gerges, N.N.; Issa, C.A.; Fawaz, S.A. Rubber Concrete: Mechanical and Dynamical Properties. Case Stud. Constr. Mater. 2018, 9, e00184. [Google Scholar] [CrossRef]

- Liu, M.; Lu, J.; Jiang, W.; Ming, P. Study on Fatigue Damage and Fatigue Crack Propagation of Rubber Concrete. J. Build. Eng. 2023, 65, 105718. [Google Scholar] [CrossRef]

- Thilakarathna, P.S.M.; Kristombu Baduge, K.S.; Mendis, P.; Vimonsatit, V.; Lee, H. Mesoscale Modelling of Concrete—A Review of Geometry Generation, Placing Algorithms, Constitutive Relations and Applications. Eng. Fract. Mech. 2020, 231, 106974. [Google Scholar] [CrossRef]

- Lazar, D.; Jiyad, P.; Nagarajan, P. Mesoscopic Model Generation for Different Grades of Concrete. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Fang, J.; Yuan, Z.; Liang, J.; Li, S.; Qin, Y. Research on Compressive Damage Mechanism of Concrete Based on Material Heterogeneity. J. Build. Eng. 2023, 79, 107740. [Google Scholar] [CrossRef]

- Jin, L.; Hao, H.; Zhang, R.; Du, X. Determination of the Effect of Elevated Temperatures on Dynamic Compressive Properties of Heterogeneous Concrete: A Meso-Scale Numerical Study. Constr. Build. Mater. 2018, 188, 685–694. [Google Scholar] [CrossRef]

- Nitka, M.; Tejchman, J. A Three-Dimensional Meso-Scale Approach to Concrete Fracture Based on Combined DEM with X-Ray μCT Images. Cem. Concr. Res. 2018, 107, 11–29. [Google Scholar] [CrossRef]

- Ouyang, H.; Chen, X. 3D Meso-Scale Modeling of Concrete with a Local Background Grid Method. Constr. Build. Mater. 2020, 257, 119382. [Google Scholar] [CrossRef]

- Salsavilca, J.; Tarque, N.; Yacila, J.; Camata, G. Numerical Analysis of Bonding between Masonry and Steel Reinforced Grout Using a Plastic–Damage Model for Lime–Based Mortar. Constr. Build. Mater. 2020, 262, 120373. [Google Scholar] [CrossRef]

- Rong, Y.; Ren, H.; Xu, X. An Improved Damage-Plasticity Material Model for Concrete Subjected to Dynamic Loading. Case Stud. Constr. Mater. 2023, 19, e02568. [Google Scholar] [CrossRef]

- Fang, X.; Pan, Z.; Chen, A. Phase Field Modeling of Concrete Cracking for Non-Uniform Corrosion of Rebar. Theor. Appl. Fract. Mech. 2022, 121, 103517. [Google Scholar] [CrossRef]

- Zhang, P.; Hu, X.; Yang, S.; Yao, W. Modelling Progressive Failure in Multi-Phase Materials Using a Phase Field Method. Eng. Fract. Mech. 2019, 209, 105–124. [Google Scholar] [CrossRef]

- Schröder, J.; Pise, M.; Brands, D.; Gebuhr, G.; Anders, S. Phase-Field Modeling of Fracture in High Performance Concrete during Low-Cycle Fatigue: Numerical Calibration and Experimental Validation. Comput. Methods Appl. Mech. Eng. 2022, 398, 115181. [Google Scholar] [CrossRef]

- Wu, L.; Huang, D.; Wang, H.; Ma, Q.; Cai, X.; Guo, J. A Comparison Study on Numerical Analysis for Concrete Dynamic Failure Using Intermediately Homogenized Peridynamic Model and Meso-Scale Peridynamic Model. Int. J. Impact Eng. 2023, 179, 104657. [Google Scholar] [CrossRef]

- Shi, C.; Shi, Q.; Tong, Q.; Li, S. Peridynamics Modeling and Simulation of Meso-Scale Fracture in Recycled Coarse Aggregate (RCA) Concretes. Theor. Appl. Fract. Mech. 2021, 114, 102949. [Google Scholar] [CrossRef]

- Guo, Q.; Wang, S.; Zhang, R. Intrinsic Damage Characteristics for Recycled Crumb Rubber Concrete Subjected to Uniaxial Pressure Employing Cohesive Zone Model. Constr. Build. Mater. 2022, 317, 125773. [Google Scholar] [CrossRef]

- Malachanne, E.; Jebli, M.; Jamin, F.; Garcia-Diaz, E.; El Youssoufi, M.-S. A Cohesive Zone Model for the Characterization of Adhesion between Cement Paste and Aggregates. Constr. Build. Mater. 2018, 193, 64–71. [Google Scholar] [CrossRef]

- Mier, J. Mode II Fracture Localization in Concrete Loaded in Compression. J. Eng. Mech.-ASCE. 2009, 135, 1–8. [Google Scholar] [CrossRef]

- Camanho, P. Mixed-Mode Decohesion Finite Elements for the Simulation of Delamination in Composite Materials; NASA/TP-2007-214869; NASA: Washington, DC, USA, 2002; pp. 1–37. [Google Scholar]

- Karnati, S.R.; Shivakumar, K. Limited Input Benzeggagh and Kenane Delamination Failure Criterion for Mixed-Mode Loaded Fiber Reinforced Composite Laminates. Int. J. Fract. 2020, 222, 221–230. [Google Scholar] [CrossRef]

- Roe, K.L.; Siegmund, T. An Irreversible Cohesive Zone Model for Interface Fatigue Crack Growth Simulation. Eng. Fract. Mech. 2003, 70, 209–232. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, Y.; Zhuo, J.; Zhang, P.; Hu, S. Mesoscale Synergistic Effect Mechanism of Aggregate Grading and Specimen Size on Compressive Strength of Concrete with Large Aggregate Size. Constr. Build. Mater. 2023, 367, 130346. [Google Scholar] [CrossRef]

- Ma, H.; Xu, W.; Li, Y. Random Aggregate Model for Mesoscopic Structures and Mechanical Analysis of Fully-Graded Concrete. Comput. Struct. 2016, 177, 103–113. [Google Scholar] [CrossRef]

- Zhong, G.Q.; Guo, Y.C.; Li, L.J.; Liu, F. Analysis of Mechanical Performance of Crumb Rubber Concrete by Different Aggregate Shape under Uniaxial Compression on Mesoscopic. Key Eng. Mater. 2011, 462–463, 219–222. [Google Scholar] [CrossRef]

- Wang, X.; Yang, Z.; Jivkov, A.P. Monte Carlo Simulations of Mesoscale Fracture of Concrete with Random Aggregates and Pores: A Size Effect Study. Constr. Build. Mater. 2015, 80, 262–272. [Google Scholar] [CrossRef]

- Ma, H.; Song, L.; Xu, W. A Novel Numerical Scheme for Random Parameterized Convex Aggregate Models with a High-Volume Fraction of Aggregates in Concrete-like Granular Materials. Comput. Struct. 2018, 209, 57–64. [Google Scholar] [CrossRef]

- Wang, B.; Wang, H.; Zhang, Z.; Zhou, M. Mesoscopic modeling method of concrete aggregates with arbitrary shapes based on mesh generation. Chin. J. Comput. Mech. 2017, 34, 591–596. [Google Scholar]

- Sasano, H.; Maruyama, I. Mechanism of Drying-Induced Change in the Physical Properties of Concrete: A Mesoscale Simulation Study. Cem. Concr. Res. 2021, 143, 106401. [Google Scholar] [CrossRef]

- Xiong, X.; Xiao, Q. A unified meso-scale simulation method for concrete under both tension and compression based on Cohesive Zone Model. J. Hydraul. Eng. 2019, 50, 448–462. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.; Jivkov, A.P.; Zhang, J. 3D Mesoscale Modeling and Fracture Property Study of Rubberized Self-Compacting Concrete Based on Uniaxial Tension Test. Theor. Appl. Fract. Mech. 2019, 104, 102363. [Google Scholar] [CrossRef]

- Liu, F.; Zheng, W.; Li, L.; Feng, W.; Ning, G. Mechanical and Fatigue Performance of Rubber Concrete. Constr. Build. Mater. 2013, 47, 711–719. [Google Scholar] [CrossRef]

- Liu, F.; Meng, L.; Ning, G.-F.; Li, L.-J. Fatigue Performance of Rubber-Modified Recycled Aggregate Concrete (RRAC) for Pavement. Constr. Build. Mater. 2015, 95, 207–217. [Google Scholar] [CrossRef]

- Xiang, Y. A Visco-Elastic-Plastic Model for Fatigue Strain of Concrete at High Levels of Stress. Mag. Concr. Res. 2016, 68, 844–858. [Google Scholar] [CrossRef]

- Liang, L.; Liu, C.; Cui, Y.; Li, Y.; Chen, Z.; Wang, Z.; Yao, Z. Characterizing Fatigue Damage Behaviors of Concrete Beam Specimens in Varying Amplitude Load. Case Stud. Constr. Mater. 2023, 19, e02305. [Google Scholar] [CrossRef]

- Mohammadi, Y.; Kaushik, S.K. Flexural Fatigue-Life Distributions of Plain and Fibrous Concrete at Various Stress Levels. J. Mater. Civ. Eng. 2005, 17, 650–658. [Google Scholar] [CrossRef]

- Bjørheim, F.; Siriwardane, S.C.; Pavlou, D. A Review of Fatigue Damage Detection and Measurement Techniques. Int. J. Fatigue 2022, 154, 106556. [Google Scholar] [CrossRef]

- Sun, X. Research on Numerical Simulation of Fatigue Crack Propagation in Concrete under Cyclic Loading. Master’s Thesis, Southeast University, Nanjing, China, 2017. [Google Scholar]

- Walid, M.; Abdelrahman, A.; Kohail, M.; Moustafa, A. Stress–Strain Behavior of Rubberized Concrete under Compressive and Flexural Stresses. J. Build. Eng. 2022, 59, 105026. [Google Scholar] [CrossRef]

| Rubber Content (%) | 5–10 mm (mm2) | 5–10 mm (mm2) | 5–10 mm (mm2) | Rubber (mm2) |

|---|---|---|---|---|

| 0 | 10,754 | 7587 | 4464 | 0 |

| 5 | 10,754 | 7587 | 4464 | 1335 |

| 10 | 10,754 | 7587 | 4464 | 2669 |

| 15 | 10,754 | 7587 | 4464 | 4004 |

| Parameter | Aggregate | Mortar | Rubber |

|---|---|---|---|

| Modulus of elasticity (GPa) | 72 | 36 | 7 |

| Poisson’s ratio | 0.16 | 0.2 | 0.495 |

| Parameter | Mortar ITZ | Aggregate–Mortar ITZ | Rubber–Mortar ITZ |

|---|---|---|---|

| Normal strength (MPa) | 4 | 2.6 | 1.82 |

| Shear strength (MPa) | 30 | 10 | 7 |

| Normal fracture energy (N/mm) | 0.1 | 0.025 | 0.0175 |

| Shear fracture energy (N/mm) | 2.5 | 0.625 | 0.438 |

| Type | Material (kg/m3) | |||||

|---|---|---|---|---|---|---|

| Water | Cement | Sand | Gravel | Rubber | Water Reducer | |

| RC-0 | 131.5 | 420 | 555 | 1296 | 0 | 5.0 |

| RC-5 | 131.5 | 420 | 527 | 1296 | 11.68 | 5.0 |

| RC-10 | 131.5 | 420 | 500 | 1296 | 22.95 | 5.0 |

| RC-15 | 131.5 | 420 | 472 | 1296 | 34.66 | 5.0 |

| 0% | 5% | 10% | 15% | ||

|---|---|---|---|---|---|

| S = 0.9 | Experimental Min/Max | 450/1090 | 1070/10,745 | 5653/10,176 | 14,134/30,465 |

| Simulation | 783 | 4607 | 9175 | 25,395 | |

| S = 0.8 | Experimental Min/Max | 12,215/20,686 | 24,587/30,250 | 40,997/53,110 | 66,498/70,716 |

| Simulation | 13,496 | 26,171 | 44,398 | 68,346 |

| RC-0 | RC-5 | RC-10 | RC-15 | |

|---|---|---|---|---|

| S = 0.9 | 783 | 4607 | 9175 | 20,395 |

| S = 0.85 | 5450 | 13,936 | 23,058 | 38,462 |

| S = 0.8 | 13,496 | 26,171 | 41,398 | 62,194 |

| S = 0.75 | 25,279 | 41,921 | 63,793 | 93,807 |

| Rubber Replacement Rate | Fitting Function | R2 |

|---|---|---|

| 0% | 0.995 | |

| 5% | 0.998 | |

| 10% | 0.993 | |

| 15% | 0.998 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Li, H.; Min, K.; Li, W.; Wu, K. Numerical Simulation of Rubber Concrete Considering Fatigue Damage Accumulation of Cohesive Zone Model. Materials 2024, 17, 5018. https://doi.org/10.3390/ma17205018

Liu C, Li H, Min K, Li W, Wu K. Numerical Simulation of Rubber Concrete Considering Fatigue Damage Accumulation of Cohesive Zone Model. Materials. 2024; 17(20):5018. https://doi.org/10.3390/ma17205018

Chicago/Turabian StyleLiu, Cai, Houmin Li, Kai Min, Wenchao Li, and Keyang Wu. 2024. "Numerical Simulation of Rubber Concrete Considering Fatigue Damage Accumulation of Cohesive Zone Model" Materials 17, no. 20: 5018. https://doi.org/10.3390/ma17205018

APA StyleLiu, C., Li, H., Min, K., Li, W., & Wu, K. (2024). Numerical Simulation of Rubber Concrete Considering Fatigue Damage Accumulation of Cohesive Zone Model. Materials, 17(20), 5018. https://doi.org/10.3390/ma17205018