NiCoCrFeY High Entropy Alloy Nanopowders and Their Soft Magnetic Properties

Abstract

1. Introduction

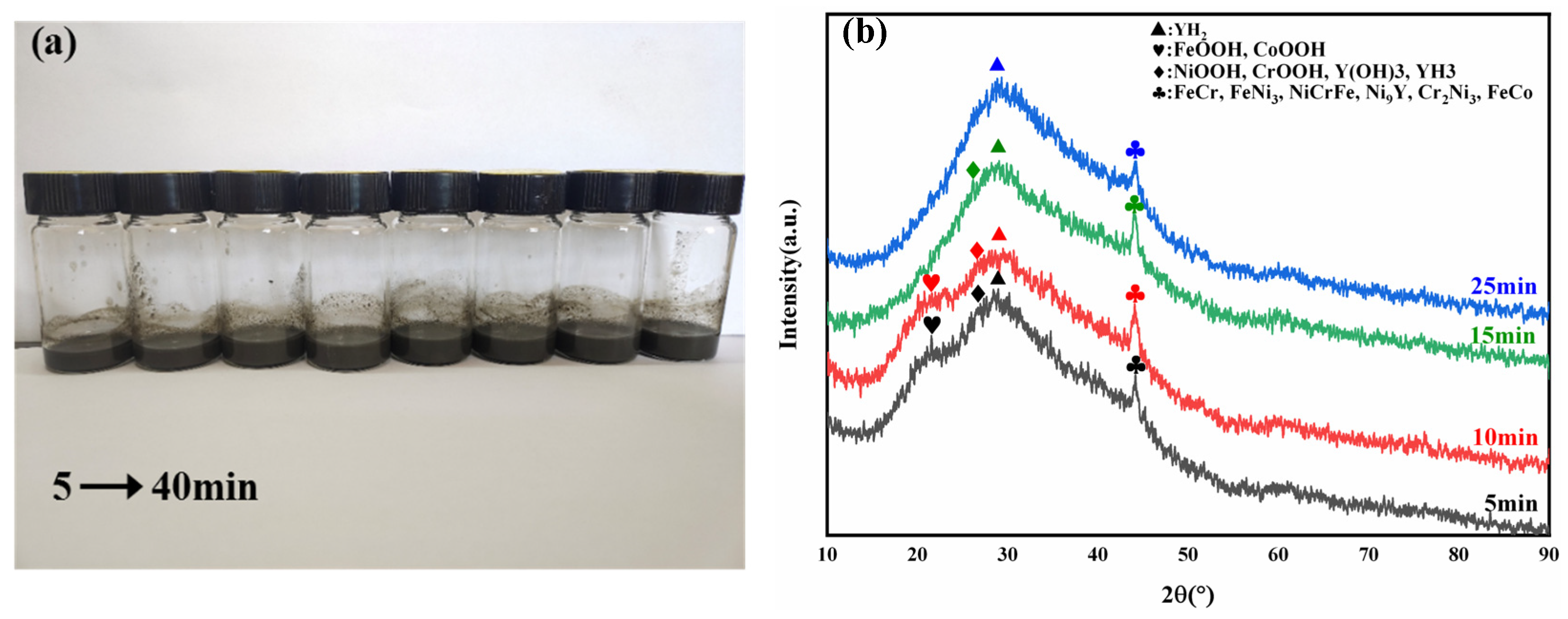

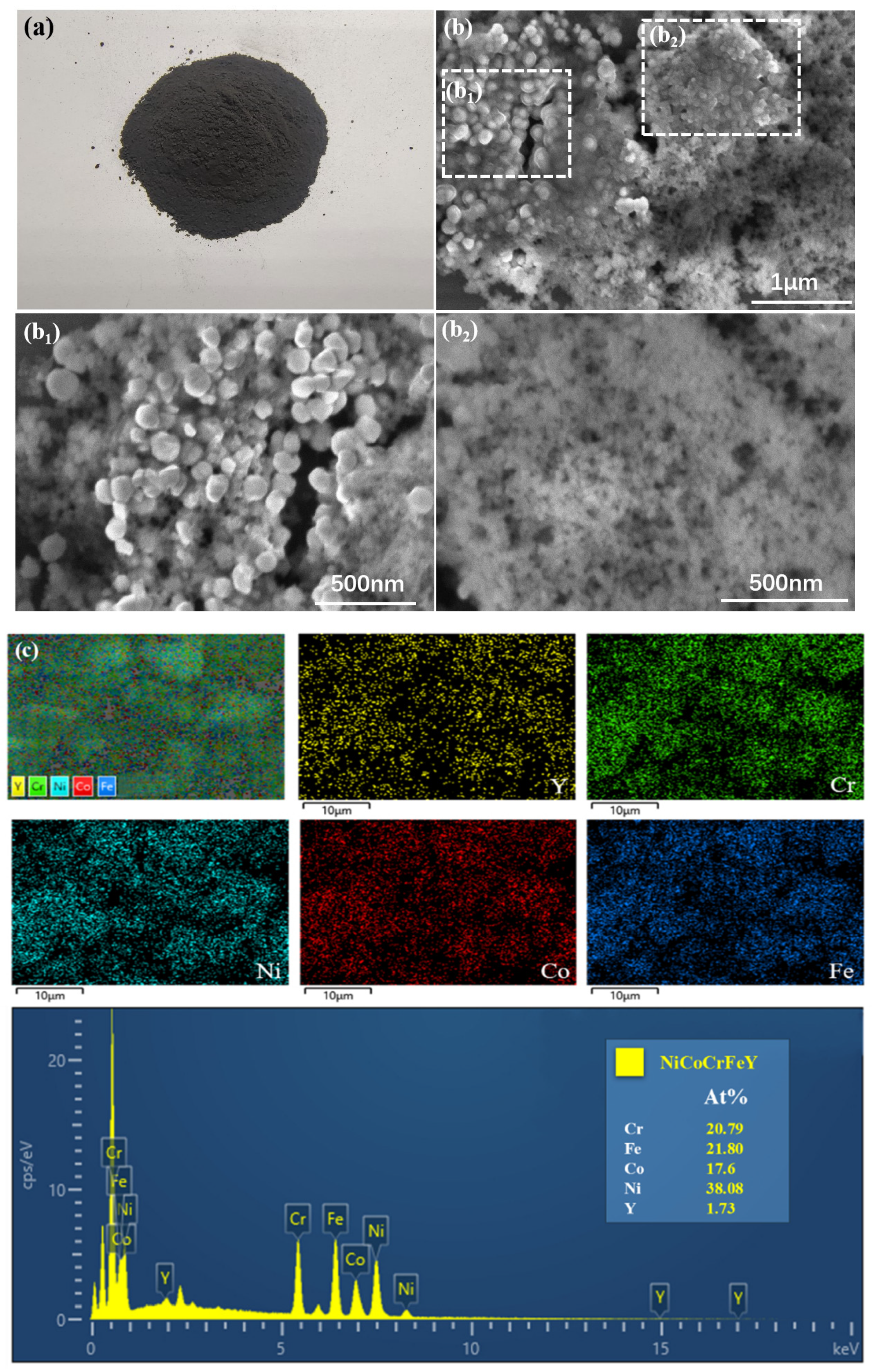

2. Experimental

2.1. Preparation and Characterization of High Entropy Alloy Nanopowders

2.2. Preparation of High Entropy Alloy Nanopowder Composites and Characterization of Soft Magnetic Properties

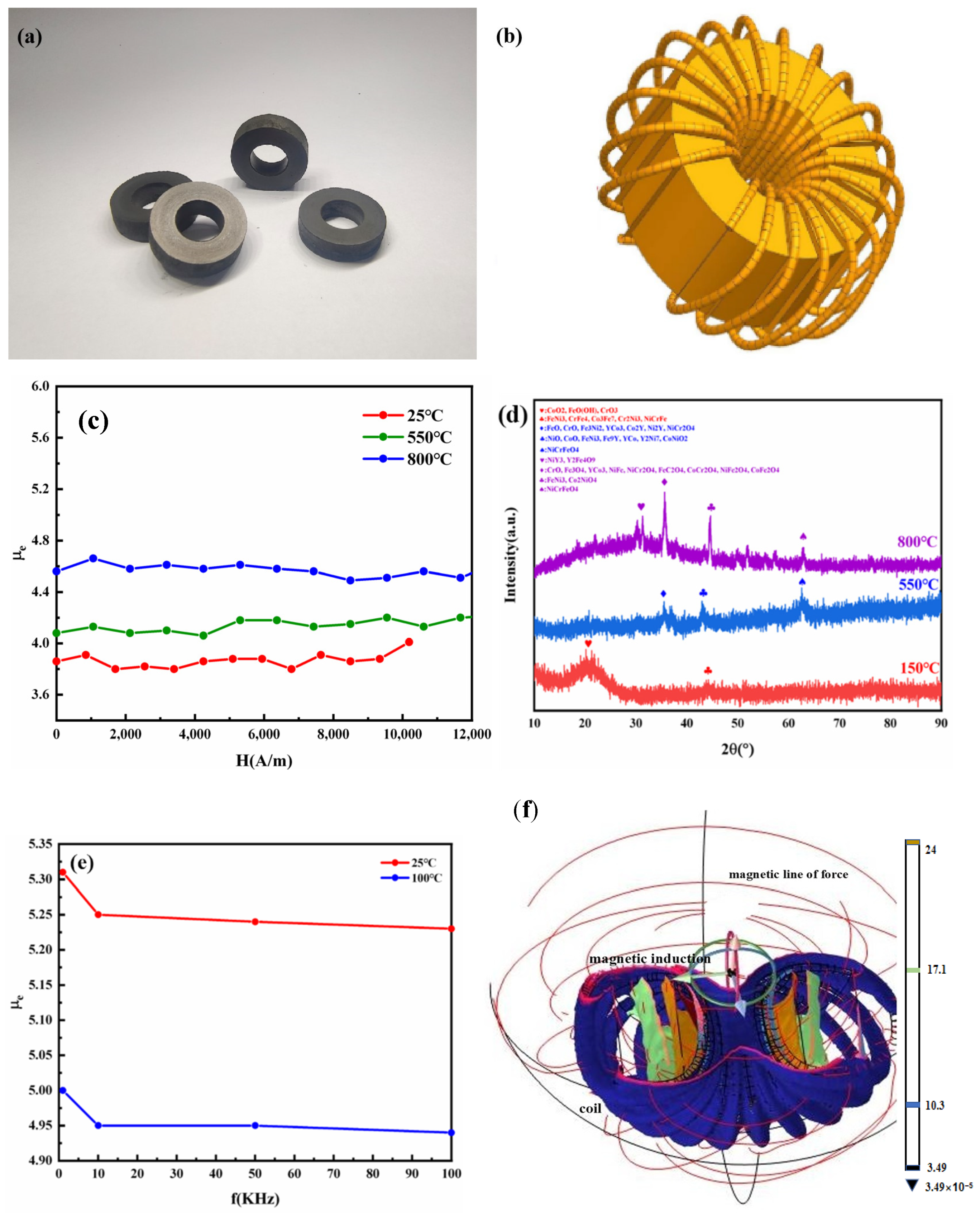

3. Preparation Process, Powder Morphology, Structure and Properties of High Entropy Alloy Nanopowders

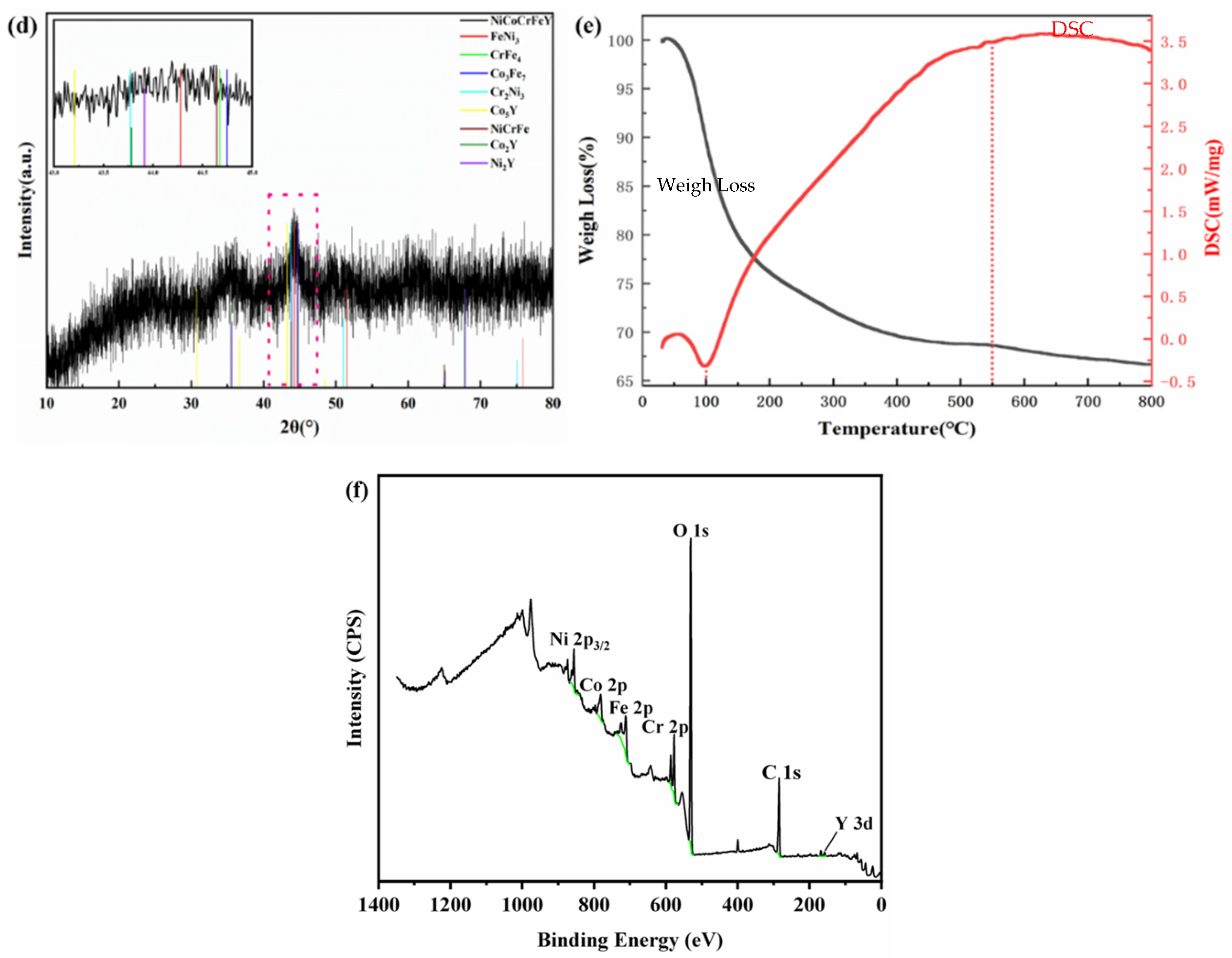

4. Soft Magnetic Properties of High Entropy Alloy Nanopowders

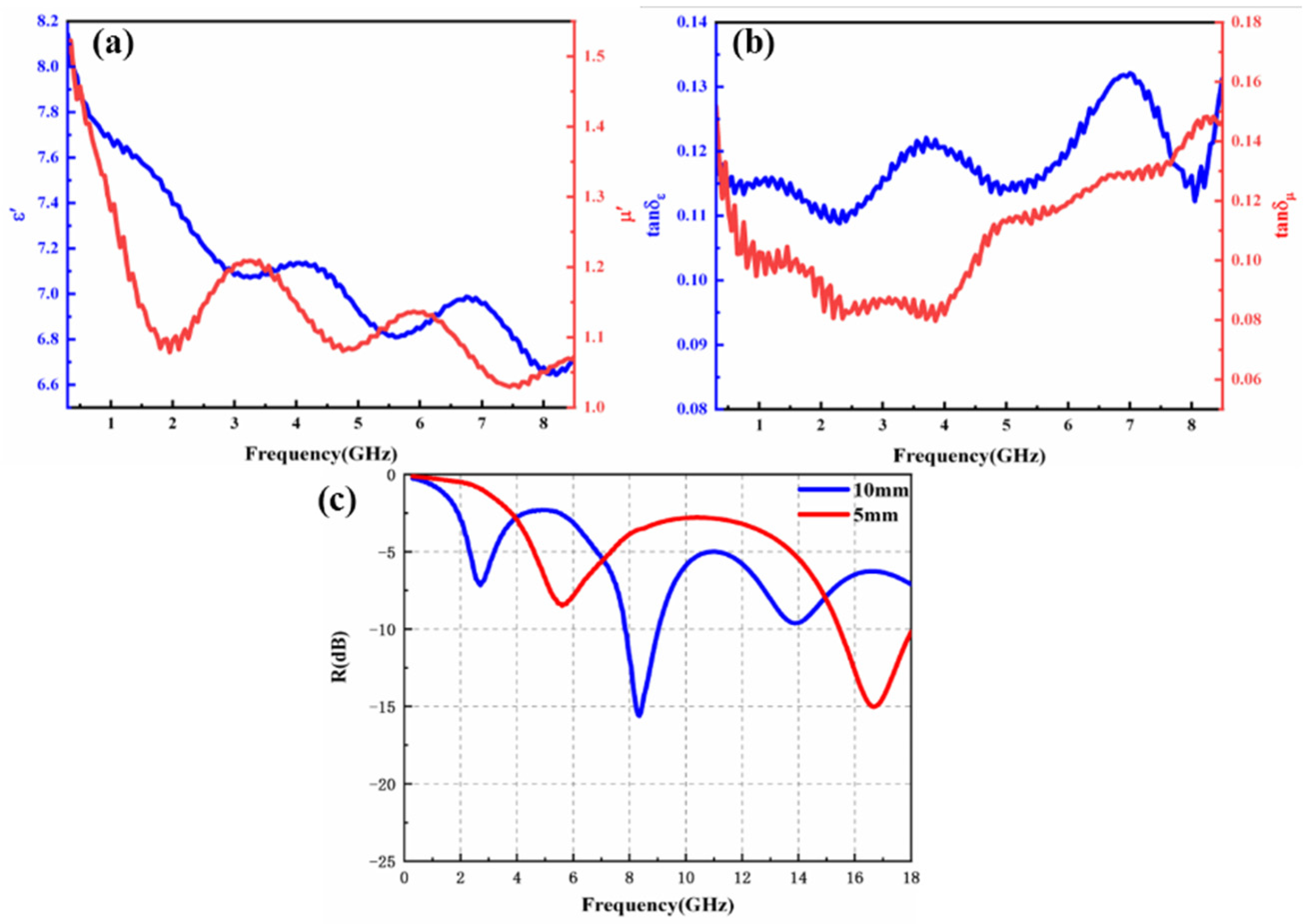

4.1. Electromagnetic Properties of High Entropy Alloy Nanopowders

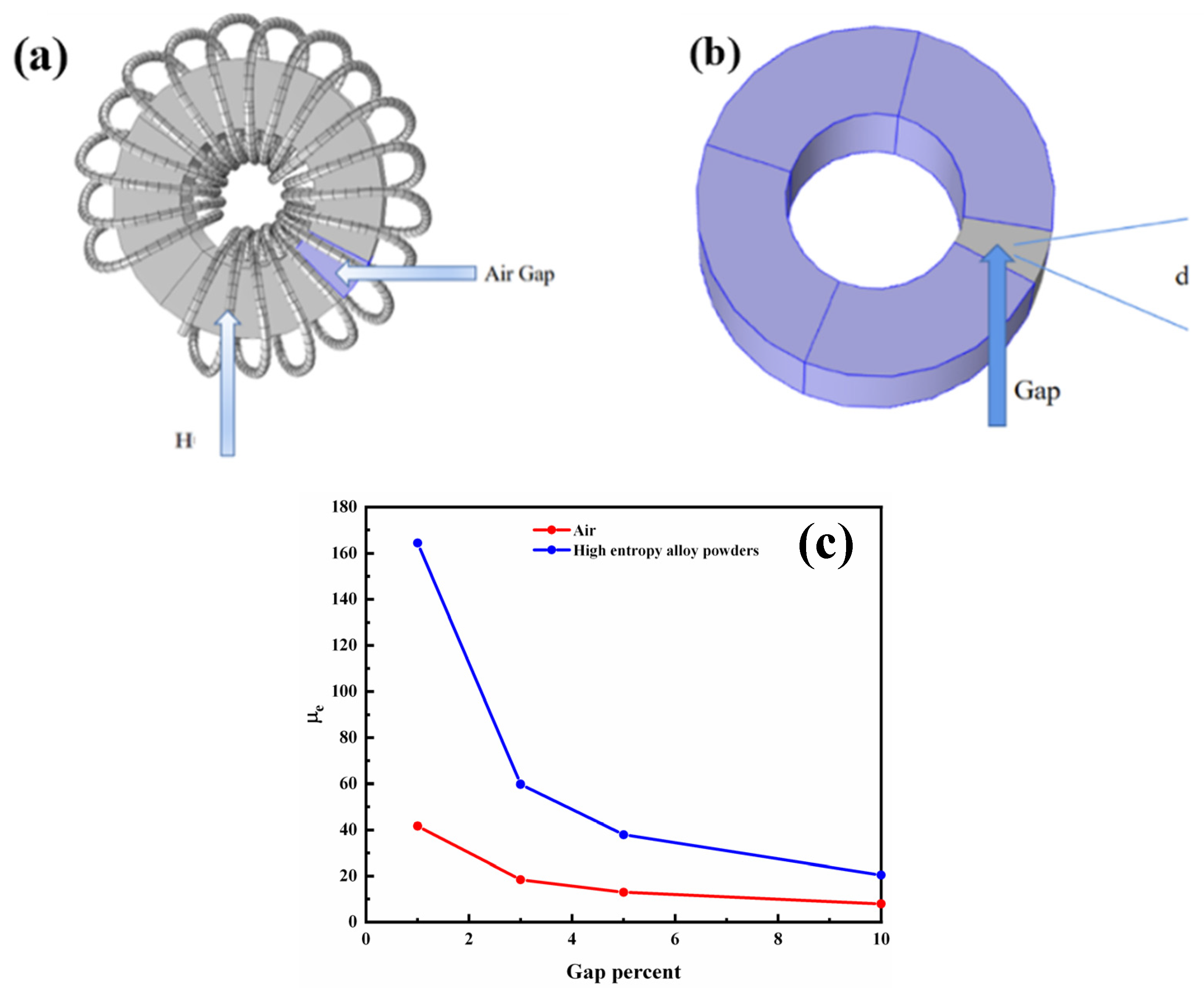

4.2. Inductance Properties of High Entropy Alloy Nanopowders

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, W.; Dong, Y.; Jia, X.; Yang, L.; Li, X.; Wu, S.; Zhao, R.; Wu, H.; Li, Q.; He, A.; et al. Novel CoFeAlMn high-entropy alloys with excellent soft magnetic properties and high thermal stability. J. Mater. Sci. Technol. 2023, 153, 22–31. [Google Scholar] [CrossRef]

- Dormann, J.L. Le phénomène de superparamagnétisme. Rev. Phys. Appl. 1981, 16, 275–301. [Google Scholar] [CrossRef]

- Silveyra, J.M.; Huber, D.L. Soft magnetic materials for a sustainable and electrified world. Science 2018, 362, 0195. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Jiang, L.; Zhu, S.; Wang, L.; Hu, Y.; Zhang, X.; Wu, A. Excellent electromagnetic-wave absorbing performances and great harsh-environment resistance of FeCoNiCrxMn high entropy alloys. J. Alloy Compd. 2023, 936, 168282. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Ye, Y.; Wang, Q.; Lu, J.; Liu, C.; Yang, Y. High-entropy alloy: Challenges and prospects. Mater. Today 2015, 19, 349–362. [Google Scholar] [CrossRef]

- Minouei, H.; Jalaly, M.; Kheradmandfard, M.; Rizi, M.S.; Kim, D.-E.; Hong, S.I. Rapid microwave-assisted synthesis and magnetic properties of high-entropy spinel (Cr0.2Mn0.2Fe0.2Co0.2-Ni Zn)3O4 nanoparticles. Ceram. Int. 2023, 49, 11885–11892. [Google Scholar] [CrossRef]

- Jiang, H.; Han, K.; Qiao, D.; Lu, Y.; Cao, Z.; Li, T. Effects of Ta addition on the microstructures and mechanical properties of CoCrFeNi high entropy alloy. Mater. Chem. Phys. 2018, 210, 43–48. [Google Scholar] [CrossRef]

- Pan, Q.; Zhang, L.; Feng, R.; Lu, Q.; An, K.; Chuang, A.C.; Poplawsky, J.D.; Liaw, P.K.; Lu, L. Gradient cell–structured high-entropy alloy with exceptional strength and ductility. Science 2021, 374, 984–989. [Google Scholar] [CrossRef]

- Niu, C.; LaRosa, C.R.; Miao, J.; Mills, M.J.; Ghazisaeidi, M. Magnetically-driven phase transformation strengthening in high entropy alloys. Nat. Commun. 2018, 9, 1363. [Google Scholar] [CrossRef]

- Nene, S.; Frank, M.; Liu, K.; Sinha, S.; Mishra, R.; McWilliams, B.; Cho, K. Corrosion-resistant high entropy alloy with high strength and ductility. Scr. Mater. 2019, 166, 168–172. [Google Scholar] [CrossRef]

- Abid, T.; Akram, M.A.; Bin Yaqub, T.; Karim, M.R.A.; Fernandes, F.; Zafar, M.F.; Yaqoob, K. Design and development of porous CoCrFeNiMn high entropy alloy (Cantor alloy) with outstanding electrochemical properties. J. Alloys Compd. 2024, 970, 172633. [Google Scholar] [CrossRef]

- Cui, J.; Yang, M.; Liu, G.; Wang, L.; Sun, S.; Wang, B.; Cai, H.; Xue, Y. Work-hardening ability enhancement of lightweight high entropy alloys via adding yttrium. J. Alloys Compd. 2024, 970, 172734. [Google Scholar] [CrossRef]

- Lee, D.; Agustianingrum, M.P.; Park, N.; Tsuji, N. Synergistic effect by Al addition in improving mechanical performance of CoCrNi medium-entropy alloy. J. Alloys Compd. 2019, 800, 372–378. [Google Scholar] [CrossRef]

- Yen, C.C.; Lu, H.N.; Tsai, M.H.; Wu, B.W.; Lo, Y.C.; Wang, C.C.; Chang, S.Y.; Yen, S.K. Corrosion mechanism of annealed equiatomic AlCoCrFeNi tri-phase high-entropy alloy in 0.5 M H2SO4 aerated aqueous solution. Corros. Sci. 2019, 157, 462–471. [Google Scholar] [CrossRef]

- Huang, L.; Wang, X.; Zhao, X.; Wang, C.; Yang, Y. Analysis on the key role in corrosion behavior of CoCrNiAlTi-based high entropy alloy. Mater. Chem. Phys. 2021, 259, 124007. [Google Scholar] [CrossRef]

- Li, M.; Chen, Q.; Cui, X.; Peng, X.; Huang, G. Evaluation of corrosion resistance of the single-phase light refractory high entropy alloy TiCrVNb0.5Al0.5 in chloride environment. J. Alloys Compd. 2021, 857, 158278. [Google Scholar] [CrossRef]

- Kumar, N.A.P.K.; Li, C.; Leonard, K.J.; Bei, H.; Zinkle, S.J. Microstructural stability and mechanical behavior of FeNiMnCr high entropy alloy under ion irradiation. Acta Mater. 2016, 113, 230–244. [Google Scholar] [CrossRef]

- Wu, S.; Lu, J.; Lu, T.; Pan, Y. Entrapment of AlCrFeMn based high entropy alloys in calcium alginate hydrogel balls for decolorization of azo dyes. Mater. Res. Express 2019, 6, 1165d4. [Google Scholar] [CrossRef]

- Wang, P.; Wang, J.-Q.; Li, H.; Yang, H.; Huo, J.; Wang, J.; Chang, C.; Wang, X.; Li, R.-W.; Wang, G. Fast decolorization of azo dyes in both alkaline and acidic solutions by Al-based metallic glasses. J. Alloys Compd. 2017, 701, 759–767. [Google Scholar] [CrossRef]

- Huang, H.; Wu, Y.; He, J.; Wang, H.; Liu, X.; An, K.; Wu, W.; Lu, Z. Phase-transformation ductilization of brittle high-entropy alloys via metastability engineering. Adv. Mater. 2017, 29, 1701678. [Google Scholar] [CrossRef] [PubMed]

- Miracle, D.B.; Senkov, O.N.; Wilks, J. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- MacDonald, B.E.; Fu, Z.; Zheng, B.; Chen, W.; Lin, Y.; Chen, F.; Zhang, L.; Ivanisenko, J.; Zhou, Y.; Hahn, H.; et al. Recent Progress in High Entropy Alloy Research. JOM 2017, 69, 2024–2031. [Google Scholar] [CrossRef]

- Fan, C.; Li, L.; Wen, W.; Li, H.; Fu, J.; Ruan, W.; Ren, S.; Sohrabi, S.; Zhang, Z.; Liang, X.; et al. Rapid amorphization of CrMnFeCoNi high-entropy alloy under ultrasonic vibrations. Mater. Des. 2023, 225, 111575. [Google Scholar] [CrossRef]

- Ma, D.; Grabowski, B.; Körmann, F.; Neugebauer, J.; Raabe, D. Ab initio thermodynamics of the CoCrFeMnNi high entropy alloy: Importance of entropy contributions beyond the configurational one. Acta Mater. 2015, 100, 90–97. [Google Scholar] [CrossRef]

- Wang, K.; Chen, R.; Yang, H.; Chen, Y.; Jia, H.; He, Y.; Song, S.; Wang, Y. The Elements Selection of High Entropy Alloy Guided by Thermodynamics and the Enhanced Electrocatalytic Mechanism for Oxygen Reduction Reaction. Adv. Funct. Mater. 2023, 2310683. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Rosenkranz, L.; Feuerbacher, M.; Gadelmeier, C.; Schleifer, F.; Glatzel, U. Tensile behavior of hexagonal rare-earth-based low, medium, and high entropy alloys: Strengthening effect of configurational entropy. Intermetallics 2023, 155, 107835. [Google Scholar] [CrossRef]

- Chen, W.; Hilhorst, A.; Bokas, G.; Gorsse, S.; Jacques, P.J.; Hautier, G. A map of single-phase high-entropy alloys. Nat. Commun. 2023, 14, 2856. [Google Scholar] [CrossRef]

- Song, X.; Zhang, Y. Progress of high entropy alloys. Powder Metall. Technol. 2022, 40, 451–457. [Google Scholar]

- Périgo, E.A.; Jacimovic, J.; García Ferré, F.; Scherf, L.M. Additive manufacturing of magnetic materials. Addit. Manuf. 2019, 30, 100870. [Google Scholar] [CrossRef]

- Hou, Y.; Su, H.; Zhang, H.; Wang, X.; Wang, C. Fabricating Homogeneous FeCoCrNi High-Entropy Alloys via SLM In Situ Alloying. Metals 2021, 11, 942. [Google Scholar] [CrossRef]

- Torralba, J.M.; Campos, M. High Entropy Alloys Manufactured by Additive Manufacturing. Metals 2020, 10, 639. [Google Scholar] [CrossRef]

- Tracy, C.L.; Park, S.; Rittman, D.R.; Zinkle, S.J.; Bei, H.; Lang, M.; Ewing, R.C.; Mao, W.L. High pressure synthesis of a hexagonal close-packed phase of the high-entropy alloy CrMnFeCoNi. Nat. Commun. 2017, 8, 15634. [Google Scholar] [CrossRef] [PubMed]

- Tokarewicz, M.; Grądzka-Dahlke, M. Review of Recent Research on AlCoCrFeNi High-Entropy Alloy. Metals 2021, 11, 1302. [Google Scholar] [CrossRef]

- Zhu, J.; Lv, M.; Liu, C.; Tan, X.; Xu, H. Effect of neodymium and yttrium addition on microstructure and DC soft magnetic property of dual-phase FeCoNi (CuAl) 0.8 high-entropy alloy. J. Rare Earth 2023, 41, 1562–1567. [Google Scholar] [CrossRef]

- Ma, X.; Duan, Y.; Shi, Y.; Huang, L.; Pang, H. Broadband asymmetric transmission in quasiperiodic-metamaterials based on high entropy alloys ribbon. J. Alloys Compd. 2023, 946, 169349. [Google Scholar] [CrossRef]

| Temperature (°C) | μi (k) | μm (k) | |||||

|---|---|---|---|---|---|---|---|

| 25 | 0.020 | 0.237 | 711.2 | 8.472 | 1.012 | 54.31 | 0.119 |

| 550 | 0.019 | 0.850 | 503.9 | 6.274 | 0.224 | 325.7 | 0.036 |

| 800 | 0.017 | 0.359 | 1679 | 12.41 | 1.729 | 223.9 | 0.139 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, D.; Yuan, Z.; Zhu, Z.; Yao, M. NiCoCrFeY High Entropy Alloy Nanopowders and Their Soft Magnetic Properties. Materials 2024, 17, 534. https://doi.org/10.3390/ma17020534

Jiang D, Yuan Z, Zhu Z, Yao M. NiCoCrFeY High Entropy Alloy Nanopowders and Their Soft Magnetic Properties. Materials. 2024; 17(2):534. https://doi.org/10.3390/ma17020534

Chicago/Turabian StyleJiang, Donghan, Zhifen Yuan, Zhenghou Zhu, and Mengke Yao. 2024. "NiCoCrFeY High Entropy Alloy Nanopowders and Their Soft Magnetic Properties" Materials 17, no. 2: 534. https://doi.org/10.3390/ma17020534

APA StyleJiang, D., Yuan, Z., Zhu, Z., & Yao, M. (2024). NiCoCrFeY High Entropy Alloy Nanopowders and Their Soft Magnetic Properties. Materials, 17(2), 534. https://doi.org/10.3390/ma17020534