Optimization of Ultra-High Performance Concrete Based on Response Surface Methodology and NSGA-II

Abstract

1. Introduction

2. Materials and Methods

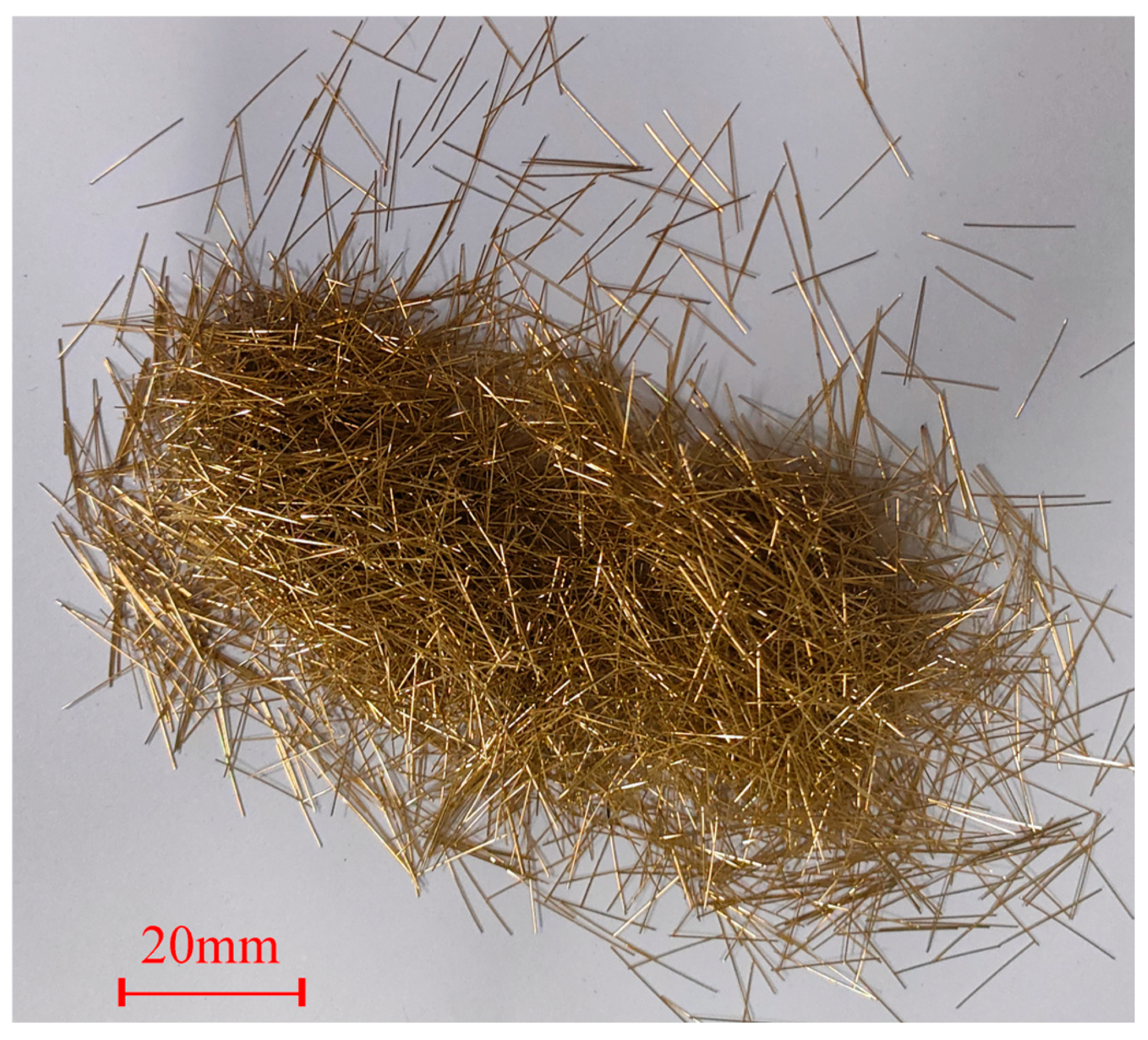

2.1. Materials

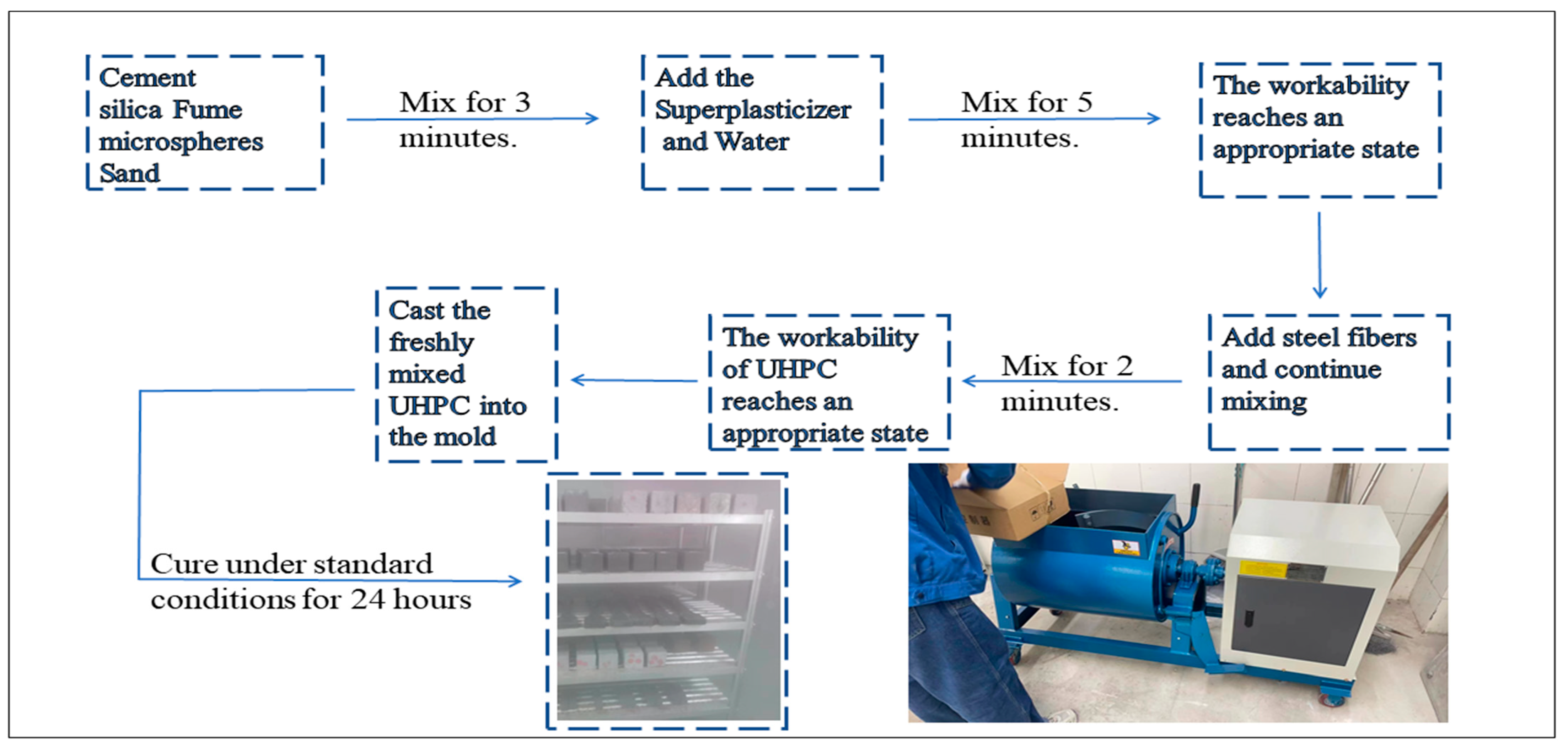

2.2. Specimens Preparation

2.3. Experimental Design and RSM

2.4. Experimental Methods

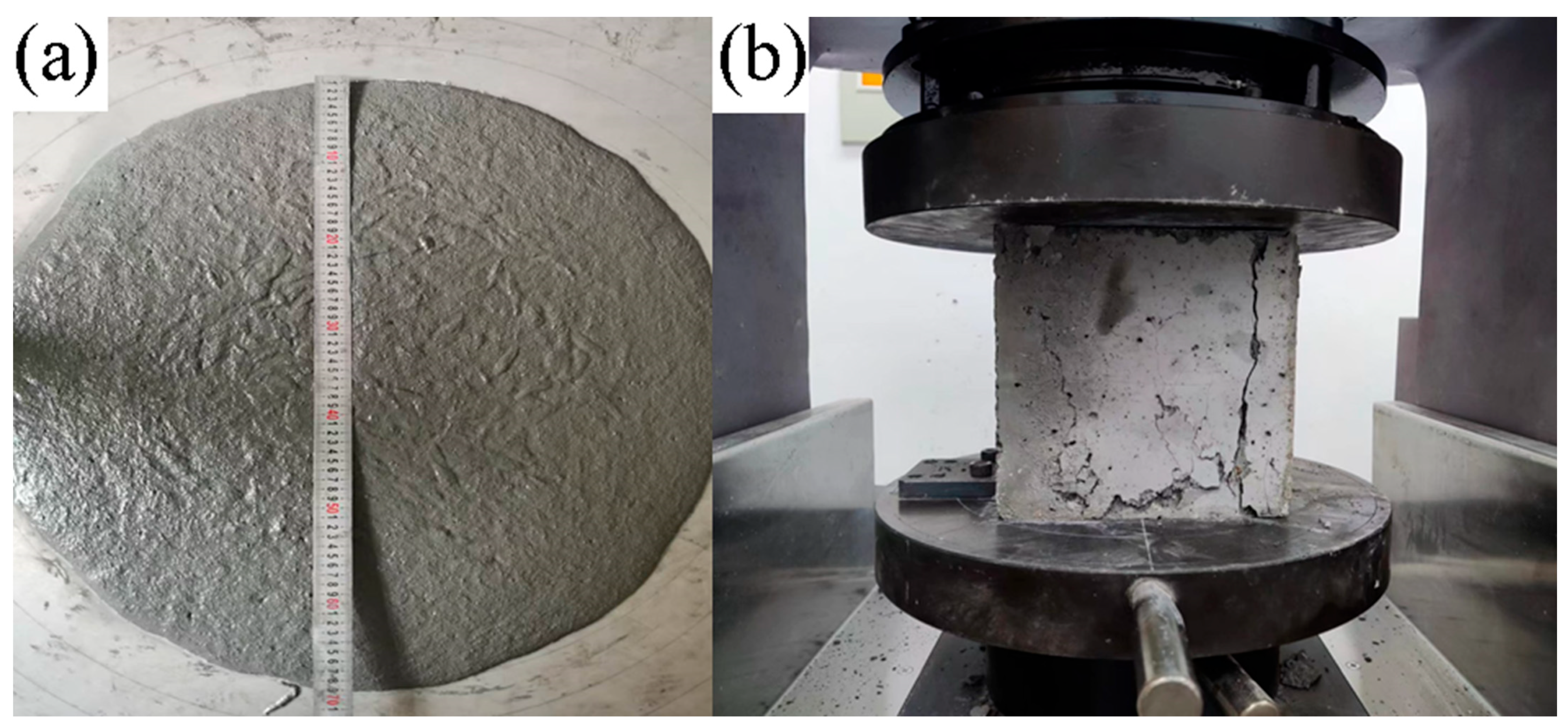

2.4.1. Workability

2.4.2. Compressive Strength

2.4.3. Flexural Strength

3. Results and Analysis

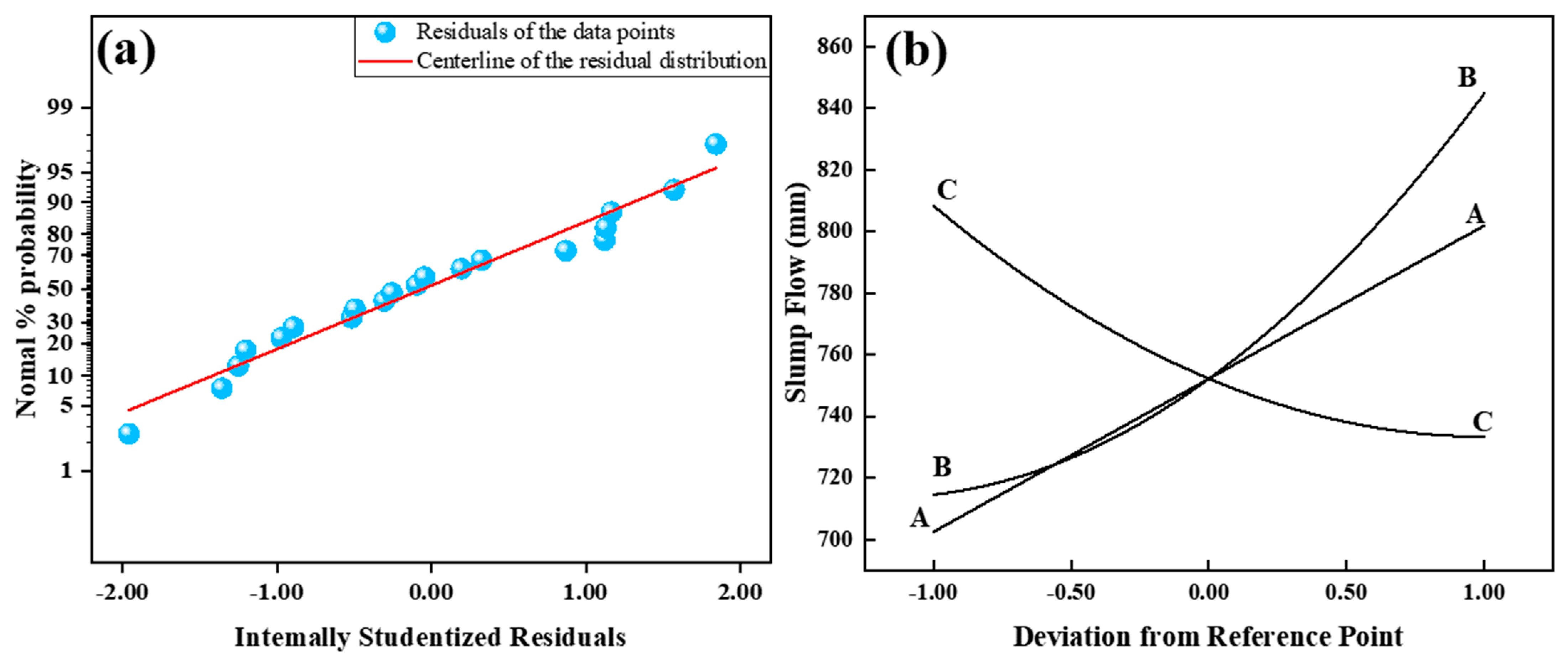

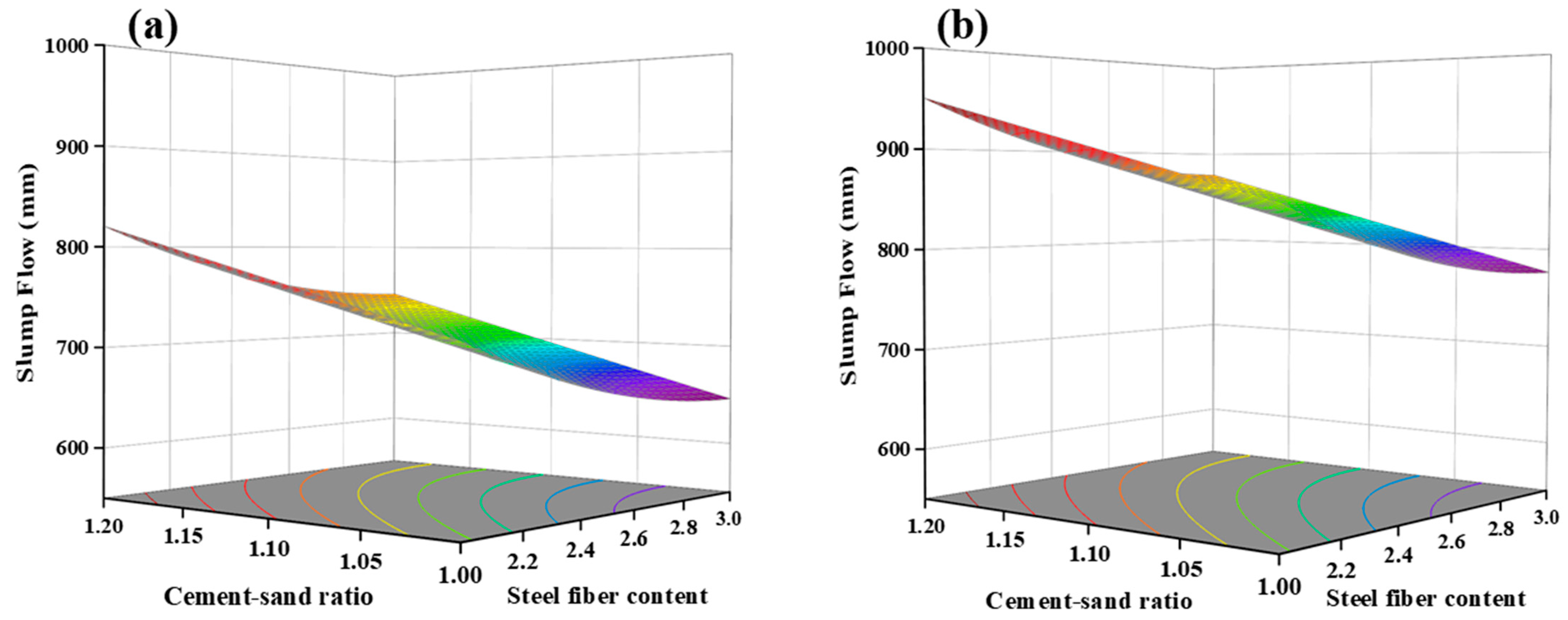

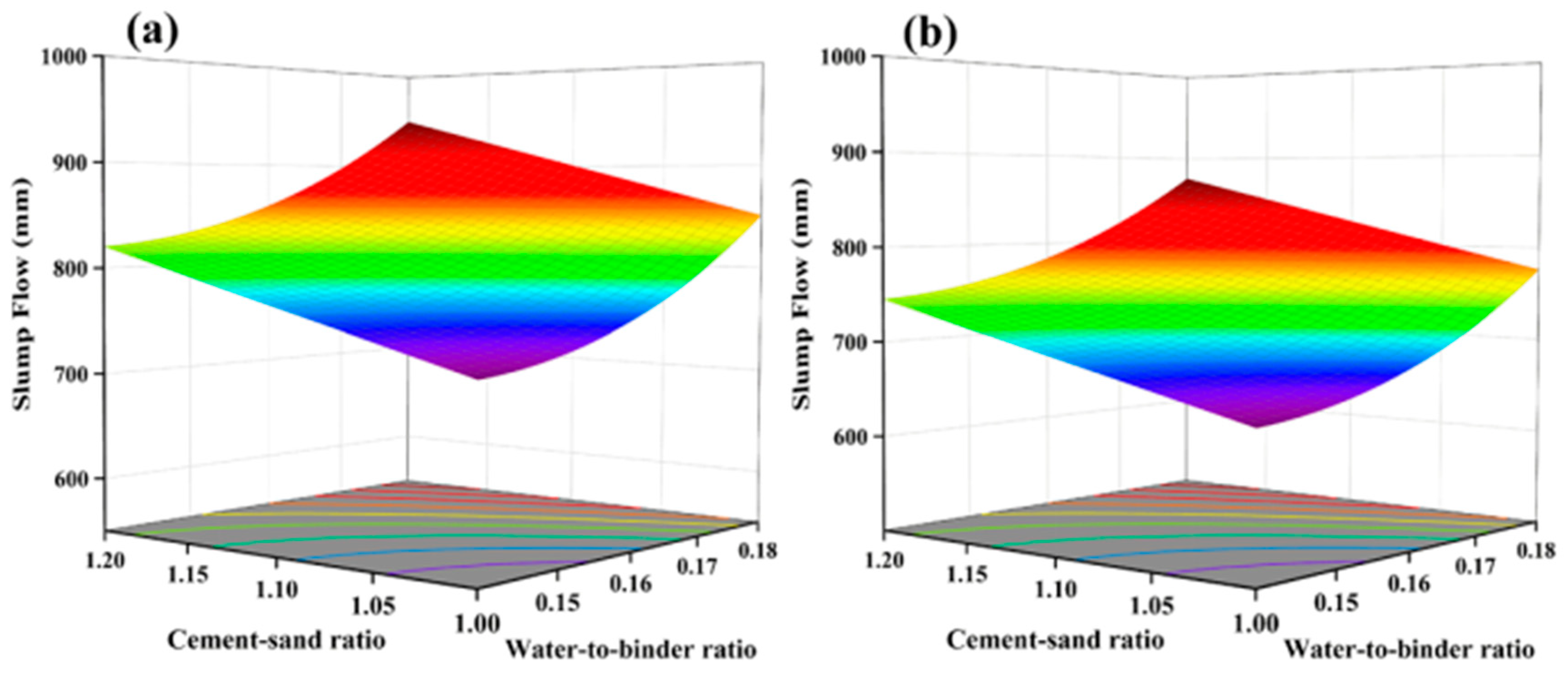

3.1. Analysis of Working Performance

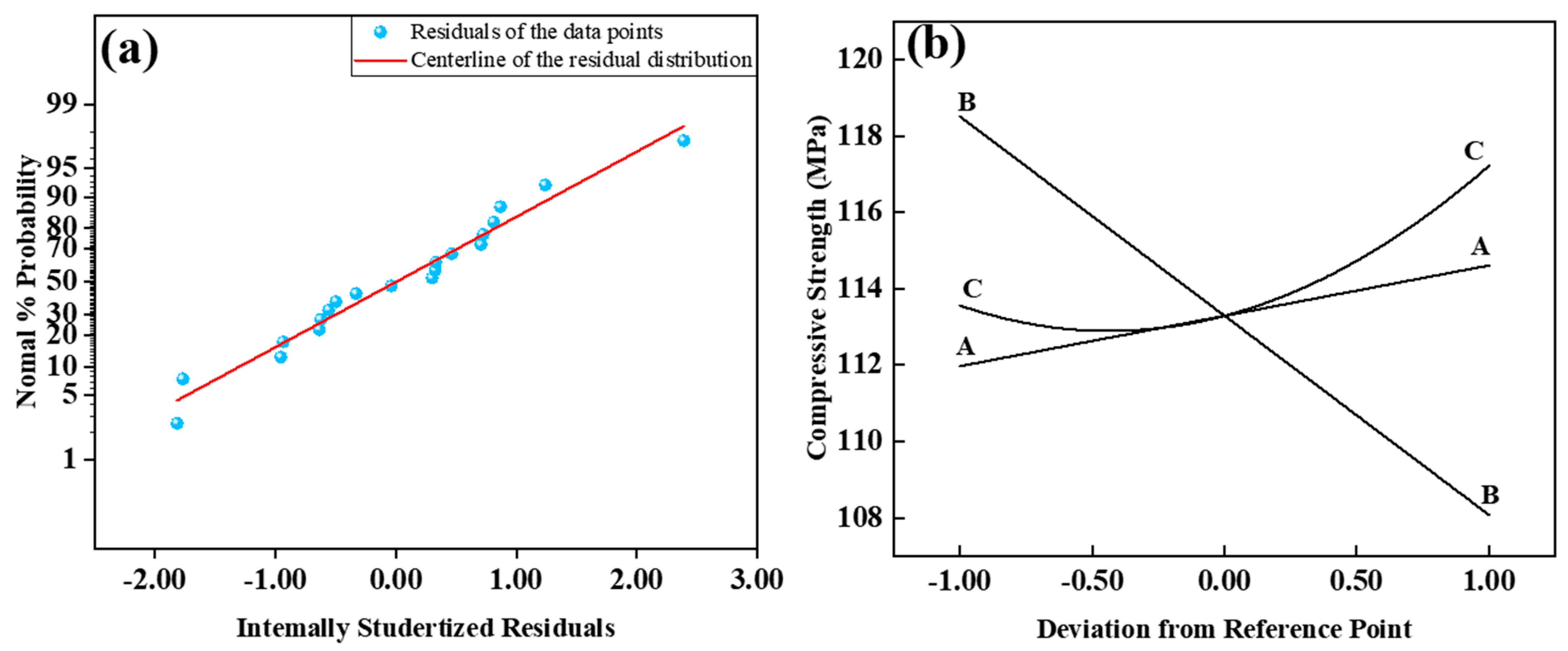

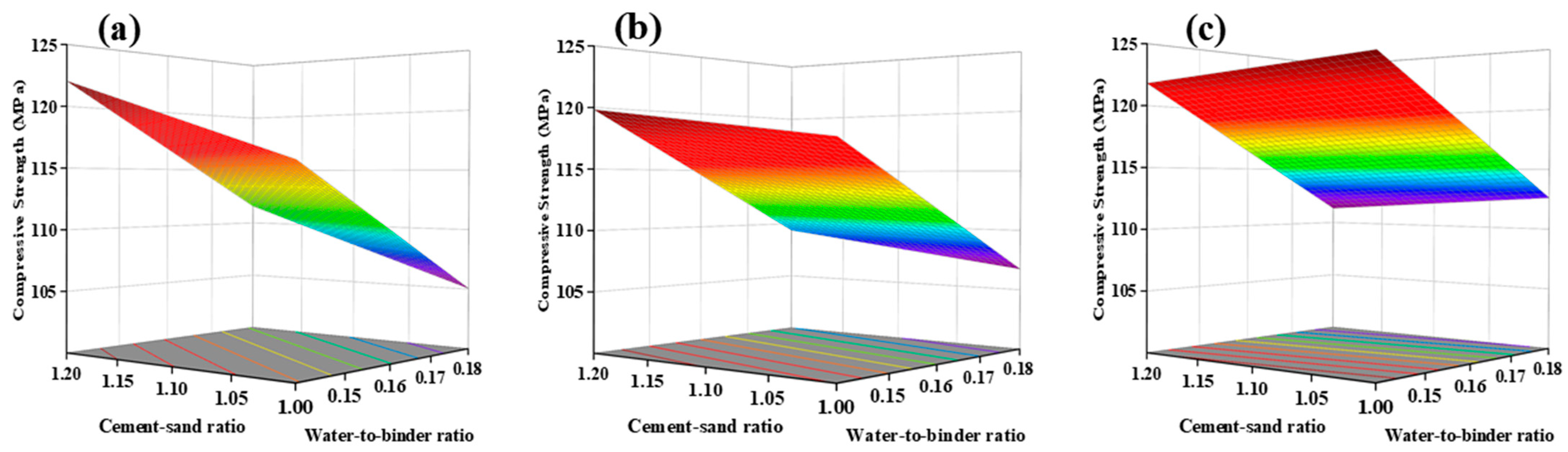

3.2. Analysis of Compressive Strength Performance

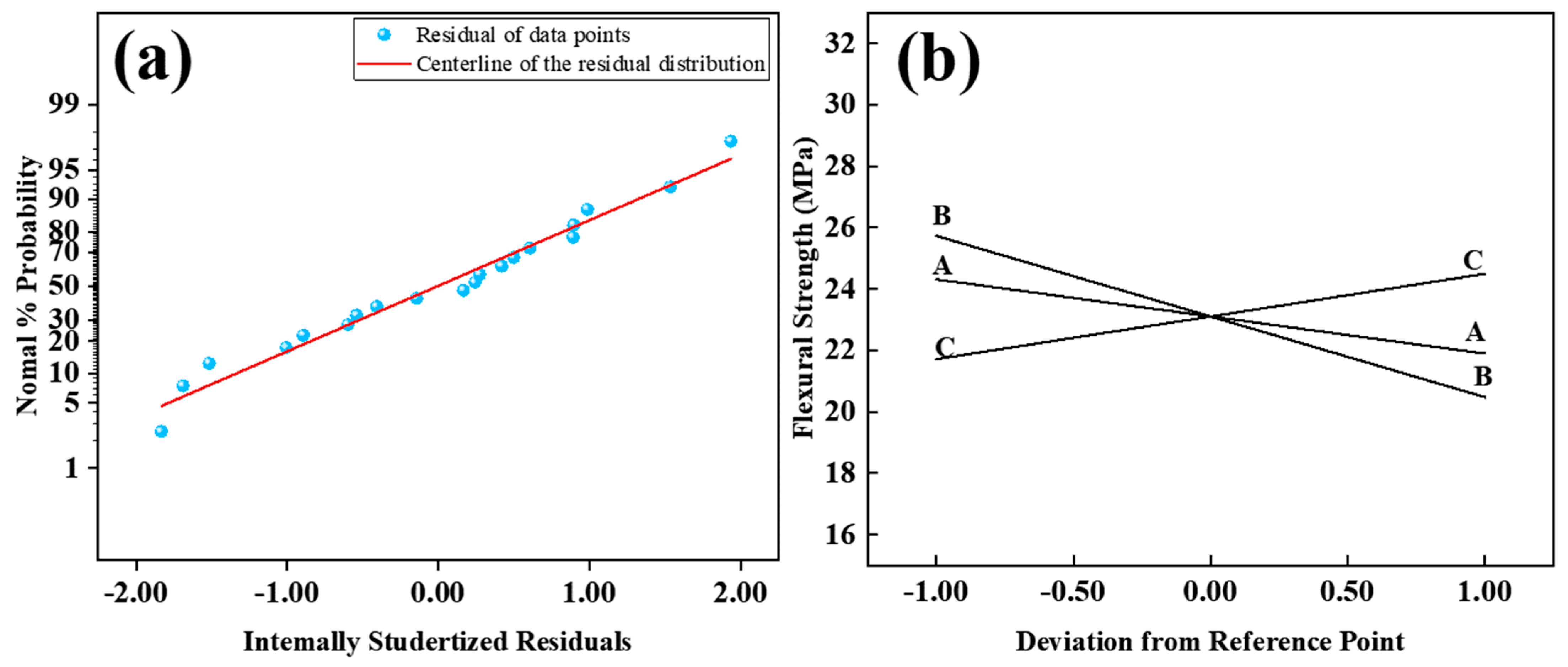

3.3. The Flexural Strength Performance Analysis

3.4. Optimization Validation

3.4.1. Constraints in Multi-Objective Optimization

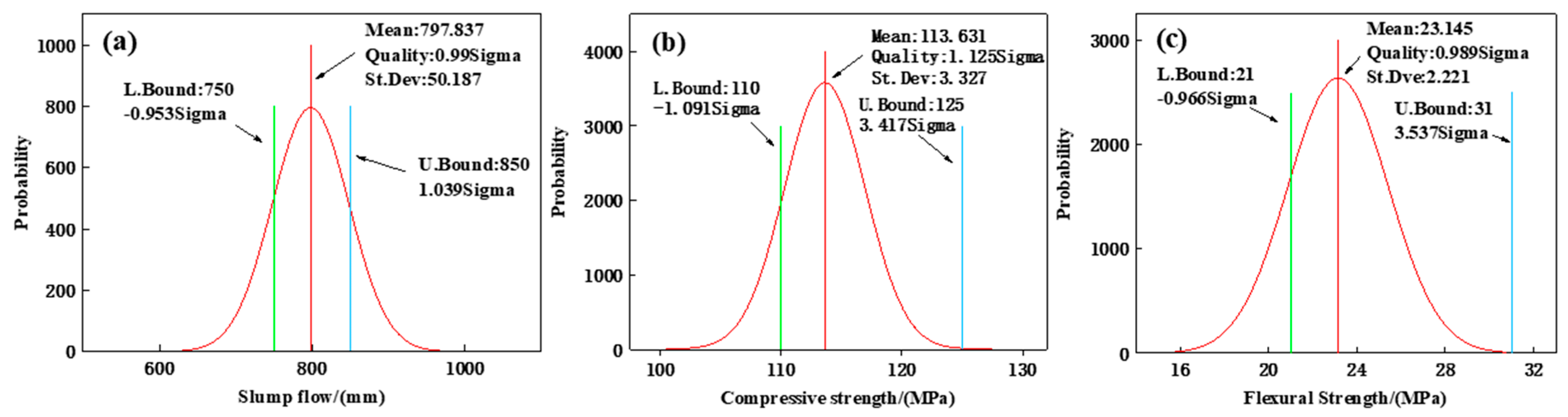

3.4.2. Reliability Analysis

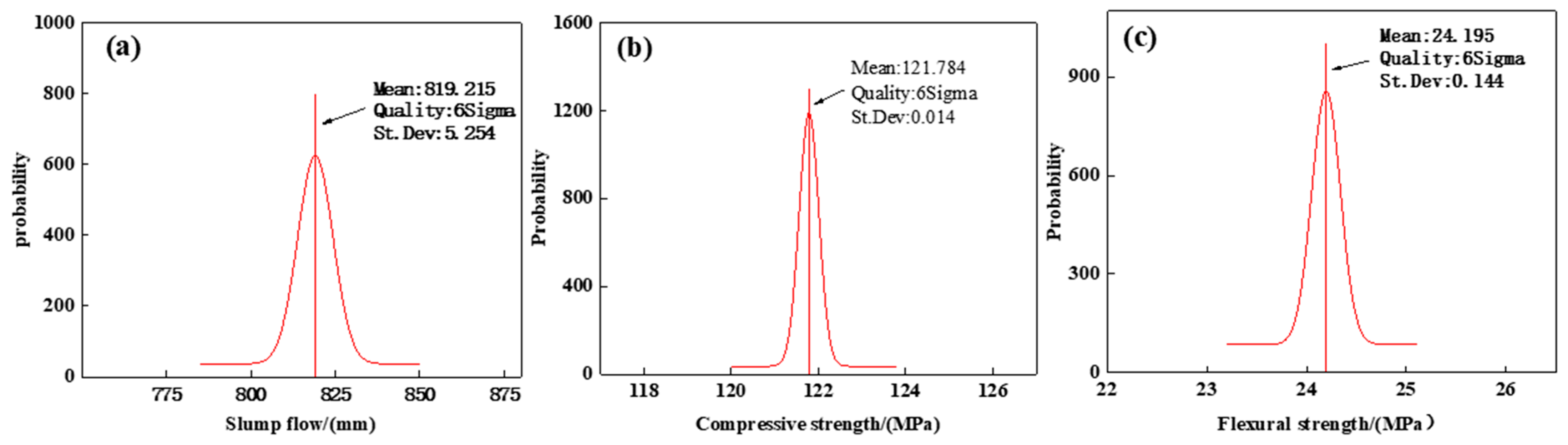

3.4.3. Pareto Frontier of Response Variables and Reliability Analysis

3.4.4. Multi-Objective Optimization Result Verification

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- De Larrard, F.; Sedran, T. Optimization of ultra-high-performance concrete by the use of a packing model. Cem. Concr. Res. 1994, 24, 997–1009. [Google Scholar] [CrossRef]

- Du, J.; Meng, W.; Khayat, K.H.; Bao, Y.; Guo, P.; Lyu, Z.; Abu-Obeidah, A.; Nassif, H.; Wang, H. New development of ultra-high-performance concrete (UHPC). Compos. Part B Eng. 2021, 224, 109220. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.-S.; Onaizi, A.M.; Makul, N.; Abdelgader, H.S.; Ozbakkaloglu, T. Recent trends in ultra-high performance concrete (UHPC): Current status, challenges, and future prospects. Constr. Build. Mater. 2022, 352, 129029. [Google Scholar] [CrossRef]

- Russell, H.G.; Graybeal, B.A.; Russell, H.G. Ultra-High Performance Concrete: A State-of-the-Art Report for the Bridge Community; Federal Highway Administration, Office of Infrastructure Research and Development: Washington, DC, USA, 2013.

- Habel, K.; Gauvreau, P. Response of ultra-high performance fiber reinforced concrete (UHPFRC) to impact and static loading. Cem. Concr. Compos. 2008, 30, 938–946. [Google Scholar] [CrossRef]

- Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Agwa, I.S. Effects of nano cotton stalk and palm leaf ashes on ultrahigh-performance concrete properties incorporating recycled concrete aggregates. Constr. Build. Mater. 2021, 302, 124196. [Google Scholar] [CrossRef]

- Graybeal, B.A. Material Property Characterization of Ultra-High Performance Concrete; Federal Highway Administration, Office of Infrastructure Research and Development: Washington, DC, USA, 2006.

- Hirschi, T.; Wombacher, F. Influence of different superplasticizers on UHPC. In Proceedings of the Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008; Kassel University Press: Kassel, Germany, 2008; pp. 77–84. [Google Scholar]

- Du, Y.; Zhang, L.; Ruan, S.; Qian, X.; Qian, K.; Cheng, P.; Lin, G. Powder gradation effect on the fresh, mechanical, and early-age shrinkage properties of UHPC. J. Build. Eng. 2023, 67, 105958. [Google Scholar] [CrossRef]

- Yin, T.; Liu, K.; Fan, D.; Yu, R. Derivation and verification of multilevel particle packing model for Ultra-High Performance Concrete (UHPC): Modelling and experiments. Cem. Concr. Compos. 2023, 136, 104889. [Google Scholar] [CrossRef]

- Wang, X.; Wu, D.; Zhang, J.; Yu, R.; Hou, D.; Shui, Z. Design of sustainable ultra-high performance concrete: A review. Constr. Build. Mater. 2021, 307, 124643. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostofinejad, D. Microstructure of ultra-high-performance concrete (UHPC)—A review study. J. Build. Eng. 2022, 50, 104118. [Google Scholar] [CrossRef]

- Huang, W.; Kazemi-Kamyab, H.; Sun, W.; Scrivener, K. Effect of cement substitution by limestone on the hydration and microstructural development of ultra-high performance concrete (UHPC). Cem. Concr. Compos. 2017, 77, 86–101. [Google Scholar] [CrossRef]

- Fan, D.; Rui, Y.; Liu, K.; Tan, J.; Shui, Z.; Wu, C.; Wang, S.; Guan, Z.; Hu, Z.; Su, Q. Optimized design of steel fibres reinforced ultra-high performance concrete (UHPC) composites: Towards to dense structure and efficient fibre application. Constr. Build. Mater. 2021, 273, 121698. [Google Scholar]

- Ahmad, S.; Al-Fakih, A.; Bahraq, A.A.; Yusuf, M.O. Fracture toughness of UHPC mixtures: Effects of w/b ratio, cement and silica fume contents. Constr. Build. Mater. 2024, 417, 135327. [Google Scholar] [CrossRef]

- Prem, P.R.; Ramachandra Murthy, A.; Bharatkumar, B.H. Influence of curing regime and steel fibres on the mechanical properties of UHPC. Mag. Concr. Res. 2015, 67, 988–1002. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, J.; Dong, X.; Wang, J.; Liu, C.; Liu, J. Optimization of nitrogen removal conditions based on response surface methodology and nitrogen removal pathway of Paracoccus sp. QD-19. Sci. Total Environ. 2024, 908, 168348. [Google Scholar] [CrossRef]

- Zhang, X.; Su, P.; Wang, W.; Yang, W.; Ge, Y.; Jiang, K.; Huang, J. Optimized carbonization of coffee shell via response surface methodology: A circular economy approach for environmental remediation. Environ. Pollut. 2023, 346, 123018. [Google Scholar] [CrossRef]

- Bezerra, M.A.; Santelli, R.E.; Oliveira, E.P.; Villar, L.S.; Escaleira, L.A. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 2008, 76, 965–977. [Google Scholar] [CrossRef]

- Ho, C.M.; Doh, S.I.; Li, X.; Chin, S.C.; Ashraf, T. RSM-based modelling of cement mortar with various water to cement ratio and steel slag content. Phys. Chem. Earth 2022, 128, 103256. [Google Scholar] [CrossRef]

- Li, Z.; Lu, D.; Gao, X. Multi-objective optimization of gap-graded cement paste blended with supplementary cementitious materials using response surface methodology. Constr. Build. Mater. 2020, 248, 118552. [Google Scholar] [CrossRef]

- Ferdosian, I.; Camões, A. Eco-efficient ultra-high performance concrete development by means of response surface methodology. Cem. Concr. Compos. 2017, 84, 146–156. [Google Scholar] [CrossRef]

- Wille, K.; Naaman, A.E.; Parra-Montesinos, G.J. Ultra-High Performance Concrete with Compressive Strength Exceeding 150 MPa (22 ksi): A Simpler Way. ACI Mater. J. 2011, 108, 46. [Google Scholar]

- Mohammed, B.H.; Sherwani, A.F.H.; Faraj, R.H.; Qadir, H.H.; Younis, K.H. Mechanical properties and ductility behavior of ultra-high performance fiber reinforced concretes: Effect of low water-to-binder ratios and micro glass fibers. Ain Shams Eng. J. 2021, 12, 1557–1567. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kim, S.; Park, G.J.; Park, J.J.; Kim, S.W. Effects of fiber shape, aspect ratio, and volume fraction on flexural behavior of ultra-high-performance fiber-reinforced cement composites. Compos. Struct. 2017, 174, 375–388. [Google Scholar] [CrossRef]

- Hannawi, K.; Bian, H.; Prince-Agbodjan, W.; Raghavan, B. Effect of different types of fibers on the microstructure and the mechanical behavior of ultra-high performance fiber-reinforced concretes. Compos. Part B Eng. 2016, 86, 214–220. [Google Scholar] [CrossRef]

- Mu, R.; Chen, J.; Chen, X.; Diao, C.; Wang, X.; Qing, L. Effect of the orientation of steel fiber on the strength of ultra-high-performance concrete (UHPC). Constr. Build. Mater. 2023, 406, 133431. [Google Scholar] [CrossRef]

- Wang, R.; Gao, X.; Huang, H.; Han, G. Influence of rheological properties of cement mortar on steel fiber distribution in UHPC. Constr. Build. Mater. 2017, 144, 65–73. [Google Scholar] [CrossRef]

- Fan, M.; Li, Y.; Shen, J.; Jin, K.; Shi, J. Multi-objective optimization design of recycled aggregate concrete mixture proportions based on machine learning and NSGA-II algorithm. Adv. Eng. Softw. 2024, 192, 103631. [Google Scholar] [CrossRef]

- Tanhadoust, A.; Madhkhan, M.; Nehdi, M.L. Two-stage multi-objective optimization of reinforced concrete buildings based on non-dominated sorting genetic algorithm (NSGA-III). J. Build. Eng. 2023, 75, 107022. [Google Scholar] [CrossRef]

- T/CECS 864; Standard for Test Method of Ultra-High Performance Concrete. Shanghai Research Institute of Building Science Co., Ltd.: Shanghai, China, 2021.

- Li, Q.; Fan, Y. Rheological evaluation of nano-metakaolin cement pastes based on the water film thickness. Constr. Build. Mater. 2022, 324, 126517. [Google Scholar] [CrossRef]

- Amparano, F.E.; Xi, Y.; Roh, Y.-S. Experimental study on the effect of aggregate content on fracture behavior of concrete. Eng. Fract. Mech. 2000, 67, 65–84. [Google Scholar] [CrossRef]

- Rao, G.A. Generalization of Abrams’ law for cement mortars. Cem. Concr. Res. 2001, 31, 495–502. [Google Scholar] [CrossRef]

- Mohamad, G.; Lourenço, P.B.; Camões, A.; Roman, H.R. Estudo de Caracterização Mecânica das Argamassas de Assentamento para Alvenaria Estrutural. 2007. Available online: https://repositorium.sdum.uminho.pt/handle/1822/9139 (accessed on 28 September 2024).

- Cordon, W.A.; Gillespie, H.A. Variables in concrete aggregates and Portland cement paste which influence the strength of concrete. J. Proc. 1963, 60, 1029–1052. [Google Scholar]

- Pourbaba, M.; Asefi, E.; Sadaghian, H.; Mirmiran, A. Effect of age on the compressive strength of ultra-high-performance fiber-reinforced concrete. Constr. Build. Mater. 2018, 175, 402–410. [Google Scholar] [CrossRef]

- Giaccio, G.; Zerbino, R. Failure mechanism of concrete: Combined effects of coarse aggregates and strength level. Adv. Cem. Based Mater. 1998, 7, 41–48. [Google Scholar] [CrossRef]

- Fernandes, V.; Silva, L.; Ferreira, V.; Labrincha, J. Evaluation of mixing and application process parameters of single-coat mortars. Cem. Concr. Res. 2005, 35, 836–841. [Google Scholar] [CrossRef]

- Wu, Z.; Khayat, K.H.; Shi, C. How do fiber shape and matrix composition affect fiber pullout behavior and flexural properties of UHPC? Cem. Concr. Compos. 2018, 90, 193–201. [Google Scholar] [CrossRef]

- Abed, M.; Fořt, J.; Rashid, K. Multicriterial life cycle assessment of eco-efficient self-compacting concrete modified by waste perlite powder and/or recycled concrete aggregate. Constr. Build. Mater. 2022, 348, 128696. [Google Scholar] [CrossRef]

| Code | CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | K2O | Na2O | MgO | Loss |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 63.06 | 21.01 | 3.76 | 3.34 | 3.63 | 0.89 | 0.19 | 3.03 | 2.1 |

| Silica fume | 0.35 | 97.43 | 0.42 | 0.13 | 0.33 | 0.16 | 0.33 | 0.22 | 1.2 |

| microspheres | 7.9 | 45.28 | 39.76 | 2.9 | 0.47 | 0.91 | 0.42 | 0.18 | 1.8 |

| Variables | Coded | Actual | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| Cement/sand ratio | A | 1.00 | 1.10 | 1.20 |

| Water-to-binder ratio | B | 0.14 | 0.16 | 0.18 |

| Steel Fiber Content (%) | C | 2.00 | 2.50 | 3.00 |

| Sample | Actual | Cement | Silica Fume | Microspheres | Sand | Superplasticizer | Steel Fiber | Water | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C/S | W/B | SFC | 20–40 | 40–80 | |||||||

| 1 | 1.20 | 0.18 | 3.00 | 865 | 110 | 110 | 275 | 629 | 28 | 234 | 195.3 |

| 2 | 1.10 | 0.16 | 1.66 | 865 | 110 | 110 | 300 | 687 | 28 | 129.5 | 173.6 |

| 3 | 1.20 | 0.18 | 2.00 | 865 | 110 | 110 | 275 | 629 | 28 | 156 | 195.3 |

| 4 | 1.10 | 0.16 | 2.50 | 865 | 110 | 110 | 300 | 687 | 28 | 195 | 173.6 |

| 5 | 1.00 | 0.14 | 3.00 | 865 | 110 | 110 | 330 | 755 | 28 | 234 | 151.9 |

| 6 | 1.10 | 0.13 | 2.50 | 865 | 110 | 110 | 300 | 687 | 28 | 195 | 141.1 |

| 7 | 1.00 | 0.14 | 2.00 | 865 | 110 | 110 | 330 | 755 | 28 | 156 | 151.9 |

| 8 | 1.10 | 0.19 | 2.50 | 865 | 110 | 110 | 300 | 687 | 28 | 195 | 206.2 |

| 9 | 1.10 | 0.16 | 2.50 | 865 | 110 | 110 | 300 | 687 | 28 | 195 | 173.6 |

| 10 | 1.20 | 0.14 | 3.00 | 865 | 110 | 110 | 275 | 629 | 28 | 234 | 151.9 |

| 11 | 1.10 | 0.16 | 2.50 | 865 | 110 | 110 | 300 | 687 | 28 | 195 | 173.6 |

| 12 | 1.27 | 0.16 | 2.50 | 865 | 110 | 110 | 260 | 595 | 28 | 195 | 173.6 |

| 13 | 0.93 | 0.16 | 2.50 | 865 | 110 | 110 | 355 | 812 | 28 | 195 | 173.6 |

| 14 | 1.00 | 0.18 | 2.00 | 865 | 110 | 110 | 330 | 755 | 28 | 156 | 195.3 |

| 15 | 1.10 | 0.16 | 2.50 | 865 | 110 | 110 | 300 | 687 | 28 | 195 | 173.6 |

| 16 | 1.10 | 0.16 | 3.34 | 865 | 110 | 110 | 300 | 687 | 28 | 160.5 | 173.6 |

| 17 | 1.20 | 0.14 | 2.00 | 865 | 110 | 110 | 275 | 629 | 28 | 156 | 151.9 |

| 18 | 1.10 | 0.16 | 2.50 | 865 | 110 | 110 | 300 | 687 | 28 | 195 | 173.6 |

| 19 | 1.00 | 0.18 | 3.00 | 865 | 110 | 110 | 330 | 755 | 28 | 234 | 195.3 |

| 20 | 1.10 | 0.16 | 2.50 | 865 | 110 | 110 | 300 | 687 | 28 | 195 | 173.6 |

| Sample | Workability (mm) | 28 d-Compressive Strength (MPa) | 28 d-Flexural Strength (Mpa) |

|---|---|---|---|

| 1 | 900 | 112.6 | 21.59 |

| 2 | 860 | 116.6 | 23.17 |

| 3 | 930 | 110.5 | 18.53 |

| 4 | 720 | 114.3 | 24.68 |

| 5 | 670 | 124.6 | 27.51 |

| 6 | 700 | 122 | 30.55 |

| 7 | 720 | 116.1 | 24.02 |

| 8 | 920 | 101.1 | 16.33 |

| 9 | 740 | 111.2 | 23.54 |

| 10 | 740 | 118.6 | 23.09 |

| 11 | 760 | 114 | 24.85 |

| 12 | 840 | 120.1 | 21.5 |

| 13 | 650 | 110 | 24.93 |

| 14 | 870 | 106.5 | 19.68 |

| 15 | 750 | 112.2 | 21.54 |

| 16 | 710 | 121.8 | 26.84 |

| 17 | 860 | 120.4 | 20.54 |

| 18 | 780 | 116 | 23.99 |

| 19 | 810 | 113.9 | 23.34 |

| 20 | 745 | 111.9 | 22.06 |

| ANOVA | Responses | |||||

|---|---|---|---|---|---|---|

| Slump Flow | p-Value | 28 d-Compressive Strength (MPa) | p-Value | 28 d-Flexural Strength (Mpa) | p-Value | |

| intercept | +752.26 | +113.29 | +23.11 | |||

| Linear terms | ||||||

| A | +49.76 | <0.0001 | +1.32 | 0.0510 | −1.21 | 0.0245 |

| B | +65.17 | <0.0001 | −5.22 | <0.0001 | −2.63 | <0.0001 |

| C | −37.51 | <0.0001 | +1.83 | 0.0103 | +1.39 | 0.0119 |

| Quadratic terms | ||||||

| A2 | ||||||

| B2 | +27.48 | 0.001 | ||||

| C2 | +18.64 | 0.0141 | +2.10 | 0.0034 | ||

| Interaction terms | ||||||

| AB | ||||||

| AC | −1.95 | 0.0298 | ||||

| BC | ||||||

| Other terms | ||||||

| R2 | 0.9333 | 0.8806 | 0.7298 | |||

| Adj-R2 | 0.9094 | 0.8380 | 0.6792 | |||

| Pred-R2 | 0.8245 | 0.7531 | 0.5405 | |||

| F-Value | 20.66 | 20.66 | 14.41 | |||

| Lack of Fit | 1.92 | 1.92 | 2.08 | |||

| Model p-Value | <0.0001 | <0.0001 | <0.0001 | |||

| Response Quantity | Slump Flow/mm | Relative Error | 28 d-Compressive Strength/MPa | Relative Error | 28 d-Flexural Strength/MPa | Relative Error |

|---|---|---|---|---|---|---|

| Predicted value | 815 | — | 123.6 | — | 24.4 | — |

| Test 1 | 800 | −1.84% | 122.3 | −1.05% | 25.2 | 3.28% |

| Test 2 | 795 | −2.45% | 124.1 | 0.4% | 24.1 | −1.23% |

| Test 3 | 810 | −0.6% | 121.7 | −1.54% | 23.6 | −4.51% |

| average | 802 | −1.6% | 122.7 | −0.73% | 24.3 | −0.41% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Wu, J.; Su, L.; Gao, Z.; Yin, C.; Ye, Z. Optimization of Ultra-High Performance Concrete Based on Response Surface Methodology and NSGA-II. Materials 2024, 17, 4885. https://doi.org/10.3390/ma17194885

Wang Z, Wu J, Su L, Gao Z, Yin C, Ye Z. Optimization of Ultra-High Performance Concrete Based on Response Surface Methodology and NSGA-II. Materials. 2024; 17(19):4885. https://doi.org/10.3390/ma17194885

Chicago/Turabian StyleWang, Zhenxing, Jiaming Wu, Lei Su, Zhaolin Gao, Chenglin Yin, and Zhengmao Ye. 2024. "Optimization of Ultra-High Performance Concrete Based on Response Surface Methodology and NSGA-II" Materials 17, no. 19: 4885. https://doi.org/10.3390/ma17194885

APA StyleWang, Z., Wu, J., Su, L., Gao, Z., Yin, C., & Ye, Z. (2024). Optimization of Ultra-High Performance Concrete Based on Response Surface Methodology and NSGA-II. Materials, 17(19), 4885. https://doi.org/10.3390/ma17194885