Bonding Behavior and Quality of Pressureless Ag Sintering on (111)-Oriented Nanotwinned Cu Substrate in Ambient Air

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Characteristics Analysis

3. Experimental Results

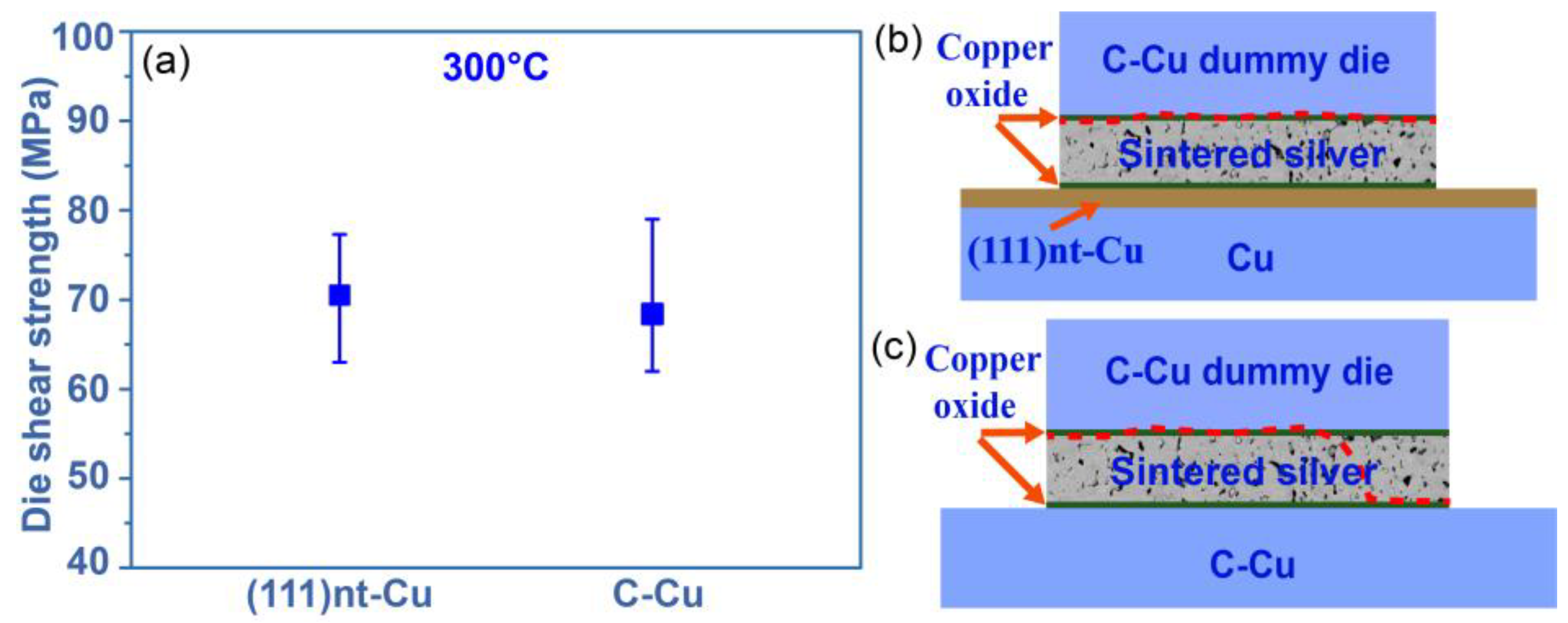

3.1. Ag-Cu Joint at 300 °C

3.2. Ag-Cu Joint at 250 °C

3.3. Ag-Cu Joint at 200 °C

4. Discussion

5. Conclusions

- (1)

- The shear strength on (111)nt-Cu after sintering at 200 °C for 10 min was about 61.0 MPa, lower than that at 300 °C for 10 min. The bonding strength at all of the studied temperatures was within the acceptable range (≥55 MPa).

- (2)

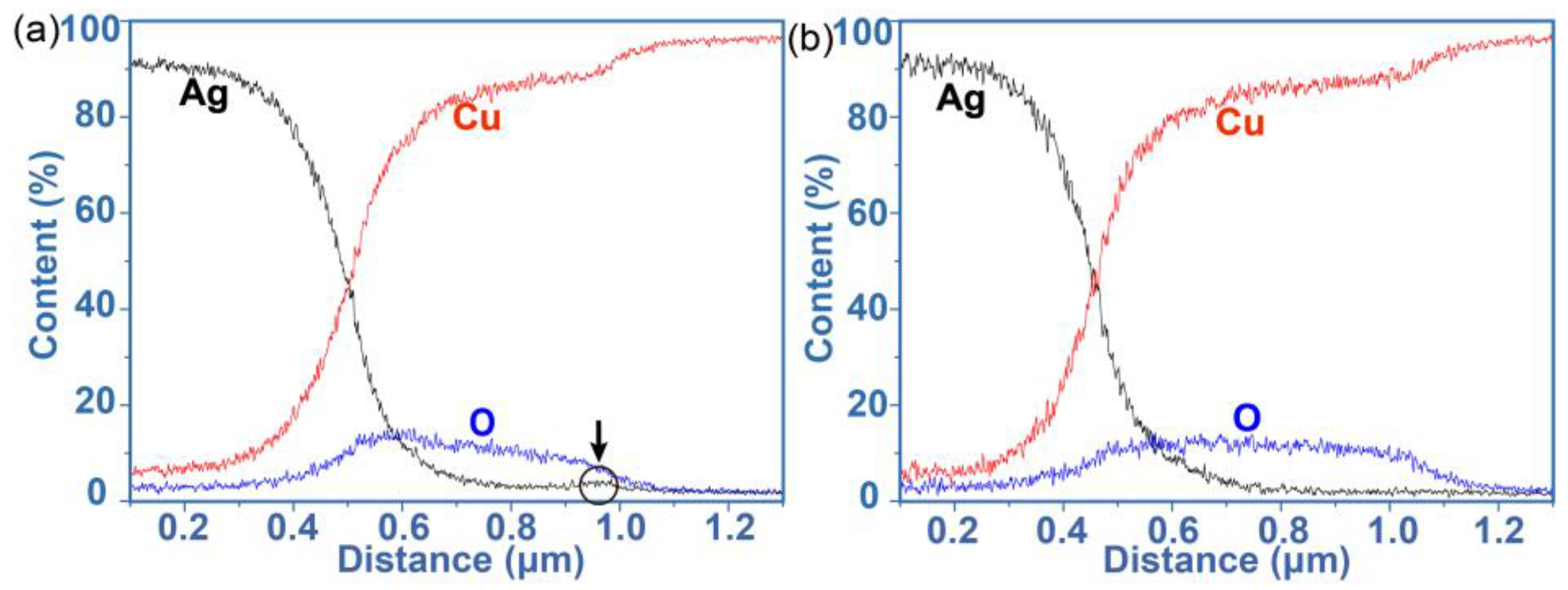

- The thickness of copper oxide on (111)nt-Cu was thinner than that on C-Cu, e.g., 0.17 μm on (111)nt-Cu vs. 0.29 μm on C-Cu at 250 °C, indicating the better oxidation resistance for (111)nt-Cu.

- (3)

- The higher connection ratio of interface of Ag/copper oxide was determined on (111)nt-Cu after 10 min of sintering. Meanwhile, the interface of the copper oxide/Cu substrate showed a tight connection on both substrates, besides at 300 °C/10 min on C-Cu. The better connecting quality could be acquired on (111)nt-Cu after 10 min’ sintering.

- (4)

- Longer sintering time or higher sintering temperature increased the amount of small voids in the interface of copper oxide/(111)nt-Cu. However, these dispersive small voids would not induce failure during the shear test unless the aggregation of them happened to produce delamination. Controlling the sintering time and temperature or controlling the number of impurities on (111)nt-Cu is an efficient way to further improve the occurrence of voids. Sintering at 200 °C for 10 min might be considered to be one of the optimal parameters.

- (5)

- The fracture surface on (111)nt-Cu varied from Ag/die at 300 °C to mixed fracture mode involving the Ag/Cu substrate and Ag/die at 200 °C. The specific failure position happened at the interface between Ag/copper oxide or copper oxide/Cu on both connection structures. That was related with the poor connection between Ag/copper oxide or the formation of huge holes in the interface of copper oxide/C-Cu.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Millan, J.; Godignon, P.; Perpina, X.; Pérez-Tomás, A.; Rebollo, J. A survey of wide bandgap power semiconductor devices. IEEE Trans. Power Electron. 2014, 29, 2155–2163. [Google Scholar] [CrossRef]

- Neudeck, P.G.; Okojie, R.S.; Chen, L.-Y. High-temperature electronics-a role for wide bandgap Semiconductors. Proc. IEEE. 2002, 90, 1065–1076. [Google Scholar] [CrossRef]

- Chen, T.F.; Siow, K.S. Comparing the mechanical and thermal-electrical properties of sintered copper (Cu) and sintered silver (Ag) joints. J. Alloys Compd. 2021, 866, 158783. [Google Scholar] [CrossRef]

- Yan, J.F. A review of sintering-bonding technology using Ag nanoparticles for electronic packaging. Nanomaterials 2021, 11, 927. [Google Scholar] [CrossRef]

- Yang, F.; Hu, B.; Peng, Y.; Han, C.J.; Chen, H.T.; Lee, C.W.; Wei, J.; Li, M.Y. Ag microflake-reinforced nano-Ag paste with high mechanical reliability for high-temperature applications. J. Mater. Sci. Mater. Electron. 2019, 30, 5526–5535. [Google Scholar] [CrossRef]

- Du, C.J.; Li, X.; Mei, Y.H.; Lu, G.Q. Bonding performance of sintered nanosilver joints on bare copper substrates with different grain structures. J. Mater. Sci. Mater. Electron. 2019, 30, 12860–12868. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, C.T.; Zhang, Z.; Ueshima, M.; Sakamoto, T.; Naoe, T.; Nishikawa, H.; Oda, Y.; Suganuma, K. Development of crack-less and deformation-resistant electroplated Ni/electroless Ni/Pt/Ag metallization layers for Ag-sintered joint during a harsh thermal shock. Mater. Des. 2022, 224, 111389. [Google Scholar] [CrossRef]

- Kim, D.J.; Lee, S.M.; Chen, C.T.; Lee, S.J.; Nagao, S.; Suganuma, K. Fracture mechanism of microporous Ag-sintered joint in a GaN power device with Ti/Ag and Ni/Ti/Ag metallization layer at different thermo-mechanical stresses. J. Mater. Sci. 2021, 56, 9852–9870. [Google Scholar] [CrossRef]

- Chen, C.T.; Zhang, Z.; Wang, Q.; Zhang, B.W.; Gao, Y.; Sasamura, T.; Oda, Y.; Ma, N.S.; Suganuma, K. Robust bonding and thermal-stable Ag-Au joint on ENEPIG substrate by micron-scale sinter Ag joining in low temperature pressure-less. J. Alloys Compd. 2020, 828, 154397. [Google Scholar] [CrossRef]

- Lin, L.T.; Li, X.; Zhang, H.Y. An explanation for the effect of Au surface finish on the quality of sintered Ag-Au joints. Appl. Surf. Sci. 2023, 615, 156356. [Google Scholar] [CrossRef]

- Chua, S.T.; Siow, K.S. Microstructural studies and bonding strength of pressureless sintered nano-silver joints on silver, direct bond copper (DBC) and copper substrates aged at 300 C. J. Alloys Compd. 2016, 687, 486–498. [Google Scholar] [CrossRef]

- Chen, C.; Suganuma, K. Ag Sinter Joining Technology for Different Metal Interface (Au, Ag, Ni, Cu, Al) in Wide Band Gap Power Modules. ECS Trans. 2019, 92, 147–153. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Wang, L.; Mei, Y.H.; Lu, G.Q. A novel multiscale silver paste for die bonding on bare copper by low-temperature pressure-free sintering in air. Mater. Des. 2018, 140, 64–72. [Google Scholar] [CrossRef]

- Du, C.J.; Li, X.; Mei, Y.H.; Lu, G.Q. An explanation of sintered silver bonding formation on bare copper substrate in air. Appl. Surf. Sci. 2019, 490, 403–410. [Google Scholar] [CrossRef]

- Li, X.; Lin, L.; Du, C.J.; Li, J. Effect of Oxygen Content on Bonding Performance of Sintered Silver Joint on Bare Copper Substrate. IEEE Trans. Compon. Packag. Manuf. Technol. 2023, 13, 391–398. [Google Scholar] [CrossRef]

- Yang, F.; Zhu, W.; Wu, W.; Ji, H.J.; Hang, C.; Li, M.Y. Microstructural evolution and degradation mechanism of Si-Cu chip attachment using sintered nano-Ag paste during high-temperature ageing. J. Alloys Compd. 2020, 846, 156442. [Google Scholar] [CrossRef]

- Lu, L.; Shen, Y.; Chen, X.; Lu, K. Ultrahigh strength and high electrical conductivity in copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef]

- Hsiao, H.Y.; Liu, C.M.; Lin, H.W.; Liu, C.L.; Huang, Y.S.; Chen, C.; Tu, K.N. Unidirectional growth of microbumps on (111)-oriented and nanotwinned copper. Science 2012, 336, 1007–1010. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.M.; Lin, H.W.; Chu, Y.C.; Chen, C.; Lyu, D.R.; Chen, K.N.; Tu, K.N. Low-temperature direct copper-to-copper bonding enabled by creep on highly (111)-oriented Cu surfaces. Scr. Mater. 2014, 78, 65–68. [Google Scholar] [CrossRef]

- Shie, K.C.; Gusak, A.M.; Tu, K.N.; Chen, C. A kinetic model of copper-to-copper direct bonding under thermal compression. J. Mater. Res. Technol. 2021, 15, 2332–2344. [Google Scholar] [CrossRef]

- Chang, S.Y.; Chu, Y.C.; Tu, K.N.; Chen, C. Effect of anisotropic grain growth on improving the bonding strength of <111>-oriented nanotwinned copper films. Mater. Sci. Eng. A Struct. 2021, 804, 140754. [Google Scholar] [CrossRef]

- Lin, H.; Lu, C.; Liu, C.; Chen, C.; Chen, D.; Kuo, J.C.; Tu, K.N. Microstructure control of unidirectional growth of η-Cu6Sn5 in microbumps on <111> oriented and nanotwinned Cu. Acta Mater. 2013, 61, 4910–4919. [Google Scholar] [CrossRef]

- Zhou, S.Q.; Zhang, Y.B.; Gao, L.Y.; Li, Z.; Liu, Z.Q. The self-healing of Kirkendall voids on the interface between Sn and (111) oriented nanotwinned Cu under thermal aging. Appl. Surf. Sci. 2022, 588, 152900. [Google Scholar] [CrossRef]

- Sa, Z.; Wang, S.; Feng, J.; Wen, J.Y.; Liu, X.D.; Tian, Y.H. Study on Cu6Sn5 morphology and grain orientation transition at the interface of (111) nt-Cu and liquid Sn. Mater. Res. Technol. 2023, 26, 9112–9126. [Google Scholar] [CrossRef]

- Agrawal, P.M.; Rice, B.M.; Thompson, D.L. Predicting trends in rate parameters for self-diffusion on FCC metal surfaces. Sur. Sci. 2002, 515, 21–35. [Google Scholar] [CrossRef]

- Liu, C.M.; Lin, H.W.; Huang, Y.S.; Chu, Y.C.; Chen, C.; Lyu, D.R.; Chen, K.N.; Tu, K.N. Low-temperature direct copper-to-copper bonding enabled by creep on (111) surfaces of nanotwinned Cu. Sci. Rep. 2015, 5, 9734. [Google Scholar] [CrossRef]

- Xu, Z.G.; Zhou, S.Q.; Li, X.; Liu, Z.Q. Excellent Oxidation Resistance and Solder Wettability of (111)-Oriented Nanotwinned Cu. Acta Metall. Sin. 2024, 59, 1–17. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, C.; Yang, Y.; Zhang, H.; Kim, D.J.; Sugahara, T.; Nagao, S.; Suganuma, K. Low-temperature and pressureless sinter joining of Cu with micron/submicron Ag particle paste in air. J. Alloys Compd. 2019, 780, 435–442. [Google Scholar] [CrossRef]

- Yang, S.; Xu, M.; Yu, C. Evolution Modes and Self-Healing Phenomenon of Kirkendall Voids at the Sn/Cu Solder Joints. In Transactions on Intelligent Welding Manufacturing; Springer: Singapore, 2019; pp. 129–137. [Google Scholar] [CrossRef]

- Yu, J.; Kim, J.Y. Effects of residual S on Kirkendall void formation at Cu/Sn-3.5Ag solder joints. Acta Mater. 2008, 56, 5514–5523. [Google Scholar] [CrossRef]

- Shang, P.J.; Liu, Z.Q.; Pang, X.Y.; Li, D.X.; Shang, J.K. Growth mechanisms of Cu3Sn on polycrystalline and single crystalline Cu substrates. Acta Mater. 2009, 57, 4697–4706. [Google Scholar] [CrossRef]

- Huang, M.L.; Wu, Y. Growth Mechanism of Interfacial IMCs on (111) Preferred Orientation Nanotwinned Cu UBM for 3D IC Packaging. In Proceedings of the 2020 IEEE 70th ECTC, Orlando, FL, USA, 3–30 June 2020; pp. 1881–1887. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, X.; He, W.; Liang, J.; Yang, H.-K.; Zhou, C.; Liu, Z.-Q. Bonding Behavior and Quality of Pressureless Ag Sintering on (111)-Oriented Nanotwinned Cu Substrate in Ambient Air. Materials 2024, 17, 4423. https://doi.org/10.3390/ma17174423

Huang X, He W, Liang J, Yang H-K, Zhou C, Liu Z-Q. Bonding Behavior and Quality of Pressureless Ag Sintering on (111)-Oriented Nanotwinned Cu Substrate in Ambient Air. Materials. 2024; 17(17):4423. https://doi.org/10.3390/ma17174423

Chicago/Turabian StyleHuang, Xingming, Wei He, Jialong Liang, Hao-Kun Yang, Chunliang Zhou, and Zhi-Quan Liu. 2024. "Bonding Behavior and Quality of Pressureless Ag Sintering on (111)-Oriented Nanotwinned Cu Substrate in Ambient Air" Materials 17, no. 17: 4423. https://doi.org/10.3390/ma17174423

APA StyleHuang, X., He, W., Liang, J., Yang, H.-K., Zhou, C., & Liu, Z.-Q. (2024). Bonding Behavior and Quality of Pressureless Ag Sintering on (111)-Oriented Nanotwinned Cu Substrate in Ambient Air. Materials, 17(17), 4423. https://doi.org/10.3390/ma17174423