Experimental and Numerical Investigation of the Flexural Behavior of Reinforced-Concrete Beams Utilizing Waste Andesite Dust

Abstract

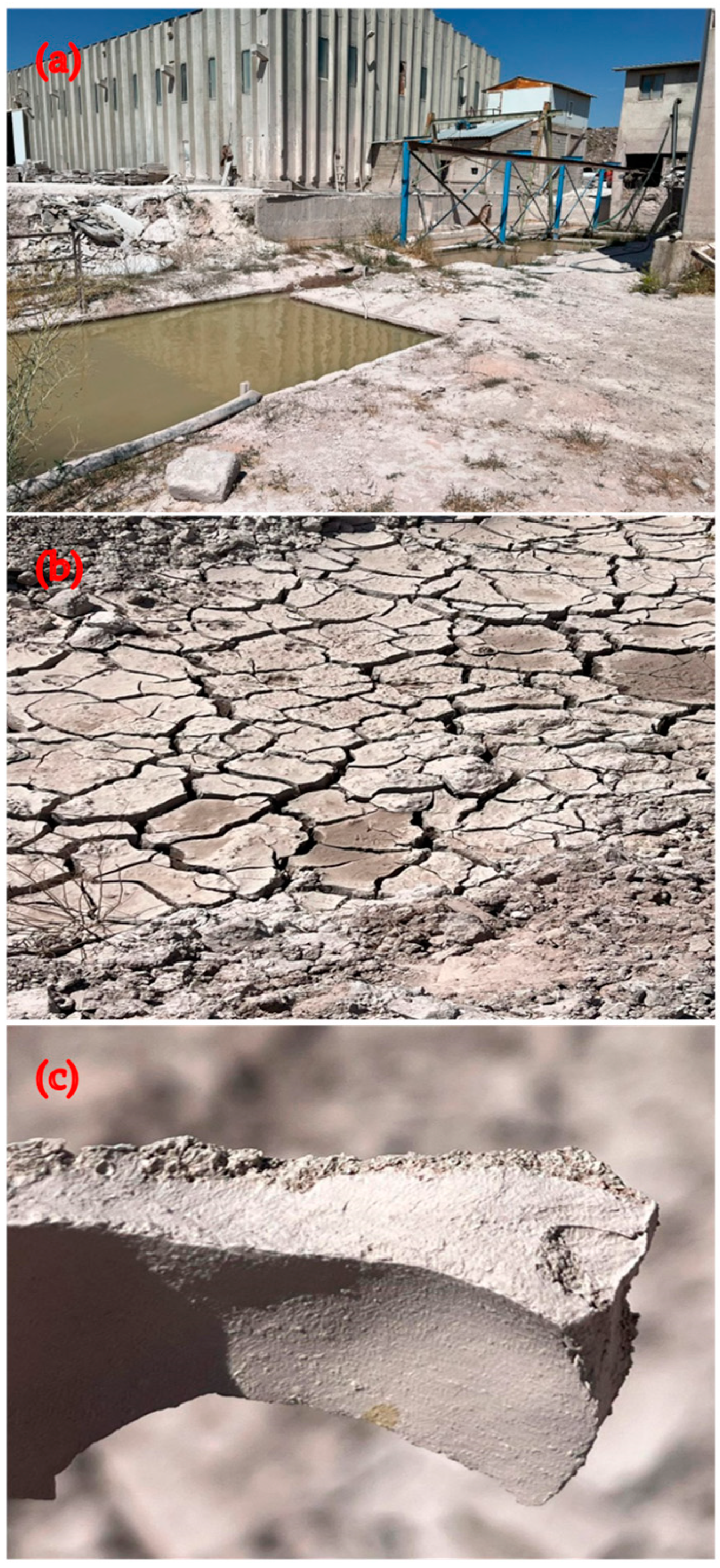

1. Introduction

2. Study Objectives

3. Experimental Test Configuration

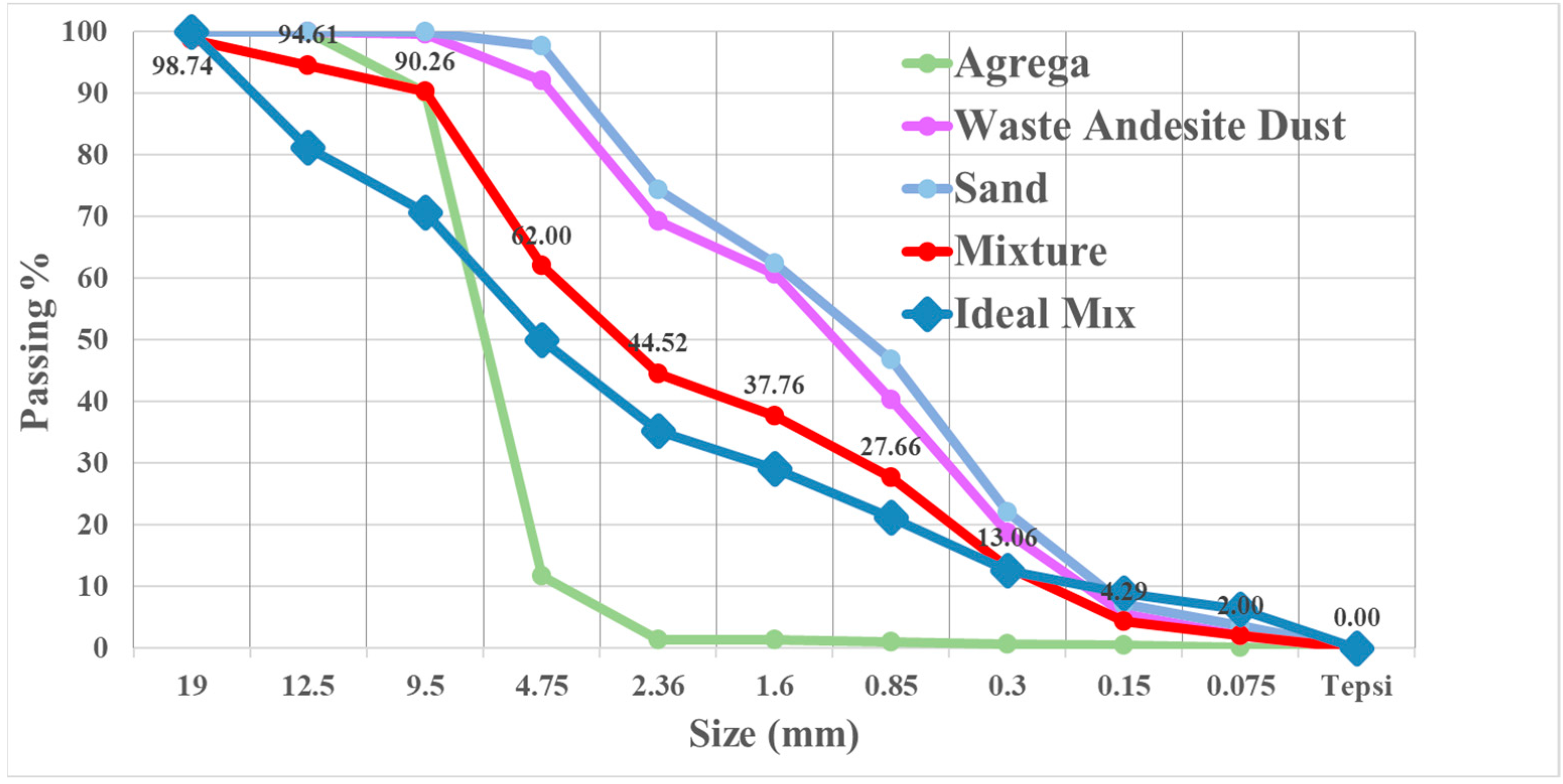

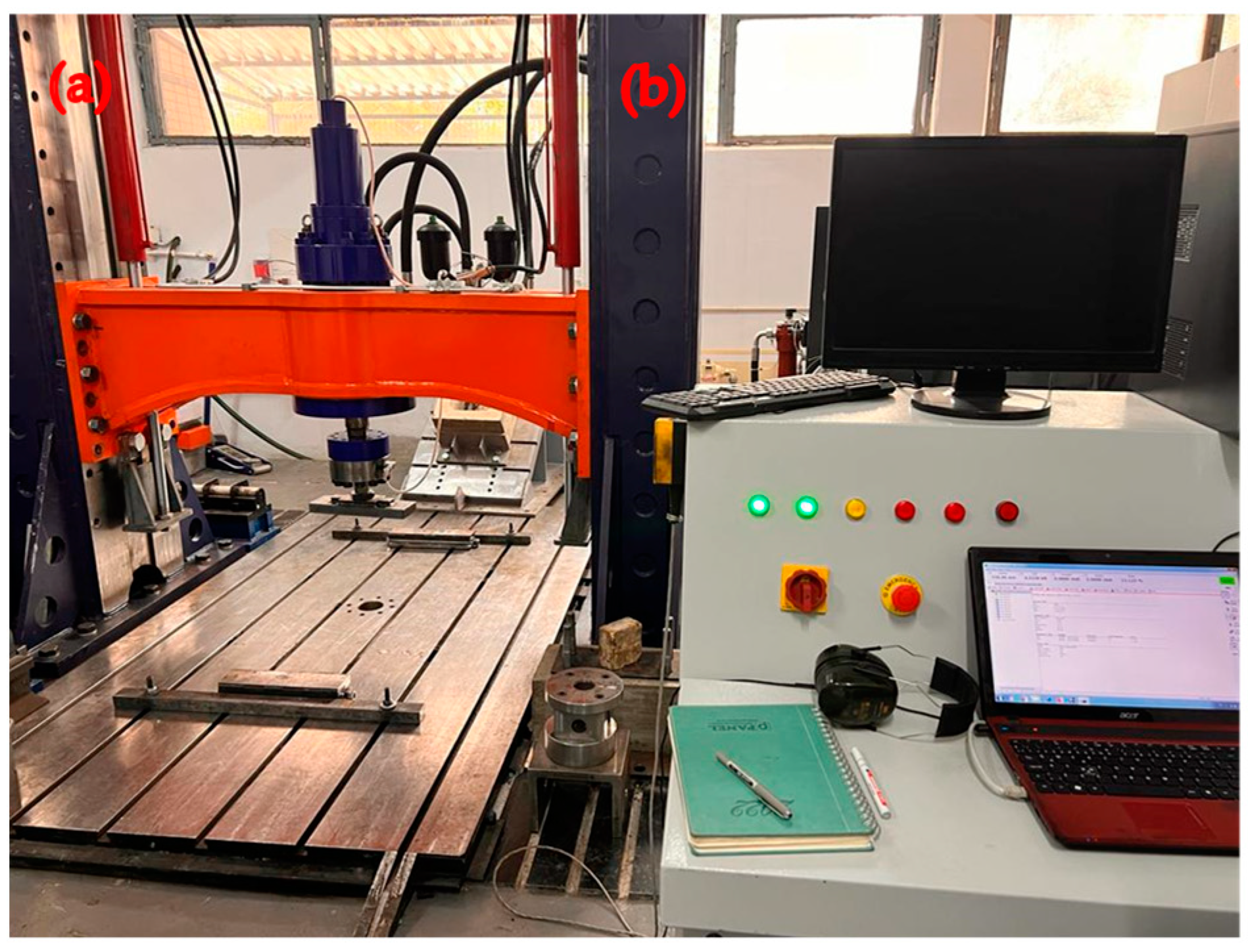

Characteristics of the Materials and Examination Method

4. Modeling RCBs Using 3D Nonlinear FEM

5. Structure of Investigational Tests

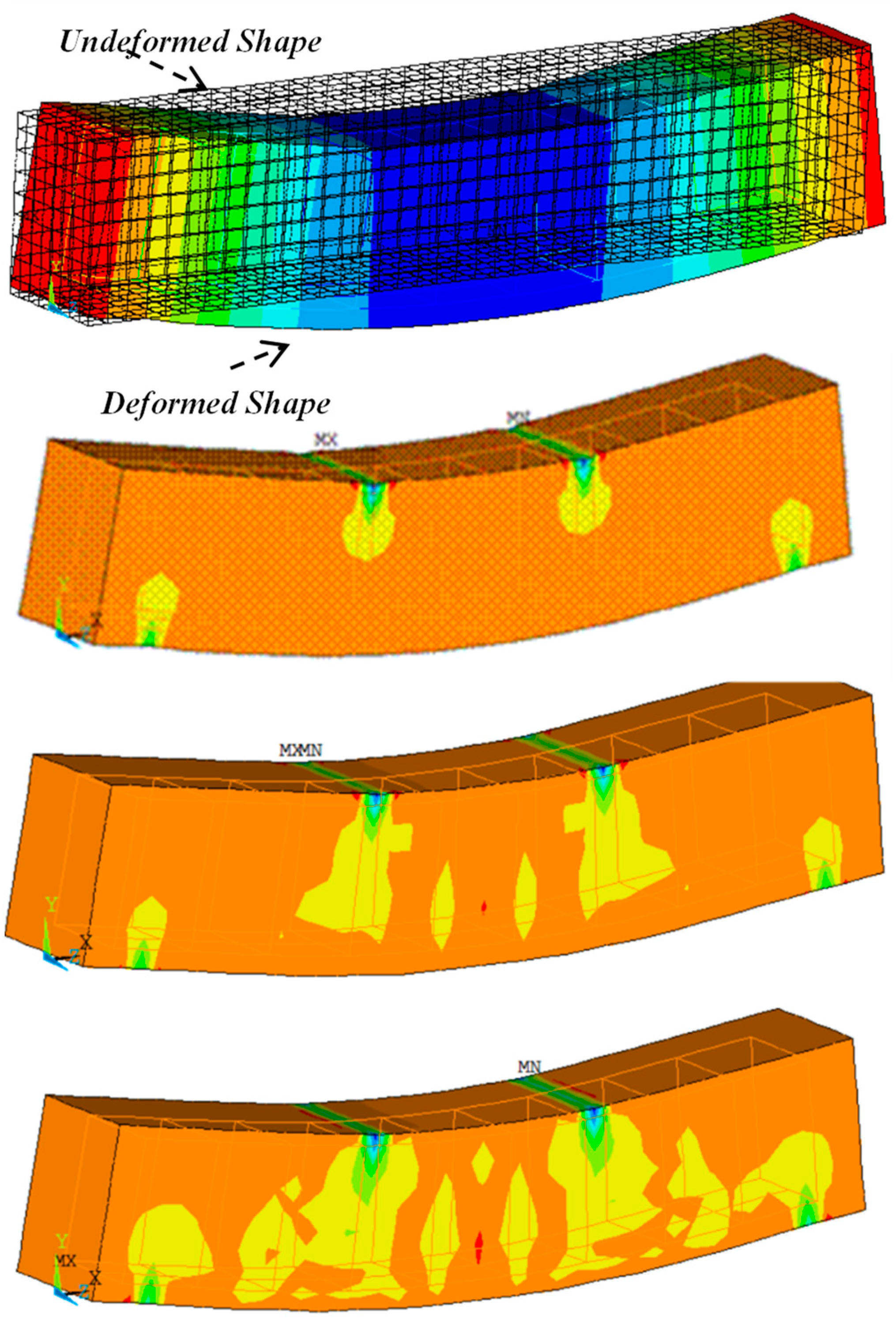

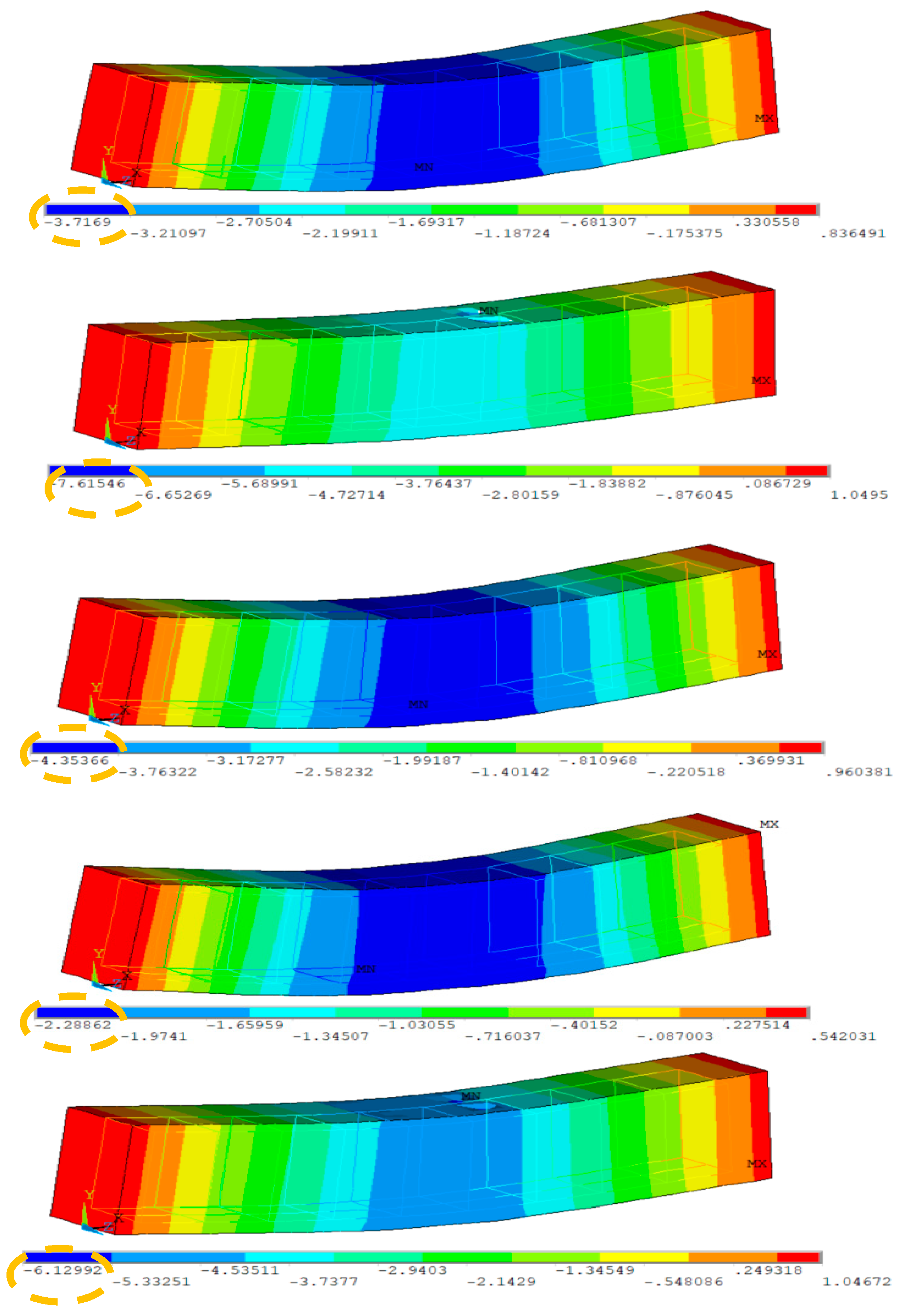

6. Investigational Test Outcomes and Analysis

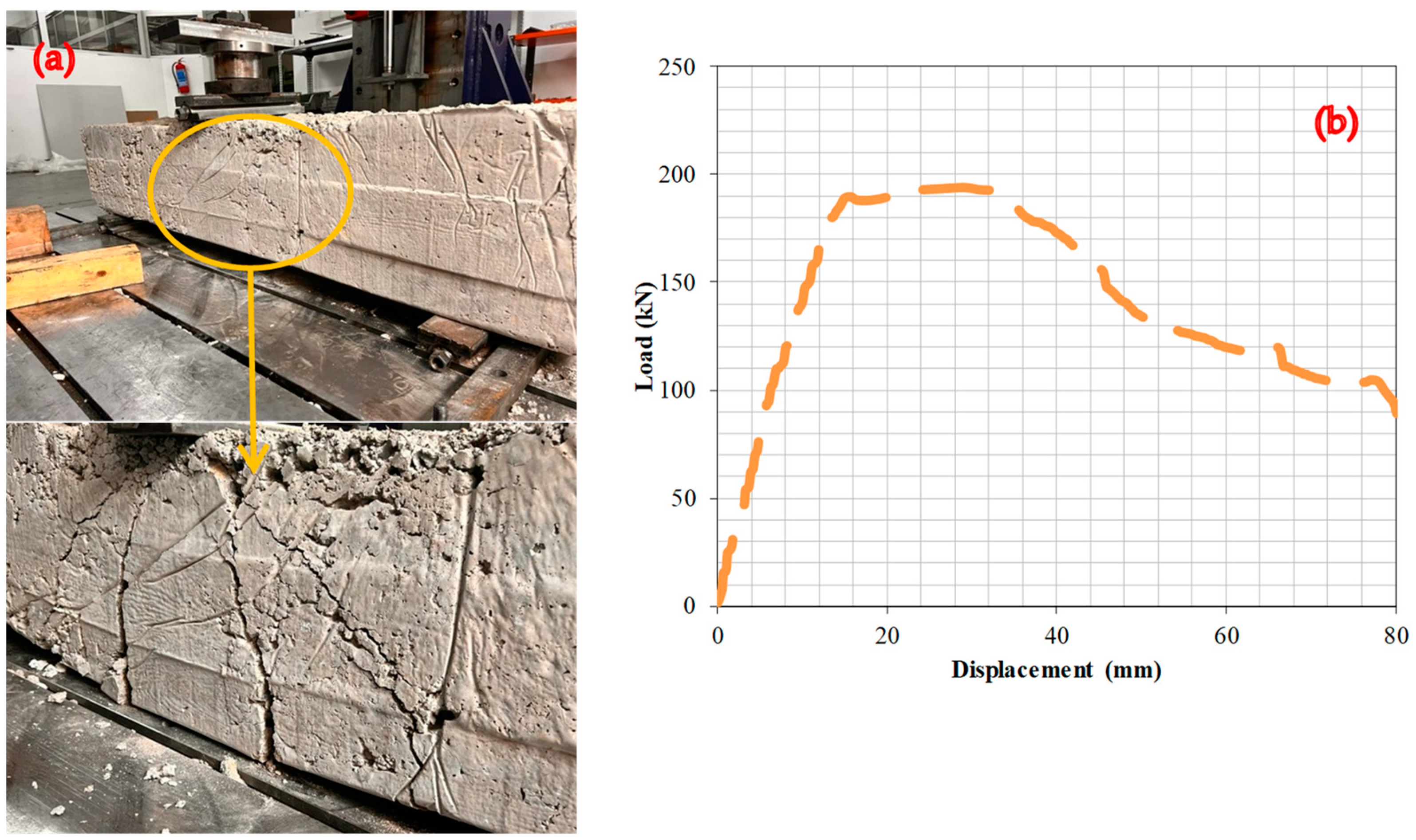

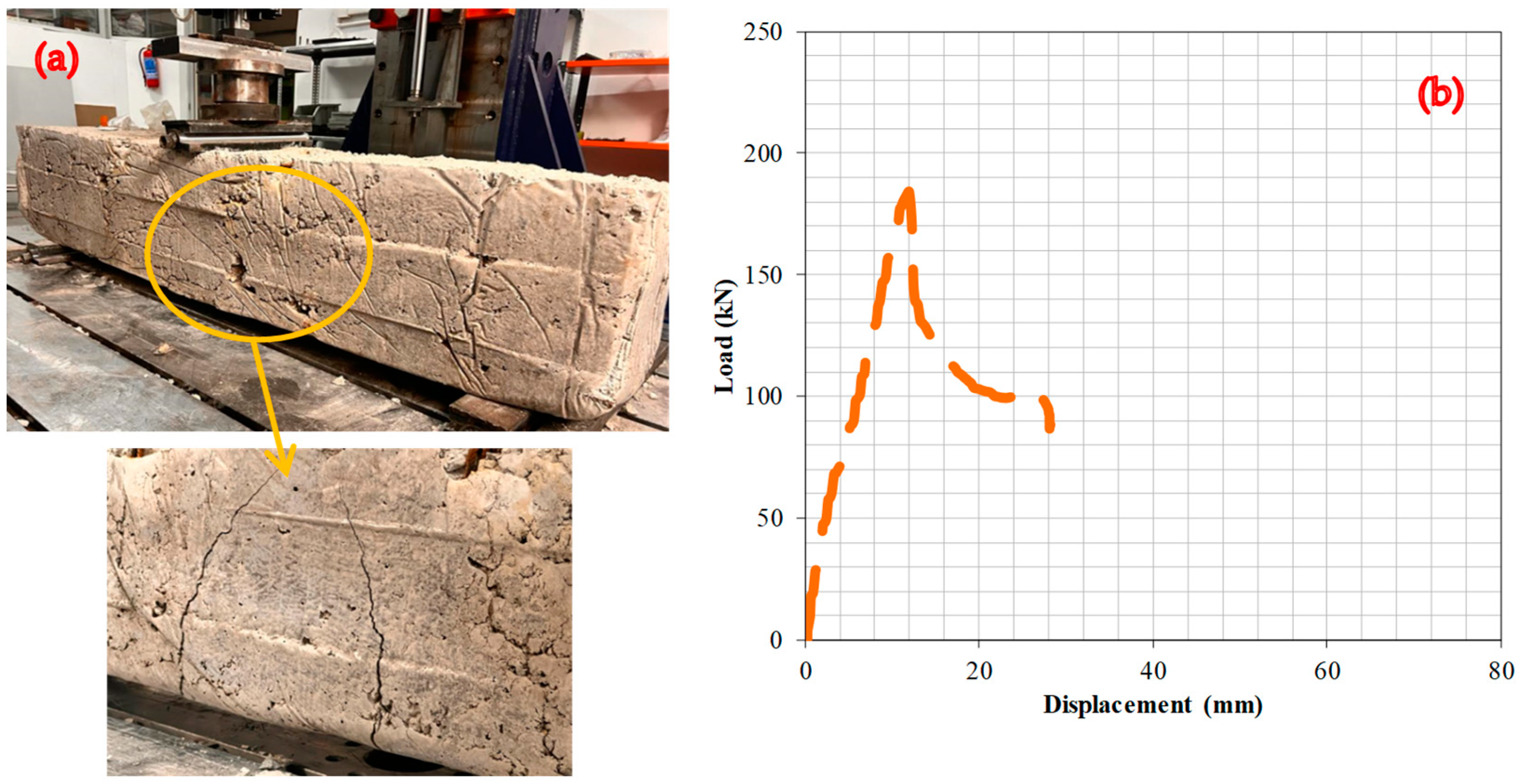

6.1. Experiment 1: Analysis of the Fracture Behavior and Load–Deformation Characteristics of RCBs Containing 0% WAD

6.2. Experiment 2: Analysis of the Fracture Behavior and Load–Deformation Characteristics of RCBs Containing 10% WAD

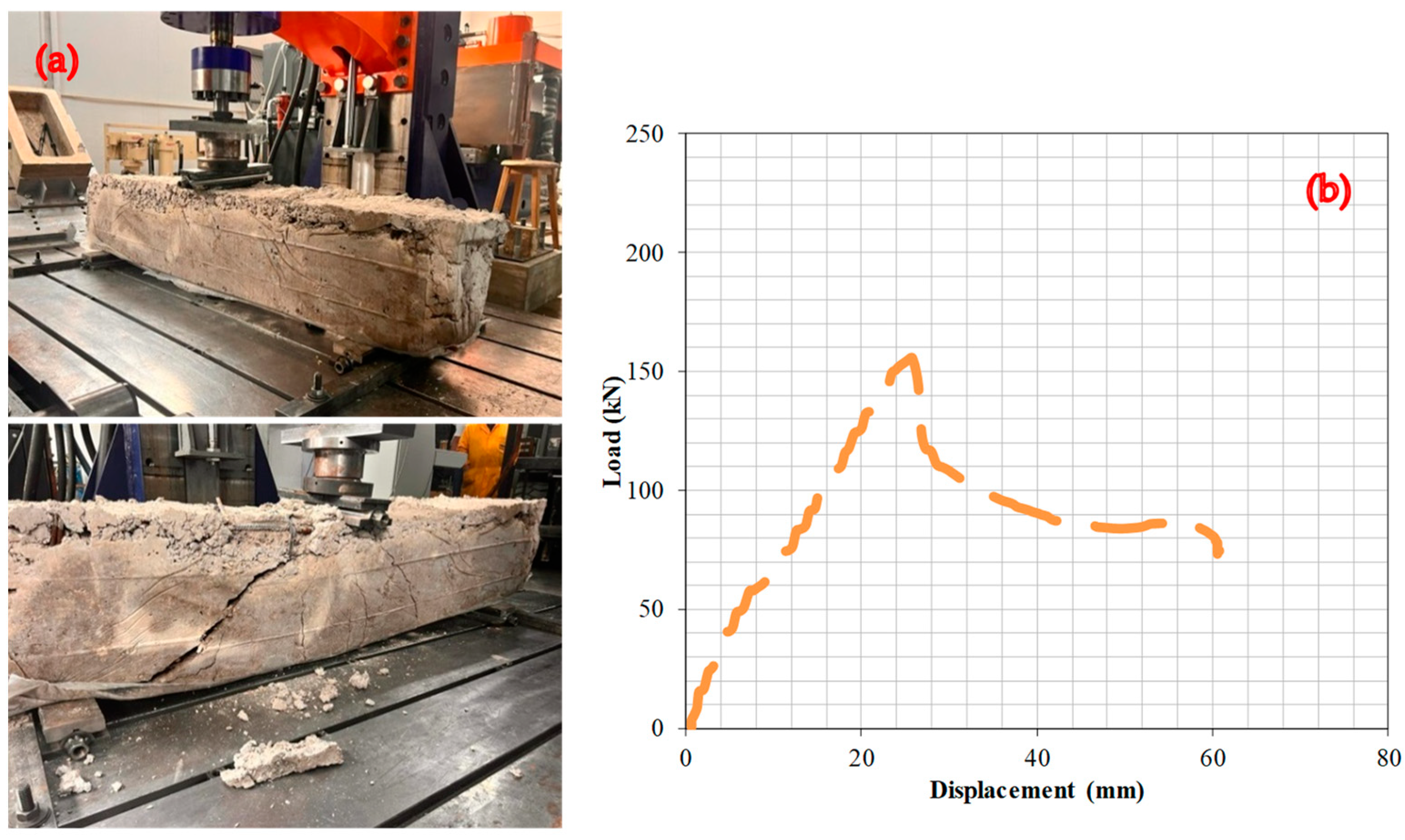

6.3. Experiment 3: Analysis of the Fracture Behavior and Load–Deformation Characteristics of RCBs Containing 20% WAD

6.4. Experiment 4: Analysis of the Fracture Behavior and Load–Deformation Characteristics of RCBs Containing 30% WAD

6.5. Experiment 5: Analysis of the Fracture Behavior and Load–Deformation Characteristics of RCBs Containing 40% WAD

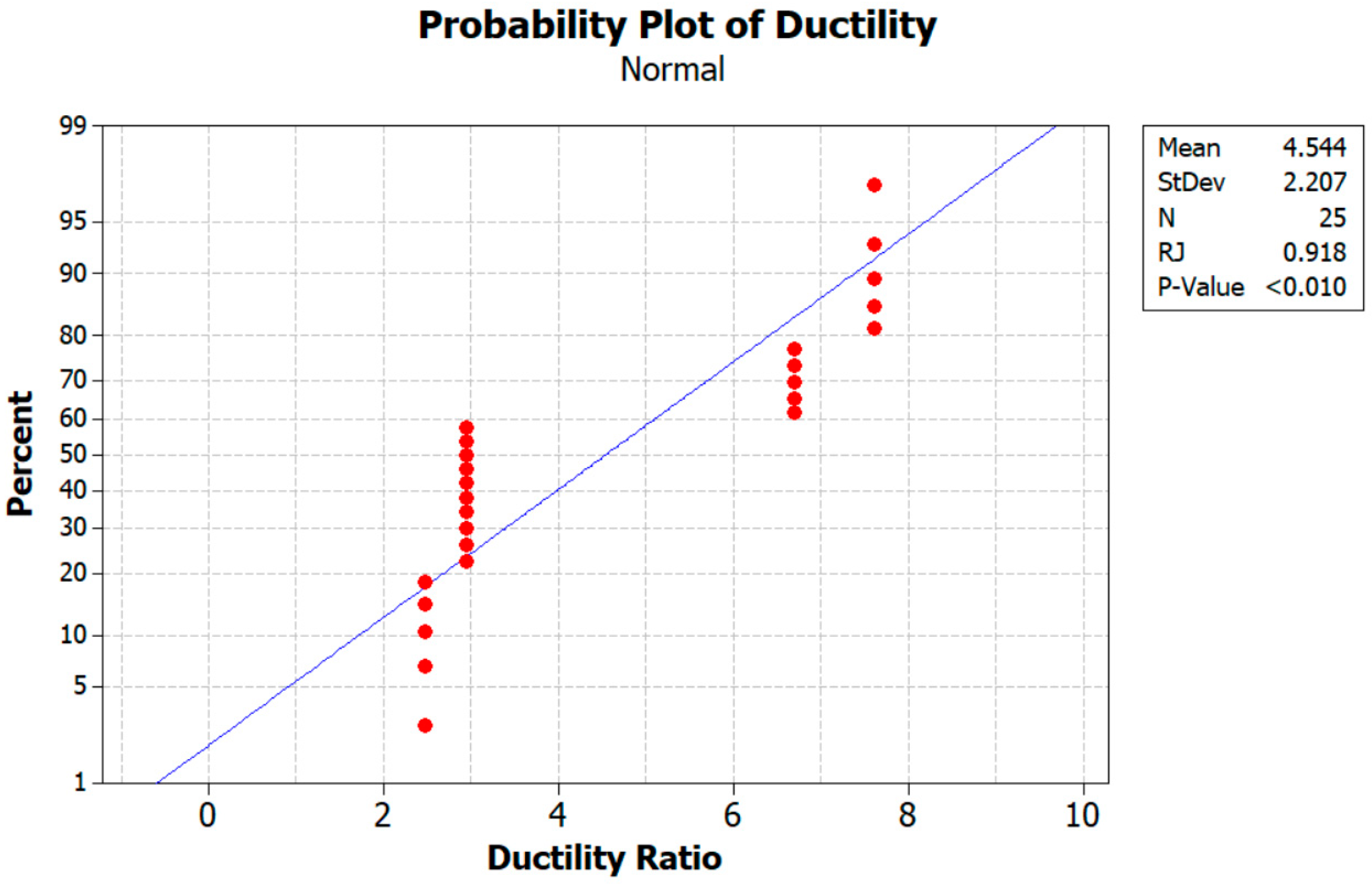

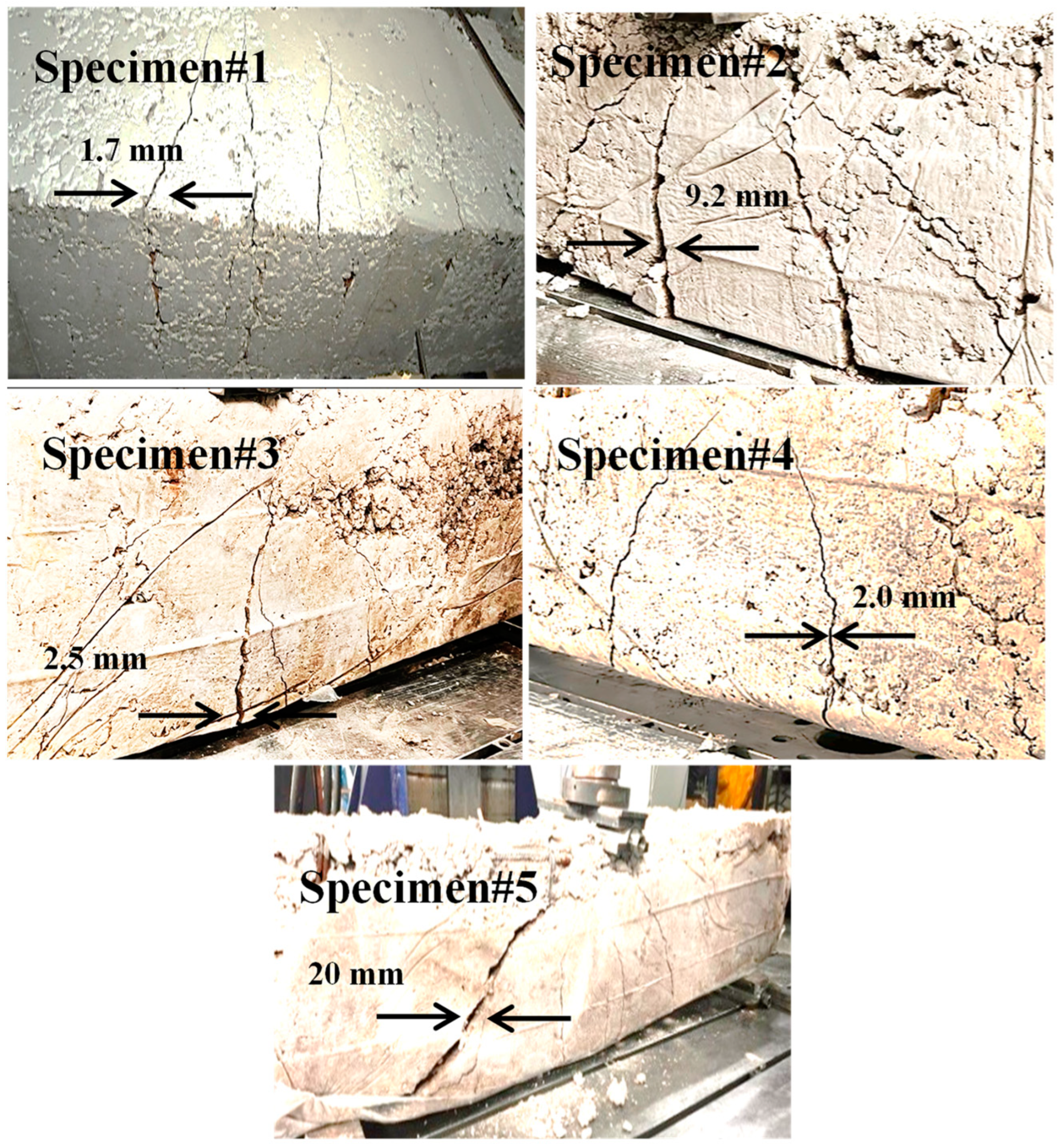

7. Fracture Characteristics

8. Analysis of FEM Processes

9. Conclusions

- The compression test results revealed that increasing WAD content in concrete consistently reduced its compressive strength. With no WAD, the compressive strength was 23.5 MPa, but it dropped to 22.2 MPa at 10% WAD and further declined to 16.8 MPa at 40% WAD. The reduction in compressive strength was particularly rapid beyond 20% WAD.

- A depletion in compressive strength can mainly be attributed to the dilution of cement because the efficiency factor drops as the andesite content increases. It is found that such an impact can hardly be compensated for by the small pozzolanic activity of andesite.

- The RCB containing 10% WAD exhibited slightly lower load-bearing and ductility capacities compared to reference beam; however, these properties experienced significant declines when the WAD content exceeded 10%. At 40% WAD, both load-bearing capacity and ductility were substantially reduced. Based on the experimental findings, replacing cement with 10% WAD is an optimum choice for producing eco-friendly concrete.

- With acceptable variations in the results, the results strongly suggest that FE modeling is an excellent alternative to laboratory experiments of RCBs with WAD. Therefore, it may be possible to accurately predict the behavior of RCBs in real-life scenarios using FE simulations.

- In light of the findings presented above, the recycling of WAD in mixes has the potential to have a beneficial influence on the elimination of the adverse environmental effects produced by waste storage areas created by natural-stone processing industries, as well as on the reduction of the costs associated with the manufacturing of materials.

Recommendations for Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Behforouz, B.; Memarzadeh, P.; Eftekhar, M.; Fathi, F. Regression and ANN models for durability and mechanical characteristics of waste ceramic powder high performance sustainable concrete. Comput. Concr. 2020, 25, 119–132. [Google Scholar] [CrossRef]

- Ansari, M.; Safiey, A. Corrosion effects on mechanical behavior of steel fiber reinforced concrete, including fibers from recycled tires. Comput. Concr. 2020, 26, 367–375. [Google Scholar] [CrossRef]

- Ren, R.; Qi, L.; Xue, J.; Zhang, X.; Ma, H.; Liu, X.; Ozbakkaloglu, T. Concrete-steel bond-slip behavior of recycled concrete: Experimental investigation. Steel Compos. Struct. Int. J. 2021, 38, 241–255. [Google Scholar]

- Nematzadeh, M.; Baradaran-Nasiri, A.; Hosseini, M. Effect of pozzolans on mechanical behavior of recycled refractory brick concrete in fire. Struct. Eng. Mech. Int’l J. 2019, 72, 339–354. [Google Scholar]

- Ali, L.; El Ouni, M.H.; Raza, A.; Kahla, N.B. Investigation of FRP-reinforced recycled concrete compressive members: Experimental and theoretical analysis. Steel Compos. Struct. Int. J. 2021, 41, 99–113. [Google Scholar]

- Ozkilic, Y.O.; Zeybek, O.; ihsan Celik, A.; Althaqafi, E.; Mydin, M.A.O.; Dulaimi, A.; Karalar, M.; Jagadesh, P. Fresh and hardened properties of expansive concrete utilizing waste aluminum lathe. Steel Compos. Struct. 2024, 50, 595–608. [Google Scholar] [CrossRef]

- Almeshal, I.; Özkılıç, Y.O.; Aksoylu, C.; Karalar, M.; Alharthai, M. Ductility and strength of reinforced concrete beams strengthened with aluminum CNC waste. Struct. Concr. 2024. [Google Scholar] [CrossRef]

- Sariisik, A.; Sariisik, G.; Şentürk, A. Applications of glaze and decor on dimensioned andesites used in construction sector. Constr. Build. Mater. 2011, 25, 3694–3702. [Google Scholar] [CrossRef]

- Hamidi, M.; Kacimi, L.; Cyr, M.; Clastres, P. Evaluation and improvement of pozzolanic activity of andesite for its use in eco-efficient cement. Constr. Build. Mater. 2013, 47, 1268–1277. [Google Scholar] [CrossRef]

- Davraz, M.; Ceylan, H.; Topçu, İ.B.; Uygunoğlu, T. Pozzolanic effect of andesite waste powder on mechanical properties of high strength concrete. Constr. Build. Mater. 2018, 165, 494–503. [Google Scholar] [CrossRef]

- Labbaci, Y.; Abdelaziz, Y.; Mekkaoui, A.; Alouani, A.; Labbaci, B. The use of the volcanic powders as supplementary cementitious materials for environmental-friendly durable concrete. Constr. Build. Mater. 2017, 133, 468–481. [Google Scholar] [CrossRef]

- Kawabata, Y.; Dunant, C.; Yamada, K.; Scrivener, K. Impact of temperature on expansive behavior of concrete with a highly reactive andesite due to the alkali–silica reaction. Cem. Concr. Res. 2019, 125, 105888. [Google Scholar] [CrossRef]

- Sogancioglu, M.; Yel, E.; Yilmaz-Keskin, U.S. Utilization of andesite processing wastewater treatment sludge as admixture in concrete mix. Constr. Build. Mater. 2013, 46, 150–155. [Google Scholar] [CrossRef]

- Çelikten, S. Mechanical and microstructural properties of waste andesite dust-based geopolymer mortars. Adv. Powder Technol. 2021, 32, 1–9. [Google Scholar] [CrossRef]

- Ceylan, H.; Davraz, M. Atık andezit tozu ve uçucu küllerin betonda kullanımının karşılaştırılması. Doğal Afetler Çevre Derg. 2019, 5, 110–115. [Google Scholar] [CrossRef][Green Version]

- Özkan, Ş.; Ceylan, H. The effects on mechanical properties of sustainable use of waste andesite dust as a partial substitution of cement in cementitious composites. J. Build. Eng. 2022, 58, 104959. [Google Scholar] [CrossRef]

- Soykan, O.; Özel, C.; Öcal, C. Arduvaz ve Andezit’in Beton Agregası Olarak Kulanılabilirliğinin Araştırılması. Süleyman Demirel Üniversitesi Fen Bilim. Enstitüsü Derg. 2015, 19, 69–74. [Google Scholar]

- Eken, M. Mechanical and Durability Properties of Concrete with Volcanic Rock Additives. J. Mater. Civ. Eng. 2023, 35, 04023196. [Google Scholar] [CrossRef]

- Uzun, İ. Andezitin Asfalt Betonunda Agrega Olarak Kullanılabilirliğinin Araştırılması; SDÜ Fen Bilimleri Enstitüsü: Yerleşkesi, Turkey, 2011. [Google Scholar]

- Uzun, İ.; Terzi, S. Evaluation of andesite waste as mineral filler in asphaltic concrete mixture. Constr. Build. Mater. 2012, 31, 284–288. [Google Scholar] [CrossRef]

- Orhan, M.; Işık, N.; Topal, T.; Özer, M. Effect of weathering on the geomechanical properties of andesite, Ankara–Turkey. Environ. Geol. 2006, 50, 85–100. [Google Scholar] [CrossRef]

- Özkan, Ş. The impact of ternary hybrid fibers on the mechanical characteristics of cement-based composites with waste andesite dust substitution. J. Build. Eng. 2024, 88, 109102. [Google Scholar] [CrossRef]

- Bayraktar, O.Y.; Yakupoglu, U.; Benli, A. Slag/diatomite-based alkali-activated lightweight composites containing waste andesite sand: Mechanical, insulating, microstructural and durability properties. Arch. Civ. Mech. Eng. 2023, 23, 230. [Google Scholar] [CrossRef]

- Özkan, Ş.; Ceylan, H. Atık Malzeme Olarak Uçucu Kül ve Andezit Tozu İçeren PVA Lif Donatılı Çimento Esaslı Kompozitlerin Basınç Dayanımının Tahmininde Yanıt Yüzey Metodolojisinin Kullanılması. Afyon Kocatepe Üniversitesi Fen Ve Mühendislik Bilim. Derg. 2024, 24, 103–116. [Google Scholar]

- Handayani, A.F.; Rosyidah, D.H.; Sulaksitaningrum, R.; Susanto, P.B.; Umniati, S. Andesite waste powder as mineral admixture in concrete: A Review. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2023; p. 01030. [Google Scholar]

- Çelikten, S.; Sarıdemir, M.; Soloğlu, M. Effects of elevated temperatures and cooling regimes on the waste andesite dust-based geopolymer mortars. Constr. Build. Mater. 2024, 422, 135857. [Google Scholar] [CrossRef]

- Martín, D.A.; Costafreda, J.L.; Sanjuán, M.A.; Costafreda-Velázquez, J.L. Mineral, Chemical and Technical Characterization of Altered Pyroxenic Andesites from Southeastern Spain for Use as Eco-Efficient Natural Materials. Appl. Sci. 2023, 13, 12866. [Google Scholar] [CrossRef]

- ANSYS, R. Academic Research Mechanical, Release 19.2, Help System; ANSYS, Inc.: Canonsburg, PA, USA, 2020. [Google Scholar]

- Sabbağ, N.; Uyanık, O. Determination of the reinforced concrete strength by apparent resistivity depending on the curing conditions. J. Appl. Geophys. 2018, 155, 13–25. [Google Scholar] [CrossRef]

- Gemi, L.; Alsdudi, M.; Aksoylu, C.; Yazman, S.; Ozkilic, Y.O.; Arslan, M.H. Optimum amount of CFRP for strengthening shear deficient reinforced concrete beams. Steel Compos. Struct. Int. J. 2022, 43, 735–757. [Google Scholar]

- Karalar, M. Experimental and numerical investigation on flexural and crack failure of reinforced concrete beams with bottom ash and fly ash. Iran. J. Sci. Technol. Trans. Civ. Eng. 2020, 44, 331–354. [Google Scholar] [CrossRef]

- Karalar, M.; Bilir, T.; Çavuşli, M. 3D experimental and numerical investigation on crack behaviour of RC beams under% 75 bottom ash ratio. In Proceedings of the Structures20 Congress, Seoul, Republic of Korea, 25–28 August 2020. [Google Scholar]

- Karalar, M.; Ozturk, H.; Ozkilic, Y.O. Experimental and numerical investigation on flexural response of reinforced rubberized concrete beams using waste tire rubber. Steel Compos. Struct. 2023, 48, 43–57. [Google Scholar] [CrossRef]

- Korkut, F.; Karalar, M. Investigational and numerical examination on bending response of reinforced rubberized concrete beams including plastic waste. Materials 2023, 16, 5538. [Google Scholar] [CrossRef]

- Minitab Inc. MINITAB Release 17: Statistical Software for Windows; Minitab Inc.: State College, PA, USA, 2014; Volume 371. [Google Scholar]

- Casas, J.R.; Pascual, J. Debonding of FRP in bending: Simplified model and experimental validation. Constr. Build. Mater. 2007, 21, 1940–1949. [Google Scholar] [CrossRef]

- Ceci, A.M.; Casas, J.R.; Ghosn, M. Statistical analysis of existing models for flexural strengthening of concrete bridge beams using FRP sheets. Constr. Build. Mater. 2012, 27, 490–520. [Google Scholar] [CrossRef][Green Version]

| Mix Number # | Statement |

|---|---|

| Mix 1 | RCB including 0% WAD |

| Mix 2 | RCB including 10% WAD |

| Mix 3 | RCB including 20% WAD |

| Mix 4 | RCB including 30% WAD |

| Mix 5 | RCB including 40% WAD |

| Material (kg/m3) | WAD | ||||

|---|---|---|---|---|---|

| 0% | 10% | 20% | 30% | 40% | |

| Cement | 350 | 315 | 280 | 245 | 210 |

| Sand | 800 | 800 | 800 | 800 | 800 |

| Coarse aggregate | 920 | 920 | 920 | 920 | 920 |

| Water | 165 | 165 | 165 | 165 | 165 |

| Andesite | 0 | 80 | 160 | 240 | 320 |

| Component | Cement | Andesite |

|---|---|---|

| SiO2 (%) | 18.85 | 56.93 |

| Al2O3 (%) | 4.80 | 16.86 |

| Fe2O3 (%) | 2.40 | 5.39 |

| CaO (%) | 62.80 | 5.49 |

| MgO (%) | 2.50 | 2.89 |

| Na2O + K2O (%) | 1.14 | 9.89 |

| SO3 (%) | 3.69 | — |

| Free CaO (%) | 0.90 | — |

| Loss on ignition | 3.50 | 2.55 |

| Density (g/cm3) | 3.12 | 2.65 |

| Test No. | Pmax (kN) | Def. at the Pmax (mm) | δu (mm) | Stiffness at Pmax (kN/mm) | Pu (0.85 Pmax) (kN) | Displ. at Yield δy (mm) | Stiffness at Yield (kN/mm) | Ductility Ratio |

|---|---|---|---|---|---|---|---|---|

| Test #1 | 228.5 | 27.8 | 32.7 | 8.2 | 194.2 | 4.2 | 45.3 | 7.62 |

| Test #2 | 193.9 | 28.8 | 80.1 | 6.7 | 164.8 | 11.9 | 13.8 | 6.70 |

| Test #3 | 191.7 | 24.8 | 42.3 | 7.7 | 162.9 | 17.0 | 9.6 | 2.48 |

| Test #4 | 184.3 | 11.9 | 28.0 | 15.4 | 156.6 | 9.5 | 16.5 | 2.96 |

| Test #5 | 155.6 | 25.8 | 60.6 | 6.0 | 132.2 | 20.5 | 6.5 | 2.96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korkut, F.; Karalar, M.; Motameni, A.; Althaqafi, E.; Özdöner, N.; Özkılıç, Y.O. Experimental and Numerical Investigation of the Flexural Behavior of Reinforced-Concrete Beams Utilizing Waste Andesite Dust. Materials 2024, 17, 4413. https://doi.org/10.3390/ma17174413

Korkut F, Karalar M, Motameni A, Althaqafi E, Özdöner N, Özkılıç YO. Experimental and Numerical Investigation of the Flexural Behavior of Reinforced-Concrete Beams Utilizing Waste Andesite Dust. Materials. 2024; 17(17):4413. https://doi.org/10.3390/ma17174413

Chicago/Turabian StyleKorkut, Fuat, Memduh Karalar, Ali Motameni, Essam Althaqafi, Nebi Özdöner, and Yasin Onuralp Özkılıç. 2024. "Experimental and Numerical Investigation of the Flexural Behavior of Reinforced-Concrete Beams Utilizing Waste Andesite Dust" Materials 17, no. 17: 4413. https://doi.org/10.3390/ma17174413

APA StyleKorkut, F., Karalar, M., Motameni, A., Althaqafi, E., Özdöner, N., & Özkılıç, Y. O. (2024). Experimental and Numerical Investigation of the Flexural Behavior of Reinforced-Concrete Beams Utilizing Waste Andesite Dust. Materials, 17(17), 4413. https://doi.org/10.3390/ma17174413