3.1. Derivation of the Joint Elastic Modulus Formula

The elastic modulus of the joint is a significant indicator of the component’s strength, with higher values indicating greater resistance to deformation [

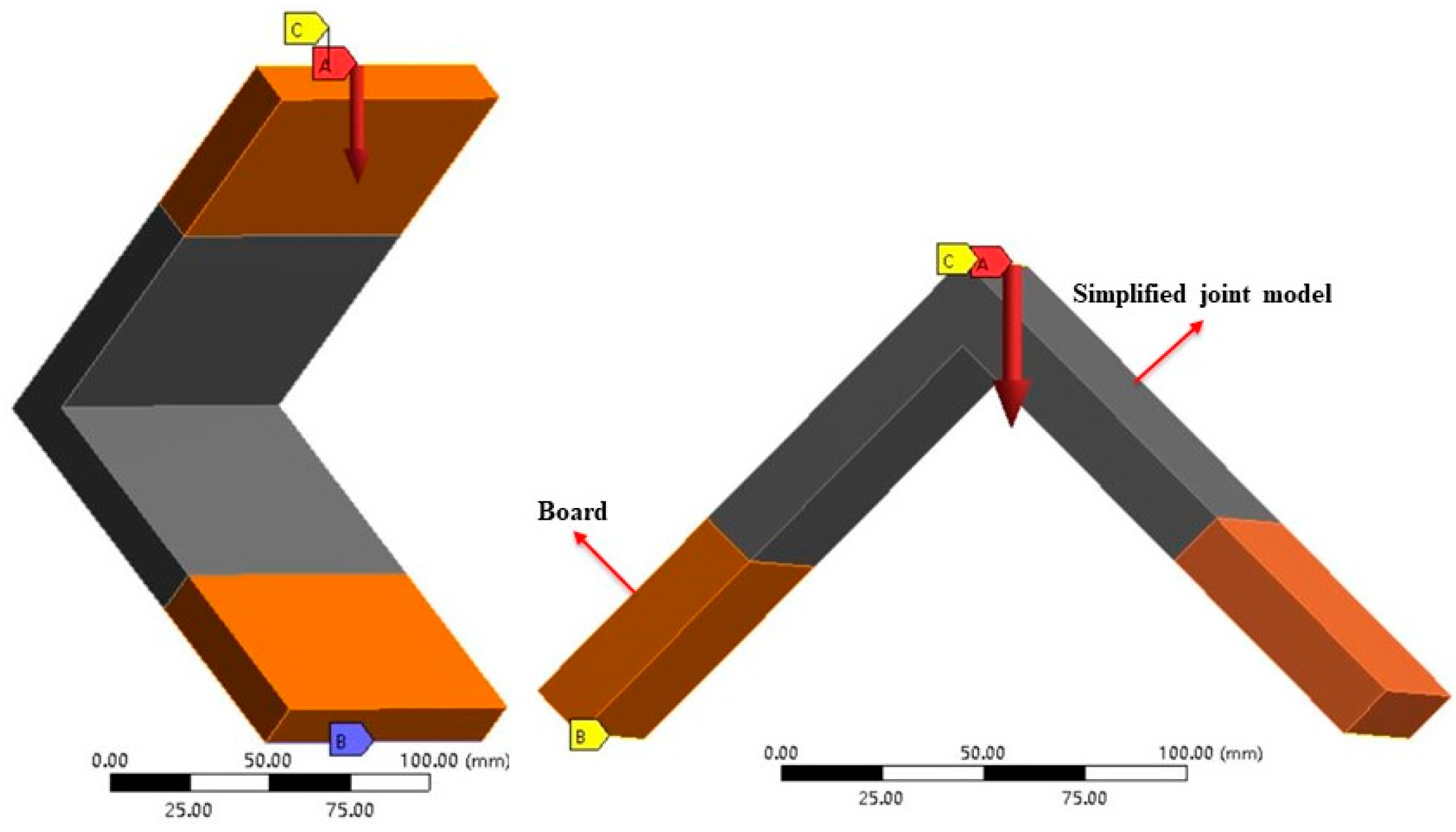

29]. Under small deformation conditions, the bending of the components’ arms can be considered equivalent to that of a combined cantilever beam. The deflection of the cantilever beam was calculated using the superposition technique. The theoretical calculation formula for component deformation established the correlation between the elastic modulus and the length of the simplified joint. Therefore, by adjusting the length of the joint and determining its elastic modulus, this value was used in the FEA of a simplified joint model to calculate its deflection. Subsequently, the deflection was compared with empirical data in order to determine the most favorable simplified model. The procedure for determining the elastic modulus when subjected to compressive and tensile loads for joints was as follows.

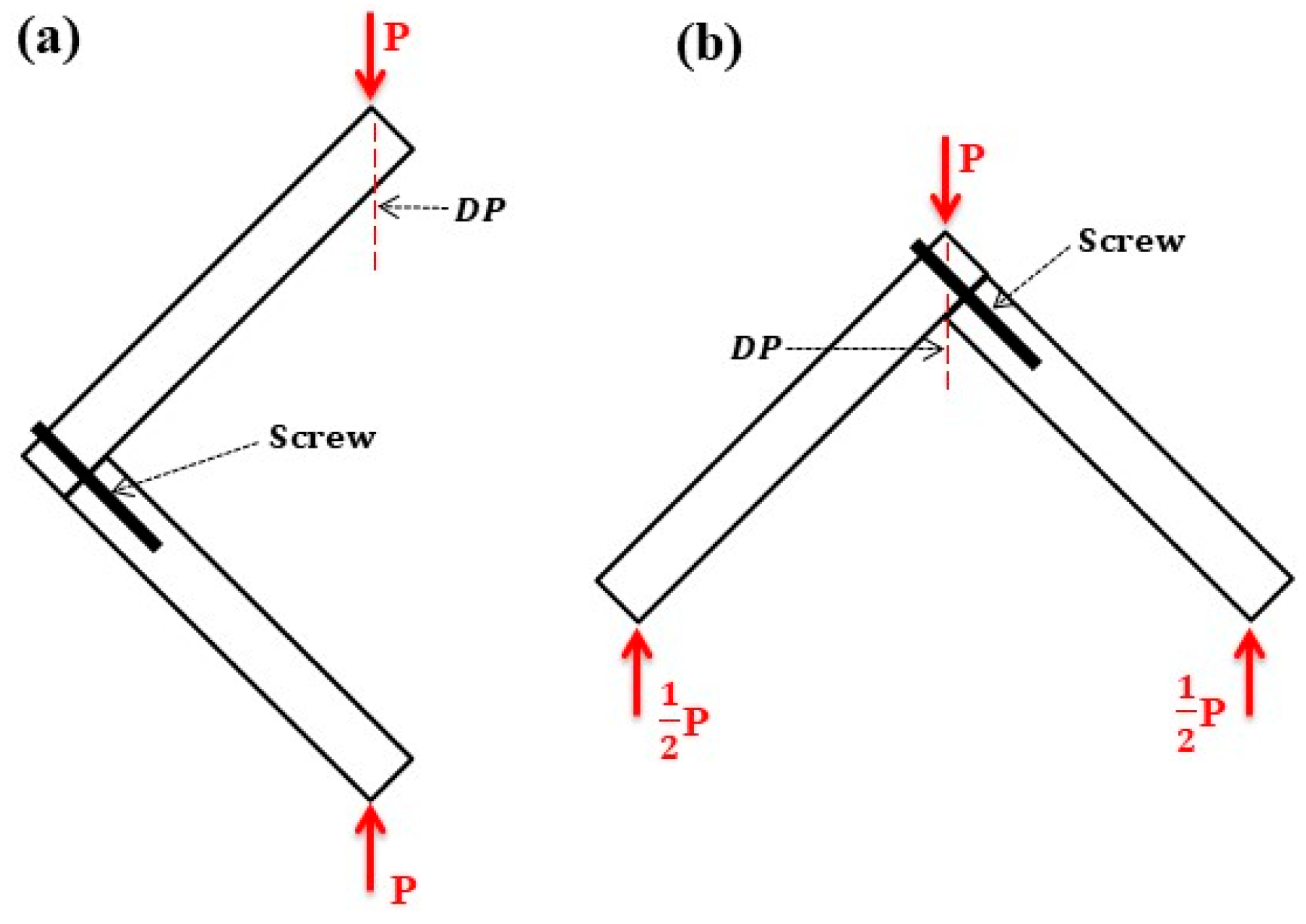

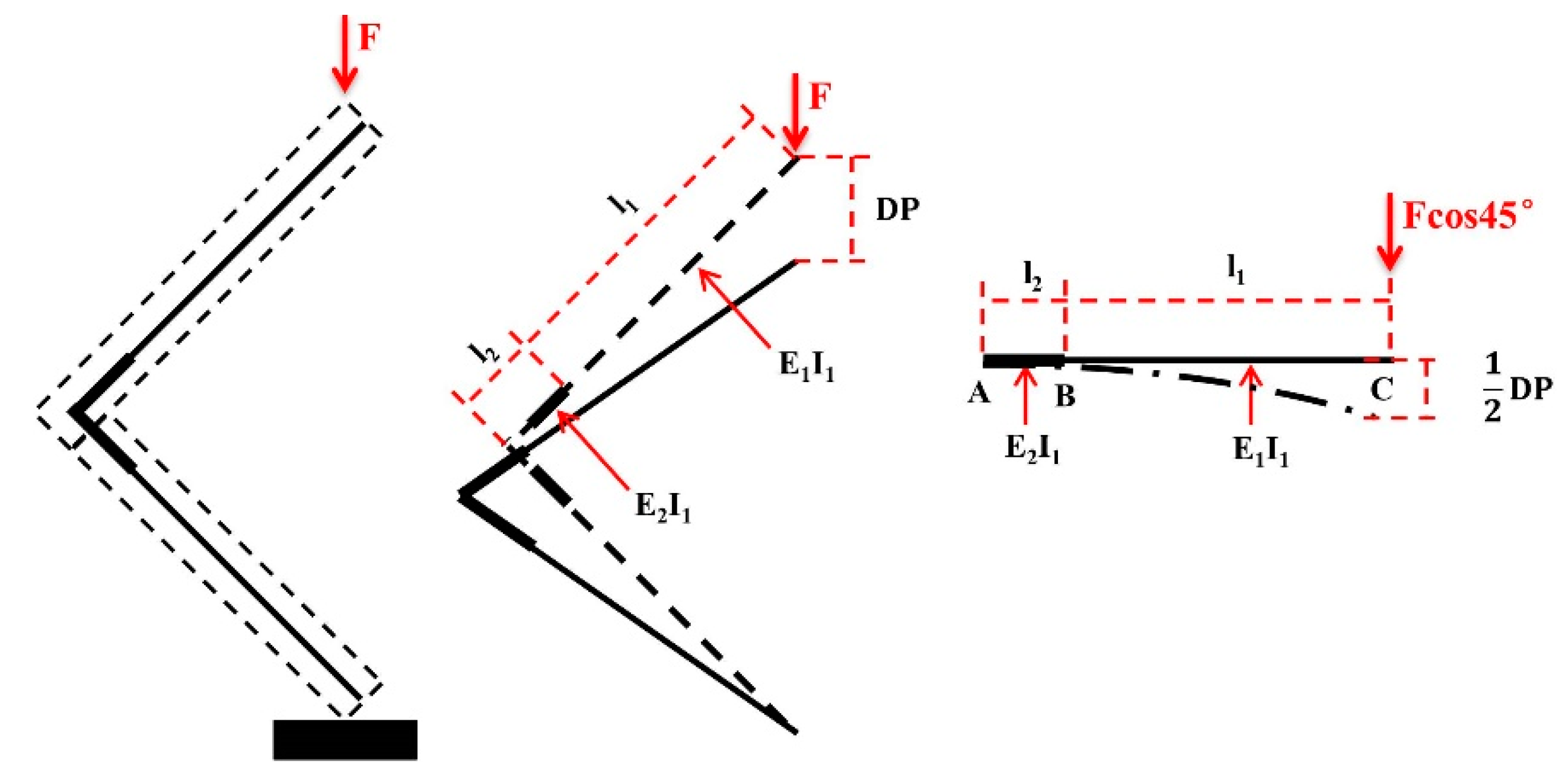

Figure 5 depicts the component simplification process during compression. The AB segment first underwent rigidifying, followed by analysis of the cantilever beam’s bending deformation.

When rigidifying the BC section, point B was subject to force

F and torque

FI, and the point’s deflection

yB and angle

θB were calculated as follows:

The deflection at point C, denoted as

yC2, is influenced by the deformation at point B and equal to the sum of the deflection at point B and the upward deflection (

θBl1) at point C caused by the angle of rotation

θB.

The deflection at point C is as follows:

The following is obtained:

The deflection at point C is obtained:

Solving this equation, the following is obtained:

where

P is the vertical part of the force acting on the cantilever and has the value

Fcosα (α = 45°); F is the force collected during the experiment;

F = 0.4

Fmax − 0.1

Fmax;

Fmax is the maximum of the force (N);

E1 is the board’s elastic modulus;

E2 is the joint’s elastic modulus;

I1 is the board’s inertia moment;

I1 =

Lb3/12 (

b is the board’s thickness (m) and

L is its width (m));

l1 is the joint’s arms’ length (m);

l2 is the simplified joint model’s length (m);

l2 =

xb,

x ranges from 1 to 10;

DP =

DP0.4max −

DP0.1max;

DPPmax is the displacement at which the force reaches its maximum value (m).

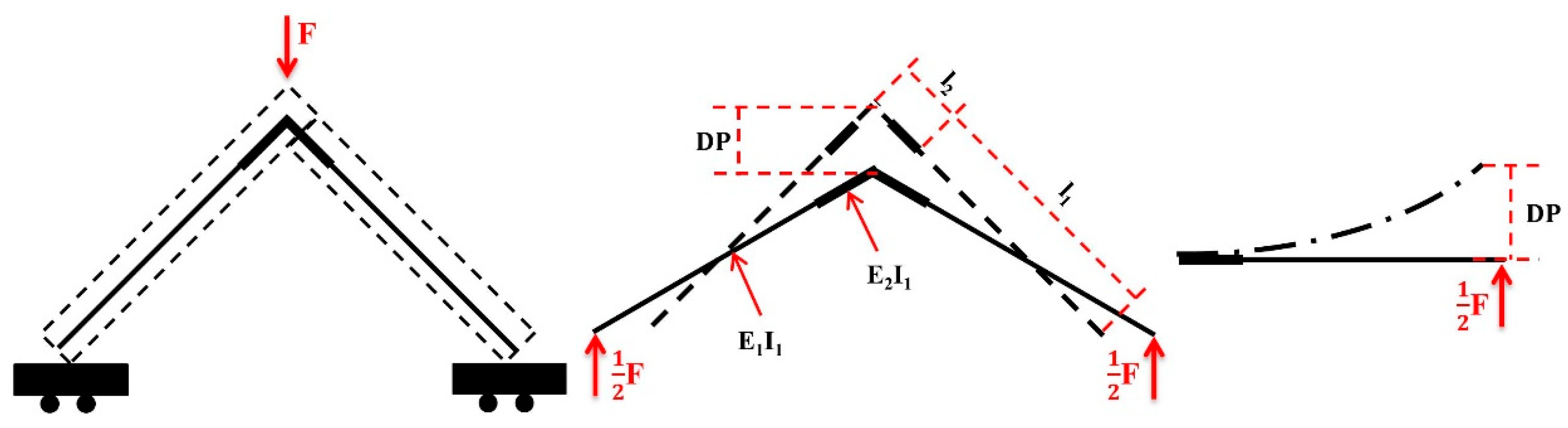

Under tension, the component’s force situation was similar to that under compression. However, the joint deflection under tension aligned with the cantilever deflection and did not display a 2:1 relationship.

P = 1/2

Fcos

α (

α = 45°).

Figure 6 shows the component simplification process in tension.

The following formula determines the deflection at point C of the tempered AB section of the cantilever beam:

After tempering the BC section, the deflection

yB and angle of turn B at point B were calculated as follows:

The formula for the deflection at point C is as follows:

As a result, the joint’s elasticity modulus under tension assumes the following form:

where

P is the vertical part of the force acting on the cantilever and has the value

Fcosα (α = 45°);

F is the force collected during the experiment;

F = 0.4

Fmax − 0.1

Fmax;

Fmax is the maximum of the force (N);

E1 is the board’s elastic modulus;

E2 is the joint’s elastic modulus;

I1 is the board’s inertia moment;

I1 =

Lb3/12 (

b is the board’s thickness (m) and

L is its width (m));

l1 is the joint’s arms’ length (m);

l2 is the simplified joint model’s length (m);

l2 =

xb,

x ranges from 1 to 10;

DP =

DP0.4max −

DP0.1max;

DPPmax is the displacement at which the force reaches its maximum value (m).

3.2. Elastic Modulus of Joints

Equations (11) and (20) calculate the joint elastic modulus of the L-shaped component.

Figure 7 shows the joint elastic moduli of the BOSB and WOSB components.

Figure 7a,b show that the joint elastic modulus increased proportionally to the length of the simplified BOSB joints. When the length of the simplified BOSB joints was six times the board’s thickness, the elastic modulus reached a stable state. Furthermore, the elastic modulus increased initially and then decreased as the spacing increased under compressive load. The BOSB component with a spacing of 48 mm had the highest elastic modulus, followed by those with spacings of 64 mm and 16 mm. The BOSB component with a spacing of 32 mm exhibited the lowest elastic modulus. Under tension, the elastic modulus decreased as the screw spacing increased. Similarly, in the case of the WOSB components, the joint elastic modulus initially increased and then decreased as the spacing increased. Furthermore, it was observed that the WOSB components with a 48 mm screw spacing had the highest compressive joint elastic modulus. This was the same for the BOSB components. As the screw spacing increased, the tension elastic modulus increased. Additionally, the BOSB components had a significantly higher joint elasticity modulus than the WOSB components. This is due to the strong dependence between the load of the connections and the density of the boards [

32]. The mean density of the BOSB was 806.61 kg·m

−3, which is about 1.4 times that of the WOSB. The Young’s modulus and tensile strength of the BOSB were both about three times those of the WOSB [

19]. The changes were the same according to the stiffness analysis. This suggests that the joints’ elastic modulus can be used as a good indicator for the deformation resistance of components. The joint elastic modulus dates of the components fixed with screws were fitted using the exponential function

y = a − bcx, and the fitting results are shown in

Table 4. In the table, it can be seen that the fitting degree R

2 can reach more than 99%, and the fitting effect is very good.

The simplified model of components was imported into ANSYS Workbench software. The simplified joint model was assigned a joint elastic modulus, while the remaining parts were assigned a material elastic modulus. The load was 0.4 Pmax, and the constraint conditions imposed were identical to those employed in the physical experiments.

Figure 8 displays the numerical simulation results illustrating the deflection of the L-shaped components fixed by screws. As the simplified joint’s length increased, the component’s deflection increased. When the length of the simplified joint reached six times the board’s thickness, this deflection stabilized. This result is consistent with the patterns observed in the joint elastic modulus.

To verify the accuracy of the FEA, a simplified joint model was used, and its deflection was compared with the experimental results under the same load. The model’s length was six times the board’s thickness.

Figure 9 depicts the screw-fixed component’s experimental and numerical deflections under a load of 0.4 Pmax. As shown in the figure, the numerical and experimental results follow the same pattern. Most of the numerical deflection falls within the range of the experimental results, which proves that the FEA is correct. When the components were compressed, the numerical deflections for the BOSB and WOSB were about 5–11% and 13–19% lower than the experimental results. When the components were tensed, the reductions were about 2–8% and 13–15%, respectively. These findings suggest that the numerical and experimental data are more in line with each other for the BOSB components. They also suggest that FEA can simulate BOSB furniture structures more effectively than WOSB ones. Furthermore, it is worth noting that this simplified model method significantly reduces the time requirements for FEA in comparison to using actual models, highlighting its precision and efficiency.

This paper evaluates the applicability of the model simplification method by analyzing L-shaped components with common eccentric connections and wood dowel pins commonly found on the market.

Figure 10 presents the joint elastic moduli of a simplified joint fixed with five common connectors. It is evident from the figure that as the length of the simplified joint increased, the joint elastic modulus of the components also increased and gradually stabilized.

Figure 10a shows that the BOSB components attached with wooden dowel pins had the highest compression elastic modulus. Those attached with metal nuts and two-in-one connectors trailed behind. The elastic moduli of those attached with converse-spine and nylon nuts were lower. The tensile elastic moduli were higher for the BOSB components attached with wooden dowel pins and metal nuts, whereas they were lower for those attached with converse-spine nuts. Regarding the WOSB components, those fixed with wooden dowel pins had the highest joint elastic modulus, followed by those secured using nylon nuts, while those connected using two-in-one connectors displayed lower values. In addition, the elastic modulus of the components fixed with a common connection exhibited a similar variation trend to stiffness.

Table 5 shows the fitting results between the joint elastic modulus and the joint length

l2/b of the components fixed with connectors using the exponential function

y = a − bcx. In the table, it is shown that the fitting coefficients

R2 are all greater than 0.99, indicating that the equation is very well fitted.

The FEA program imported the simplified model of screw-secured L-shaped components. Then, a load of 0.4 times the maximum load (Pmax) was applied to the model while maintaining the same restrictions as in the experiment. Next, the numerical deflection was compared with the experimental results, as depicted in

Figure 11. The figure shows that not only do the FEA results exhibit similar variation trends as the experimental results, but they also show smaller discrepancies in values.

Particularly, the components fastened with nylon nuts and wooden dowel pins showed a larger deflection difference between the numerical and experimental results, whereas those fastened with metal nuts and converse-spine nuts showed a smaller difference. The numerical simulation findings for the BOSB components, when secured by metal nuts and subjected to compressive and tensile stresses, showed decreases of 0.08% and 9%, respectively, compared to the experimental data. For the components secured with converse-spine nuts, the differences were 0.2% and 0.3%, respectively. In terms of the WOSB components fixed by two-in-one connectors, the numerical simulation showed the best accuracy, with differences of about 0.02% and 6% from the experimental results. Taken together, these results indicate that the model simplification method is also applicable to L-type components fixed by common connectors, further demonstrating the effectiveness of the method.

3.3. Strength of Joints

The L-shaped components used in the experiment had uniform dimensions, and the ultimate load represented their strength.

Figure 12 shows the strength of the components fixed with differently spaced screws.

Figure 12a shows that the compressive strength of the L-shaped component decreased initially and then increased as the screw spacing increased. The maximum load was achieved with a screw spacing of 48 mm, resulting in compressive ultimate loads of 561 N for the BOSB components and 169 N for the WOSB components.

Figure 12b presents the ultimate tensile load for the L-shaped components. As the screw spacing increased, the tensile strength of the BOSB components gradually decreased, while that of the WOSB components first increased and then decreased, reaching its maximum at a spacing of 48 mm. This demonstrates that screw spacing has a significant influence on the strength of BOSB components [

29]. The trends for these two kinds of board components differed mostly due to their failure mechanisms: BOSB components fail due to bending screws, while WOSB components fail due to board failure [

19]. The analysis of variance (

Table 6 and

Table 7) revealed substantial differences in the maximum loads for the components connected with different screw spacings. The compressive strength of the WOSB components was more influenced by the screw spacing compared to that of the BOSB components. However, in tension, the impact of screw spacing on the WOSB components was comparatively weaker than on the BOSB components. This confirms that the screw spacing directly affects the bending strength.

Compared to the WOSB component, the BOSB component was significantly stronger due to its 3.5-fold higher tensile strength. This is because of the strong dependence between the load of the connections and the density of the boards [

32]. Under compression, the ultimate load of the BOSB component was approximately 3.3–3.7 times greater than that of the WOSB component, whereas under tension, it was about 2.4–3.3 times greater. Furthermore, the tensile strength of the BOSB component was 2.4–3.3 times higher than the compressive strength, whereas that of the WOSB component was 3–3.6 times higher. In furniture structural design, it is undesirable to have a significant difference in the component strength under different load conditions. This is because furniture components experience both tension and compression, and they need to have similar stiffness to ensure greater structural reliability [

33]. The results indicate that the L-shaped components of BOSB are not only significantly stronger than those of WOSB but also more stable.

Figure 13 shows the strength of the L-shaped components with common eccentric connections and wood dowel pin fixings. By comparing the two figures, it is evident that the tensile strength of the components is considerably higher than their compressive strength. Among them, the BOSB component had a tensile strength of 2.9–4.7 times its compressive strength, while that of the WOSB component was 3.4–5.2 times higher. Similar to the components fixed with screws, the strength of the BOSB fixed by common connectors was more stable than that of the WOSB. Unlike the screw-fixed components, there were cases where the strength of the BOSB components was less than that of the WOSB components. For example, under compression, the ultimate load of the WOSB component fixed by the wooden dowel pin was 99 N, which is obviously higher than that of the BOSB component (67 N). Under tension, the ultimate loads for the WOSB component fixed with a nylon nut and wooden dowel pin reached 347 N and 350 N, respectively, which are slightly greater than those of the BOSB component (343 N and 305 N). This indicates that, apart from the material strength, the type and performance of the connector also affect the L-shaped component strength [

34], and different material choices with suitable connectors can improve the component’s bearing capacity [

14]. The analysis of variance (

Table 8 and

Table 9) shows that the components fixed by different connectors had significant strength differences. The difference in the type of connectors had a significantly greater effect on the strength of the BOSB components than on that of WOSB components (F (BOSB) > F (WOSB), which suggests that the selection of appropriate connectors is more effective in improving the structural strength of BOSB components.

The compressive strength of L-shaped components attached to different connectors is shown in

Figure 13a. The BOSB components attached with a two-in-one connector had the highest compressive strength (259 N), followed by those attached with metal nuts (178 N) and converse-spine nuts (147 N). The compressive strength of those attached with nylon nuts (108 N) and wooden dowel pins (67 N) was lower. The WOSB components fixed with metal nuts, a converse-spine nut, and a two-in-one connector had a lower compressive strength (106 N and 99 N, respectively), whereas those fixed with nylon nuts and wooden dowel pins had higher compressive strength, at 102 N and 99 N, respectively. This further indicates that the different materials are suitable for different connectors. Two-in-one connectors and metal nuts use threads embedded in the board to achieve connection. The BOSB material had a higher density, strength, and hardness than the WOSB; the threads grip the board tightly, so these components have a higher compressive strength [

35]. Screwing threaded connectors, such as two-in-one connectors, metal nuts, and converse-spine nuts, into WOSB causes damage and loosens the surrounding material. This weakens the connection between the connectors and the board, thereby reducing the components’ strength [

36]. On the other hand, when embedded in WOSB, nylon nuts and wooden dowel pins can create more friction with the material, thereby improving board fixation.

According to

Figure 12b, the BOSB component with a metal nut, a two-in-one connection, and a converse-spine nut had substantially greater tensile strength than the one with a nylon nut and a wooden dowel pin. The WOSB component with a nylon nut and wooden dowel pin had somewhat higher tensile strength than the one with a metal nut and a converse-spine nut. The eccentric connection and wooden dowel pin-fixed L-shaped component were weaker than the screw-fixed one. The compressive and tensile strengths of the BOSB components fixed with a 48 mm screw spacing were 3.1 and 1.4 times higher than those of the components fixed with metal nuts. Compared to the nylon nuts, the WOSB components secured with a 48 mm screw spacing were 1.7 and 1.4 times stronger. Compared to two-in-one, three-in-one (with an embedded nut), wood screw, and other threaded connectors, the thread end of self-drilling screws is narrower, the thread spacing is smaller, and the thread has a greater effect on the shear and extrusion deformation of bamboo fiber, so its connection strength is greater than other threaded connectors [

14].

3.4. Stiffness of Joints

Figure 13a,b show the stiffness of the L-shaped BOSB and WOSB components fixed by screws with different spacings.

Figure 14a shows that the BOSB and WOSB components’ compressive stiffness increased and then decreased with the screw spacing. The compressive stiffness of both the BOSB and WOSB components was at the maximum with a screw spacing of 48 mm, with stiffnesses of 21.8 N/mm and 11.5 N/mm, respectively.

Figure 14b shows that the BOSB component’s tensile stiffness decreased as the screw spacing increased, whereas that of the WOSB increased gradually. This shows that the screw spacing affected the components’ stiffness and had a slightly different pattern than that of the strength.

Table 10 and

Table 11 demonstrate significant differences in the stiffness of the components fixed with varying screw spacings. This proves that screw spacing affects components’ stiffness. Furthermore, screw spacing affects the tensile stiffness more than the compressive stiffness and affects the compressive stiffness of BOSB components more than that of WOSB components, while the effect on the tensile stiffness of BOSB components is slightly less than that of WOSB components.

The tensile stiffness was significantly greater than the compressive stiffness, and the stiffness of the BOSB components was higher than that of the WOSB components. The tensile stiffness of the BOSB components was about 1.3–2.4 times their compressive stiffness, with the smallest difference noted for the component with a screw spacing of 64 mm, followed by 48 mm. Regarding the WOSB components, their tensile stiffness was roughly 1.9–2.8 times greater than their compressive stiffness, with the smallest difference for components with a screw spacing of 48 mm. This shows that BOSB component stiffness is more stable [

33]. In addition, the difference in the component stiffness between the two different loads was small compared to that of the component strength.

Figure 15 shows the stiffness of an L-shaped component fixed with eccentric connections and wooden dowel pins. The comparison revealed that the tensile stiffness of the components was significantly greater than the compressive stiffness. This was the same pattern as the components’ strength. Moreover, the stiffnesses of both the BOSB and WOSB components fixed by wooden dowel pins were at the maximum under two different loads.

Figure 15a demonstrates that when compressed, the stiffness of the metal nut-, converse-spine nut-, two-in-one connector-, and wooden dowel pin-fixed BOSB components surpassed that of the WOSB components. BOSB with high hardness is more suitable for thread connections to obtain greater mechanical strength compared to non-threaded connections [

35,

37]. However, the compressive stiffness of the nylon nut-fixed BOSB components was less than that of the WOSB components. The wooden dowel pin-fixed BOSB component had the greatest compressive stiffness (9.3 N/mm), followed by those fixed with the metal nut (4.7 N/mm) and the two-in-one connector (4.2 N/mm). the nylon nuts-fixed BOSB component had the lowest stiffness (2.4 N/mm). For the WOSB component, the compressive stiffness of the wooden dowel pin fixation was again the highest, followed by that of the nylon nut (5.1 N/mm); that of the two-in-one connector was the lowest (0.8 N/mm).

Figure 14b shows that the stiffness of the BOSB components fixed by eccentric connections was much greater than that of the WOSB components. Moreover, for the BOSB components, the tensile stiffness was relatively high for those fixed with metal nuts and wooden dowel pins at 20.2 N/mm and 20.5 N/mm, respectively, followed by those fixed with nylon nuts and two-in-one connectors. The BOSB components fixed with converse-spine nuts had the lowest tensile stiffness. Among the WOSB components, the tensile stiffness of the wooden dowel pin-fixed component was the highest (21.4 N/mm), followed by that with the nylon nut; that of the metal nut was the lowest (3.2 N/mm). The analysis of variance (ANOVA) in

Table 12 and

Table 13 shows that the type of connector affects the component stiffness, with a greater effect on the stiffness of WOSB components than on that of BOSB components.

In summary, the wooden dowel pin-fixed BOSB component exhibited the highest stiffness; however, its ultimate load was comparatively lower. Therefore, wooden dowel pin fixation is not an optimal choice for BOSB components. Metal nut fixation is a more suitable option for BOSB components, with a stiffness slightly lower than that of wooden dowel pin fixation, and compressive and tensile ultimate loads approximately 2.7 times higher. For WOSB components, it is more suitable to fix them with wooden dowel pins, which not only have higher strength but also better stiffness.