The MSCR test results for four types of asphalt under stress levels of 0.1 kPa and 3.2 kPa yield strain–time curves, as shown in

Figure 10a,b. From these figures, it can be observed that, under different stress levels, the cumulative non-recoverable strain for all asphalts exhibits a similar trend, with increasing strain over time. Additionally, the higher the applied shear stress, the greater the cumulative strain in the modified asphalt. For the same type of asphalt, the cumulative non-recoverable strain under 3.2 kPa of stress is significantly higher than that under 0.1 kPa of stress, indicating that higher shear stress leads to larger and less recoverable strains. Under both 0.1 kPa and 3.2 kPa loads, SBS-modified asphalt shows the highest non-recoverable residual strain, indicating that the nano-OMMT modifier can improve the high-temperature creep performance of the modified asphalt and enhance its resistance to flow deformation at high temperatures. This improvement is due to the insertion structure formed by OMMT in the asphalt, which effectively hinders the movement of asphalt molecular chains, thereby enhancing the high-temperature performance of the modified asphalt. At both stress levels, the strain for 4%S+3%O is less than that for 4%S+1%O and 4%S+5%O, suggesting that an optimal amount of OMMT has the most significant effect on improving the flow deformation resistance of the modified asphalt.

The MSCR test results for modified asphalt at 64 °C, showing J

nr and R, are depicted in

Figure 11.

Figure 11a presents the non-recoverable shear modulus J

nr for four types of modified asphalt. It can be seen from the figure that as the stress level increases, the J

nr of the asphalt material becomes larger, indicating a poorer high-temperature rutting resistance and a higher tendency for permanent deformation. The test results show that the J

nr of SBS-modified asphalt is the largest at the same stress level, which reflects that the energy loss of SBS-modified asphalt in the creep process is large, and it is easy to produce large cumulative deformation and forms permanent ruts under a high temperature and load. It also shows that the high-temperature rutting resistance of SBS-modified asphalt is significantly improved after OMMT modification. At the stress levels of 0.1 kPa and 3.2 kPa, J

nr of OMMT/SBS-modified asphalt changes in the same way, that is, with the increase in OMMT modifier content, J

nr first decreases and then increases, among which J

nr of 4%S+3%O is the smallest. Compared with SBS-modified asphalt, the J

nr of OMMT/SBS-modified asphalt is the smallest. The J

nr0.1 and J

nr3.2 values decreased by 28.6% and 61.1%, respectively, which indicates that the high temperature rutting resistance of 4%S+3%O under load is the most prominent, and the permanent deformation is also the smallest. At a higher load stress level (3.2 kPa), the change amplitude of J

nr is also larger and more obvious, which indicates that the OMMT modifier has a more significant effect on the high-temperature resistance to permanent deformation of SBS-modified asphalt under heavy traffic.

Figure 11b shows the calculation results of four groups of modified asphalt R. As can be seen from the figure, the higher the stress level, the smaller the R, the worse the elastic recovery ability, and the worse the high-temperature performance, which is exactly the opposite trend of J

nr. The R

0.1 and R

3.2 of the four groups of modified bitumen are high, indicating that the modified bitumen prepared in this study has a strong elastic recovery ability. In addition, when the stress level is high, the R of the four modified bitumen groups is small, and the elastic recovery ability is poor. Under the creep stress levels of 0.1 kPa and 3.2 kPa, the R of SBS-modified asphalt is the smallest among the four groups, indicating that the OMMT modifier can improve the elastic recovery ability of SBS-modified asphalt. When the load stress is 0.1 kPa, the R of the four groups of modified bitumen is very high and the difference is very small, which is close to 99%, indicating that the four groups of modified bitumen have excellent creep properties at high temperatures under low loads. When the load stress is 3.2 kPa, the change of R of the four groups of modified asphalt is more obvious. With the increase in OMMT content from 1% to 5%, R increases slightly at first and then decreases slightly, in which the R of 4%S+3%O is the largest, indicating that its elastic recovery ability is strong. The variation law of modified asphalt R under a 3.2 kPa load stress level is different from that under 0.1 kPa of stress, which indicates that the OMMT modifier has a more obvious effect on the high-temperature deformation resistance of asphalt under heavy traffic, which is consistent with the law shown by J

nr.

Stress sensitivity is an index reflecting the degree of influence of stress on asphalt rheological properties, which will affect the service quality and stability of asphalt pavement [

24]. The more sensitive the modified asphalt is to load stress, the easier it is to deform. The J

nr-diff and R

diff of SBS-modified asphalt and OMMT/SBS-modified asphalt at 64 °C are shown in

Figure 12. As can be seen from the figure, J

nr-diff and R

diff change in the same law, SBS-modified asphalt showed the highest sensitivity to stress, 4%S+1%O, 4%S+3%O, and 4%S+5%O J

nr-diff and R

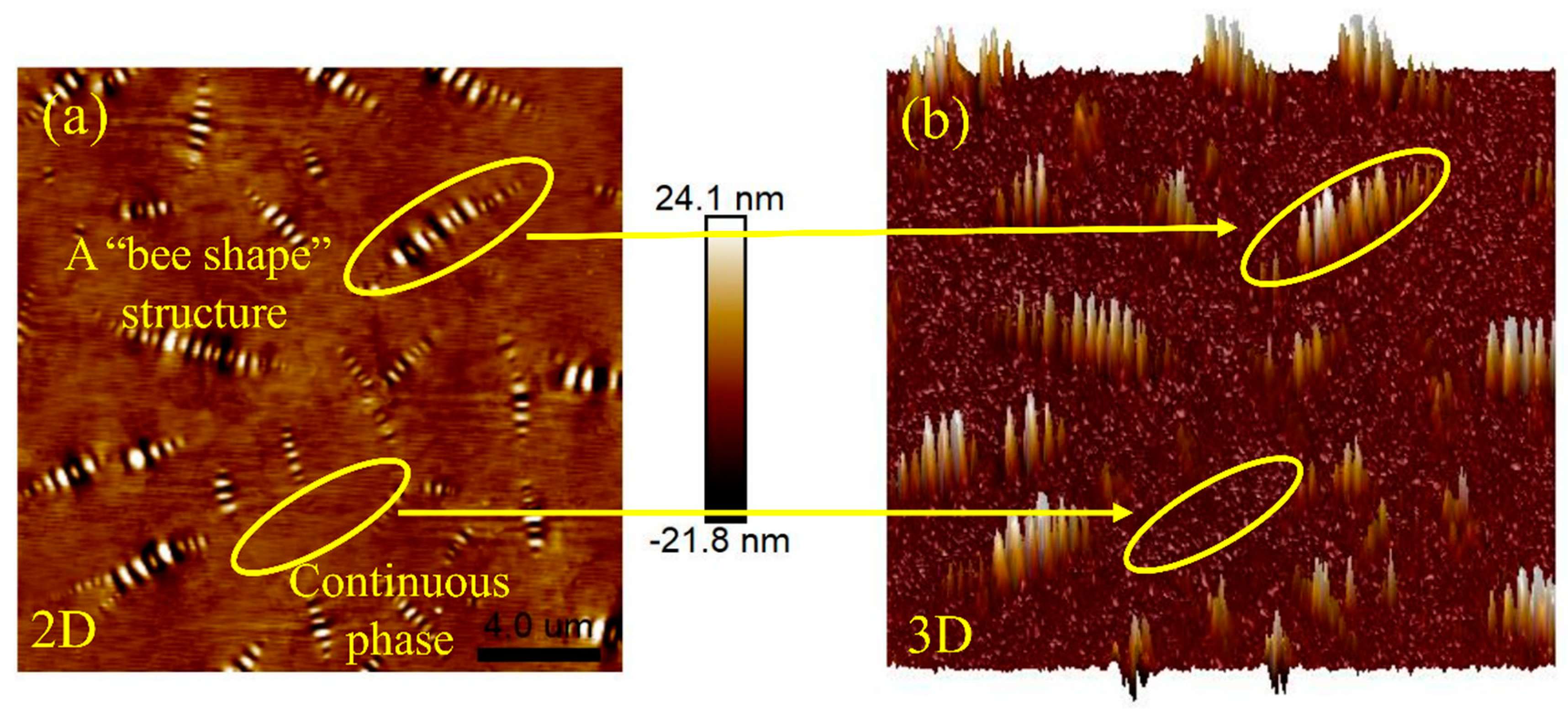

diff were lower, and the incorporation of OMMT improved the stress sensitivity of SBS-modified asphalt. This is because the asphalt will expand when heated, the internal void will increase, the intermolecular force will weaken, and the intermolecular arrangement will not be tight enough, resulting in deformation under the action of stress. After OMMT modification, the compatibility between SBS and asphalt is enhanced, and a good spatial network crosslinked structure is formed inside the modified asphalt, and OMMT and SBS modified asphalt form an intercalated nanocomposite structure. The synergistic effect of these two structures has a good effect on the thermal movement of the asphalt molecular chain, so that the molecular arrangement is closer, and the relative displacement between the asphalt molecules does not easily occur, which effectively improves the thermal stability of the asphalt so that the high-temperature performance of the modified asphalt is improved.