The simulation modelling process can be mainly divided into three steps. Step 1 is the statistical analysis of the on-site data used as the driving data for the simulation model, including heat weight, CC casting speed range, processing cycle for each process, overhead crane transfer time among adjacent processes, ladle turnover cycle, etc. Step 2 establishes the static model of the production site according to the workshop layout of the target steelmaking plants, a process which mainly includes determining the location of each device and placing them, and then establishing the physical-connection relationships among the devices and generating movable objects such as the molten steel and ladle. Step 3 involves the design of the dynamic control program for each device and ladle based on SimTalk language and realizes the simulation of the production process through the dynamic judgment and decision-making for the real-time production-operation situation.

3.1. Drive Data

The steelmaking process is a complex and multi-factorial system production process, subject to factors such as unclear metallurgical mechanisms and frequent disturbances. The processing time of each smelting process is not constant. Therefore, with the aim of achieving an accurate simulation of the dynamic operational conditions, it is necessary to generate accurate statistical analyses and descriptions of the actual on-site operational data before building the simulation model in order to obtain the driving data for the simulation model.

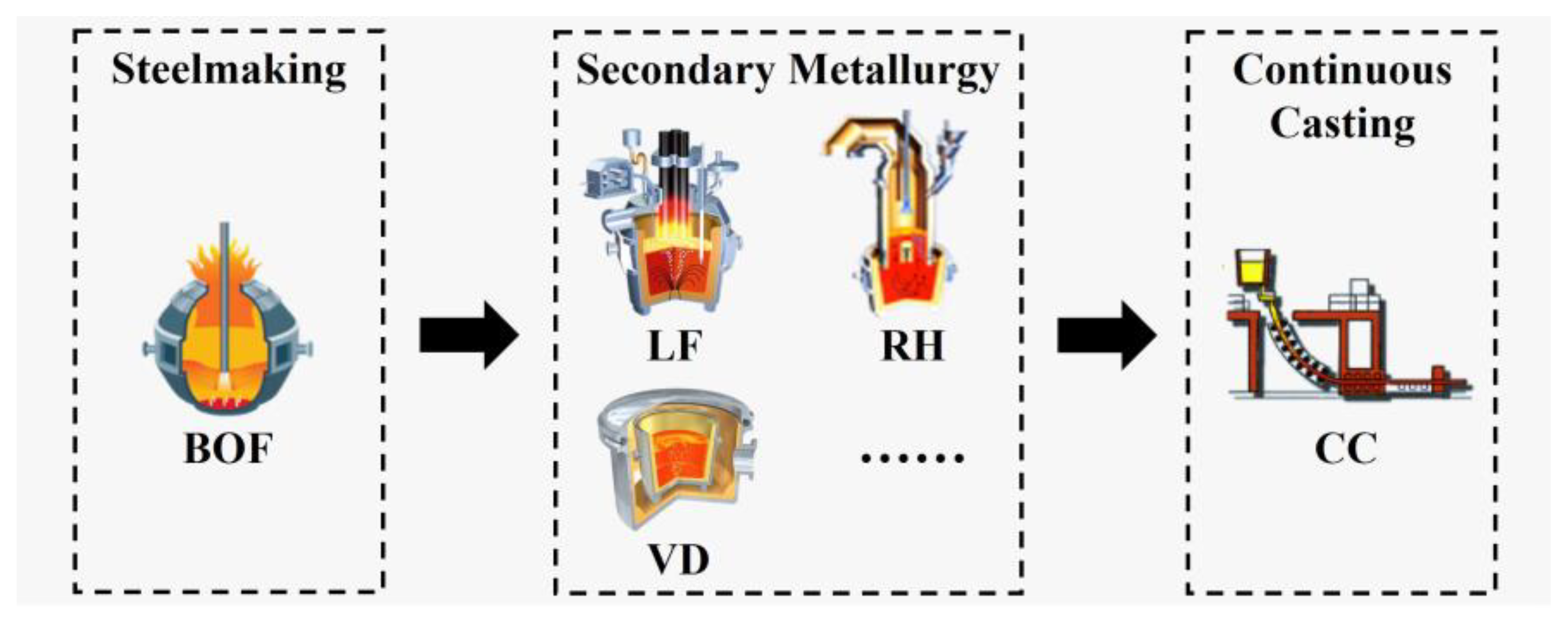

As the first process in the SCCP, the converter is subject to intense physical–chemical reactions in completing the transformation from hot metal to molten steel, a process with complex metallurgical mechanisms and numerous factors causing disturbances. Consequently, the converter smelting cycle is relatively uncontrollable. The fluctuations of the converter smelting cycle, especially the continuous tapping delay, undoubtedly cause great damage to the stable operation of the entire production process and are often a crucial factor in interruptions in sequence casting. The flexible production characteristics of LF and RH refining contribute to their being regarded as typical buffering processes used for production-operation rhythm adjustment [

34]. Hence, their refining cycles are relatively controllable, which is consistent with the results of on-site surveys. In this paper, the distribution of converter smelting cycle is analyzed, and the standard processing cycles and buffering time for the refining processes are examined. Additionally, due to the constraints of steel grade solidification characteristics and the blank quality requirements, the allowable casting speeds for different blank cross-section sizes are specified by the process specifications. Under the condition of fixed cross-section size in CC, there will be a strong positive correlation between the heat weight and the casting cycle. Therefore, a detailed statistical analysis of the heat weight is also performed for the simulation modeling.

The 4317 sets of historical data are taken from the studied steelmaking plants during the period of October to December in 2021.

Figure 2 shows the distributions of the converter smelting cycle and heat weight in the studied steelmaking plants. From

Figure 2a, it can be observed that the distribution of the converter smelting cycle has a left-skewed peak and a rightward extending long tail, indicating a positively skewed distribution. The reason behind this skewed distribution characteristic is the frequent occurrence of disturbance events that disrupt the timely tapping of the converter, which in turn leads to the tendency of the converter smelting cycle to extend in the direction of increase. Skewness coefficient is a statistical parameter that reflects the degree and direction of asymmetry in data distribution. The larger the absolute value of the skewness coefficient is, the more serious the skewness of the distribution is.

The converter smelting cycle distribution has a skewness coefficient of 0.73, indicating a skewed distribution. Therefore, the commonly used normal distribution, as seen in related literature [

23,

24], is not entirely suitable for describing the distribution of the converter smelting cycle. Instead, the lognormal distribution, with its more upwardly fluctuating values, is better suited for describing datasets with positively skewed distributions. This conclusion is further supported by the good-fit measures. For the converter smelting cycle, the lognormal distribution has a good fit of 0.9595, which is significantly superior to the normal distribution’s good fit of 0.9318. Similarly, as depicted in

Figure 2b, steelmaking plants tend to increase the heat weight to enhance steel production in the real-world production environment. As a result, the heat weight also follows a positively skewed distribution, with a skewness coefficient of 0.15, indicating a slight skewness. In terms of good fit, the lognormal distribution displays superior good fit, with a value of 0.9893, in contrast to 0.9839 for the normal distribution.

Based on the data analysis and on-site investigation, the statistical results for the processing cycles, soft-blowing times and buffer times of refining processes in the studied steelmaking plants are presented in

Table 2, in which soft blowing is an integral part of the refining process. As for soft blowing, its primary role is to further improve the quality of the molten steel, and its secondary role is to ensure continuous production. Therefore, with the objective of ensuring the lowest time value, the soft blowing can be compressed. This process characteristic makes the soft-blowing process undertake the main buffering task. In accord with the results of an on-site investigation and data analysis, a buffer time of 5 min was set in the soft-blowing process for the studied steelmaking plants.

Table 3 displays the allowable casting speed ranges for different section sizes in CC. Accordingly, these statistics were utilized to define the processing cycles for each process in the simulation modeling.

In addition, the simulation process also involves the transportation of ladles among different processes. The actual transfer time among different processes is not constant. Therefore, in the context of the studied steelmaking plants, and based on their actual production situations, the model has magnified the transfer time, and the ladle transfer time among the different processes is set to a constant value of 12 min, which is longer than the shortest transfer time among the different processes.

3.2. Static Modeling

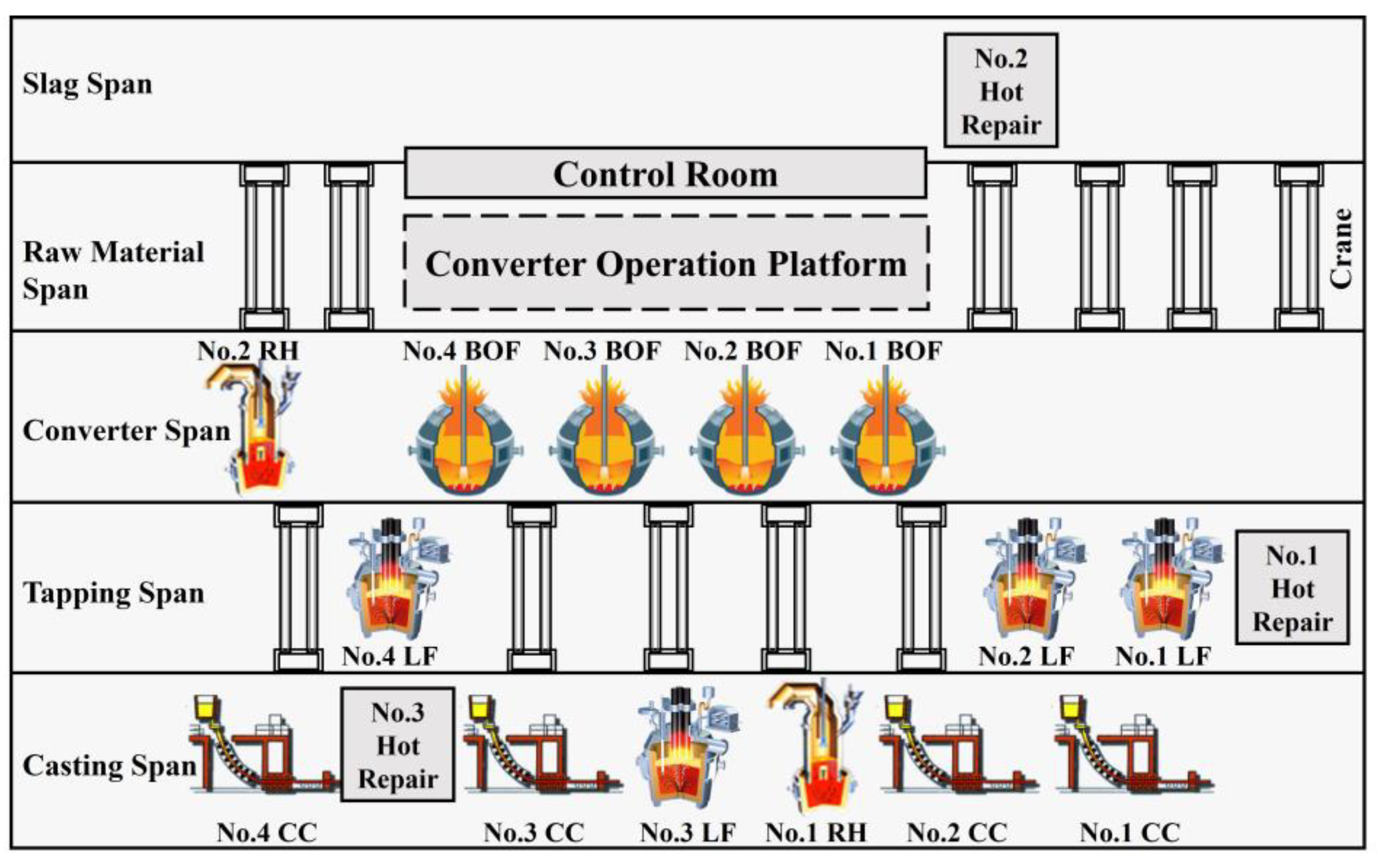

After the simulation-driven data is obtained, a static model of the simulation objects is built, based on the workshop layouts of the studied steelmaking plants, as shown in

Figure 3. The steelmaking plants under study include four converters (No. 1 BOF to No. 4 BOF), four LF refining furnaces (No. 1 LF to No. 4 LF), two RH refining furnaces (No. 1 RH and No. 2 RH), and four continuous casting machines (No. 1 CC to No. 4 CC). Additionally, the steelmaking plants also have three ladle hot-repair stations (No. 1 HotRepair to No. 3 HotRepair) and several overhead cranes, five of which are positioned within the tapping span.

Given the on-site positions of each device, the simulation workstations can be arranged reasonably within the simulation platform. The various devices in the physical workshop are mainly distributed in the converter span, tapping span, and casting span. Therefore, when building the static architecture of the simulation model, the focus is on the three operational spans of the steelmaking plants. The three operational spans, named Converter Span, Tapping Span, and Casting Span, are first created within the simulation platform; then, the corresponding simulation stations are added to the simulation span according to the device configuration of each operational span in the physical workshop. It is important to note that, since each process is a collection of multiple operations, it is advisable to decompose the process functions into multiple simulation workstations during the simulation modeling process in order to enhance clarity and intuitiveness. Taking the BOF as an example, the decomposition of BOF is shown schematically in

Figure 4. The BOF was decomposed into a processing workstation, an assembly workstation, and a buffer workstation, representing the smelting process, molten-steel tapping process, and liquid-steel waiting process, respectively. The other processes are also decomposed according to their functions. Finally, the static architecture of the multi-process dynamic-operation simulation model for SCCP is gradually established, as shown in

Figure 5. The introductions and functions of the main simulation objects in the static model are summarized in

Table 4.

In addition to the above logistics objects, the simulation model also includes three types of movable objects, namely, parts, containers, and carts, representing molten steel, ladles, and overhead cranes, respectively. All three types of movable objects offer customizable attribute settings, including the current state of the movable objects, import and export status, current controls information, etc., which can be used for the development of Method control programs, which can in turn be flexibly configured based on simulation requirements to facilitate the implementation of various simulation-based functionalities.

3.3. Dynamic Modeling

To satisfy the sequence-casting constraint, it is essential to develop dynamic-operation rules for SCCP based on the static model. This is because the SCCP is subject to dynamic variations, and the schedules that can initially meet the sequence-casting constraint with excellent performance may become ineffective during actual production due to fluctuations in the processing cycles of the preceding processes. Therefore, the key to achieving dynamic simulation lies in dynamic-operation rules implemented through SimTalk.

- (1)

Dynamic-operation rules

Dynamic-operation rules are implemented to provide guidance for schedules, enabling real-time adjustments that ensure the stability of the entire production process when normal production is disrupted. These rules primarily encompass refining buffer adjustments and continuous casting controls. The specific operational rules are outlined as follows:

Rule 1: When there is a delay in the completion time of converter smelting, and this delay is within the maximum buffer time allowed for the refining process, the start time and duration of the refining process are adjusted based on the converter delay time.

Rule 2: If there is a delay in the completion time of converter smelting, and the delay time exceeds the maximum buffer time allowed for the refining process but is still within the adjustable time of the CC, the CC casting speed is promptly reduced based on the converter delay time in order to extend the casting completion time of preceding heats, and the start time and duration of the refining process are adjusted according to the maximum refining buffer capacity.

Rule 3: If there is a delay in the completion time of converter smelting, and the delay time exceeds the sum of the maximum buffer time allowed for the refining process and the adjustable time of the CC, there will be a temporary interchange of two converter smelting heats; the other converter smelting heats are urgently called to supply the strand, and the start time and duration of the refining process as well as the CC casting speed are accordingly adjusted.

Rule 4: When the completion time of the refining heat is delayed, and the delay time is within the maximum buffer time allowed for the refining process, the refining duration is adjusted based on the delay time.

Rule 5: When the completion time of the refining heat is delayed and the delay time exceeds the maximum buffer time allowed for the refining process but is within the CC adjustable time, the refining duration is accordingly adjusted, and the casting speed is immediately reduced.

Rule 6: If the completion time of the refining heat is delayed and the delay time exceeds the sum of the maximum buffer time allowed for the refining process and the CC adjustable time, the steel grade of the other refining device is urgently reordered to supply the strand, and the refining duration and the CC casting speed are adjusted accordingly. In this scenario, there will be a temporary interchange of heats between the two refining devices.

Rule 7: Empty ladles, after completion of casting, are prioritized for repair at the hot-repair station to ensure fewer waiting ladles. If multiple hot-repair stations have the same number of ladles waiting, the ladle is sent to the nearest hot-repair station.

Rule 8: The ladle with the longest waiting time is given priority to receive the molten steel when converter-tapping. If there are multiple ladles with the same waiting time, the ladle nearest to the converter is chosen.

Based on the above rules, the corresponding control program can be written for Method control through the SimTalk programming language, as shown in

Figure A1 and

Figure A2 in

Appendix A, which illustrates an example of a control program written in SimTalk. After encapsulating the Method control, it is attached to the corresponding workstation. This allows the program segment to be triggered when a movable object reaches this workstation, enabling the appropriate control actions.

- (2)

Dynamic operational programs

The logic control mechanism of the SCCP simulation model is illustrated in

Figure 6. The control programs for each workstation are encapsulated within their respective Method objects, and the corresponding Methods are triggered when movable objects are conveyed to the respective workstations. When elaborated step by step, the operation control of each process in the simulation process can be better illustrated.

In Step 1, set up the simulation data and release the heats according to the schedule scheme. Create a DataTable, as shown in

Figure 7, for storing the schedule scheme used in the simulation experiment, including the release time, process route, heat name, and other information associated with each heat. Bind the DataTable to the corresponding HotMetal (Source), as shown in

Figure 8. At the same time, write a Method for the initialization of the customized attributes of each heat.

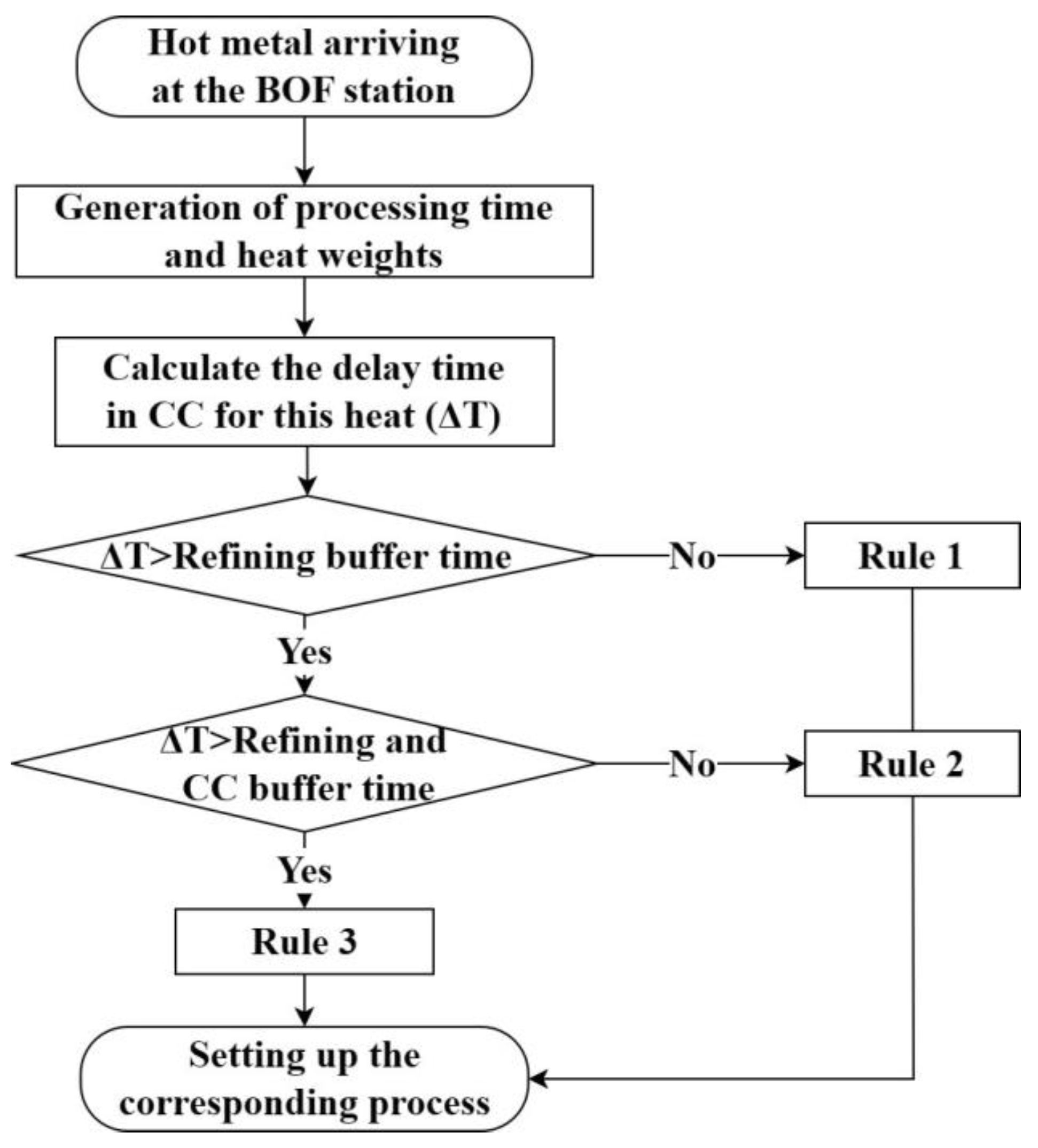

In Step 2, generate the processing time and heat weight for each heat according to the data distribution characteristics and determine the dynamic-operation rules. When the HotMetal releases iron to the converter, the converter will generate the corresponding heat-weight and processing time for each heat and assess the current production situation to determine the required dynamic-operation rules at the time of molten-steel-tapping. The corresponding judgment process is shown in

Figure 9, and the subsequent processes are set according to the rules. This step is the key to realizing the caster sequence-casting target. Previous studies focused on setting corresponding processing times for each process, lacking the assessment of current production-operation situation and the selection of dynamic-operation rules. This lack of dynamic assessment and adjustment in the production process has, in related studies, led to the dilemma involved in attempting to meet the sequence-casting constraint. By incorporating dynamic operating-rule assessment and selection into the simulation process, the gaps identified in previous studies can be effectively addressed.

Step 3 is the ladle allocation for converter-tapping. Before the converter completes the smelting, the converter sends out a ladle allocation command. At this point, firstly, determine whether there is an online ladle available in the LadleWait station, and secondly, choose to call a new ladle from LadleS if there is no ladle online. The ladle allocation process is shown in

Figure 10. After the ladle arrives at the converter-tapping station, the tapping operation is performed. The corresponding simulation process is the combination process of the molten steel and the ladle. After passing through this station, both will be composed of a new movable object.

Step 4 Implements the judgement of the dynamic-operation rules for the refining processes. After the ladle allocation and molten-steel-tapping at the converter, the ladle with molten-steel is sent to the corresponding refining process according to the designed process route. The refining process will perform the refining according to the processing time set by the previous dynamic-operation rules and determine the required dynamic-operation rules at that time. The corresponding judgment flow is shown in

Figure 11. After the LF refining is completed, the molten steel is sent to RH refining or the CC process for casting according to the requirements of the process route.

Step 5 involves the separation of molten steel and ladle in the CC and the determination of the empty ladle’s destination. After the molten steel arrives at the CC process, it is cast at the casting speed set by the previous rules, and the molten steel separates from the ladle at the LadChange station. The separated molten steel is recovered by the Drain, and the empty ladle will then return to the HotRepair station for hot repair according to Rule 7.