Effect of Light Irradiance and Curing Duration on Degree of Conversion of Dual-Cure Resin Core in Various Cavities with Different Depths and Diameters

Abstract

1. Introduction

2. Materials and Methods

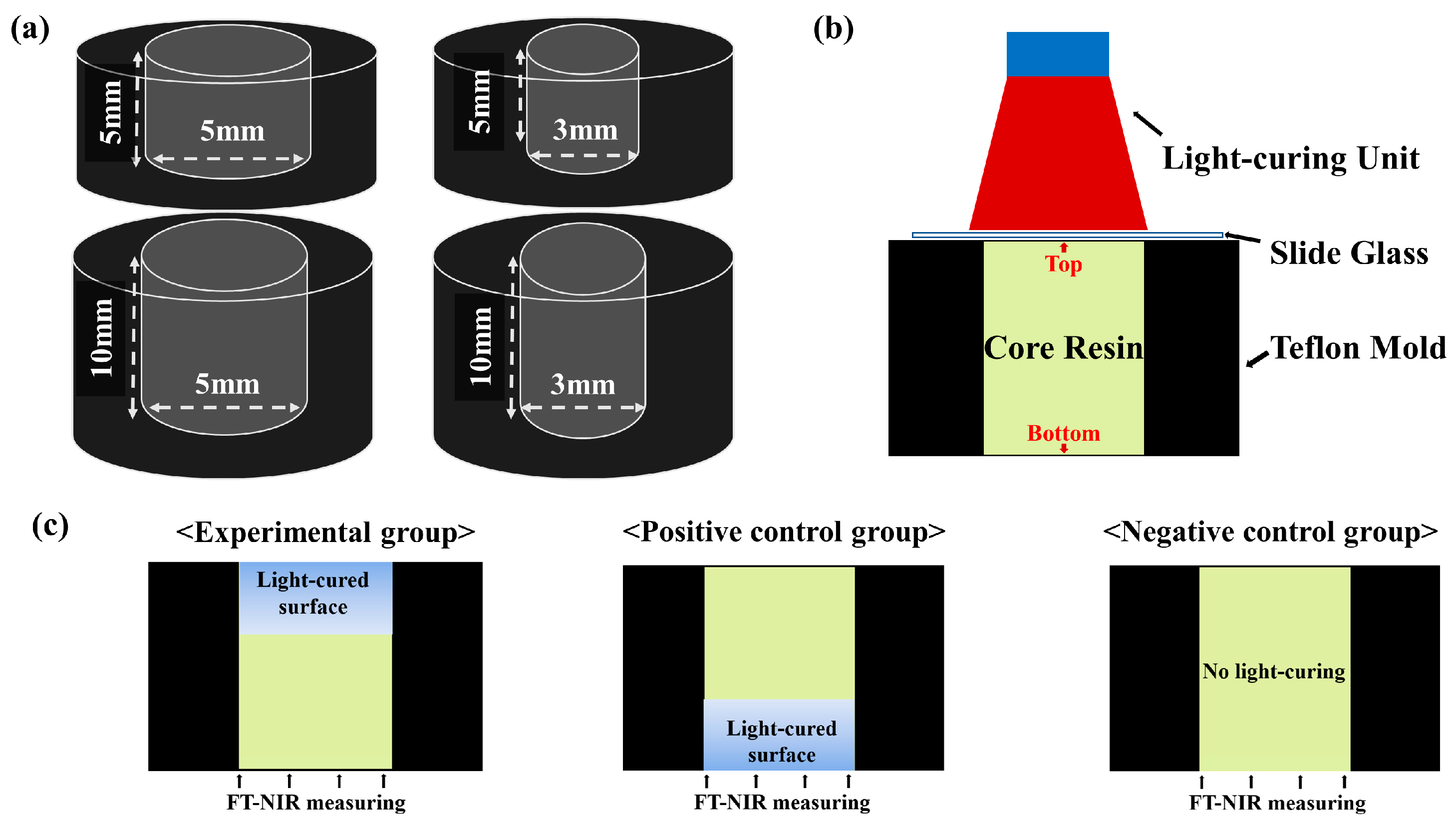

2.1. Teflon Mold Fabrication

2.2. Light Curing of Various Teflon Molds and Measuring Light Irradiance at the Bottom of Teflon Mold

2.3. Preparation of Specimen for Measuring DC

2.4. Measuring the DC

2.5. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Glossary of Prosthodontic Terms Committee of the Academy of Prosthodontics. The Glossary of Prosthodontic Terms: Ninth Edition. J. Prosthet. Dent. 2017, 117, e1–e105. [Google Scholar] [CrossRef] [PubMed]

- Kovarik, R.E.; Breeding, L.C.; Caughman, W.F. Fatigue life of three core materials under simulated chewing conditions. J. Prosthet. Dent. 1992, 68, 584–590. [Google Scholar] [CrossRef]

- Cheung, W. A review of the management of endodontically treated teeth. Post, core and the final restoration. J. Am. Dent. Assoc. 2005, 136, 611–619. [Google Scholar] [CrossRef]

- Matsumoto, M.; Miura, J.; Takeshige, F.; Yatani, H. Mechanical and morphological evaluation of the bond-dentin interface in direct resin core build-up method. Dent. Mater. 2013, 29, 287–293. [Google Scholar] [CrossRef] [PubMed]

- Moldovan, M.; Balazsi, R.; Soanca, A.; Roman, A.; Sarosi, C.; Prodan, D.; Vlassa, M.; Cojocaru, I.; Saceleanu, V.; Cristescu, I. Evaluation of the Degree of Conversion, Residual Monomers and Mechanical Properties of Some Light-Cured Dental Resin Composites. Materials 2019, 12, 2109. [Google Scholar] [CrossRef] [PubMed]

- Aguiar, T.R.; Di Francescantonio, M.; Arrais, C.A.; Ambrosano, G.M.; Davanzo, C.; Giannini, M. Influence of curing mode and time on degree of conversion of one conventional and two self-adhesive resin cements. Oper. Dent. 2010, 35, 295–299. [Google Scholar] [CrossRef]

- Aravamudhan, K.; Rakowski, D.; Fan, P.L. Variation of depth of cure and intensity with distance using LED curing lights. Dent. Mater. 2006, 22, 988–994. [Google Scholar] [CrossRef]

- Alkhudhairy, F.; Vohra, F. Compressive strength and the effect of duration after photo-activation among dual-cure bulk fill composite core materials. Pak. J. Med. Sci. 2016, 32, 1199–1203. [Google Scholar] [CrossRef]

- Shim, J.S.; Lee, S.Y.; Song, S.Y.; Jha, N.; Ryu, J.J. Polymerization efficiency of dental dual-cured resin cement light-cured at various times after the initiation of chemical activation. Int. J. Polym. Mater. Polym. Biomater. 2020, 69, 622–628. [Google Scholar] [CrossRef]

- Uctasli, S.; Tezvergil, A.; Lassila, L.V.; Vallittu, P.K. The degree of conversion of fiber-reinforced composites polymerized using different light-curing sources. Dent. Mater. 2005, 21, 469–475. [Google Scholar] [CrossRef]

- Bahari, M.; Savadi Oskoee, S.; Kimyai, S.; Mohammadi, N.; Saati Khosroshahi, E. Effect of Light Intensity on the Degree of Conversion of Dual-cured Resin Cement at Different Depths with the use of Translucent Fiber Posts. J. Dent. 2014, 11, 248–255. [Google Scholar]

- Musanje, L.; Darvell, B.W. Polymerization of resin composite restorative materials: Exposure reciprocity. Dent. Mater. 2003, 19, 531–541. [Google Scholar] [CrossRef] [PubMed]

- Mills, R.W.; Uhl, A.; Jandt, K.D. Optical power outputs, spectra and dental composite depths of cure, obtained with blue light emitting diode (LED) and halogen light curing units (LCUs). Br. Dent. J. 2002, 193, 459–463. [Google Scholar] [CrossRef]

- Wiggins, K.M.; Hartung, M.; Althoff, O.; Wastian, C.; Mitra, S.B. Curing performance of a new-generation light-emitting diode dental curing unit. J. Am. Dent. Assoc. 2004, 135, 1471–1479. [Google Scholar] [CrossRef]

- Shim, J.S.; Han, S.H.; Jha, N.; Hwang, S.T.; Ahn, W.; Lee, J.Y.; Ryu, J.J. Effect of Irradiance and Exposure Duration on Temperature and Degree of Conversion of Dual-Cure Resin Cement for Ceramic Restorations. Oper. Dent. 2018, 43, E280–E287. [Google Scholar] [CrossRef]

- Tsukiyama, T.; Marcushamer, E.; Griffin, T.J.; Arguello, E.; Magne, P.; Gallucci, G.O. Comparison of the anatomic crown width/length ratios of unworn and worn maxillary teeth in Asian and white subjects. J. Prosthet. Dent. 2012, 107, 11–16. [Google Scholar] [CrossRef]

- Hasegawa, Y.; Amarsaikhan, B.; Chinvipas, N.; Tsukada, S.I.; Terada, K.; Uzuka, S.; Miyashita, W.; Iguchi, S.; Arai, K.; Kageyama, I.; et al. Comparison of mesiodistal tooth crown diameters and arch dimensions between modern Mongolians and Japanese. Odontology 2014, 102, 167–175. [Google Scholar] [CrossRef] [PubMed]

- Kerns, D.G.; Greenwell, H.; Wittwer, J.W.; Drisko, C.; Williams, J.N.; Kerns, L.L. Root trunk dimensions of 5 different tooth types. Int. J. Periodontics Restor. Dent. 1999, 19, 83–91. [Google Scholar]

- Stansbury, J.W.; Dickens, S.H. Determination of double bond conversion in dental resins by near infrared spectroscopy. Dent. Mater. 2001, 17, 71–79. [Google Scholar] [CrossRef]

- Blankenau, R.J.; Kelsey, W.P.; Powell, G.L.; Shearer, G.O.; Barkmeier, W.W.; Cavel, W.T. Degree of composite resin polymerization with visible light and argon laser. Am. J. Dent. 1991, 4, 40–42. [Google Scholar]

- Paradowska-Stolarz, A.; Wieckiewicz, M.; Kozakiewicz, M.; Jurczyszyn, K. Mechanical Properties, Fractal Dimension, and Texture Analysis of Selected 3D-Printed Resins Used in Dentistry That Underwent the Compression Test. Polymers 2023, 15, 1772. [Google Scholar] [CrossRef] [PubMed]

- Ataol, A.S.; Ergun, G.; Yayman, M. Effects of the substructure thickness, the resin cement color and the finishing procedure on the color and translucency of zirconia-based ceramic restorations. Dent. Med. Probl. 2023, 60, 137–144. [Google Scholar] [CrossRef] [PubMed]

- Martin, F.E. A survey of the efficiency of visible light curing units. J. Dent. 1998, 26, 239–243. [Google Scholar] [CrossRef] [PubMed]

- Prati, C.; Chersoni, S.; Montebugnoli, L.; Montanari, G. Effect of air, dentin and resin-based composite thickness on light intensity reduction. Am. J. Dent. 1999, 12, 231–234. [Google Scholar]

- Price, R.B.; Derand, T.; Sedarous, M.; Andreou, P.; Loney, R.W. Effect of distance on the power density from two light guides. J. Esthet. Dent. 2000, 12, 320–327. [Google Scholar] [CrossRef]

- Fan, P.L.; Stanford, C.M.; Stanford, W.B.; Leung, R.; Stanford, J.W. Effects of backing reflectance and mold size on polymerization of photo-activated composite resin. J. Dent. Res. 1984, 63, 1245–1247. [Google Scholar] [CrossRef]

- Yearn, J.A. Factors affecting cure of visible light activated composites. Int. Dent. J. 1985, 35, 218–225. [Google Scholar] [PubMed]

- Harrington, E.; Wilson, H.J. Depth of cure of radiation-activated materials--effect of mould material and cavity size. J. Dent. 1993, 21, 305–311. [Google Scholar] [CrossRef]

- Leonard, D.L.; Charlton, D.G.; Roberts, H.R.; Hilton, T.J.; Zionic, A. Determination of the minimum irradiance required for adequate polymerization of a hybrid and a microfill composite. Oper. Dent. 2001, 26, 176–180. [Google Scholar]

- Knežević, A.; Tarle, Z.; Meniga, A.; Šutalo, J.; Pichler, G.; Ristić, M. Degree of conversion and temperature rise during polymerization of composite resin samples with blue diodes. J. Oral Rehabil. 2001, 28, 586–591. [Google Scholar] [CrossRef]

- Rueggeberg, F.A.; Caughman, W.F.; Curtis, J.W., Jr. Effect of light intensity and exposure duration on cure of resin composite. Oper. Dent. 1994, 19, 26–32. [Google Scholar]

- Manga, R.K.; Charlton, D.G.; Wakefield, C.W. In vitro evaluation of a curing radiometer as a predictor of polymerization depth. Gen. Dent. 1995, 43, 241–243; quiz 245–246. [Google Scholar]

- Tanoue, N.; Matsumura, H.; Atsuta, M. Curing depth of a composite veneering material polymerized with seven different laboratory photo-curing units. J. Oral Rehabil. 1998, 25, 199–203. [Google Scholar] [CrossRef]

- Warren, K. An investigation into the microhardness of a light cured composite when cured through varying thicknesses of porcelain. J. Oral Rehabil. 1990, 17, 327–334. [Google Scholar] [CrossRef] [PubMed]

- Lynch, C.D.; Roberts, J.L.; Al-Shehri, A.; Milward, P.J.; Sloan, A.J. An ex-vivo model to determine dental pulp responses to heat and light-curing of dental restorative materials. J. Dent. 2018, 79, 11–18. [Google Scholar] [CrossRef] [PubMed]

- Jo, S.A.; Lee, C.H.; Kim, M.J.; Ferracane, J.; Lee, I.B. Effect of pulse-width-modulated LED light on the temperature change of composite in tooth cavities. Dent. Mater. 2019, 35, 554–563. [Google Scholar] [CrossRef] [PubMed]

- Price, R.B.; Ferracane, J.L.; Shortall, A.C. Light-Curing Units: A Review of What We Need to Know. J. Dent. Res. 2015, 94, 1179–1186. [Google Scholar] [CrossRef]

- Shim, J.S.; Kang, J.K.; Jha, N.; Ryu, J.J. Polymerization Mode of Self-Adhesive, Dual-Cured Dental Resin Cements Light Cured Through Various Restorative Materials. J. Esthet. Restor. Dent. 2017, 29, 209–214. [Google Scholar] [CrossRef]

| Cavity Type (Diameter × Length) /Irradiating Methods (Intensity, Duration) | Low Intensity/Short Duration (L20, 400 mW/cm2, 20 s) | Low Intensity/Long Duration (L40, 400 mW/cm2, 40 s) | High Intensity/Short Duration (H20, 800 mW/cm2, 20 s) |

|---|---|---|---|

| Narrow/Shallow (NS, Ø 3.0 × 5.0 mm) | NS-L20 (N = 12) | NS-L40 (N = 12) | NS-H20 (N = 12) |

| Narrow/Deep (ND, Ø 3.0 × 10.0 mm) | ND-L20 (N = 12) | ND-L40 (N = 12) | ND-H20 (N = 12) |

| Wide/Shallow (WS, Ø 5.0 × 5.0 mm) | WS-L20 (N = 12) | WS-L40 (N = 12) | WS-H20 (N = 12) |

| Wide/Deep (WD, Ø 5.0 × 10.0 mm) | WD-L20 (N = 12) | WD-L40 (N = 12) | WD-H20 (N = 12) |

| N | Mean (SD) | Median (IQR) | p-Value * | p-Value † | |

|---|---|---|---|---|---|

| 400 mW/cm2 | <0.001 | <0.001 | |||

| Narrow/Shallow | 10 | 29.2 (3.1) | 29.0 (27.0, 31.0) | b | a |

| Narrow/Deep | 10 | 21.5 (3.0) | 21.0 (19.0, 22.0) | a | a |

| Wide/Shallow | 10 | 83.9 (6.5) | 83.5 (78.0, 87.0) | d | a |

| Wide/Deep | 10 | 64.8 (4.6) | 64.5 (61.0, 69.0) | c | a |

| 800 mW/cm2 | |||||

| Narrow/Shallow | 10 | 63.4 (5.9) | 64.5 (62.0, 67.0) | b | b |

| Narrow/Deep | 10 | 47.7 (2.8) | 48.5 (45.0, 50.0) | a | b |

| Wide/Shallow | 10 | 184.7 (5.1) | 187.0 (183.0, 188.0) | d | b |

| Wide/Deep | 10 | 141.7 (5.8) | 143.0 (141.0, 146.0) | c | b |

| N | Mean (SD) | Median (IQR) | p-Value * | |

|---|---|---|---|---|

| Irradiance | <0.001 | |||

| 400 mW/cm2, 20 s | 48 | 43.8 (4.7) | 44.4 (40.2, 47.3) | a |

| 400 mW/cm2, 40 s | 48 | 49.3 (10.0) | 48.8 (41.7, 59.0) | b |

| 800 mW/cm2, 20 s | 48 | 52.7 (7.6) | 51.7 (46.5, 59.5) | b |

| Teflon Mold | <0.001 | |||

| Narrow/Shallow | 36 | 42.6 (4.2) | 42.9 (39.3, 45.5) | a |

| Narrow/Deep | 36 | 41.9 (4.4) | 41.7 (39.4, 44.8) | a |

| Wide/Shallow | 36 | 57.1 (7.2) | 59.3 (50.6, 62.9) | c |

| Wide/Deep | 36 | 52.8 (5.5) | 52.1 (48.0, 56.8) | b |

| Mean (SD) | Median (IQR) | p-Value * | |

|---|---|---|---|

| Narrow/Shallow | <0.001 | ||

| Negative control | 39.9 (2.5) | 39.2 (38.0, 42.4) | a |

| 400 mW/cm2, 20 s | 39.9 (2.6) | 40.2 (38.0, 40.5) | a |

| 400 mW/cm2, 40 s | 40.9 (3.5) | 42.1 (37.0, 43.6) | a |

| 800 mW/cm2, 20 s | 46.9 (2.8) | 47.0 (44.0, 50.1) | b |

| Positive control | 72.3 (5.3) | 73.8 (67.3, 76.7) | c |

| Narrow/Deep | <0.001 | ||

| Negative control | 39.9 (2.5) | 39.2 (38.0, 42.4) | a |

| 400 mW/cm2, 20 s | 40.2 (3.8) | 40.8 (37.3, 42.6) | a |

| 400 mW/cm2, 40 s | 39.7 (3.5) | 39.8 (37.5, 41.7) | a |

| 800 mW/cm2, 20 s | 45.9 (3.0) | 46.0 (43.4, 47.8) | b |

| Positive control | 72.3 (5.3) | 73.8 (67.3, 76.7) | c |

| Wide/Shallow | <0.001 | ||

| Negative control | 39.9 (2.5) | 39.2 (38.0, 42.4) | a |

| 400 mW/cm2, 20 s | 48.7 (2.5) | 49.0 (46.5, 50.6) | b |

| 400 mW/cm2, 40 s | 60.9 (4.4) | 59.5 (58.4, 65.5) | c |

| 800 mW/cm2, 20 s | 61.8 (4.6) | 61.6 (60.3, 64.6) | c |

| Positive control | 72.3 (5.3) | 73.8 (67.3, 76.7) | d |

| Wide/Deep | <0.001 | ||

| Negative control | 39.9 (2.5) | 39.2 (38.0, 42.4) | a |

| 400 mW/cm2, 20 s | 46.5 (2.2) | 46.9 (45.4, 48.0) | b |

| 400 mW/cm2, 40 s | 55.8 (3.4) | 56.1 (52.1, 59.1) | c |

| 800 mW/cm2, 20 s | 56.3 (3.8) | 56.0 (53.2, 58.6) | c |

| Positive control | 72.3 (5.3) | 73.8 (67.3, 76.7) | d |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, H.-K.; Keerthana, S.; Song, S.-Y.; Li, C.; Shim, J.S.; Ryu, J.J. Effect of Light Irradiance and Curing Duration on Degree of Conversion of Dual-Cure Resin Core in Various Cavities with Different Depths and Diameters. Materials 2024, 17, 4342. https://doi.org/10.3390/ma17174342

Lim H-K, Keerthana S, Song S-Y, Li C, Shim JS, Ryu JJ. Effect of Light Irradiance and Curing Duration on Degree of Conversion of Dual-Cure Resin Core in Various Cavities with Different Depths and Diameters. Materials. 2024; 17(17):4342. https://doi.org/10.3390/ma17174342

Chicago/Turabian StyleLim, Ho-Kyung, Subramanian Keerthana, So-Yeon Song, Chongyang Li, Ji Suk Shim, and Jae Jun Ryu. 2024. "Effect of Light Irradiance and Curing Duration on Degree of Conversion of Dual-Cure Resin Core in Various Cavities with Different Depths and Diameters" Materials 17, no. 17: 4342. https://doi.org/10.3390/ma17174342

APA StyleLim, H.-K., Keerthana, S., Song, S.-Y., Li, C., Shim, J. S., & Ryu, J. J. (2024). Effect of Light Irradiance and Curing Duration on Degree of Conversion of Dual-Cure Resin Core in Various Cavities with Different Depths and Diameters. Materials, 17(17), 4342. https://doi.org/10.3390/ma17174342