Experimental Study on Shear Strengthening of Reinforced Concrete Beams by Fabric-Reinforced Cementitious Matrix

Abstract

1. Introduction

2. Experimental Scheme

2.1. Specimen Detail

2.2. FRCM Strengthening

2.3. Loading and Measurement

3. Experimental Results

3.1. Failure Mode and Crack Pattern

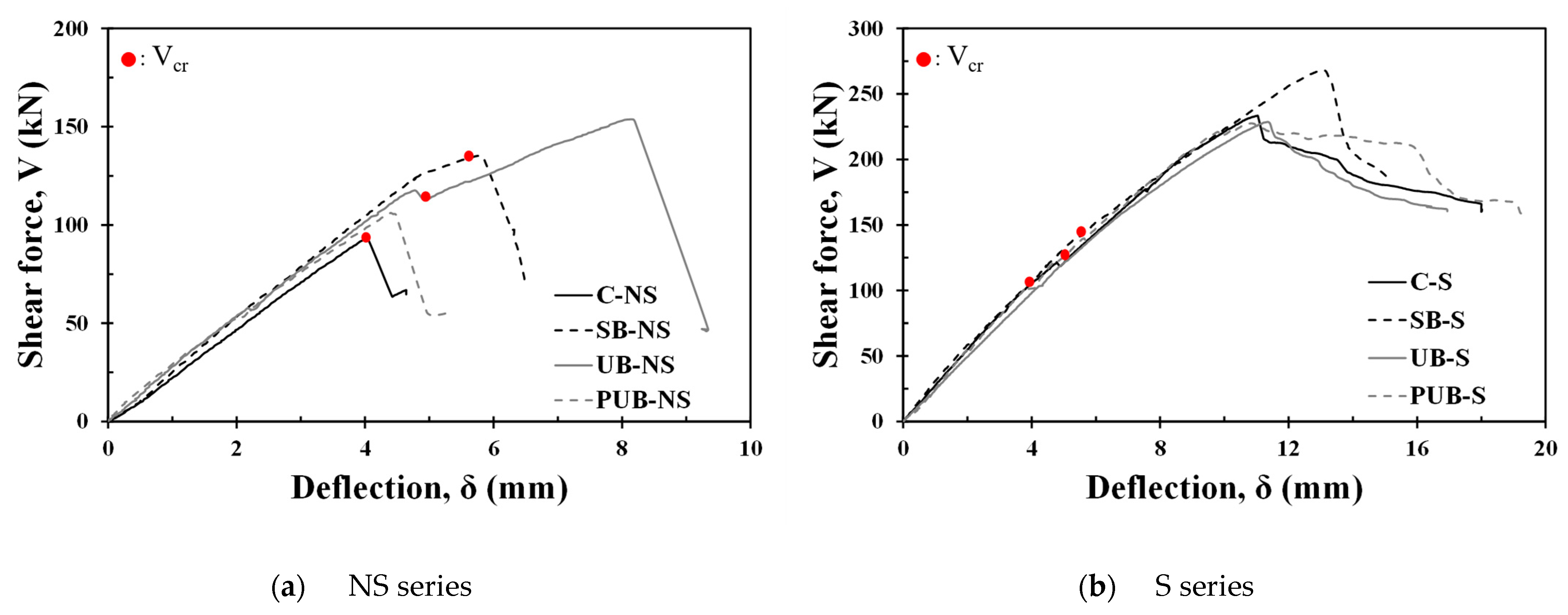

3.2. Load–Deflection Relationship

3.3. Shear Reinforcement Strain

3.4. Digital Image Correlation Analysis

4. Evaluation of Shear Capacity

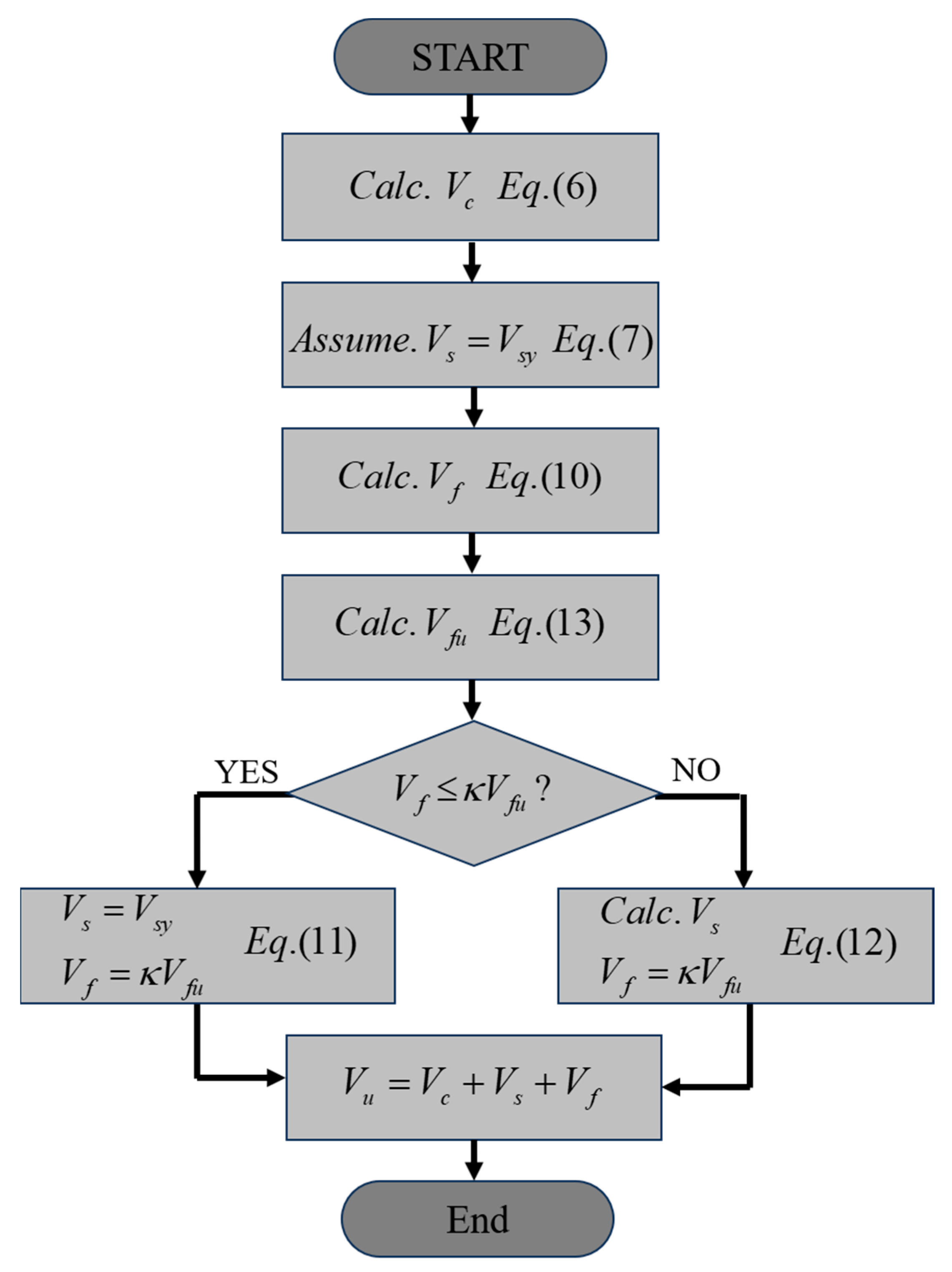

4.1. Evaluation Model

4.2. Application of the Proposed Model

5. Conclusions

- (1)

- All the specimens failed with diagonal cracking within the shear span. The FRCM shear strengthening effect ranged from 14% to 65% in specimens without shear reinforcement. For the specimens with shear reinforcement, a shear strength improvement of 16% was confirmed in the FRCM-sided bond type; however, in the U-shaped strengthening specimen, it was difficult to confirm the strength improvement effect owing to the lack of bond capacity between the FRCM and concrete substrate, which caused the FRCM to fall off and the concrete to crush before the shear strength fully developed;

- (2)

- For the PUB specimen strengthened using the prefabricated FRCM panel, the load was not transferred from the concrete member to the FRCM panel, and the strengthening effect could not be confirmed because the FRCM panel detached from the member. Therefore, the strengthening method should be improved to secure the bond capacity so that the FRCM and concrete substrate can exhibit fully bonded behavior;

- (3)

- Based on the experimental data, the average shear strain data obtained through DIC displacement tracking were compared with the trend of the experimental data, and it was found that the shear stiffness tends to decrease after crack initiation, and FRCM strengthening can control the decrease in shear stiffness. In particular, U-shaped FRCM strengthening exhibited the best control of cracking and shear stiffness reduction;

- (4)

- Based on the DIC displacement data, longitudinal, vertical, and shear strains were derived, and the principal strain angle was calculated using the strain data. The principal strain angles of the FRCM-strengthened specimens were lower. The results of the comparison of the crack pattern and the calculated principal strain angle showed a similar trend overall but were quantitatively quite different. In addition, the contributions of shear and flexure to the vertical deflection were analyzed, and it was confirmed that the deflection contribution due to shear increased after shear cracking occurred;

- (5)

- A shear strength evaluation model for FRCM-strengthened RC beams was developed by applying the bond reduction factor, and the shear strengths of the specimens were evaluated to be 28–35% conservative. To apply the proposed model to the FRCM strengthening design, it is necessary to verify the strength evaluation model using more experimental data.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Raoof, S.M.; Koutas, L.N.; Bournas, D.A. Textile-reinforced mortar (TRM) versus fibre-reinforced polymers (FRP) in flexural strengthening of RC beams. Constr. Build. Mater. 2017, 151, 279–291. [Google Scholar] [CrossRef]

- Zaman, A.; Gutub, S.A.; Wafa, M.A. A review on FRP composites applications and durability concerns in the construction sector. J. Reinf. Plast. Compos. 2013, 32, 1966–1988. [Google Scholar] [CrossRef]

- Shi, J. Fiber-Reinforced Polymers and Fiber-Reinforced Concrete in Civil Engineering. Buildings 2023, 13, 1755. [Google Scholar] [CrossRef]

- Ju, H.; Han, S.J.; Cho, H.C.; Lee, D.H.; Kim, K.S. Flexural Performance of Slabs Strengthened by Fiber-Reinforced Polymer Sheet with Hydrophilic Epoxy. J. Korea Concr. Inst. 2016, 28, 85–94. [Google Scholar] [CrossRef]

- Koutas, L.N.; Tetta, Z.; Bournas, D.A.; Triantafillou, T.C. Strengthening of concrete structures with textile reinforced mortars: State-of-the-art review. J. Compos. Constr. 2019, 23, 03118001. [Google Scholar] [CrossRef]

- Seo, Y.; Ju, H.; Choi, D. Flexural Performance of One-Way Reinforced Concrete Slab Strengthened by Carbon Fabric Reinforced Cementitious Matrix. J. Korea Concr. Inst. 2023, 35, 37–47. [Google Scholar] [CrossRef]

- Donnini, J.; Corinaldesi, V. Mechanical characterization of different FRCM systems for structural reinforcement. Constr. Build. Mater. 2017, 145, 565–575. [Google Scholar] [CrossRef]

- Ascione, L.; de Felice, G.; de Santis, S. A qualification method for externally bonded Fibre Reinforced Cementitious Matrix (FRCM) strengthening systems. Compos. Part B Eng. 2015, 78, 497–506. [Google Scholar] [CrossRef]

- Donnini, J.; Spagnuolo, S.; Corinaldesi, V. A comparison between the use of FRP, FRCM and HPM for concrete confinement. Compos. Part B Eng. 2019, 160, 586–594. [Google Scholar] [CrossRef]

- Jo, M.S.; Kim, H.G.; Lee, Y.J.; Kim, D.H.; Kim, K.H. Evaluation of mechanical properties and flexural behavior of FRCM system composed of different types of textile grid and AL powder. Constr. Build. Mater. 2022, 323, 126552. [Google Scholar] [CrossRef]

- Aljazaeri, Z.R.; Myers, J.J. Strengthening of reinforced-concrete beams in shear with a fabric-reinforced cementitious matrix. J. Compos. Constr. 2017, 21, 04017041. [Google Scholar] [CrossRef]

- Lee, D.; Han, S.J.; Ju, H.; Kim, K.S. Shear Strength of Prestressed Concrete Beams Considering Bond Mechanism in Reinforcement. ACI Struct. J. 2021, 118, 267–277. [Google Scholar]

- Yerzhanov, M.; Ju, H.; Zhang, D.; Moon, S.W.; Kim, J.; Lee, D.H. Shear Strengths Model of Reinforced Concrete Beams without Stirrup Used in the CIS Countries. J. Struct. Integr. Maint. 2019, 4, 15–25. [Google Scholar] [CrossRef]

- Lee, D.; Han, S.J.; Ju, H.; Zhang, D.; Kim, K.S. Shear Strength Model for Prestressed Concrete Beams with Steel Fibers Failed in Shear. Mag. Concr. Res. 2021, 73, 731–742. [Google Scholar] [CrossRef]

- Loreto, G.; Babaeidarabad, S.; Leardini, L.; Nanni, A. RC beams shear-strengthened with fabric-reinforced-cementitious-matrix (FRCM) composite. Int. J. Adv. Struct. Eng. (IJASE) 2015, 7, 341–352. [Google Scholar] [CrossRef]

- Tetta, Z.C.; Koutas, L.N.; Bournas, D.A. Textile-reinforced mortar (TRM) versus fiber-reinforced polymers (FRP) in shear strengthening of concrete beams. Compos. Part B Eng. 2015, 77, 338–348. [Google Scholar] [CrossRef]

- Awani, O.; El-Maaddawy, T.; El Refai, A. Numerical simulation and experimental testing of concrete beams strengthened in shear with fabric-reinforced cementitious matrix. J. Compos. Constr. 2016, 20, 04016056. [Google Scholar] [CrossRef]

- Trapko, T.; Urbańska, D.; Kamiński, M. Shear strengthening of reinforced concrete beams with PBO-FRCM composites. Compos. Part B Eng. 2015, 80, 63–72. [Google Scholar] [CrossRef]

- Tzoura, E.; Triantafillou, T.C. Shear strengthening of reinforced concrete T-beams under cyclic loading with TRM or FRP jackets. Mater. Struct. 2016, 49, 17–28. [Google Scholar] [CrossRef]

- Blanksvärd, T.; Täljsten, B.; Carolin, A. Shear strengthening of concrete structures with the use of mineral-based composites. J. Compos. Constr. 2009, 13, 25. [Google Scholar] [CrossRef]

- Azam, R.; Soudki, K. FRCM strengthening of shear-critical RC beams. J. Compos. Constr. 2014, 18, 04014012. [Google Scholar] [CrossRef]

- Escrig, C.; Gil, L.; Bernat-Maso, E.; Puigvert, F. Experimental and analytical study of reinforced concrete beams shear strengthened with different types of textile-reinforced mortar. Constr. Build. Mater. 2015, 83, 248–260. [Google Scholar] [CrossRef]

- Awani, O.; El-Maaddawy, T.; Ismail, N. Fabric-reinforced cementitious matrix: A promising strengthening technique for concrete structures. Constr. Build. Mater. 2017, 132, 94–111. [Google Scholar] [CrossRef]

- Košćak, J.; Damjanović, D.; Bartolac, M.; Duvnjak, I. Shear behavior of RC beams without transverse reinforcement: An analysis of crack kinematics and transfer mechanisms based on stereophotogrammetric measurements. Eng. Struct. 2022, 255, 113886. [Google Scholar] [CrossRef]

- Hwang, J.H.; Lee, D.H.; Ju, H.; Kim, K.S.; Kang TH, K.; Pan, Z. Shear deformation of steel fiber-reinforced prestressed concrete beams. Int. J. Concr. Struct. Mater. 2016, 10, 53–63. [Google Scholar] [CrossRef]

- Raoof, S.M.; Koutas, L.N.; Bournas, D.A. Bond between textile-reinforced mortar (TRM) and concrete substrates: Experimental investigation. Compos. Part B Eng. 2016, 98, 350–361. [Google Scholar] [CrossRef]

- D’Ambrisi, A.; Feo, L.; Focacci, F. Bond-slip relations for PBO-FRCM materials externally bonded to concrete. Compos. Part B 2012, 43, 2938–2949. [Google Scholar] [CrossRef]

- Seo, Y. Bond Capacity between Fabric Reinforced Cementitious Matrix and Concrete Considering Fabric Characteristics. Master’s Thesis, Hankyong National University, Anseong-si, Republic of Korea, 2024. [Google Scholar]

- Lee, J.Y.; Hwang, H.B.; Doh, J.H. Effective strain of RC beams strengthened in shear with FRP. Compos. Part B Eng. 2012, 43, 754–765. [Google Scholar] [CrossRef]

- Han, S.J.; Ju, H.; Joo, H.E.; Kim, K.S. Shear Resistance Mechanism of Prefabricated Large-Scale Gerber Girder. J. Build. Eng. 2024, 83, 108424. [Google Scholar] [CrossRef]

- Ju, H.; Han, S.J.; Joo, H.E.; Cho, H.C.; Kim, K.S.; Oh, Y.H. Shear Performance of Optimized-Section Precast Slab with Tapered Cross Section. Sustainability 2019, 11, 163. [Google Scholar] [CrossRef]

- Bischoff, P.H. Reevaluation of deflection prediction for concrete beams reinforced with steel and fiber reinforced polymer bars. J. Struct. Eng. 2005, 131, 752–767. [Google Scholar] [CrossRef]

- Goszczyńska, B.; Trąmpczyński, W.; Tworzewska, J. Analysis of Crack Width Development in Reinforced Concrete Beams. Materials 2021, 14, 3043. [Google Scholar] [CrossRef] [PubMed]

- Vecchio, F.J.; Collins, M.P. The modified compression-field theory for reinforced concrete elements subjected to shear. ACI J. 1986, 83, 219–231. [Google Scholar]

- ACI Committee 549. Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitious Matrix (FRCM) Systems for Repair and Strengthening Concrete and Masonry Structures (ACI 549.4R-13); American Concrete Institute (ACI): Farmington Hills, MI, USA, 2013. [Google Scholar]

- ACI Committee 318-19. Building Code Requirements for Structural Concrete (ACI 318-19); American Concrete Institute (ACI): Farmingtom Hills, MI, USA, 2019. [Google Scholar]

- Cho, H.C.; Park, M.K.; Ju, H.; Oh, J.Y.; Oh, Y.H.; Kim, K.S. Shear Strength Reduction Factor of Prestressed Hollow-Core Slab Units Based on the Reliability Approach. Adv. Mater. Sci. Eng. 2017, 2017, 8280317. [Google Scholar] [CrossRef]

| Concrete | Rebar | ||||

|---|---|---|---|---|---|

(MPa) | (MPa) | Type | Modulus of Elasticity (GPa) | Yield Strength (MPa) | Ultimate Strength (MPa) |

| 36.84 | 2.18 | D10 | 200 | 483 | 621 |

| D13 | 526 | 635 | |||

| D19 | 557 | 701 | |||

| Mortar | Fabric | |||||||

|---|---|---|---|---|---|---|---|---|

| Type | Compressive Strength (MPa) | Tensile Strength (MPa) | Type | Distance between Tows (mm) | Area (mm2) | Modulus of Elasticity (GPa) | Tensile Strength (MPa) | (%) |

| C | - | - | Carbon | 20 | 0.838 | 184 | 1962 | 1.07 |

| SB | 59.00 | 7.41 | ||||||

| UB | 62.70 | 6.51 | ||||||

| PUB | 41.58 | 5.86 | ||||||

| Specimen | (kN) | (mm) | (kN) | (mm) | ) |

|---|---|---|---|---|---|

| C-NS | 93.3 | 4.04 | 93.3 | 4.04 | 0 |

| SB-NS | 135.3 | 5.78 | 134.4 | 5.62 | 42 |

| UB-NS | 153.8 | 8.14 | 112 | 4.96 | 60.5 |

| PUB-NS | 106.1 | 4.40 | - | - | 12.8 |

| C-S | 233.4 | 11.04 | 105 | 3.98 | 0 |

| SB-S | 268.0 | 13.08 | 141 | 5.56 | 34.6 |

| UB-S | 228.7 | 11.36 | 122.4 | 5.08 | −4.7 |

| PUB-S | 227.5 | 10.82 | - | - | −5.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, C.; Seo, Y.; Hong, J.; Heo, J.; Cho, H.-C.; Ju, H. Experimental Study on Shear Strengthening of Reinforced Concrete Beams by Fabric-Reinforced Cementitious Matrix. Materials 2024, 17, 4336. https://doi.org/10.3390/ma17174336

Jung C, Seo Y, Hong J, Heo J, Cho H-C, Ju H. Experimental Study on Shear Strengthening of Reinforced Concrete Beams by Fabric-Reinforced Cementitious Matrix. Materials. 2024; 17(17):4336. https://doi.org/10.3390/ma17174336

Chicago/Turabian StyleJung, Chanseo, Yujae Seo, Junseo Hong, Jinhyeong Heo, Hae-Chang Cho, and Hyunjin Ju. 2024. "Experimental Study on Shear Strengthening of Reinforced Concrete Beams by Fabric-Reinforced Cementitious Matrix" Materials 17, no. 17: 4336. https://doi.org/10.3390/ma17174336

APA StyleJung, C., Seo, Y., Hong, J., Heo, J., Cho, H.-C., & Ju, H. (2024). Experimental Study on Shear Strengthening of Reinforced Concrete Beams by Fabric-Reinforced Cementitious Matrix. Materials, 17(17), 4336. https://doi.org/10.3390/ma17174336