Influences of Pre-Existing Fissure Angles and Bridge Angles on Concrete Tensile Failure Characteristics: Insights from Meshless Numerical Simulations

Abstract

1. Introduction

2. SPH Foundation Property Equations and Fracture Treatment Method

2.1. SPH Fundamental Property Equations

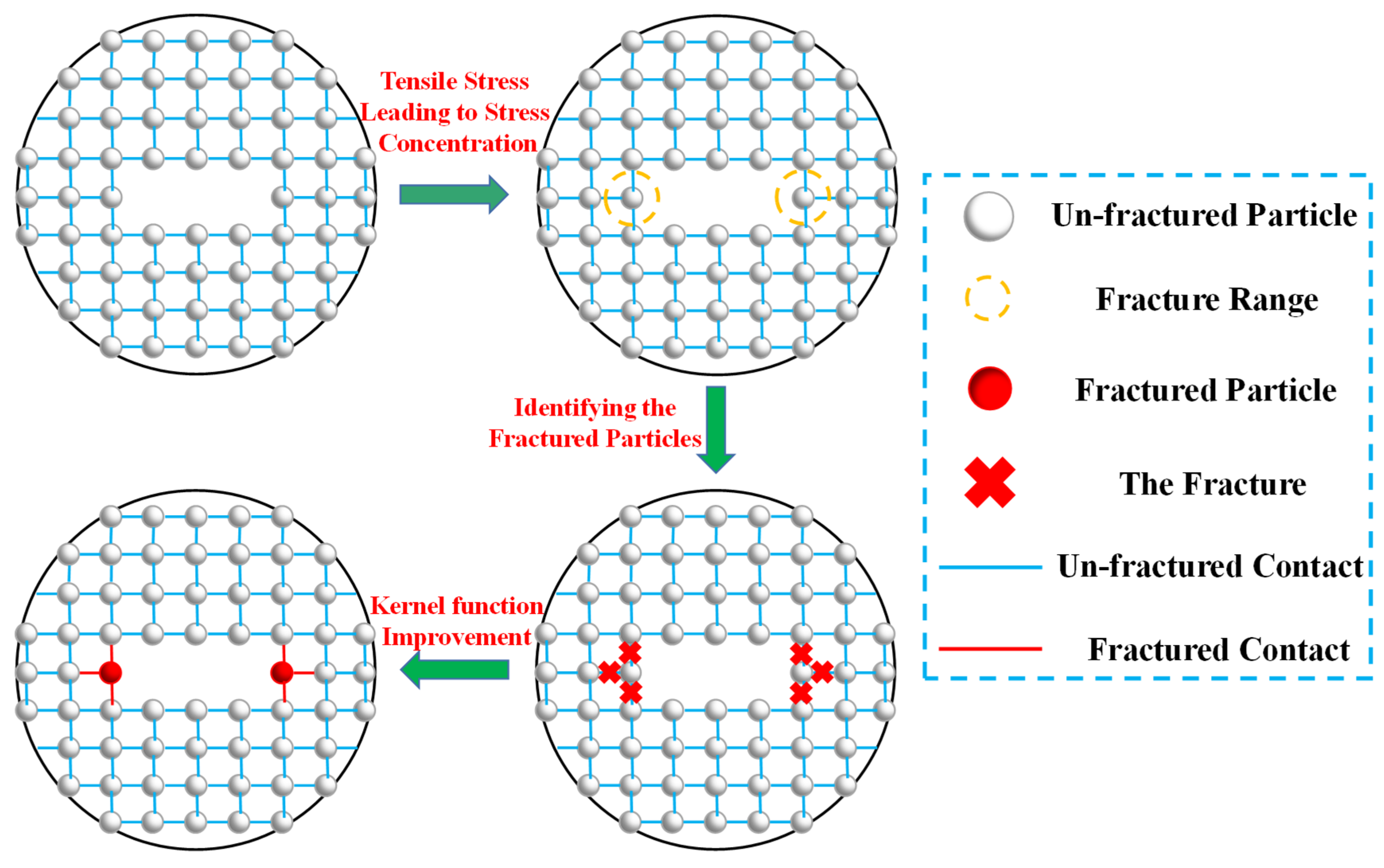

2.2. SPH Fracture Treatments

3. SPH Generation Methods of Aggregates, Pores, and Transition Layers

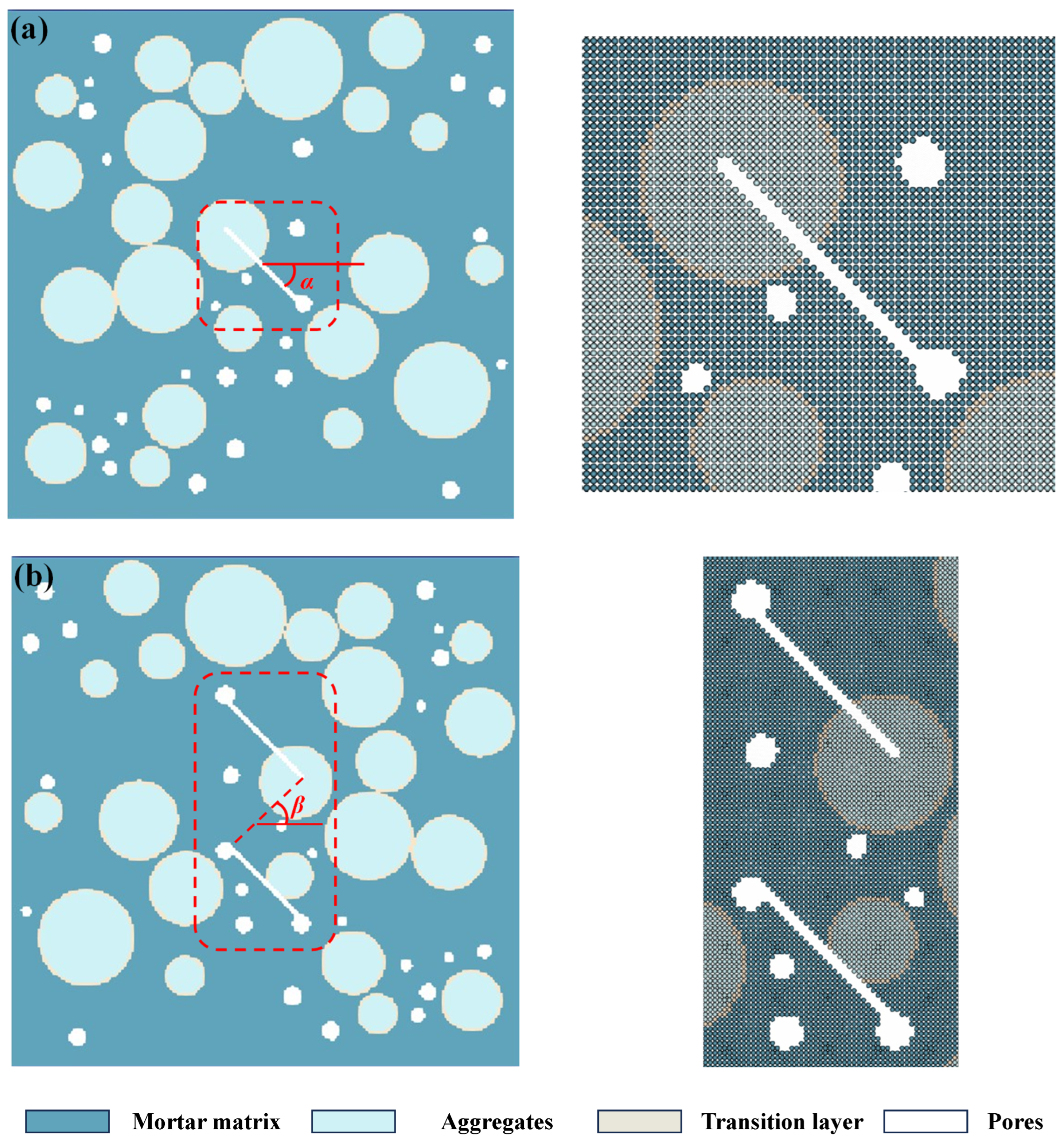

3.1. Determination Method for Mesoscopic Parameters of Aggregates, Pores and Transition Layers

- (1)

- Determine the model parameters. According to the requirements of the numerical simulation, the size of the model is determined. For the two-dimensional condition, determine the length l and width m of the model. At the same time, according to the composition statistics of each meso-structure of the concrete model, it is determined that the percentage of aggregate is Pa and the percentage of porosity is Pv.

- (2)

- The center coordinates (xai, yai) of the random circular aggregate and the radius rai of the circular aggregate are generated by setting random number seeds. Before generation, it is necessary to compare the generated circular aggregate i with the previously generated circular core aggregate i − 1 to make sure that the ith circular aggregate does not overlap with the previous i − 1 circular aggregates. The principle of determination is that the center distance between the ith circular aggregate and the i − 1 circular aggregates must be greater than the sum of the radii of the i circular aggregate and the i − 1 circular aggregate. For each circular aggregate that is determined to be generated, the particles around the periphery are the transition layer particles. For each ith circular aggregate generated, determine whether the ratio of the area of 1~i aggregates to the model area l × m has reached the predetermined percentage Pa. If so, step (3) is performed; if not, step (2) is repeated.

- (3)

- The center coordinates (xvi, yvi) of random pores are generated by setting random number seeds, and the radius of circular pore is rvi. Before the formation, it is necessary to compare the generated circular pore i with the previously generated i − 1 circular center pores to make sure that the ith circular pore does not overlap with the former i − 1 circular pores and the circular aggregates generated in step (2). The determination principle is that the distance between the center of the circles of the ith circular pore and the i − 1th circular pore must be greater than the sum of the radius of the ith circular pore and the i − 1th circular pore. For each circular center pore i generated, determine whether the ratio of the area of 1~i circular pores to the model area l × m has reached the predetermined percentage Pv. If so, perform step (4); if not, repeat step (3).

- (4)

- Enter the generated concrete mesoscopic model parameters into the model input files.

3.2. SPH Meso-Structure Generation Processes

- (1)

- Generate SPH matrix particles first, and their regular distributions are in the l × m range of the model. The parameters of the concrete pore structure generated in Section 3.1 are introduced. If SPH matrix particles are within the circle of the concrete pore, then no SPH particles are generated there, indicating that this place is a pore.

- (2)

- Generate aggregate particles. Import the aggregate parameters in Section 3.1. If SPH matrix particles are within the circle of concrete pores, then SPH particles there are set as aggregate particles.

- (3)

- Generate transition layer particles. Import the parameters of the transition layer in Section 3.1. If the SPH matrix particle is within the range of the transition layer, the SPH particle there is set as the transition layer particles.

- (4)

- Different material mechanical parameters are assigned to different concrete meso-structures, and finally the concrete meso-SPH model is generated.

4. Numerical Simulation Results

4.1. Numerical Model and Parameters

4.2. Numerical Simulation Results Analysis

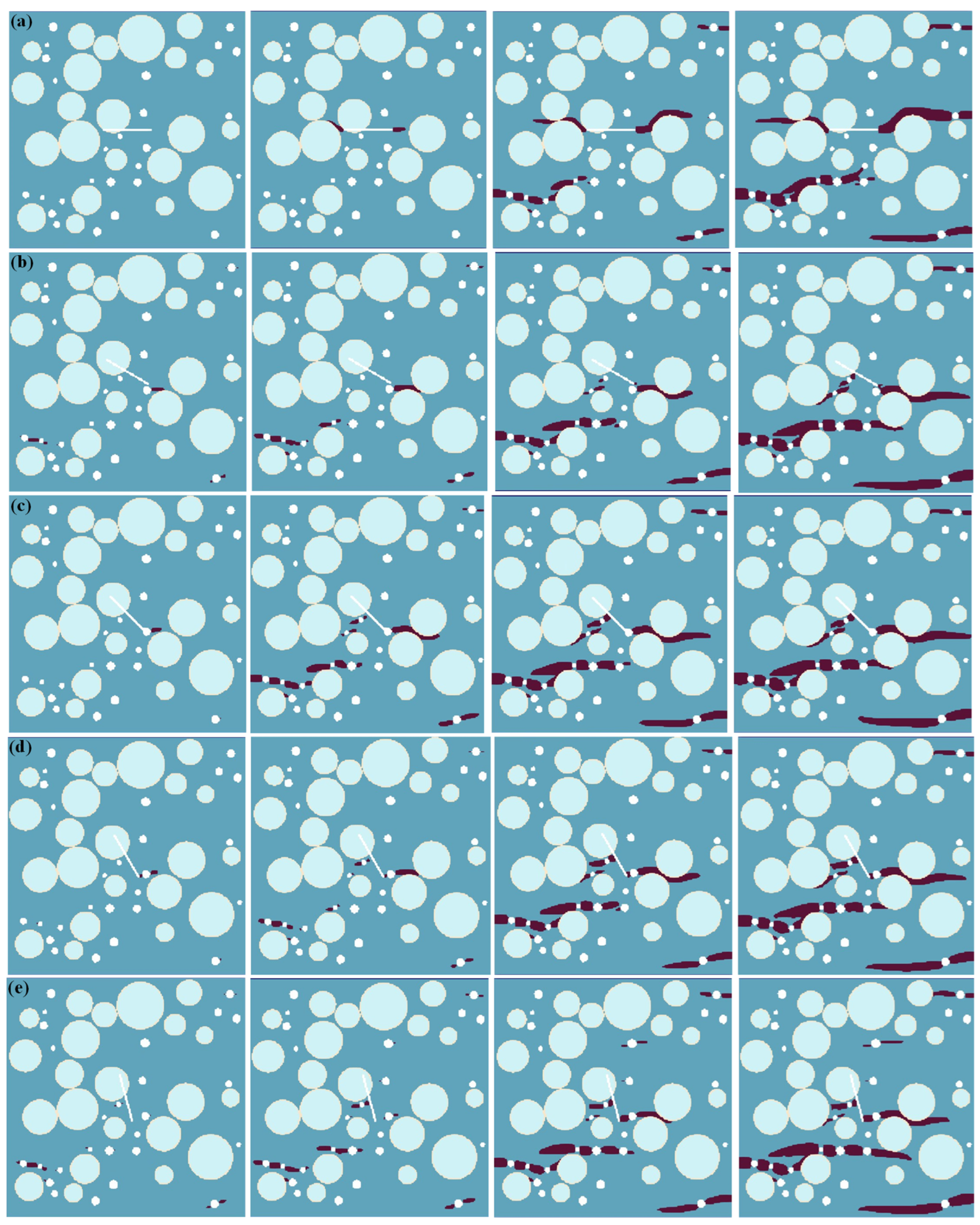

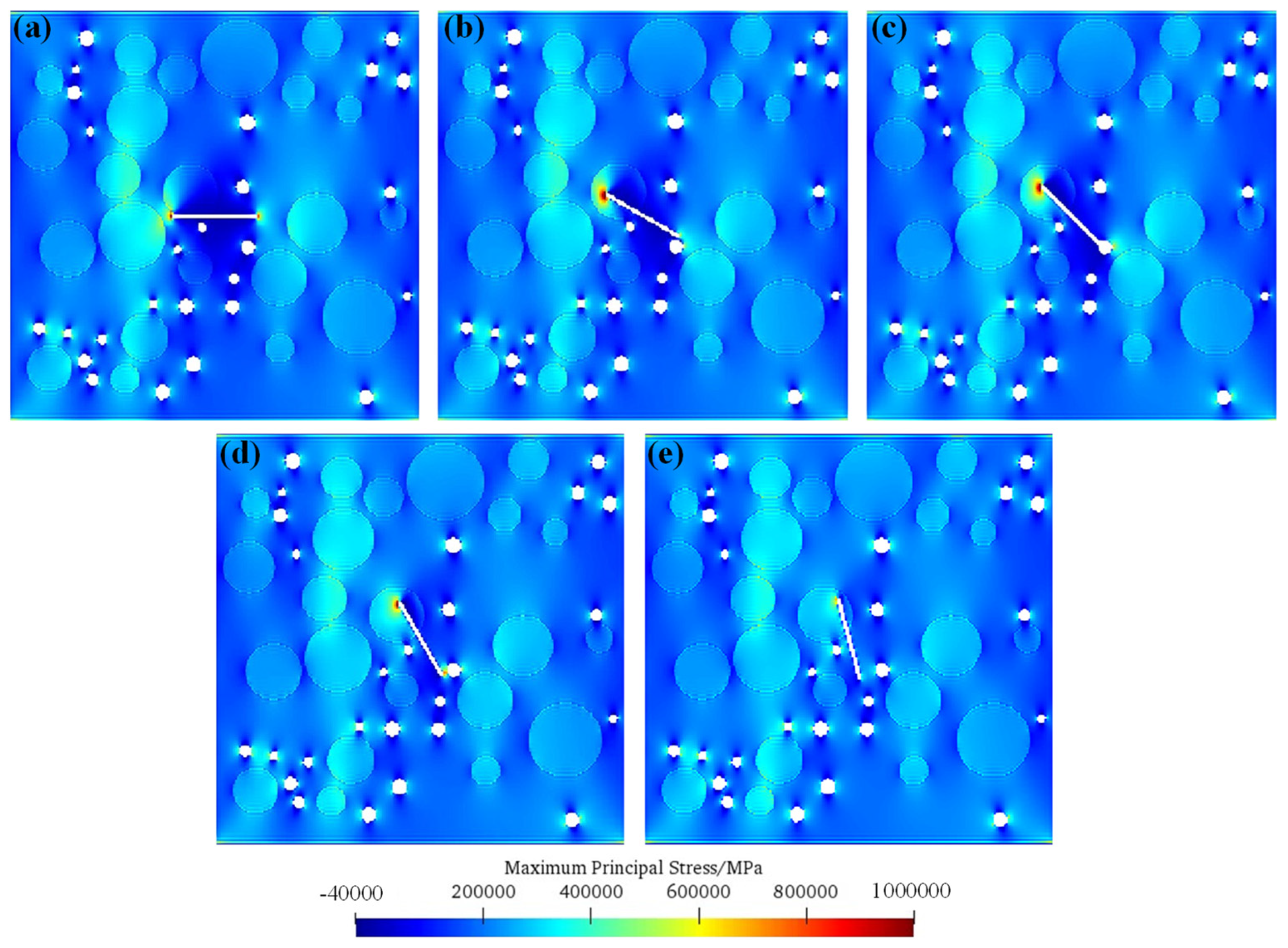

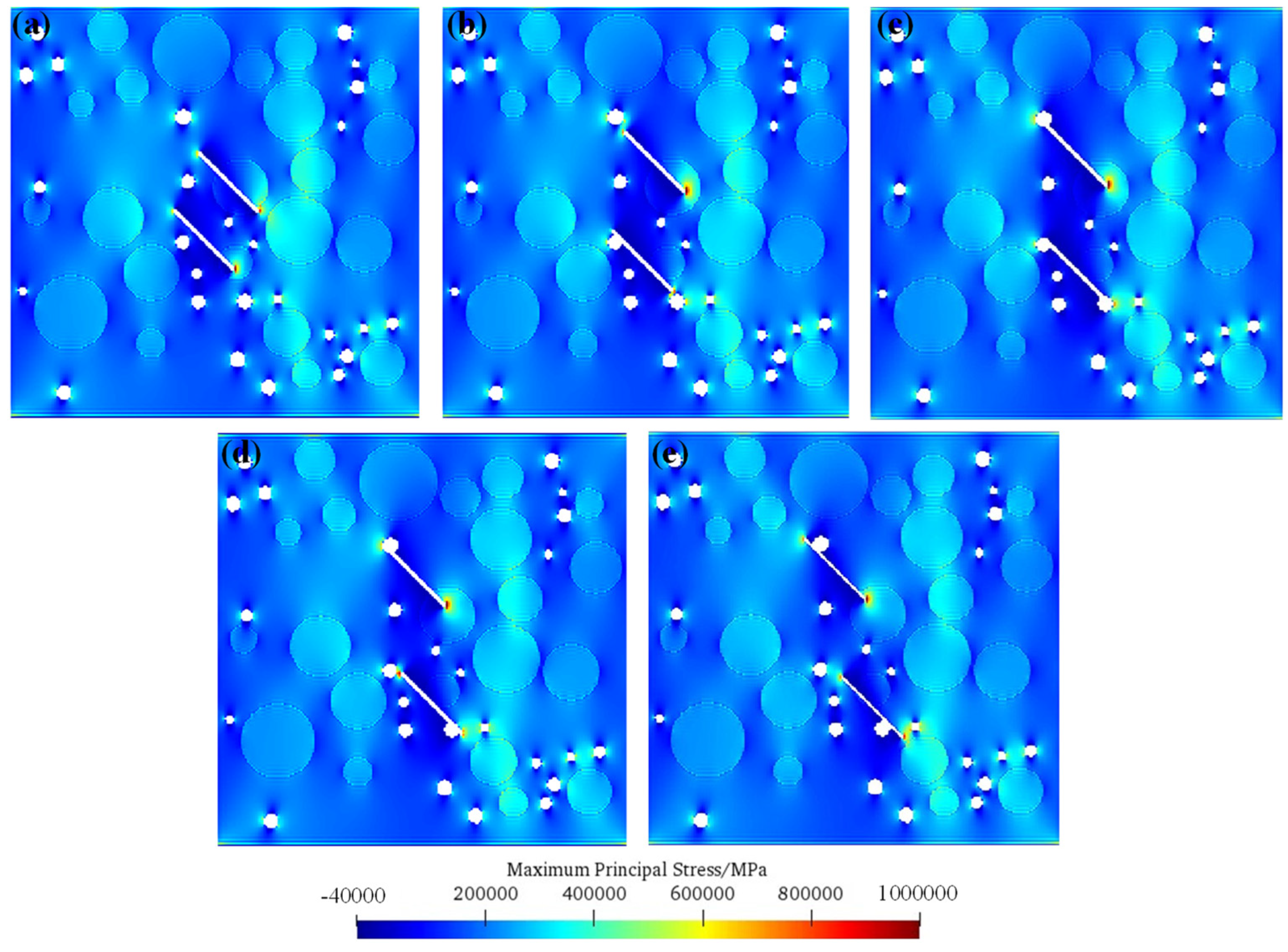

4.2.1. Progressive Crack Propagation Processes

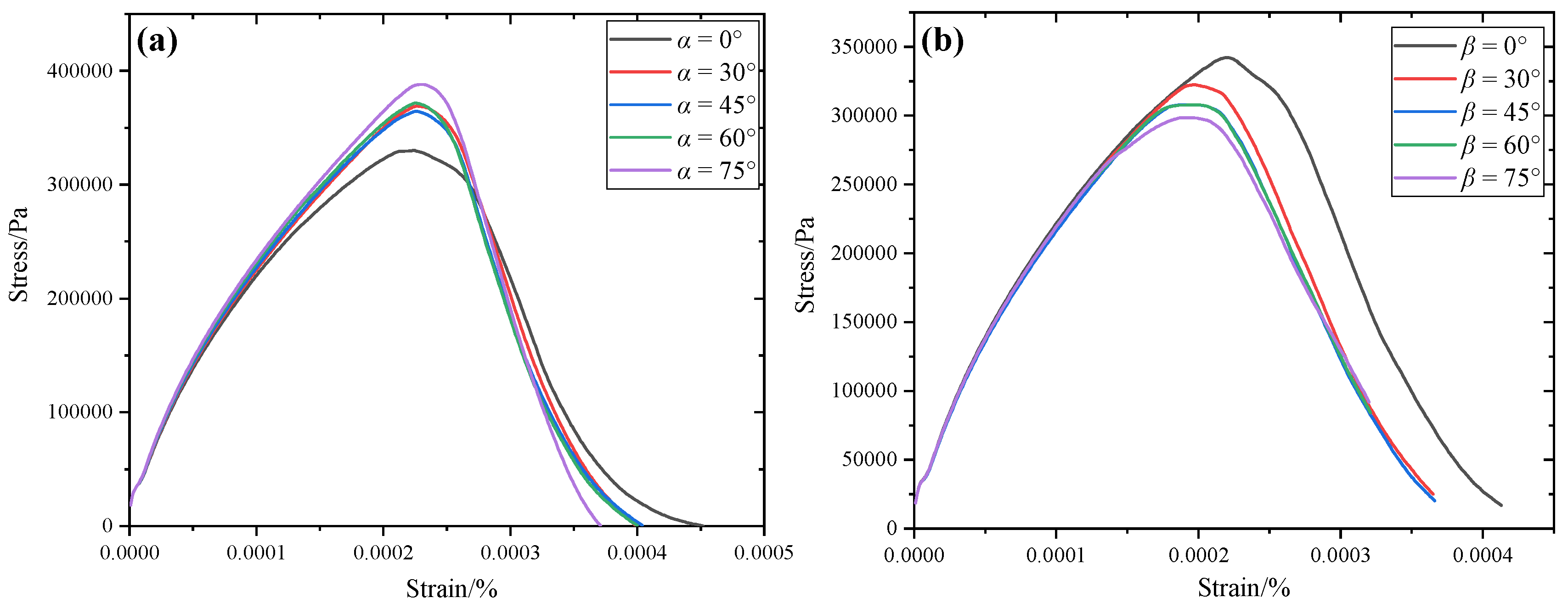

4.2.2. Stress–Strain Curve Analysis

5. Discussions

5.1. Initiation Mechanisms of Fissured Concrete under Single-Fissure Condition

5.2. Initiation Mechanisms of Fissured Concrete under Double-Fissure Condition

5.3. Application Prospects of SPH Method in Concrete Damage Evolution Simulation

6. Conclusions

- (1)

- A simulation method that can reflect the particle fracture processes in SPH is proposed, and the generation of the aggregate, pore, and transition layer in concrete is realized under the SPH framework, which can simulate the meso-tensile failure processes of concrete.

- (2)

- The transition layer, pore, and pre-existing micro-fissures are the weak parts of concrete, which are easy to crack. With the increase in the inclination angle of the pre-existing micro-fissure, the probability of crack growth in the pre-existing micro-fissure decreases gradually, while the probability of crack growth in the pore increases.

- (3)

- Except for the part in the double pre-existing micro-fissure tip, the rest of the crack growth occurs first. Finally, the crack growth generated by the pore and the crack growth generated by the pre-existing micro-fissure tip lead to the final failure of the model. With the increase in the bridge angle, the expansion degree of the crack also increases.

- (4)

- The stress–strain curve for the concrete model presents four typical stages: linear elastic stage, crack propagation stage, failure stage, and post-peak stage. The strength of the concrete model increases with the increase in the inclination angle of the pre-existing micro-fissure, but decreases with the increase in the bridge angle.

- (5)

- The initiation mechanisms of fissured concrete under different schemes are discussed. With the increase in the inclination angle of the pre-existing micro-fissure, the stress concentration degree of the pre-existing micro-fissure that is not embedded in the aggregate end gradually decreases, and with the increase in the bridge angle, the stress concentration degree of the double pre-existing micro-fissure that is not embedded in the aggregate end gradually increases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pan, J.; Xiong, S. Deformation, failure and restoration of the Trier arch dam in Switzerland. Dam Saf. 1987, 1, 2–22. [Google Scholar]

- Zhu, B. Re-discussion on the cause of fracture during construction of Xiaowan arch dam. Water Resour. Hydropower Eng. 2015, 46, 1–5. [Google Scholar]

- Ru, N.; Jiang, Z. Dam Accidents and Safety Arch Dams; Water Resources and Hydropower Press: Beijing, China, 1995. [Google Scholar]

- Morales-Alonso, G.; Rey-de-Pedraza, V.; Gálvez, F.; Cendón, D.A. Numerical simulation of fracture of concrete at different loading rates by using the cohesive crack model. Theor. Appl. Fract. Mech. 2018, 96, 308–325. [Google Scholar] [CrossRef]

- Zhang, W.; Li, H.; Shi, D.; Shen, Z.; Zhao, S.; Guo, C. Determination of Safety Monitoring Indices for Roller-Compacted Concrete Dams Considering Seepage-Stress Coupling Effects. Mathematics 2023, 11, 3224. [Google Scholar] [CrossRef]

- Trawiński, W.; Bobiński, J.; Tejchman, J. Two-dimensional simulations of concrete fracture at aggregate level with cohesive elements based on X-ray μCT images. Eng. Fract. Mech. 2016, 168, 204–226. [Google Scholar] [CrossRef]

- Leite, J.; Slowik, V.; Mihashi, H. Computer simulation of fracture processes of concrete using mesolevel models of lattice structures. Cem. Concr. Res. 2004, 34, 1025–1033. [Google Scholar] [CrossRef]

- Rashid, Y. Ultimate strength analysis of prestressed concrete pressure vessels. Nucl. Eng. Des. 1968, 7, 334–344. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, J. Fully automatic modelling of cohesive discrete crack propagation in concrete beams using local arc-length methods. Int. J. Solids Struct. 2004, 41, 801–826. [Google Scholar] [CrossRef]

- Yang, Z. Fully automatic modelling of mixed-mode crack propagation using scaled boundary finite element method. Eng. Fract. Mech. 2006, 73, 1711–1731. [Google Scholar] [CrossRef]

- Yang, Z.; Deeks, A. Fully-automatic modelling of cohesive crack growth using a finite element-scaled boundary finite element coupled method. Eng. Fract. Mech. 2007, 74, 2547–2573. [Google Scholar] [CrossRef]

- Barenblatt, G. The formation of equilibrium cracks during brittle fracture. General ideas and hypotheses. Axially-symmetric cracks. J. Appl. Math. Mech. 1959, 23, 622–636. [Google Scholar] [CrossRef]

- Dugdale, D. Yielding of steel sheets containing slits. J. Mech. Phys. Solids 1960, 8, 100–104. [Google Scholar] [CrossRef]

- Hillerborg, A.; Modéer, M.; Petersson, P. Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem. Concr. Res. 1976, 6, 773–782. [Google Scholar] [CrossRef]

- Xie, M.; Gerstle, W. Energy-based cohesive crack propagation modeling. J. Eng. Mech. 1995, 121, 1349–1358. [Google Scholar] [CrossRef]

- Yang, Z.; Frank, X. A heterogeneous cohesive model for quasi-brittle materials considering spatially varying random fracture properties. Comput. Methods Appl. Mech. Eng. 2008, 197, 4027–4039. [Google Scholar] [CrossRef]

- Yang, Z.; Su, X.; Chen, J.; Liu, G. Monte Carlo simulation of complex cohesive fracture in random heterogeneous quasi-brittle materials. Int. J. Solids Struct. 2009, 46, 3222–3234. [Google Scholar] [CrossRef]

- Xu, X.; Needleman, A. Numerical simulations of fast crack growth in brittle solids. J. Mech. Phys. Solids 1994, 42, 1397–1434. [Google Scholar] [CrossRef]

- López, C.; Carol, I.; Aguado, A. Meso-structural study of concrete fracture using interface elements. I: Numerical model and tensile behavior. Mater. Struct. 2008, 41, 583–599. [Google Scholar] [CrossRef]

- Santiago, G.; Jaime, C.; Gálvez, A.; Sancho, J.M. Modelling of corrosion-induced cover cracking in reinforced concrete by an embedded cohesive crack finite element. Eng. Fract. Mech. 2012, 93, 92–107. [Google Scholar]

- Su, X.; Yang, Z.; Liu, G. Finite element modelling of complex 3D static and dynamic crack propagation by embedding cohesive elements in abaqus. Acta Mech. Solida Sin. 2010, 23, 271–282. [Google Scholar] [CrossRef]

- Nicolas, M. A finite element method for crack growth without remeshing. Int. J. Numer. Methods Eng. 1999, 46, 131–150. [Google Scholar]

- Dolbow,·J. An Extended Finite Element Method with Discontinuous Enrichment for Applied Mechanics. Ph.D. Thesis, Northwestern University, Evanston, IL, USA, 1999.

- Areias, P.; Belytschko, T. Analysis of three-dimensional crack initiation and propagation using the extended finite element method. Int. J. Numer. Methods Eng. 2005, 63, 760–788. [Google Scholar] [CrossRef]

- Melenk, J.; Babuška, I. The partition of unity finite element method: Basic theory and applications. Comput. Methods Appl. Mech. Eng. 1996, 139, 289–314. [Google Scholar] [CrossRef]

- Zhou, X.; Zhao, Y.; Qian, Q. Smooth particle hydrodynamic numerical simulation of rock failure under uniaxial compression. Chin. J. Rock Mech. Eng. 2015, 34 (Suppl. S1), 2647–2658. [Google Scholar]

- Zhao, Y.; Zhou, X.; Qian, Q. Progressive failure processes of reinforced slopes based on general particle dynamic method. J. Cent. South Univ. 2015, 22, 4049–4055. [Google Scholar] [CrossRef]

- Bi, J. The Fracture Mechanisms of Rock Mass Under Stress, Seepage, Temperature and Damage Coupling Condition and Numerical Simulations by Using the General Particle Dynamics (GPD) Algorithm. Ph.D. Thesis, Chongqing University, Chongqing, China, 2016. [Google Scholar]

- Libersky, L.; Peetschek, A. High strain Lagrangian hydrodynamics: A three-dimensional SPH code for dynamic material response. J. Comput. Appl. Mech. Eng. 1996, 139, 375–408. [Google Scholar]

- Yang, S.; Ren, X.; Zhang, J. Study on hydraulic fracture of gravity dam using the numerical manifold method. Rock Soil Mech. 2018, 39, 3055–3060+3070. [Google Scholar]

- Yu, S.; Sun, Z.; Yu, J.; Yang, J.; Zhu, C. An improved meshless method for modeling the mesoscale cracking processes of concrete containing random aggregates and initial defects. Constr. Build. Mater. 2023, 363, 129770. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, C.; Li, T.; Fu, Z.; Mao, H.; Wang, S.; Liang, Z.; Yu, S. Influences of Pre-Existing Fissure Angles and Bridge Angles on Concrete Tensile Failure Characteristics: Insights from Meshless Numerical Simulations. Materials 2024, 17, 4305. https://doi.org/10.3390/ma17174305

Hu C, Li T, Fu Z, Mao H, Wang S, Liang Z, Yu S. Influences of Pre-Existing Fissure Angles and Bridge Angles on Concrete Tensile Failure Characteristics: Insights from Meshless Numerical Simulations. Materials. 2024; 17(17):4305. https://doi.org/10.3390/ma17174305

Chicago/Turabian StyleHu, Cong, Taicheng Li, Zhaoqing Fu, Haiying Mao, Siyao Wang, Zilin Liang, and Shuyang Yu. 2024. "Influences of Pre-Existing Fissure Angles and Bridge Angles on Concrete Tensile Failure Characteristics: Insights from Meshless Numerical Simulations" Materials 17, no. 17: 4305. https://doi.org/10.3390/ma17174305

APA StyleHu, C., Li, T., Fu, Z., Mao, H., Wang, S., Liang, Z., & Yu, S. (2024). Influences of Pre-Existing Fissure Angles and Bridge Angles on Concrete Tensile Failure Characteristics: Insights from Meshless Numerical Simulations. Materials, 17(17), 4305. https://doi.org/10.3390/ma17174305