Improvement of Hydrogen-Resistant Gas Turbine Engine Blades: Single-Crystal Superalloy Manufacturing Technology

Abstract

1. Introduction

2. Materials and Methods for Investigation

3. Results and Discussion

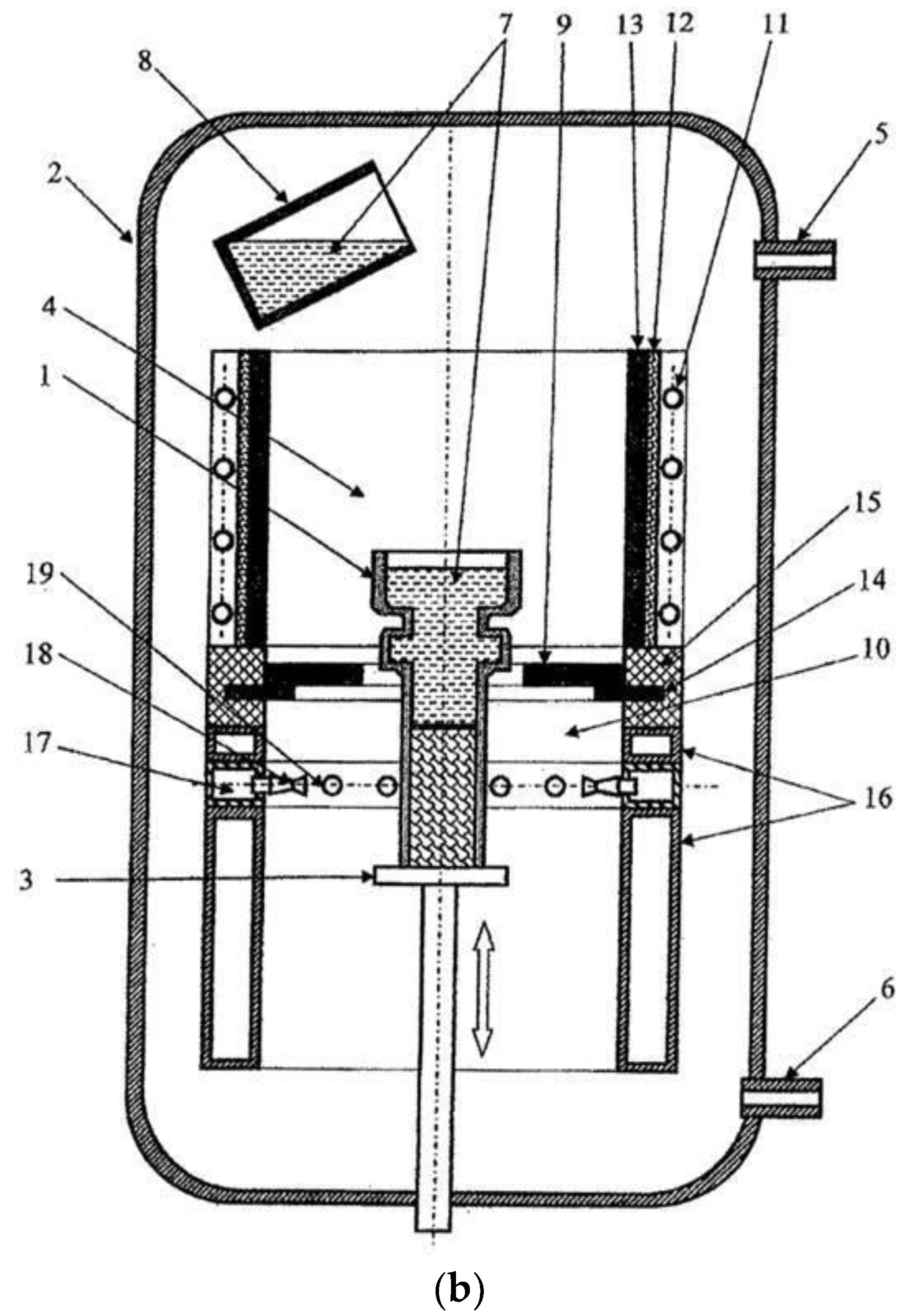

- It is recommended to provide a temperature gradient at the crystallization front of ~170 °C/cm to obtain a regular structure with orientation [001] of the cast second-stage turbine blades of the UGT25000 gas turbine engine for power generation.

- Technological schemes have been developed to obtain ceramic molds made by 3D printing based on polymer models using environmentally friendly binders for the repair of gas turbine engine blades. Their use leads to an increase in the dimensional accuracy of blade castings by 30–45%, significantly reduces the time of casting production, and helps to preserve the health of the company’s employees.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature and Abbreviations

| σu | ultimate tensile strength (UTS) |

| σy | yield strength (YS) |

| δ | elongation |

| ψ | reduction of area |

| σ | stress during long-term loading |

| τ | time to fracture under long-term load |

| LMC | liquid metal cooling |

| GTE | gas turbine engine |

| RPM | rotation per minute |

| GCC | gas cooling casting |

| HRS | high-rate solidification |

| DC | directional crystallization (Bridgman–Stockbarger method) |

| TS | solidus temperature |

| TL | liquidus temperature |

| R | speed of the crystallization front movement |

| ∆l | distance between the thermocouples |

| ∆τ | time interval |

| G | the temperature gradient at the crystallization front |

| ∆T | temperature interval |

| λ | distance between dendrite axes |

References

- Sims, C.T.; Stoloff, N.S.; Hagel, W.C. Superalloys II: High-Temperature Materials for Aerospace and Industrial Power; John Wiley & Sons: New York, NY, USA, 1987; 640p, Available online: https://www.wiley.com/en-us/Superalloys+II%3A+High+Temperature+Materials+for+Aerospace+and+Industrial+Power-p-9780471011477 (accessed on 19 January 2024).

- Narivskiy, A.; Shinsky, O.; Shalevska, I.; Kvasnitska, Y.; Kaliuzhnyi, P.; Polyvoda, S. Modern technological processes of obtaining cast products and structures of responsible purpose from aluminum, ferrous carbon and heatresistant alloys. In Structural Materials: Manufacture, Properties, Conditions of Use: Collective Monograph; Technology Center: Kharkiv, Ukraine, 2023; pp. 32–67. [Google Scholar] [CrossRef]

- Glotka, A.A.; Haiduk, S.V.; Ol’shanetskii, V.Y. Modeling thermophysical characteristics of nickel-based superalloys. J. Eng. Phys. Thermophys. 2021, 94, 1363–1368. [Google Scholar] [CrossRef]

- Chapman, N.; Gray, S.; Sumner, J.; Nicholls, J. Stress Corrosion Testing of CMSX-4, CM247LC DS and IN6203DS Ni-Base Superalloys. Oxid. Met. 2020, 95, 85–104. [Google Scholar] [CrossRef]

- Klochikhin, V.; Naumyk, V. Improvement of technological processes obtaining a heat-resistant nickel alloys for turbine blades using foundry return. Mater. Sci. Technol. 2019, 2019, 1454–1458. [Google Scholar] [CrossRef]

- Wu, X.; Makineni, S.K.; Liebscher, C.H.; Dehm, G.; Mianroodi, J.R. Unveiling the Re effect in Ni-based single crystal superalloys. Nat. Commun. 2020, 11, 389. [Google Scholar] [CrossRef]

- Kuznetsov, P.; Lesnikov, V.P.; Konakova, I.P.; Popov, N.A.; Kvasnitskaya, Y.G. Structural and phase transformations in single-crystal rhenium- and ruthenium-alloyed nickel alloy under testing for long-term strength. Met. Sci. Heat Treat. 2015, 57, 503–506. [Google Scholar] [CrossRef]

- Ivaskevich, L.; Balitskii, A.; Kvasnytska, I.; Kvasnytska, K.; Myalnitsa, H. Thermal Stability, Cyclic Durability and Hydrogen Resistance of Cast Nickel-cobalt Alloys for Gas Turbine Blades. In Proceedings of the 14th International Conference on Advanced Mechanical and Power Engineering, CAMPE 2021, Kharkiv, Ukraine, 18–21 October 2021; Lecture Notes in Mechanical Engineering. pp. 147–155. [Google Scholar] [CrossRef]

- Singla, Y.K.; Miller, J.D.; Raja, K.; Maughan, M.R. Toward single crystal nickel fabrication using WAAM—A first report. J. Mater. Res. Technol. 2023, 27, 4801–4804. [Google Scholar] [CrossRef]

- Balitskii, O.I.; Kvasnytska, Y.H.; Ivaskevych, L.M.; Mialnitsa, H.P.; Kvasnytska, K.H. Fatigue fracture of the blades of gas turbine engine made of a new refractory nickel alloy. Mater. Sci. 2022, 57, 475–483. [Google Scholar] [CrossRef]

- Qingyan, X.; Cong, Y.; Xuewei, Y.; Baicheng, L. Development of Numerical Simulation in Nickel-Based Superalloy Turbine Blade Directional Solidification. Acta Met. Sin. 2019, 55, 1175–1184. [Google Scholar] [CrossRef]

- Glotka, O.A.; Olshanetskii, V.Y. Mathematical Prediction of the Properties of Heat-Resistant Nickel Alloys After Directional Crystallization. Mater. Sci. 2023, 58, 679–685. [Google Scholar] [CrossRef]

- Stanford, N.; Djakovic, A.; Shollock, B.; McLean, M.; D’Souza, N.; Jennings, P. Seeding of single crystal superalloys—Role of seed melt-back on casting defects. Scr. Mater. 2004, 50, 159–163. [Google Scholar] [CrossRef]

- Harris, K.; Wahl, J.B. Developments in superalloy castability and new applications for advanced superalloys. Mater. Sci. Technol. 2009, 25, 147–153. [Google Scholar] [CrossRef]

- Zhang, W.-G.; Liu, L.; Zhao, X.-B.; Qu, M.; Yu, Z.-H.; Fu, H.-Z. Progress in directionally solidified superalloys. Zhuzao/Foundry 2009, 58, 1–6. Available online: https://www.researchgate.net/publication/288429900_Progress_in_directionally_solidified_super_alloys (accessed on 19 January 2024).

- Makineni, S.K.; Lenz, M.; Neumeier, S.; Spiecker, E.; Raabe, D.; Gault, B. Elemental segregation to antiphase boundaries in a crept CoNi-based single crystal superalloy. Scr. Mater. 2018, 157, 62–66. [Google Scholar] [CrossRef]

- Dexin, M.A. Novel casting processes for single-crystal turbine blades of superalloys. Front. Mech. Eng. 2018, 13, 3–16. [Google Scholar] [CrossRef]

- Long, H.; Mao, S.; Liu, Y.; Zhang, Z.; Han, X. Microstructural and compositional design of Ni-based single crystalline superalloys—A review. J. Alloys Compd. 2018, 743, 203–220. [Google Scholar] [CrossRef]

- Fu, H.; Geng, X. High rate directional solidification and its application in single crystal superalloys. Sci. Techn. Advan. Mater. 2001, 2, 197–204. Available online: https://iopscience.iop.org/article/10.1016/S1468-6996(01)00049-3/pdf (accessed on 19 January 2024). [CrossRef]

- Giamei, A.F.; Tschinkel, J.G. Liquid Metal Cooling: A New Solidification Technique. Metal. Trans. A 1976, 7, 1427–1434. [Google Scholar] [CrossRef]

- Franke, M.M.; Hilbinger, R.M.; Lohmüller, A.; Singer, R.F. The effect of liquid metal cooling on thermal gradients in directional solidification of superalloys: Thermal analysis. J. Mater. Proces. Technol. 2013, 213, 2081–2088. [Google Scholar] [CrossRef]

- Miller, J.D.; Pollock, T.M. Stability of dendrite growth during directional solidification in the presence of a non-axial thermal field. Acta Mater. 2014, 78, 23–36. [Google Scholar] [CrossRef]

- Zhang, J.; Luo, L. Directional solidification assisted by liquid metal cooling. J. Mater. Sci. Technol. 2007, 23, 289–300. [Google Scholar] [CrossRef]

- Kubiak, K.; Szeliga, D.; Sieniawski, J.; Onyszko, A. The Unidirectional Crystallization of Metals and Alloys (Turbine Blades). In Handbook of Crystal Growth, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 413–457. [Google Scholar] [CrossRef]

- Xu, J.; Kang, J.; Zheng, L.; Mao, W.; Wang, J. Numerical simulation of the directional solidification process with multi-shell mold being gradually immersed in water. J. Mater. Res. Technol. 2022, 19, 2705–2716. [Google Scholar] [CrossRef]

- Plancher, E.; Gravier, P.; Chauvet, E.; Blandin, J.; Boller, E.; Martin, G.; Salvo, L.; Lhuissier, P. Tracking pores during solidification of a Ni-based superalloy using 4D synchrotron microtomography. Acta Mater. 2019, 181, 1–9. [Google Scholar] [CrossRef]

- Xu, J.-J.; Chen, Y.-Q. Steady spatially-periodic eutectic growth with the effect of triple point in directional solidification. Acta Mater. 2014, 80, 220–238. [Google Scholar] [CrossRef]

- Peterson, L.G. Directional Solidification of Land-Base Gas Turbine Buckets; Gas Turbine and Aero Engine Congres and Exposition: Toronto, ON, Canada, 1989; Paper No: 89-GT-332, V005T11A016. [Google Scholar] [CrossRef]

- Horichok, I.V.; Kryskov, T.A.; Liuba, T.S.; Rachkovskyi, O.M.; Freik, D.M. Device for Growing Crystals from the Melt with Variable Temperature Gradient in the Crystallization Area. Ukrainian Patent number: 78465. Published: 25.03.2013. Available online: https://uapatents.com/5-78465-pristrijj-zi-zminnim-gradiehntom-temperaturi-v-oblasti-kristalizaci-dlya-viroshhuvannya-kristaliv-z-rozplavu.html (accessed on 19 January 2024).

- Liu, L.; Huang, T.; Qu, M. High thermal gradient directional solidification and its application in the processing of nickel-based superalloys. J. Mater. Proces. Technol. 2010, 210, 159–165. [Google Scholar] [CrossRef]

- Xuan, W.; Ren, Z.; Liu, H. Formation of stray grains in directionally solidified Ni-based superalloys with cross-section change regions. Mater. Sci. Forum 2013, 747–748, 535–539. [Google Scholar] [CrossRef]

- Ma, D.; Wu, Q.; Bührig-Polaczek, A. Some new observations on freckle formation in directionally solidified superalloy components. Metall. Mater. Trans. B 2012, 43, 344–353. [Google Scholar] [CrossRef]

- Balitskii, A.I.; Kvasnytska, Y.H.; Ivaskevych, L.M.; Kvasnytska, K.H.; Balitskii, O.A.; Shalevska, I.A.; Shynskii, O.Y.; Jaworski, J.M.; Dowejko, J.M. Hydrogen and Corrosion Resistance of Nickel Superalloys for Gas Turbines, Engines Cooled Blades. Energy 2023, 16, 1154. [Google Scholar] [CrossRef]

- Wisniewski, P.; Sitek, R.; Towarek, A.; Choinska, E.; Moszczynska, D.; Mizera, J. Molding Binder Influence on the Porosity and Gas Permeability of Ceramic Casting Molds. Materials 2020, 13, 2735. [Google Scholar] [CrossRef] [PubMed]

- Mei, J.; Rehren, T. (Eds.) The early history of lost-wax casting. In Metallurgy and Civilisation: Eurasia and Beyond Archetype; Archetype: London, UK, 2009; ISBN 1234 5678 9 1011. [Google Scholar]

- Specification Z88YF1-S2 for Supplying Remelting Stocks of Alloy CM-88Y; Technical Specifications; “Zorya”–“Mashproekt”; GTRPC: Mykolaiv, Ukraine, 2016; pp. 2016–2018.

- Wiechczynski, A.; Lisiewicz, M.; Kwasnicka, J.; Kostrica, W. Method of the Directional Solidification of the Castings of Gas Turbine Blades and a Device for Producing the Castings of Gas Turbine Blades of the Directional Solidified and Monocrystalline Structure. Espacenet EP2921244 (A1)—Published: 23 September 2015, Classification B22D27/04, B22D25/045. Available online: https://patents.google.com/patent/EP2921244A1/da (accessed on 19 January 2024).

- Borasi, L.; Casamenti, E.; Charvet, R.; Dénéréaz, C.; Pollonghini, S.; Deillon, L.; Yang, T.; Ebrahim, F.; Mortensen, A.; Bellouard, Y. 3D metal freeform micromanufacturing. J. Manuf. Process. 2021, 68, 867–876. [Google Scholar] [CrossRef]

- Glotka, A. Prediction thermo-physical characteristics heat-resistant nickel alloys directional crystallization. Acta Metall. Slovaca 2021, 27, 68–71. [Google Scholar] [CrossRef]

- Kvasnytska, Y.H.; Ivaskevich, L.M.; Balitskii, A.I.; Kvasnytska, K.H.; Mialnitsa, H.P. Structural and mechanical properties of the nickel alloy of gas-turbine engine blades. Mater. Sci. 2022, 57, 688–694. [Google Scholar] [CrossRef]

- Sifi, O.; Djeghlal, M.E.; Mebdoua, Y.; Djeraf, S.; Fayçal, H. -L. The effect of the solution and aging treatments on the microstructures and microhardness of nickel-based superalloy. Appl. Phys. A 2020, 126, 345. [Google Scholar] [CrossRef]

- Mehta, K.K.; Mitra, R.; Chawla, S. Effect of post-solutionizing cooling rate on microstructure and low cycle fatigue behavior of a cast nickel based superalloy. Mater. Sci. Eng. A 2014, 611, 280–289. [Google Scholar] [CrossRef]

- Holländer, D.; Kulawinski, D.; Weidner, A.; Thiele, M.; Biermann, H.; Gampe, U. Small-scale specimen testing for fatigue life assessment of service-exposed industrial gas turbine blades. Int. J. Fatigue 2016, 92, 262–271. [Google Scholar] [CrossRef]

- Glotka, О.A. Distribution of Alloying Elements in Carbides of Refractory Nickel Alloys under the Conditions of Equiaxial Crystallization. Mater. Sci. 2021, 56, 714–721. [Google Scholar] [CrossRef]

- Rayapati, S. Gas turbine blade failure scenario due to thermal loads in case of Nickel based super alloys. Mater. Today Proc. 2021, 46, 8119–8126. [Google Scholar] [CrossRef]

- Park, K.H.; Withey, P. General view of rhenium-rich particles along defect grain boundaries formed in nickel-based single-crystal superalloy turbine blades: Formation, dissolution and comparison with other phases. Crystals 2021, 11, 1201. [Google Scholar] [CrossRef]

- Wee, S.; Do, J.; Kim, K.; Lee, C.; Seok, C.; Choi, B.-G.; Kim, W. Review on mechanical thermal properties of superalloys and thermal barrier coating used in gas turbines. Appl. Sci. 2020, 10, 5476. [Google Scholar] [CrossRef]

- Kvasnytska, Y.H.; Shalevska, I.A.; Balitskii, A.I.; Ivaskevich, L.M.; Maksiuta, I.I.; Kvasnytska, K.H. Influence of Refractory Elements on Phase–Structural Stability of Heat-Resistant Corrosion-Resistant Alloys for Gas Turbine Blades. Metallofiz. I Noveishie Tekhnologii 2023, 45, 975–992. [Google Scholar] [CrossRef]

- Talal, A.Q.; Rahman, K.F. Design and Analysis of a Gas Turbine Blade. Int. Res. J. Eng. Technol. 2020, 7, 479–486. Available online: https://www.irjet.net/archives/V7/i11/IRJET-V7I1178.pdf (accessed on 19 January 2024).

- Šmíd, M.; Horník, V.; Kunz, L.; Hrbáček, K.; Hutař, P. High cycle fatigue data transferability of MAR-M 247 superalloy from separately cast specimens to real gas turbine blade. Metals 2020, 10, 1460. [Google Scholar] [CrossRef]

- Lambert, H.; Roche, R.; Jemeï, S.; Ortega, P.; Hissel, D. Combined cooling and power management strategy for a standalone house using hydrogen and solar energy. Hydrogen 2021, 2, 207–224. [Google Scholar] [CrossRef]

- Balitskii, A.I.; Ivaskevich, L.M. Hydrogen effect on cumulation of failure, mechanical properties, and fracture toughness of Ni-Cr alloys. Adv. Mat. Sci. Eng. 2019, 2019, 3680253. [Google Scholar] [CrossRef]

- Stefan, E.; Talic, B.; Larring, Y.; Gruber, A.; Peters, T.A. Materials challenges in hydrogen-fuelled gas turbines. Int. Mater. Rev. 2022, 67, 461–486. [Google Scholar] [CrossRef]

- Syrotyuk, A.M.; Dmytrakh, I.M. Methods for the evaluation of fracture and strength of pipeline steels and structures under the action of working media. Part I. Influence of the corrosion factor. Mater. Sci. 2014, 50, 324–339. [Google Scholar] [CrossRef]

- Dmytrakh, I.M.; Syrotyuk, A.M.; Leshchak, R.L. Effect of preliminary hydrogenation–dehydrogenation of low-alloy steel on its ability to absorb electrochemical hydrogen. Mater. Sci. 2021, 57, 387–396. [Google Scholar] [CrossRef]

- Zhang, Z.; Obasi, G.; Morana, R.; Preuss, M. In-situ observation of hydrogen induced crack initiation in a nickel-based superalloy. Scr. Mater. 2017, 140, 40–44. [Google Scholar] [CrossRef]

- Taji, I.; Hajilou, T.; Karimi, S.; Schott, F.; Plesiutschnig, E.; Barnoush, A.; Johnsen, R. Role of grain boundaries in hydrogen embrittlement of alloy 725: Single and bi-crystal microcantilever bending study. Int. J. Hydrogen Energy 2022, 47, 12771–12781. [Google Scholar] [CrossRef]

- Michler, T.K.; Schweizer, F. Review and assessment of the effect of hydrogen gas pressure on the embrittlement of steels in gaseous hydrogen environment. Metals 2021, 11, 637. [Google Scholar] [CrossRef]

- Lee, A. Hydrogen embrittlement of nickel, cobalt and iron-based superalloys. In Gaseous Hydrogen Embrittlement of Materials in Energy Technologies, 1: The Problem, Its Characterization and Effects on Particular Alloy Classes; Gangloff, R.P., Somerday, B.P., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2012; pp. 624–667. [Google Scholar] [CrossRef]

- Chen, S.; Zhao, M.; Rong, L. Effect of grain size on the hydrogen embrittlement sensitivity of a precipitation strengthened Fe-Ni based alloy. Mat. Sci. Eng. A 2014, 594, 98–102. [Google Scholar] [CrossRef]

- Harris, Z.D.; Bhattacharyya, J.J.; Ronevich, J.A.; Agnew, S.R.; Burns, J.T. The combined effects of hydrogen and aging condition on the deformation and fracture behavior of a precipitation-hardened nickel-base superalloy. Acta Mater. 2020, 186, 616–630. [Google Scholar] [CrossRef]

- Kindrachuk, M.; Volchenko, D.; Balitskii, A.; Abramek, K.F.; Volchenko, M.; Balitskii, O.; Skrypnyk, V.; Zhuravlev, D.; Yurchuk, A.; Kolesnikov, V. Wear resistance of spark ignition engine piston rings in hydrogen-containing environments. Energies 2021, 14, 4801. [Google Scholar] [CrossRef]

- Shpotyuk, O.I.; Balitska, V.O.; Vakiv, M.M.; Shpotyuk, L.I. Sensors of high-energy radiation based on amorphous chalcogenides. Sens. Actuators A Phys. 1998, 68, 356–358. [Google Scholar] [CrossRef]

- Reising, R.F. High temperature corrosion of nickel by sodium sulfat. Corrosion 1977, 33, 84–91. [Google Scholar] [CrossRef]

- Ogawa, Y.; Hosoi, H.; Tsuzaki, K.; Redarce, T.; Takakuwa, O.; Matsunaga, H. Hydrogen, as an alloying element, enables a greater strength-ductility balance in an Fe-Cr-Ni-based, stable austenitic stainless steel. Acta Mater. 2020, 199, 181–192. [Google Scholar] [CrossRef]

- Balitskii, A.; Ivaskevich, L.; Mochulskyi, V.; Eliasz, J.; Skolozdra, O. Influence of high pressure and high temperature hydrogen on fracture toughness of Ni-containing steels and alloys. Arch. Mech. Eng. 2014, 61, 129–138. [Google Scholar] [CrossRef]

- Zhang, Z.; Obasis, G.; Morana, R.; Preuss, M. Hydrogen assisted crack initiation and propagation in a nickel-based superalloy. Acta Mater. 2016, 113, 272–283. [Google Scholar] [CrossRef]

- Drexler, A.; He, S.; Pippan, R.L.; Romaner, V.; Razumovskiy, I.; Ecker, W. Hydrogen segregation near a crack tip in nickel. Scr. Mater. 2021, 194, 113697. [Google Scholar] [CrossRef]

- Balitskii, A.I.; Panasyuk, V.V. Workability assessment of structural steels of power plant units in hydrogen environments. Strength Mater. 2009, 41, 52–57. [Google Scholar] [CrossRef]

- Ma, D.; Blazej Grabowski, B.; Körmann, F.; Neugebauer, J.; Raabe, D. Ab initio thermodynamics of the CoCrFeMnNi high entropy alloy: Importance of entropy contributions beyond the configurational one. Acta Mater. 2015, 100, 90–97. [Google Scholar] [CrossRef]

- Balitskii, O.A.; Kolesnikov, V.O.; Balitskii, A.I.; Eliasz, J.; Havrylyuk, M.R. Hydrogen effect on the high-nickel surface steel properties during machining and wear with lubricants. Arch. Mater. Sci. Eng. 2020, 104, 49–57. [Google Scholar] [CrossRef]

- Tarzimoghadam, Z.; Ponge, D.; Klöwer, J.; Raabe, D. Hydrogen-assisted failure in Ni-based superalloy 718 studied under in situ hydrogen charging: The role of localized deformation in crack propagation. Acta Mater. 2017, 128, 365–374. [Google Scholar] [CrossRef]

- Van Sluytman, J.S.; Pollock, T.M. Optimal precipitate shapes in nickel-base γ-γ՛ alloys. Acta Mater. 2012, 60, 1771–1783. [Google Scholar] [CrossRef]

- Moustabchir, H.; Azari, Z.; Hairi, S.; Dmytrakh, I. Experimental and computed stress distribution ahead of notch in pressure vessel: Application of T-stress conception. Comput. Mater. Sci. 2012, 58, 59–66. [Google Scholar] [CrossRef]

- Kozak, L.Y. Discrete models of plastic deformation of solids under the action of high hydrostatic pressure. Mater. Sci. 2016, 52, 108–112. [Google Scholar] [CrossRef]

- Syrotyuk, A.M.; Dmytrakh, I.M. Methods for the evaluation of fracture and strength of pipeline steels and structures under the action of working media. Part II: Influence of hydrogen-containing media. Mater. Sci. 2015, 50, 475–487. [Google Scholar] [CrossRef]

- Balyts’kyi, O.O. Elastic characteristics of laminated gallium and indium chalcogenides. Mater. Sci. 2004, 40, 706–709. [Google Scholar] [CrossRef]

- Capelle, J.; Dmytrakh, I.; Gilgert, J.; Jodin, P.; Pluvinage, G. A comparison of experimental results and computations for ctacked tubes subjected to internal pressure. Mat. Techn. 2006, 40, 233–237. Available online: http://mit.imt.si/izvodi/mit066/capelle.pdf (accessed on 14 January 2024).

- Romaniv, O.N.; Nikiforchin, G.N.; Kozak, L.Y. Structural sensitivity of the cyclic crack resistance of rotor steel in gaseous hydrogen. Sov. Mater. Sci. 1984, 20, 424–429. [Google Scholar] [CrossRef]

- Rozumek, D.; Macha, E. Elastic-plastic fatigue crack growth in 18G2A steel under proportional bending with torsion loading. Fatigue Fract. Eng. Mater. Struct. 2006, 29, 135–145. [Google Scholar] [CrossRef]

- Romaniv, O.N.; Nikiforchin, G.N.; Kozak, L.Y. Cyclic rack resistance of constructional steel in gaseous hydrogen. Sov. Mater. Sci. 1987, 23, 439–450. [Google Scholar] [CrossRef]

- Eckardt, D.; Rufli, P. Advanced gas turbine technology: ABB/BCC historical first. J. Eng. Gas Turbines Power 2002, 124, 542–549. Available online: https://pdfcoffee.com/advanced-gt-technology-abb-bcc-historical-firsts-pdf-free.html (accessed on 14 January 2024). [CrossRef]

- Ogawa, Y.; Noguchi, K.; Takakuwa, O. Criteria for hydrogen-assisted crack initiation in Ni-based superalloy 718. Acta Mater. 2022, 229, 117789. [Google Scholar] [CrossRef]

- Balitska, V.; Shpotyuk, Y.; Filipecki, J.; Shpotyuk, O.; Iovu, M. Post-irradiation relaxation in vitreous arsenic/antimony trisulphides. J. Non-Cryst. Solids 2011, 357, 487–489. [Google Scholar] [CrossRef]

- Chauvet, E.; Kontis, P.; Jägle, E.A.; Gault, B.; Raabe, D.; Tassin, C.; Blandin, J.-J.; Dendievel, R.; Vayre, B.; Abed, S.; et al. Hot cracking mechanism affecting a non-weldable Ni-based superalloy produced by selective electron beam melting. Acta Mater. 2018, 142, 82–94. [Google Scholar] [CrossRef]

- Tytko, D.; Choi, P.-P.; Klöwer, J.; Kostka, A.; Inden, G.; Raabe, D. Microstructural evolution of a Ni-based superalloy (617B) at 700 °C studied by electron microscopy and atom probe tomography. Acta Mater. 2012, 60, 1731–1740. [Google Scholar] [CrossRef]

- Haghighat, G.H.; Eggeler, G.; Raabe, D. Effect of climb on dislocation mechanisms and creep rates in γ′-strengthened Ni base superalloy single crystals: A discrete dislocation dynamics study. Acta Mater. 2013, 61, 3709–3723. [Google Scholar] [CrossRef]

- Djukic, M.B.; Bakic, G.M.; Zeravcic, V.S.; Sedmak, A.; Rajicic, B. The synergistic action and interplay of hydrogen embrittlement mechanisms in steels and iron: Localized plasticity and decohesion. Eng. Fract. Mech. 2019, 216, 106528. [Google Scholar] [CrossRef]

- Kindrachuk, V.; Fedelich, B. Stress update algorithm for the combined viscoplastic and plastic behaviours of single-crystal superalloys. Int. J. Numer. Methods Eng. 2011, 88, 83–102. [Google Scholar] [CrossRef]

- Wasim, M.; Djukic, M.; Ngo, T.D. Influence of hydrogen-enhanced plasticity and decohesion mechanisms of hydrogen embrittlement on the fracture resistance of steel. Eng. Fail. Anal. 2021, 123, 105312. [Google Scholar] [CrossRef]

- Dub, S.N.; Haftaoglu, C.; Kindrachuk, V.M. Estimate of theoretical shear strength of C60 single crystal by nanoindentation. J. Mater. Sci. 2021, 56, 10905–10914. [Google Scholar] [CrossRef]

- Takeishi, K. Evolution of turbine cooled vanes and blades applied for large industrial gas turbines and its trend toward carbon neutrality. Energies 2022, 15, 8935. [Google Scholar] [CrossRef]

- Balitska, V.O.; Golovchak, R.; Kovalskiy, A.; Skordeva, E.; Shpotyuk, O. Effect of Co60 γ-irradiation on the optical properties of As-Ge-S glasses. J. Non-Cryst. Solids 2003, 326–327, 130–134. [Google Scholar] [CrossRef]

- Liu, X.; Han, X.; Yin, G.; Song, X.; Cui, L. Design and processing of gas turbine blades based on additive manufacturing technology. Micromachines 2023, 14, 1675. [Google Scholar] [CrossRef] [PubMed]

- Kindrachuk, V.; Fedelich, B.; Rehmer, B.; Peter, F. Computational methods for lifetime prediction of metallic components under high-temperature fatigue. Metals 2019, 9, 390. [Google Scholar] [CrossRef]

- Alnaeli, M.; Alnajideen, M.; Navaratne, R.; Shi, H.; Czyzewski, P.; Wang, P.; Eckart, S.; Alsaegh, A.; Alnasif, A.; Mashruk, S.; et al. High-temperature materials for complex components in ammonia/hydrogen gas turbines: A critical review. Energies 2023, 16, 6973. [Google Scholar] [CrossRef]

- Kindrachuk, V.; Wanderka, N.; Banhart, J.; Mukherji, D.; Del Genovesse, D.; Rösler, J. Intragranular precipitation in inconel 706: 3D atom-probe and HRTEM investigations. Steel Res. Int. 2004, 75, 74–78. [Google Scholar] [CrossRef]

- Peck, D.; Zappi, M.; Gang, D.; Guillory, J.; Hernandez, R.; Buchireddy, P. Review of porous ceramics for hot gas cleanup of biomass syngas using catalytic ceramic filters to produce green hydrogen/fuels/chemicals. Energies 2023, 16, 2334. [Google Scholar] [CrossRef]

- Fathyunes, L.; Mohtadi-Bonab, M.A. A Review on the Corrosion and Fatigue Failure of Gas Turbines. Metals 2023, 13, 701. [Google Scholar] [CrossRef]

| Alloy | Content of Elements, wt.% (Ni-Balance) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Co | Mo | Ti | Al | W | Nb | Hf | Fe | B | Mn | Si | |

| CM88 | 0.074 | 15.17 | 10.82 | 1.95 | 4.40 | 2.85 | 5.38 | 0.18 | 0.27 | 4.07 | 0.01 | 0.028 | 0.16 |

| Limits [36] | 0.06–0.12 | 15.0–16.2 | 10.0–11.5 | 1.6–2.3 | 4.2–5.2 | 2.8–3.3 | 4.7–5.9 | 0.1–0.3 | 0.3–0.6 | 3.7–4.3 | 0.01–0.16 | ≤0.30 | ≤0.30 |

| Structural Components Parameters | Limits, µm |

|---|---|

| Average size of eutectic γ′-phase islands | 5–7 |

| Average particle size of the secondary γ′-phase in the interaxial space | 0.2–0.4 |

| Average size of MC-type carbides | 1.0–1.5 |

| The average size of secondary γ′-phase particles in the axes of dendrites | 0.1–0.3 |

| Sample Number | Short-Term Properties | Long-Term Properties | ||

|---|---|---|---|---|

| σu, MPa | δ, % | σ, MPa | τ, h | |

| 1 | 650 | 28 | 320 | 110 |

| 2 | 646 | 23 | 320 | 132 |

| 3 | 655 | 19 | 320 | 104 |

| Stardart [36] | 640 | 9 | 320 | 104 |

| Material | Test Environment | σu MPa | σy MPa | δ % | ψ % |

|---|---|---|---|---|---|

| CM-88 | air | 970 | 880 | 12 | 15 |

| CM-88 | hydrogen | 950 | 870 | 8 | 12 |

| CM-88U | air | 960 | 890 | 5 | 8 |

| CM-88U | hydrogen | 930 | 860 | 2 | 4 |

| CM-90 | air | 970 | 860 | 13 | 16 |

| CM-90 | hydrogen | 920 | 820 | 7 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balitskii, A.I.; Kvasnytska, Y.H.; Ivaskevych, L.M.; Kvasnytska, K.H.; Balitskii, O.A.; Miskiewicz, R.M.; Noha, V.O.; Parkhomchuk, Z.V.; Veis, V.I.; Dowejko, J.M. Improvement of Hydrogen-Resistant Gas Turbine Engine Blades: Single-Crystal Superalloy Manufacturing Technology. Materials 2024, 17, 4265. https://doi.org/10.3390/ma17174265

Balitskii AI, Kvasnytska YH, Ivaskevych LM, Kvasnytska KH, Balitskii OA, Miskiewicz RM, Noha VO, Parkhomchuk ZV, Veis VI, Dowejko JM. Improvement of Hydrogen-Resistant Gas Turbine Engine Blades: Single-Crystal Superalloy Manufacturing Technology. Materials. 2024; 17(17):4265. https://doi.org/10.3390/ma17174265

Chicago/Turabian StyleBalitskii, Alexander I., Yulia H. Kvasnytska, Ljubomyr M. Ivaskevych, Katrine H. Kvasnytska, Olexiy A. Balitskii, Radoslaw M. Miskiewicz, Volodymyr O. Noha, Zhanna V. Parkhomchuk, Valentyn I. Veis, and Jakub Maciej Dowejko. 2024. "Improvement of Hydrogen-Resistant Gas Turbine Engine Blades: Single-Crystal Superalloy Manufacturing Technology" Materials 17, no. 17: 4265. https://doi.org/10.3390/ma17174265

APA StyleBalitskii, A. I., Kvasnytska, Y. H., Ivaskevych, L. M., Kvasnytska, K. H., Balitskii, O. A., Miskiewicz, R. M., Noha, V. O., Parkhomchuk, Z. V., Veis, V. I., & Dowejko, J. M. (2024). Improvement of Hydrogen-Resistant Gas Turbine Engine Blades: Single-Crystal Superalloy Manufacturing Technology. Materials, 17(17), 4265. https://doi.org/10.3390/ma17174265