Microstructure, Mechanical, and Tribological Properties of Nb-Doped TiAl Alloys Fabricated via Laser Metal Deposition

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructure

3.2. Microstructural Evolution Analysis

3.3. Mechanical Properties

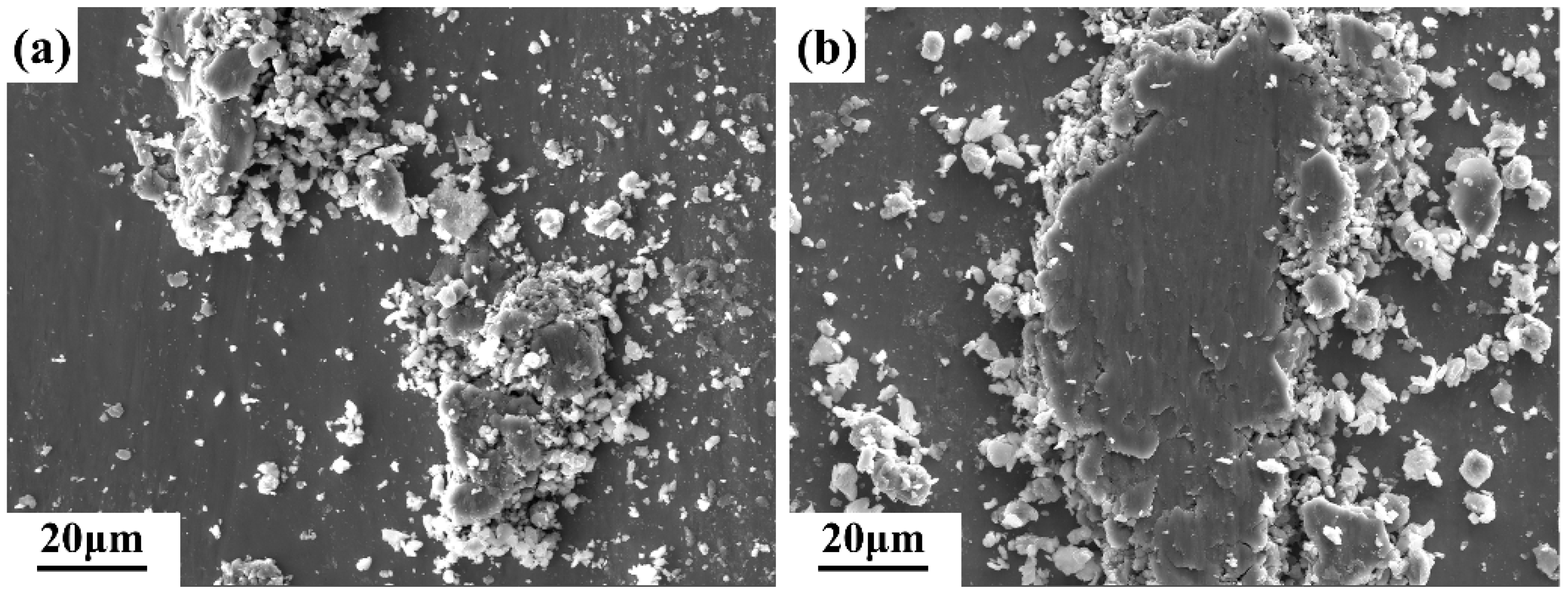

3.4. Tribological Properties

4. Conclusions

- The TiAl alloys prepared by LMD showed a decrease in the β0 phase and an increase in the γ phase with increasing Nb content. The presence of the residual β0 phase was primarily caused by Cr segregation and weakly correlated with the Nb content. Conversely, the increase in Nb altered the solidification path of TiAl alloys from peritectic solidification to β-solidification. The increase in Nb content obviously refined the microstructures and increased the tendency for S-segregation.

- As the Nb content increased, the microhardness of the sample initially increased and then decreased with the alloy containing an additional 2 at.% Nb exhibiting the highest hardness value of 359.2 ± 6.5 HV0.3. Furthermore, this alloy exhibited a fracture strength of 568 ± 7.8 MPa, which was nearly 100 MPa higher than that of the modified alloy with an additional 1 at. % Nb. The alloy with more Nb (4 at.%) showed the same strength as that with an additional 2 at.%.

- The wear resistance of the as-fabricated alloys decreased with increasing Nb content. The main wear mechanism for all alloys was abrasive wear, while oxidative wear occurred without the formation of tribo-oxide layers. In addition, local plastic deformation and pile-ups at the edges of the wear tracks occurred.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Clemens, H.; Mayer, S. Design, Processing, Microstructure, Properties, and Applications of Advanced Intermetallic TiAl Alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Lu, Q.; Xu, Z.; Chen, X.; Feng, P.; Li, C.; Yi, J. Evading the strength and ductility trade-off dilemma in titanium matrix composites through supersaturated solid solution and phase transformation. Mater. Sci. Eng. A 2024, 894, 146211. [Google Scholar] [CrossRef]

- Park, J.-S.; Yang, G.; Kim, S.-W. A high tensile strength above 900 °C in β-solidified TiAl alloy through alloy design and microstructure optimization. J. Alloys Compd. 2023, 947, 169676. [Google Scholar] [CrossRef]

- Zheng, G.; Tang, B.; Zhao, S.; Wang, J.; Xie, Y.; Chen, X.; Wang, W.Y.; Liu, D.; Yang, R.; Li, J. Breaking the high-temperature strength-ductility trade-off in TiAl alloys through microstructural optimization. Int. J. Plast. 2023, 170, 103756. [Google Scholar] [CrossRef]

- Gao, P.; Huang, W.; Yang, H.; Jing, G.; Liu, Q.; Wang, G.; Wang, Z.; Zeng, X. Cracking behavior and control of β-solidifying Ti-40Al-9V-0.5Y alloy produced by selective laser melting. J. Mater. Sci. Technol. 2020, 39, 144–154. [Google Scholar] [CrossRef]

- Cho, K.; Kobayashi, R.; Oh, J.Y.; Yasuda, H.Y.; Todai, M.; Nakano, T.; Ikeda, A.; Ueda, M.; Takeyama, M. Influence of unique layered microstructure on fatigue properties of Ti-48Al-2Cr-2Nb alloys fabricated by electron beam melting. Intermetallics 2018, 95, 1–10. [Google Scholar] [CrossRef]

- Lu, X.; Li, J.; Chen, X.; Qiu, J.; Wang, Y.; Liu, B.; Liu, Y.; Rashad, M.; Pan, F. Mechanical, tribological and electrochemical corrosion properties of in-situ synthesized Al2O3/TiAl composites. Intermetallics 2020, 120, 106758. [Google Scholar] [CrossRef]

- Liu, S.; Ding, H.; Chen, R.; Guo, J.; Fu, H. Evolution of rapidly grown cellular microstructure during heat treatment of TiAl-based intermetallic and its effect on micromechanical properties. Intermetallics 2021, 132, 107166. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Wei, L.; He, S.; Cuiuri, D.; Li, H. Introduction of ternary alloying element in wire arc additive manufacturing of titanium aluminide intermetallic. Addit. Manuf. 2019, 27, 236–245. [Google Scholar] [CrossRef]

- Liang, Y.-F.; Xu, X.-J.; Lin, J.-P. Advances in phase relationship for high Nb-containing TiAl alloys. Rare Met. 2016, 35, 15–25. [Google Scholar] [CrossRef]

- Duan, B.; Yang, Y.; He, S.; Feng, Q.; Mao, L.; Zhang, X.; Jiao, L.; Lu, X.; Chen, G.; Li, C. History and development of γ-TiAl alloys and the effect of alloying elements on their phase transformations. J. Alloys Compd. 2022, 909, 164811. [Google Scholar] [CrossRef]

- Yu, J.; Lin, X.; Wang, J.; Chen, J.; Huang, W. Mechanics and energy analysis on molten pool spreading during laser solid forming. Appl. Surf. Sci. 2010, 256, 4612–4620. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Clemens, H.; Mayer, S.; Lindemann, J.; Klose, J.; Smarsly, W.; Güther, V. Microstructural design and mechanical properties of a cast and heat-treated intermetallic multi-phase γ-TiAl based alloy. Intermetallics 2014, 44, 128–140. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, S.; Sun, Z.; Liu, B.; Wang, L.; Wang, Y.; Liu, Y. Microstructural evolution during annealing of a powder metallurgical TiAl-Nb composite and its effect on mechanical properties. J. Mater. Res. Technol. 2023, 25, 3654–3669. [Google Scholar] [CrossRef]

- Schloffer, M.; Iqbal, F.; Gabrisch, H.; Schwaighofer, E.; Schimansky, F.-P.; Mayer, S.; Stark, A.; Lippmann, T.; Göken, M.; Pyczak, F.; et al. Microstructure development and hardness of a powder metallurgical multi phase γ-TiAl based alloy. Intermetallics 2012, 22, 231–240. [Google Scholar] [CrossRef]

- Zhang, S.; Tian, N.; Li, J.; Yang, G.; Yang, W.; Wang, G.; Liu, Z.; Li, Y. Microstructure evolution of a forged TiAl-Nb alloy during high-temperature tensile testing. Mater. Charact. 2023, 205, 113268. [Google Scholar] [CrossRef]

- Zhang, S.Z.; Zhao, Y.B.; Zhang, C.J.; Han, J.C.; Sun, M.J.; Xu, M. The microstructure, mechanical properties, and oxidation behavior of beta-gamma TiAl alloy with excellent hot workability. Mater. Sci. Eng. A 2017, 700, 366–373. [Google Scholar] [CrossRef]

- Liu, S.; Ding, H.; Zhang, H.; Chen, R.; Guo, J.; Fu, H. High-density deformation nanotwin induced significant improvement in the plasticity of polycrystalline γ-TiAl-based intermetallic alloys. Nanoscale 2018, 10, 11365–11374. [Google Scholar] [CrossRef]

- Li, H.; Qi, Y.; Liang, X.; Zhu, Z.; Lv, F.; Liu, Y.; Yang, Y. Microstructure and high temperature mechanical properties of powder metallurgical Ti-45Al-7Nb-0.3W alloy sheets. Mater. Des. 2016, 106, 90–97. [Google Scholar] [CrossRef]

- Ren, Y.; Han, B.; Wu, H.; Wang, J.; Liu, B.; Wei, B.; Jiao, Z.; Baker, I. Copper segregation-mediated formation of nanotwins and 9R phase in titanium alloys produced by laser powder bed fusion. Scr. Mater. 2023, 224, 115115. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, C.-T. Design of titanium alloys by additive manufacturing: A critical review. Adv. Powder Mater. 2022, 1, 100014. [Google Scholar] [CrossRef]

- Xue, H.; Liu, C.; Song, Y.; Liang, Y.; Tong, X.; Wang, Y.; Lin, J. Additive manufacturing of nano-W composite high Nb-TiAl alloys fabricated via selective laser melting. Mater. Lett. 2023, 347, 134569. [Google Scholar] [CrossRef]

- Liu, M.; Wang, J.; Hu, T.; Xu, S.; Shuai, S.; Xuan, W.; Yin, S.; Chen, C.; Ren, Z. Laser powder bed fusion of a Ni3Al-based intermetallic alloy with tailored microstructure and superior mechanical performance. Adv. Powder Mater. 2024, 3, 100152. [Google Scholar] [CrossRef]

- Sun, J.e.; Zhang, B.; Qu, X. High strength Al alloy development for laser powder bed fusion. J. Micromech. Mol. Phys. 2021, 6, 2141001. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater Sci. 2018, 92, 112–224. [Google Scholar]

- Xue, H.; Liang, Y.; Peng, H.; Wang, Y.; Shang, S.-L.; Liu, Z.-K.; Lin, J. An additively manufactured γ-based high Nb-TiAl composite via coherent interface regulation. Scr. Mater. 2023, 223, 115102. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, Z.; Yu, B.; Li, G.; Xue, Y.; Liang, Y.-J. Additive manufacturing of fine-grain fully lamellar titanium aluminide alloys. Mater. Des. 2023, 230, 111989. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, S.; Cheng, X.; Wang, H. Investigation on solid-state phase transformation in a Ti-47Al-2Cr-2V alloy due to thermal cycling during laser additive manufacturing process. J. Alloys Compd. 2019, 799, 325–333. [Google Scholar] [CrossRef]

- Wang, D.; Yang, Y.; Wang, Y.; Yang, L.; Wang, H.; Yang, S. Introduction to the Special Issue on Design and Simulation in Additive Manufacturing. Cmes-Comput. Model. Eng. Sci. 2021, 126, 1–4. [Google Scholar]

- Cao, L. Mesoscopic-Scale Numerical Investigation Including the Influence of Process Parameters on LPBF Multi-Layer Multi-Path Formation. Cmes-Comput. Model. Eng. Sci. 2021, 126, 5–23. [Google Scholar]

- Liu, Z.; Zhao, D.; Wang, P.; Yan, M.; Yang, C.; Chen, Z.; Lu, J.; Lu, Z. Additive manufacturing of metals: Microstructure evolution and multistage control. J. Mater. Sci. Technol. 2022, 100, 224–236. [Google Scholar] [CrossRef]

- Zhang, X.; Li, C.; Wu, M.; Ye, Z.; Wang, Q.; Gu, J. Atypical pathways for lamellar and twinning transformations in rapidly solidified TiAl alloy. Acta Mater. 2022, 227, 117718. [Google Scholar] [CrossRef]

- Sui, S.; Chew, Y.; Hao, Z.; Weng, F.; Tan, C.; Du, Z.; Bi, G. Effect of cyclic heat treatment on microstructure and mechanical properties of laser aided additive manufacturing Ti–6Al–2Sn–4Zr–2Mo alloy. Adv. Powder Mater. 2022, 1, 100002. [Google Scholar] [CrossRef]

- Fan, H.; Liu, Y.; Yang, S. Martensite decomposition during post-heat treatments and the aging response of near-α Ti–6Al–2Sn–4Zr–2Mo (Ti-6242) titanium alloy processed by selective laser melting (SLM). J. Micromech. Mol. Phys. 2021, 6, 2050018. [Google Scholar] [CrossRef]

- Sharman, A.; Hughes, J.; Ridgway, K. Characterisation of titanium aluminide components manufactured by laser metal deposition. Intermetallics 2018, 93, 89–92. [Google Scholar] [CrossRef]

- Zheng, G.; Tang, B.; Chen, W.; Zhao, S.; Xie, Y.; Chen, X.; Li, J.; Zhu, L. Long-period stacking ordering induced ductility of nanolamellar TiAl alloy at elevated temperature. Mater. Res. Lett. 2023, 11, 414–421. [Google Scholar] [CrossRef]

- Wang, J.; Luo, Q.; Wang, H.; Wu, Y.; Cheng, X.; Tang, H. Microstructure characteristics and failure mechanisms of Ti-48Al-2Nb-2Cr titanium aluminide intermetallic alloy fabricated by directed energy deposition technique. Addit. Manuf. 2020, 32, 101007. [Google Scholar] [CrossRef]

- Zhang, X.; Li, C.; Zheng, M.; Ye, Z.; Yang, X.; Gu, J. Anisotropic tensile behavior of Ti-47Al-2Cr-2Nb alloy fabricated by direct laser deposition. Addit. Manuf. 2020, 32, 101087. [Google Scholar] [CrossRef]

- Fatoba, O.S.; Lasisi, A.M.; Ikumapayi, O.M.; Akinlabi, S.A.; Akinlabi, E.T. Computational modelling of laser additive manufactured (LAM) Titanium alloy grade 5. Mater. Today Proc. 2021, 44, 1254–1262. [Google Scholar] [CrossRef]

- Shi, X.; Wang, H.; Feng, W.; Zhang, Y.; Ma, S.; Wei, J. The crack and pore formation mechanism of Ti–47Al–2Cr–2Nb alloy fabricated by selective laser melting. Int. J. Refract. Met. Hard Mater. 2020, 91, 105247. [Google Scholar] [CrossRef]

- Chlupová, A.; Heczko, M.; Obrtlík, K.; Polák, J.; Roupcová, P.; Beran, P.; Kruml, T. Mechanical properties of high niobium TiAl alloys doped with Mo and C. Mater. Des. 2016, 99, 284–292. [Google Scholar] [CrossRef]

- Xu, R.; Li, M.; Zhao, Y. A review of microstructure control and mechanical performance optimization of γ-TiAl alloys. J. Alloys Compd. 2023, 932, 167611. [Google Scholar] [CrossRef]

- Tetsui, T. Effects of high niobium addition on the mechanical properties and high-temperature deformability of gamma TiAl alloy. Intermetallics 2002, 10, 239–245. [Google Scholar] [CrossRef]

- Liu, Z.C.; Lin, J.P.; Li, S.J.; Chen, G.L. Effects of Nb and Al on the microstructures and mechanical properties of high Nb containing TiAl base alloys. Intermetallics 2002, 10, 653–659. [Google Scholar] [CrossRef]

- Fang, H.; Chen, R.; Liu, Y.; Tan, Y.; Su, Y.; Ding, H.; Guo, J. Effects of niobium on phase composition and improving mechanical properties in TiAl alloy reinforced by Ti2AlC. Intermetallics 2019, 115, 106630. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Q.; Zeng, L.; Zhang, H.; Ding, H. Microstructure, mechanical and tribological performances of a directionally solidified γ-TiAl alloy. Mater. Charact. 2021, 179, 111393. [Google Scholar] [CrossRef]

- Cheng, J.; Yang, J.; Zhang, X.; Zhong, H.; Ma, J.; Li, F.; Fu, L.; Bi, Q.; Li, J.; Liu, W. High temperature tribological behavior of a Ti-46Al-2Cr-2Nb intermetallics. Intermetallics 2012, 31, 120–126. [Google Scholar] [CrossRef]

- Wang, Q.; Ding, H.; Zhang, H.; Chen, R.; Guo, J.; Fu, H. Influence of Mn addition on the microstructure and mechanical properties of a directionally solidified γ-TiAl alloy. Mater. Charact. 2018, 137, 133–141. [Google Scholar] [CrossRef]

- Chen, G.L.; Xu, X.J.; Teng, Z.K.; Wang, Y.L.; Lin, J.P. Microsegregation in high Nb containing TiAl alloy ingots beyond laboratory scale. Intermetallics 2007, 15, 625–631. [Google Scholar] [CrossRef]

- Zhang, W.J.; Liu, Z.C.; Chen, G.L.; Kim, Y.W. Deformation mechanisms in a high-Nb containing γ–TiAl alloy at 900 °C. Mater. Sci. Eng. A 1999, 271, 416–423. [Google Scholar] [CrossRef]

- Nath, P.; Bar, H.N.; Bhattacharjee, A.; Sen, I. Designing of novel microstructure and its impact on the improved service temperature mechanical performance of 2nd and 3rd generation advanced intermetallic TiAl alloys. Mater. Sci. Eng. A 2024, 893, 146108. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, X.; Ren, Y.; Song, M.; Baker, I.; Wu, H. Microstructural evolution and cryogenic and ambient temperature deformation behavior of the near-α titanium alloy TA15 fabricated by laser powder bed fusion. J. Alloys Compd. 2024, 1001, 175075. [Google Scholar] [CrossRef]

- He, P.; Webster, R.F.; Yakubov, V.; Kong, H.; Yang, Q.; Huang, S.; Ferry, M.; Kruzic, J.J.; Li, X. Fatigue and dynamic aging behavior of a high strength Al-5024 alloy fabricated by laser powder bed fusion additive manufacturing. Acta Mater. 2021, 220, 117312. [Google Scholar] [CrossRef]

- Singh, V.; Mondal, C.; Sarkar, R.; Bhattacharjee, P.P.; Ghosal, P. Effects of Cr alloying on the evolution of solidification microstructure and phase transformations of high-Nb containing γ-TiAl based alloys. Intermetallics 2021, 131, 107117. [Google Scholar] [CrossRef]

- Fang, H.; Chen, R.; Chen, X.; Yang, Y.; Su, Y.; Ding, H.; Guo, J. Effect of Ta element on microstructure formation and mechanical properties of high-Nb TiAl alloys. Intermetallics 2019, 104, 43–51. [Google Scholar] [CrossRef]

- Agbedor, S.-O.; Wu, H.; Ren, Y.; Liang, L.; Yang, D.; Liu, B.; Liu, Y.; Baker, I. A two-decade odyssey in fusion-based additive manufacturing of titanium alloys and composites. Appl. Mater. Today 2024, 39, 102242. [Google Scholar] [CrossRef]

- Ovcharenko, A.; Halperin, G.; Verberne, G.; Etsion, I. In situ investigation of the contact area in elastic-plastic spherical contact during loading-unloading. Tribol. Lett. 2007, 25, 153–160. [Google Scholar] [CrossRef]

- Rastkar, A.R.; Bloyce, A.; Bell, T. Sliding wear behaviour of two gamma-based titanium aluminides. Wear 2000, 240, 19–26. [Google Scholar] [CrossRef]

- Wang, Q.; Ding, H.; Zhang, H.; Chen, R.; Guo, J.; Fu, H. Variations of microstructure and tensile property of γ-TiAl alloys with 0–0.5 at% C additives. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2017, 700, 198–208. [Google Scholar] [CrossRef]

- Du, J.; Ren, Y.; Liu, X.; Xu, F.; Wang, X.; Zhou, R.; Baker, I.; Wu, H. Microstructural Evolution, Mechanical Properties and Tribological Behavior of B(4)C-Reinforced Ti In Situ Composites Produced by Laser Powder Bed Fusion. Materials 2023, 16, 4890. [Google Scholar] [CrossRef]

- Cheng, F.; Lin, J.; Liang, Y. Friction and wear properties of a high Nb-containing TiAl alloy against WC-8Co, Si3N4, and GCr15 in an unlubricated contact. Intermetallics 2019, 106, 7–12. [Google Scholar] [CrossRef]

- Zhou, H.; Su, Y.; Liu, N.; Kong, F.; Wang, X.; Zhang, X.; Chen, Y. Modification of microstructure and properties of Ti-47Al-2Cr-4Nb-0.3W alloys fabricated by SPS with trace multilayer graphene addition. Mater. Charact. 2018, 138, 1–10. [Google Scholar] [CrossRef]

| Label | Chemical Composition (at.%) | Identified Phase | |||

|---|---|---|---|---|---|

| Ti | Al | Nb | Cr | ||

| A | 54.1 | 35.6 | 2.0 | 8.3 | β0 |

| B | 44.1 | 52.5 | 2.2 | 1.2 | γ |

| C | 48.4 | 46.2 | 2.5 | 3.0 | β0 |

| D | 47.7 | 47.8 | 2.6 | 1.9 | γ/α2 |

| E | 45.9 | 46.5 | 4.6 | 3.0 | β0 |

| F | 44.7 | 49.6 | 3.3 | 2.4 | γ/α2 |

| G | 45.8 | 47.8 | 4.3 | 2.0 | γ/α2 |

| H | 44.8 | 47.4 | 4.1 | 3.7 | β0 |

| I | 44.8 | 49.4 | 3.7 | 2.1 | γ/α2 |

| J | 45.4 | 48.0 | 4.7 | 1.9 | γ/α2 |

| Alloys | Phase Content (%) | ||

|---|---|---|---|

| γ-TiAl | β0/B2 | α2-Ti3Al | |

| S1 | 92.8 | 5.7 | 1.5 |

| S2 | 97.7 | 1.9 | 0.4 |

| S3 | 98.6 | 1 | 0.4 |

| Label | Composition in at.% | |||||

|---|---|---|---|---|---|---|

| Ti | Al | Nb | Cr | O | Si | |

| A | 31.4 | 32.7 | 2.8 | 1.2 | 31.7 | 0.1 |

| B | 46.9 | 43.1 | 3.5 | 2.0 | 4.3 | 0.2 |

| C | 40.7 | 39.1 | 3.2 | 1.7 | 15.2 | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, K.; Xu, F.; Liu, X.; Liu, S.; Wang, Q.; Baker, I.; Song, M.; Wu, H. Microstructure, Mechanical, and Tribological Properties of Nb-Doped TiAl Alloys Fabricated via Laser Metal Deposition. Materials 2024, 17, 4260. https://doi.org/10.3390/ma17174260

Huang K, Xu F, Liu X, Liu S, Wang Q, Baker I, Song M, Wu H. Microstructure, Mechanical, and Tribological Properties of Nb-Doped TiAl Alloys Fabricated via Laser Metal Deposition. Materials. 2024; 17(17):4260. https://doi.org/10.3390/ma17174260

Chicago/Turabian StyleHuang, Kai, Feng Xu, Xinyan Liu, Shiqiu Liu, Qingge Wang, Ian Baker, Min Song, and Hong Wu. 2024. "Microstructure, Mechanical, and Tribological Properties of Nb-Doped TiAl Alloys Fabricated via Laser Metal Deposition" Materials 17, no. 17: 4260. https://doi.org/10.3390/ma17174260

APA StyleHuang, K., Xu, F., Liu, X., Liu, S., Wang, Q., Baker, I., Song, M., & Wu, H. (2024). Microstructure, Mechanical, and Tribological Properties of Nb-Doped TiAl Alloys Fabricated via Laser Metal Deposition. Materials, 17(17), 4260. https://doi.org/10.3390/ma17174260