Analysis of Rheological Properties and Regeneration Mechanism of Recycled Styrene–Butadiene–Styrene Block Copolymer (SBS) Modified Asphalt Binder Using Different Rejuvenators

Abstract

1. Introduction

2. Methodology

2.1. Rejuvenation Agent

2.2. Asphalt Binder

2.2.1. Preparation of Aged Asphalt Binder

2.2.2. Preparation of Recycled Asphalt Binder

2.3. Experimental Test Methods

2.3.1. General Performance Tests

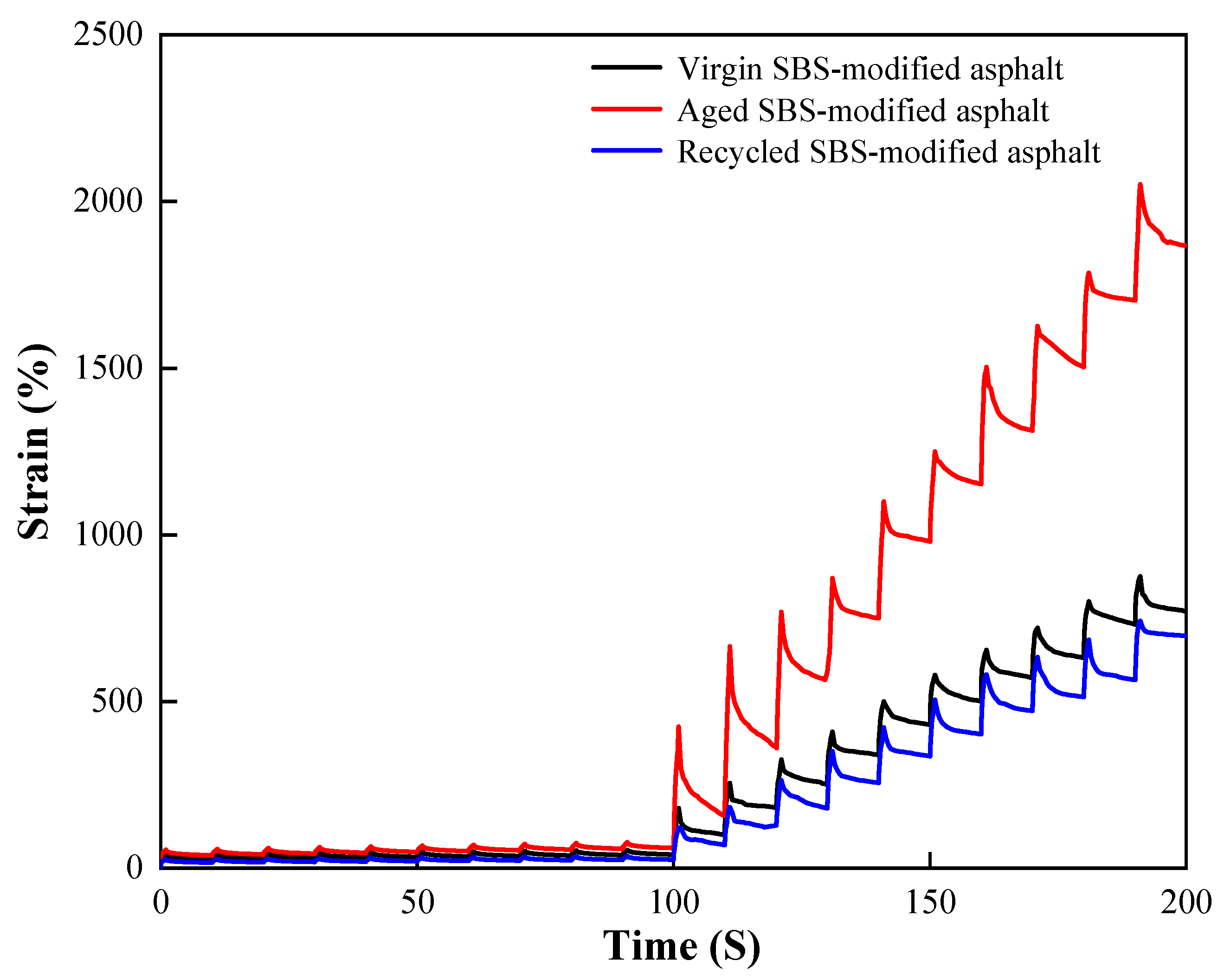

2.3.2. Multiple Stress Creep Recovery (MSCR) Tests

- is the applied stress level, 0.1 kPa and 3.2 kPa, respectively;

- is the unrecovered strain, dimensionless;

- is the loading cycle, times;

- is the peak strain, dimensionless;

- is the irrecoverable creep softness at the Nth loading cycle, kPa−1;

- is the elastic recovery rate at the N loading cycle, %;

- is the average irrecoverable creep softness, kPa−1;

- R is the average elastic recovery rate, %;

- is the stress sensitivity parameter, %.

2.3.3. Microanalysis Test

3. Results and Discussion

3.1. Regeneration Performance Analysis

3.2. Analysis of MSCR Trial Results

3.3. Analysis of Aging and Regeneration Mechanism of Modified Asphalt

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pang, T.; Yang, J.G.; Zhang, W.; Huang, J.H. Properties and aging mechanism of high content SBS polymer modified asphalt during aging process. J. Sci. Technol. Eng. 2022, 22, 6308–6316. [Google Scholar]

- Cong, P.; Zhang, Y.H.; Liu, N. Investigation of the properties of asphalt mixtures incorporating reclaimed SBS modified asphalt pavement. Constr. Build. Mater. 2016, 113, 334–340. [Google Scholar] [CrossRef]

- Cui, Y.N.; Cui, S.Y.; Guo, L.D. Performance and mechanism of waste oil recycled SBS modified asphalt. J. Build. Mater. 2022, 25, 164–170. [Google Scholar]

- Li, N.; Zhan, H.; Yu, X.; Tang, W.; Yu, H.; Dong, F.Q. Research on the high temperature performance of asphalt pavement based on field cores with different rutting development levels. Mater. Struct. 2021, 54, 70. [Google Scholar] [CrossRef]

- Xian, Y.; Zhang, J.M.; Luo, C.B.; Yang, L. Study on the regeneration performance of SBS modified asphalt by vegetable oil-based regenerant. Contemp. Chem. Ind. 2022, 51, 2847–2850. [Google Scholar]

- Wu, W.; Dai, S.; Si, L. Study on rheological and temperature sensitive properties of recycled asphalt from furfural extraction oil. J. Zhengzhou Univ. (Eng. Sci.) 2022, 43, 52–58+66. [Google Scholar]

- Yu, G.X.; Zhou, X.L.; Jin, Y.Q.; Li, C.L. Experimental study on the regenerant of waste asphalt. ACTA Pet. Sin. (Pet. Process. Sect.) 2006, 22, 96–100. [Google Scholar]

- Zhang, Y.R.; Zhou, C.G.; Zou, P.; Hu, M.G.; Cao, P. A novel WCO-MDI reactive rejuvenation method for aged SBS modified asphalt toward sustainable asphalt pavements. J. Clean. Prod. 2023, 434, 140199. [Google Scholar] [CrossRef]

- Shi, K.; Ma, F.; Liu, J.; Fu, Z.; Song, R.M.; Yuan, D.D.; Ogbon, A.W. Evolution of SBS-modified asphalt performance under aging and rejuvenation cycle conditions. Constr. Build. Mater. 2024, 416, 35156. [Google Scholar] [CrossRef]

- Xu, S.; Tang, G.M.; Pan, S.L.; Ji, Z.Y.; Fang, L.; Zhang, C.L.; Cao, Z.L.; Zhou, X.X.; Jia, X.J. Application of reactive rejuvenator in aged SBS modified asphalt regeneration: A review. Constr. Build. Mater. 2024, 421, 135696. [Google Scholar] [CrossRef]

- Eltwati, A.; Mohamed, A.; Hainin, M.R.; Jusli, E.; Enieb, M. Rejuvenation of aged asphalt binders by waste engine oil and SBS blend: Physical, chemical, and rheological properties of binders and mechanical evaluations of mixtures. Constr. Build. Mater. 2022, 346, 128441. [Google Scholar] [CrossRef]

- Stefanidou, M.; Kamperidou, V.; Konstandinidis, A.; Koltsou, P.; Papadopoulos, S. 24-Rheological properties of biofibers in cementitious composite matrix. In Advances in Bio-Based Fiber; Woodhead Publishing: Cambridge, UK, 2022; pp. 553–573. [Google Scholar] [CrossRef]

- Han, X.B.; Mao, S.P.; Zeng, S.H.; Cao, Z.L.; He, P.; Du, W.; Yu, J.Y. Influence of novel long-chain active composite rejuvenators on interfacial adhesion between aged SBS modified asphalt and aggregate. Constr. Build. Mater. 2022, 328, 127108. [Google Scholar] [CrossRef]

- Zhu, C.Z.; Zhang, H.L.; Tan, B.Y.; Li, Q.; Xu, F. Evaluation on recycling effect of a novel rejuvenator combined with fresh asphalt on field-aged SBS modified asphalt by rheological and micro characteristics. Constr. Build. Mater. 2023, 392, 131875. [Google Scholar] [CrossRef]

- Dong, F.Q.; Wang, J.C.; Yu, X.; Jiang, M.M.; Guo, Y.J.; Wang, S.Y.; Zu, Y.Z.; Ren, S.S. Regeneration mechanisms of aged SBS modified asphalt from RAP materials: Molecule structure, morphology, phase transition, and interface adhesion characteristics. Constr. Build. Mater. 2023, 388, 131689. [Google Scholar] [CrossRef]

- Shi, K.; Ma, F.; Fu, Z.; Liu, J.; Song, R.M.; Yuan, D.D.; Tang, Y.J. Molecular dynamics simulation insights into rejuvenating aged asphalt with waste soybean oil and polymers. Constr. Build. Mater. 2024, 439, 137260. [Google Scholar] [CrossRef]

- Hu, M.J.; Sun, D.Q.; Hofko, B.; Sun, Y.R.; Mirwald, J.; Xu, L. Multiscale optimization on polymer-based rejuvenators for the efficient recycling of aged high-viscosity modified asphalt: Molecular dynamics simulation and experimental analysis. J. Clean. Prod. 2024, 449, 141736. [Google Scholar] [CrossRef]

- Sun, G.Q.; Li, B.; Sun, D.Q.; Yu, F.; Hu, M.J. Chemo-rheological and morphology evolution of polymer modified bitumens under thermal oxidative and all-weather aging. Fuel 2021, 285, 118989. [Google Scholar] [CrossRef]

- Xu, J.; Pei, J.Z.; Cai, J.; Liu, T.; Wen, Y. Performance improvement and aging property of oil/SBS modified asphalt. Constr. Build. Mater. 2021, 300, 123735. [Google Scholar] [CrossRef]

- Yao, X.G.; Wang, Y.; Xu, T.; Zhang, Q.Q. Research on Aging Simulation and Recycling of SBS Modified Asphalt. Eng. J. Wuhan Univ. 2019, 52, 1070–1078. [Google Scholar]

- Liu, H.D.; Zeiada, W.; Al-Khateeb, G.G.; Shanableh, A.; Samarai, M. Use of the multiple stress creep recovery (MSCR) test to characterize the rutting potential of asphalt binders: A literature review. Constr. Build. Mater. 2021, 269, 121320. [Google Scholar] [CrossRef]

- Elnasri, M.; Airey, G.; Thom, N. Developing the multiple stress–strain creep recovery (MS-SCR) test. Mech. Time-Depend. Mater. 2019, 23, 97–117. [Google Scholar] [CrossRef]

- Hao, G.R.; Huang, W.D.; Yuan, J.; Tang, N.P.; Xiao, F.P. Effect of aging on chemical and rheological properties of SBS modified asphalt with different compositions. Constr. Build. Mater. 2017, 156, 902–910. [Google Scholar] [CrossRef]

- Shi, K.; Ma, F.; Liu, J.; Song, R.M.; Fu, Z.; Dai, J.S.; Wen, Y.L. Development of a new rejuvenator for aged SBS modified asphalt binder. J. Clean. Prod. 2022, 380, 134986. [Google Scholar] [CrossRef]

- Zhang, N.; Fan, G.; Lv, S.; He, F.; Fan, X.; Peng, X.; Liu, H. The influence of SBS modification on the rheological property of asphalt before and after regeneration. Constr. Build. Mater. 2021, 310, 125239. [Google Scholar] [CrossRef]

- Pan, P.; Kuang, Y.; Hu, X.; Zhang, X. A comprehensive evaluation of rejuvenator on mechanical properties, durability, and dynamic characteristics of artificially aged asphalt mixture. Materials 2018, 11, 1554. [Google Scholar] [CrossRef]

- Wu, S.; He, R.; Chen, H.; Li, W.; Li, G. Rheological properties of SBS/CRP composite modified asphalt under different aging treatments. Materials 2020, 13, 4921. [Google Scholar] [CrossRef]

- Du, B.; Li, R.; Guo, F.; Cai, R.; Pei, J. Evaluation of Rheological and Microscopic Properties of SBS-Modified Asphalt Binder with Multiple Regeneration. J. Mater. Civ. Eng. 2023, 35, 04023461. [Google Scholar] [CrossRef]

- Bai, X.P. Research on Aging Mechanism and Characteristics of SBS Modified Asphalt Based on Ultraviolet Radiation. Ph.D. Thesis, Changsha University of Science & Technology, Changsha, China, 2019. [Google Scholar]

- Liu, Q.; Han, B.; Wang, S.; Falchetto, A.C.; Wang, D.; Yu, B.; Zhang, J. Evaluation and molecular interaction of asphalt modified by rubber particles and used engine oil. J. Clean. Prod. 2022, 375, 134222. [Google Scholar] [CrossRef]

- Jiang, X.M.; Li, P.L.; Ding, Z.; Yue, L.; Li, H.F.; Bing, H.; Zhang, J. Physical, chemical and rheological investigation and optimization design of asphalt binders partially replaced by bio-based resins. Constr. Build. Mater. 2022, 350, 128845. [Google Scholar] [CrossRef]

- Yan, C.Q.; Huang, W.D.; Lin, P.; Zhang, Y.; Lv, Q. Chemical and rheological evaluation of aging properties of high content SBS polymer modified asphalt. Fuel 2019, 252, 417–426. [Google Scholar] [CrossRef]

- Xiao, H.; Cao, D.; Qin, Z.; Yi, H.; Chen, X. Research on the effects of SBS swelling, thermal-oxidative aging, and sulfur crosslinking on chemical composition and rheological properties of SBS-modified asphalt. Int. J. Pavement Res. Technol. 2023, 1–21. [Google Scholar] [CrossRef]

- Li, Z.; Chen, W.; Li, Y.; Liu, H.; Zhao, Z.; Cao, L. Characteristic evolution of GO/SBS-modified asphalt during aging. Adv. Civ. Eng. 2022, 2022, 4060013. [Google Scholar] [CrossRef]

- Deng, M.; Cao, X.; Yuan, Y.; Yang, X.; Tang, B.; Li, X. Response of oxidized asphaltene aggregations in presence of rejuvenators and characteristics of molecular assembly behavior. Constr. Build. Mater. 2023, 397, 132468. [Google Scholar] [CrossRef]

- JTG E20-2011; Specifications and Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communication Press: Beijing, China, 2011.

- Li, H.; Liu, G.; Dong, B.; Zhao, G.; Guo, P.; Huang, J.; Sheng, Y. Research on the development and regeneration performance of asphalt rejuvenator based on the mixed waste engine oil and waste cooking oil. Int. J. Pavement Res. Technol. 2019, 12, 336–346. [Google Scholar] [CrossRef]

- Yang, C.D.; Gong, X.Y.; Han, X.B.; Li, X.; Yu, J.Y. Influence of thermal aging on the composition structure and properties of different asphalts. Sci. Technol. Eng. 2023, 23, 8839–8845. [Google Scholar]

- Hong, C.F.; Wang, H.G.; Liao, K.J. Study on regeneration and aging kinetics of asphalt. Petrochem. Technol. Appl. 2016, 34, 102–106. [Google Scholar]

- Yang, Z. Study on multi-scale behavior of asphalt before and after aging. Ph.D. Thesis, South China University of Technology, Guangzhou, China, 2018. [Google Scholar]

- Zhang, X.J.; Feng, H.X.; Wang, Y.N.; Li, B.; Zhang, Z.H. Microscopic mechanism of short-term aging SBS modified asphalt regeneration based on fourier transform infrared spectroscopy. J. Mater. Sci. Eng. 2020, 38, 232–237. [Google Scholar]

| Schemes | Rejuvenator Name | Component | Percentages Included (%) |

|---|---|---|---|

| 1# | Rubber powder modification rejuvenator | Softeners | 45 |

| Plasticizers | 20 | ||

| Polymerizing agents | 5 | ||

| Aluminate coupling agents | 1 | ||

| Restorative | 2 | ||

| Anti-aging ingredients | 3 | ||

| Rubber powder 40 mesh | 5 | ||

| 2# | SBS-modified rejuvenating agent | Softeners | 60 |

| Plasticizers | 20 | ||

| Polymerizing agents | 10 | ||

| Aluminate coupling agents | 3 | ||

| Restorative | 10 | ||

| Antioxidant BHT | 2 | ||

| Ultraviolet absorber UV-326 | 2 | ||

| SBS | 10 | ||

| 3# | SBR + SBS-modified blend rejuvenating agent | Softeners | 60 |

| Plasticizers | 20 | ||

| Polymerizing agents | 15 | ||

| Aluminate coupling agents | 3 | ||

| Restorative | 15 | ||

| SBR | 10 | ||

| SBS | 20 | ||

| 4# | SBR + SBS + PPA (polyphosphoric acid) complex modification rejuvenator | Softeners | 70 |

| Plasticizers | 20 | ||

| Polymerizing agents | 10 | ||

| Restorative agents | 10 | ||

| SBR | 5 | ||

| SBS | 25 | ||

| PPA | 7 |

| Asphalt | 25 °C Penetration (0.1 mm) | Ductility (cm) | Softening Point °C |

|---|---|---|---|

| 70# virgin asphalt | 74 | >100 (15 °C) | 48.5 |

| SBS-modified asphalt | 71 | 41 (5 °C) | 88 |

| Asphalt Binder | Dosage of Regenerant | Penetration at 25 °C (0.1 mm) | 5 °C Ductility (cm) | Softening Point (°C) | 135 °C Kinematic Viscosity (Pa.s) |

|---|---|---|---|---|---|

| SBS-modified asphalt | 0% | 71 | 41 | 88 | 1.71 |

| Aging of SBS-modified asphalt | 0% | 45 | 1.5 | 90 | 2.14 |

| 1# | 4% | 48.7 | 9.6 | 56.7 | 2.07 |

| 8% | 66.8 | 13.2 | 59.0 | 1.53 | |

| 12% | 90.7 | 17.0 | 64.3 | 1.25 | |

| 2# | 4% | 54.1 | 25.6 | 69.0 | 3.09 |

| 8% | 63.0 | 37.2 | 71.0 | 2.87 | |

| 12% | 73.9 | 49.5 | 77.0 | 2.08 | |

| 3# | 4% | 54.2 | 25.6 | 65.7 | 2.82 |

| 8% | 66.9 | 39.6 | 66.2 | 2.74 | |

| 12% | 97.5 | 71.4 | 65.6 | 2.23 | |

| 4# | 4% | 54.1 | 25.6 | 68.9 | 3.52 |

| 8% | 63.0 | 37.2 | 71.2 | 3.36 | |

| 12% | 71.9 | 4905 | 75.3 | 3.07 |

| Asphalt Type | Jnr/(kPa−1) | R/(%) | Jnr-diff/ (%) | ||

|---|---|---|---|---|---|

| 0.1 kPa | 3.2 kPa | 0.1 kPa | 3.2 kPa | ||

| Virgin SBS-modified asphalt | 0.206 | 0.236 | 60.3 | 55.4 | 14.6 |

| Aged SBS-modified asphalt | 0.506 | 0.586 | 42.6 | 36.1 | 15.8 |

| Recycled SBS-modified asphalt | 0.233 | 0.268 | 49.5 | 46.8 | 15.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, H.; Guo, F.; Han, J.; Zhi, P. Analysis of Rheological Properties and Regeneration Mechanism of Recycled Styrene–Butadiene–Styrene Block Copolymer (SBS) Modified Asphalt Binder Using Different Rejuvenators. Materials 2024, 17, 4258. https://doi.org/10.3390/ma17174258

Ma H, Guo F, Han J, Zhi P. Analysis of Rheological Properties and Regeneration Mechanism of Recycled Styrene–Butadiene–Styrene Block Copolymer (SBS) Modified Asphalt Binder Using Different Rejuvenators. Materials. 2024; 17(17):4258. https://doi.org/10.3390/ma17174258

Chicago/Turabian StyleMa, Hongmei, Fucheng Guo, Jihong Han, and Pengfei Zhi. 2024. "Analysis of Rheological Properties and Regeneration Mechanism of Recycled Styrene–Butadiene–Styrene Block Copolymer (SBS) Modified Asphalt Binder Using Different Rejuvenators" Materials 17, no. 17: 4258. https://doi.org/10.3390/ma17174258

APA StyleMa, H., Guo, F., Han, J., & Zhi, P. (2024). Analysis of Rheological Properties and Regeneration Mechanism of Recycled Styrene–Butadiene–Styrene Block Copolymer (SBS) Modified Asphalt Binder Using Different Rejuvenators. Materials, 17(17), 4258. https://doi.org/10.3390/ma17174258