Research Progress on the Microstructure Evolution Mechanisms of Al-Mg Alloys by Severe Plastic Deformation

Abstract

1. Introduction

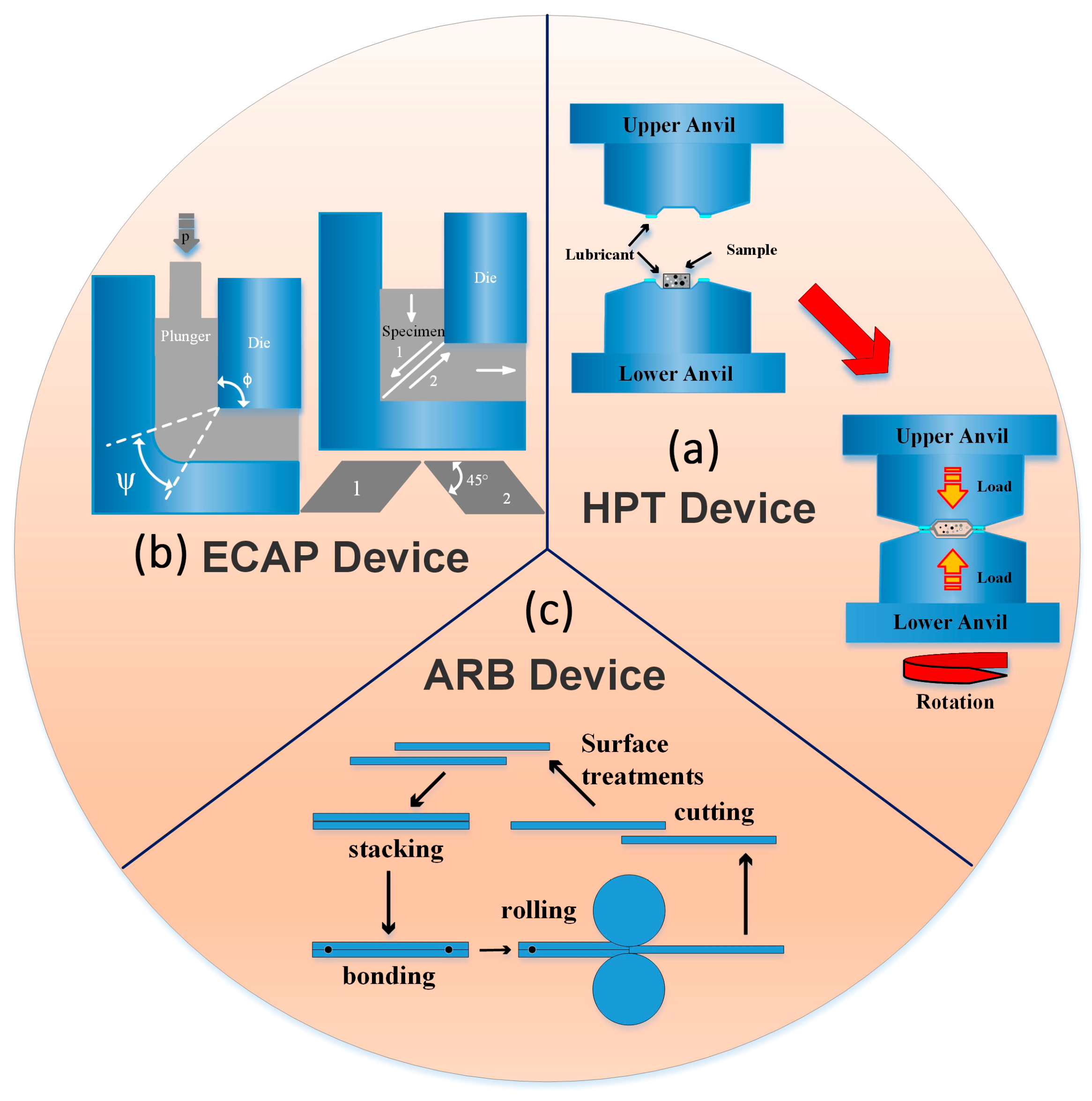

2. Severe Plastic Deformation (SPD) of Al-Mg Alloys

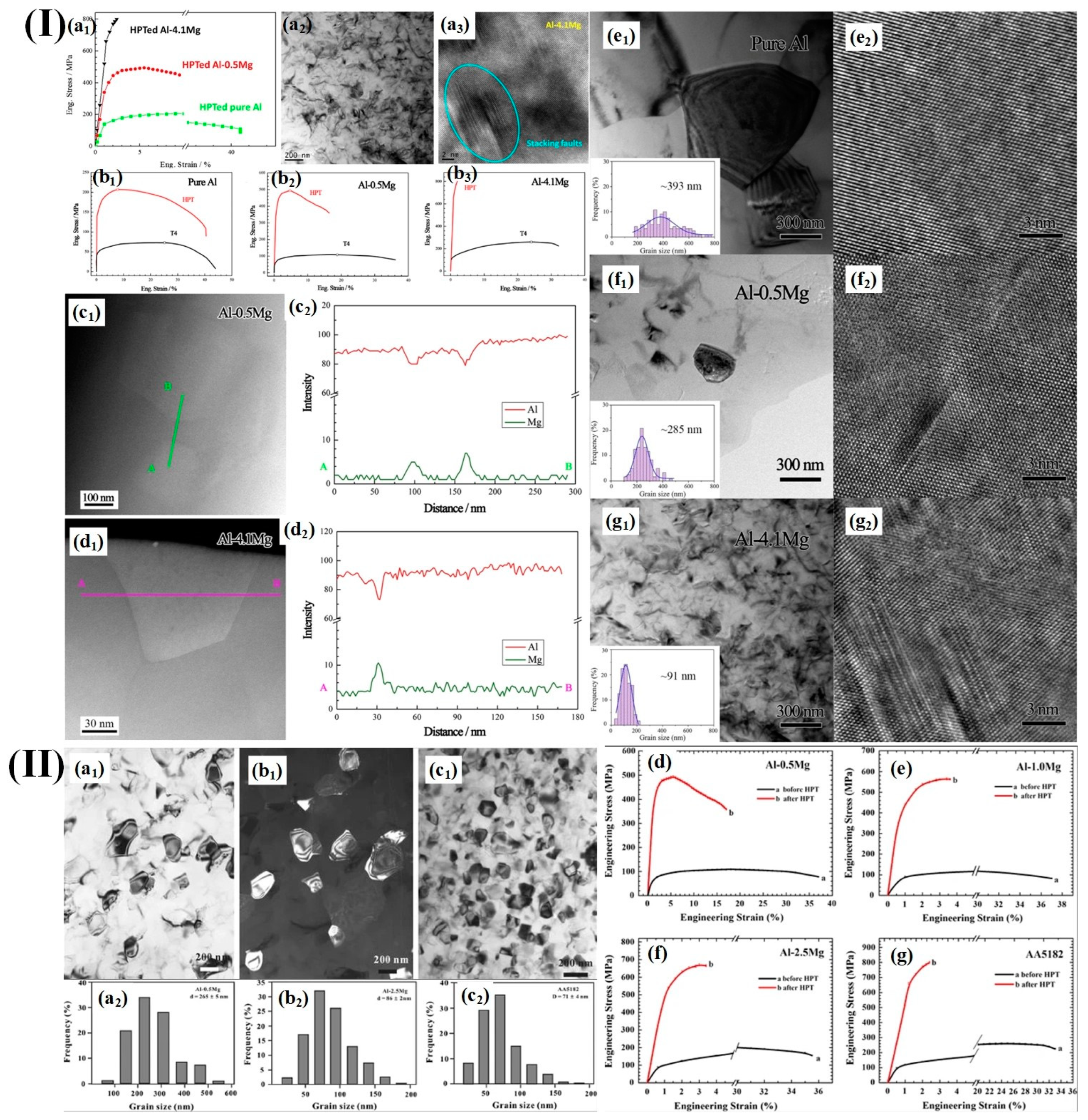

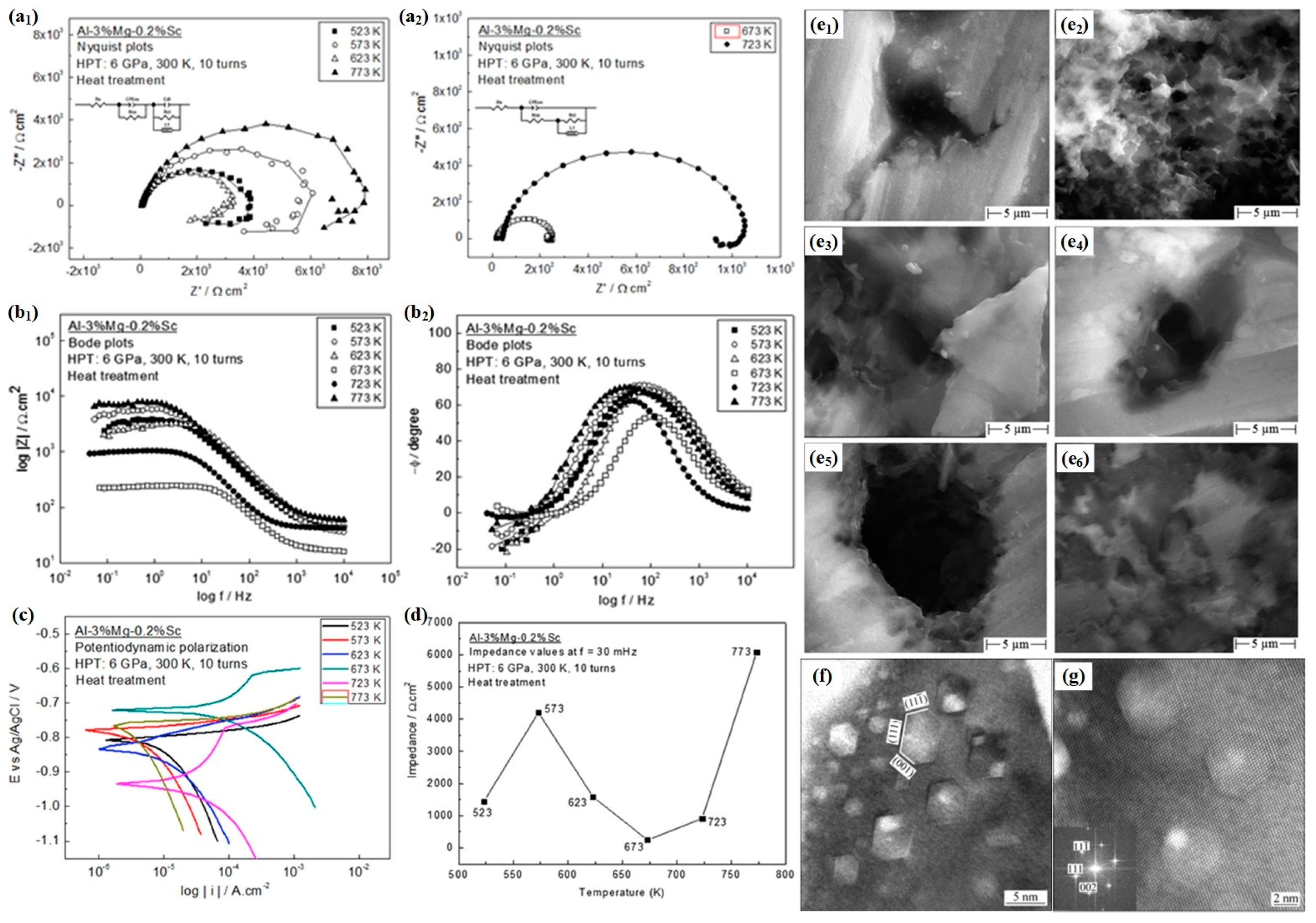

2.1. High Pressure and Torsion

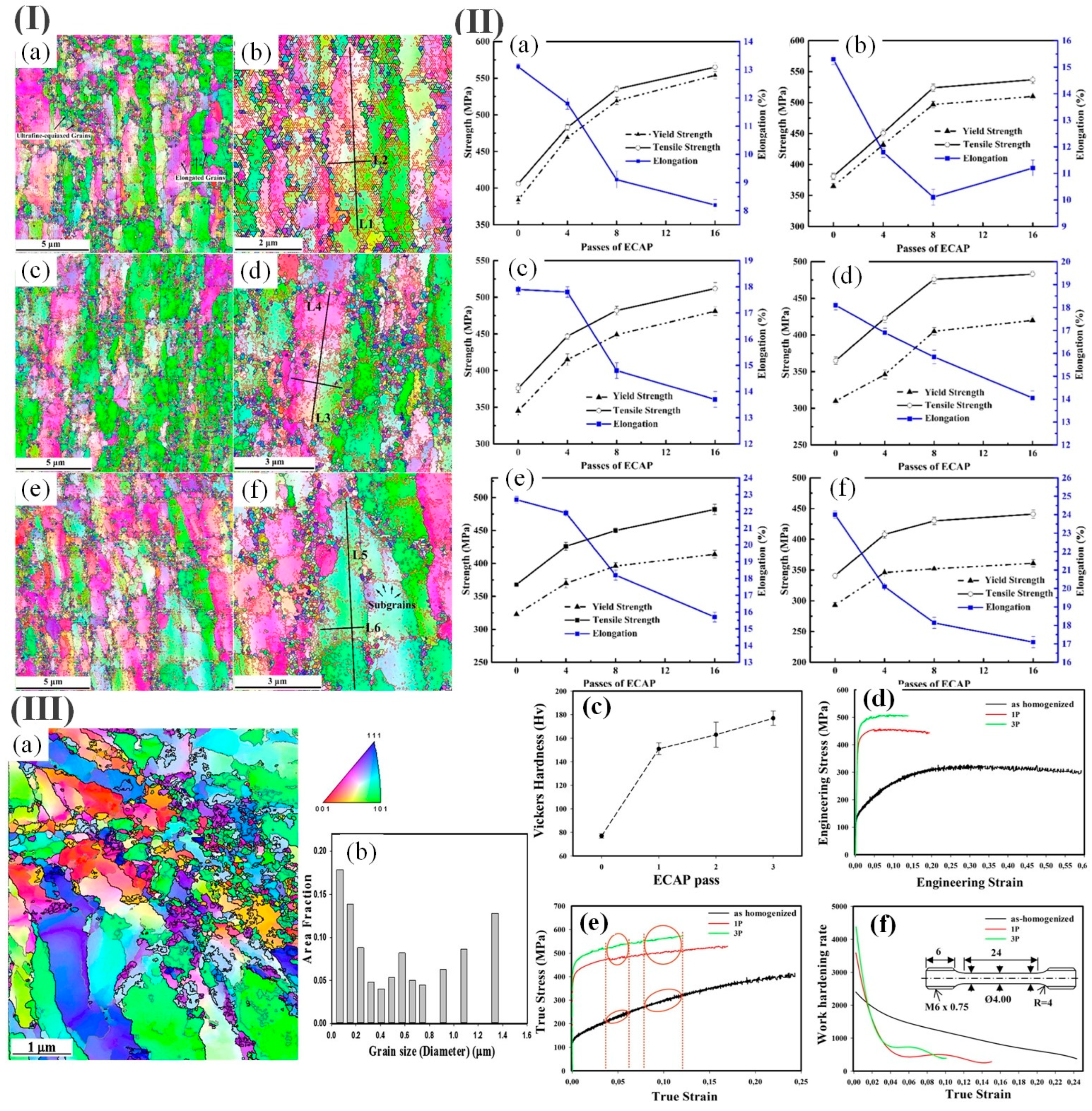

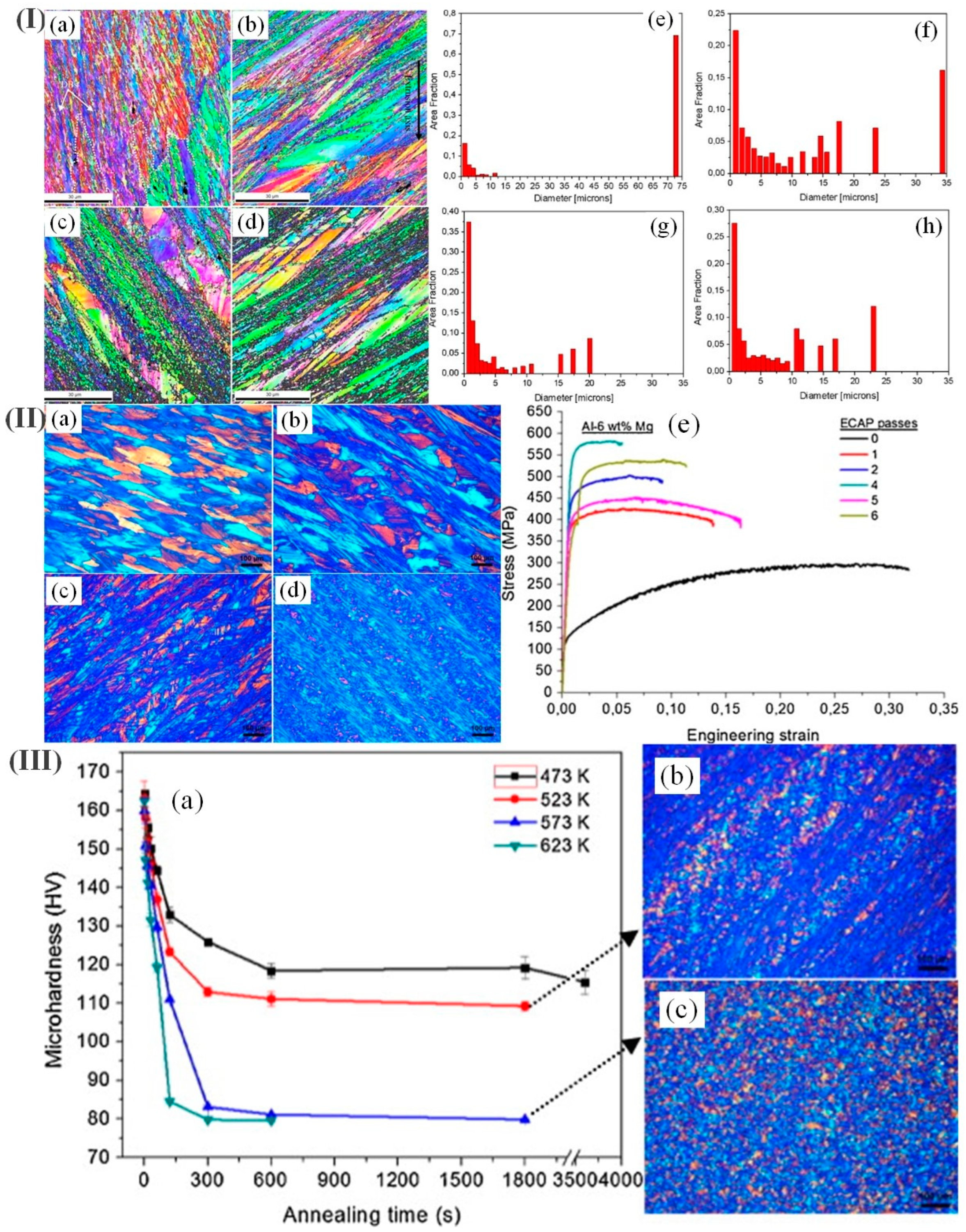

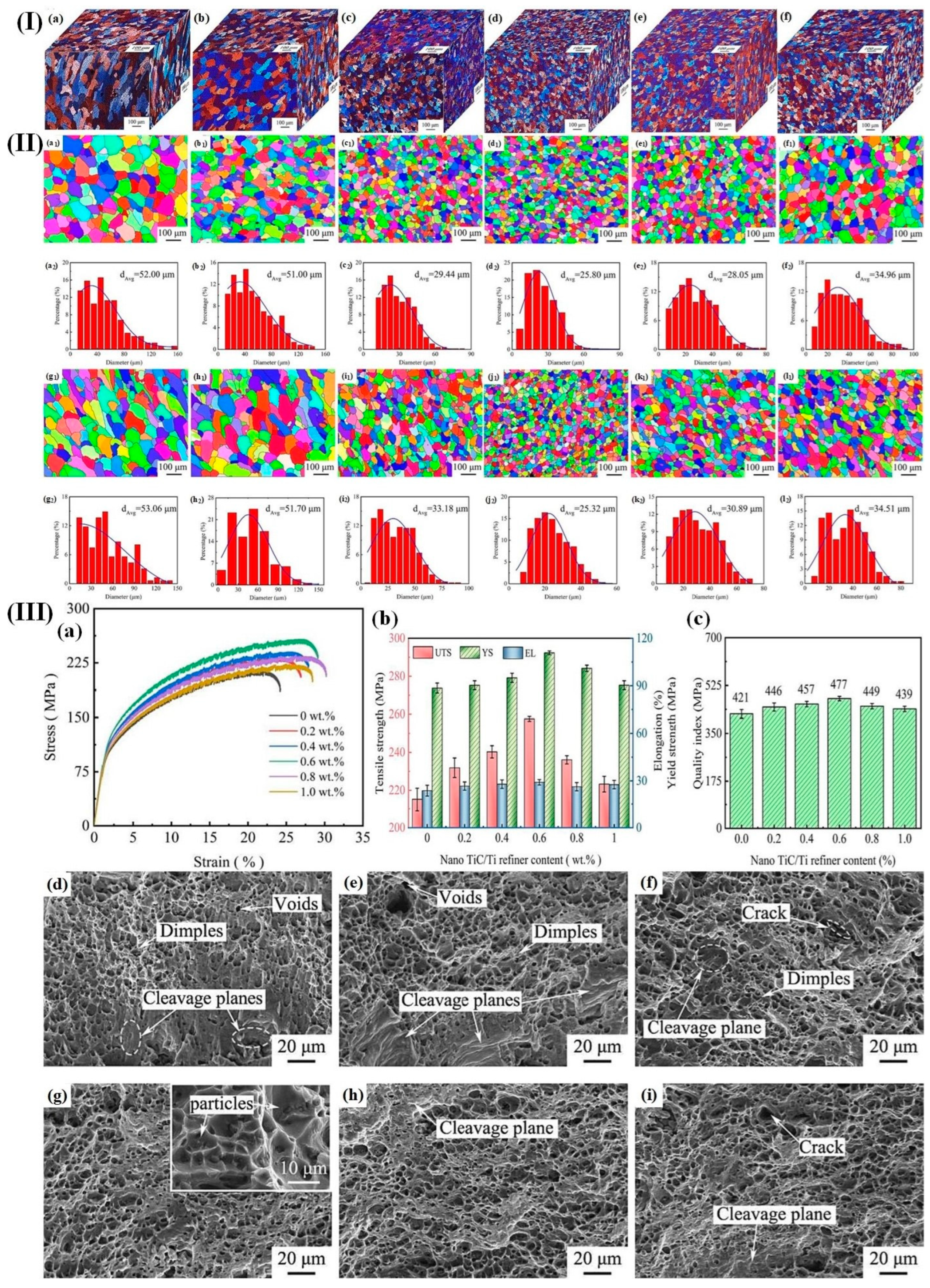

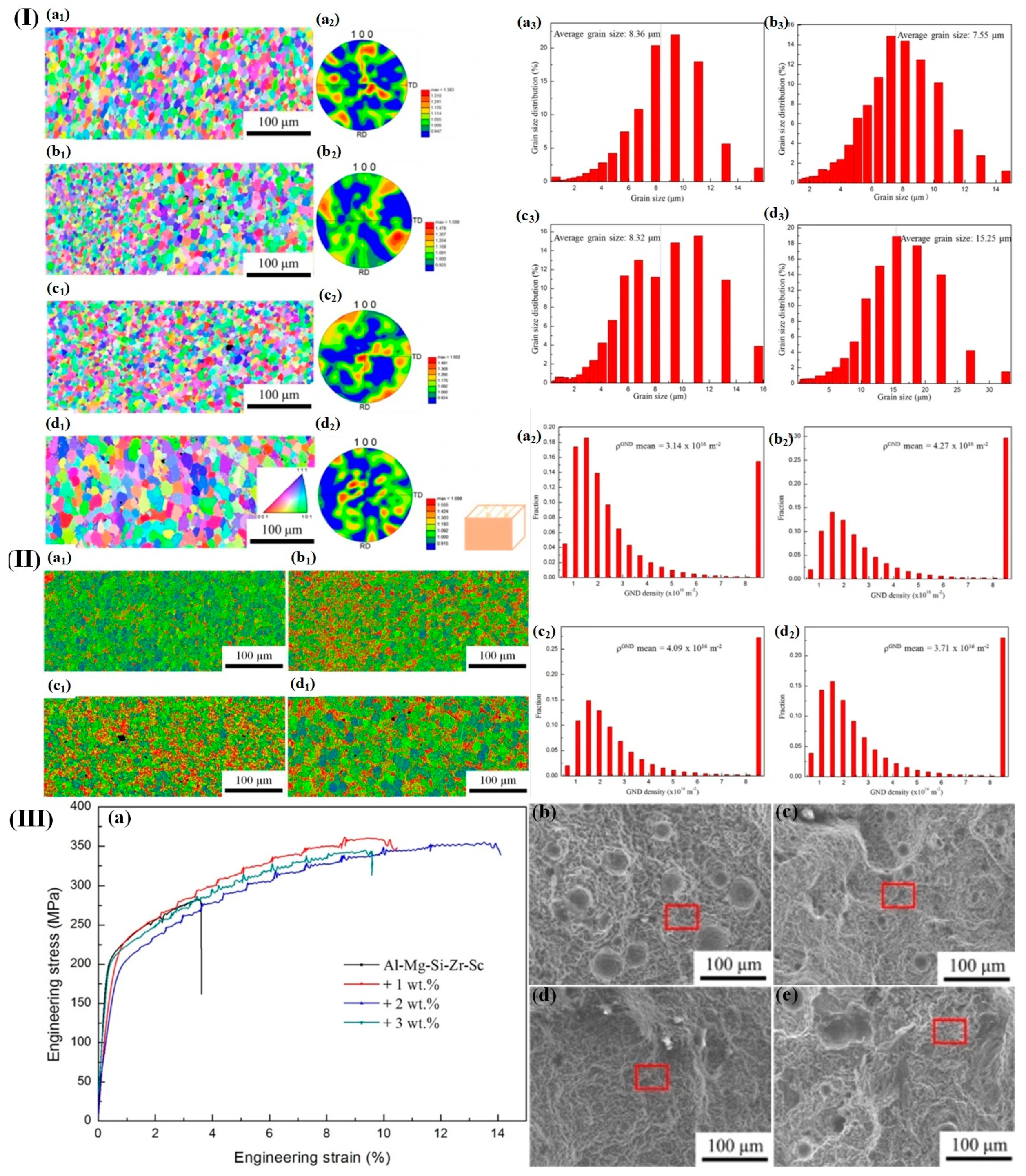

2.2. Equal-Channel Angular Pressing (ECAP)

2.3. Accumulative Roll Bonding

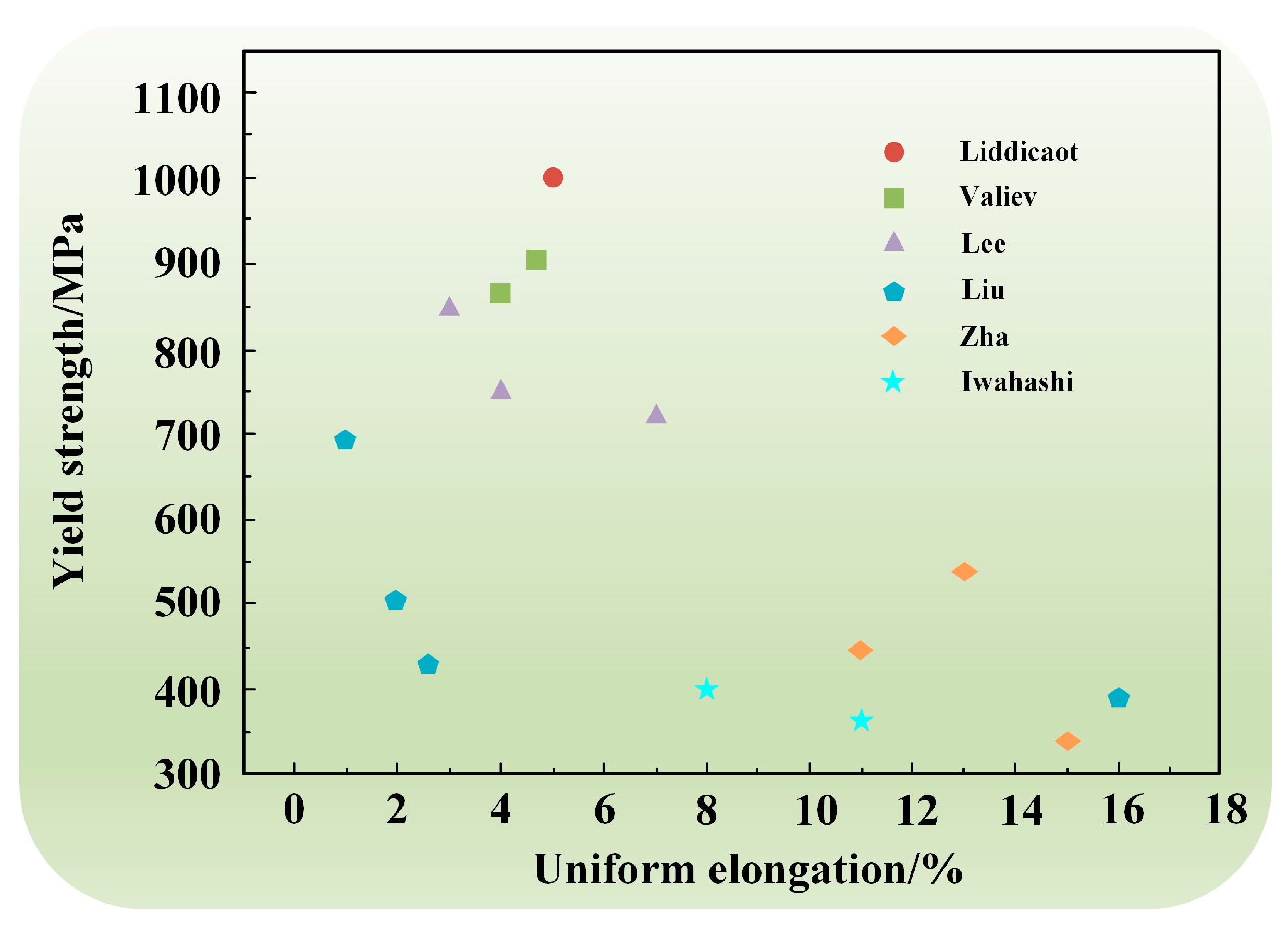

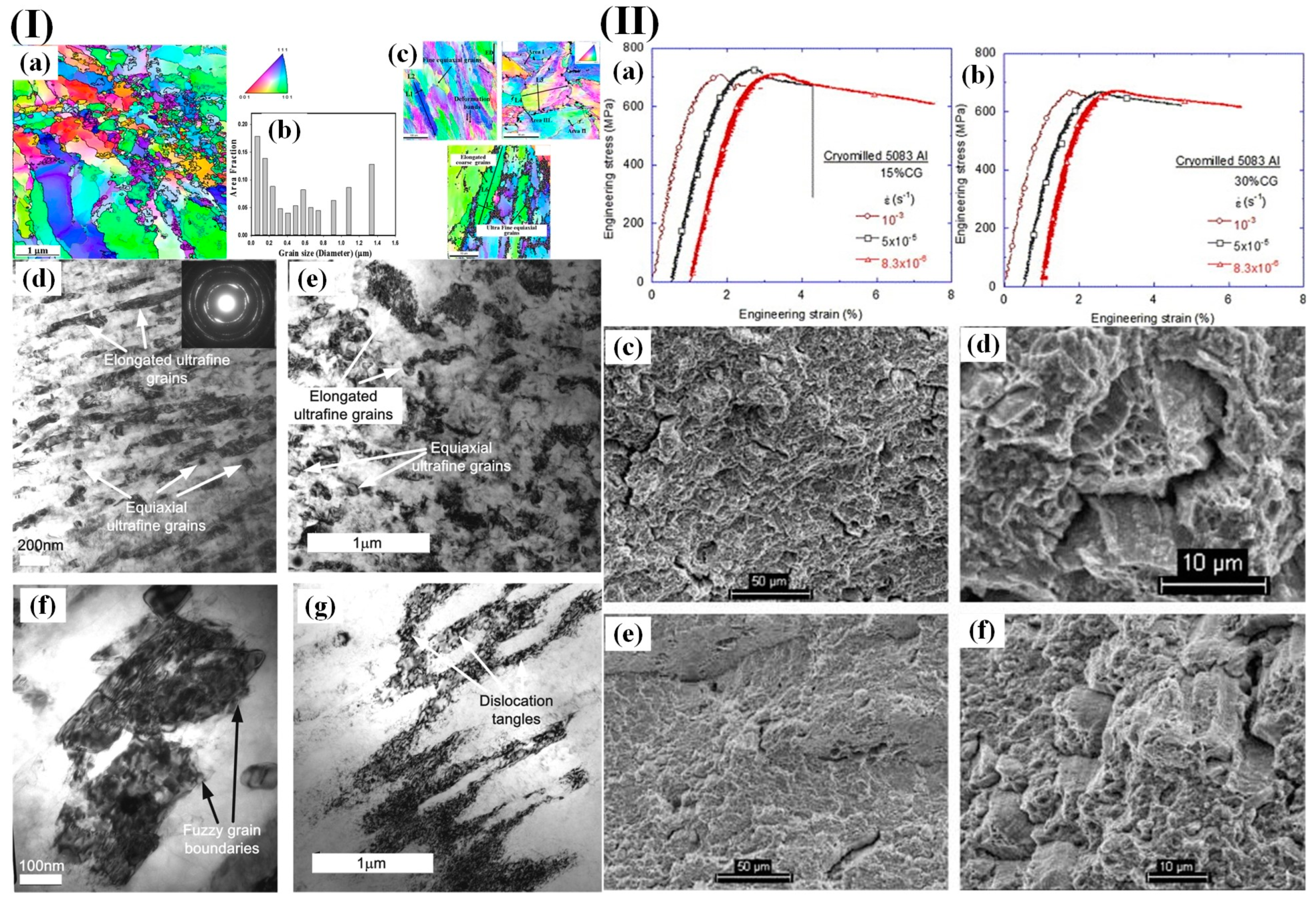

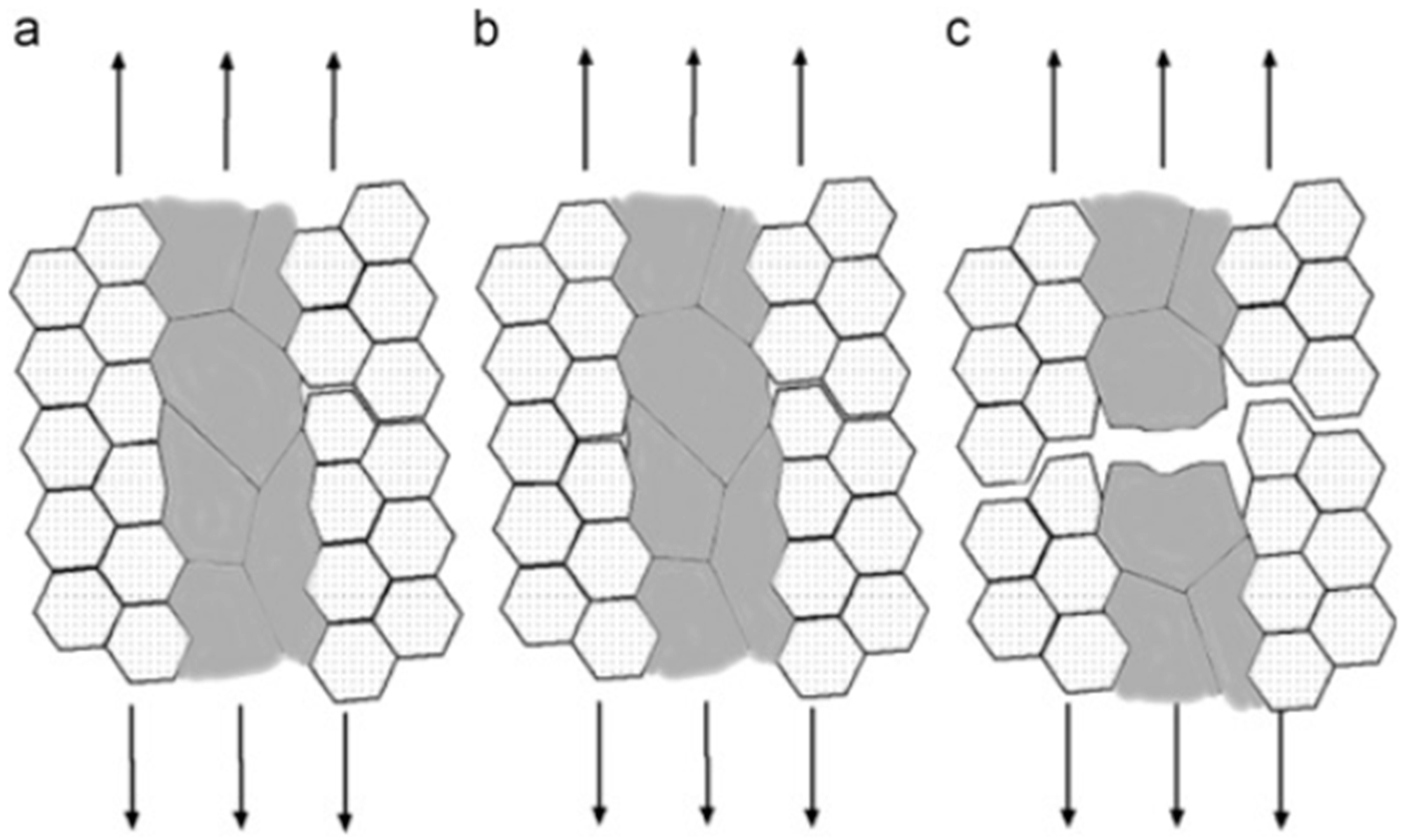

3. The Influence of a Bimodal Microstructure on the Properties of Al-Mg Alloys and Its Formation Mechanism

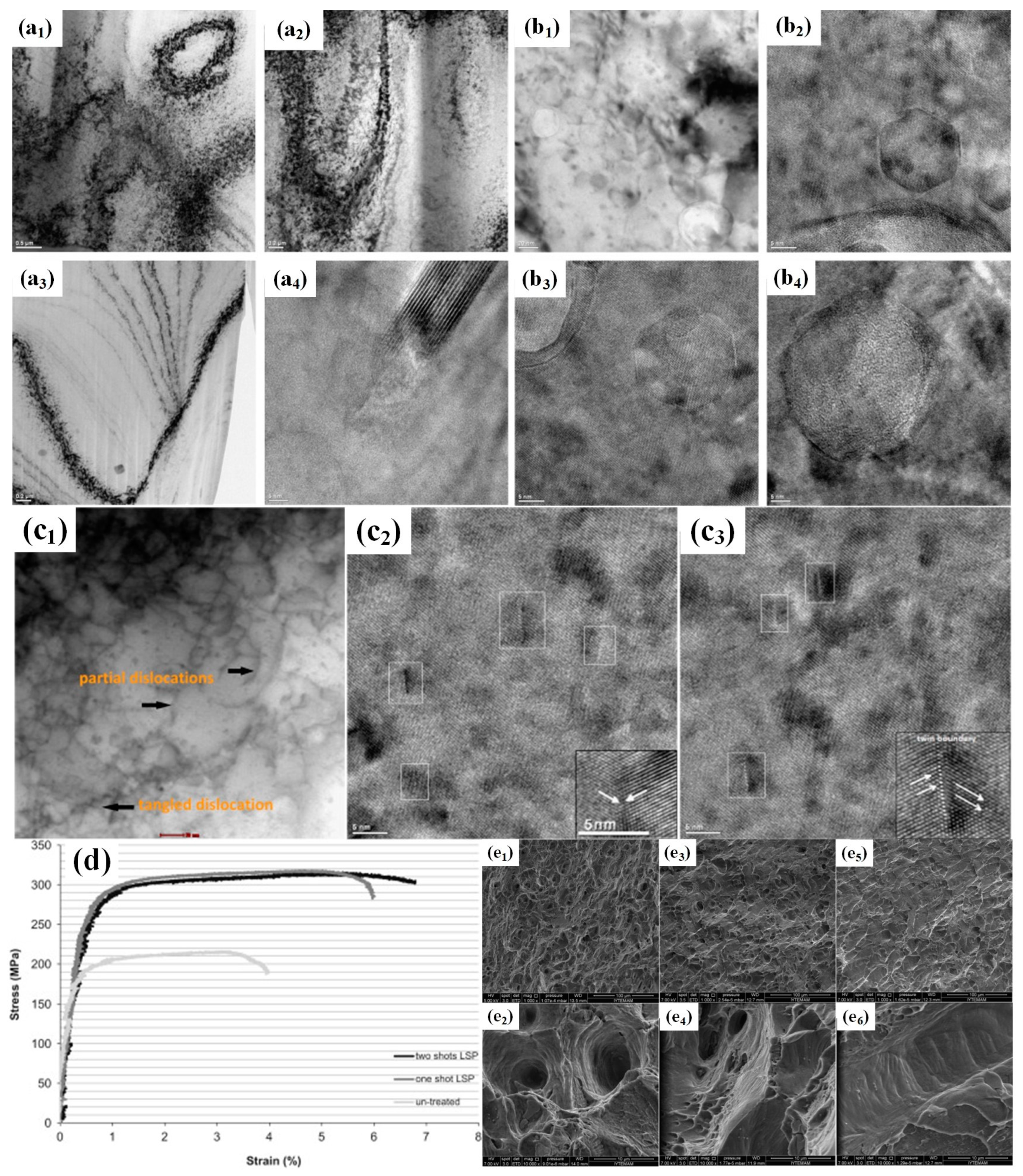

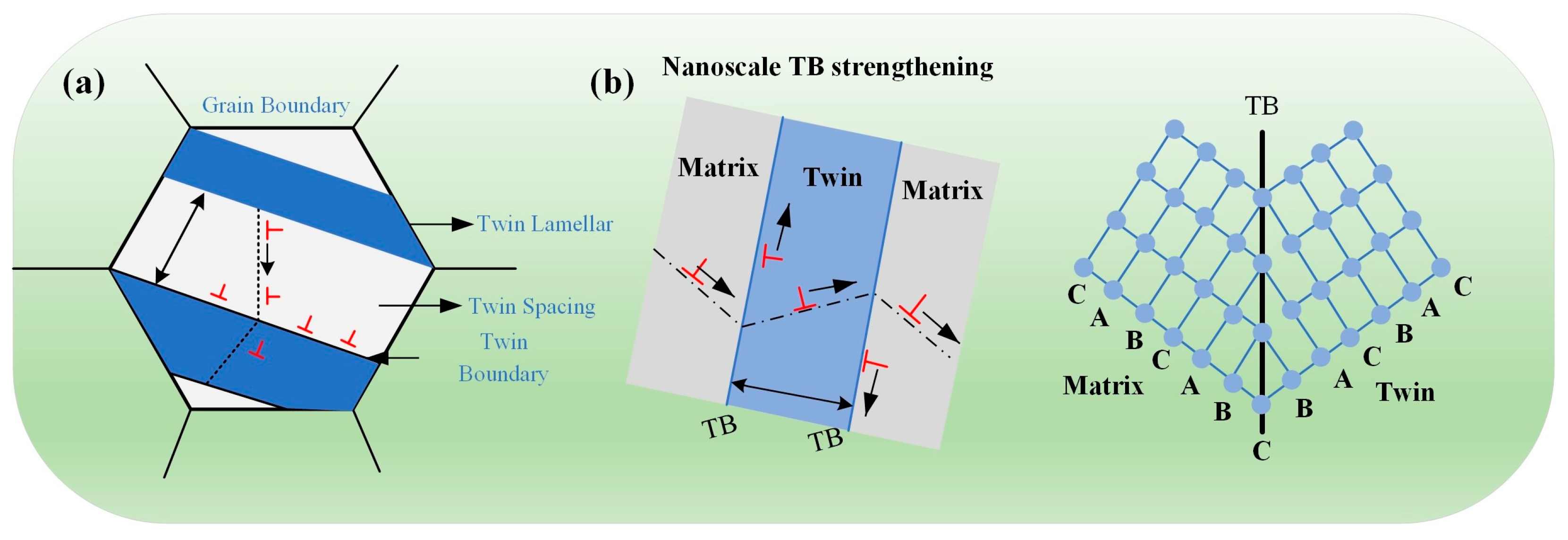

4. The Influence of the Formation of Nanotwin Microstructure within Al-Mg Alloys on Their Properties and Its Mechanism

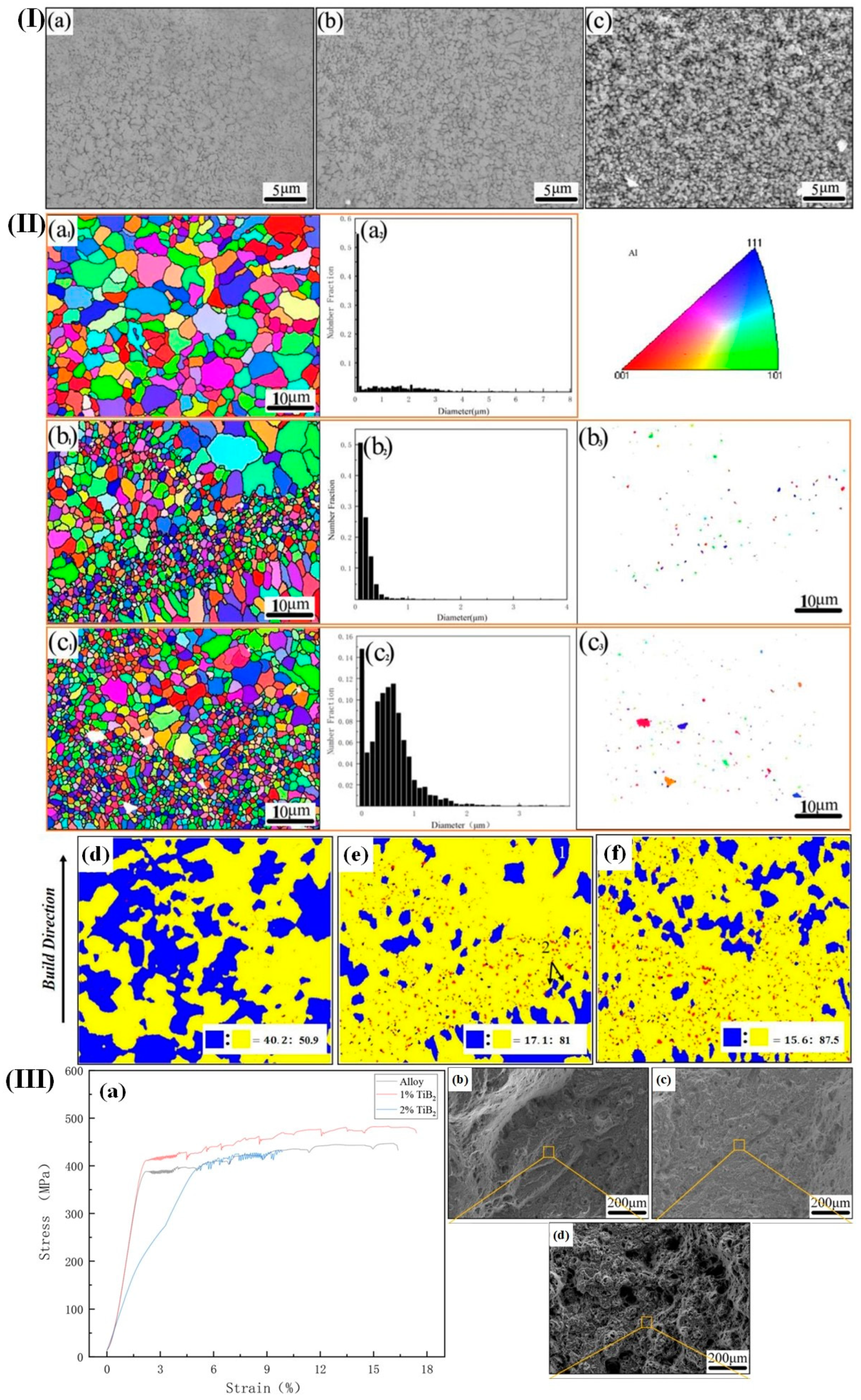

5. The Effects of Diffusely Distributed Nanoparticles on the Microstructure and Properties of Al-Mg Alloys and Their Mechanisms

6. Summary and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Starke, E.A.; Staley, J.T. Application of modern aluminum alloys to aircraft. Prog. Aeronaut. Sci. 1996, 32, 131–172. [Google Scholar] [CrossRef]

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.; De Smet, P.; Haszler, A.; Vieregge, A.J.M.S. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Cheng, S.; Zhao, Y.H.; Zhu, Y.T.; Ma, E. Optimizing the strength and ductility of fine structured 2024 Al alloy by nano-precipitation. Acta Mater. 2007, 55, 5822–5832. [Google Scholar] [CrossRef]

- Dontsova, E.; Rottler, J.; Sinclair, C.W. Solute-defect interactions in Al-Mg alloys from diffusive variational Gaussian calculations. Phys. Rev. B 2014, 90, 174102. [Google Scholar] [CrossRef]

- Zhao, D.; Løvvik, O.M.; Marthinsen, K.; Li, Y. Impurity effect of Mg on the generalized planar fault energy of Al. J. Mater. Sci. 2016, 51, 6552–6568. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, J.; Li, X.; Chen, Y.; Zhou, D.; Zhou, G.; Xu, W. Effect of pre-deformation on the microstructures and properties of 2219 aluminum alloy during aging treatment. J. Alloys Compd. 2017, 699, 1140–1145. [Google Scholar] [CrossRef]

- Han, J.-H.; Huh, M.Y.; Suh, J.-Y.; Lee, J.-C. Controlling the textures of the Al alloy sheet via dissimilar channel angular pressing. Mater. Sci. Eng. A 2005, 394, 60–65. [Google Scholar] [CrossRef]

- Chaudhury, P.K.; Cherukuri, B.; Srinivasan, R. Scaling up of equal-channel angular pressing and its effect on mechanical properties, microstructure, and hot workability of AA 6061. Mater. Sci. Eng. A 2005, 410–411, 316–318. [Google Scholar] [CrossRef]

- Liu, W.C.; Morris, J.G. Effect of hot and cold deformation on the β fiber rolling texture in continuous cast AA 5052 aluminum alloy. Scr. Mater. 2005, 52, 1317–1321. [Google Scholar] [CrossRef]

- Liu, W.C.; Man, C.S.; Raabe, D.; Morris, J.G. Effect of hot and cold deformation on the recrystallization texture of continuous cast AA 5052 aluminum alloy. Scr. Mater. 2005, 53, 1273–1277. [Google Scholar] [CrossRef]

- Zhu, H.; Ghosh, A.K.; Maruyama, K. Effect of cold rolling on microstructure and material properties of 5052 alloy sheet produced by continuous casting. Mater. Sci. Eng. A 2006, 419, 115–121. [Google Scholar] [CrossRef]

- Lowe, T.C.; Zhu, Y.T.; Semiatin, S.L.; Berg, D.R. Overview and Outlook for Materials Processed by Severe Plastic Deformation. In Investigations and Applications of Severe Plastic Deformation; Springer: Berlin/Heidelberg, Germany, 2000; pp. 347–356. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Korznikov, A.V.; Mulyukov, R.R. Structure and properties of ultrafine-grained materials produced by severe plastic deformation. Mater. Sci. Eng. A 1993, 168, 141–148. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Lowe, T.C.; Zhu, Y.T. Commercialization of Nanostructured Metals Produced by Severe Plastic Deformation Processing. Adv. Eng. Mater. 2003, 5, 373–378. [Google Scholar] [CrossRef]

- Gleiter, H. Nanostructured materials: Basic concepts and microstructure. Acta Mater. 2000, 48, 1–29. [Google Scholar] [CrossRef]

- Valiev, R. Nanostructuring of metals by severe plastic deformation for advanced properties. Nat. Mater. 2004, 3, 511–516. [Google Scholar] [CrossRef]

- Nakashima, K.; Horita, Z.; Nemoto, M.; Langdon, T.G. Development of a multi-pass facility for equal-channel angular pressing to high total strains. Mater. Sci. Eng. A 2000, 281, 82–87. [Google Scholar] [CrossRef]

- Gleiter, H. Nanocrystalline Materials. In Advanced Structural and Functional Materials; Springer: Berlin/Heidelberg, Germany, 1991; pp. 1–37. [Google Scholar] [CrossRef]

- Sabirov, I.; Enikeev, N.A.; Murashkin, M.Y.; Valiev, R.Z. Nanostructures in Materials Subjected to Severe Plastic Deformation. In Bulk Nanostruct Mater with Multifunct Prop; Springer: Berlin/Heidelberg, Germany, 2015; pp. 11–26. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Liao, X.Z.; Wu, X.L. Deformation twinning in bulk nanocrystalline metals: Experimental observations. JOM 2008, 60, 60–64. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zechetbauer, M.J.; Zhu, Y.T. Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 2006, 58, 33–39. [Google Scholar] [CrossRef]

- Edalati, K.; Ahmed, A.Q.; Akrami, S.; Ameyama, K.; Aptukov, V.; Asfandiyarov, R.N.; Ashida, M.; Astanin, V.; Bachmaier, A.; Beloshenko, V.; et al. Severe plastic deformation for producing superfunctional ultrafine-grained and heterostructured materials: An interdisciplinary review. J. Alloys Compd. 2024, 1002, 174667. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Koch, C.C. Nanocrystalline materials—Current research and future directions. Hyperfine Interact. 2000, 130, 5–44. [Google Scholar] [CrossRef]

- Ortiz-Cuellar, E.; Hernandez-Rodriguez, M.A.L.; García-Sanchez, E. Evaluation of the tribological properties of an Al–Mg–Si alloy processed by severe plastic deformation. Wear 2011, 271, 1828–1832. [Google Scholar] [CrossRef]

- Mann, J.B.; Chandrasekar, S.; Compton, W.D.; Trumble, K.P.; Saldana, C.; Swaminathan, S.; John, G.E.; Moscoso, W.; Murthy, T.G. 7—Severe plastic deformation and the production of nanostructured alloys by machining. Nanostruct Met. Alloys. 2011, 49, 178–210. [Google Scholar] [CrossRef]

- Xu, C.; Xu, X.J.; Ma, W.H.; Dong, X.F.; Lu, Y.D.; Guo, Y.F. Microstructure and strengthening mechanism of Al-1.5% Mg single-phase alloy by recovery annealing. J. Rare Met. 2017, 41, 239. [Google Scholar] [CrossRef]

- Tang, F.; Hagiwara, M.; Schoenung, J.M. Microstructure and tensile properties of bulk nanostructured Al-5083/SiCp composites prepared by cryomilling. Mater. Sci. Eng. A 2005, 407, 306–314. [Google Scholar] [CrossRef]

- Kumar, N.; Biswas, K. Cryomilling: An environment friendly approach of preparation large quantity ultra refined pure aluminium nanoparticles. J. Mater. Res. Technol. 2019, 8, 63–74. [Google Scholar] [CrossRef]

- Huo, W.T.; Shi, J.T.; Hou, L.G.; Zhang, J.S. An improved thermo-mechanical treatment of high-strength Al–Zn–Mg–Cu alloy for effective grain refinement and ductility modification. J. Mater. Process Technol. 2017, 239, 303–314. [Google Scholar] [CrossRef]

- Wang, Y.M.; Ma, E. Three strategies to achieve uniform tensile deformation in a nanostructured metal. Acta Mater. 2004, 52, 1699–1709. [Google Scholar] [CrossRef]

- Sun, P.-L.; Zhao, Y.; Tseng, T.-Y.; Su, J.-R.; Lavernia, E.J. Annealing behaviour of ultrafine-grained aluminium. Philos. Mag. 2014, 94, 476–491. [Google Scholar] [CrossRef]

- Hasegawa, H.; Komura, S.; Utsunomiya, A.; Horita, Z.; Furukawa, M.; Nemoto, M.; Langdon, T.G. Thermal stability of ultrafine-grained aluminum in the presence of Mg and Zr additions. Mater. Sci. Eng. A 1999, 265, 188–196. [Google Scholar] [CrossRef]

- Duan, Y.; Xu, G.; Tang, L.; Liu, Y.; Xu, J.; Deng, Y.; Yin, Z. Excellent high strain rate superplasticity of Al-Mg-Sc-Zr alloy sheet produced by an improved asymmetrical rolling process. J. Alloys Compd. 2017, 715, 311–321. [Google Scholar] [CrossRef]

- Avtokratova, E.; Sitdikov, O.; Markushev, M.; Mulyukov, R. Extraordinary high-strain rate superplasticity of severely deformed Al–Mg–Sc–Zr alloy. Mater. Sci. Eng. A 2012, 538, 386–390. [Google Scholar] [CrossRef]

- Li, M.; Pan, Q.; Shi, Y.; Sun, X.; Xiang, H. High strain rate superplasticity in an Al–Mg–Sc–Zr alloy processed via simple rolling. Mater. Sci. Eng. A 2017, 687, 298–305. [Google Scholar] [CrossRef]

- Duan, Y.L.; Xu, G.F.; Peng, X.Y.; Deng, Y.; Li, Z.; Yin, Z.M. Effect of Sc and Zr additions on grain stability and superplasticity of the simple thermal–mechanical processed Al–Zn–Mg alloy sheet. Mater. Sci. Eng. A 2015, 648, 80–91. [Google Scholar] [CrossRef]

- Duan, Y.L.; Tang, L.; Deng, Y.; Cao, X.W.; Xu, G.F.; Yin, Z.M. Superplastic behavior and microstructure evolution of a new Al-Mg-Sc-Zr alloy subjected to a simple thermomechanical processing. Mater. Sci. Eng. A 2016, 669, 205–217. [Google Scholar] [CrossRef]

- Malopheyev, S.; Mironov, S.; Vysotskiy, I.; Kaibyshev, R. Superplasticity of friction-stir welded Al–Mg–Sc sheets with ultrafine-grained microstructure. Mater. Sci. Eng. A 2016, 649, 85–92. [Google Scholar] [CrossRef]

- Sauvage, X.; Ganeev, A.; Ivanisenko, Y.; Enikeev, N.; Murashkin, M.; Valiev, R. Grain Boundary Segregation in UFG Alloys Processed by Severe Plastic Deformation. Adv. Eng. Mater. 2012, 14, 968–974. [Google Scholar] [CrossRef]

- Gwalani, B.; Salloom, R.; Alam, T.; Valentin, S.G.; Zhou, X.; Thompson, G.; Srinivasan, G.; Banerjee, R. Composition-dependent apparent activation-energy and sluggish grain-growth in high entropy alloys. Mater. Res. Lett. 2019, 7, 267–274. [Google Scholar] [CrossRef]

- Kalidindi, A.R.; Schuh, C.A. Stability criteria for nanocrystalline alloys. Acta Mater. 2017, 132, 128–137. [Google Scholar] [CrossRef]

- Kotov, A.D.; Mochugovskiy, A.G.; Mosleh, A.O.; Kishchik, A.A.; Rofman, O.V.; Mikhaylovskaya, A.V. Microstructure, superplasticity, and mechanical properties of Al–Mg–Er–Zr alloys. Mater. Charact. 2022, 186, 111825. [Google Scholar] [CrossRef]

- Majchrowicz, K.; Pakieła, Z.; Chrominski, W.; Kulczyk, M. Enhanced strength and electrical conductivity of ultrafine-grained Al-Mg-Si alloy processed by hydrostatic extrusion. Mater. Charact. 2018, 135, 104–114. [Google Scholar] [CrossRef]

- Pereira PH, R.; Huang, Y.; Langdon, T.G. Examining the microhardness evolution and thermal stability of an Al–Mg–Sc alloy processed by high-pressure torsion at a high temperature. J. Mater. Res. Technol. 2017, 6, 348–354. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Edalati, K.; Horita, Z. A review on high-pressure torsion (HPT) from 1935 to 1988. Mater. Sci. Eng. A 2016, 652, 325–352. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Sitdikov, O.; Sakai, T.; Avtokratova, E.; Kaibyshev, R.; Tsuzaki, K.; Watanabe, Y. Microstructure behavior of Al–Mg–Sc alloy processed by ECAP at elevated temperature. Acta Mater. 2008, 56, 821–834. [Google Scholar] [CrossRef]

- Elhefnawey, M.; Shuai, G.L.; Li, Z.; Zhang, D.T.; Tawfik, M.M.; Li, L. On achieving ultra-high strength and improved wear resistance in Al–Zn–Mg alloy via ECAP. Tribol. Int. 2021, 163, 107188. [Google Scholar] [CrossRef]

- Damavandi, E.; Nourouzi, S.; Rabiee, S.M.; Jamaati, R.; Szpunar, J.A. EBSD study of the microstructure texture evolution in an Al–Si–Cu alloy processed by route, A ECAP. J. Alloys Compd. 2021, 858, 157651. [Google Scholar] [CrossRef]

- Naydenkin, E.V.; Mishin, I.P.; Zabudchenko, O.V. Thermal Stability and S-Phase Evolution in Ultrafine-Grained Al−Mg−Li Alloy Produced by Equal-Channel Angular Pressing. Adv. Eng. Mater. 2021, 23, 2100181. [Google Scholar] [CrossRef]

- Ramesh Kumar, S.; Hari Sankar, V.; Arunvinthan, S.; Nadarajapillai, S. Structure and Properties of Al Mg alloy Processed by Equal Channel Angular pressing at different channel angles—90o, 120o. Mater. Today Proc. 2018, 5, 21482–21488. [Google Scholar] [CrossRef]

- Hidalgo-Manrique, P.; Orozco-Caballero, A.; Cepeda-Jiménez, C.M.; Ruano, O.A.; Carreño, F. Influence of the Accumulative Roll. Bonding Process Severity on the Microstructure and Superplastic Behaviour of 7075 Al Alloy. J. Mater. Sci. Technol. 2016, 32, 774–782. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel ultra-high straining process for bulk materials—Development of the accumulative roll-bonding (ARB) process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Jamaati, R.; Toroghinejad, M.R.; Edris, H. Effect of stacking fault energy on nanostructure formation under accumulative roll bonding (ARB) process. Mater. Sci. Eng. A 2013, 578, 191–196. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Pérez-Prado, M.T.; Valle, D.; Ruano, O.A. Grain refinement of Mg–Al–Zn alloys via accumulative roll bonding. Scr. Mater. 2004, 51, 1093–1097. [Google Scholar] [CrossRef]

- Roghani, H.; Borhani, E.; Shams SA, A.; Lee, C.S.; Jafarian, H.R. Effect of concurrent accumulative roll bonding (ARB) process and various heat treatment on the microstructure, texture and mechanical properties of AA1050 sheets. J. Mater. Res. Technol. 2022, 18, 1295–1306. [Google Scholar] [CrossRef]

- Karami, S.; Piroozi, B.; Borhani, E. Fatigue-induced microstructure evolution and ratcheting behavior of ultrafine-grained (UFG) pure aluminum processed by accumulative roll bonding (ARB). Mater. Charact. 2023, 196, 112578. [Google Scholar] [CrossRef]

- Straumal, B.B.; Baretzky, B.; Mazilkin, A.A.; Phillipp, F.; Kogtenkova, O.A.; Volkov, M.N.; Valiev, R.Z. Formation of nanograined structure and decomposition of supersaturated solid solution during high pressure torsion of Al–Zn and Al–Mg alloys. Acta Mater. 2004, 52, 4469–4478. [Google Scholar] [CrossRef]

- Sakai, G.; Horita, Z.; Langdon, T.G. Grain refinement and superplasticity in an aluminum alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2005, 393, 344–351. [Google Scholar] [CrossRef]

- Kumar, H.; Devade, K.; Pratap Singh, D.; Mohan Giri, J.; Kumar, M.; Arun, V. Severe plastic deformation: A state of art. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Kumaran, S.N.; Sahoo, S.K.; Haase, C.; Barrales-Mora, L.A.; Toth, L.S. Nano-structuring of a high entropy alloy by severe plastic deformation: Experiments and crystal plasticity simulations. Acta Mater. 2023, 250, 118814. [Google Scholar] [CrossRef]

- Xu, C.; Horita, Z.; Langdon, T.G. The evolution of homogeneity in an aluminum alloy processed using high-pressure torsion. Acta Mater. 2008, 56, 5168–5176. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, M.; Chen, X.; Cao, Y.; Roven, H.J.; Murashkin, M.; Valiev, R.Z.; Zhou, H. Effect of Mg on microstructure and mechanical properties of Al-Mg alloys produced by high pressure torsion. Scr. Mater. 2019, 159, 137–141. [Google Scholar] [CrossRef]

- Liu, M.P.; Roven, H.J.; Murashkin, M.Y.; Valiev, R.Z.; Kilmametov, A.; Zhang, Z.; Yu, Y. Structure and mechanical properties of nanostructured Al–Mg alloys processed by severe plastic deformation. J. Mater. Sci. 2013, 48, 4681–4688. [Google Scholar] [CrossRef]

- Tang, Y.; Goto, W.; Hirosawa, S.; Horita, Z.; Lee, S.; Matsuda, K.; Terada, D. Concurrent strengthening of ultrafine-grained age-hardenable Al-Mg alloy by means of high-pressure torsion and spinodal decomposition. Acta Mater. 2017, 131, 57–64. [Google Scholar] [CrossRef]

- Lage, A.; de Oliveira, M.D.; Pereira, R.; Figueiredo, R.B.; Lins, C. Corrosion behavior of Al–3Mg–0.2Sc alloy processed by high-pressure torsion and thermal treated. J. Mater. Res. Technol. 2022, 18, 2745–2753. [Google Scholar] [CrossRef]

- Liu, M.-p.; Jiang, T.-h.; Xie, X.-f.; Liu, Q.; Li, X.-f.; Roven, H.J. Microstructure evolution and dislocation configurations in nanostructured Al–Mg alloys processed by high pressure torsion. Trans. Nonferrous Met. Soc. China 2014, 24, 3848–3857. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Straumal, B.; Langdon, T.G. Using Severe Plastic Deformation to Produce Nanostructured Materials with Superior Properties. Annu. Rev. Mater. Res. 2022, 52, 357–382. [Google Scholar] [CrossRef]

- Furukawa, M.; Horita, Z.; Nemoto, M.; Valiev, R.Z.; Langdon, T.G. Microstructural characteristics of an ultrafine grain metal processed with equal-channel angular pressing. Mater. Charact. 1996, 37, 277–283. [Google Scholar] [CrossRef]

- Zhernakov, V.S.; Budilov, I.N.; Raab, G.I.; Alexandrov, I.V.; Valiev, R.Z. A numerical modelling and investigations of flow stress and grain refinement during equal-channel angular pressing. Scr. Mater. 2001, 44, 1765–1769. [Google Scholar] [CrossRef]

- Sabirov, I.; Kolednik, O.; Valiev, R.Z.; Pippan, R. Equal channel angular pressing of metal matrix composites: Effect on particle distribution and fracture toughness. Acta Mater. 2005, 53, 4919–4930. [Google Scholar] [CrossRef]

- Ivanisenko, Y.; Valiev, R.Z.; Fecht, H.J. Grain boundary statistics in nano-structured iron produced by high pressure torsion. Mater. Sci. Eng. A 2005, 390, 159–165. [Google Scholar] [CrossRef]

- Raab, G.I.; Soshnikova, E.P.; Valiev, R.Z. Influence of temperature and hydrostatic pressure during equal-channel angular pressing on the microstructure of commercial-purity Ti. Mater. Sci. Eng. A 2004, 387–389, 674–677. [Google Scholar] [CrossRef]

- Wu, S.D.; Wang, Z.G.; Jiang, C.B.; Li, G.Y.; Alexandrov, I.V.; Valiev, R.Z. Shear bands in cyclically deformed ultrafine grained copper processed by ECAP. Mater. Sci. Eng. A 2004, 387–389, 560–564. [Google Scholar] [CrossRef]

- Semenova, I.P.; Raab, G.I.; Saitova, L.R.; Valiev, R.Z. The effect of equal-channel angular pressing on the structure and mechanical behavior of Ti–6Al–4V alloy. Mater. Sci. Eng. A 2004, 387–389, 805–808. [Google Scholar] [CrossRef]

- Ivanisenko, Y.; Lojkowski, W.; Valiev, R.Z.; Fecht, H.J. The mechanism of formation of nanostructure and dissolution of cementite in a pearlitic steel during high pressure torsion. Acta Mater. 2003, 51, 5555–5570. [Google Scholar] [CrossRef]

- Segal, V.M. Equal channel angular extrusion: From macromechanics to structure formation. Mater. Sci. Eng. A 1999, 271, 322–333. [Google Scholar] [CrossRef]

- Segal, V.M. Slip line solutions, deformation mode and loading history during equal channel angular extrusion. Mater. Sci. Eng. A 2003, 345, 36–46. [Google Scholar] [CrossRef]

- Segal, V.M. Engineering and commercialization of equal channel angular extrusion (ECAE). Mater. Sci. Eng. A 2004, 386, 269–276. [Google Scholar] [CrossRef]

- Segal, V.M. Mechanics of continuous equal-channel angular extrusion. J. Mater. Process Technol. 2010, 210, 542–549. [Google Scholar] [CrossRef]

- Radhi, H.N.; Aljassani AM, H.; Mohammed, M.T. Effect of ECAP on microstructure, mechanical and tribological properties of aluminum and brass alloys: A review. Mater. Today Proc. 2020, 26, 2302–2307. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, B.; Gao, M.; Zhao, E.; Guan, R. Microstructure evolution, mechanical property response and strengthening mechanism induced by compositional effects in Al–6 Mg alloys. Mater. Des. 2022, 220, 110849. [Google Scholar] [CrossRef]

- Tang, L.; Peng, X.; Huang, J.; Ma, A.; Deng, Y.; Xu, G. Microstructure and mechanical properties of severely deformed Al-Mg-Sc-Zr alloy and their evolution during annealing. Mater. Sci. Eng. A 2019, 754, 295–308. [Google Scholar] [CrossRef]

- Zha, M.; Li, Y.; Mathiesen, R.H.; Bjørge, R.; Roven, H.J. Microstructure evolution and mechanical behavior of a binary Al–7Mg alloy processed by equal-channel angular pressing. Acta Mater. 2015, 84, 42–54. [Google Scholar] [CrossRef]

- Zha, M.; Li, Y.; Mathiesen, R.H.; Bjørge, R.; Roven, H.J. High ductility bulk nanostructured Al–Mg binary alloy processed by equal channel angular pressing and inter-pass annealing. Scr. Mater. 2015, 105, 22–25. [Google Scholar] [CrossRef]

- Chen, Y.J.; Chai, Y.C.; Roven, H.J.; Gireesh, S.S.; Yu, Y.D.; Hjelen, J. Microstructure and mechanical properties of Al–xMg alloys processed by room temperature ECAP. Mater. Sci. Eng. A 2012, 545, 139–147. [Google Scholar] [CrossRef]

- Ungár, T.; Alexandrov, I.; Zehetbauer, M. Ultrafine-grained microstructures evolving during severe plastic deformation. JOM 2000, 52, 34–36. [Google Scholar] [CrossRef]

- Gholinia, A.; Prangnell, P.B.; Markushev, M.V. The effect of strain path on the development of deformation structures in severely deformed aluminium alloys processed by ECAE. Acta Mater. 2000, 48, 1115–1130. [Google Scholar] [CrossRef]

- Iwahashi, Y.; Horita, Z.; Nemoto, M.; Langdon, T.G. The process of grain refinement in equal-channel angular pressing. Acta Mater. 1998, 46, 3317–3331. [Google Scholar] [CrossRef]

- Oh-Ishi, K.; Horita, Z.; Nemoto, M.; Furukawa, M.; Langdon, T.G. Optimizing the rotation conditions for grain refinement in equal-channel angular pressing. Metall. Mater. Trans. A 1998, 29, 2011–2013. [Google Scholar] [CrossRef]

- Yamashita, A.; Yamaguchi, D.; Horita, Z.; Langdon, T.G. Influence of pressing temperature on microstructural development in equal-channel angular pressing. Mater. Sci. Eng. A 2000, 287, 100–106. [Google Scholar] [CrossRef]

- Shin, D.H.; Pak, J.-J.; Kim, Y.K.; Park, K.-T.; Kim, Y.-S. Effect of pressing temperature on microstructure and tensile behavior of low carbon steels processed by equal channel angular pressing. Mater. Sci. Eng. A 2002, 323, 409–415. [Google Scholar] [CrossRef]

- Kim, I.; Kim, J.; Shin, D.H.; Lee, C.S.; Hwang, S.K. Effects of equal channel angular pressing temperature on deformation structures of pure Ti. Mater. Sci. Eng. A 2003, 342, 302–310. [Google Scholar] [CrossRef]

- Berbon, P.B.; Furukawa, M.; Horita, Z.; Nemoto, M.; Langdon, T.G. Influence of pressing speed on microstructural development in equal-channel angular pressing. Metall. Mater. Trans. A 1999, 30, 1989–1997. [Google Scholar] [CrossRef]

- Lee, J.C.; Seok, H.K.; Suh, J.Y. Microstructural evolutions of the Al strip prepared by cold rolling and continuous equal channel angular pressing. Acta Mater. 2002, 50, 4005–4019. [Google Scholar] [CrossRef]

- Saito, Y.; Tsuji, N.; Utsunomiya, H.; Sakai, T.; Hong, R.G. Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process. Scripta Mater. 1998, 39, 1221–1227. [Google Scholar] [CrossRef]

- Azushima, A.; Kopp, R.; Korhonen, A.; Yang, D.Y.; Micari, F.; Lahoti, G.D.; Groche, P.; Yanagimoto, J.; Tsuji, N.; Rosochowski, A.; et al. Severe plastic deformation (SPD) processes for metals. CIRP Ann. 2008, 57, 716–735. [Google Scholar] [CrossRef]

- Lakshmanan, P.; Amith, S.C.; Ganesan, K. Accumulative roll bonding behavior of Al8011/SiC metal matrix nanocomposites. Mater. Today Proc. 2020, 27, 1417–1421. [Google Scholar] [CrossRef]

- Alil, A.; Popović, M.; Radetić, T.; Romhanji, E. Influence of an accumulative roll bonding (ARB) process on the properties of AA5083 Al-Mg alloy sheets. Metallu Mater. Eng. 2014, 20, 285–295. [Google Scholar] [CrossRef]

- Reza Toroghinejad, M.; Ashrafizadeh, F.; Jamaati, R. On the use of accumulative roll bonding process to develop nanostructured aluminum alloy 5083. Mater. Sci. Eng. A 2013, 561, 145–151. [Google Scholar] [CrossRef]

- Yu, Q.; Qi, L.; Tsuru, T.; Traylor, R.; Rugg, D.; Morris, J.W.; Asta, M.; Chrzan, D.C. Origin of dramatic oxygen solute strengthening effect in titanium. Science 2015, 347, 635–639. [Google Scholar] [CrossRef]

- Lu, L.; Chen, X.; Huang, X.; Lu, K. Revealing the Maximum Strength in Nanotwinned Copper. Science 2009, 323, 607–610. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Fan, G. An overview of tailoring strain delocalization for strength-ductility synergy. Prog. Mater. Sci. 2020, 113, 100675. [Google Scholar] [CrossRef]

- Pan, Q.; Zhou, H.; Lu, Q.; Gao, H.; Lu, L. History-independent cyclic response of nanotwinned metals. Nature 2017, 551, 214–217. [Google Scholar] [CrossRef]

- Clouet, E.; Caillard, D.; Chaari, N.; Onimus, F.; Rodney, D. Dislocation locking versus easy glide in titanium and zirconium. Nat. Mater. 2015, 14, 931–936. [Google Scholar] [CrossRef]

- Zhong, L.; Sansoz, F.; He, Y.; Wang, C.; Zhang, Z.; Mao, S.X. Slip-activated surface creep with room-temperature super-elongation in metallic nanocrystals. Nat. Mater. 2017, 16, 439–445. [Google Scholar] [CrossRef]

- He, B.B.; Hu, B.; Yen, H.W.; Cheng, G.J.; Wang, Z.K.; Luo, H.W.; Huang, M.X. High dislocation density–induced large ductility in deformed and partitioned steels. Science 2017, 357, 1029–1032. [Google Scholar] [CrossRef]

- Lu, K. Making strong nanomaterials ductile with gradients. Science 2014, 345, 1455–1456. [Google Scholar] [CrossRef]

- Zha, M.; Zhang, H.M.; Yu, Z.Y.; Zhang, X.H.; Meng, X.T.; Wang, H.Y.; Jiang, Q.C. Bimodal microstructure—A feasible strategy for high-strength and ductile metallic materials. J. Mater. Sci. Technol. 2018, 34, 257–264. [Google Scholar] [CrossRef]

- Lee, Y.B.; Shin, D.H.; Park, K.-T.; Nam, W.J. Effect of annealing temperature on microstructures and mechanical properties of a 5083 Al alloy deformed at cryogenic temperature. Scr. Mater. 2004, 51, 355–359. [Google Scholar] [CrossRef]

- Gang, U.G.; Lee, S.H.; Nam, W.J. The Evolution of Microstructure and Mechanical Properties of a 5052 Aluminium Alloy by the Application of Cryogenic Rolling and Warm Rolling. Mater. Trans. 2009, 50, 82–86. [Google Scholar] [CrossRef]

- Cheng, S.; Ma, E.; Wang, Y.M.; Kecskes, L.J.; Youssef, K.M.; Koch, C.C.; Trociewitz, U.P.; Han, K. Tensile properties of in situ consolidated nanocrystalline Cu. Acta Mater. 2005, 53, 1521–1533. [Google Scholar] [CrossRef]

- Wang, H.-Y.; Nan, X.-L.; Zhang, N.; Wang, C.; Wang, J.-G.; Jiang, Q.-C. Strong strain hardening ability in an as-cast Mg–3Al–3Sn alloy. Mater. Chem. Phys. 2012, 132, 248–252. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Liao, X.Z.; Cheng, S.; Ma, E.; Zhu, Y.T. Simultaneously Increasing the Ductility and Strength of Nanostructured Alloys. Adv. Mater. 2006, 18, 2280–2283. [Google Scholar] [CrossRef]

- Liddicoat, P.V.; Liao, X.-Z.; Zhao, Y.; Zhu, Y.; Murashkin, M.Y.; Lavernia, E.J.; Valiev, R.Z.; Ringer, S.P. Nanostructural hierarchy increases the strength of aluminium alloys. Nat. Commun. 2010, 1, 63. [Google Scholar] [CrossRef]

- Murashkin, M.Y.; Kil’mametov, A.R.; Valiev, R.Z. Structure and mechanical properties of an aluminum alloy 1570 subjected to severe plastic deformation by high-pressure torsion. Phys. Met. Metallogr. 2008, 106, 90–96. [Google Scholar] [CrossRef]

- Lee, Z.; Witkin, D.B.; Radmilovic, V.; Lavernia, E.J.; Nutt, S.R. Bimodal microstructure and deformation of cryomilled bulk nanocrystalline Al–7.5Mg alloy. Mater. Sci. Eng. A 2005, 410–411, 462–467. [Google Scholar] [CrossRef]

- Iwahashi, Y.; Horita, Z.; Nemoto, M.; Langdon, T.G. Factors influencing the equilibrium grain size in equal-channel angular pressing: Role of Mg additions to aluminum. Metall. Mater. Transa A 1998, 29, 2503–2510. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Wu, X.L. Ductility and plasticity of nanostructured metals: Differences and issues. Mater. Today Nano 2018, 2, 15–20. [Google Scholar] [CrossRef]

- He, G.; Eckert, J.; Löser, W.; Schultz, L. Novel Ti-base nanostructure–dendrite composite with enhanced plasticity. Nat. Mater. 2003, 2, 33–37. [Google Scholar] [CrossRef]

- Dao, M.; Lu, L.; Asaro, R.J.; De Hosson JT, M.; Ma, E. Toward a quantitative understanding of mechanical behavior of nanocrystalline metals. Acta Mater. 2007, 55, 4041–4065. [Google Scholar] [CrossRef]

- Ahn, B.; Lavernia, E.J.; Nutt, S.R. Dynamic observations of deformation in an ultrafine-grained Al–Mg alloy with bimodal grain structure. J. Mater. Sci. 2008, 43, 7403–7408. [Google Scholar] [CrossRef]

- Ertorer, O.; Topping, T.; Li, Y.; Moss, W.; Lavernia, E.J. Enhanced tensile strength and high ductility in cryomilled commercially pure titanium. Scr. Mater. 2009, 60, 586–589. [Google Scholar] [CrossRef]

- Han, B.Q.; Huang, J.Y.; Zhu, Y.T.; Lavernia, E.J. Strain rate dependence of properties of cryomilled bimodal 5083 Al alloys. Acta Mater 2006, 54, 3015–3024. [Google Scholar] [CrossRef]

- Lavernia, E.J.; Han, B.Q.; Schoenung, J.M. Cryomilled nanostructured materials: Processing and properties. Mater. Sci. Eng. A 2008, 493, 207–214. [Google Scholar] [CrossRef]

- Lee, Z.; Radmilovic, V.; Ahn, B.; Lavernia, E.J.; Nutt, S.R. Tensile Deformation and Fracture Mechanism of Bulk Bimodal Ultrafine-Grained Al-Mg Alloy. Metall. Mater. Trans. A 2010, 41, 795–801. [Google Scholar] [CrossRef]

- Magee, A.; Ladani, L.; Topping, T.D.; Lavernia, E.J. Effects of tensile test parameters on the mechanical properties of a bimodal Al–Mg alloy. Acta Mater. 2012, 60, 5838–5849. [Google Scholar] [CrossRef]

- Nelson, S.; Ladani, L.; Topping, T.; Lavernia, E. Fatigue and monotonic loading crack nucleation and propagation in bimodal grain size aluminum alloy. Acta Mater. 2011, 59, 3550–3570. [Google Scholar] [CrossRef]

- Ye, J.; Han, B.Q.; Lee, Z.; Ahn, B.; Nutt, S.R.; Schoenung, J.M. A tri-modal aluminum based composite with super-high strength. Scr. Mater. 2005, 53, 481–486. [Google Scholar] [CrossRef]

- Zhao, Y.; Topping, T.; Bingert, J.F.; Thornton, J.J.; Dangelewicz, A.M.; Li, Y.; Liu, W.; Zhu, Y.; Zhou, Y.; Lavernia, E.J. High Tensile Ductility and Strength in Bulk Nanostructured Nickel. Adv. Mater. 2008, 20, 3028–3033. [Google Scholar] [CrossRef]

- Zha, M.; Li, Y.; Mathiesen, R.H.; Bjørge, R.; Roven, H.J. Achieve high ductility and strength in an Al–Mg alloy by severe plastic deformation combined with inter-pass annealing. Mater. Sci. Eng. A 2014, 598, 141–146. [Google Scholar] [CrossRef]

- Edalati, K.; Akama, D.; Nishio, A.; Lee, S.; Yonenaga, Y.; Cubero-Sesin, J.M.; Horita, Z. Influence of dislocation–solute atom interactions and stacking fault energy on grain size of single-phase alloys after severe plastic deformation using high-pressure torsion. Acta Mater. 2014, 69, 68–77. [Google Scholar] [CrossRef]

- Han, B.Q.; Lavernia, E.J.; Lee, Z.; Nutt, S.; Witkin, D. Deformation behavior of bimodal nanostructured 5083 Al alloys. Metall. Mater. Trans. A 2005, 36, 957–965. [Google Scholar] [CrossRef]

- Mahajan, S. Critique of mechanisms of formation of deformation, annealing and growth twins: Face-centered cubic metals and alloys. Scr. Mater. 2013, 68, 95–99. [Google Scholar] [CrossRef]

- Chuang, T.H.; Wang, H.C.; Tsai, C.H.; Chang, C.C.; Chuang, C.H.; Lee, J.D.; Tsai, H.H. Thermal stability of grain structure and material properties in an annealing-twinned Ag–8Au–3Pd alloy wire. Scr. Mater. 2012, 67, 605–608. [Google Scholar] [CrossRef]

- Field, D.P.; Bradford, L.T.; Nowell, M.M.; Lillo, T.M. The role of annealing twins during recrystallization of Cu. Acta Mater. 2007, 55, 4233–4241. [Google Scholar] [CrossRef]

- Zhao, W.S.; Tao, N.R.; Guo, J.Y.; Lu, Q.H.; Lu, K. High density nano-scale twins in Cu induced by dynamic plastic deformation. Scr. Mater. 2005, 53, 745–749. [Google Scholar] [CrossRef]

- Lin, B.; Jin, Y.; Hefferan, C.M.; Li, S.F.; Lind, J.; Suter, R.M.; Bernacki, M.; Bozzolo, N.; Rollett, A.D.; Rohrer, G.S. Observation of annealing twin nucleation at triple lines in nickel during grain growth. Acta Mater. 2015, 99, 63–68. [Google Scholar] [CrossRef]

- Lu, L.; Shen, Y.; Chen, X.; Qian, L.; Lu, K. Ultrahigh Strength and High Electrical Conductivity in Copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef]

- Li, B.; Cao, B.Y.; Ramesh, K.T.; Ma, E. A nucleation mechanism of deformation twins in pure aluminum. Acta Mater. 2009, 57, 4500–4507. [Google Scholar] [CrossRef]

- Liu, L.; Chen, J.; Fan, T.; Shang, S.; Shao, Q.; Yuan, D.; Dai, Y. The stability of deformation twins in aluminum enhanced by alloying elements. J. Mater. Sci. Technol. 2019, 35, 2625–2629. [Google Scholar] [CrossRef]

- Bufford, D.C.; Wang, Y.M.; Liu, Y.; Lu, L. Synthesis and microstructure of electrodeposited and sputtered nanotwinned face-centered-cubic metals. MRS Bull. 2016, 41, 286–291. [Google Scholar] [CrossRef]

- Yamakov, V.; Wolf, D.; Phillpot, S.R.; Gleiter, H. Deformation twinning in nanocrystalline Al by molecular-dynamics simulation. Acta Mater. 2002, 50, 5005–5020. [Google Scholar] [CrossRef]

- Gencalp Irizalp, S.; Saklakoglu, N. High. strength and high ductility behavior of 6061-T6 alloy after laser shock processing. Opt. Lasers Eng. 2016, 77, 183–190. [Google Scholar] [CrossRef]

- Ma, E.; Wang, Y.M.; Lu, Q.H.; Sui, M.L.; Lu, L.; Lu, K. Strain hardening and large tensile elongation in ultrahigh-strength nano-twinned copper. Appl. Phys. Lett. 2004, 85, 4932–4934. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Liao, X.Z.; Horita, Z.; Langdon, T.G.; Zhu, Y.T. Determining the optimal stacking fault energy for achieving high ductility in ultrafine-grained Cu–Zn alloys. Mater. Sci. Eng. A 2008, 493, 123–129. [Google Scholar] [CrossRef]

- Ma, E. Eight routes to improve the tensile ductility of bulk nanostructured metals and alloys. JOM 2006, 58, 49–53. [Google Scholar] [CrossRef]

- Sun, P.L.; Zhao, Y.H.; Cooley, J.C.; Kassner, M.E.; Horita, Z.; Langdon, T.G.; Lavernia, E.J.; Zhu, Y.T. Effect of stacking fault energy on strength and ductility of nanostructured alloys: An evaluation with minimum solution hardening. Mater. Sci. Eng. A 2009, 525, 83–86. [Google Scholar] [CrossRef]

- Fedorov, V.A.; Pluzhnikova, T.N.; Kirillov, A.M.; Dolgikh, D.E. Influence of the grain size of Fe-3.25% Si polycrystalline alloy on twinning over a broad range of temperature and strain rate. Steel Transl. 2009, 39, 463–465. [Google Scholar] [CrossRef]

- Lu, K.; Lu, L.; Suresh, S. Strengthening Materials by Engineering Coherent Internal Boundaries at the Nanoscale. Science 2009, 324, 349–352. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, K.Y.; Lu, J.Z.; Zhang, Y.K.; Dai, F.Z.; Zhong, J.W. Effects of laser shock processing with different shocked paths on mechanical properties of laser welded ANSI 304 stainless steel joint. Mater. Sci. Eng. A 2011, 528, 4652–4657. [Google Scholar] [CrossRef]

- Liao, X.Z.; Huang, J.Y.; Zhu, Y.T.; Zhou, F.; Lavernia, E.J. Nanostructures and deformation mechanisms in a cryogenically ball-milled Al-Mg alloy. Philos. Mag. 2003, 83, 3065–3075. [Google Scholar] [CrossRef]

- Wang, Z.W.; Wang, Y.B.; Liao, X.Z.; Zhao, Y.H.; Lavernia, E.J.; Zhu, Y.T.; Horita, Z.; Langdon, T.G. Influence of stacking fault energy on deformation mechanism and dislocation storage capacity in ultrafine-grained materials. Scr. Mater. 2009, 60, 52–55. [Google Scholar] [CrossRef]

- Xue, S.; Li, Q.; Fan, Z.; Wang, H.; Zhang, Y.; Ding, J.; Wang, H.; Zhang, X. Strengthening mechanisms and deformability of nanotwinned AlMg alloys. J. Mater. Res. 2018, 33, 3739–3749. [Google Scholar] [CrossRef]

- Liu, M.P.; Roven, H.J.; Liu, X.T.; Murashkin, M.; Valiev, R.Z.; Ungar, T.; Balogh, L. Special nanostructures in Al-Mg alloys subjected to high pressure torsion. Trans. Nonferrous Met. Soc. China 2010, 20, 2051–2056. [Google Scholar] [CrossRef]

- Liu, M.; Roven, H.J.; Ungár, T.; Balogh, L.; Murashkin, M.Y.; Valiev, R. Grain Boundary Structure and Deformation Defects in Nanostructured Al–Mg Alloys Processed by High Pressure Torsion. Mater. Sci. Forum. 2008, 584–586, 528–534. [Google Scholar] [CrossRef]

- Liu, M.; Roven, H.J.; Murashkin, M.; Valiev, R.Z. Structural characterization by high-resolution electron microscopy of an Al–Mg alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2009, 503, 122–125. [Google Scholar] [CrossRef]

- Liu, M.; Roven, H.J.; Murashkin, M.Y.; Valiev, R. Deformation Twins and Stacking Faults in an AA5182 Al-Mg Alloy Processed by High Pressure Torsion. Mater. Sci. Forum 2008, 579, 147–154. [Google Scholar] [CrossRef]

- Van Swygenhoven, H. Grain Boundaries and Dislocations. Science 2002, 296, 66–67. [Google Scholar] [CrossRef]

- Yang, W.; Dong, R.; Jiang, L.; Wu, G.; Hussain, M. Unstable stacking faults in submicron/micron Al grammins in multi-SiCp/multi-Al nanocomposite. Vacuum 2015, 122, 1–5. [Google Scholar] [CrossRef]

- Koch, C.C.; Morris, D.G.; Lu, K.; Inoue, A. Ductility of Nanostructured Materials. MRS Bull. 1999, 24, 54–58. [Google Scholar] [CrossRef]

- Wang, H.; Tiwari, A.; Kvit, A.; Zhang, X.; Narayan, J. Epitaxial growth of TaN thin films on Si(100) and Si(111) using a TiN buffer layer. Appl. Phys. Lett. 2002, 80, 2323–2325. [Google Scholar] [CrossRef]

- Shen, Y.F.; Lu, L.; Lu, Q.H.; Jin, Z.H.; Lu, K. Tensile properties of copper with nano-scale twins. Scr. Mater. 2005, 52, 989–994. [Google Scholar] [CrossRef]

- Meng, M.; Chen, G.; Zhang, Z.; Zhao, Y. Analysis of properties for in situ Al2O3p/A356 composites synthesised from the Al-SiO2 system. Mater. Sci. Technol. 2017, 33, 2290–2297. [Google Scholar] [CrossRef]

- Tian, W.S.; Zhou, D.S.; Qiu, F.; Jiang, Q.C. Superior tensile properties of in situ nano-sized TiCp/Al-Cu composites fabricated by reaction in melt method. Mater. Sci. Eng. A 2016, 658, 409–414. [Google Scholar] [CrossRef]

- Wang, Q.; Guo, Y.; Li, F.; Zhao, J.; Wang, Y.; He, P.; Wu, D.; Wang, L.; Kang, J.; Ma, H.; et al. Microstructures and mechanical properties of nano-TiC/Ti-refined AlMg alloys prepared by wire arc additive manufacturing. Mater. Charact. 2024, 208, 113614. [Google Scholar] [CrossRef]

- Xu, R.; Li, R.; Yuan, T.; Zhu, H.; Li, P. Microstructure and Mechanical Properties of TiC-Reinforced Al–Mg–Sc–Zr Composites Additively Manufactured by Laser Direct Energy Deposition. Acta Metall. Sin. 2022, 35, 411–424. [Google Scholar] [CrossRef]

- Wu, M.; Tao, J.; Wang, J.; Jiang, W.; Sun, Y.; Dong, D.; Zhao, Y.; Wang, M.; Liu, T.; Luo, L.; et al. Effects of TiB2 additions on microstructure and mechnical properties of Al–Mg–Sc alloy fabricated by selective laser melting. J. Mater. Res. Technol. 2023, 23, 3537–3546. [Google Scholar] [CrossRef]

- Li, S.S.; Qiu, F.; Yang, H.Y.; Liu, S.; Liu, T.S.; Chen, L.Y.; Jiang, Q.C. Strengthening of dislocation and precipitation for high strength and toughness casting Al–Zn–Mg–Cu alloy via trace TiB2+TiC particles. Mater. Sci. Eng. A 2022, 857, 144107. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, C.-R.; Zhang, S.-Y.; Liu, L.; Yang, H.-Y.; Kang, J.; Meng, J.; Luo, C.-J.; Wang, C.-G.; Cao, K.; Qiao, J.; et al. Research Progress on the Microstructure Evolution Mechanisms of Al-Mg Alloys by Severe Plastic Deformation. Materials 2024, 17, 4235. https://doi.org/10.3390/ma17174235

Song C-R, Zhang S-Y, Liu L, Yang H-Y, Kang J, Meng J, Luo C-J, Wang C-G, Cao K, Qiao J, et al. Research Progress on the Microstructure Evolution Mechanisms of Al-Mg Alloys by Severe Plastic Deformation. Materials. 2024; 17(17):4235. https://doi.org/10.3390/ma17174235

Chicago/Turabian StyleSong, Chang-Rong, Si-Yu Zhang, Lin Liu, Hong-Yu Yang, Jie Kang, Jia Meng, Chang-Jie Luo, Cheng-Gang Wang, Kuang Cao, Jian Qiao, and et al. 2024. "Research Progress on the Microstructure Evolution Mechanisms of Al-Mg Alloys by Severe Plastic Deformation" Materials 17, no. 17: 4235. https://doi.org/10.3390/ma17174235

APA StyleSong, C.-R., Zhang, S.-Y., Liu, L., Yang, H.-Y., Kang, J., Meng, J., Luo, C.-J., Wang, C.-G., Cao, K., Qiao, J., Shu, S.-L., Zhu, M., Qiu, F., & Jiang, Q.-C. (2024). Research Progress on the Microstructure Evolution Mechanisms of Al-Mg Alloys by Severe Plastic Deformation. Materials, 17(17), 4235. https://doi.org/10.3390/ma17174235