Study on Crack Behavior of GH3230 Superalloy Fabricated via High-Throughput Additive Manufacturing

Abstract

1. Introduction

2. Experimental Materials and Methods

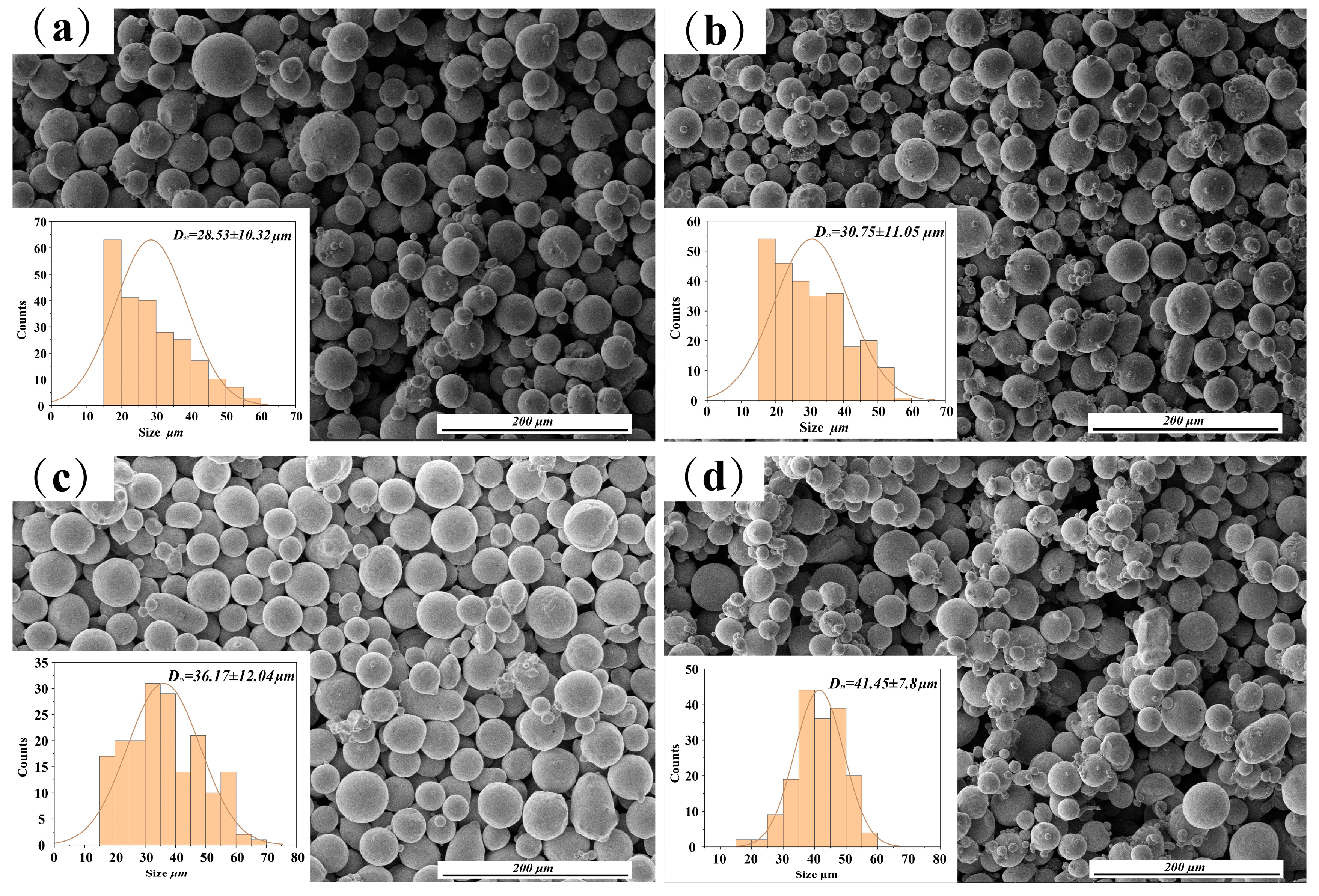

2.1. Experimental Materials

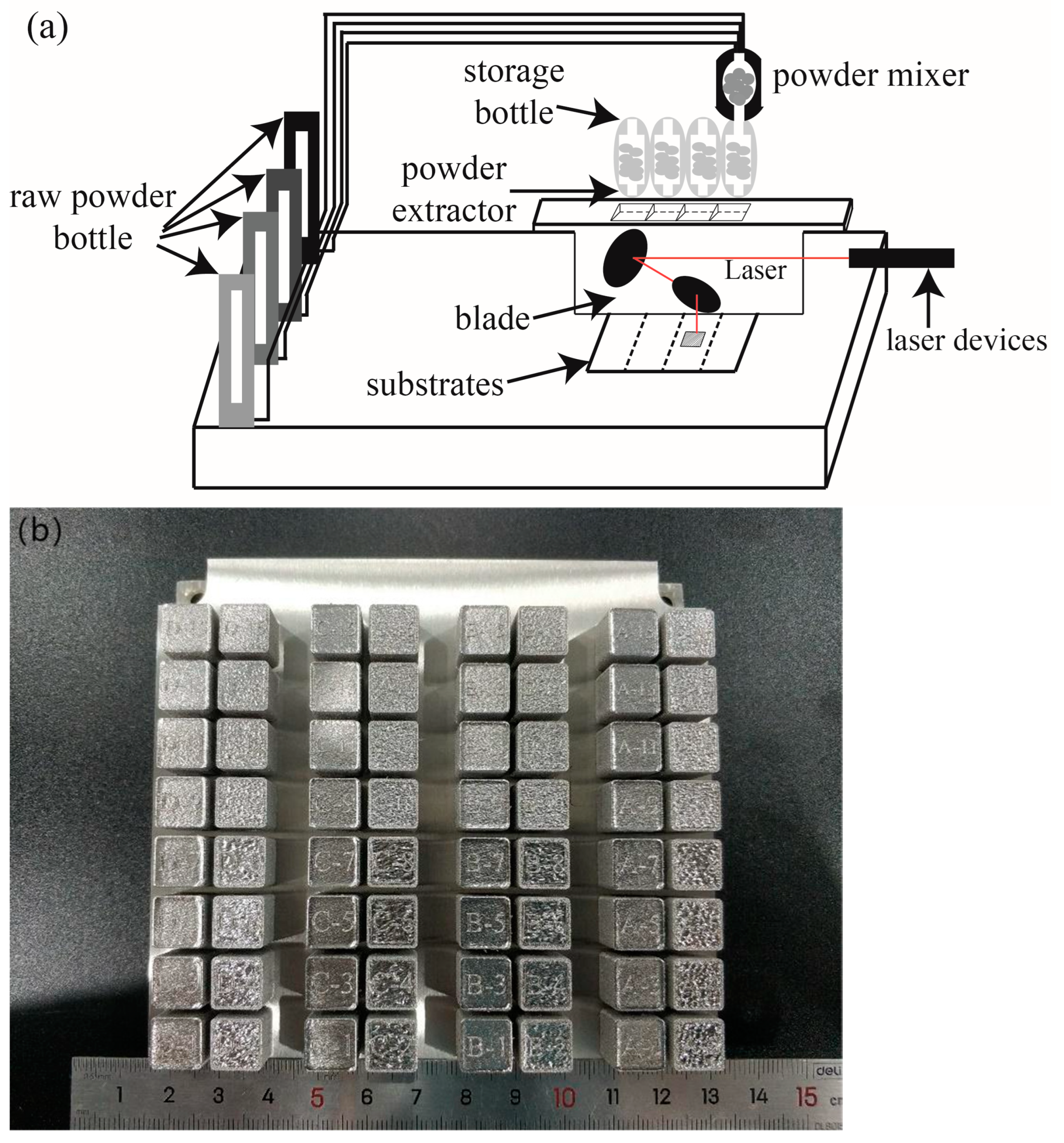

2.2. Sample Preparation

2.3. Experimental Methods

3. Calculation and Modeling

3.1. Quantitative Crack Statistics Algorithm

3.2. Thermodynamic Calculation

4. Results and Analysis

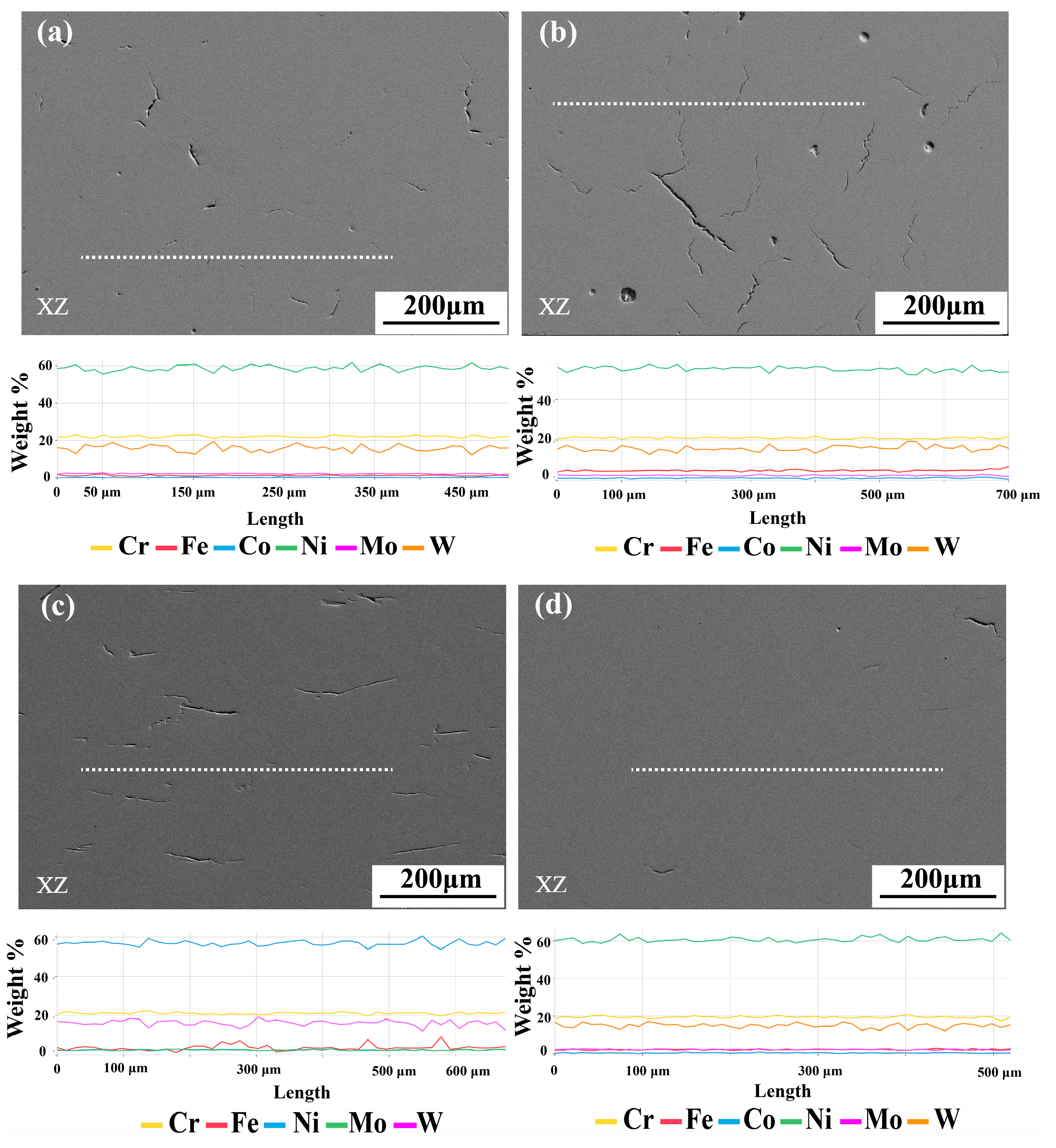

4.1. Composition Analysis

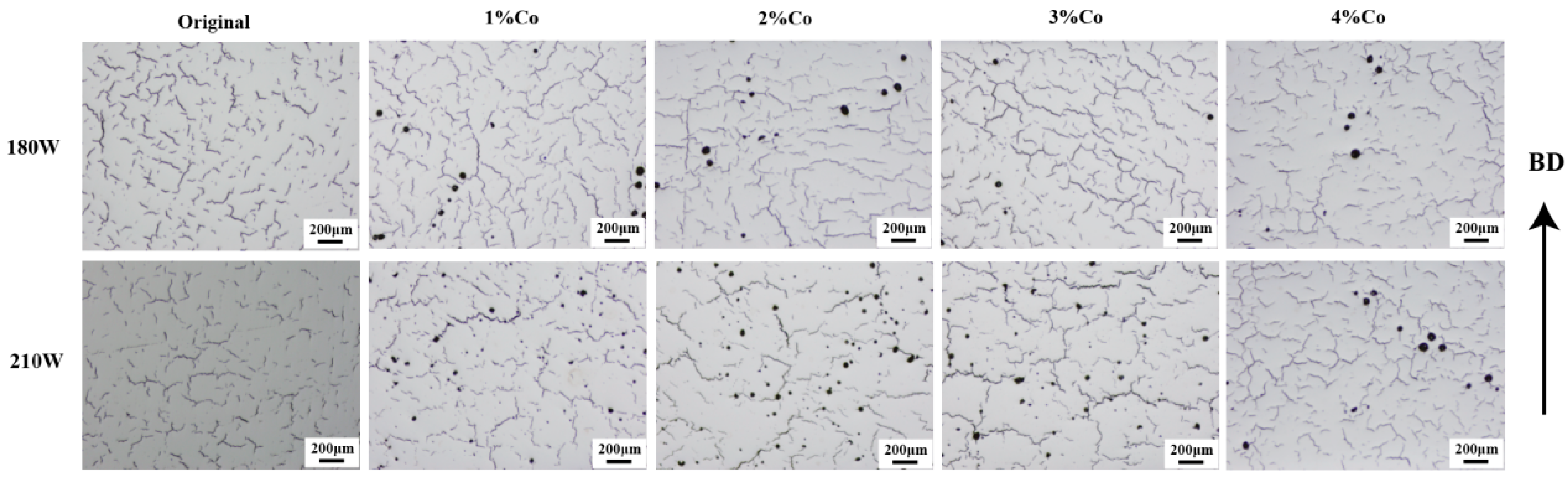

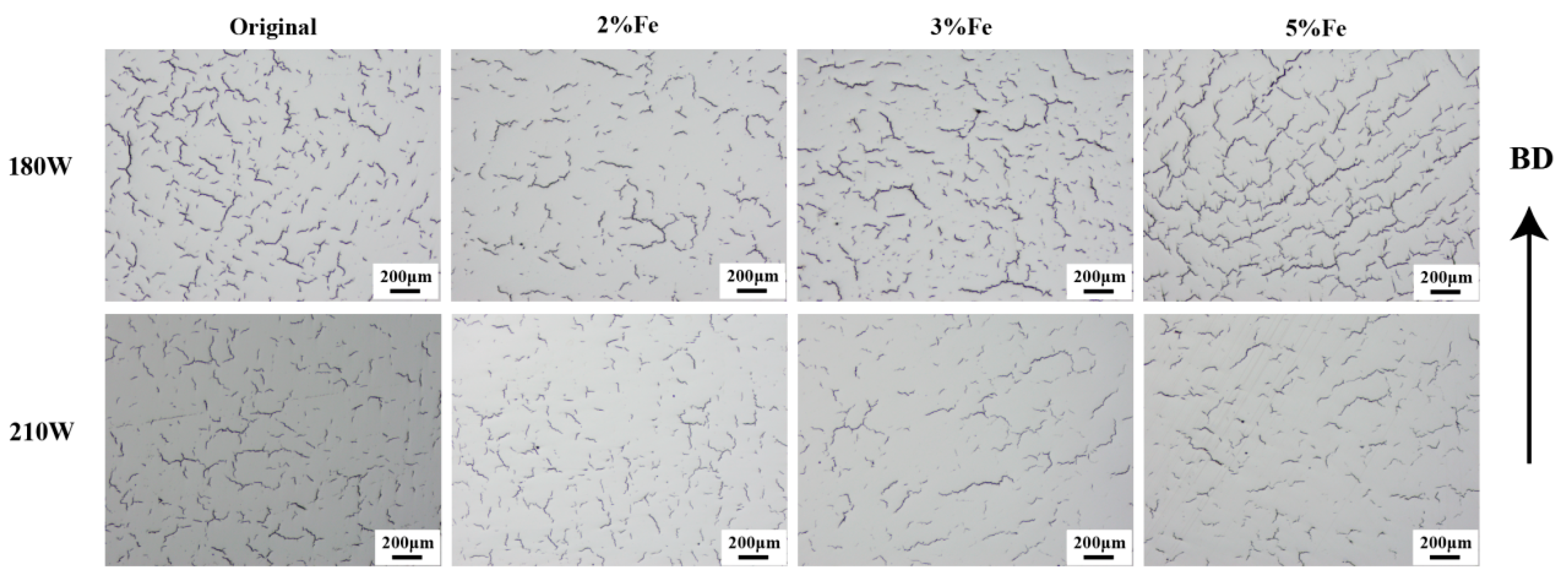

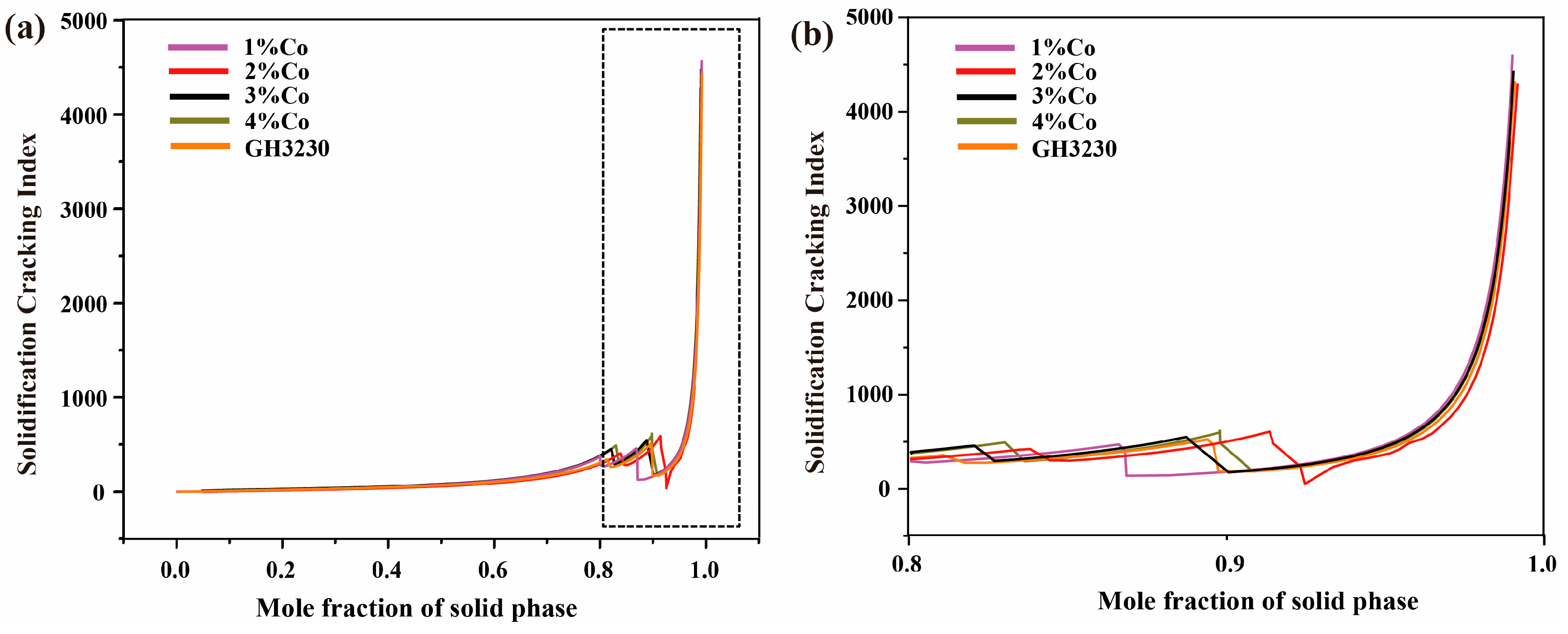

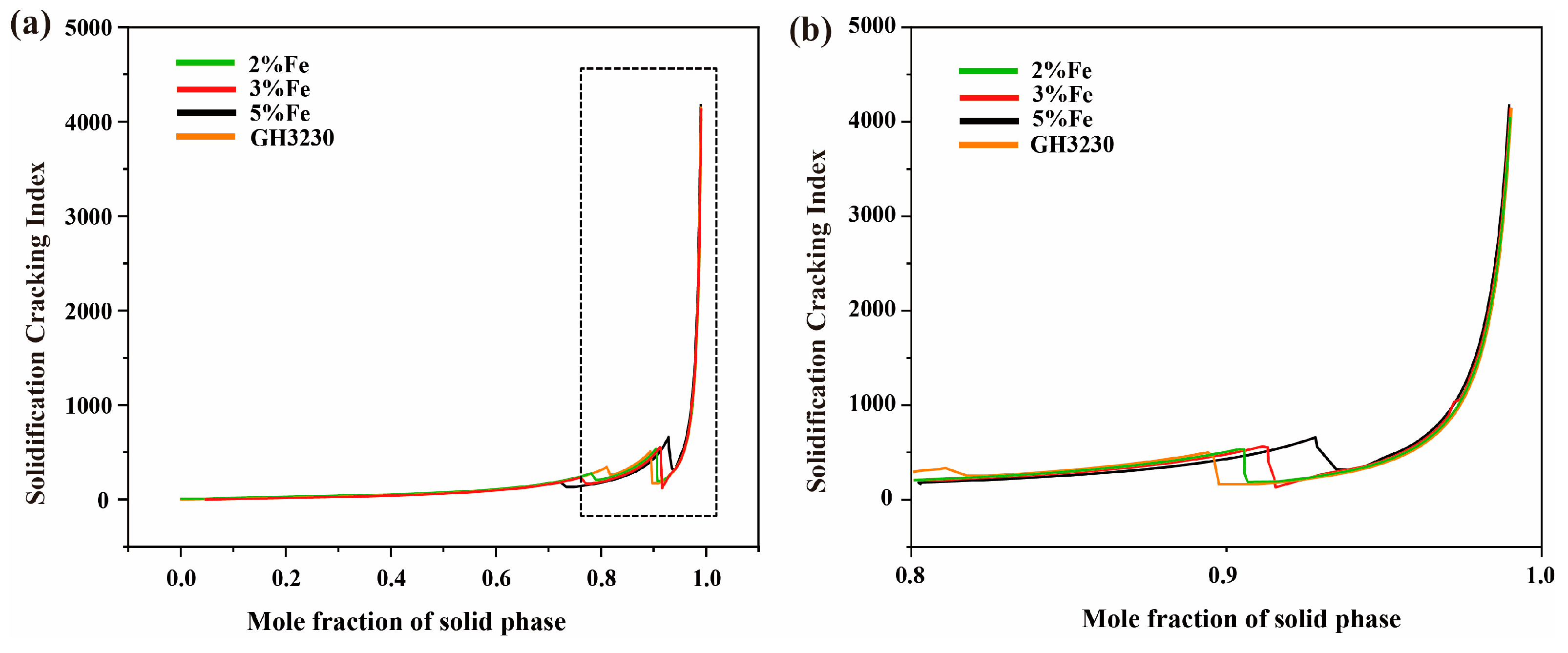

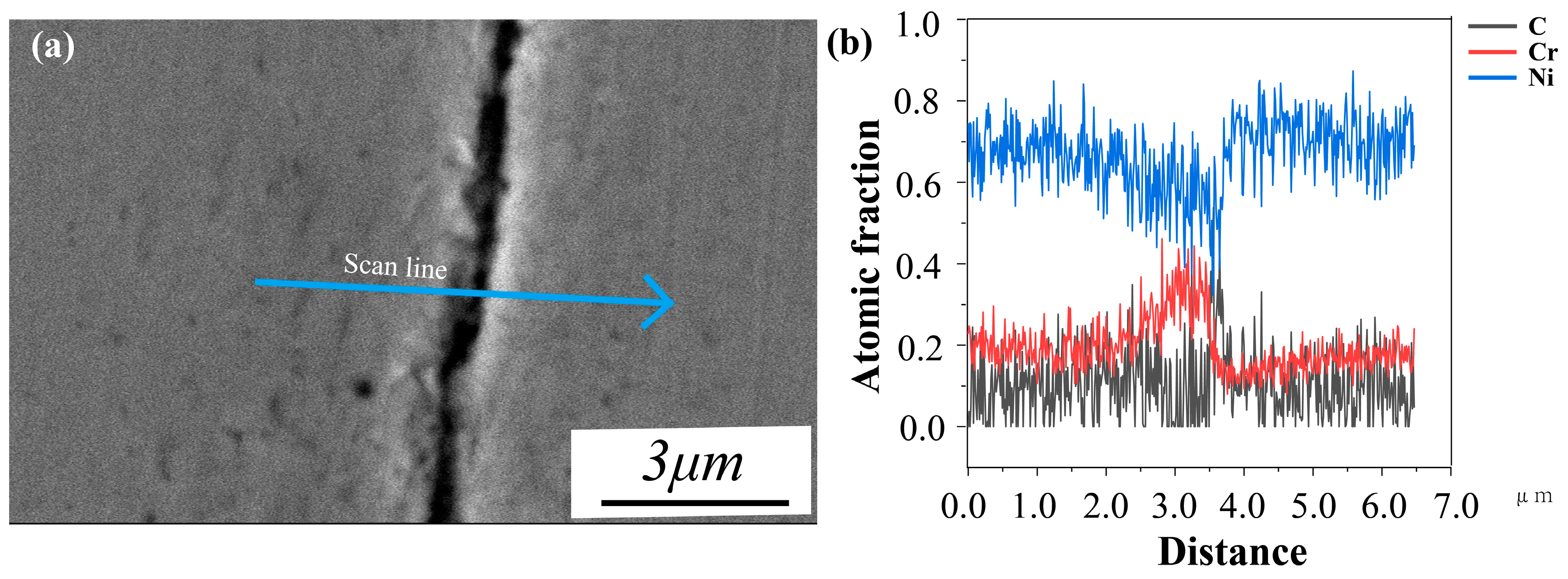

4.2. Influence of Fe and Co Elements on Formability and Crack Behavior

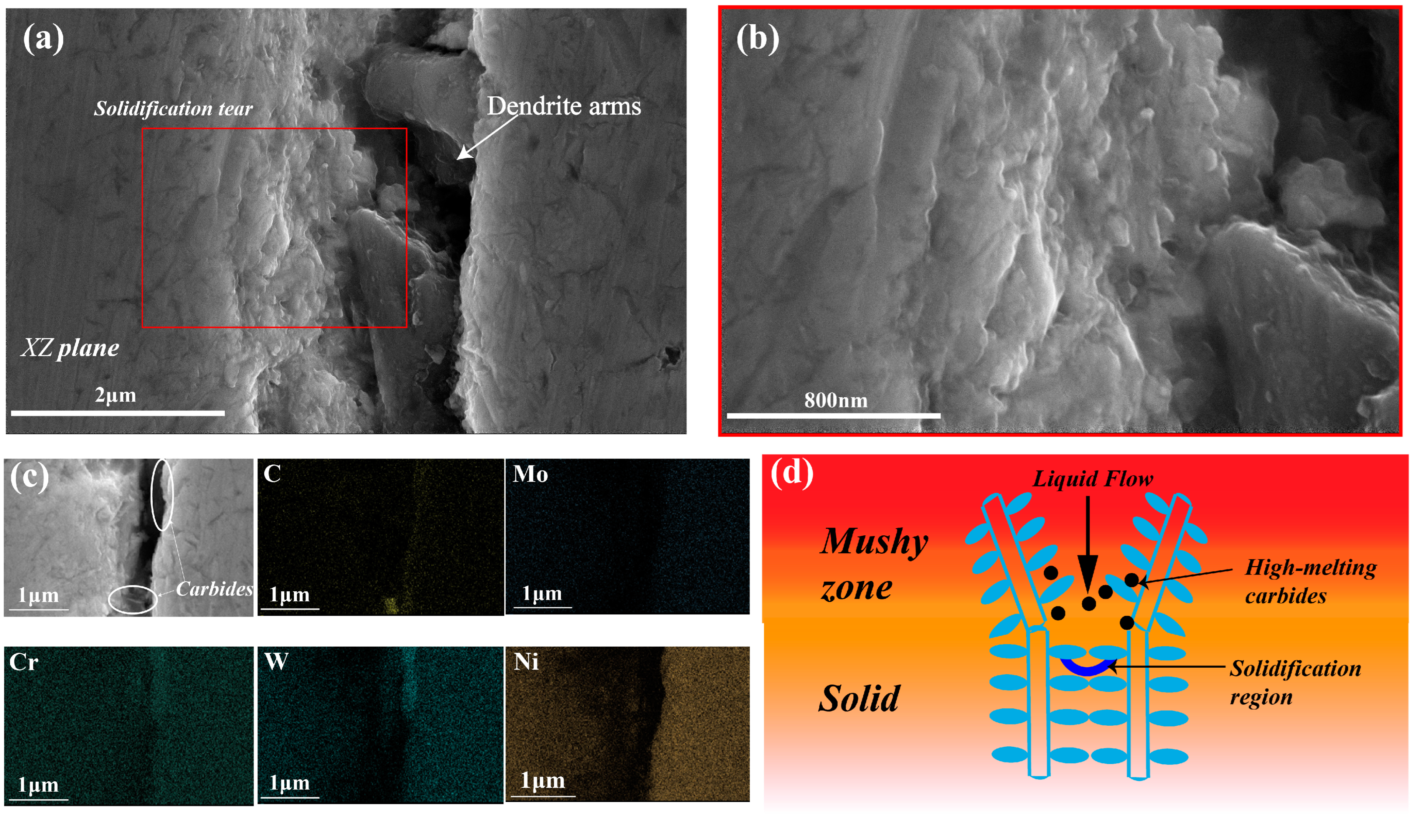

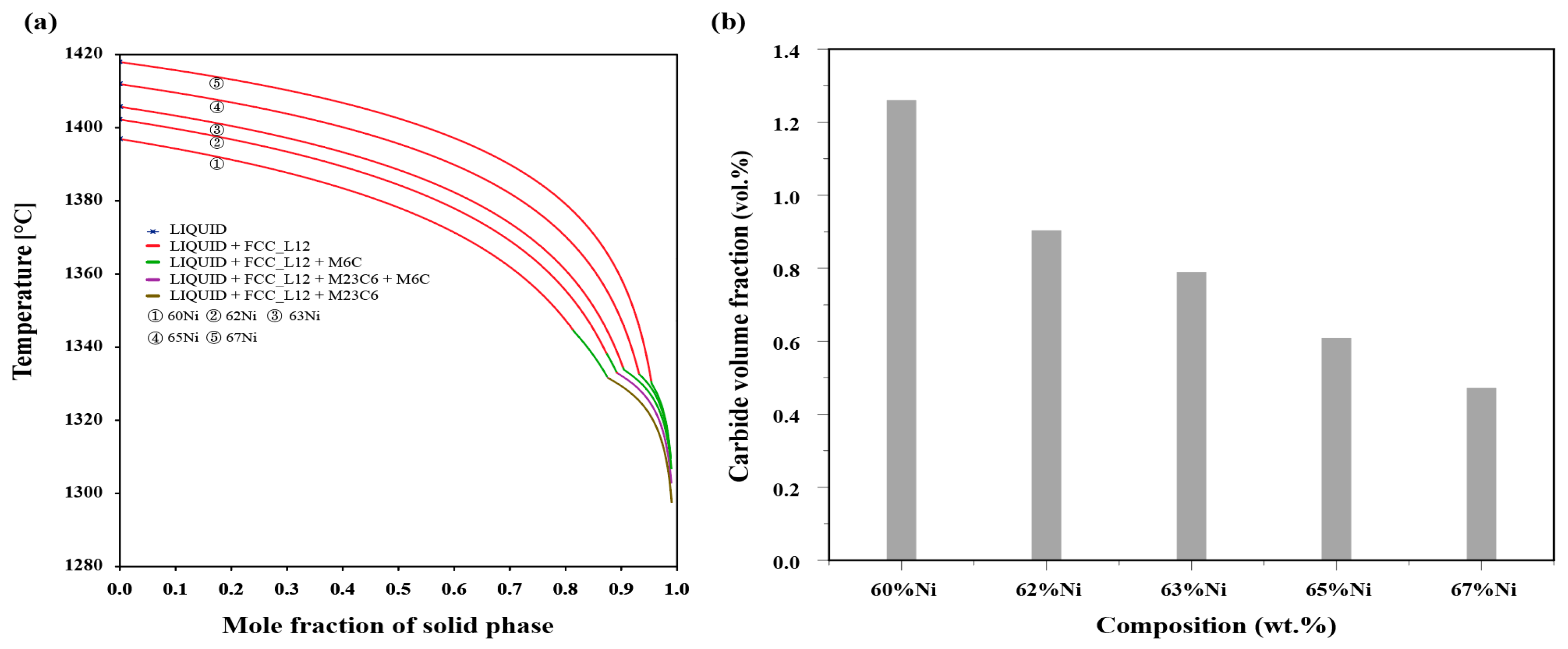

4.3. Influence of Ni Element on Formability and Crack Behavior

5. Conclusions

- Samples of GH3230 prepared by high-throughput additive manufacturing based on LPBF in situ alloying technology perform an excellent formability, and demonstrate an accurate element composition; the composition deviation is lower than 0.69 wt.%. However, the adjustment of laser parameters has no significant effect on inter-micro-crack control.

- Regarding the impact of increased Co and Fe element content on crack defects, our experiments did not yield significant effects in reducing sample cracks. The analysis suggests that Fe and Co alloys have a large freezing range and solidification cracking indices, making them prone to crack formation. Additionally, the fluctuations in Fe content resulted in a mere 2 °C change in FR, while variations in Co content led to a relatively modest shift of only 7.02 °C in the FR. Variations in Fe and Co content did not significantly reduce the freezing range and solidification cracking index.

- The addition of Ni elements showed a more significant reduction in cracks, effectively lowering the solidification cracking index. Calculational results showed a significant decrease in the volume fraction of carbides during the solidification stage, weakening the pinning effect of carbides and resulting in fewer cracks. Moreover, the increase in Ni content reduced the alloy’s residence time in the critical temperature range (ΔTCTR), decreasing the probability of thermal crack formation, and significantly reducing the number of cracks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pollock, T.M.; Tin, S. Nickel-based superalloys for advanced turbine engines: Chemistry, microstructure and properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Odenberger, E.L.; Jansson, M.; Thilderkvist, P.; Gustavsson, H.; Oldenburg, M. A short lead time methodology for design, compensation and manufacturing of deep drawing tools for Inconel 718. In International Deep Drawing Research Group Conference: Best in Class Stamping 16/06/2008–18/06/2008; Industriellt Utvecklingscentrum i Olofström AB: Olofström, Sweden, 2008. [Google Scholar]

- Buddaraju, K.M.; Sastry, G.R.K.; Kosaraju, S. A review on turning of Inconel alloys. Mater. Today Proc. 2021, 44, 2645–2652. [Google Scholar] [CrossRef]

- Sanchez, S.; Smith, P.; Xu, Z.; Gaspard, G.; Hyde, C.J.; Wits, W.W.; Ian, A.A.; Hao, C.; Clare, A.T. Powder Bed Fusion of nickel-based superalloys: A review. Int. J. Mach. Tools Manuf. 2021, 165, 103729. [Google Scholar] [CrossRef]

- Ni, M.; Chen, C.; Wang, X.; Wang, P.; Li, R.; Zhang, X.; Zhou, K. Anisotropic tensile behavior of in situ precipitation strengthened Inconel 718 fabricated by additive manufacturing. Mater. Sci. Eng. A 2017, 701, 344–351. [Google Scholar] [CrossRef]

- Trosch, T.; Strößner, J.; Völkl, R.; Glatzel, U. Microstructure and mechanical properties of selective laser melted Inconel 718 compared to forging and casting. Mater. Lett. 2016, 164, 428–431. [Google Scholar] [CrossRef]

- Alfaify, A.; Saleh, M.; Abdullah, F.M.; Al-Ahmari, A.M. Design for additive manufacturing: A systematic review. Sustainability 2020, 12, 7936. [Google Scholar] [CrossRef]

- Santa-Aho, S.; Kiviluoma, M.; Jokiaho, T.; Gundgire, T.; Honkanen, M.; Lindgren, M.; Vippola, M. Additive manufactured 316l stainless-steel samples: Microstructure, residual stress and corrosion characteristics after post-processing. Metals 2021, 11, 182. [Google Scholar] [CrossRef]

- Arbogast, A.; Roy, S.; Nycz, A.; Noakes, M.W.; Masuo, C.; Babu, S.S. Investigating the linear thermal expansion of additively manufactured multi-material joining between invar and steel. Materials 2020, 13, 5683. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, V.; Mantri, S.A.; Ramanujan, R.V.; Banerjee, R. Additive manufacturing of magnetic materials. Prog. Mater. Sci. 2020, 114, 100688. [Google Scholar] [CrossRef]

- Tofail, S.A.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Liu, C.; Le Roux, L.; Ji, Z.; Kerfriden, P.; Lacan, F.; Bigot, S. Machine Learning-enabled feedback loops for metal powder bed fusion additive manufacturing. Procedia Comput. Sci. 2020, 176, 2586–2595. [Google Scholar] [CrossRef]

- Kumar, S. Additive Manufacturing Processes; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Hocine, S.; Van Swygenhoven, H.; Van Petegem, S. Verification of selective laser melting heat source models with operando X-ray diffraction data. Addit. Manuf. 2021, 37, 101747. [Google Scholar] [CrossRef]

- Neuberger, H.; Hernandez, F.; Rey, J.; Joerg, R.; Simon, B.; Michael, R.; Jonas, K.; Bianca, S.; Oliver, M.; Kai-Uwe, V.; et al. Fabrication of HCPB breeding blanket components using the additive manufacturing processes of selective laser melting and cold spray. Fusion Eng. Des. 2020, 160, 112026. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Su, Y.; Wang, H.; Enz, J.; Ebel, T.; Yan, M. Selective laser melting additive manufacturing of 7xxx series Al-Zn-Mg-Cu alloy: Cracking elimination by co-incorporation of Si and TiB2. Addit. Manuf. 2020, 36, 101458. [Google Scholar] [CrossRef]

- Han, Q.; Gu, Y.; Huang, J.; Wang, L.; Low, K.W.; Feng, Q.; Yin, Y.; Setchi, R. Selective laser melting of Hastelloy X nanocomposite: Effects of TiC reinforcement on crack elimination and strength improvement. Compos. Part B Eng. 2020, 202, 108442. [Google Scholar] [CrossRef]

- Xia, W.; Zhao, X.; Yue, L.; Zhang, Z. A review of composition evolution in Ni-based single crystal superalloys. J. Mater. Sci. Technol. 2020, 44, 76–95. [Google Scholar] [CrossRef]

- Fu, J.; Li, H.; Song, X.; Fu, M.W. Multi-scale defects in powder-based additively manufactured metals and alloys. J. Mater. Sci. Technol. 2022, 122, 165–199. [Google Scholar] [CrossRef]

- Pakniat, M.; Ghaini, F.M.; Torkamany, M.J. Hot cracking in laser welding of Hastelloy X with pulsed Nd: YAG and continuous wave fiber lasers. Mater. Des. 2016, 106, 177–183. [Google Scholar] [CrossRef]

- Vishwakarma, K.R.; Richards, N.L.; Chaturvedi, M.C. Microstructural analysis of fusion and heat affected zones in electron beam welded ALLVAC® 718PLUSTM superalloy. Mater. Sci. Eng. A 2008, 480, 517–528. [Google Scholar] [CrossRef]

- Ahmad, M.; Akhter, J.I.; Akhtar, M.; Iqbal, M.; Ahmed, E.; Choudhry, M.A. Microstructure and hardness studies of the electron beam welded zone of Hastelloy C-276. J. Alloys Compd. 2005, 390, 88–93. [Google Scholar] [CrossRef]

- Yu, K.; Jiang, Z.; Li, C.; Chen, S.; Tao, W.; Zhou, X.; Li, Z. Microstructure and mechanical properties of fiber laser welded GH3535 superalloy. J. Mater. Sci. Technol. 2017, 33, 1289–1299. [Google Scholar] [CrossRef]

- Griffiths, S.; Tabasi, H.G.; Ivas, T.; Maeder, X.; De Luca, A.; Zweiacker, K.; Wróbel, R.; Jhabvala, J.; Logé, R.E.; Leinenbach, C. Combining alloy and process modification for micro-crack mitigation in an additively manufactured Ni-base superalloy. Addit. Manuf. 2020, 36, 101443. [Google Scholar] [CrossRef]

- Bidron, G.; Doghri, A.; Malot, T.; Fournier-Dit-Chabert, F.; Thomas, M.; Peyre, P. Reduction of the hot cracking sensitivity of CM-247LC superalloy processed by laser cladding using induction preheating. J. Mater. Process. Technol. 2020, 277, 116461. [Google Scholar] [CrossRef]

- Tang, Y.T.; Panwisawas, C.; Ghoussoub, J.N.; Gong, Y.; Clark, J.W.; Németh, A.A.; McCartney, D.G.; Reed, R.C. Alloys-by-design: Application to new superalloys for additive manufacturing. Acta Mater. 2021, 202, 417–436. [Google Scholar] [CrossRef]

- Zhong, M.; Sun, H.; Liu, W.; Zhu, X.; He, J. Boundary liquation and interface cracking characterization in laser deposition of Inconel 738 on directionally solidified Ni-based superalloy. Scr. Mater. 2005, 53, 159–164. [Google Scholar] [CrossRef]

- Wang, F.; Wu, X.H.; Clark, D. On direct laser deposited Hastelloy X: Dimension, surface finish, microstructure and mechanical properties. Mater. Sci. Technol. 2011, 27, 344–356. [Google Scholar] [CrossRef]

- Tomus, D.; Rometsch, P.A.; Heilmaier, M.; Wu, X. Effect of minor alloying elements on crack-formation characteristics of Hastelloy-X manufactured by selective laser melting. Addit. Manuf. 2017, 16, 65–72. [Google Scholar] [CrossRef]

- Cloots, M.; Uggowitzer, P.J.; Wegener, K. Investigations on the microstructure and crack formation of IN738LC samples processed by selective laser melting using Gaussian and doughnut profiles. Mater. Des. 2016, 89, 770–784. [Google Scholar] [CrossRef]

- Wan, H.Y.; Liu, Z.Z.; Han, Q.Q.; Yi, X. Laser Additive Manufacturing of Cracking-Resistant Superalloys. Aeronaut. Sci. Technol. 2022, 33, 26–42. [Google Scholar]

- Kozeschnik, E.; Rindler, W.; Buchmayr, B. Scheil–Gulliver simulation with partial redistribution of fast diffusers and simultaneous solid–solid phase transformations. Int. J. Mater. Res. 2007, 98, 826–831. [Google Scholar] [CrossRef]

- Kołodziejczak, P.; Bober, M.; Chmielewski, T. Wear Resistance Comparison Research of High-Alloy Protective Coatings for Power Industry Prepared by Means of CMT Cladding. Appl. Sci. 2022, 12, 4568. [Google Scholar] [CrossRef]

- Xi, X.; Lin, D.; Song, X.; Luo, X.; Ma, R.; Shi, Z.; Bian, H.; Fu, W.; Dong, Z.; Tan, C. Strength-plasticity transition mechanism after the solution treatment of GH3230 superalloy fabricated via laser powder bed fusion. Mater. Sci. Eng. A 2023, 876, 145124. [Google Scholar] [CrossRef]

- Dong, Y.; Hao, M.; Mu, Y.; Liang, J.; Qiu, K.; Li, J. Effect of Carbon Content on the Microstructure and Mechanical Properties of GH3230 Alloy Formed by Laser Melting Deposition. Adv. Eng. Mater. 2023, 25, 2201887. [Google Scholar] [CrossRef]

- Zhang, Z.; Han, Q.; Liu, Z.; Wang, L.; Zhang, H.; Zhao, P.; Zhu, G.; Huang, C.; Setchi, R. Cracking behaviour and its suppression mechanisms with TiB2 additions in the laser additive manufacturing of solid-solution-strengthened Ni-based alloys. Compos. Part B Eng. 2023, 266, 111023. [Google Scholar] [CrossRef]

- Zhang, Z.; Han, Q.; Liu, Z.; Wang, X.; Wang, L.; Yang, X.; Ma, T.; Gao, Z. Influence of the TiB2 content on the processability, microstructure and high-temperature tensile performance of a Ni-based superalloy by laser powder bed fusion. J. Alloys Compd. 2022, 908, 164656. [Google Scholar] [CrossRef]

- Zhang, H.; Su, H.; Hou, Y.; Wang, X.; He, Y.; Li, F. The microstructure evolution of equiaxed-to-columnar in compositionally graded samples from pure Fe to Fe-27 wt.% Cr fabricated by laser powder bed fusion. Mater. Lett. 2023, 330, 133255. [Google Scholar] [CrossRef]

- Wang, X.D.; Li, N.; Su, H.; Meng, H.M. Prior austenite grain boundary recognition in martensite microstructure based on deep learning. J. Iron Steel Res. Int. 2023, 30, 1050–1056. [Google Scholar] [CrossRef]

- Andersson, J.O.; Helander, T.; Höglund, L.; Shi, P.; Sundman, B. Thermo-Calc & DICTRA, computational tools for materials science. Calphad 2002, 26, 273–312. [Google Scholar]

- Martinez, D.; King, P.; Sama, S.R.; Sim, J.; Toykoc, H.; Manogharan, G. Effect of freezing range on reducing casting defects through 3D sand-printed mold designs. Int. J. Adv. Manuf. Technol. 2023, 126, 569–581. [Google Scholar] [CrossRef]

- Kou, S. A simple index for predicting the susceptibility to solidification cracking. Weld. J. 2015, 94, 374–388. [Google Scholar]

- Liu, J.; Wen, P. Metal vaporization and its influence during laser powder bed fusion process. Mater. Des. 2022, 215, 110505. [Google Scholar] [CrossRef]

- Chen, H.; Yan, W. Spattering and denudation in laser powder bed fusion process: Multiphase flow modelling. Acta Mater. 2020, 196, 154–167. [Google Scholar] [CrossRef]

- Kou, S. A criterion for cracking during solidification. Acta Mater. 2015, 88, 366–374. [Google Scholar] [CrossRef]

- Zhou, Z.; Huang, L.; Shang, Y.; Li, Y.; Jiang, L.; Lei, Q. Causes analysis on cracks in nickel-based single crystal superalloy fabricated by laser powder deposition additive manufacturing. Mater. Des. 2018, 160, 1238–1249. [Google Scholar] [CrossRef]

- Ploshikhin, V.; Prikhodovsky, A.; Makhutin, M.; Ilin, A.; Zoch, H.W. Integrated Mechanical-Metallurgical Approach to Modeling of Solidification Cracking in Welds; Springer: Berlin/Heidelberg, Germany, 2005; pp. 223–244. [Google Scholar]

- Chandra, S.; Tan, X.; Narayan, R.L.; Wang, C.; Tor, S.B.; Seet, G. A generalised hot cracking criterion for nickel-based superalloys additively manufactured by electron beam melting. Addit. Manuf. 2021, 37, 101633. [Google Scholar] [CrossRef]

- Attallah, M.M.; Jennings, R.; Wang, X.; Carter, L.N. Additive manufacturing of Ni-based superalloys: The outstanding issues. MRS Bull. 2016, 41, 758–764. [Google Scholar] [CrossRef]

- Zhang, J.; Singer, R.F. Hot tearing of nickel-based superalloys during directional solidification. Acta Mater. 2002, 50, 1869–1879. [Google Scholar] [CrossRef]

| C | Cr | B | Al | Fe | Mn | Mo |

| 0.1 | 21.74 | 0.0002 | 0.31 | 0.55 | 0.34 | 2.05 |

| Ti | Co | Si | La | W | Ni | / |

| 0.011 | <0.005 | 0.47 | <0.001 | 13.99 | Bal. | / |

| Powder Blend | Sample No. | Composition of Base Material | Composition of Elemental Powder | Power/W | Scan Speed mm/s | Layer Thicknessμm | Hatch/m | Spot Diameter/μm |

|---|---|---|---|---|---|---|---|---|

| GH3230+Ni | 1 | 96.05 | 3.95 | 180 | 750 | 25 | 60 | 50 |

| 2 | 93.52 | 6.48 | ||||||

| 3 | 88.47 | 11.53 | ||||||

| 4 | 83.42 | 16.58 | ||||||

| 5 | 96.05 | 3.95 | 210 | |||||

| 6 | 93.52 | 6.48 | ||||||

| 7 | 88.47 | 11.53 | ||||||

| 8 | 83.42 | 16.58 | ||||||

| GH3230+Co | 9 | 99.00 | 1.00 | 180 | 750 | 25 | 60 | 50 |

| 10 | 98.00 | 2.00 | ||||||

| 11 | 97.00 | 3.00 | ||||||

| 12 | 96.00 | 4.00 | ||||||

| 13 | 99.00 | 1.00 | 210 | |||||

| 14 | 98.00 | 2.00 | ||||||

| 15 | 97.00 | 3.00 | ||||||

| 16 | 96.00 | 4.00 | ||||||

| GH3230+Fe | 17 | 98.00 | 2.00 | 180 | 750 | 25 | 60 | 50 |

| 18 | 97.00 | 3.00 | ||||||

| 19 | 96.00 | 4.00 | ||||||

| 20 | 98.00 | 2.00 | 210 | |||||

| 21 | 97.00 | 3.00 | ||||||

| 22 | 96.00 | 4.00 |

| Sample No. | 1 | 2 | 3 | 4 | 9 | 10 | 11 | 12 | 17 | 18 | 19 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Element | Ni wt.% | Co wt.% | Fe wt.% | ||||||||

| Designed composition | 62.00 | 63.00 | 65.00 | 67.00 | 1.00 | 2.00 | 3.00 | 4.00 | 2.00 | 3.00 | 5.00 |

| Measured composition | 62.59 | 63.40 | 65.69 | 67.66 | 0.98 | 1.73 | 2.77 | 3.92 | 2.10 | 2.84 | 4.45 |

| Deviation | 0.59 | 0.4 | 0.69 | 0.66 | −0.02 | −0.27 | −0.23 | −0.08 | 0.1 | −0.16 | −0.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Hou, Y.; Cai, W.; Yu, H.; Wang, X.; Li, F.; He, Y.; He, D.; Zhang, H. Study on Crack Behavior of GH3230 Superalloy Fabricated via High-Throughput Additive Manufacturing. Materials 2024, 17, 4225. https://doi.org/10.3390/ma17174225

Li X, Hou Y, Cai W, Yu H, Wang X, Li F, He Y, He D, Zhang H. Study on Crack Behavior of GH3230 Superalloy Fabricated via High-Throughput Additive Manufacturing. Materials. 2024; 17(17):4225. https://doi.org/10.3390/ma17174225

Chicago/Turabian StyleLi, Xiaoqun, Yaqing Hou, Weidong Cai, Hongyao Yu, Xuandong Wang, Fafa Li, Yazhou He, Dupeng He, and Hao Zhang. 2024. "Study on Crack Behavior of GH3230 Superalloy Fabricated via High-Throughput Additive Manufacturing" Materials 17, no. 17: 4225. https://doi.org/10.3390/ma17174225

APA StyleLi, X., Hou, Y., Cai, W., Yu, H., Wang, X., Li, F., He, Y., He, D., & Zhang, H. (2024). Study on Crack Behavior of GH3230 Superalloy Fabricated via High-Throughput Additive Manufacturing. Materials, 17(17), 4225. https://doi.org/10.3390/ma17174225