Insight into Grain Refinement Mechanisms of WC Cemented Carbide with Al0.5CoCrFeNiTi0.5 Binder

Abstract

1. Introduction

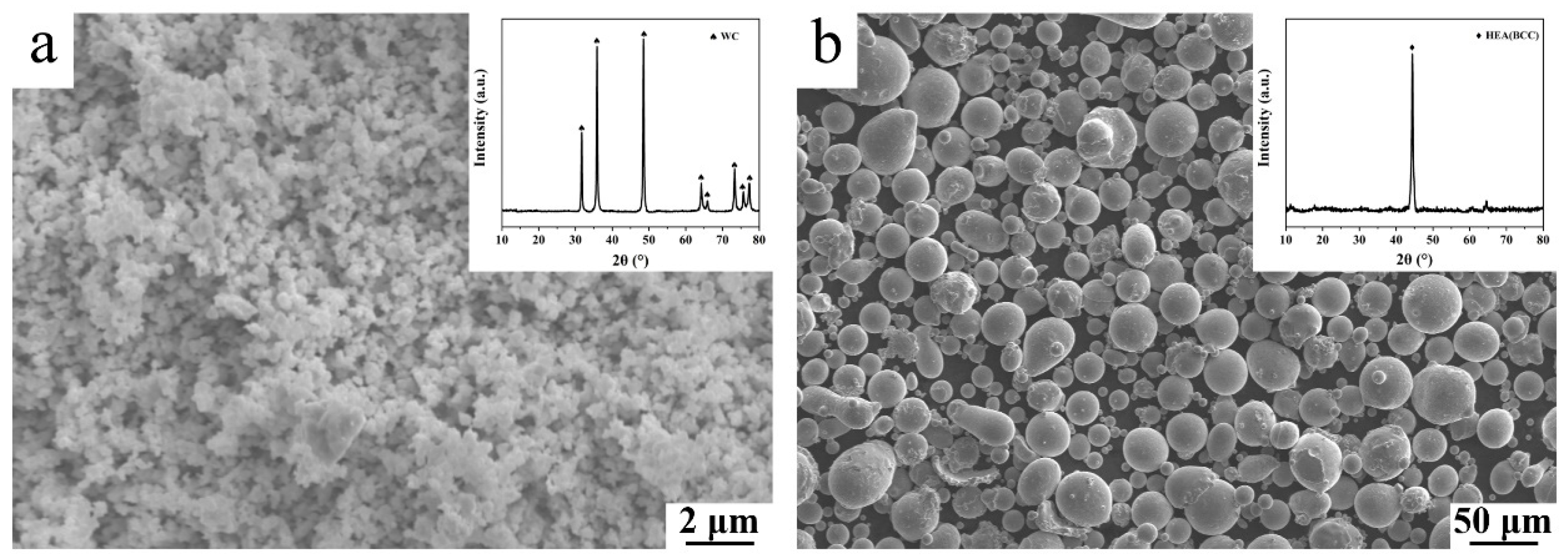

2. Experimental Materials and Methods

3. Results and Discussion

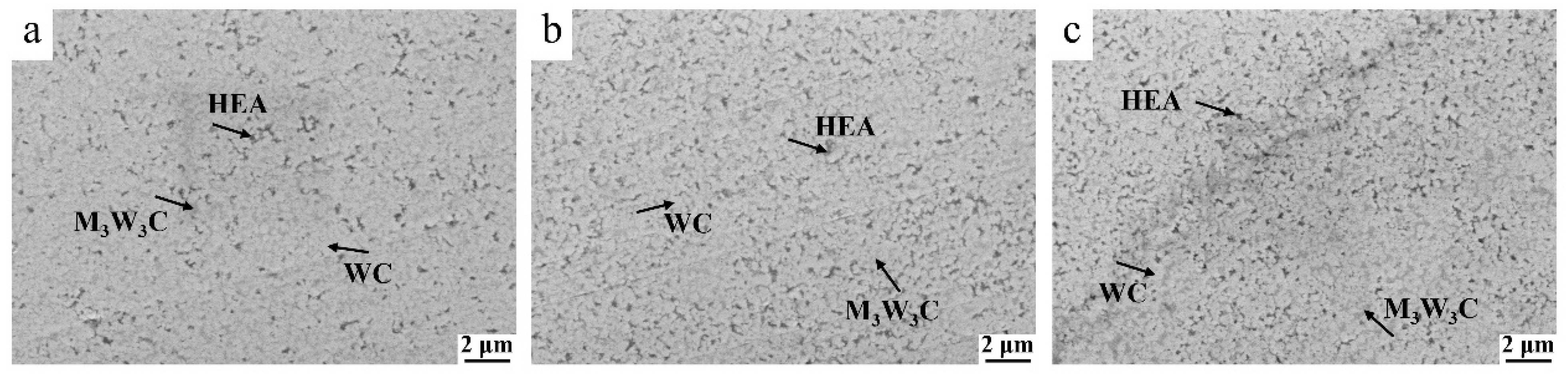

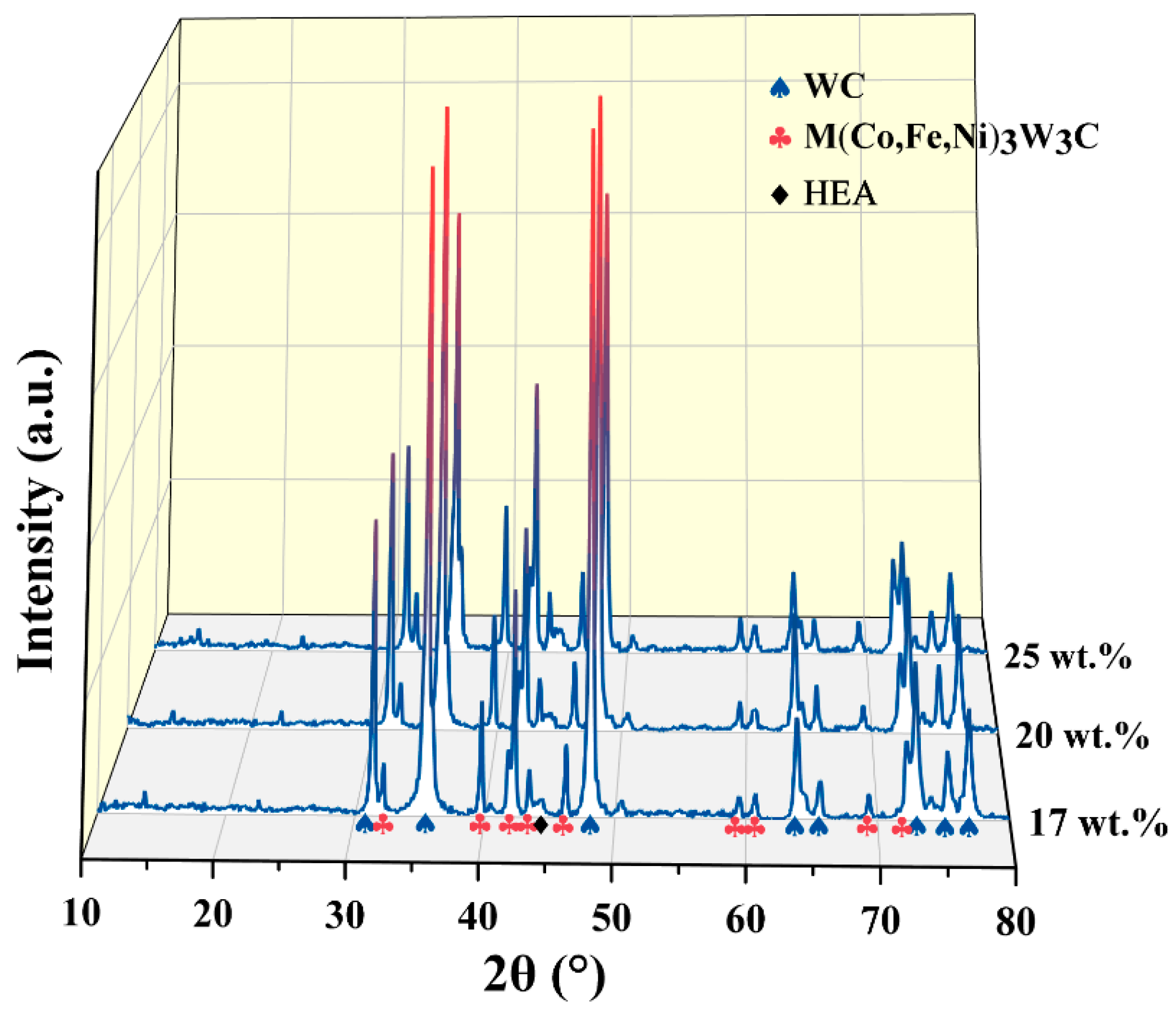

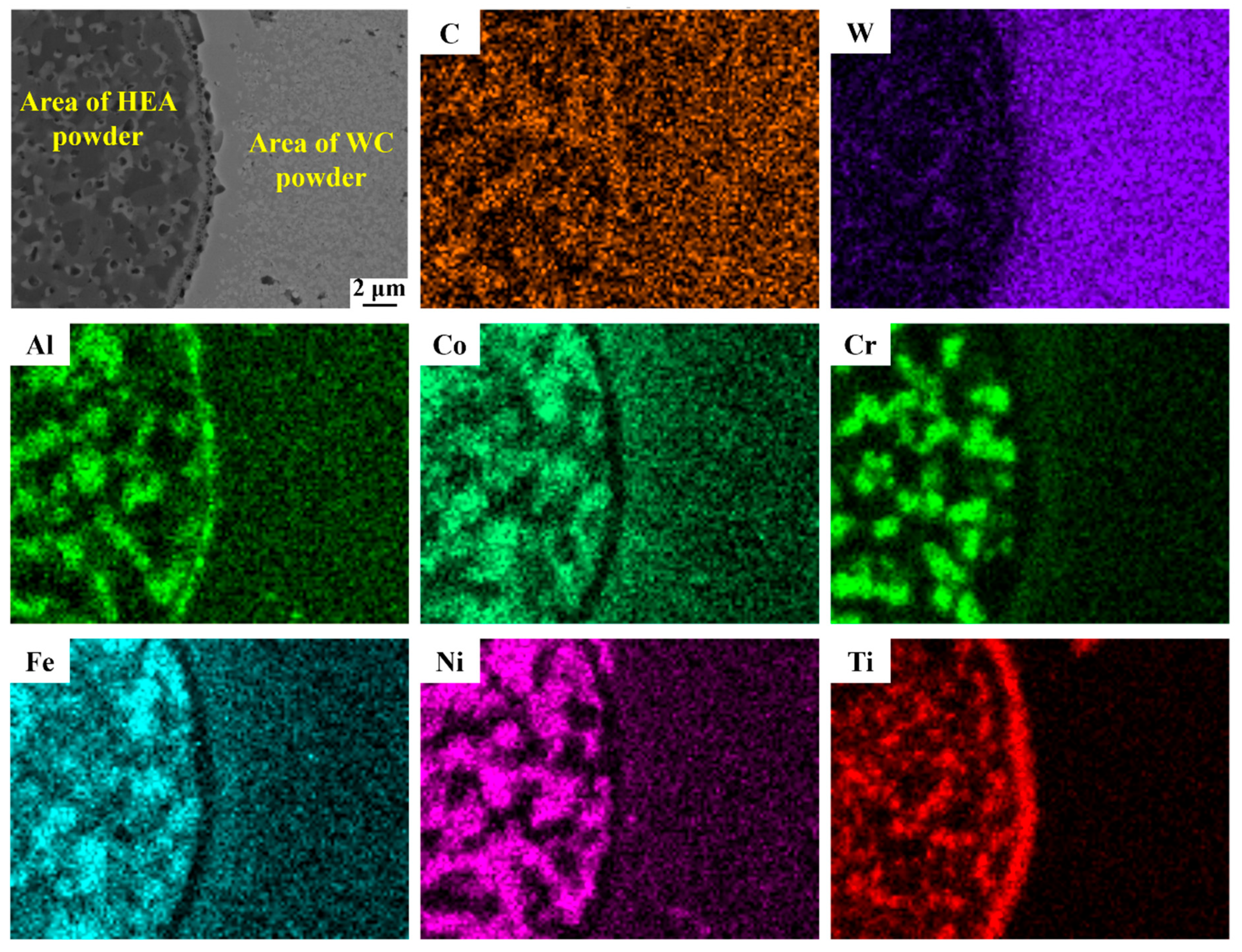

3.1. Formation of Carbides in HPSed WC/HEA

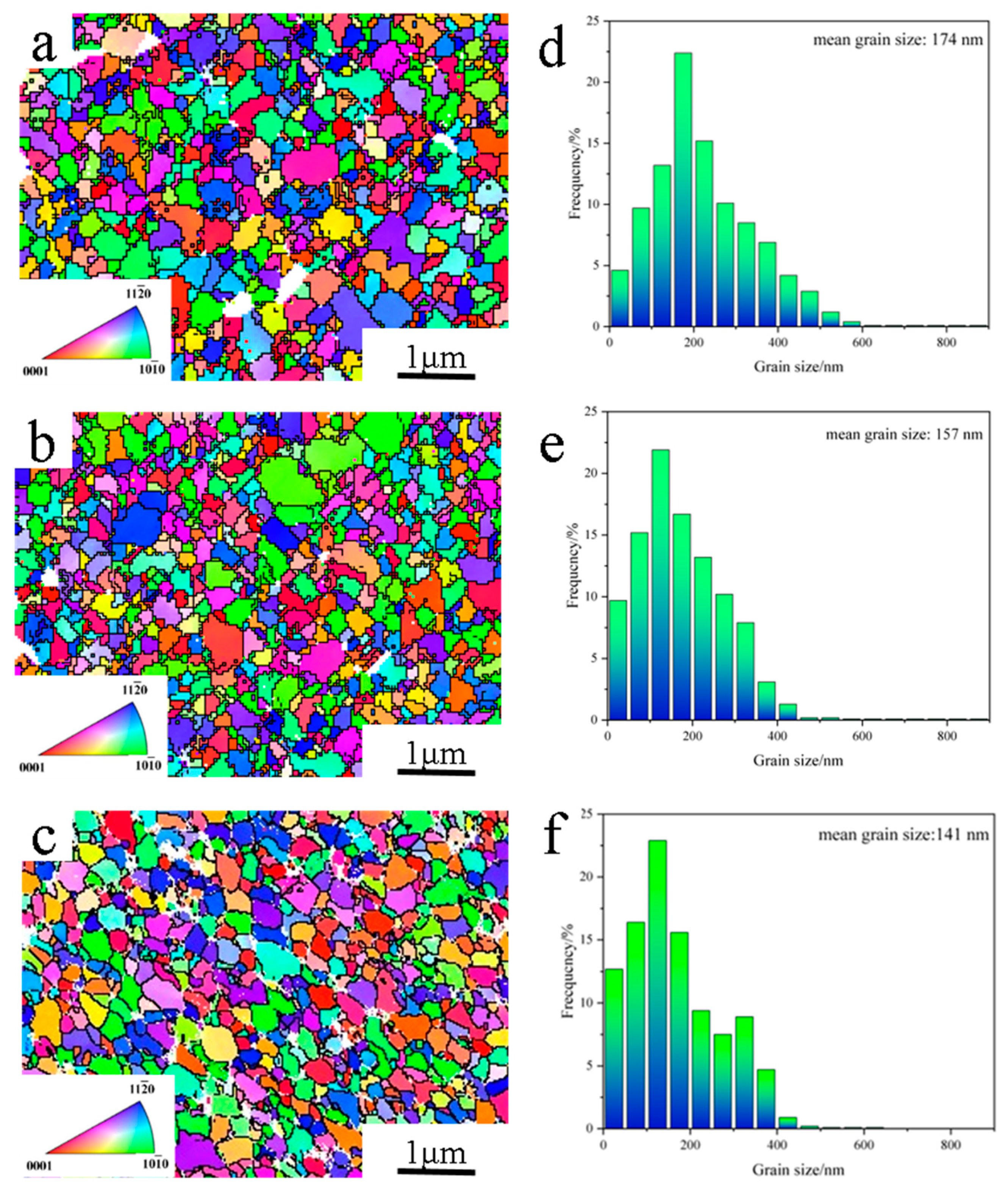

3.2. Mechanism of WC Grain Size Evolution in HPSed WC/HEA

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fang, G.; Tang, H.; Ren, Z.; Cheng, Y.; Yu, Y.; Wang, L.; Li, T.; Zhang, Y.; Qiao, Z. Effect of Grain Size on Oxidation Resistance of WC-6wt%Co Cemented Carbide Sintered by Spark Plasma Sintering. Int. J. Refract. Met. Hard Mater. 2023, 111, 106108. [Google Scholar] [CrossRef]

- Zhu, S.; Hui, J.; Qin, J.; Weiwei, D. High Temperature Oxidation Behavior of Spark Plasma Sintered WC-CoCrFeNiAl Hard Alloys. Int. J. Refract. Met. Hard Mater. 2023, 113, 106157. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Y.; Tu, C. Wetting Behaviors and Interfacial Characteristics of Molten Al CoCrCuFeNi High-Entropy Alloys on a WC Substrate. J. Mater. Sci. Technol. 2021, 78, 192–201. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Y.; Shen, J. Effects of Binders on the Microstructures and Mechanical Properties of Ultrafine WC-10%AlxCoCrCuFeNi Composites by Spark Plasma Sintering. J. Alloys Compd. 2019, 791, 540–549. [Google Scholar] [CrossRef]

- Chen, C.-S.; Yang, C.-C.; Chai, H.-Y.; Yeh, J.-W.; Chau, J.L.H. Novel Cermet Material of WC/Multi-Element Alloy. Int. J. Refract. Met. Hard Mater. 2014, 43, 200–204. [Google Scholar] [CrossRef]

- Liang, F.; Du, J.; Su, G.; Zhang, P.; Zhang, C. Investigating the Effect of Al, Mo or Mn Addition to CoCrFeNi Entropy Alloys on the Interface Binding Properties of WC/HEA Cemented Carbides. Mater. Today Commun. 2023, 35, 105891. [Google Scholar] [CrossRef]

- Zhou, R.; Chen, G.; Liu, B.; Wang, J.; Han, L.; Liu, Y. Microstructures and Wear Behaviour of (FeCoCrNi)1-x(WC)x High Entropy Alloy Composites. Int. J. Refract. Met. Hard Mater. 2018, 75, 56–62. [Google Scholar] [CrossRef]

- Güler, S.; Alkan, E.D.; Alkan, M. Vacuum Arc Melted and Heat Treated AlCoCrFeNiTiX Based High-Entropy Alloys: Thermodynamic and Microstructural Investigations. J. Alloys Compd. 2022, 903, 163901. [Google Scholar] [CrossRef]

- Konyashin, I.; Hlawatschek, S.; Ries, B.; Mazilkin, A. Co Drifts between Cemented Carbides Having Various WC Grain Sizes. Mater. Lett. 2016, 167, 270–273. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Senos, A.M.R. Cemented Carbide Phase Diagrams: A Review. Int. J. Refract. Met. Hard Mater. 2011, 29, 405–418. [Google Scholar] [CrossRef]

- Zhou, P.; Du, Y.; Lengauer, W. Morphology of η Phase in Cemented Carbides with Fe-Based Binders Influenced by Carbon Content and Nitrogen Atmosphere. Ceram. Int. 2019, 45, 20774–20779. [Google Scholar] [CrossRef]

- Dong, D.; Xiang, X.; Huang, B.; Xiong, H.; Zhang, L.; Shi, K.; Liao, J. Microstructure and Properties of WC-Co/CrMnFeCoNi Composite Cemented Carbides. Vacuum 2020, 179, 109571. [Google Scholar] [CrossRef]

- Suetin, D.V.; Medvedeva, N.I. Structural, Electronic and Magnetic Properties of η-Carbides M3W3C (M = Ti, V, Cr, Mn, Fe, Co, Ni). J. Alloys Compd. 2016, 681, 508–515. [Google Scholar] [CrossRef]

- Yang, J.; Miao, X.; Wang, X.; Yang, F. Influence of Mn Additions on the Microstructure and Magnetic Properties of FeNiCr/60% WC Composite Coating Produced by Laser Cladding. Int. J. Refract. Met. Hard Mater. 2014, 46, 58–64. [Google Scholar] [CrossRef]

- García, J.; Ciprés, V.C.; Blomqvist, A.; Kaplan, B. Cemented Carbide Microstructures: A Review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Lifshttz, I.M.; Slyozov, V.V. The Kinetics of Precipitation from Supersaturated Solid Solutions. J. Phys. Chem. Solids 1961, 19, 35–50. [Google Scholar] [CrossRef]

- Verma, V.; Belcher, C.H.; Apelian, D.; Lavernia, E.J. Diffusion in High Entropy Alloy Systems—A Review. Prog. Mater. Sci. 2024, 142, 101245. [Google Scholar] [CrossRef]

- Zhu, S.; Hui, J.; Sun, X.; Bin, H.; Weiwei, D. Effect of Phase Transformation of CoCrFeNiAl High-Entropy Alloy on Mechanical Properties of WC-CoCrFeNiAl Composites. Ceram. Int. 2023, 49, 32388–32398. [Google Scholar] [CrossRef]

| Element | Al | Cr | Fe | Ni | Ti | Co | |

|---|---|---|---|---|---|---|---|

| Content | wt.% | 4.95 | 19.55 | 21.43 | 22.13 | 8.95 | Bal. |

| at.% | 9.67 | 19.82 | 20.23 | 19.87 | 9.85 | Bal. | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiang, F.; Zheng, P.; He, P.; Wang, W.; Zhang, Y.; Han, P.; Wang, K. Insight into Grain Refinement Mechanisms of WC Cemented Carbide with Al0.5CoCrFeNiTi0.5 Binder. Materials 2024, 17, 4223. https://doi.org/10.3390/ma17174223

Qiang F, Zheng P, He P, Wang W, Zhang Y, Han P, Wang K. Insight into Grain Refinement Mechanisms of WC Cemented Carbide with Al0.5CoCrFeNiTi0.5 Binder. Materials. 2024; 17(17):4223. https://doi.org/10.3390/ma17174223

Chicago/Turabian StyleQiang, Fengming, Pengfei Zheng, Pan He, Wen Wang, Ying Zhang, Peng Han, and Kuaishe Wang. 2024. "Insight into Grain Refinement Mechanisms of WC Cemented Carbide with Al0.5CoCrFeNiTi0.5 Binder" Materials 17, no. 17: 4223. https://doi.org/10.3390/ma17174223

APA StyleQiang, F., Zheng, P., He, P., Wang, W., Zhang, Y., Han, P., & Wang, K. (2024). Insight into Grain Refinement Mechanisms of WC Cemented Carbide with Al0.5CoCrFeNiTi0.5 Binder. Materials, 17(17), 4223. https://doi.org/10.3390/ma17174223