Mechanical and Drying Shrinkage Performance Study of Ultra-High-Performance Concrete Prepared from Titanium Slag under Different Curing Conditions

Abstract

1. Introduction

2. Experimental

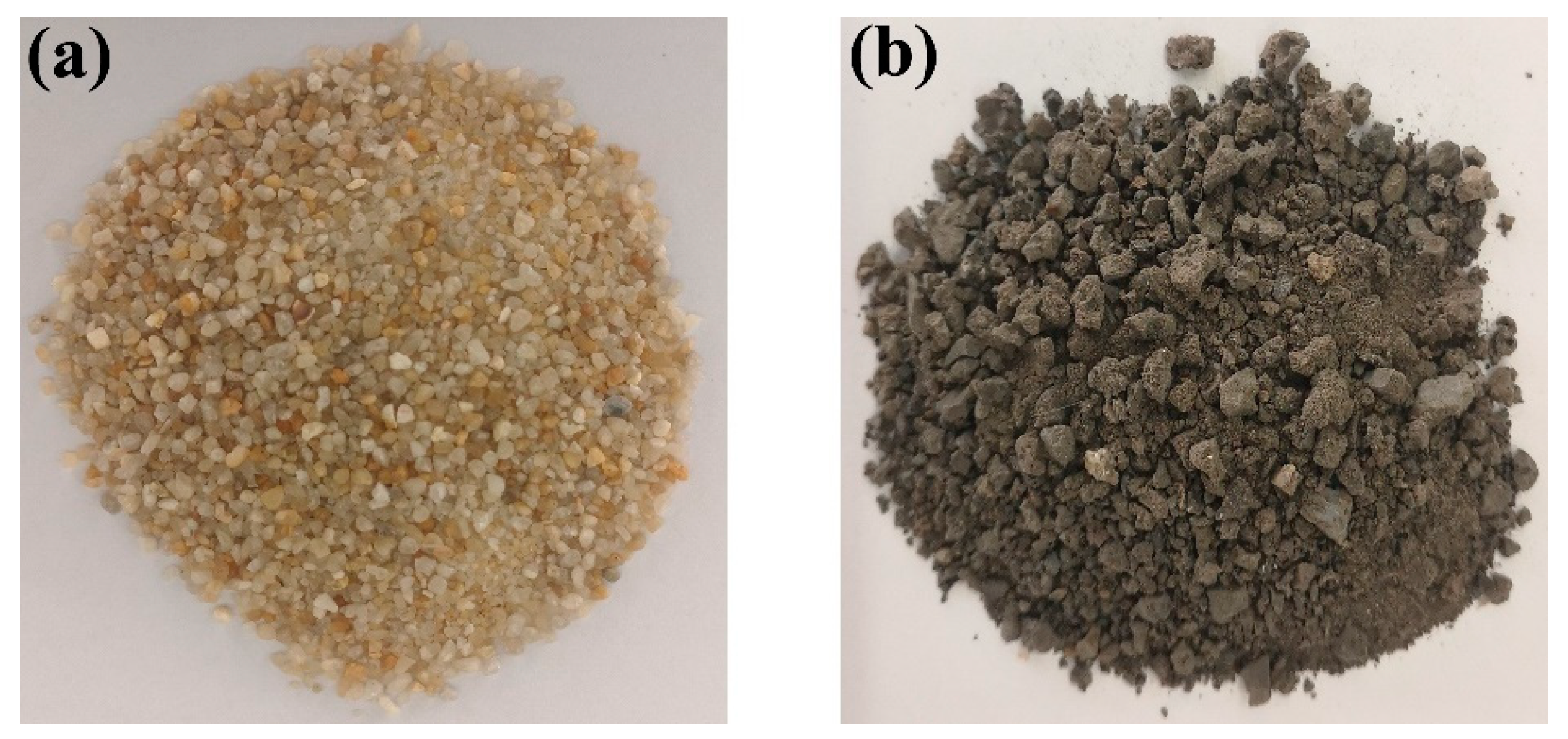

2.1. Material

2.2. Sample Preparation and Maintenance

2.3. Test Methods

2.3.1. Mechanical Flexural and Compressive Strength

2.3.2. XRD/XRF

2.3.3. TG

2.3.4. MIP

2.3.5. Drying Shrinkage Teste

3. Results and Discussion

3.1. Mechanical Properties

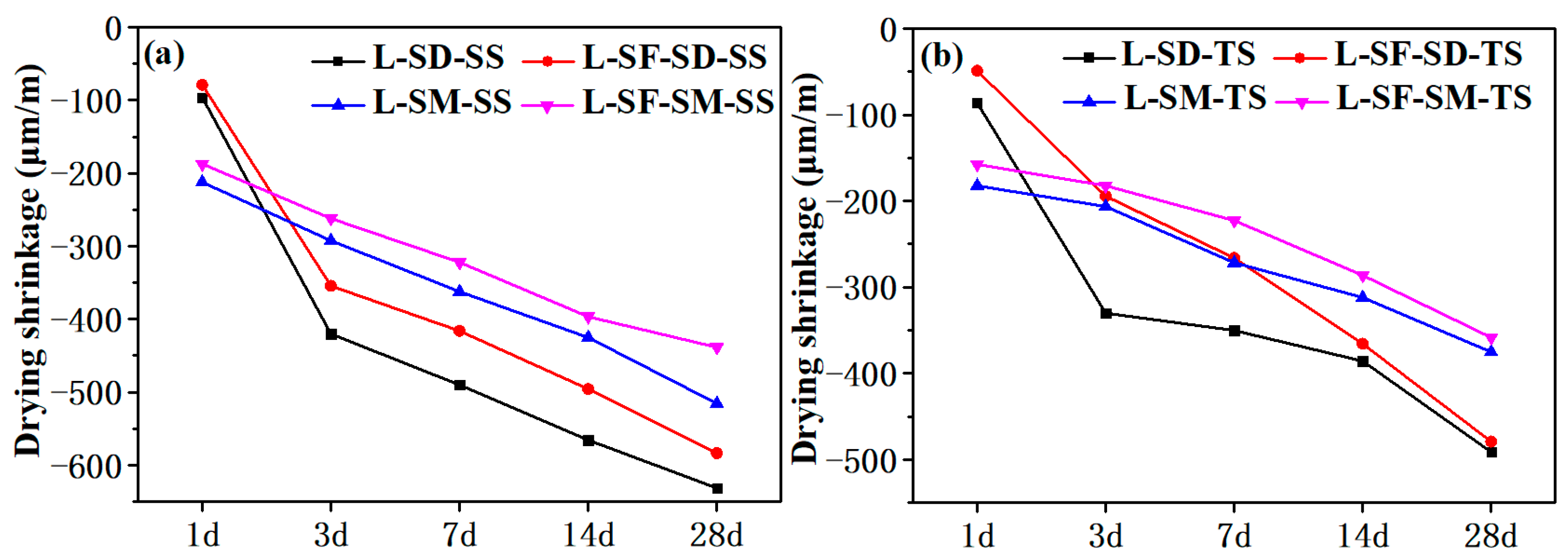

3.2. Drying Shrinkage

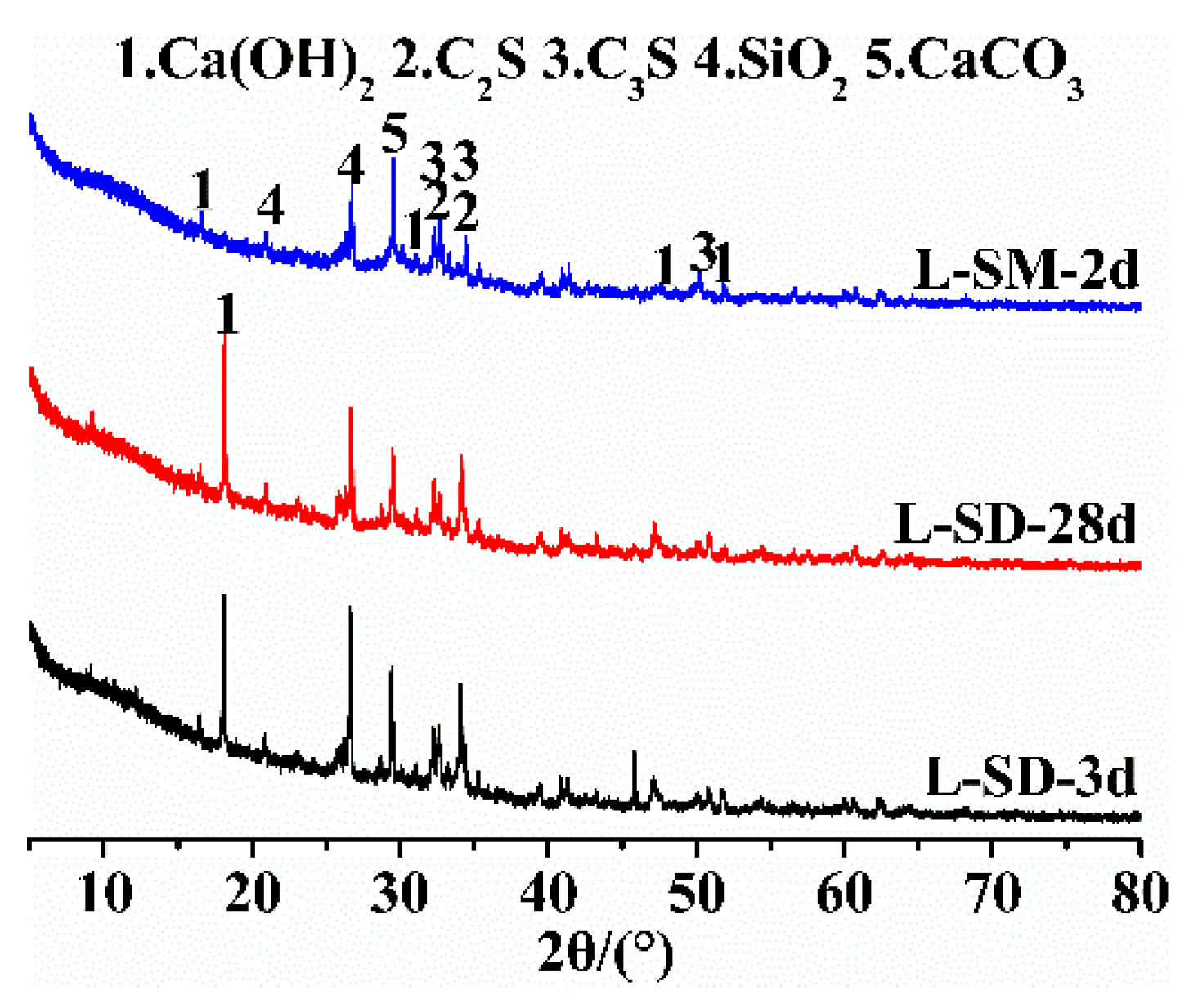

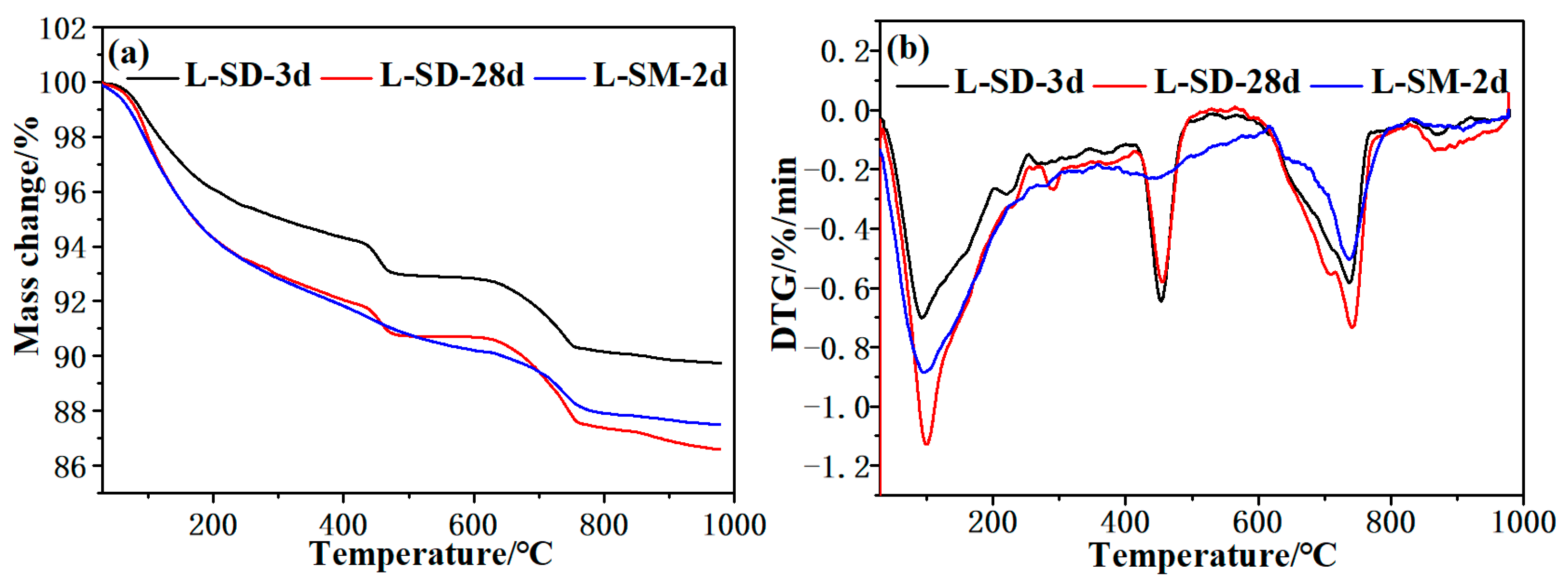

3.3. XRD/TG

3.4. Pore Structure

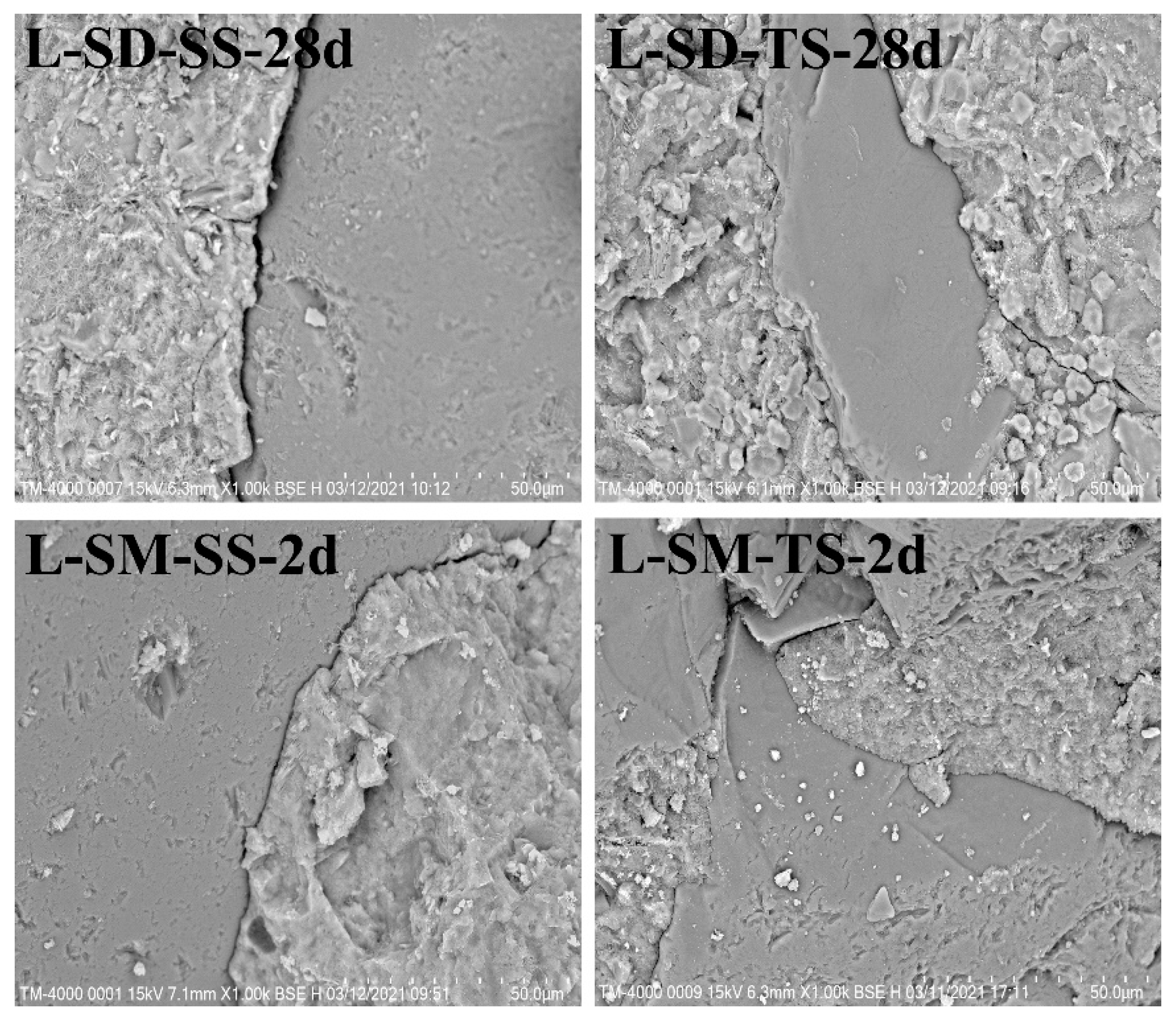

3.5. SEM

4. Conclusions

- (1)

- Steel fibers enhance the flexural and compressive strengths of UHPC by impeding microcrack propagation, improving load transfer, and boosting load-bearing capacity. Titanium slag (TS) aggregates improve strength over silica sand (SS) aggregates by enhancing interfacial bonding with the cement paste. Steam curing surpasses standard curing by fostering advanced hydration and denser microstructure formation with increased C-S-H gel volume.

- (2)

- Steam curing notably reduces UHPC drying shrinkage, especially with steel fibers, restraining crack development and deformation. UHPC with TS aggregates exhibits lower shrinkage due to compactness and reduced porosity from these aggregates.

- (3)

- Steam curing enhances UHPC density by increasing hydration, consuming more Ca(OH)₂, and producing additional C-S-H gel. Elevated temperature and pressure accelerate hydration reactions, refining pore structure and densifying the matrix. TS aggregate UHPC boasts a finer pore distribution from improved packing and reduced porosity.

- (4)

- TS aggregates in UHPC form a stronger bond with cement, reducing cracks and enhancing microstructure integrity, particularly under steam curing. TS aggregates’ rough texture aids in a robust transition zone, lessening microcrack formation and improving load transfer for a cohesive, durable microstructure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qaidi, S.M.; Atrushi, D.S.; Mohammed, A.S.; Ahmed, H.U.; Faraj, R.H.; Emad, W.; Tayeh, B.A.; Najm, H.M. Ultra-high-performance geopolymer concrete: A review. Constr. Build. Mater. 2022, 346, 128495. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Singla, R.; Senna, M.; Mishra, T.; Alex, T.; Kumar, S. High strength metakaolin/epoxy hybrid geopolymers: Synthesis, characterization and mechanical properties. Appl. Clay Sci. 2022, 221, 106459. [Google Scholar] [CrossRef]

- Sekkal, W.; Zaoui, A. High strength metakaolin-based geopolymer reinforced by pristine and covalent functionalized carbon nanotubes. Constr. Build. Mater. 2022, 327, 126910. [Google Scholar] [CrossRef]

- Meng, Q.; Wu, C.; Su, Y.; Li, J.; Liu, J.; Pang, J. Experimental and numerical investigation of blast resistant capacity of high performance geopolymer concrete panels. Compos. Part B Eng. 2019, 171, 9–19. [Google Scholar] [CrossRef]

- Li, J.; Wu, C.; Hao, H.; Liu, Z. Post-blast capacity of ultra-high performance concrete columns. Eng. Struct. 2017, 134, 289–302. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Y.J.; He, P.Y.; Li, C.J.; Liu, L.C. Novel activated carbon route to low-cost geopolymer based porous composite with high mechanical resistance and enhanced CO2 capacity. Microporous Mesoporous Mater. 2020, 305, 110282. [Google Scholar] [CrossRef]

- Ren, L.; Fang, Z.; Wang, K. Design and behavior of super-long span cable-stayed bridge with CFRP cables and UHPC members. Compos. Part B Eng. 2019, 164, 72–81. [Google Scholar] [CrossRef]

- Alkaysi, M.; El-Tawil, S.; Liu, Z.; Hansen, W. Effects of silica powder and cement type on durability of ultra high performance concrete (UHPC). Cem. Concr. Compos. 2016, 66, 47–56. [Google Scholar] [CrossRef]

- Qin, T. Design and Performances of Ultra-High Perfoamanceconcrete Based on High Titanium Slag. Master’ Thesis, Southwest University of Science and Technology, Mianyang, China, 2023. [Google Scholar]

- Chen, J. Preparation and Properties of Water Quenched Light Weight High Strength Concrete with High TitaniumSlag. Master’ Thesis, Southwest University of Science and Technology, Mianyang, China, 2021. [Google Scholar]

- Wang, M.; Li, Y.; Zhang, K.; Gao, X.; Huang, W.; Shen, X. Study on mechanical properties of ultra-high-performance concrete with low heat cement under different curing systems. Cement 2023, 7, 17. [Google Scholar]

- Zhao, H.; Liu, C.; Huang, H.; Gao, X. Effect of steam curing on strength, permeability, and pore structure of UHPC made with desert sand. Concrete 2022, 12, 38–43. [Google Scholar]

- Tafraoui, A.; Escadeillas, G.; Vidal, T. Durability of the Ultra High Performances Concrete containing metakaolin. Constr. Build. Mater. 2016, 112, 980–987. [Google Scholar] [CrossRef]

- Bian, C.; Guo, J.; Xiao, J.; Zhao, C. Effect of Nano-metakaolin and Fine Aggregate on the Mechanical Behavior of Ultra High Performance Concrete. Mater. Rep. 2023, 37, 59–63. [Google Scholar]

- Xu, D.; Cui, Y.; Li, H.; Yang, K.; Xu, W.; Chen, Y. On the future of Chinese cement industry. Cem. Concr. Res. 2015, 78, 2–13. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.A.; Rafiq, S.; Mohammed, A.S.; Mosavi, A.; Sor, N.H.; Qaidi, S.M.A. Compressive Strength of Sustainable Geopolymer Concrete Composites: A State-of-the-Art Review. Sustainability 2021, 13, 13502. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Fly ash-based geopolymers: The relationship between composition, pore structure and efflorescence. Cem. Concr. Res. 2014, 64, 30–41. [Google Scholar] [CrossRef]

- Li, N.; Shi, C.; Wang, Q.; Zhang, Z.; Ou, Z. Composition design and performance of alkali-activated cements. Mater. Struct. 2017, 50, 178. [Google Scholar] [CrossRef]

- Cheng, C.; Zhou, C.; Jiang, C. Effect of metakaolin mixed with different fibers on mechanical properties of UHPC. Concrete 2022, 9, 115–120. [Google Scholar]

- Xie, J.; Wu, Z.; Zhang, X.; Hu, X.; Shi, C. Trends and developments in low-heat portland cement and concrete: A review. Constr. Build. Mater. 2023, 392, 131535. [Google Scholar] [CrossRef]

- Alzaza, A.; Ohenoja, K.; Isteri, V.; Hanein, T.; Geddes, D.; Poikelispää, M.; Illikainen, M. Blending eco-efficient calcium sulfoaluminate belite ferrite cement to enhance the physico–mechanical properties of Portland cement paste cured in refrigerated and natural winter conditions. Cem. Concr. Compos. 2022, 129, 104469. [Google Scholar] [CrossRef]

- Baral, A.; Roesler, J.R. Performance of photocatalytic, carbonated calcium sulfoaluminate-belite cement. Cem. Concr. Compos. 2022, 134, 104787. [Google Scholar] [CrossRef]

- Koumpouri, D.; Angelopoulos, G. Effect of boron waste and boric acid addition on the production of low energy belite cement. Cem. Concr. Compos. 2016, 68, 1–8. [Google Scholar] [CrossRef]

- Chatterjee, A. High belite cements—Present status and future technological options: Part I. Cem. Concr. Res. 1996, 26, 1213–1225. [Google Scholar] [CrossRef]

- Jang, J.G.; Lee, H.K. Microstructural densification and CO2 uptake promoted by the carbonation curing of belite-rich Portland cement. Cem. Concr. Res. 2016, 82, 50–57. [Google Scholar] [CrossRef]

- Maheswaran, S.; Kalaiselvam, S.; Karthikeyan, S.S.; Kokila, C.; Palani, G. β-Belite cements (β-dicalcium silicate) obtained from calcined lime sludge and silica fume. Cem. Concr. Compos. 2016, 66, 57–65. [Google Scholar] [CrossRef]

- Wang, J. Research on Application of Metakaolinmineral Admixture Based on Low-Heat Andearly-Strength Concrete. Master’ Thesis, Southwest University of Science and Technology, Mianyang, China, 2021. [Google Scholar]

- Wang, L.; Yang, H.; Zhou, S.; Chen, E.; Tang, S. Mechanical properties, long-term hydration heat, shinkage behavior and crack resistance of dam concrete designed with low heat Portland (LHP) cement and fly ash. Constr. Build. Mater. 2018, 187, 1073–1091. [Google Scholar] [CrossRef]

- Cyr, M.; Carles-Gibergues, A.; Tagnit-Hamou, A. Titanium fume and ilmenite fines characterization for their use in cement-based materials. Cem. Concr. Res. 2000, 30, 1097–1104. [Google Scholar] [CrossRef]

- Li, X. Study on Properties and Paste-Aggregate Concrete with High Titanium Slag as Aggregateinteraction Mechanism of High Performance. Master’ Thesis, Southwest University of Science and Technology, Mianyang, China, 2021. [Google Scholar]

- Wang, A.; Shi, Y.; Liu, K.; Sun, D.; Lu, B.; Liu, P. Effect of Air-cooled Blast Furnace Slag as Fine Aggregate on the Properties of Cement Mortar. Mater. Rep. 2017, 31, 121–125. [Google Scholar]

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). Standardization Administration of China (SAC): Beijing, China, 2021.

- Su, J.; Liu, W.; Shi, C.; Fang, Z. Scale Effect of Cubic Compressive Strength of Ultra-high Performance Concrete. J. Chin. Ceram. Soc. 2021, 49, 305–311. [Google Scholar]

- Xiong, Y.; Yang, M.; Zhao, J.; Yuan, Y.; Liu, Y.; Shi, H. Transverse isotropic compression behavior of aligned steel fiber UHPC produced by electromagnetic field. Constr. Build. Mater. 2024, 411, 134579. [Google Scholar] [CrossRef]

- Chen, J.; Li, J.; Lu, Z.; Li, X.; Zhao, J.; Qing, G.; Liu, S. Preparation and Performance of Reactive Powder Concrete by Using Water-quenched Titantium Slag. J. Southwest Univ. Sci. Technol. 2021, 36, 28–35. [Google Scholar]

- Yazıcı, H.; Yiğiter, H.; Karabulut, A.; Baradan, B. Utilization of fly ash and ground granulated blast furnace slag as an alternative silica source in reactive powder concrete. Fuel 2008, 87, 2401–2407. [Google Scholar] [CrossRef]

- Huang, H.; Qian, C.; Zhao, F.; Qu, J.; Guo, J.; Danzinger, M. Improvement on microstructure of concrete by polycarboxylate superplasticizer (PCE) and its influence on durability of concrete. Constr. Build. Mater. 2016, 110, 293–299. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; Lu, Z.; Hou, L.; Li, X.; Zhang, C.; Li, R.; Deng, Y.; Zheng, X. Hydration and performances of ordinary Portland cement containing metakaolin and titanium slag. Constr. Build. Mater. 2024, 415, 135056. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; Lu, Z.; Chen, X.; Xu, Y.; Zhong, W.; Cai, P. Effect of metakaolin on properties of mediumheat and lowheat Portland cement. Concrete 2021, 7, 5–11. [Google Scholar]

- Pereira, C.G.; Castro-Gomes, J.; de Oliveira, L.P. Influence of natural coarse aggregate size, mineralogy and water content on the permeability of structural concrete. Constr. Build. Mater. 2009, 23, 602–608. [Google Scholar] [CrossRef]

- Wang, L.; Yang, H.; Dong, Y.; Chen, E.; Tang, S. Environmental evaluation, hydration, pore structure, volume deformation and abrasion resistance of low heat Portland (LHP) cement-based materials. J. Clean. Prod. 2018, 203, 540–558. [Google Scholar] [CrossRef]

- Wang, L.; Jin, M.; Wu, Y.; Zhou, Y.; Tang, S. Hydration, shrinkage, pore structure and fractal dimension of silica fume modified low heat Portland cement-based materials. Constr. Build. Mater. 2021, 272, 121952. [Google Scholar] [CrossRef]

| Sample | Water Requirement of Normal Consistency (%) | Specific Grain Area (m2/kg) | Bulk Density (g/cm3) | Setting Time/min | Flexural Strength/MPa | Compressive Strength/MPa | |||

|---|---|---|---|---|---|---|---|---|---|

| Initial Setting Time | Final Setting Time | 3d | 28d | 3d | 28d | ||||

| FA | - | 458 | 0.89 | - | - | - | - | - | - |

| SF | - | 486 | 0.56 | - | - | - | - | - | - |

| TS | - | - | 1.18 | - | - | - | - | - | - |

| LHPC | 22.0 | 358 | 1.24 | 230 | 306 | 3.9 | 8.7 | 15.6 | 45.7 |

| Material | CaO | SiO2 | Fe2O3 | Al2O3 | SO3 | MgO | K2O | Na2O | LOI |

|---|---|---|---|---|---|---|---|---|---|

| LHPC | 64.05 | 20.92 | 4.98 | 3.30 | 2.95 | 2.03 | 0.51 | 0.37 | 1.12 |

| SF | 0.46 | 97.29 | 0.05 | 0.25 | 0.71 | 0.59 | 0.34 | 0.02 | 2.53 |

| FA | 9.64 | 51.78 | 9.50 | 18.97 | 1.52 | 0.77 | 3.93 | 0.23 | 2.48 |

| TS | 26.14 | 23.52 | 4.11 | 13.25 | 1.25 | 8.14 | 0.12 | 0.38 | 0.00 |

| Screen Size | Standard Sand | Titanium Slag Sand |

|---|---|---|

| Cumulative Screening (%) | Cumulative Screening (%) | |

| 4.75 | - | 0.6 |

| 2.36 | - | 26.3 |

| 1.18 | 37.8 | 46.7 |

| 0.6 | 72.6 | 56.8 |

| 0.3 | 89.6 | 69.7 |

| 0.15 | 93.8 | 79.7 |

| 0.08 | 100.0 | 100.0 |

| Specimen No. | LHPC | SF | FA | W/C | Water Reducing Agent | TS | SS | Steel Fiber (SF) |

|---|---|---|---|---|---|---|---|---|

| L-SD-TS | 515.19 | 85.8 | 257.66 | 0.2 | 13 | 1683.52 | ||

| L-SF-SD-TS | 515.19 | 85.8 | 257.66 | 1683.52 | 120 | |||

| L-SM-TS | 515.19 | 85.8 | 257.66 | 1683.52 | ||||

| L-SF-SM-TS | 515.19 | 85.8 | 257.66 | 1683.52 | 120 | |||

| L-SD-SS | 515.19 | 85.8 | 257.66 | 1683.52 | ||||

| L-SF-SD-SS | 515.19 | 85.8 | 257.66 | 1683.52 | 120 | |||

| L-SM-SS | 515.19 | 85.8 | 257.66 | 1683.52 | ||||

| L-SF-SM-SS | 515.19 | 85.8 | 257.66 | 1683.52 | 120 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Li, J.; Gao, Y.; Lu, Z.; Hou, L. Mechanical and Drying Shrinkage Performance Study of Ultra-High-Performance Concrete Prepared from Titanium Slag under Different Curing Conditions. Materials 2024, 17, 4201. https://doi.org/10.3390/ma17174201

Wang J, Li J, Gao Y, Lu Z, Hou L. Mechanical and Drying Shrinkage Performance Study of Ultra-High-Performance Concrete Prepared from Titanium Slag under Different Curing Conditions. Materials. 2024; 17(17):4201. https://doi.org/10.3390/ma17174201

Chicago/Turabian StyleWang, Jinxin, Jun Li, Yan Gao, Zhongyuan Lu, and Li Hou. 2024. "Mechanical and Drying Shrinkage Performance Study of Ultra-High-Performance Concrete Prepared from Titanium Slag under Different Curing Conditions" Materials 17, no. 17: 4201. https://doi.org/10.3390/ma17174201

APA StyleWang, J., Li, J., Gao, Y., Lu, Z., & Hou, L. (2024). Mechanical and Drying Shrinkage Performance Study of Ultra-High-Performance Concrete Prepared from Titanium Slag under Different Curing Conditions. Materials, 17(17), 4201. https://doi.org/10.3390/ma17174201